#WirelessHART

Explore tagged Tumblr posts

Text

Differences in Mesh Networking for Home or Industry

Reliability and Redundancy: Home Automation uses lightweight protocols (like Zigbee or Z-Wave) with some redundancy, but isn’t critical if a node temporarily drops out. Industrial use requires high fault tolerance, redundant paths, and self-healing capabilities to ensure uninterrupted ops, implemented using WirelessHART, ISA100.11a, or LoRaWAN.

Power and Maintenance: Home Automation is usually a simple battery powered unit with months to years of battery life. Data packets are small (…like switching a light on or off). Industrial devices may need grid power and uninterrupted supply.

#Endpoint#Home automation#Internet of things#ISA100.11a#LoRaWAN#Redundancy#Reliabiability#Security#System integration#WirelessHART#Z-Wave#Zigbee

0 notes

Text

The Rise of Wireless HART: Shaping the Future of Industrial Automation 🌐⚙️

The Global Wireless HART Market is booming! 📈 In 2023, it was valued at USD 416 million and is projected to grow at a 12.5% CAGR, reaching USD 961 million by 2030. With industries like oil & gas, pharmaceuticals, and food & beverages adopting new communication technologies, Wireless HART is at the heart of this revolution.

Download Sample : click

🔑 Why is it growing?

Industrial Automation & Industry 4.0 are driving the demand for efficient communication solutions.

IoT & Predictive Maintenance are reshaping how companies manage operations and reduce downtime.

Enhanced Security ensures data integrity, making it perfect for sensitive industries.

But it’s not all smooth sailing! 😬 The challenges, such as compatibility with legacy systems and high initial investment costs, still need to be tackled for widespread adoption.

🌍 Opportunities are massive in smart manufacturing and emerging markets like Asia-Pacific and Latin America, where the digital transformation is just getting started!

Inquire to Buy : click

As industries evolve, Wireless HART is shaping the future of automation, offering scalable, flexible solutions for a connected world.

#WirelessHART#IndustrialAutomation#SmartManufacturing#IoT#Industry4#PredictiveMaintenance#TechTrends#Innovation

0 notes

Text

0 notes

Text

Industrial Wireless Sensor Network Market Insights: Key Players, Innovations & Opportunities

The global industrial wireless sensor network market size is expected to reach USD 11.37 billion by 2030, growing at a CAGR of 12.1% from 2024 to 2030, according to a new study conducted by Grand View Research, Inc. The benefits offered by industrial wireless sensor network (IWSN) over wired networks, such as mobility, self-discovery capability, compact size, cost-effectiveness, and reduced complexity, are anticipated to play a significant role in increasing global demand.

IWSN is an advanced method of communication between two or more remotely located devices without interruption. The systems comprise nodes that act as access points to form a better communication system. In IWSN, sensor nodes are connected through various wireless technologies such as ZigBee, Wi-Fi, Bluetooth, and WirelessHART. Increasing adoption of wireless communication, need for strong connectivity across remote locations, and demand for network infrastructure are expected to fuel market growth.

Recent advancements in the fields of Internet of Things (IoT) and Artificial Intelligence (AI) have further increased demand for wireless networks and strong connectivity. Accelerated adoption of these technologies by the oil and gas, manufacturing, utilities, and automotive verticals is expected to boost the growth of the industrial wireless sensor network market. In addition, key players in the market are investing heavily in R&D to explore the scope of the technology for innovations, integration, and new product developments. For instance, ABB Ltd., which has 7 research centers and more than 8,000 technologists, invested USD 1.5 billion in R&D in 2016.

The hardware segment is anticipated to witness substantial growth as they detect activities and send information from one device to another through various communication technologies. Increasing miniaturization of electronic components and advancements in communication technology make it possible to develop a seamless network. The software handles device-specific tasks, such as initialization of hardware, memory management, and process management, as well as scheduling. The software segment generated the highest revenue in 2023 and the trend is expected to continue over the forecast period.

Global players in the IWSN market are collaborating with new entrants to provide improved products and systems with enhanced performance. In January 2017, Honeywell Process Solutions collaborated with AEREON to develop solutions that help the industrial sector improve operational efficiency, safety, and reliability.

Industrial Wireless Sensor Network Market Report Highlights

The software segment is anticipated to emerge as the fastest-growing segment over the forecast period owing to the increasing demand for advanced process & control monitoring, data collection, and data processing software.

The gas sensors segment is anticipated to emerge as the fastest growing segment due to rapidly increasing focus on workplace safety in industries such as oil & gas, pharmaceuticals, chemical & petroleum, building automation, and food & beverages.

The Asia Pacific regional market is expected to grow at the highest CAGR from 2024 to 2030 owing to the significant growth in manufacturing sector in developing countries such as India and China.

The cellular network segment is expected to witness fastest growth over the forecast period due to the rapidly growing demand for Low Power Wide Area Network (LPWAN) technologies-based Internet of Things (IoT) devices using LTE-M and Narrowband-IoT (NB-IoT) networks.

Curious about the Industrial Wireless Sensor Network Market? Get a FREE sample copy of the full report and gain valuable insights.

Industrial Wireless Sensor Network Market Segmentation

Grand View Research has segmented the global industrial wireless sensor network market report based on component, sensor network, technology, application, end use, and region:

Industrial Wireless Sensor Network (IWSN) Component Outlook (Revenue, USD Million, 2018 - 2030)

Hardware

Software

Services

Industrial Wireless Sensor Network (IWSN) Sensor Network Outlook (Revenue, USD Million, 2018 - 2030)

Temperature Sensor Networks

Pressure Sensor Networks

Level Sensor Networks

Flow Sensor Networks

Humidity Sensor Networks

Motion & Position Sensor Networks

Gas Sensor Networks

Light Sensor Networks

Chemical Sensor Networks

Others

Industrial Wireless Sensor Network (IWSN) Technology Outlook (Revenue, USD Million, 2018 - 2030)

Bluetooth

ZigBee

Wi-Fi

Near Field Communication (NFC)

Cellular Network

WirelessHART

ISA 100.11a

Industrial Wireless Sensor Network (IWSN) Application Outlook (Revenue, USD Million, 2018 - 2030)

Machine Monitoring

Process Monitoring

Asset Tracking

Safety & Surveillance

Industrial Wireless Sensor Network (IWSN) End Use Outlook (Revenue, USD Million, 2018 - 2030)

Automotive

Oil & Gas

Utilities

Mining

Food & Beverage

Manufacturing

Others

Industrial Wireless Sensor Network (IWSN) Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

S.

