#Virtual Reality for Hazardous Training

Explore tagged Tumblr posts

Text

In today’s rapidly evolving technological landscape, Metaverse technology is ushering in new dimensions for industries worldwide. As businesses adopt immersive digital environments for training, simulations, and customer experiences, one metaverse company in India is truly making its mark — Simulanis. This company specializes in creating cutting-edge metaverse development solutions and virtual reality (VR) simulators, transforming industries from fire safety to pharmaceutical training.

#Virtual Reality Safety Training#Immersive VR Simulators#VR Training for Firefighters#Metaverse Training Solutions#Virtual Reality Fire Training#Industrial VR Simulators#VR Training for Paint Spraying#VR Fire Extinguisher Simulator#Virtual Reality Emergency Training#VR-based Skill Training#Metaverse for Workforce Development#3D VR Simulators#Fire Safety VR Training Programs#Virtual Reality for Hazardous Training#Immersive VR Training for Manufacturing#Augmented Reality Productivity Tools#Metaverse Learning Experiences#Virtual Fire Safety Training India#VR Training for Healthcare#Simulation Training in Metaverse#Realistic VR Fire Training Simulators#Advanced VR Training Solutions#Virtual Reality Training for Engineers#Industrial Fire Extinguisher Simulator#Pharmaceutical VR Training Simulators#VR Training for High-Risk Jobs#Fire Safety Simulation Tools#Remote Assistance in VR Training#Metaverse Development for Enterprises#Immersive VR Training for Safety Procedures

0 notes

Text

Top Innovations Transforming the Heavy Machinery Industry

Innovations are not only enhancing operational efficiency and safety but are also addressing pressing environmental concerns and labour shortages. Autonomous heavy machinery is becoming increasingly prevalent, reducing the reliance on manual labour and minimising human error.

Simultaneously, the shift towards electric and hybrid equipment is contributing to a significant reduction in carbon emissions, aligning with global sustainability goals. Moreover, the incorporation of Internet of Things (IoT) devices and data analytics is enabling real-time monitoring and predictive maintenance, leading to reduced downtime and extended equipment lifespan.

Autonomous Machinery and Robotics

Companies have integrated lidar sensors into their equipment, enhancing the capabilities of their Cat Command autonomy platform. This technology enables machinery to operate with minimal human intervention, improving safety and efficiency, especially in hazardous environments.

Similarly, John Deere has introduced autonomous tractors equipped with advanced sensors and AI, addressing labour shortages in the agriculture and construction sectors. These autonomous solutions not only increase productivity but also allow human workers to focus on more complex tasks, thereby optimising workforce utilisation.

Electrification and Sustainable Practices

The push towards sustainability has led to significant strides in electrifying heavy machinery. In the mining sector, Fortescue has committed to a $2.8 billion deal with Liebherr to convert two-thirds of its mining fleet to zero-emission battery technology.

Integration of IoT and Predictive Maintenance

IoT-enabled sensors facilitate real-time monitoring of equipment health, enabling predictive maintenance strategies that preemptively address potential failures. This approach minimises unplanned downtime and extends the lifespan of machinery.

Companies are leveraging data analytics to optimise maintenance schedules and enhance asset management. By analysing performance data, operators can make informed decisions, improving overall productivity and reducing operational costs.

Advanced Materials and Lightweight Design

Innovations in materials science are contributing to the development of lighter and more durable heavy machinery components. Mechatronix, for example, has introduced carbon-fibre reinforcement technology to replace traditional steel chassis in mining trucks. This advancement not only reduces the weight of the equipment but also enhances payload capacity and operational efficiency.

The adoption of advanced materials leads to improved fuel efficiency and reduced wear and tear, ultimately lowering maintenance costs and environmental impact.

Augmented and Virtual Reality for Training and Maintenance

Augmented Reality (AR) and Virtual Reality (VR) technologies are transforming training and maintenance procedures in the Heavy Equipment industry. AR provides interactive overlays that assist technicians in performing complex repairs, while VR offers immersive training environments that enhance operator skills without the risks associated with real-world training.

These technologies not only improve the proficiency of the workforce but also reduce equipment downtime by facilitating quicker and more accurate maintenance processes.

3D Printing for Rapid Prototyping and Parts Manufacturing

Additive manufacturing, or 3D printing, is streamlining the production of machinery components. This technology allows for the rapid prototyping of parts, reducing lead times and enabling on-demand manufacturing. By minimising the need for large inventories, companies can lower storage costs and respond swiftly to equipment repair needs.

The customisation capabilities of 3D printing also facilitate the creation of specialised components tailored to specific operational requirements, enhancing the versatility and performance of Earth moving Equipment.

End Notes

As the heavy machinery industry continues to evolve, embracing these technological advancements is crucial for staying competitive and achieving operational excellence. Whether it's adopting autonomous equipment, integrating IoT for predictive maintenance, or utilising advanced materials for improved efficiency, staying abreast of these trends can significantly impact productivity and sustainability.

For businesses seeking to navigate this dynamic landscape, partnering with a forward-thinking equipment provider is essential. Dar of Equipment stands at the forefront of innovation, offering a comprehensive range of cutting-edge machinery solutions tailored to meet the evolving needs of the industry. With a commitment to quality, sustainability, and customer satisfaction, they are your trusted partner in driving progress and achieving success in the modern machinery sector.

#heavy machinery#Heavy Equipment#heavy equipment near me#Earth moving Equipment#heavy machinery company#heavy equipment dealers in uae#heavy equipment marketplace

1 note

·

View note

Text

Virtual Reality Business Training: real-world experience in a controlled and safe way!

Virtual Reality (VR) is rapidly transforming the way organizations approach training and education. Traditional training methods rely on lectures, slideshows, or passive videos. But, VR provides a deeply immersive and experience-based learning model. People learn best by doing and that is exactly what VR offers. Rather than simply telling learners what to do, VR shows them how to do it and allows them to practice in realistic and risk-free environments.

This active participation enhances understanding and long-term retention. University of Warwick study confirmed that students remember information better in VR settings and find the process more engaging and emotionally positive. From military training and complex surgical procedures to financial education and cultural immersion, virtual reality business training is enabling learners to gain direct and real-world experience in a controlled and safe way.

Sliced Bread Animation is an award-winning studio creating world-class engaging and immersive content. They specialize in transforming how organizations communicate, train, and inspire. They have developed numerous high-quality VR training projects for their clients, designed to create intuitive understanding and demonstrate 'real-life responses'. Their VR solutions enable remote learning and simplify even the most complex problems. This revolutionizes how businesses approach training and engagement.

Addressing the Fire Safety Challenge in Corporate Training

Fire safety is a critical component of workplace health and safety (H&S) compliance. However, traditional training methods often fall short and they are also time-consuming, expensive, and separating. Companies are legally required to train employees in emergency procedures. The standard classroom or video-based approach doesn’t equip them with the skills to act decisively under pressure.

