#World of Basalt Reinforcement

Explore tagged Tumblr posts

Text

World Of Basalt Reinforcement written By Mahesh Kumar Jogani and launched by Chetan Bhagat

Renowned author and IIT alumnus Chetan Bhagat added his voice to the sustainability movement by launching the book World of Basalt Reinforcement by Shri Mahesh Kumar Jogani at a celebrity-filled event in Mumbai. The event brought together the worlds of literature, engineering, and environmental consciousness under one roof—marking a significant moment in the evolving conversation around sustainability and industrial development.

Lauding the book, Bhagat emphasized its importance in today’s rapidly urbanizing world. “As an engineer, I see this work as not just timely but necessary. Sustainable materials are not a luxury—they are the need of the hour,” he said. He commended Jugani’s deep expertise and dedication to practical innovation in the reinforcement sector, particularly in crack control and structural durability.

A Book That Bridges Sustainability and Technology

World of Basalt Reinforcement introduces readers to basalt fiber—an advanced material derived from volcanic rock. Celebrated for its strength, corrosion resistance, and minimal environmental impact, basalt fiber is emerging as a serious alternative to traditional reinforcement materials like steel and glass fibers.

The book focuses on the synergy between nature and technology. It provides a detailed look at the formation and properties of basalt, followed by real-world applications ranging from Aerospace to automobile. With its clear explanations and real-life insights, the book serves as both an entry point for students and introduction guide for engineers and innovators.

This book is available in Amazon. https://amzn.in/d/4ystcNR

The Author: A Career in Sustainable Innovation

Shri Mahesh Kumar Jogani brings over 20 years of experience to this work. A research engineer by profession and a techno-entrepreneur by passion, Jogani holds multiple patents and has led innovations across composites, industrial reinforcement, and material science. His work consistently emphasizes durability, efficiency, and environmental stewardship.

Jogani is best known for his hands-on approach and commitment to real-world solutions. His focus on crack control in concrete and reinforcement technologies has positioned him as a key voice in the advancement of sustainable construction methods. His belief in the transformative power of basalt fiber is evident throughout the book.

Our article also posted in the week channel, please refer this: https://asiannews.in/famous-writer-chetan-bhagat-launches-world-of-basalt-reinforcement-by-mahesh-kumar-jogani-pnn-digital/

“My aim,” Jogani says, “is to make engineers think differently. Innovation doesn’t have to come at the cost of nature. With basalt, we can have both performance and environmental care and responsibility.” He added “With basalt, we can have both performance and sustainability”

As infrastructure demands rise globally and the climate crisis escalates, World of Basalt Reinforcement arrives at a critical juncture. It’s not just a technical manual—it’s a call to action for a new generation of builders, designers, and policymakers. The book resonates beyond construction. It reflects a broader shift in mindset—where innovation and sustainability are no longer seen as separate goals but as partners in progress.

Chetan Bhagat summed it up best: “This isn’t just a book for engineers—it’s a message for anyone who believes in a smarter, greener future.”

For more information on this subject please visit www.joganireinforcement.com

#basalt fiber#World of Basalt Reinforcement#Basalt Fiber#best Fiber glass Mesh#Brass Coated Micro Steel Fiber#JOGANI Reinforcement#Best crack control material#Carbon Fibers#best Concrete Fibers#best Waterproofing Mesh#Scrim Mesh for industrial Reinforcement#industrial reinforcement#best for crack resistance

0 notes

Text

Transmechanicus Biologis Study Log #726//Expunged

Magos Xanthor Vell, Formerly of Ryza Forge - Log Date: 943.M41

Location: Designation Nullius-57, Segmentum Obscurus

“Knowledge, even forbidden, cannot be unwitnessed.”

Subject: Xenobiological Study of Orkoid Symbiosis with Alien Fungal Organism: Golden Cordycep and Host Species “Gargantuan Hammerfist Champignat”

Status Note: This record is no longer recognized by the Mechanicus due to the heretical nature of my affection for the greenskin xenos. I continue my studies in exile, sustained by the machine-logic of truth and the song of biological revelation. Praise the Omnissiah, even if He no longer hears me.

INITIAL DISCOVERY

Upon my fifth solar cycle surveying Nullius-57—a geothermically volatile world rife with fungal ecologies and Orkoid spore-nodes—I came across a remarkable insectoid entity. The local feral Ork population (primitive even by greenskin standards) referred to this beast as “Hammer-Hands-Big-Bug.” My own designation, however, is the Gargantuan Hammerfist Champignat.

Vital statistics:

• Height: Approximately 6 meters at rest (measured dorsally)

• Length: ~25 meters from anterior claw-socket to abdominal tip

• Locomotion: Octopedal with significant muscle mass in posterior three pairs of legs—capable of near-sonic percussion via specialized forelimb mandibles

• Diet: Primarily fungivorous; secondary carnivorous behavior observed against smaller insectoid competition

The Hammerfist’s mandibles exhibit convergent morphology with Terran Odontodactylus scyllarus (mantis shrimp), able to deliver percussive strikes potent enough to shatter basalt. On three occasions I recorded the creatures engaging in territorial duels—sonic vibrations from the impact alone rendered smaller fauna comatose. A marvel of biomechanical design.

THE GOLDEN CORDYCEP

During a dissection of a deceased specimen (likely deceased due to fungal overgrowth from local sporepits), I noticed a peculiar golden-hued fungal growth adorning the abdominal chitin, clustered near soft tissue seams and around neural ganglia.

At first I assumed Cordycep sp. parasitica, given the obvious fungal infiltration. However, tissue scans revealed a non-destructive relationship: mycoproteins were reinforcing torn muscle fiber and emitting localized biochemical signals promoting regeneration.

Subsequent histological assays and auspex-readings confirmed: this is no parasitism. It is symbiosis. The fungus integrates with the host’s immune response, stimulating cell mitosis and supplying metabolic resources drawn from its own photosynthetic conversion and fungal substrate digestion.

I designate this species: Mycocladium aureum symbiotica.

FERALS AND FUNGUS

The true revelation came when I observed the feral Orks interacting with the Hammerfist carcass. A group of five, evidently local hunters, approached the deceased creature. One of them—massive even by Ork standards—was grievously wounded. The entire right hemisphere of his face had been sheared away, likely by a hammerfist blow.

Without ceremony, the Ork scooped the golden mold with his crude bone-dagger and slathered it directly into the wound. I recorded every detail:

• Within eight hours, the bleeding had ceased.

• By thirty-six hours, rudimentary tissue regrowth was visible—ruddy green with streaks of golden fungal weave.

• In three days, the Ork had returned to hunting, now sporting a partial fungal exo-plate over the affected region.

The Orks believe the fungus is a form of divine ichor, a gift from Gork (or possibly Mork). Some wear its dried form as ritual armor or chew it during rites of battle-healing. Crude. Inefficient. And yet… functional.

CLOSING THOUGHTS

I remain in exile. But I am not alone. The Orks tolerate me—barely. Some call me “Squig-brain-with-light(glowing)-eyes.” I take it as a term of endearment.

My laboratory is mobile. My data is redundant across twelve cortical backups. One day, perhaps, the Imperium will learn to see past its fear. Until then, I watch. I record. I learn.

And when the Hammer-Hands-Big-Bugs thunder through the canyons, I listen. For in the rhythm of their strike lies a pattern.