Canada

Mexico

Europe

UK

Germany

France

Asia Pacific

Japan

China

India

Australia

South Korea

Latin America

Brazil

Middle East & Africa

South Africa

Saudi Arabia

UAE

Key Players of Industrial Wireless Sensor Network Market

Cisco Systems, Inc.

Huawei Technologies Co., Ltd.

Advantech Co., Ltd.

Honeywell International Inc.

Analog Devices, Inc.

Texas Instruments Incorporated

Intel Corporation

ABB

NXP Semiconductors

Sensirion AG

Order a free sample PDF of the Industrial Wireless Sensor Network Market Intelligence Study, published by Grand View Research.

0 notes

Text

Chi tiết các tiêu chuẩn và quy định về đồng hồ đo lưu lượng

Việc hiểu rõ các tiêu chuẩn và quy định về đồng hồ đo lưu lượng đóng vai trò quan trọng trong đảm bảo độ chính xác, độ tin cậy của phép đo và hiệu suất của toàn hệ thống. Kim Thiên Phú sẽ giới thiệu các tiêu chuẩn quốc tế và quy định trong nước liên quan đến đồng hồ đo lưu lượng, đồng thời cập nhật những quy định mới nhất về lắp đặt và kiểm định hiện nay.

Các tiêu chuẩn về đồng hồ đo lưu lượng

Các tiêu chuẩn và quy chuẩn được áp dụng cho đồng hồ đo lưu lượng giúp định hướng việc thiết kế, sản xuất, lắp đặt và vận hành đồng hồ một cách an toàn và hiệu quả.

Tiêu chuẩn ISO

Tổ chức Tiêu chuẩn hóa Quốc tế (ISO) đã phát hành nhiều tiêu chuẩn liên quan đến đồng hồ đo lưu lượng, bao gồm:

ISO 5167: Định nghĩa các phương pháp đo lưu lượng chất lỏng trong đường ống kín bằng các thiết bị đo chênh lệch áp suất, như tấm lỗ orifice, ống Venturi, và vòi phun.

ISO 14155: Cung cấp hướng dẫn về thiết kế, hiệu chuẩn và vận hành cho các đồng hồ đo lưu lượng tuabin.

ISO 2533: Tập trung vào đồng hồ đo lưu lượng điện từ, là loại phổ biến để đo lưu lượng chất lỏng dẫn điện.

Tiêu chuẩn IEC

Ủy ban Kỹ thuật Điện Quốc tế (IEC) cũng ban hành các tiêu chuẩn cho đồng hồ đo lưu lượng, đặc biệt là đồng hồ đo lưu lượng điện tử và kỹ thuật số. Các tiêu chuẩn quan trọng bao gồm:

IEC 61508: Đưa ra khuôn khổ an toàn chức năng cho các hệ thống điện, điện tử, và lập trình, bao gồm cả đồng hồ đo lưu lượng.

IEC 60529: Định nghĩa các cấp độ bảo vệ IP chống bụi và nước, quan trọng khi lựa chọn đồng hồ cho môi trường khắc nghiệt.

IEC 62591: Đề cập đến giao thức truyền thông không dây WirelessHART, phổ biến trong các ứng dụng đo lường công nghiệp, bao gồm đồng hồ đo lưu lượng.

Quy chuẩn Việt Nam TCVN

Tại Việt Nam, Tổng cục Tiêu chuẩn Đo lường Chất lượng (TCVN) đã ban hành các quy chuẩn quốc gia nhằm đảm bảo sự phù hợp với tiêu chuẩn quốc tế và điều kiện sử dụng thực tế trong nước:

TCVN 5747:2008: Quy chuẩn cho đồng hồ đo nước lạnh dùng trong gia đình và công nghiệp, bao gồm yêu cầu về thiết kế, hiệu chuẩn và kiểm định.

TCVN 6458:2012: Quy chuẩn cho đồng hồ đo lưu lượng turbin khí, hướng dẫn chọn lựa, lắp đặt và vận hành.

TCVN 10894:2015: Đề cập đến đồng hồ đo lưu lượng siêu âm, công nghệ đo hiện đại và không xâm lấn.

Quy chuẩn Việt Nam QCVN

Ngoài các tiêu chuẩn quốc gia, Bộ Khoa học và Công nghệ cũng ban hành các quy chuẩn kỹ thuật quốc gia QCVN, đặc biệt trong các lĩnh vực đo lường dầu khí và môi trường:

QCVN 01:2017/BKHCN: Quy định về đo lường dầu thô và sản phẩm dầu mỏ, bao gồm cả đồng hồ đo lưu lượng.

QCVN 40:2011/BTNMT: Giám sát chất lượng nước thải, yêu cầu sử dụng đồng hồ đo lưu lượng để đo lưu lượng nước thải.

QCVN 50:2013/BTNMT: Giám sát chất lượng khí thải, với yêu cầu sử dụng đồng hồ đo lưu lượng để đo lưu lượng khí thải.

Quy định về lắp đặt đồng hồ đo lưu lượng

Việc lắp đặt chính xác đóng vai trò quan trọng để đảm bảo đồng hồ đo lưu lượng hoạt động ổn định và đạt độ tin cậy cao.