Seeing these limitations, Sliced Bread Animation has developed an innovative VR fire safety training solution. This eight-module program immerses users in a lifelike virtual office, complete with staircases, emergency exits, and potential fire hazards. From overloaded sockets to paper stored near space heaters, the experience helps users identify dangers and take the appropriate actions for preventing that.

Hands-On Learning That Delivers Real Results

The strength of virtual reality business training lies in its ability to simulate realistic scenarios. During the fire safety module, learners face a virtual fire emergency. They must assess the situation, locate extinguishers, choose the correct response, and act quickly what they would do in a real crisis. The result is not just theoretical understanding, but users gain actual hands-on experience. That will build both confidence and competence.

Flexible, Scalable, and Measurable Learning

Another key advantage of VR training is its flexibility. Employees can complete modules at their own pace, which is independent of trainers or large group sessions. This not only saves time and money but also ensures consistent delivery across locations. Next, with Learning Management System (LMS) integration and advanced analytics, employers can track performance, identify gaps, and optimize the learning experience using real-time data.

0 notes

Text

Research and Innovation Assistant

Job title: Research and Innovation Assistant Company: Nottingham Trent University Job description: Assistant to support a 19-month project in the development and delivery of a hybrid VR/clblockroom training course in hazard… psychology in general (and hazard perception in particular); virtual reality hardware and software; video editing skills… Expected salary: £26712 – 28047 per year Location:…

0 notes

Text

Advancing Your Hazmat Career: Why the Right Hazmat Tech Training Matters More Than Certification

In the emergency response world, real progress comes not from chasing certificates but from gaining true, actionable skill. If you’re looking to move forward in your hazmat career, you don’t need another piece of paper—you need the kind of hazmat tech class that gives you the knowledge, confidence, and capability to perform under pressure. At Signet North America, we specialize in delivering high-impact hazmat technician training directly to the organizations that need it most.

Understanding Hazmat Training Without the Certification Hype

One of the biggest misconceptions in the industry is that you must be “certified” by a training provider to progress in your career. In reality, only your employer can officially certify your skills in accordance with OSHA guidelines. Training providers are not legally authorized to issue formal certification. What we do offer at Signet North America is professional, in-person training that your employer can use to determine and document your readiness for hazardous materials incident response.

So if your career feels stuck because you think you need outside certification, it's time to reframe the goal. It’s not about chasing credentials—it’s about gaining relevant, high-quality training that equips you for real-world scenarios. And that’s exactly what our hazmat tech classes are built to provide.

Hazmat Tech Training That Moves With You

We don’t run a traditional school or offer walk-in classes. Our clients are organizations—fire departments, medical facilities, chemical plants, manufacturing sites—who contact us directly to train their teams. We come to you. We deliver in-person, on-site instruction that reflects your work environment, your protocols, and your unique emergency response needs. This means you won’t just sit through a generic program. You’ll train using your tools, your people, and your risk profile.

This immersive, scenario-driven approach provides the type of learning that sticks. Whether the class is focused on decontamination, PPE, hazard recognition, or emergency scene coordination, the emphasis is on application. Participants leave the training not just more informed—but truly prepared.

Why In-Person, On-Site Training Makes a Difference

Online videos and remote modules can’t replicate the urgency and complexity of a hazmat situation. In-person training is essential because hazardous materials incidents require physical decision-making, gear usage, and teamwork that you simply cannot practice in a virtual format.

At Signet North America, our trainers create realistic scenarios using props and drills that mimic the types of situations your team may face in the field. From managing unknown substances to coordinating with multiple response units, your team gains practical experience that prepares them for emergency response operations. This isn’t abstract knowledge—it’s readiness.

Invest in Skills That Matter to Employers

When employers seek hazmat technicians, they aren’t looking for a framed certificate—they want people who know what to do in high-stakes situations. They need team members who can operate safely, efficiently, and confidently. That starts with the right training.

The hazmat tech class you choose should deliver more than just information. It should teach real skills in containment, detection, and incident response. It should build the muscle memory needed for rapid decisions and complex environments. At Signet North America, that’s our entire focus. Our courses don’t just prepare students—they empower employers to confidently designate their team members as capable and competent in hazmat roles.

Professional Training That Builds Long-Term Capability

Each course we provide is designed to support long-term emergency response capacity. Whether your organization needs training for a small team or a full department, we can tailor the course structure to your environment and operational goals. No one-size-fits-all curriculum. No unnecessary theory. Just straightforward, high-impact learning that aligns with industry needs and OSHA expectations.

If you’ve been searching for a hazmat tech class to “level up,” this is your sign to focus on quality, relevance, and real-world application. Your growth doesn’t depend on a certificate—it depends on professional development that actually prepares you for the job.

Call us at 877-875-2921 and bring any of our classes directly to you and your team.

0 notes

Text

How Mining Companies Are Adopting VR to Train Safer, Faster, and Smarter

The mining industry faces some of the world’s most dangerous and demanding work environments. From operating heavy machinery to navigating underground shafts, workers must be trained to handle complex, high-risk situations with precision and confidence. Traditional training methods, however, often fall short, relying on manuals, lectures, and limited field exposure.

To address these limitations, mining companies are turning to Virtual Reality (VR) training as a game-changing solution. By simulating real-world mining scenarios in immersive, interactive environments, VR mining training is helping organizations train their workforce more safely, quickly, and effectively.

Why Mining Needs a Smarter Training Approach

Mining operations demand skills that are hard to replicate in traditional training setups. Field-based training can be risky, expensive, and logistically challenging. Paper-based instructions or videos often fail to convey the spatial awareness and decision-making required on-site.

VR training eliminates these barriers by creating hyper-realistic simulations of mining operations, from surface equipment handling to underground drilling tasks. This allows workers to experience hazardous scenarios such as equipment failure, emergency evacuations, or confined space navigation without any real-world risk.

How VR is Transforming Training in the Mining Sector

1. Safety Without Risk Mining companies are using VR training solutions to replicate potentially hazardous situations in a zero-risk environment. Trainees can practice responses to rockfalls, gas leaks, or mechanical breakdowns repeatedly until they gain confidence and mastery, something not possible in live settings.

2. Faster Onboarding and Upskilling Instead of spending weeks shadowing experienced operators, new recruits can be immersed in a mining simulator on day one. Tasks such as excavator handling, haul truck navigation, or blasting procedures can be learned more efficiently using interactive VR mining training.

3. Standardized Training Across Sites A major challenge for multinational mining companies is maintaining training consistency across regions. VR allows them to deploy standardized modules across all training centers, ensuring a unified learning experience regardless of geography.

4. Real-Time Performance Feedback Advanced VR training systems integrate analytics and real-time feedback. Trainers can assess response time, accuracy, and compliance, and adjust learning modules to suit individual needs. This leads to better retention and measurable improvements in competency.

Use Cases of VR Mining Trainings

Drill Operator Training: Simulate equipment controls, terrain, and geological conditions to train on proper drill positioning and extraction techniques.