I am getting more and more accustomed to this new lifestyle

#warhammer 40000#warhammer 40k#drawing#40k orks#orks#my art#ork speculative biology#warhammer fanart#creature design#speculative evolution#traditional drawing#fake study logs#ork world building

23 notes

·

View notes

Text

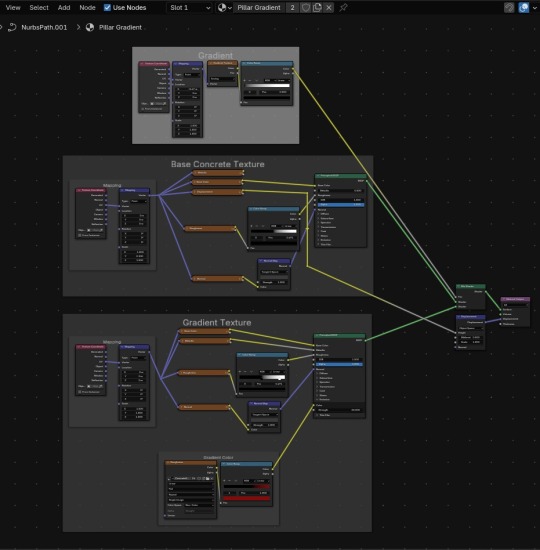

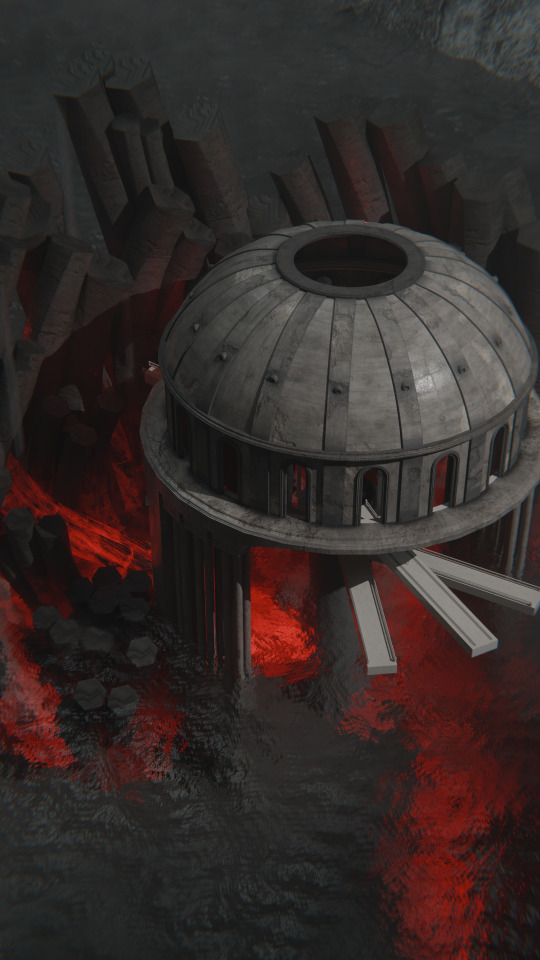

Visual Intrigue: Adding and Animating Basalt Pillars

As much as I liked how the exterior of the court was coming along, I could not shake the feeling that something was missing. Visually, it looked polished and atmospheric, but emotionally, it felt too calm. Too serene. And that directly conflicted with the kind of dread and unease I want the film to carry from its very first shots.

Since the court is the deciding space between heaven and hell, I started thinking more about its actual placement in this surreal world. Heaven, in my film, is distant and unreachable. It is far beyond even the court's domain. But hell? Hell is close. Almost too close. So it made sense that the court should feel like it is perched on top of something dangerous — something restless.

[The Darvaza gas crater, also known as the Door to Hell or Gates of Hell]

That is where the idea came in to place the court directly above the entrance to hell. I wanted the audience to feel that presence, not through direct visuals of fire or lava, but through geological formations that hint at something bubbling underneath the surface.

I began researching basalt pillars — also known as columnar basalt. These are real geological formations that occur when lava cools and fractures, forming tall, vertical columns that are often hexagonal or polygonal in shape. They look like they are growing from the ground itself, unnatural but organic at the same time.

I thought this would be a perfect way to show that hell is not just below — it is rising. These basalt pillars would be growing out from the ocean floor beneath the court, as if the underworld is growing impatient. As if it is eager to claim more souls. That creeping, upward motion adds to the sense that time is running out, and judgment is closing in.

I began designing the pillars in Blender and to do so I used curves as the foundation, animating them with the start and end mapping settings in the curve properties to simulate the pillars growing from the ocean floor. By lowering the curve’s resolution, I was able to achieve the angular, hexagonal shapes that give real basalt columns their signature look.

Texture played a huge role in making these pillars feel alive and distinct. I built a custom shader node setup to procedurally control where the pillars burn with fire and where they cool down as they rise. As they reach the ocean’s surface and breach into open air, they shift in appearance.

What is interesting here is that the burning and cooling logic is intentionally reversed, normally, lava would cool in water and burn in air. But here, it is the opposite. That subtle surrealism reinforces that this is not a normal ocean. The rules here are different. They bend in ways that hint at something more sinister under the surface.

The texture itself is also a direct reference to the statue of disloyalty, which erupts during the climax of the film. The bright red glow seen in the cracks of the pillars, mirror the red that flashes in the eyes of all eight statues during judgment. These are intentional links, visual cues that tie the world together and trace everything back to hell, disloyalty, and consequence.

Once I was happy with the animation and look of the pillars, I added the sound design to finish the shot. With the audio and visuals working together, the entire moment feels more grounded in the world I am building. The pillars are no longer just environmental decoration, they are foreshadowing. They are a warning.

0 notes

Text

Basalt Fiber Market: Revolutionizing Industries with Sustainability and High Performance

Basalt fiber might not yet be a household name, but it’s quickly earning its place as a material that’s rewriting the rules in several industries. What makes basalt fiber stand out is its ability to combine sustainability with high performance—two qualities that industries today are desperate to balance.

Sourced from volcanic rock, basalt fibers are incredibly strong, lightweight, and resistant to extreme conditions. Unlike some conventional materials, their production doesn’t require harmful chemicals, making them an eco-friendly alternative. For industries like construction, automotive, wind energy, electronics, and marine, basalt fiber isn’t just an option—it’s a necessity for staying relevant in a world demanding greener and better-performing materials.

The global basalt fiber market is poised for significant growth, with an expected valuation of USD 279 million in 2023, and a projected Compound Annual Growth Rate (CAGR) of

12.5% throughout the forecasted period, aiming to reach USD 503 million by 2028.

The Unique Strength of Basalt Fiber

The appeal of basalt fiber goes beyond its novelty. It is naturally robust, boasting high tensile strength and resistance to corrosion. Imagine a material that can endure the harshest environments—extreme heat, chemicals, or even saltwater—without breaking down. That’s basalt fiber.

But what really excites engineers and designers is its versatility. It’s lightweight yet tough, cost-effective yet high-performing, and, perhaps most importantly in today’s climate-conscious world, recyclable and non-toxic.

Unlike carbon fiber, which can be expensive, or fiberglass, which may fall short in eco-credentials, basalt fiber is the perfect middle ground. Its production process—melting volcanic rock at high temperatures and pulling it into fibers—requires no additives, which keeps it clean and simple.

Applications Driving Basalt Fiber Demand

1. Building Stronger, Greener Infrastructure

In construction, basalt fiber is making waves as a revolutionary reinforcement material. For decades, we’ve relied on steel, but in environments prone to moisture or chemicals, steel corrodes, leading to costly repairs and maintenance. Basalt fibers offer a solution with corrosion resistance and durability that outlasts traditional materials.