Vị trí lắp đặt

Lựa chọn vị trí lắp đặt đồng hồ đo lưu lượng phải đảm bảo dòng chảy ổn định, tránh nhiễu loạn. Nên tránh các vị trí có dòng chảy xoáy, gần van hoặc các phụ kiện gây trở ngại dòng chảy. Đối với đồng hồ đo lưu lượng dựa trên chênh lệch áp suất, cần đảm bảo có đủ chiều dài ống thẳng trước và sau đồng hồ để dòng chảy ổn định.

Hướng lắp đặt

Hướng lắp đặt thường được chỉ rõ trong tài liệu kỹ thuật của nhà sản xuất. Lắp đặt sai hướng có thể làm giảm độ chính xác hoặc gây hư hỏng cho đồng hồ.

Khoảng cách lắp đặt

Không nên lắp đặt đồng hồ quá gần các thiết bị có thể gây nhiễu điện từ như động cơ điện hoặc biến tần. Cần đảm bảo không gian xung quanh để dễ dàng bảo trì.

Yêu cầu về đường ống

Đường ống lắp đặt đồng hồ cần đáp ứng các yêu cầu về kích thước, vật liệu và độ sạch. Kích thước đường ống phải phù hợp với đồng hồ, vật liệu tương thích với lưu chất đo và đảm bảo không gây ăn mòn hoặc phản ứng hóa học.

Quy định về kiểm định đồng hồ đo lưu lượng

Việc kiểm định định kỳ đảm bảo đồng hồ đo lưu lượng duy trì độ chính xác trong thời gian dài và sau các lần bảo trì.

Tần suất kiểm định

Tần suất kiểm định phụ thuộc vào loại đồng hồ và ứng dụng cụ thể. Thông thường, nên kiểm định đồng hồ đo lưu lượng ít nhất một lần mỗi năm, hoặc thường xuyên hơn nếu yêu cầu ứng dụng đòi hỏi độ chính xác cao.

Cơ quan kiểm định

Việc kiểm định cần được thực hiện bởi các tổ chức được công nhận về năng lực kỹ thuật. Ở Việt Nam, Tổng cục Tiêu chuẩn Đo lường Chất lượng (TCVN) là cơ quan quản lý và giám sát các tổ chức kiểm định.

Quy trình kiểm định

Quá trình kiểm định thường bao gồm:

Kiểm tra trực quan: Đánh giá tình trạng bên ngoài của đồng hồ.

Kiểm tra chức năng: Đánh giá hoạt động, khả năng hiển thị và các chức năng khác.

Hiệu chuẩn: Đối chiếu kết quả đo với tiêu chuẩn đã biết và điều chỉnh khi cần thiết.

Lập báo cáo kiểm định: Ghi lại thông số kỹ thuật, sai số và tình trạng đồng hồ.

Giấy chứng nhận kiểm định

Sau khi kiểm định, đồng hồ đo lưu lượng sẽ được cấp giấy chứng nhận kiểm định, là minh chứng về độ chính xác và sự tuân thủ tiêu chuẩn, và có thể là yêu cầu từ các cơ quan quản lý hoặc đối tác kinh doanh.

Kim Thiên Phú hy vọng những thông tin trên giúp bạn hiểu rõ hơn về các tiêu chuẩn quốc tế, quy chuẩn trong nước và các quy định về lắp đặt, kiểm định đồng hồ đo lưu lượng. Việc cập nhật những tiêu chuẩn và quy định mới nhất sẽ giúp bạn lựa chọn và sử dụng đồng hồ đo lưu lượng một cách hiệu quả.

0 notes

Text

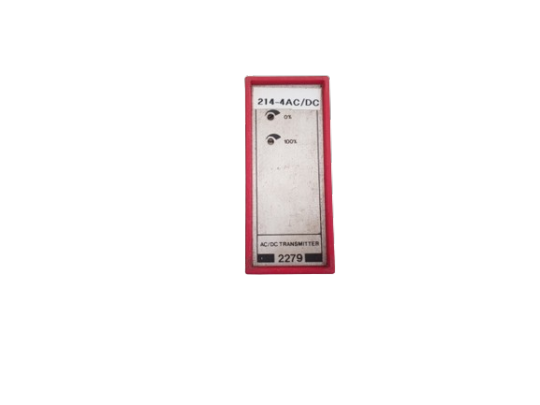

Innovations in Transmitters: Advancing Industrial Automation

In the world of industrial automation, transmitters play a essential role. These devices are the crucial contributor, quietly working to ensure that data is accurately transmitted for monitoring and control purposes. Over the years, innovations in transmitter technology have revolutionized industrial processes, leading to increased efficiency, safety, and reliability. In this blog, we will look into the exciting advancements in transmitters that are shaping the future of industrial automation.

The Evolution of Transmitter Technology

Transmitters have come a long way since their setting up. Initially used for basic signal transmission, they have evolved into sophisticated devices with a wide range of capabilities. Let's explore the key milestones in the evolution of transmitter technology:

Analog to Digital: The shift from analog to digital transmitters marked a significant advancement. Digital transmitters offer higher accuracy, improved reliability, and better compatibility with modern control systems.

Wireless Communication: The introduction of wireless transmitters revolutionized industrial communication. These devices eliminate the need for complex wiring, allowing for flexible and cost-effective installations.

Smart Transmitters: Smart transmitters represent a major leap forward. These devices are equipped with microprocessors and advanced diagnostics, enabling self-calibration, remote monitoring, and predictive maintenance.

Advanced Features and Functionalities

Modern transmitters boast an array of advanced features that enhance their performance and usability. Let's explore some of these key features:

Multivariable Measurement: Transmitters can now measure multiple process variables such as temperature, pressure, and flow rate simultaneously. This consolidation of measurements simplifies installations and reduces equipment costs.

HART Protocol: The Highway Addressable Remote Transducer (HART) protocol enables two-way digital communication with smart transmitters. This allows for configuration, diagnostics, and monitoring of devices remotely.

WirelessHART: Building upon the HART protocol, WirelessHART offers the benefits of wireless communication for industrial applications. It provides reliable data transmission with high security and scalability.