Emergency Response: Prepare teams for underground evacuations, fire scenarios, or gas leaks through timed virtual drills.

Maintenance Training: Teach equipment diagnostics and repair procedures with detailed 3D models and interaction-based tasks.

Hazard Identification: Guide workers through virtual inspections to identify potential risks in both open-pit and underground sites.

Benefits for Mining Companies

✔️ Reduced Downtime — Trainees can practice offsite without interrupting operations ✔️ Lower Training Costs — No need for physical setups or extensive travel ✔️ Improved Safety Records — Fewer incidents caused by undertrained staff ✔️ Higher Retention Rates — Interactive learning improves engagement and recall

Final Thoughts

Mining is evolving, and so should its training methods. VR training provides a scalable, efficient, and safe alternative to outdated approaches. By integrating VR mining training, companies can prepare their workforce for complex tasks while reducing operational risks and improving performance. At DevDen, we specialize in creating industry-specific VR training solutions tailored to real-world mining challenges. From equipment simulations to emergency drills, our immersive modules are designed to train your workforce smarter, faster, and safer. If you’re looking to implement impactful VR trainings in your mining operations, DevDen is here to help you lead the way.

#augmented reality#3d product modeling#vr training#mixed reality#xr development company#vr training solution#virtual reality#metaverse#xr development#ar development company#metaverse development conpany#metaverse development

0 notes

Text

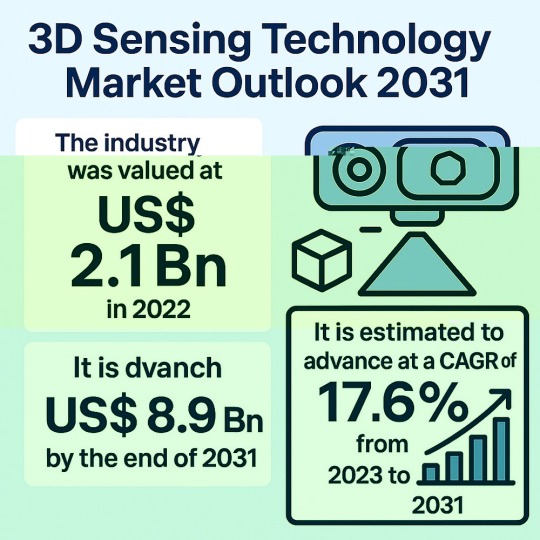

3D Sensing Technology Market to Witness Major Growth as Industries Embrace Digital Transformation

The 3D sensing technology market is witnessing an exciting phase of growth, driven by advancements in several key industries, ranging from consumer electronics to automotive and healthcare. As the global economy increasingly embraces digital transformation, the demand for innovative and immersive technologies is fueling the growth of 3D sensing solutions. The market, valued at US$ 2.1 Bn in 2022, is set to expand at a Compound Annual Growth Rate (CAGR) of 17.6%, reaching US$ 8.9 Bn by 2031, according to the latest market analysis.

Market Overview

3D sensing technology refers to the ability of devices to detect, measure, and interpret spatial information in three dimensions. This technology captures depth and creates detailed three-dimensional representations of objects using methods like structured light, time-of-flight (ToF), and stereoscopic vision. These innovations are increasingly integrated into diverse sectors such as automotive, industrial, healthcare, consumer electronics, and security & surveillance, offering new opportunities for product development and enhancement.

As demand for immersive technologies such as augmented reality (AR), virtual reality (VR), and advanced robotics escalates, 3D sensing technology is becoming a central component in the design of cutting-edge consumer and industrial applications. The future of this market is set to be propelled by the growing adoption of 3D sensing solutions in gaming, smart cities, and autonomous vehicles, with significant advancements anticipated across multiple segments.

Market Drivers & Trends

Several factors are propelling the 3D sensing technology market:

Rising Demand in Consumer Electronics: The proliferation of smartphones, gaming consoles, and wearables is a primary driver of the market. 3D sensing technology enhances the user experience by enabling features such as facial recognition, gesture control, and augmented reality (AR). These advancements are transforming how consumers interact with devices.

Government Initiatives in Smart Cities: The rapid urbanization and industrialization of emerging economies are fueling the demand for smart city infrastructure. 3D sensing technologies, including depth sensing cameras, LiDAR, and time-of-flight (ToF) sensors, are integral to urban planning, waste management, public safety, environmental monitoring, and infrastructure development.

Automotive Advancements: The growing need for autonomous vehicles and advanced driver-assistance systems (ADAS) is boosting demand for 3D sensors. Technologies such as LiDAR and radar systems are being incorporated into navigation systems, offering real-time updates on road traffic, weather conditions, and potential hazards.

Healthcare Applications: The adoption of robotics in healthcare is growing, and with it, the use of 3D sensing technologies. Surgeons are using 3D imaging for minimally invasive surgeries, improving diagnostic accuracy and enabling precise drug delivery. The medical sector's shift towards robotic surgeries is creating ample growth opportunities for 3D sensing technology providers.

Increased Popularity of Virtual and Augmented Reality: Virtual reality (VR) and augmented reality (AR) are rapidly evolving sectors, both of which rely heavily on 3D sensing technologies. Whether for gaming, training, or immersive experiences, 3D sensing is essential to providing realistic and interactive environments.

Latest Market Trends

Integration with Artificial Intelligence (AI) and IoT: AI and Internet of Things (IoT) technologies are increasingly being integrated with 3D sensing solutions to provide smarter, more intuitive systems. AI-driven data analysis enables real-time decision-making, while IoT devices are leveraging 3D sensing for applications in smart homes, industrial automation, and healthcare.

Miniaturization of Sensors: The continuous miniaturization of 3D sensors is allowing these devices to be integrated into smaller, more compact applications, especially in mobile devices, wearables, and drones. The ability to offer high-precision measurements in smaller form factors is expanding the potential for 3D sensing technology.

Advancements in Sensor Accuracy: New generations of 3D sensors are becoming more accurate and versatile. With improvements in depth sensing capabilities, these sensors are finding more applications in precision industries such as medical diagnostics, automotive, and manufacturing.

Key Players and Industry Leaders

The 3D sensing technology market is competitive and consists of key players leading the way in innovation and product development. Some of the leading companies in the market include:

ams-OSRAM AG

Infineon Technologies AG

PMD Technologies AG

STMicroelectronics N.V.

Texas Instruments Incorporated

Coherent Corp.

Lumentum Operations LLC

Himax Technologies, Inc.

Intel

Sony Depthsensing Solutions

Recent Developments

In recent months, several key developments have been observed in the 3D sensing technology space:

ams OSRAM AG launched a low-power, small-sized global shutter visible and near-infrared (NIR) image sensor for 2D and 3D sensing systems, making it ideal for applications in VR, drones, and industrial sensors.

Senet, Inc. and Iota Communications, Inc. partnered to offer 3D sensing technologies that support smart infrastructure, paving the way for increased adoption of 3D sensors in IoT-enabled environments.