Think of bridges, seawalls, or even underground tunnels—structures where durability is critical. Basalt fiber-reinforced concrete doesn’t just last longer; it’s also lighter, which reduces transportation costs and simplifies installation.

2. Transforming Automotive and Transportation

The automotive world is laser-focused on cutting weight to improve fuel efficiency and meet stringent emission norms. Basalt fiber fits perfectly into this equation. From car body panels to interior components, its strength-to-weight ratio is hard to ignore.

It’s also popping up in trucks, trains, and even shipping containers. A lighter vehicle isn’t just more fuel-efficient—it also reduces wear and tear on roads, making basalt fiber a win-win for the entire transportation ecosystem.

3. Boosting Wind Energy Efficiency

The renewable energy industry is turning to basalt fiber for its ability to handle stress and environmental extremes. Wind turbine blades, in particular, face constant mechanical and environmental challenges. Basalt fibers provide the strength, flexibility, and weather resistance needed to enhance blade performance and longevity.

For a sector trying to reduce costs while improving energy output, basalt fiber-based composites are becoming the go-to material.

4. Enhancing Electrical and Electronic Safety

Basalt fiber’s non-conductive properties make it a natural fit for the electrical and electronics industry. It’s used in circuit boards, insulation, and protective casings. With the growing emphasis on energy-efficient appliances and safer electronics, basalt fiber ensures products meet performance and safety standards.

5. Sailing Ahead in the Marine Industry

Saltwater is unforgiving, especially for traditional materials like steel or fiberglass. Basalt fiber’s resistance to saltwater and chemicals makes it ideal for marine applications like boat hulls, underwater pipelines, and fishing rods.

It’s lightweight, meaning ships and boats consume less fuel, contributing to greener maritime operations. For an industry battling both environmental and cost pressures, basalt fiber is a breath of fresh air.

Why Basalt Fiber is the Future

Sustainability Leads the Way

The days of choosing materials purely for performance are over. Sustainability is no longer optional. Basalt fiber’s eco-friendly production process—requiring no harmful additives—makes it a leader in sustainable materials.

Infrastructure Investments

With nations modernizing old infrastructure and building new projects, there’s a growing need for corrosion-resistant, durable materials. Basalt fiber fits the bill perfectly, ensuring longevity in everything from highways to high-rises.

Growing Demand in Emerging Markets

Emerging economies in regions like Asia-Pacific and the Middle East are adopting basalt fibers rapidly, thanks to their cost-effectiveness and versatility. These regions are investing heavily in infrastructure, automotive production, and renewable energy, making them hotbeds for basalt fiber adoption.

To know more download PDF Brochure :

Basalt fiber isn’t just a trend—it’s a material that aligns perfectly with the needs of modern industries. Whether it’s reducing carbon footprints, improving performance, or cutting costs, basalt fiber is proving its worth across sectors.

For experts in construction, automotive, wind energy, electronics, or marine industries, basalt fiber is no longer something to keep an eye on—it’s something to embrace. It’s not just the material of the future; it’s the material of today.

#Basalt Fiber Market#Sustainable Materials#Construction Materials#Automotive Industry#Wind Energy Components#Eco-Friendly Materials#Renewable Energy Materials

0 notes

Text

Wind Turbine Composite Materials Market - Forecast(2024 - 2030)

Wind Turbine Composite Materials Market Overview

Request Sample :

The government across the globe is also investing huge amounts in alternative energy sources such as solar and wind which is further supporting the market growth for composite materials. The increasing focus of governments on offshore wind energy installations is driving the market growth between 2021–2026. However, the high cost of carbon fiber and epoxy resin and recyclability issue of composites will likely hamper the market growth during the forecast period.

COVID-19 Impact

The COVID-19 pandemic has impacted the composite materials industry which has further impacted the wind turbine market. Due to the Covid-19, the manufacturing industry is impacted very badly that further impacted the wind turbine composite materials market. The slowdown in wind turbine installations and lack of raw material supplies, and workforce are impacting the market negatively. The covid-19 impacted every operation such as supply chain, production, sales, and others. However, the companies resumed their operation in 2021, which may positively impact the market.

Report Coverage

The report: “Wind Turbine Composite Materials Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Wind Turbine Composite Materials industry. By Fiber Type: Glass Fiber, Carbon Fiber, Aramid Fiber, and Basalt fiber By Resin Type: Thermoplastic [Polyethylene, Polystyrene, Polyamides, Nylon, Polypropylene, Others], and Thermoset [Epoxy, Polyester, Phenolic Polyamide, and Others] By Technology: Injection Molding, Compression Molding, Pultrusion, Filament Winding, and Layup By Application: Blades, Wind turbine Hub, Rotor, Tower, Nacelle, Cables, Blade Pitch Controller, Propellers, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Netherlands, Belgium, Spain, Denmark, and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and Rest of the World (the Middle East and Africa)

Inquiry Before Buying :

Key Takeaways

The Asia Pacific region is expected to dominate the market and register the highest CAGR of 12.8% during the forecast period (2021–2026). The presence of leading chemical companies along with rapid growth in the personal care industry is propelling regional growth.

Epoxy resin is one of the widely used resins in wind turbine manufacturing. The segment is expected to register a high growth rate during the forecast period.

The growing installation of wind turbines in developing countries such as Brazil, Mexico, India, and China is creating a positive impact on the usage of wind turbine composite materials.

Figure: Asia Wind Turbine Composite Materials Market Revenue, 2020–2026 (US$ Billion)

For More Details on This Report — Request for Sample

Wind Turbine Composite Materials Market Segment Analysis: By Fiber Type

The glass fiber reinforced plastics segment accounted for the largest share of more than 55% in the wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Glass fiber offers various properties including high strength, high durability, weather-resistant, and lightweight have boosted its demand in numerous end-use industries. The easy availability and cost-effectiveness of glass fiber reinforced plastics are the key factors propelling the demand for glass fiber composites in wind turbine manufacturing. The carbon fiber segment will register a significant growth rate during the forecast period. Carbon fibers offer various properties such as low thermal expansion, high stiffness, high-temperature tolerance, and high chemical resistance among others.

Schedule A Call:

Wind Turbine Composite Materials Market Segment Analysis: By Resin Type

The thermoset segment accounted for the largest share of more than 70% in the Wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Thermoset composite is usually based on carbon, glass, and aramid fibers. Epoxy resin is the widely used thermoset type in wind turbine composite materials. Approximately 50% of European wind blades are manufactured from epoxy resin. These resins offer lightweight, and good adhesion compared to other resin types. Generally, they are combined with glass fibers and carbon fibers to manufacture wind blades. The thermoplastic segment is expected to register a significant growth rate during the forecast period. Thermoplastics are less expensive compared to thermoset resin types. They are easily weld-able, non-toxic in nature, and recyclable. These are some of the driving factors supporting the market growth between 2021–2026.

Wind Turbine Composite Materials Market Segment Analysis: By Technology

The Layup segment accounted for the largest share of more than 33% in the wind turbine composite materials market in 2020 and is estimated to grow at a significant rate during the forecast period. Layup is the most common method used for the production of composites. The method is involved in placing layers of composite fiber in a structured order by using a matrix of resin and hardener. This method is widely used for the production of wind blades.

Wind Turbine Composite Materials Market Segment Analysis: By Application

The blades segment accounted for the largest market share of more than 55% of the market in 2020 and is estimated to grow significantly during the forecast period. Turbine blades serve as the most important composite-based part of wind turbines. The growing demand for wind energy is driving manufacturers to develop large wind blades for the high production of wind energy. For the development of large blades, a huge quantity of composite materials is used. Glass fibers and carbon fibers are used for the manufacturing of wind blades.