Intrinsically Safe Designs: Safety is dominant in industrial environments. Intrinsically safe transmitters are designed to operate in hazardous areas without risk of causing ignition, making them essential for applications in chemical plants, oil refineries, and more.

Applications in Diverse Industries

The versatility of transmitters enables their use across a wide range of industries. Let's explore how these innovations are making an impact:

Oil and Gas: In the oil and gas sector, transmitters are used for monitoring wellheads, pipelines, and storage tanks. Advanced features such as remote diagnostics and wireless communication improve operational efficiency and safety.

Chemical Processing: Transmitters play a critical role in chemical processing plants, where precise measurements are crucial. Intrinsically safe designs and smart capabilities enable accurate monitoring of volatile substances.

Power Generation: From traditional power plants to renewable energy facilities, transmitters are vital for monitoring parameters such as steam pressure, water levels, and gas flow. This data ensures optimal performance and maintenance scheduling.

Water and Wastewater: In water treatment facilities, transmitters help monitor water quality, flow rates, and pressure. Wireless transmitters simplify installations in sprawling treatment plants, improving overall efficiency.

Manufacturing: In manufacturing, transmitters are used for process control, ensuring consistent product quality. The integration of IoT allows manufacturers to gather real-time data for predictive maintenance and process optimization.

Future Trends and Innovations

The world of industrial automation is constantly evolving, and transmitters are at the forefront of innovation. Here are some exciting trends shaping the future:

5G Integration: The integration of 5G technology with transmitters will enable ultra-fast and reliable communication. This opens up possibilities for real-time control and monitoring in remote or mobile applications.

Edge Computing: Transmitters equipped with edge computing capabilities can process data locally, reducing latency and dependence on central servers. This is particularly useful for applications where real-time decisions are critical.

Energy Harvesting: Future transmitters may harness ambient energy sources such as vibrations or heat to power them. This reduces the reliance on batteries and enables sustainable, maintenance-free operation.

Conclusion

Innovations in transmitter technology are driving extraordinary advancements in industrial automation. From analog to smart, from wired to wireless, transmitters have undergone a remarkable transformation. These devices are not just tools for measurement; they are enablers of efficiency, safety, and reliability in industrial processes. The journey of transmitters in industrial automation is far from over. With each innovation, they bring us closer to a future where automation is not just efficient but also intelligent and adaptive to the needs of the industry.

#industrial automation#industrial equipment#auto2mation#industrial spare parts#industrial automation equipment#industrial and marine automation#industrial and marine automation equipment#transmitters

0 notes

Text

Boosting Performance and Reliability: How Rosemont Pressure Transmitters Drive Success in the Rosemont Company

In the world of process control, Rosemont Pressure Transmitters have established themselves as an indispensable tool for ensuring optimal performance and reliability. ترانسمیتر فشار ROSEMOUNT These advanced devices play a crucial role in measuring and transmitting accurate pressure readings, providing vital information for various industrial applications. From oil and gas to manufacturing and refining, Rosemont Pressure Transmitters have become the go-to solution for companies seeking to streamline their operations and achieve enhanced efficiency. This article will delve into the significance of pressure transmitters in process control, explore the features and benefits of Rosemont Pressure Transmitters, and showcase a compelling case study that highlights their undeniable impact on the success of the Rosemont Company.

The Importance of Pressure Transmitters in Process Control

In any industrial setting, maintaining precise control over pressure levels is of paramount importance. Pressure transmitters serve as a critical link between the process being monitored and the control system, ensuring that accurate measurements are obtained and transmitted in real-time. By accurately detecting and converting pressure signals into electronic data, these devices enable operators to make informed decisions and adjust process parameters accordingly. This level of control is essential for optimizing production, minimizing downtime, and ensuring product quality. Without reliable pressure transmitters, companies would be operating in the dark, unable to monitor and regulate pressure effectively.

Features and Benefits of Rosemont Pressure Transmitters

Rosemont Pressure Transmitters have gained a reputation for their exceptional performance and reliability. These cutting-edge devices boast a range of features that set them apart from the competition. One of their key strengths is their ability to provide accurate and precise measurements, even in the harshest environments. Built to withstand extreme temperatures, vibrations, and pressure variations, Rosemont Pressure Transmitters offer unparalleled durability and resilience.

Furthermore, these transmitters are equipped with advanced diagnostics capabilities, allowing for proactive maintenance and troubleshooting. By continuously monitoring their own performance, they can detect potential issues and provide early warnings, enabling technicians to address problems before they escalate. This predictive maintenance approach saves time, reduces costs, and enhances overall system reliability.

Rosemont Pressure Transmitters also incorporate state-of-the-art communication protocols, such as HART and WirelessHART, facilitating seamless integration with modern control systems. This connectivity enables easy configuration and remote monitoring, streamlining the entire process control workflow.

Case Study: How Rosemont Pressure Transmitters Improved Performance at the Rosemont Company

The Rosemont Company, a leading player in the oil and gas industry, faced significant challenges in maintaining optimal performance and reliability across their operations. The company relied heavily on accurate pressure measurements to ensure safety and efficiency. However, their existing pressure transmitters were proving to be unreliable and prone to frequent failures, leading to costly downtime and compromised production.

Recognizing the need for a robust solution, the Rosemont Company turned to Rosemont Pressure Transmitters. The implementation of these advanced devices brought about a transformative change in their operations. The accurate and reliable pressure measurements provided by Rosemont Pressure Transmitters allowed the company to fine-tune their processes, resulting in improved productivity and reduced waste.

Moreover, the advanced diagnostics capabilities of Rosemont Pressure Transmitters enabled the Rosemont Company to proactively address potential issues before they caused any major disruptions. This proactive maintenance approach significantly minimized downtime and enhanced overall system reliability. With the newfound confidence in their pressure measurement capabilities, the Rosemont Company was able to optimize their operations and achieve unprecedented levels of performance.

The Different Types of Rosemont Pressure Transmitters Available

Rosemont offers a wide range of pressure transmitters to cater to diverse industrial requirements. Each model is designed to meet specific application needs, ensuring that companies can choose the most suitable solution for their unique processes.