Market Opportunities and Challenges

As the 3D sensing technology market expands, several opportunities and challenges emerge:

Opportunities:

The growing demand for robotics and automation in healthcare offers substantial growth potential for 3D sensing solutions, particularly in surgical applications.

Government investments in smart cities create new avenues for 3D sensing technologies, which are essential for efficient urban planning and management.

Technological advancements in augmented reality and virtual reality open new market opportunities for 3D sensing in gaming, training, and entertainment.

Challenges:

The high cost of 3D sensors and technology may pose a challenge to widespread adoption, particularly in emerging markets.

Data privacy concerns, especially regarding facial recognition and biometric security, could limit the deployment of 3D sensing solutions in certain sectors.

Integration and compatibility with existing systems across industries may require significant investment in research and development.

Future Outlook

Looking ahead, the global 3D sensing technology market is set to experience robust growth. The increasing adoption of IoT, AI, and automation will drive demand for more precise and innovative 3D sensing solutions. Additionally, the continued push towards autonomous vehicles and smart cities will create new applications for this technology.

The key to sustained growth will lie in the ability of companies to innovate and address challenges such as cost-effectiveness and data privacy while capitalizing on new opportunities in the healthcare, automotive, and consumer electronics sectors.

Market Segmentation

Technology:

Stereoscopic Vision

Structured Light Pattern

Time of Flight (ToF)

Ultrasound

Sensor Type:

Pressure Sensors

Image Sensors

Gyro Sensors

Proximity Sensors

End-user Industries:

Consumer Electronics

Media & Entertainment

Automotive

Security & Surveillance

Industrial

Regional Insights:

North America

Europe

Asia Pacific

South America

Middle East & Africa

Why Buy This Report?

This comprehensive report on the 3D sensing technology market provides:

In-depth market analysis: With segment and regional-level insights, market trends, and forecasts for the period 2023-2031.

Competitive landscape: Profiles of key players, their strategies, financial performance, and recent developments.

Future insights: Detailed analysis of emerging opportunities and challenges, as well as technological innovations in 3D sensing.

For businesses, investors, and professionals looking to understand the dynamic landscape of the 3D sensing technology market, this report offers valuable insights that will inform strategic decisions, product development, and market entry.

0 notes

Text

How AI Is Transforming OSHA 10 Online Training

Workplace safety is evolving and artificial intelligence (AI) is leading the charge. Traditional OSHA 10 training is going virtual, using AI to deliver smarter, more engaging learning experiences. AI helps reduce Total Recordable Incident Rates (TRIR) by analysing historical and real-time data to predict potential spikes and prevent incidents. AI also boosts training completion rates through personalized learning and increases near-miss reporting by making the process simpler and more accessible.

Platforms powered by Artificial Intelligence (AI) now provide personalized content, real-time feedback, and interactive simulations that empower workers to retain critical information at the time and place of their choosing.

In this blog, we will investigate how virtual learning is facilitating the transition to OSHA 10 online training (Occupational Safety and Health Administration) and the future of workplace safety.

How AI Is Enhancing OSHA 10 Training

The integration of Artificial Intelligence (AI), Virtual Reality (VR), and Augmented Reality (AR) into authorized OSHA 10 online training makes the process easier, more engaging, and of better quality. The platforms allow laborers to learn independently at their own pace while immersing them in real-world situations that resemble unsafe conditions.

For instance, VR permits workers to prepare for risky activities under simulation. In doing so, they get hands-on experience while the risks cannot occur in actual situations. The following are a few ways in which AI usage has improved the learning experience:

Personalized Learning

AI operates on employee information to customize training modules. It adjusts content according to roles, skill levels, and past performance. This allows employees to be trained on safety topics relevant to their workplace hazards.

For example, a construction worker operating heavy machinery may be guided through modules on equipment safety, hazard recognition, and the proper use of personal protective equipment (PPE). This focused approach helps them understand OSHA regulations and confidently apply safety practices in their daily work.

Better Knowledge Retention

A study by the National Research and Development Institute on Occupational Safety shows that AI-based e-learning solutions enhance retention rates by as much as 60%. Interactive elements such as VR simulations allow employees to retain safety principles better.

When information is closely related to their daily tasks, employees are more likely to pay attention to and retain it. Employees are more motivated to put what they've learned into practice when they perceive how the training relates to their particular tasks, which promotes safer work practices.

Efficiency and Speed

AI greatly improves the effectiveness of OSHA 10 training programs through enhanced safety and productivity through predictive maintenance and real-time risk assessment. Developing and revising training programs to satisfy the unique requirements of a varied workforce is one of the most time-consuming duties for safety administrators. A large portion of this process is automated by AI, which speeds up and improves training management.

AI recommends the most pertinent courses based on data-driven insights rather than choosing courses by hand for every employee. This eliminates the uncertainty associated with traditional training management and allows employees to acquire the training they require more quickly. In addition to AI, other immersive technologies like Virtual Reality (VR) are redefining how workers experience OSHA 10 training.

The Role of Virtual Reality in OSHA 10 Online Training

VR is emerging as one of the most effective tools for workplace safety training. Its immersive nature allows workers to experience realistic scenarios, such as fire emergencies or construction site hazards, and practice their responses in a safe, simulated environment.

A study by the University of Maryland found that trainees who used VR responded more quickly and effectively to fire incidents than those who received traditional training. In the construction industry, VR-based simulations have been linked to a nearly 48% reduction in on-site accidents, highlighting the technology’s role in preparing workers for hazardous conditions.

VR also enhances engagement and collaboration in OSHA 10 online training. Team-based simulations foster active participation, improve decision-making skills, and help employees internalize safety protocols through interactive problem-solving.

Challenges and Future

Despite its advantages, virtual training comes with challenges. Some workers may resist change, preferring traditional classroom-based instruction. Others may face technology barriers, such as limited access to VR equipment or low digital literacy.

To overcome these hurdles, companies should introduce new technology in phases, offer robust support, and tailor training to different learning styles and job roles.

Looking ahead, AI is set to play an even bigger role in workplace safety. Predictive analytics may soon identify risks based on past data, enabling organizations to take proactive safety measures. As these technologies evolve, OSHA 10 training will become an even more essential and intelligent part of workforce development.

Creating a Safe Workplace for Everyone!

AI-based virtual learning is revolutionizing OSHA 10 online training. It enhances safety training with greater interaction, personalization, and accessibility. AR and VR technologies are equipping workers with in-the-field risk readiness and significantly lowering workplace injuries.

When businesses adopt these technologies, they not only create safer working environments but also ensure compliance becomes second nature. Now is the time to invest in AI-powered OSHA 10 training solutions that prioritize safety, compliance, and performance. So, explore smarter training options today!.

0 notes

Text

How Safety Platforms Help Prevent Accidents Before They Happen

In today’s fast-paced work environments, preventing accidents before they occur is not just a goal—it’s a necessity. Safety platforms have emerged as pivotal tools in achieving this proactive approach. By leveraging advanced technologies and fostering a culture of safety, these platforms are transforming workplaces across industries.