Wind Turbine Composite Materials Market Segment Analysis — By Geography

The Asia Pacific region held the largest share of more than 45% in the Wind Turbine Composite Materials market in 2020, owing to the rapid growth in the installation of wind turbines. The presence of developing nations such as China and India is driving the market growth. The presence of leading wind turbine manufacturers including Suzlon Energy Limited, and AVIC Huiteng Windpower Equipment Co., Ltd are supporting the region’s growth during the forecast period. The increasing investments by key developers for manufacturing efficient wind turbines are also boosting the market growth during the forecast period. According to the data published by Global Wind Energy Council (GWEC), China installed about 52 gigawatts of new wind power capacity in 2020.

Buy Now :

Wind Turbine Composite Materials Market Drivers

Rising Demand for Renewable Energy Sources

Wind energy is one of the fastest-growing renewable energies globally. Wind power is a clean energy source, and its usage is on the rise worldwide. The U.S. wind energy occupies approximately 38% of total renewable energy produced in 2019. According to the IRENA’s data, wind energy generation is increased from 7.5GW in 1997 to 564GW by 2018. Some ongoing and under-construction wind projects in the U.S. include Traverse Wind Energy Center, Aviator Wind Project, Goodnight Wind Energy Project, Alle-Catt Wind Farm, and Vineyard Wind I among others. According to the Ministry of New and Renewable Energy (MNRE), India has the fourth-highest wind installed capacity in the world with a total installed capacity of 39.25 GW (as of 31st March 2021) and has generated around 60.149 billion Units during 2020–2021. According to the European Commission, the total installed wind energy capacity in Europe reached 210GW and is estimated to reach 350GW, supplying up to 24% of electricity demand

Wind Turbine Composite Materials Market Challenges

Recyclability Issue of Composites

Composite materials are preferred for wind applications because of their durability and superior strength. Proper waste disposal and recycling at the end of the useful life of composite materials are necessary. Many current and future waste management and environmental legislation are making strict regulations on engineering materials to be properly recovered and recycled. The complex material compositions and the cross-linked nature of thermoset resins are making it difficult for recyclability. However, the use of polymers that can be recycled when used with carbon and other niche fibers reduces the composite non-recyclable. This has become a major issue as the landfills are filling up at a faster pace along with the need for going green due to global warming. Biological attack on composite materials may consist of fungal growth or marine fouling

Wind Turbine Composite Materials Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Wind Turbine Composite Materials market. Major players include:

TPI Composites, Inc.

MFG Wind

LM Wind Power

Gamesa Corporation Technology

Vestas Wind Systems A/S

Suzlon Energy Limited

Siemens AG

AVIC Huiteng Windpower Equipment Co., Ltd.

AREVA and others.

Acquisitions/Technology Launches

In May 2021, Hexcel launched a range of HexPly® surface finishing prepregs and semi- prepregs for wind turbine blades and automotive and marine applications.

Relevant Reports

Composite Materials Market — Forecast(2021–2026) Report Code: CMR 0010

High-Temperature Composite Materials Market — Forecast(2021–2026) Report Code: CMR 10087

For more Chemicals and Materials Market reports, please click here

#WindTurbine#CompositeMaterials#RenewableEnergy#SustainableTech#GreenEnergy#MaterialInnovation#CleanEnergySolutions

0 notes

Text

Rock-Based Polymeric Materials: The Future of Sustainable Innovation

As the world seeks more sustainable and eco-friendly alternatives in industrial production, rock-based polymeric materials are emerging as an exciting solution in material science. These materials, derived from natural rocks and enhanced with polymers, offer a unique combination of durability, flexibility, and environmental benefits, making them increasingly popular in industries ranging from construction to consumer goods.

In this blog, we will explore what rock-based polymeric materials are, their advantages, how they’re being used today, and their potential to revolutionize manufacturing and sustainability.

What Are Rock-Based Polymeric Materials?

Rock-based polymeric materials are composites that blend natural minerals or rocks—such as basalt, granite, or limestone—with synthetic or natural polymers. These combinations create materials with enhanced properties, combining the natural strength of stone with the flexibility and versatility of polymers.

In simple terms, these materials consist of:

Mineral Component: This is the base, often in the form of finely ground rock or mineral fibers. Basalt, for example, is a common rock used due to its high strength and heat resistance.

Polymeric Binder: The polymer component binds the mineral particles together, providing additional strength, flexibility, and ease of processing. This binder could be a synthetic polymer like polyester, or bio-based alternatives such as plant-derived resins.

The end result is a material that leverages the best qualities of both rock and polymer: the strength, stability, and thermal properties of minerals, and the lightweight, moldable, and functional properties of polymers.

Advantages of Rock-Based Polymeric Materials

The combination of natural rocks and polymers yields several key benefits, making these materials a highly attractive option in various fields:

Strength and Durability: The mineral base provides exceptional mechanical strength, often exceeding that of pure polymeric or plastic materials. This makes rock-based polymers suitable for demanding applications, such as building materials, that require long-lasting performance under stress.

Eco-Friendly and Sustainable: Using natural minerals as the primary ingredient reduces reliance on petrochemical-based materials, which can be harmful to the environment. Additionally, rocks are abundant and often easier to source sustainably compared to traditional plastic feedstocks. Some rock-based polymers also incorporate bio-based polymers, further reducing their environmental footprint.

Lightweight: Despite their rock content, these composites are lighter than solid stone or concrete, thanks to the polymer matrix. This makes them easier to transport, handle, and install in applications such as construction, automotive manufacturing, and consumer goods.

Heat and Chemical Resistance: Depending on the type of rock used, rock-based polymeric materials can have excellent resistance to heat, fire, and chemicals, making them suitable for high-performance uses like fireproofing and chemical-resistant coatings.

Versatility and Customizability: The properties of rock-based polymers can be tailored to specific applications by adjusting the mineral content or choosing different polymers. This makes them versatile for a wide range of products, from lightweight panels to decorative finishes.

Applications of Rock-Based Polymeric Materials

Rock-based polymeric materials are already being used in several industries, and their potential for growth is enormous. Here are some key applications:

Construction and Building Materials:

Basalt Fiber Reinforced Polymers (BFRP): Basalt fibers, derived from volcanic rock, are used in construction as reinforcement in concrete or as a replacement for steel rebar. These composites are corrosion-resistant, lightweight, and extremely strong, making them ideal for infrastructure like bridges and highways.

Composite Panels: Rock-based polymers are used to create lightweight, durable panels for walls, roofing, and facades. These panels are often weather-resistant and provide excellent thermal insulation, reducing energy costs in buildings.

Automotive and Aerospace Industries:

Lightweight Components: The combination of strength and reduced weight makes rock-based polymeric materials ideal for automotive parts, such as body panels and interior components. These materials help reduce the overall weight of vehicles, improving fuel efficiency and reducing emissions.

Heat Shields and Insulation: In aerospace, the heat resistance of rock-based polymers can be leveraged for heat shields and thermal insulation in engines or spacecraft components.

Consumer Goods and Electronics:

Sustainable Packaging: Some companies are exploring the use of rock-based polymer materials for eco-friendly packaging, offering a biodegradable or recyclable alternative to conventional plastics.

Durable Housings: The strength and weather resistance of these materials make them suitable for electronic device housings, outdoor equipment, or consumer products that need to withstand harsh conditions.

Marine Applications:

Corrosion-Resistant Materials: In marine environments, where saltwater and moisture lead to corrosion, rock-based polymers offer a non-corrosive alternative for shipbuilding, offshore platforms, and underwater structures.