Rosemont 3051 Pressure Transmitter: This versatile transmitter offers exceptional performance and reliability in various industries, including oil and gas, chemical, and power generation. It is known for its accuracy, stability, and robustness.

Rosemont 2088 Pressure Transmitter: Ideal for high-pressure applications, this transmitter provides accurate measurements even in demanding environments. Its compact design and easy installation make it a popular choice for space-constrained installations.

Rosemont 3051S Pressure Transmitter: Designed for critical applications, this transmitter offers advanced diagnostics capabilities, enabling proactive maintenance and minimizing downtime. It is widely used in industries where precision and reliability are of utmost importance.

Rosemont 3095 Pressure Transmitter: This transmitter is specifically designed for applications that require high accuracy and stability, such as custody transfer and flow measurement. It offers industry-leading performance and long-term reliability.

How to Choose the Right Rosemont Pressure Transmitter for Your Application

When selecting a Rosemont Pressure Transmitter for a specific application, several factors need to be considered to ensure optimal performance and reliability.

Process Conditions: Evaluate the temperature, pressure range, and media compatibility requirements of your application. Choose a transmitter that can withstand the operating conditions without compromising accuracy or reliability.

Accuracy and Stability: Determine the level of accuracy and stability needed for your process control. Different applications have varying requirements, and it is essential to select a transmitter that can meet those demands.

Communication Protocols: Consider the communication protocol compatibility with your existing control system. Ensure that the chosen transmitter can seamlessly integrate with your infrastructure, allowing for efficient data exchange.

Diagnostics and Maintenance: Assess the diagnostics capabilities of the transmitter. Advanced diagnostic features can provide valuable insights into the health of the device and enable proactive maintenance, minimizing downtime.

By carefully evaluating these factors, companies can select the most suitable Rosemont Pressure Transmitter for their specific application, ensuring optimal performance and reliability.

Maintenance and Troubleshooting Tips for Rosemont Pressure Transmitters

To maintain the long-term performance and reliability of Rosemont Pressure Transmitters, it is essential to follow proper maintenance practices and have troubleshooting strategies in place.

Regular Calibration: Schedule regular calibration of the pressure transmitters to ensure accurate measurements. This will help identify any drift or inaccuracies and allow for adjustments to be made.

Keep the Transmitter Clean: Regularly clean the pressure transmitter to prevent the accumulation of dust, dirt, or debris that can affect its performance. Use appropriate cleaning agents and follow manufacturer guidelines.

Monitor Performance: Utilize the advanced diagnostics capabilities of Rosemont Pressure Transmitters to monitor their performance continuously. This will enable early detection of any potential issues and allow for timely maintenance.

Train Personnel: Ensure that personnel responsible for operating and maintaining the transmitters are properly trained. Familiarize them with the device's functionalities, troubleshooting techniques, and maintenance procedures.

By following these maintenance and troubleshooting tips, companies can maximize the lifespan and reliability of their Rosemont Pressure Transmitters, minimizing downtime and optimizing performance.

The Future of Rosemont Pressure Transmitters and Process Control Technology

As technology continues to advance, so does the field of process control. Rosemont is at the forefront of innovation, constantly pushing the boundaries of what is possible in pressure measurement and process control. The future of Rosemont Pressure Transmitters holds tremendous potential for even greater performance, reliability, and efficiency.

One area of development is the integration of Internet of Things (IoT) technology. By connecting pressure transmitters to the internet, companies can unlock a wealth of data and insights, enabling predictive maintenance, remote monitoring, and improved overall system performance.

Additionally, advancements in wireless communication protocols and sensor technology will further enhance the capabilities of Rosemont Pressure Transmitters. These developments will result in faster data transmission, improved accuracy, and increased flexibility in deploying and managing these devices.

The Rosemont Company's Commitment to Quality and Reliability

The Rosemont Company has built its reputation on a commitment to quality and reliability. As a trusted partner, they understand the importance of choosing the right pressure transmitters to drive success in their operations. By relying on Rosemont Pressure Transmitters, the Rosemont Company has been able to achieve optimal performance, minimize downtime, and ensure the highest level of product quality.

Conclusion

In conclusion, Rosemont Pressure Transmitters have become the industry standard for process control, driving success in the Rosemont Company and various other industries. Their exceptional performance, reliability, and advanced features make them an indispensable tool for optimizing operations and achieving enhanced efficiency. Through accurate measurements, proactive maintenance, and seamless integration, Rosemont Pressure Transmitters empower companies to take control of their processes and pave the way for a successful future. Choose Rosemont Pressure Transmitters to boost performance and reliability in your operations and experience the transformative impact they can have on your business.

0 notes

Text

Protocol Testing Services | Interoperability Testing | UtthungaLooking for pre-compliance and protocol testing services of HART, WirelessHART, EtherNet/IP, and OPC devices? Utthunga works closely with all the protocol standards associations, has required infrastructure and experience for interoperability testing for various protocols and providing diagnostics. Find out more on what we do!

0 notes

Text

The Evolution of Wireless Communication in Industrial Automation

This image shows a timeline of the evolution of wireless communication in industrial automation. The timeline begins in the 1980s with the introduction of proprietary wireless protocols, and progresses through the development of industrial wireless standards such as WirelessHART, ISA100.11a, and 5G. The image also shows the benefits of wireless communication in industrial automation, such as improved flexibility and mobility, improved performance and safety, and improved reliability and security.

#marine automation#industrial automation#marine spare parts#industrial equipment#industrial spare parts

0 notes

Text

Control Engineering (12/09/2018)

Self-organizing versus managed industrial wireless networks

… A plant or facility considering a wireless network to connect field devices, such as instruments and actuators, to control and monitoring systems has two main wireless protocol choices: ANSI/ISA 100.11a and WirelessHART.