What Are Safety Platforms?

Safety platforms are integrated systems designed to monitor, analyze, and enhance workplace safety. They combine hardware (like sensors and wearables) with software (such as analytics dashboards and reporting tools) to provide real-time insights and predictive analytics. These platforms aim to identify potential hazards, ensure compliance, and promote a culture of continuous safety improvement.

How Do Safety Platforms Prevent Accidents?

1. Real-Time Monitoring and Alerts

Modern safety platforms utilize sensors and IoT devices to continuously monitor workplace conditions. For instance, AI-powered systems can detect if a worker is not wearing the required PPE or if machinery is operating outside safe parameters. Immediate alerts allow for swift corrective actions, reducing the likelihood of accidents.

2. Predictive Analytics

By analyzing historical data, safety platforms can predict potential hazards. For example, if data shows a pattern of near-misses in a particular area, the system can flag it for further investigation and preventive measures.

3. Enhanced Training and Simulation

Safety platforms often include training modules that use virtual reality (VR) and augmented reality (AR) to simulate hazardous scenarios. This immersive training helps workers recognize and respond to potential dangers effectively.

4. Behavioral Safety Tracking

These platforms can monitor worker behaviors, identifying patterns that may lead to accidents. For instance, frequent short breaks might indicate fatigue, prompting interventions to prevent errors or mishaps.

What Are the Key Features of Effective Safety Platforms?

Integration with Existing Systems: Seamless compatibility with current workplace tools ensures efficient implementation.

User-Friendly Interface: Intuitive dashboards and controls make it easier for staff to engage with the platform.

Scalability: The ability to adapt to various sizes and types of operations is crucial for widespread adoption.

Compliance Management: Automated tracking of regulatory requirements helps maintain adherence to safety standards.

Why Is Proactive Safety Management Important?

Proactive safety management shifts the focus from reacting to incidents to preventing them. This approach not only safeguards employees but also reduces downtime, lowers insurance costs, and enhances overall productivity. By identifying and addressing risks before they result in accidents, organizations can create a safer and more efficient work environment.

How Do Safety Platforms Foster a Culture of Safety?

Safety platforms encourage continuous engagement with safety protocols. Features like gamified training, regular feedback, and easy reporting mechanisms empower employees to take an active role in maintaining a safe workplace. This collective responsibility reinforces a culture where safety is a shared priority.

What Are the Challenges in Implementing Safety Platforms?

Cost: Initial investment in technology and training can be substantial.

Resistance to Change: Employees may be hesitant to adopt new systems, requiring effective change management strategies.

Data Privacy Concerns: Monitoring systems must balance safety with respect for personal privacy.

Technical Issues: Integration with existing systems and ensuring uptime can pose technical challenges.

What Industries Benefit Most from Safety Platforms?

While all industries can benefit, sectors with higher risk profiles see the most significant impact:

Construction: Monitoring equipment usage and worker movements to prevent falls and equipment-related injuries.

Manufacturing: Ensuring machinery operates within safe parameters and workers follow safety protocols.

Healthcare: Protecting staff from exposure to hazardous materials and ensuring patient safety.

Transportation: Monitoring driver fatigue and vehicle conditions to prevent accidents.

How Do Safety Platforms Integrate with Wearable Technology?

Wearable devices, such as smart helmets and vests, can collect data on worker movements, environmental conditions, and physiological indicators. This data feeds into safety platforms, providing real-time insights and enabling immediate responses to potential hazards.

What Is the Future of Safety Platforms?

The evolution of safety platforms will likely include:

Advanced AI Capabilities: Improved predictive analytics for even more accurate hazard identification.

Greater Integration: Seamless connectivity with a broader range of devices and systems.

Enhanced User Experience: More intuitive interfaces and personalized safety recommendations.

Focus on Mental Health: Incorporating tools to monitor and support employee mental well-being.

FAQ

Q1: Are safety platforms suitable for small businesses?

Yes, many safety platforms offer scalable solutions tailored to the needs and budgets of small businesses.

Q2: How do safety platforms handle data privacy?

Reputable platforms comply with data protection regulations and implement robust security measures to safeguard personal information.

Q3: Can safety platforms be customized for specific industries?

Absolutely. Many platforms offer industry-specific modules and features to address unique safety challenges.

Q4: What training is required to use a safety platform?

Training requirements vary, but most platforms are designed with user-friendly interfaces and provide comprehensive onboarding resources.

Q5: How quickly can a safety platform be implemented?

Implementation timelines depend on the complexity of the system and the size of the organization but can range from a few weeks to several months.

0 notes

Text

Emerging Trends in Safety Management Courses for 2025

As we head into 2025, the landscape of safety management Course is rapidly evolving, driven by technological advancements, regulatory changes, and a heightened awareness of workplace and environmental safety. This article explores the emerging trends in safety management courses, highlighting how educational programs are adapting to meet the future demands of this critical field.

Integration of Digital Technologies A significant trend in safety management courses is the integration of digital technologies. Virtual reality (VR) and augmented reality (AR) are at the forefront, providing immersive learning experiences that are both engaging and effective. For instance, VR simulations allow students to navigate complex safety scenarios in a controlled, risk-free environment. This hands-on approach not only enhances learning outcomes but also prepares students for real-world challenges they might face in their careers. Artificial intelligence (AI) is another technology being integrated into safety management courses. AI-driven analytics tools are used to teach students how to predict potential hazards and mitigate risks effectively. By analyzing data from past incidents, AI models can help identify patterns that might lead to accidents, enabling preventative measures.

Focus on Mental Health and Wellbeing The importance of mental health in the workplace has gained recognition, prompting safety management courses to include modules on psychological safety and employee wellbeing. Courses now cover strategies for managing stress, recognizing signs of mental health struggles among employees, and creating supportive work environments. This holistic approach ensures that safety managers are equipped to handle not only physical risks but also the psychological aspects of workplace safety.

Emphasis on Sustainability and Environmental Safety With global attention on environmental issues, safety management courses in 2025 are increasingly incorporating sustainability practices. Students learn about sustainable waste management, emergency response to environmental hazards, and the implementation of eco-friendly safety measures. This trend is particularly relevant in industries like manufacturing and construction, where environmental impacts are significant.

Compliance and Regulatory Training Regulatory compliance remains a core component of safety management courses. However, the approach is shifting towards a more dynamic understanding of global and local regulations. Courses now emphasize staying ahead of regulatory changes and understanding the implications of non-compliance. This is crucial in a globalized economy where businesses may operate across multiple jurisdictions with varying safety laws.

Adaptive Learning Platforms The use of adaptive learning platforms in safety management courses personalizes the educational experience for each student. These platforms adjust the curriculum based on the learner's pace and understanding, ensuring that all students achieve mastery of the subject matter. This personalized approach helps in catering to diverse learning needs and enhances the effectiveness of the training.