3D Printing:

Advanced Composites for Additive Manufacturing: With the growing popularity of 3D printing, rock-based polymers are being used as a feedstock for creating high-strength, lightweight parts that maintain the precision and flexibility offered by additive manufacturing techniques.

Sustainability and Environmental Impact

One of the most compelling advantages of rock-based polymeric materials is their potential to contribute to a more sustainable future. As industries increasingly seek to reduce their carbon footprints, materials that combine renewable, abundant natural resources with reduced dependency on fossil fuels are highly sought after.

Lower Carbon Emissions: Producing rock-based polymers typically has a lower environmental impact compared to the manufacturing of conventional plastics or pure synthetic composites. This is due in part to the reduced reliance on petroleum-based materials and the use of natural minerals that require less processing energy.

Recyclability: Many rock-polymer composites can be designed to be recyclable at the end of their life cycle, making them a more sustainable alternative to conventional construction materials or plastic products that end up in landfills.

Reduced Resource Extraction: By utilizing natural rocks and minerals as a base material, there is less need for extracting virgin plastic, leading to decreased environmental degradation and a smaller ecological footprint.

Challenges and Future Developments

While rock-based polymeric materials hold great promise, there are still some challenges to address:

Cost: Developing high-quality rock-based composites can be more expensive than traditional materials, particularly in terms of production processes and sourcing certain polymers. As demand grows and production scales up, these costs are expected to decrease.

Processing Complexity: The incorporation of mineral particles into polymers can complicate the manufacturing process, requiring specialized techniques to ensure uniform distribution and bonding between the materials.

Research and Innovation: Continued research is needed to further improve the mechanical and environmental properties of rock-polymer composites, particularly in exploring new bio-based polymers and enhancing the recyclability of the materials.

Conclusion

Rock-based polymeric materials are at the forefront of sustainable innovation, combining the strength of nature with the versatility of modern polymers. Their growing application in industries like construction, automotive, and consumer goods demonstrates their potential to revolutionize the way we think about materials and their environmental impact.

As research continues to advance and industries adopt more eco-friendly solutions, rock-based polymeric materials could play a critical role in shaping the future of manufacturing and sustainable design. Whether it’s reducing carbon emissions in construction or creating more durable and lightweight automotive parts, these innovative materials are paving the way for a greener, more efficient world.

0 notes

Text

Concrete Fibers Market is expected to display a steady growth by 2028

According to a new report published by UnivDatos Markets Insights the Concrete Fibers Market is expected to grow at a CAGR of around 8% from 2022-2028. The analysis has been segmented into Fiber Type (Synthetic, Steel, Glass, Basalt, Natural, And Others); End-User (Transport Infrastructure, Building & Construction, Mining & Tunnel, Industrial Flooring, And Others); Region/Country.

The concrete fibers market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the concrete fibers market. The concrete fibers market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the concrete fibers market at the global and regional levels.

Market Overview

The demand for an increase in the building and construction sites for various end-users. For instance, in February 2022, Skanska along with Tarmac are working to deal with climate change using advanced low-carbon concrete. TARMAC is supplying a low-carbon basalt-fiber-reinforced concrete to try on a temporary haul road used by construction vehicles, which will be part of the National Highways’ M42 Junction 6 improvement plan.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted the construction industry and has transformed the way the construction industry is delivered. The COVID-19 pandemic has significantly affected the concrete fibers market as there has been a delay in the production of roadways, highways, expressways, airports, parking areas, mining, tunnels, dams, water tanks, waterways, elevated decks, dock areas, and recreation to which the demand for concrete fibers has decreased.

The global concrete fibers market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on fiber type, the market is fragmented into synthetic, steel, glass, basalt, natural, and others. During the forecast period, the steel segment is likely to dominate the global concrete fibers market. The steel concrete fiber leads the market owing to its exceptional properties, such as shock & fatigue resistance, remarkable tensile & flexural strength, sturdiness, and ductility. In addition, steel fiber reinforced concrete is best suited for controlling cracks that occur at an early stage of construction and crack control during enhanced load-bearing situations. Furthermore, the factors justify its use in the market which will drive its growth during the forecasted period

Based on the end-user, the market is fragmented into transport infrastructure, building & construction, mining & tunnel, industrial flooring, and others. In 2020, the transport infrastructure segment is seen dominating the growth of the concrete fibers market. In the transport industry concrete fibers are extensively employed to construct highways, roads, railways, bridges, and ports & airports. Also, many emerging countries are now shifting their focus towards concrete fibers for construction purposes. For instance, in Jun 2021, Sika AG launched a new concrete reinforcing fiber solution SikaFiber-1050 B&BA HF, which is used to enhance concrete topping durability, reduce shrinkage cracking, and can be used for block and beam floors

Concrete fibers Market Geographical Segmentation Includes:

North America (U.S., Canada, and Rest of North America)

Europe (Germany, United Kingdom, Italy, France, Spain, and the Rest of Europe)

Asia-Pacific (China, India, Australia, Japan, and the Rest of Asia-Pacific)

Rest of the World

For a better understanding of the market dynamics of the concrete fibers market, a detailed analysis was conducted for different regions across the globe including North America (U.S, Canada, and the Rest of North America), Europe (Germany, France, Spain, United Kingdom, Italy, and Rest of Europe), Asia-Pacific (China, India, Australia, Japan, and Rest of APAC), Rest of World has been conducted. Geographically, the Asia-Pacific region dominated the concrete fibers market owing to the growing construction industry in the region.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=27493

The major players targeting the market include

N.V. Bekaert S.A

Propex Operating Company LLC

Sika AG

ABC Polymer Industries LLC

Cemex S.A.B. De C.V.

BASF SE

The Euclid Chemical Company

Owens Corning

GCP Applied Technologies

Nycon Corporation

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the concrete fibers market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the concrete fibers market?

• Which factors are influencing the concrete fibers market over the forecast period?

• What are the global challenges, threats, and risks in the concrete fibers market?

• Which factors are propelling and restraining the concrete fibers market?

• What are the demanding global regions of the concrete fibers market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

About UnivDatos Market Insights (UMI)

Browse Other Related Research Reports from UnivDatos Market Insights

Radiant Cooling Systems Market

MENA Infrastructure 3D Printing Market

Construction Chemical Market

USA Builders Hardware Market

Building Insulation Materials Market

About UnivDatos Market Insights

UnivDatos Market Insights (UMI) is a passionate market research firm and a subsidiary of Universal Data Solutions. We believe in delivering insights through Market Intelligence Reports, Customized Business Research, and Primary Research. Our research studies are spread across topics across the world, we cover markets in over 100 countries using smart research techniques and agile methodologies. We offer in-depth studies, detailed analysis, and customized reports that help shape winning business strategies for our clients.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

The top 5 distinct museums in Armenia

Armenia, a country of ancient history and rich cultural heritage, has an impressive array of museums that reflect its storied past and vibrant present. This small but historically important country nestled in the Caucasus introduces visitors to its diverse artistic, historical, and scientific heritage through its museums. From the city center to the picturesque countryside, Armenia's museums present treasures spanning thousands of years, from prehistoric objects to modern art shows. Among these cultural museums, five stand out for their uniqueness and extensive collections. These institutions not only preserve Armenia’s unique heritage but also provide an insightful perspective on global history and culture. Visitors can explore the incredible Matendaran manuscripts, dive into serious history at the Armenian Genocide Museum Institute, view archaeological wonders at the Erebuni Museum, admire masterpieces at the National Gallery of Armenia, and engage in contemporary creativity in Cafesjian. They can be centers of art. Each of these museums offers a unique experience, making it accessible to anyone who wants to understand and appreciate the rich fabric of Armenian culture and history. Armenia is a treasure trove of cultural and ancient treasures, beautifully reflected in its diverse museums. These institutions now not only hold the country’s wealthiest history but also provide an insightful angle on global records and art. Here we explore five of Armenia’s most notable museums, each offering a completely unique window into the United States' vibrant past and gift.