Both were adopted by the International Electrotechnical Commission (IEC) as global standards (IEC 62734- Wireless communication network and communication profiles and IEC 62591-Industrial networks- Wireless communication network and communication profiles, respectively) and have been used for about a decade.

0 notes

Text

온세미, IoT와 스마트 미터링용 저전력 고성능 트랜시버 출시

온세미, IoT와 스마트 미터링용 저전력 고성능 트랜시버 출시

IoT와 스마트 미터링용 통신 지원하며 새 표준을 준수하는 SoC 트랜스시버 NCS3651x 제품군 출시 다양한 산업분야에서 사물인터넷(IoT)에 대한 다양한 솔루션들이 출현하고 있다. 이 모든 사물인터넷 솔루션에서 무엇보다 중요한 과제는 저에너지에 있다. 사물인터넷의 확산을 위한 핵심기술은 저전력 무선 소자에 있다. 사물인터넷과 스마트 미터링을 위한 온세미컨덕터의 저전력 무선 트랜시버 SoC(시스템온칩) 제품이 주목되는 이유다. 온세미컨덕터(www.onsemi.com)는 11월 7일 사물인터넷(IoT)과 스마트 미터링 애플리케이션용으로 고성능, 고신뢰도의 효율적인 통신을 지원하는 신제품군을 출시했다고 발혔다. 시스템온칩 트랜스시버 NCS3651x 제품군은 고집적 혼성 시그널 집적 소자 기술과 RF(라디오…

View On WordPress

0 notes

Text

Industrial Communication Market Size, Share, Industry Report, Revenue Trends and Growth Drivers 2028

The industrial communication market is projected to grow from USD 21.9 billion in 2023 to USD 29.0 billion by 2028; it is expected to grow at a CAGR of 5.7% from 2023 to 2028. Initiatives undertaken by governments of different countries to promote the adoption of industrial automation, the growing need for scalable, faster, reliable, and interoperable communication protocols, increasing use of machine-to-machine communication technology, and increasing use of digital twin to safely monitor smart manufacturing operations are among the factors driving the growth of industrial communication market.

Driver: Increasing use of machine-to-machine communication technology

Better connectivity for smooth communication and low power requirements are the key reasons for the increased adoption of new machine-to-machine (M2M) technologies. To achieve effective M2M communication, the existing capacity of mobile networks must be able to handle billions of nodes that are expected to be deployed in the next couple of years. Currently, the network capacity is not capable of handling M2M and human-based communications, as well as their different communication patterns, including latency time. For this reason, a next-level cellular network for mobile communication featuring hyper-connectivity and larger bandwidth (e.g., 5G) is required. The M2M communication technology will be widely used in the coming years in heavy manufacturing industries and process industries (e.g., food industry) to increase the efficiency of different processes and reduce human intervention for machines.

M2M technology has opened new avenues for the industrial communication market. It enables enterprises to improve their productivity and safety in work environments, thus allowing them to attain better efficiencies. Such benefits of M2M communication are expected to further drive the industrial communication market.

Restraint: Absence of standardization in industrial communication protocols and interfaces

Industrial equipment or devices communicate through various interfaces, technologies, and protocols. The lack of standardization in these communication interfaces and protocols may result in the misrepresentation of data. The lack of standardization complicates the integration of systems and hinders the use of plug-and-play features for unrelated systems. For instance, most equipment manufacturers use their proprietary interface protocols to communicate with their devices, which results in communication challenges for the devices developed by other manufacturers.

Opportunity: Upsurge in demand for wireless networks

The rapid growth in the demand for wireless technologies, such as Bluetooth Smart, WirelessHART, WLAN, and Zigbee, is opening new growth opportunities for the industrial communication market, mainly for the oil & gas, electronics, and energy & power generation industries. Zigbee helps drive the market for low-cost wireless network solutions. The Zigbee IEEE 802.15.4 technology has been adopted by many organizations worldwide. Similarly, WirelessHART-enabled communication is becoming one of the most widely used options for signal transmission in process industries using HART communication. WLAN (IEEE 802.11) is used for high-performance infrastructure networks that are also suitable for industrial applications. Advancements in wireless communication technologies, especially cellular technologies, are helping various industries to monitor their assets across the world. These technologies enable efficient and universal communication for all industrial applications. In process and infrastructure applications, industrial wireless systems simplify the process of recording data from remote stations and field devices, which would otherwise be inaccessible for accomplishing the process. The speed and simplicity of the installation of wireless networks have also made them popular among industries, as they can be deployed to facilitate M2M communication even under extreme environments. All these factors have contributed to the growth of the market for wireless technologies for industrial communication, especially in highly industrialized regions, and are expected to drive the overall market in the coming years.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=146536397

Challenge: Harsh field site conditions such as high-voltage transients, severe shocks and vibrations, and extremely high temperatures

Industrial communication technology is increasingly being deployed at remote field locations. Remote field locations are more prone to the effects of unfavorable and harsh conditions, such as high-voltage transients, shocks and vibrations, and extremely high temperatures. High voltage transients result from electrostatic discharge (ESD), surge, burst, electrical fast transients (EFT), and lightning strikes. Industrial switches should be capable of preventing high-voltage transients by providing high electromagnetic protection. Shock and vibration in machinery can separate networking wires meant for long-term exposure to shock and vibration, eventually resulting in electrical shorts, broken solder joints, loose printed circuit board (PCB) components, PCB delamination, and cracked device housings. Moreover, remote onsite locations may not have air conditioning; this raises the demand for switches with high-temperature tolerance and optimal heat dissipation to keep the switch lifecycle intact. Therefore, there is a requirement for robust industrial communication equipment to withstand harsh conditions.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem.Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research.The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry. To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

0 notes

Text

Wireless Gas Detection Market is set to Fly High Growth in Years to Come

Latest business intelligence report released on Global Wireless Gas Detection Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand Wireless Gas Detection market outlook. List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis are RAE Systems (United States),Sensidyne (United States),Gassecure (Norway),RITM Industry (Ukraine),Emerson Electric Co (United States),Trolex Ltd (England),RC System (United States),Dragerwerk AG (Germany),Citisafe (Singapore),GDS Corp (United States)