Collaboration and Interdisciplinary Learning Interdisciplinary learning is becoming a staple in safety management education. Courses often include collaborations with fields such as engineering, healthcare, and business management. This broadens students' perspectives, enabling them to implement safety practices more effectively across different sectors. Moreover, teamwork and communication skills are emphasized, reflecting the collaborative nature of the profession.

Lifelong Learning and Continuous Professional Development Finally, there is a growing emphasis on lifelong learning and continuous professional development in safety management. Courses are increasingly offering advanced modules and certifications that professionals can take throughout their careers to stay updated with the latest practices and technologies. This commitment to ongoing education helps safety managers remain effective as the field evolves. Conclusion The field of safety management is more dynamic than ever, and the trends in educational courses for 2025 reflect this evolution. By incorporating advanced technologies, focusing on mental health and sustainability, and adapting to regulatory changes, these courses prepare students to become proficient safety managers who can navigate the complexities of modern workplaces. As safety management continues to adapt to new challenges, education in this field must evolve accordingly, ensuring that safety professionals are well-prepared to protect both people and the planet. Safety Management Course

0 notes

Text

Bridging the Skills Gap in Manufacturing: Why VR Training Is the Answer

Walk into any modern manufacturing plant today, and you'll likely notice two things: cutting-edge machines running at high efficiency—and a noticeable shortage of skilled workers to operate and maintain them. As automation and smart technologies redefine the manufacturing landscape, the demand for technically skilled talent is outpacing supply. The result? A widening skills gap that threatens productivity, safety, and long-term innovation.

This isn’t just a staffing issue—it’s a training issue. And traditional learning methods simply aren’t keeping up.

The Root of the Skills Gap

In the manufacturing world, experience matters. Workers aren’t just expected to memorize procedures—they’re expected to perform under pressure, troubleshoot in real-time, and respond to unpredictable challenges. The problem? Most training programs still rely heavily on manuals, slide decks, and passive video content. These formats may deliver knowledge but fall short of building muscle memory, decision-making confidence, and hazard awareness.

Additionally, newer recruits—especially Gen Z entrants—gravitate toward digital-first experiences. They learn better through interactivity, gamification, and on-demand content. Expecting them to thrive through decades-old training models is like trying to teach CNC programming on a chalkboard.

This disconnect is precisely where Virtual Reality (VR) training steps in.

The Power of VR in Manufacturing Training

VR training flips the script by placing learners inside a fully immersive manufacturing environment. They’re not watching someone else do the task—they're doing it themselves in a simulated, risk-free setting. From operating heavy machinery to identifying safety hazards on a production floor, VR allows learners to engage with real-world scenarios without the real-world consequences.

Imagine being a new technician learning to lock out/tag out electrical equipment. Instead of just watching a video or reading instructions, you are virtually standing in front of a live panel, making decisions and receiving immediate feedback. That level of interactivity builds true readiness.

Meeting Industry Demand with Scalable Learning

One of the greatest challenges training coordinators face is scale. Training large groups on real factory floors is not always practical—or safe. VR training solves this by offering consistent learning experiences, regardless of geography or schedule. Teams can train remotely, onboard faster, and stay up to date with evolving safety and compliance standards—all with minimal disruption to operations.

For students and fresh entrants, VR serves as a powerful bridge between classroom theory and on-the-job readiness. Institutions and technical training centers that adopt VR modules are producing candidates who can hit the ground running—reducing onboarding time and increasing employer confidence.

Why XR Guru Leads the Charge in VR Manufacturing Training

XR Guru, a leader in delivering immersive, hands-on VR training experiences tailored for the manufacturing industry, is at the forefront of this training revolution. Our modules go far beyond generic simulations. With realistic environments, industry-aligned content, and engaging assessments, XR Guru equips learners with the skills they need—fast.

Our VR packages are designed to match the pace of industry evolution, offering up-to-date, relevant scenarios that reflect current manufacturing challenges.

In a time when manufacturers can’t afford training delays and learners can’t afford to fall behind, XR Guru provides a smart, scalable solution.

Conclusion

The skills gap in manufacturing isn’t going away—but how we address it can make all the difference. By embracing VR training, the manufacturing industry can prepare a new generation of skilled workers ready to thrive in high-tech environments. And with XR Guru leading the way, both learners and employers have a powerful ally in building a future-ready workforce.

For more information, visit: https://www.xrguru.com/virtual-reality-in-manufacturing

0 notes

Text

Explore how Simulanis is leading the way in fire safety VR training in India with its cutting-edge VR fire simulators and fire extinguisher training simulators. Learn how these advanced fire extinguisher simulators provide a realistic, safe, and immersive training experience for industries and individuals, preparing them for real-world fire safety situations

#VR Fire Simulator#Fire Extinguisher Simulator#Fire Extinguisher Training Simulator#fire safety vr training in india#simulanissolutions#virtualreality#Fire Safety VR Training#Virtual Reality Fire Training#Fire Prevention VR Simulation#Emergency Response VR Training#VR for Fire Drills#Industrial Fire Safety VR#VR Fire Safety Programs#Fire Safety Education in India#VR Fire Safety Simulation India#Fire Safety Awareness VR#Virtual Fire Safety Training India#VR-Based Fire Evacuation Drills#Occupational Fire Safety VR#Fire Safety VR Solutions India#Fire Hazard VR Training#Virtual Reality for Firefighters#Realistic Fire Training in VR#Fire Emergency Preparedness VR#Fire Safety Training Technology#India VR Safety Training Solutions

0 notes

Text

Exploring the Future: Immersive Technology Applications in Modern Industries

In recent years, the digital landscape has evolved rapidly, ushering in groundbreaking innovations that continue to redefine how we interact with technology. Among the most transformative is immersive technology, which includes tools like augmented reality (AR), virtual reality (VR), and mixed reality (MR). These tools offer a deeper, more interactive way of engaging with digital content—reshaping industries from education and healthcare to manufacturing and entertainment.

One of the most notable immersive technology applications is in employee training and safety simulations. Rather than relying on static manuals or traditional classroom setups, companies can now deploy realistic virtual environments to train employees. This approach boosts retention, enhances engagement, and significantly reduces the risk of real-world mistakes.

The synergy between immersive technology and virtual reality is particularly impactful in manufacturing. VR allows workers to virtually navigate hazardous scenarios, identify risks, and learn safety protocols in a fully controlled environment. This not only increases efficiency but also promotes a culture of safety across the workplace. For a deeper look into how augmented reality is being applied in industrial settings, especially to improve workplace safety, visit this detailed article on augmented reality in manufacturing.

As the adoption of immersive solutions continues to grow, organizations that embrace these technologies today are setting themselves up for a smarter, safer, and more efficient tomorrow.

0 notes

Text

Revolutionizing Immersive Technology: Granoopixr’s AR-VR Leadership Across India

In the rapidly evolving world of immersive technology, one name stands out for its innovation, reliability, and transformative impact—Granoopixr. With a stronghold in both augmented and virtual reality domains, Granoopixr has become a trusted partner for businesses, educators, entertainment studios, and brands looking to adopt cutting-edge AR and VR solutions across India. From Virtual Reality in Hyderabad to Augmented Reality in Bangalore and beyond, Granoopixr is shaping the future of digital experiences.