1. The Matenadaran: Mesrop Mashtots Institute for Ancient Manuscripts

Perched on a hill overlooking Yerevan, Matendaran is one of the oldest and most comprehensive collections of medieval manuscripts in the world. Named after Mesrop Mashtots, the inventor of the Armenian alphabet, the museum and research institute incorporate more than 23,000 manuscripts and documents. These texts cover a huge variety of topics, inclusive of theology, philosophy, records, medicinal drugs, literature, and cosmology. In his view, the collection highlights the intellectual and cultural development of Armenia and the broader vicinity over the centuries. Visitors can marvel at illuminated manuscripts, ancient texts in different languages, and rare books that survived turbulent historical times. The museum’s basalt-facing architecture, monuments, and statues of prominent Armenian scholars reinforce its importance as a fortress of knowledge and culture.

2. Armenian Genocide Museum and Institute

The Armenian Genocide Museum, located on Tsitsernakaberd Hill in Yerevan, stands as a solemn tribute to the 1.5 million Armenians who died in the genocide committed between 1915 and 1923 by the Ottoman Empire. The museum is part of a large monument, including the towering pillar and the eternal flame. Inside, visitors are guided through a series of poignant exhibitions documenting the tragedy of the genocide, the international response, and the lasting impact on the Armenian diaspora. Photographs, documents, victims the personal resources, and the testimonies of survivors also work, feeding the storm.

3. Erebuni Museum

Located on the site of the ancient Erebuni Castle, the Erebuni Museum offers a fascinating insight into the early history of Armenia. Established in 1968 in Yerevan year 2750, excavations from the citadel date back to 782 B.C. These gadgets include cuneiform inscriptions, pottery, gear, and weapons, all of which give insight into the day-to-day existence, subculture, and administrative structure of the Urartian state. The museum layout and exhibits are designed to replicate the placement of a historical citadel and beautify the academic experience. Visitors can also explore the ruins of Erebuni Castle itself, whose partitions and foundations were partially restored, providing a tangible link to Armenia’s remote past.

4. The National Gallery of Armenia

Located in central Yerevan, the National Gallery of Armenia is the country’s premier art museum. Established in 1921, it houses an in-depth collection of more than 26,000 gadgets, spanning Armenian, Russian, and European artwork. The gallery’s Armenian series is particularly noteworthy, with works ranging from illuminated medieval manuscripts to present-day paintings and sculptures. Highlights consist of works by renowned Armenian artists Martiros Saryan and Ivan Aivazovsky, whose seascapes received global acclaim. The National Gallery now not only displays the development of Armenian artwork but additionally affords a broader context through and on its numerous worldwide collections, making it a prime place for art fanatics and researchers to build

5. Cafezian Institute of Art

Located in Yerevan’s monumental staircase Cascade, the Cafesjian Art Center offers a vibrant blend of contemporary art and new architecture. Opened in 2009, the center was founded by philanthropist Gerard L. Schmidt. The museum’s exhibitions include works by renowned artists such as Fernando Botero, Arshile Gorky, and Andy Warhol. Besides temporary permanent exhibitions, the Cafezian Center hosts cultural events, educational programs, and workshops, creating a dynamic connection between the public and contemporary art and providing a view of Yerevan adorned with sculptures the whole of the

Conclusion

Visiting five of Armenia’s pinnacle museums gives a scenic adventure through the rich material of the country’s history, artwork, and tradition. From the historical manuscripts in Matenadaran to the solemn relics of the Armenian Genocide Museum, the excavations of the Erebuni Museum, the artistic beauty of the National Gallery, and the modern-day marvels of the Cafesjian Art Gallery, those institutions provide precious insight into Armenia’s precise background. For vacationers trying to explore this cultural gem, acquiring an Armenian visa is a truthful technique, paving the way for an unforgettable revel in this historically wealthy United States.

1 note

·

View note

Text

Famous writer Chetan Bhagat Launches World of Basalt Reinforcement by Mahesh Kumar Jogani

Renowned author and IIT alumnus Chetan Bhagat added his voice to the sustainability movement by launching the book World of Basalt Reinforcement by Shri Mahesh Kumar Jogani at a celebrity-filled event in Mumbai. The event brought together the worlds of literature, engineering, and environmental consciousness under one roof—marking a significant moment in the evolving conversation around sustainability and industrial development.

Lauding the book, Bhagat emphasized its importance in today’s rapidly urbanizing world. “As an engineer, I see this work as not just timely but necessary. Sustainable materials are not a luxury—they are the need of the hour,” he said. He commended Jugani’s deep expertise and dedication to practical innovation in the reinforcement sector, particularly in crack control and structural durability.

A Book That Bridges Sustainability and Technology

World of Basalt Reinforcement introduces readers to basalt fiber—an advanced material derived from volcanic rock. Celebrated for its strength, corrosion resistance, and minimal environmental impact, basalt fiber is emerging as a serious alternative to traditional reinforcement materials like steel and glass fibers.

The book focuses on the synergy between nature and technology. It provides a detailed look at the formation and properties of basalt, followed by real-world applications ranging from Aerospace to automobile. With its clear explanations and real-life insights, the book serves as both an entry point for students and introduction guide for engineers and innovators.

The Author: A Career in Sustainable Innovation

Shri Mahesh Kumar Jogani brings over 20 years of experience to this work. A research engineer by profession and a techno-entrepreneur by passion, Jogani holds multiple patents and has led innovations across composites, industrial reinforcement, and material science. His work consistently emphasizes durability, efficiency, and environmental stewardship.

Jogani is best known for his hands-on approach and commitment to real-world solutions. His focus on crack control in concrete and reinforcement technologies has positioned him as a key voice in the advancement of sustainable construction methods. His belief in the transformative power of basalt fiber is evident throughout the book.

“My aim,” Jogani says, “is to make engineers think differently. Innovation doesn’t have to come at the cost of nature. With basalt, we can have both performance and environmental care and responsibility.” He added “With basalt, we can have both performance and sustainability”.

For more information on this subject please visit www.joganireinforcement.com

Our article also posted in the week channel, please refer this https://english.loktej.com/article/19233/famous-writer-chetan-bhagat-launches-world-of-basalt-reinforcement-by-mahesh-kumar-jogani

#basalt fiber#basalt#building#construction#nature#JOGANIReinforcement#best for crack resistance#best Concrete Fibers#Reinforcement#industrial reinforcement#concrete reinforcement

0 notes

Text

Types of Fabric for Shoes

The choice of fabric plays a significant role in the quality and functionality of footwear. Recognising this, Coats provides highly engineered fabric for shoes, along with compatible sewing threads. After the acquisition of Rhenoflex and Texon, Coats now boasts a comprehensive range of components catering to the footwear industry. Let’s explore some of the specialised fabrics they offer for shoes.

Rhenoprint

A part of the Rhenoflex line, Rhenoprint is a cutting-edge reinforcement fabric for shoes. It is noteworthy for its 100% waste-free production, which not only minimises environmental impact but also allows for high customisation. Depending on customer needs, Rhenoprint can be tailored to specific hardness levels, shapes, and thicknesses while reducing the need for additional trimming or die-cutting.