Wireless Gas Detection is designed for continuous analysis of toxic and combustible gases in the air. Wireless technology is an integral component of gas detection solutions the gas detector will collect all the necessary data information from the sensor including the target gas type. Wireless gas detection use in detection for hydrogen sulfide detection in oil and gas drilling and exploration, other uses in confined space entry in a coal-fired power plant. Key Market Trends: Growing Use Of New Device Named Prorae Guardian Opportunities: Increase Use In Wireless Technology

Cost-Effective Device Market Growth Drivers: Increasing Demand For Safety Measures

Growing Use Due To Easy To Use Application

Highly Recommended Due To Environment-Friendly Concerns Challenges: Standards And Designs Are Low Levels

The Global Wireless Gas Detection Market segments and Market Data Break Down by Type (Single-Gas, Multi-Gas, Personal Gas), Application (Mining and Metals, Water and Wastewater Treatment Plants, Commercial Buildings and Public Facilities, Government and Military, Discrete Manufacturing Industries, Others), Technology (Hardware, Sensors/Detectors, Catalytic Sensors, Infrared Sensors, Photoionization Detectors, Electrochemical Sensors, Metal-Oxide-Semiconductor (MOS) Sensors, Multiple Sensor/Detectors, Wireless Gateways/Wireless Routers, Wireless Gas Monitors and Controllers, Wireless Transmitters and Repeaters, Software, Services), End-User (Industrial Safety, National Security and Military Safety, Environmental Safety, Oil and Gas, Chemical & Petrochemical, Utilities and Power Generation), Connectivity (Wi-Fi, Bluetooth, Cellular, License-free ISM Band, Wirelesshart, Near-Field Communication)

Presented By

AMA Research & Media LLP

0 notes

Text

This report studies the Industrial Wireless Vibration Sensors Network market size (value and volume) by players, regions, product types and end industries, history data 2018-2022 and forecast data 2023-2030; This report also studies the global market competition landscape, market drivers and trends, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porters Five Forces Analysis.

0 notes

Text

Wireless Health Monitoring Market - Forecast(2022 - 2027)

Global Wireless Health Monitoring market size was valued at $5.7 billion in 2020, and it is estimated to grow at a CAGR of 15.1% during 2021-2026. The growth is mainly attributed to the shift towards wireless from wired equipment devices owing to its ease of use.

Wireless health monitoring devices have made patient monitoring much sophisticated and reliable to the patients living in remote areas. The patients can easily send their health information to the respective physicians at any given time from any location at any time. This is poised to propel the wireless monitoring market.

The usage of wireless health monitoring for various applications such as mobile cardiac outpatient telemetry and blood glucose meters will drive the growth of the market.

Report Coverage

The report: “Wireless Health Monitoring System Market Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Wireless Health Monitoring System Market.

By Offering Type: Hardware (Sensing Modules, Receiver, and Transmitters, Gateways, Switches and Terminals, Others); Software; Services

By Connectivity: Zigbee, Wi-Fi, Bluetooth, WirelessHART, LoRA, Cellular, WBAN, Others

By System Type: Structural Health Monitoring System (Deflection Monitoring, Leak Detection, Pressure Monitoring, Fire Detection, Others); Machine Health Monitoring System (Vibration Monitoring, Lubricant Analysis, Temperature Monitoring, Corrosion Monitoring, Others); Patient Health Monitoring System (Vital Sign Monitoring, Medication Management, Chronic Disease Monitoring, Fitness and Wellness Monitoring & Others)

By End User: Healthcare (Hospitals, Ambulatory Centers, Clinics, Diagnostic Centers, Nursing Homes, Elder Care Facilities and Others); Industrial (Aerospace & Defense, Automotive, Chemicals, Oil & Gas, Marine, Power, Utilities, HVAC, Others); Infrastructures (Bridges, Dams, Stadiums, Others)

By Geography: North America (U.S, Canada, Mexico), Europe(Germany, UK, France, Italy, Spain, Russia, Netherlands and Others), APAC(China, Japan India, SK, Australia, Indonesia, Malaysia and Others), South America(Brazil, Argentina, Chile, Colombia and others), and RoW (Middle east and Africa)

Request Sample

Key Takeaways

North America dominated the Wireless Health Monitoring System market in terms of revenue in 2020 owing to the presence of major number of players.

Adoption of advanced technologies with the development of advanced products set to drive the market

Increasing adoption of Wireless Health Monitoring System in healthcare and other industries with growing trend of 4G and 5G technology is set to drive the market.

High cost is the major challenge that hampers market growth.

Wireless Health Monitoring Market Segment Analysis - By System Type

Structural health monitoring held the major share of 32.3% in 2020. Growing trend of 4G and 5G technologies have created demand for adoption of wireless structural health monitoring devices. Advent of industry 4.0 and implementation of Internet of Things (IoT) technologies have created demand for the market. Wireless sensing units integrate wireless communications and mobile computing with sensors to deliver a relatively inexpensive sensor platform. Integration of computing with a wireless sensing unit provides sensors with the opportunity to self-interrogate measurement data and this drives the market growth. However patient health monitoring is set to grow at a fast rate driven by applications such as mobile cardiac outpatient telemetry and blood glucose meters.

Inquiry Before Buying

Wireless Health Monitoring Market Segment Analysis - By End User

Healthcare is the fastest growing segment in Wireless Health Monitoring System market and estimated to grow at a CAGR of 15.8% during forecast period 2021-2026. In Healthcare sector, wireless health monitoring systems is majorly used in order to help the nursing staff for easy data management of different patients and exercise the ad-hoc emergency cases and requirement of advanced healthcare infrastructure. Increasing investments in healthcare sector and evolution of global pandemic diseases create opportunities for the wireless health monitoring system market growth during forecast period.