This blog delves into how Granoopixr is enabling next-gen interactions while ensuring visibility and reach in today’s search-driven, AI-curated world—without overcomplicating the technology or the terminology. Here’s how the company is establishing its presence and becoming a go-to provider in major Indian cities.

Granoopixr: Merging Innovation with Impact

Granoopixr isn’t just an immersive tech company—it is an ecosystem of creativity, deep technical expertise, and human-first design. With years of hands-on experience and a multidisciplinary team, Granoopixr delivers customized solutions for industries ranging from education and retail to healthcare, real estate, and manufacturing.

The company’s strength lies in building experiences that are not only visually engaging but also strategically aligned with business goals. Whether it’s an AR-based brand campaign or a VR training simulation, Granoopixr ensures each project delivers measurable outcomes.

Virtual Reality in Hyderabad: Building the Future of Immersive Training

Hyderabad has emerged as a tech-forward city, and Virtual Reality in Hyderabad is gaining momentum across sectors. Granoopixr has tapped into this potential by providing VR solutions to IT hubs, academic institutions, and pharmaceutical companies.

Using VR, Granoopixr helps companies simulate high-risk environments like medical labs, industrial plants, or construction sites. This eliminates safety hazards while offering a deeply engaging training experience. It’s not just about creating virtual spaces—it’s about building skill, safety, and speed for professionals in critical domains.

Augmented Reality in Hyderabad: Enhancing Learning and Retail

In addition to VR, Augmented Reality in Hyderabad is revolutionizing how people interact with real-world products and environments. Granoopixr’s AR applications are being used by retail outlets, real estate agents, and schools in the region.

Imagine a student pointing their tablet at a science book and seeing 3D models of the human body. Or a customer scanning a product in a store and instantly seeing its features in AR. These aren’t just concepts—they are real solutions developed by Granoopixr for clients in Hyderabad, making education more interactive and retail more persuasive.

Augmented Reality in Bangalore: Innovation Meets User-Centric Design

Bangalore, the Silicon Valley of India, is naturally a hotspot for Augmented Reality in Bangalore. Startups, tech giants, and R&D centers in the city seek out advanced AR tools to gain competitive advantage. Granoopixr supports this ecosystem with custom-built AR apps, product visualizers, and AR marketing experiences.

The company’s approach is rooted in user behavior. By studying how people engage with AR interfaces, Granoopixr designs tools that are intuitive, accessible, and scalable—whether it’s an AR interior design app or an interactive AR navigation guide for museums and malls.

Best VR Companies in Bangalore: Granoopixr Leads the Pack

When it comes to immersive solutions, Bangalore boasts some impressive players. However, Granoopixr ranks among the Best VR Companies in Bangalore due to its consistent delivery of high-quality, interactive content that exceeds expectations.

One of Granoopixr’s key strengths is its ability to develop VR content that’s lightweight yet graphically rich—ideal for both high-end headsets and mobile platforms. This versatility allows businesses to deploy VR at scale, without worrying about hardware limitations or performance issues.

From architectural walkthroughs to remote healthcare consultations, Granoopixr’s VR solutions are as practical as they are immersive.

Virtual Reality in Mumbai: Elevating Marketing and Entertainment

Mumbai, the media and entertainment capital of India, is embracing Virtual Reality in Mumbai with open arms. Film studios, advertising agencies, and fashion brands are investing in VR to create immersive campaigns and experiences. Granoopixr is right at the center of this movement.

By combining creative storytelling with high-end visual development, Granoopixr has produced compelling VR experiences that captivate audiences. These include virtual showrooms, 360-degree product reveals, and interactive brand worlds designed for maximum consumer engagement.

In Mumbai’s fast-paced media industry, Granoopixr’s ability to deliver on tight timelines while maintaining visual excellence makes it a top choice for VR content.

Augmented Reality in Mumbai: Powering Smarter Interactions

Just as VR is transforming entertainment, Augmented Reality in Mumbai is reshaping how brands and consumers interact. Granoopixr’s AR projects in Mumbai have catered to luxury brands, educational platforms, and real estate developers who want to offer more immersive, personalized experiences.

Using AR, consumers can try on clothing virtually, visualize home interiors before purchase, or access dynamic product tutorials. Granoopixr’s technology is built to be compatible with most smartphones, ensuring accessibility and mass adoption across the city’s diverse consumer base.

Why Granoopixr Stands Out

What sets Granoopixr apart is not just its technological excellence but its ethical, consultative, and outcome-driven approach. Clients trust Granoopixr because:

Expertise: The team consists of AR/VR specialists, UX designers, 3D artists, and data analysts with years of field experience.

Experience: From prototyping to deployment, Granoopixr has delivered successful projects across sectors and geographies.

Authority: The company is often invited to speak at tech forums and collaborate with academia for immersive tech research.

Trustworthiness: Transparent pricing, reliable timelines, and scalable support make Granoopixr a long-term partner rather than a one-time vendor.

Moreover, Granoopixr creates content and platforms that are naturally aligned with search behavior and online discoverability, ensuring that their clients' solutions are not just innovative, but also visible to the right audience.

Final Thoughts

Whether it's Augmented Reality in Bangalore, Virtual Reality in Hyderabad, or immersive experiences in Mumbai, Granoopixr is delivering solutions that combine imagination with functionality. The company’s dedication to building accessible, performance-driven AR and VR tools ensures that businesses of all sizes can leverage immersive tech to tell better stories, train smarter, and sell more effectively.

In an era where digital interaction is redefining business, Granoopixr is not just participating in the shift—it’s leading it. For brands looking to create a powerful impact with immersive technology in India, Granoopixr is the name to know.

#Virtual Reality in Hyderabad#Augmented Reality in Hyderabad#Augmented Reality in Bangalore#Best VR Companies in Bangalore#Virtual Reality in Mumbai#Augmented Reality in Mumbai

0 notes

Text

What Will Health and Safety Training Look Like in 10 Years?