ProWeave

ProWeave is a high-performance jacquard fabric for shoes designed with technical apparel in mind. It melds functional weaving with creative design and advanced technology, resulting in a highly durable and versatile fabric. One standout feature is ProWeave’s multi-directional zonal stretch, which allows for seamless and unique designs. The fabric comes in an array of yarn weights, thicknesses, and colours, offering a broad scope for innovation in luxury, industrial, and performance footwear.

Vogue

If you're looking for fabric for shoes that combines aesthetics with durability, Vogue is an excellent pick. Created primarily from cellulose material, it is washable, sustainable, and versatile. A robust alternative to leather, Vogue comes in various finishes, colours, and thicknesses. Its adaptability extends to coatings, laminations, and printing, allowing designers greater creative freedom.

Lattice and Lattice Lite

Developed to complement Synergex composite fibres, Lattice and Lattice Lite technologies focus on waste elimination and performance maximisation. Lattice employs a continuous fibre-laying technique that speeds up preform manufacturing without the need to cut fibres. This enables precise control over fibre direction and positioning. Lattice Lite, on the other hand, delivers moulded composite products tailored to customer specifications, ideal for applications like footwear plates and bindings.

Lattice Lite Eco

In line with growing eco-consciousness, Coats offers Lattice Lite Eco, a pioneering fabric for shoes that centres on sustainability. This technology enables the precise placement of fibres like PA11, recycled PA6, and basalt fibre to create high-performance, eco-friendly toe caps and footwear.

Choosing the perfect fabric for your footwear needs

If you're in the business of footwear manufacturing, Coats offers a variety of solutions tailored to your needs. Reach out to their experts to find out which fabric for shoes best suits your application. They also provide value-added services and tools to assist in selecting the perfect threads and fabrics for your specific needs.

About the author:

Coats offer different types of thread, and learning which one works best for different sewing tasks is crucial. Brush up your wardrobe with Coats thread, which is the most fashionable, durable, and affordable thread on the market. They provide some of the best sewing threads in the world, including premium polyester and fibre optic yarns. Many leading brands use Coats threads. Moreover, Coats is an expert in designing and supplying a diverse range of technical products to the Performance Materials sector, which serves various strategic end-use markets.

0 notes

Text

first off: Soul encapsulates the ability to create and destroy. It is not life, it is not a measure of worth, it is not a measure of morality or conviction. This is vital to understand.

Creepers used to be like, sapient humanoid people. They are part of the “ancient builders” alongside humans

Villagers are technically also human; same genus different species. Like Homo neanderthalensis, who were just as human as extant humanity. When I say human it includes villagers unless otherwise specified.

Humans and creepermen came together a long long time ago to create an uber mega enchantment and general magic and power generating thang. A mishmash of nuclear power, magic, and soul, made to learn more about the world. But a large amount of soul is very difficult to keep stable and contained, and the dominant culture in (primarily non-villager) humanity at the time encouraged greed and selfishness. The culturally borne inability in large sects of humans to work with each other eventually led to the project blowing the fuck up. The power of this was so insanely strong that it created new “dimensions” (the nether and the end) and led to a huge kerfuffle with the balance of soul.

a few other things that are direct results of this explosion:

Ancient debris (degraded reinforced deepslate that was used in the project)

Geiger crackle ambience in the basalt deltas

Soul sand/soil, skulk, and most non-animal hostile mobs (silverfish are normal)

All the life that originates in the other dimensions

Wardens are fucked up creepermen, descended from the tiny population of creepermen that ripped out pieces of their soul to escape the explosion

Creepers are, as you might be able to guess, also fucked up creepermen, rearranged by the explosion. They have more soul than the undead, but only enough to explode.

Soul sand/soil and skulk are two sides of the same coin, with skulk being much more potent and active, and soul sand being more reliant on time. Skulk is partially airborne in spores, but the spores can’t root into the ground, only in mobs

Skulk in high concentrations hungers for soul so bad that Wardens will kill everything with even a little bit of it, even its own ambulatory vectors. The end goal of the skulk is soul, not flesh, after all.

Undead mobs are a result of skulk. Overworld inhabitants have resistance to the airborne part, but typically will succumb to direct infection from a zombie, the main vectors of its spread. Nether and (easy to infect) End inhabitants aren’t easy to come by of course, but the spores also function as communication for the already infected, so they stay as a feature of the skulk virus. Skulk (and for that matter soul sand) is hard to see in the undead because it primarily inhabits the insides of bones

Ghasts and withers (not skeleton) actually have too much soul, too much for them to control fully. Withers can coordinate a little easier as a result of the three heads; the extra coordination is why they come to life at all.

The End has no soul virus because it has an insanely high ambient soul leeching factor. This is why it’s so barren, basically everywhere.

The initial explosion actually made many dragons in the End, and really more life in general. But the soul leeching made most unable to even reproduce and rendered the world barren, eventually leaving only the immortal queen, who subsists on the last remnants of the End’s life. She is not the reason the portal is closed, it was like that from the beginning, but her death releases enough soul to open it.

Endermen are fucked up humans, much like wardens and creepers are fucked up creepermen. Endermen are less hostile due to the lack of an endemic End virus, but looking them in the eyes lets them see your soul, and it makes them freak out over what they lost. They can’t take it from you, however, because of their lack of a soul virus. They do have normal viruses though! endermites

Experience is not souls; rather it is knowledge and memories, congealed into a physical form. It’s hard for the player to use any magic without very specific rituals, because the ambient loss of soul made wielding magic much more difficult.

Magic is able to bring to life electronics. Redstone is often enough, but when redstone can’t be used, magic can function as a substitute. This is why jukeboxes work lol.

Lightning is a mix of electricity and concentrated soul, which is why it does some weird shit

Illagers are OBSESSED with bringing the dimensions together, attempting to bring back the ancient builders, curing soul viruses, and creating new life. They want the world to be in their image, so they want to be at the forefront of every effort concerned with such things.

Lapis can work as a “fake soul”. Illagers are obsessed with it; they use it to control hostile mobs and think it’s the way they’ll be able to make new life and bring back the ancient builders. They are able to build their effigies because of lapis. Wandering traders also use lapis, though of course they use it for considerably less hostile means

Pretty much all structures are pre-explosion. Even villages, mansions, and watchtowers. They are able to be upkept by their current inhabitants, but they can’t build more. The only exceptions are ancient cities, strongholds, and ruined portals (if you consider those structures, i guess)

Ancient cities were part of the immediate response to the explosion; an attempt to use the Warden precursors, skulk, and portals to fix what had been broken. But the disorganization in society made it basically impossible to get much of anywhere with it

Strongholds were created primarily to avoid the skulk. Unfortunately all it really did was introduce it to the underground, where it was almost impossible to fight off the undead, which couldn’t burn down there. Skulk spores also seemed to really fuckin like the underground, and rooted. no end portal was ever finished

The only way to replenish the soul and bring the viruses under control was to bring in a third party—a player. The world called for you, and you answered. Resemblance to current or past inhabitants is more of a coincidence than anything (also i consider customizable player models as canon here lol)

i should minecraft lorepost (insane headcanons)

3 notes

·

View notes

Text

Basalt Fiber Market: Transforming Construction, Automotive, Wind Energy, Electronics, and Marine Industries

Basalt fiber, a remarkable material derived from volcanic rock, is fast becoming an essential component across multiple industries. Its natural origin, combined with a suite of performance advantages, makes it a unique, eco-friendly alternative to traditional materials like fiberglass, carbon fiber, and steel. The basalt fiber market is booming, supported by an increasing demand for lightweight, durable, and sustainable materials in sectors such as construction, automotive, wind energy, electronics, and marine.