Wireless Health Monitoring Market Segment Analysis - By Geography

North America dominated the Wireless Health Monitoring System market in 2020 with a market share of 37.8%, followed by Europe and APAC owing to the presence of large number of players. In addition to these, high adoption of automation technologies in industries and high purchasing power of advanced equipment drives the market growth. High investments in research and development activities for the development of advanced products is also set to drive the market growth in this region. The Medical sector will continue to drive the market in applications ranging from mobile cardiac outpatient telemetry to blood glucose meters.

Wireless Health Monitoring Market Drivers

Technological advancements

Increasing advancements in wireless communication technologies, cloud computing and robust penetration of 4G and increasing investments in 5G networks is set to drive the market growth. Technological advancements have enabled the manufacturers to develop pharmaceutical dosage forms, which contains an ingestible sensor inside the pill that transmits the data after consumption. Chip on a pill technology monitors the condition of patients, sends reminders to adhere to the respective prescribed treatment, and also notifies the neurologists on the health status reports.

Schedule a Call

Growing healthcare awareness and increasing cardiovascular diseases

Increasing cardiovascular diseases and growing healthcare awareness has created demand for wireless health monitoring system. Heart patients require continuous monitoring of certain vital body parameters such as heart rate, mobile cardiac outpatient telemetry, blood glucose meters, pulse rate and electrocardiogram (ECG) shows current health status clearly. According to World Bank, the elderly population have been increased from 625.39 million to 697.96 million during 2016-2019 period. Adoption of wireless health monitoring systems with increasing elderly population is also driving the market growth.

Wireless Health Monitoring Market Challenges

High cost

High cost is the major challenge that hampers the wireless health monitoring market growth. Lack of uniform reimbursement restricts the market growth. The cost for wireless health monitoring rises with range, precision, accuracy, resolution and repeatability. The cost include the costs of hardware, software, and services that majorly depend on the complexity of structures and cost of construction. Highly complex structures require highly efficient instrumentation solutions, which increases the overall costs. Additionally, monitoring costs involved in this are also very high. Thus, high costs involved in wireless health monitoring is restraining the market growth.

Buy Now

Wireless Health Monitoring Market Landscape

Product launches, Acquisitions, Collaboration, and R&D activities are key strategies adopted by players in the Wireless Health Monitoring market. Nihon Kohden Corporation, GE Company, Emerson Electric, Parker Hannifin Corporation, SKF AB, ABB Ltd, Banner Engineering Corp, Sensor-Works Ltd, American Telecare, Cardiocom, Carematix, Cybernet Medical Corporation, Drager Medical, GE Healthcare, Global Media Group, Honeywell and others.

Acquisitions/Technology Launches

In April 2020, GE Healthcare and Microsoft had collaborated in order to launch covid-19 patient monitoring software for health systems and hospitals. This drives the market during forecast period.

In February 2019, Nihan Kohden, had launched NK-HIQ enterprise gateway the next-generation platform that integrates data from patient monitoring devices and consolidates multiple applications into a single powerful platform. Introduction of advanced medical devices and software solutions drive the Company’s wireless health monitoring market share.

#wireless health monitoring market#Patient health monitoring systems#wireless health monitoring market size#Structural Health Monitoring System#wireless health monitoring market shape

0 notes

Text

Java modbus server

JAVA MODBUS SERVER SERIAL

JAVA MODBUS SERVER SERIES

Weinzierl offers powerful and compact KNX Gateway to Modbus The T910 allows up to 8 device variables (floating point or integer) and an extensive array of device status indicators to be passed from the Modbus device over the WirelessHART network. Softing's versatile Linking Device and Modbus Gateway (FG-200) integrates up to four FOUNDATION™ Fieldbus (FF) H1 links into control systems supporting HSE or Modbus.įieldbus International releases WirelessHART adapter with Modbus RTU interface: the T910. Modbus RTU also supported.Įxtend the Life of your Legacy DCS System by Getting Access to FOUNDATION Fieldbus Devices over Modbus Big, bright 1.2 inch (31mm) numerals are clearly visible from far away, even in bright sunlight. These instruments combine the digital indicator function of a panel meter with optional signal conditioning for 4-20mA transmitter output and/or alarm trip solid-state relays. M.2 card users can choose among loadable firmware for PROFINET IO-Device, EtherNet/IP Adapter, EtherCAT and OpenModbus/TCP.Īnnouncing Acromag's new Vertu™ brand of universal input displays Hilscher's New M.2 Format PCI Express Card Supports Fieldbuses and Real-Time EthernetsĪt the heart of the M.2 2230 card is Hilscher's award-winning netX 90 multiprotocol communication chip. Mission-critical industrial communications, such as Ethernet/IP, PROFINET, Modbus/TCP, and BACnet, are sent through the network first. The FL SWITCH 1000 features automation protocol prioritization (APP), making it easy to prioritize important traffic.

JAVA MODBUS SERVER SERIES

Phoenix Contact releases unmanaged switch series with new capabilities Opto 22's groov RIO® Ethernet edge I/O ships with PID, SSH, and LDAP supportĬlosely following the initial launch of groov RIO in early 2020, Opto 22 has further expanded the remote I/O, connectivity, and security features of its edge I/O module with the release of its version 3.0 firmware. With an MQTT protocol gateway, it is easier than ever before to move industrial device data to cloud applications like AWS IoT Core, IT or enterprise systems.Īcromag - Measuring Temperature with a High-density Ethernet I/O SolutionĪcromag's BusWorks® NT Series was a good fit for this application that required remote I/O and needed to be a Modbus server that could accept a mix of thermocouple and RTD signals. Real Time Automation releases the MQTT protocol on their bestselling 460 industrial gateway line. MQTT Gateways Create an Easy Way to Move Factory Floor Data to Cloud Application Services

JAVA MODBUS SERVER SERIAL

AutomationDirect Announces CLICK PLUS Serial Communication Option Slot Module and 2-Slot CPUsĬLICK PLC with advanced features, includes Wi-Fi capability, MQTT communication, data logging, and mobile access (supports both Modbus RTU and ASCII communication).

0 notes