June 4, 2025 What Will Health and Safety Training Look Like in 10 Years? Health and safety training has evolved significantly in the past decade, from dusty manuals and slide decks to immersive videos, interactive eLearning, and virtual simulations. But what lies ahead? With technology advancing at pace and workplaces becoming more dynamic and digitised, the next 10 years are set to bring radical changes to how organisations approach safety training. Here’s what we predict health and safety training will look like by 2035. 1. Virtual and Augmented Reality Will Go Mainstream Virtual reality (VR) and augmented reality (AR) have already begun making waves in industries like construction, manufacturing, and healthcare, but adoption is still relatively niche. Over the next decade, expect immersive training environments to become the norm. Using VR headsets, employees will be able to walk through lifelike emergency scenarios, operate virtual machinery, and experience simulated hazards, without any real-world risk. AR, on the other hand, will overlay safety instructions or hazard warnings in real-time while on site, providing immediate, location-based guidance. As this technology becomes more affordable and accessible, it will be integrated into standard training packages, especially for high-risk industries. 2. AI-Driven Personalisation Artificial intelligence will play a big role in shaping the future of training. No more one-size-fits-all content, AI systems will analyse individual learning styles, job roles, and performance data to deliver personalised safety training. This means: Adaptive quizzes that change difficulty based on the learner’s answers Targeted video modules based on previous errors or gaps in knowledge Real-time feedback and reminders triggered by workplace behaviours or wearable data This level of customisation will make training more efficient and far more relevant to each individual. 3. Interactive and Gamified Learning Gamification is already gaining traction, but it’s set to become a core part of health and safety training. Why? Because it works. Employees will engage with interactive content that includes: Scenario-based challenges Real-time decision-making Leaderboards and performance rewards These game-like features help make learning stick and increase motivation, transforming what’s often seen as a tick-box exercise into something employees actually want to take part in. 4. Real-Time Safety Data and Wearables Imagine receiving instant feedback on your safety practices as you work. With the rise of wearable tech, that’s exactly what could happen. Wearables like smart helmets, watches, and AR glasses will monitor physical indicators (such as fatigue or exposure to hazards), track proximity to dangerous areas, and offer real-time alerts or even trigger auto-pauses in work processes. These devices could also integrate with training platforms, flagging specific behaviours that need to be addressed through refresher modules. This kind of live-loop feedback system will make training a continuous, embedded part of the working day. 5. Cloud-Based, On-Demand Learning Platforms In 10 years, training won’t be tied to a classroom or even a PC. It will live in the cloud, available anytime, anywhere. Mobile-first platforms will give workers instant access to bite-sized training content, updated procedures, and interactive safety checklists right from their smartphones. This will be particularly beneficial for field-based teams, remote workers, and gig economy employees who need to stay compliant without attending formal sessions. With everything stored online, companies will also benefit from automated records, easier audits, and faster updates when policies or regulations change. 6. A Cultural Shift: Safety as a Continuous Conversation Perhaps the most significant change won’t be technological, but cultural. In 10 years, health and safety training won’t be a once-a-year event, it will be an ongoing, embedded part of company culture. Supported by tech and data, organisations will be able to: Identify trends and risks early Reinforce behaviours daily Celebrate safe actions as part of team performance Training will move from reactive to proactive, from compliance-driven to people-focused. By 2035, health and safety training will look and feel very different. It will be immersive, intelligent, interactive, and most importantly, it will be more effective. As technology reshapes how we work, it will also empower organisations to build safer, smarter, and more engaged teams. The future of safety training is already in motion. Are you ready for it? Get in touch with our friendly team today to find out more: +44 (0)113 288 3245 | [email protected] Your Industrial Story Starts Here Press The Button. Make The Call. Transform Your Media. Contact Us Your Name * Your Email * Phone * What service are you interested in? Please Select An Option Below 2D Animated Video Production 3D Animated Video Production Video Production Drone Videography E Learning Video Production Health & Safety Video Production Interactive Video Production Video Training Virtual Reality Video Production Podcast Production Message * YOUR PRIVACY * Please tick here to confirm you have read our privacy notice which gives information on how we collect and process your personal data. SUBMIT If you are human, leave this field blank. +44(0)113 2883245 [email protected] 3 Fusion Court, Garforth, Leeds, LS25 2GH

0 notes

Text

How Will VR Training Transform Automotive Trainings and Maintenance?

In the fast-evolving landscape of automotive technology, virtual reality (VR) and augmented reality (AR) stand poised to revolutionize the way professionals are trained and how maintenance tasks are carried out. As these immersive technologies become more accessible and advanced, their integration into automotive training and maintenance procedures holds the promise of enhancing efficiency, safety, and effectiveness across the industry.

One of the most significant advantages of VR/AR in automotive training lies in their ability to create immersive learning experiences. Traditional training methods often involve textbooks, lectures, and hands-on practice on real vehicles. While these methods are effective to a certain extent, they may fall short in providing comprehensive understanding and practical skills development.

VR trainings offers trainees the opportunity to interact with virtual automotive systems in a realistic environment without the risk of damage to vehicles or equipment. Trainees can explore the intricacies of engine components, electrical systems, and diagnostic procedures in a simulated setting. AR, on the other hand, overlays digital information onto the physical world, allowing trainees to receive real-time guidance and instructions while working on actual vehicles.

By immersing trainees in lifelike scenarios, VR and AR training modules can accelerate learning curves, improve retention of information, and foster better decision-making skills. Moreover, these technologies can be tailored to specific training objectives and skill levels, catering to both novice technicians and experienced professionals.

In the realm of automotive maintenance, AR holds the potential to streamline workflows and enhance efficiency. Maintenance technicians often face complex tasks that require referencing technical manuals, schematics, and diagnostic procedures. Traditional methods of accessing this information, such as printed manuals or digital screens, can be cumbersome and time-consuming, leading to delays and errors in the maintenance process.

AR solutions address these challenges by overlaying relevant information directly onto the technician’s field of view through smart glasses or heads-up displays. Imagine a technician wearing AR glasses while performing a diagnostic check on an engine. As they inspect various components, relevant data, such as service manuals, diagnostic codes, and step-by-step instructions, are displayed in real-time, enabling the technician to work hands-free and with greater precision.

Furthermore, AR can facilitate remote assistance, allowing technicians to collaborate with experts located elsewhere in the world. Through live video feeds and AR annotations, remote experts can guide on-site technicians through complex repairs and troubleshooting procedures, reducing downtime and minimizing the need for expensive travel.

Beyond improving efficiency and effectiveness, the integration of VR/AR into automotive training and maintenance also has implications for safety and quality assurance. By providing trainees with realistic simulations of hazardous scenarios, VR training solution can instill safety protocols and emergency procedures in a controlled environment, minimizing the risk of accidents and injuries in real-world situations.”

Similarly, AR-enabled maintenance procedures can ensure that technicians adhere to standardized protocols and best practices, reducing the likelihood of errors and oversights. Digital overlays can highlight critical components, indicate proper torque specifications, and flag potential safety hazards, thereby enhancing the quality and reliability of maintenance work.

As VR/AR technologies continue to evolve and become more accessible, their impact on automotive training and maintenance is poised to grow significantly. From immersive training experiences that accelerate learning curves to augmented maintenance procedures that enhance efficiency and safety, these technologies hold the potential to revolutionize the automotive industry. However, realizing this potential will require collaboration between technology developers, automotive manufacturers, training institutions, and maintenance professionals. By embracing innovation and investing in the adoption of vr automotive training solutions, stakeholders can equip the workforce with the skills and tools needed to navigate the complexities of modern automotive technology, ensuring a safer, more efficient, and more sustainable future for the industry.

#augmented reality#metaverse#virtual reality#mixed reality#vr training solution#vr training#3d product modeling#xr development#xr development company#ar development company

1 note

·

View note