Understanding Basalt Fiber

Basalt fiber starts as basalt rock, which is melted and then extruded into fine fibers. Unlike synthetic fibers, basalt fiber is natural, which makes it an attractive choice for industries striving to meet green and sustainable goals. Besides being non-corrosive and thermally stable, basalt fiber also boasts impressive strength, making it ideal for heavy-duty applications where durability matters.

What’s Driving Market Growth?

Basalt Fiber Market is expected to grow significantly over the next several years, with a predicted valuation of USD 503 million by 2028, up from USD 279 million in 2023.

The global market for basalt fiber is set to expand rapidly due to several significant factors:

Shift Towards Lightweight, High-Performance MaterialsAcross industries, there’s a strong focus on using lightweight materials that contribute to improved efficiency, lower emissions, and reduced costs. Basalt fiber’s combination of high tensile strength and low weight is leading it to replace heavier, more traditional materials, particularly in construction and transportation.

Commitment to SustainabilityMore industries are aiming to reduce their carbon footprints, making basalt fiber an attractive solution. Since it’s derived from a naturally occurring material, its production has a lower environmental impact compared to synthetic fibers, aligning well with sustainability objectives in sectors like wind energy and automotive.

Reliable Performance in Harsh ConditionsOne of the main reasons for the rising popularity of basalt fiber is its exceptional performance under extreme conditions. Basalt fiber is highly resistant to corrosion, temperature, and chemicals, making it perfect for challenging environments. This has huge implications for the marine, electrical, and electronics industries, where materials must withstand demanding situations.

Cost-Effective Alternative to Carbon FiberWhile carbon fiber is known for its strength, it’s also expensive, and that’s where basalt fiber shines. Offering comparable benefits at a fraction of the cost, basalt fiber is a budget-friendly option for industries like construction and automotive that are conscious of their bottom line but still need top-notch performance.

Expanding Applications of Basalt Fiber

Let’s look at how basalt fiber is finding its way into key industries, adding value through its durability, strength, and environmental benefits.

1. Construction and Infrastructure

In the construction world, basalt fiber is gaining popularity as a reinforcement in concrete structures, providing an alternative to steel rebars. Basalt rebar doesn’t corrode, handles thermal fluctuations well, and is lightweight, making it ideal for bridges, highways, and buildings exposed to severe weather. It’s also used in applications like soil stabilization, erosion control, and roofing solutions, where strength and longevity are key.

2. Automotive and Transportation

As vehicle manufacturers look to reduce weight to improve fuel efficiency, basalt fiber is proving to be a valuable asset. It’s increasingly being used in car body panels, engine parts, and other automotive components. Additionally, basalt fiber’s ability to dampen vibrations and insulate against heat makes it ideal for enhancing passenger comfort and safety in electric and hybrid vehicles.

3. Wind Energy

Wind turbine blades, one of the most vital components in wind energy generation, need materials that can endure high-stress environments. Basalt fiber’s fatigue resistance and ability to withstand constant exposure to harsh weather make it an ideal candidate for turbine blades. Its use here supports the renewable energy sector’s push for materials that align with long-term sustainability.

4. Electrical and Electronics

With its excellent insulative properties, basalt fiber is being adopted in electrical applications, where reliable insulation against heat and electricity is a must. It’s used in cables, circuit boards, and other components that require resistance to high temperatures and fire, making it especially valuable for safety-critical applications.

5. Marine Industry

Saltwater corrosion and UV exposure are ongoing challenges in marine applications. Basalt fiber’s durability in marine environments makes it perfect for use in ship hulls, decks, and underwater structures. Its resistance to biological degradation means it will last longer in these challenging environments, making it a wise choice for marine manufacturers.

What’s Next for Basalt Fiber?

Looking ahead, the basalt fiber market has a promising future as more industries recognize its value. Key advancements, such as improvements in manufacturing processes to reduce costs, will help make basalt fiber even more accessible.

Despite its growth, some hurdles remain. Production is still limited compared to more conventional materials like fiberglass. Increasing the availability of basalt fiber, building stronger supply chains, and raising awareness of its benefits will be crucial to fully unlocking its potential. Once these challenges are addressed, basalt fiber has the potential to reshape the materials landscape in many sectors.

To know more Download PDF Brochure :

Basalt fiber is set to make waves across construction, automotive, wind energy, electronics, and marine industries. With its combination of strength, durability, and sustainability, it is becoming an essential part of the solution for companies looking to innovate while also prioritizing environmental responsibility. As production scales up and research continues to improve its properties, basalt fiber is likely to become a mainstay in advanced materials.

For companies looking to stay competitive, investing in basalt fiber technology now could align with long-term goals of sustainability, resilience, and efficiency. The shift to basalt fiber is a step toward a smarter, greener future

#Basalt Fiber#Sustainable Materials#Construction Innovation#Automotive Materials#Wind Energy#Marine Industry#Advanced Composites

0 notes

Note

Minecraft world building is always interesting!! What are your nether worldbuilding ideas? T

well i do Not feel like giving the entire 4k so i will just talk about my thoughts on the history of the nether bc that is the part that i like best of it

so the nether was canonically not always like that; the soul sand valley might have once been "a habitable paradise full of huge, bygone creatures," the ancient debris is the remains of historical netherite mining by piglins, stuff like that. as such, i decided that i wanted to take what we're given in the game, use that to figure out what the original nether was like, and then go from there to the modern nether.

and me and @bananasofthorns were listening to some of the ambiance tracks for the different nether biomes, and we realized that hey, some of these sound very Hm. like, there's a couple in the basalt deltas that sound a little like laughter, or like war drums. and after listening to literally all of the nether ambiance tracks and tossing ideas back and forth and such, i settled on this idea, under the cut because it's Long:

the nether was originally a much more habitable place, with a lot more biodiversity than exists now. originally, there were four intelligent races, not just piglins, and they were loosely settled into the four biomes which existed at the time- the crimson forests, the nether wastes, the basalt deltas, and the soul sand valleys, though they weren't very wasteland-y or soul sand-y at all, so they were probably called something else.

the soul sand valley was home to a bunch of very powerful mages, as well as the massive beasts which became the fossils. they were probably the most able to use magic of all of the societies, and any overworld enchantments which can be found originated in the nether (like the ones on piglin armor) are actually a completely different form of that enchantment derived from ancient enchanted books from this society; soul speed was essentially reverse-engineered from them. the valleys were probably the most utopian of all the biomes at the time, full of many, many different kinds of flora and fauna.

the basalt deltas, on the other hand, were very hostile even then, with practically nothing living there except for the delta warriors. they were very warlike and probably conquerors, and were the ones who built the nether fortresses for military purposes. they spent decades at war with the valley mages, and while they most definitely had access to some pretty powerful magic it was not to their level of artistry.

there was also a society in the nether wastes, which has been next to forgotten. both the biome and the people were caught in the crossfire between the valley mages and the delta warriors and over a very long period of time, their entire civilization pretty much got wiped out. the land itself is still basically barren, and sometimes unstable.

the fourth, of course, was the piglins of the crimson forests. they didn't get involved with the wars, and managed to avoid getting much damage from the massive amount of fighting. they, and the hoglins, are the only mobs who are still around from this period of time.

the war did, of course, come to a catastrophic end in what i'm calling the cataclysm. the delta warriors gained access to very powerful and very volatile magic. what did they do with it? attempt to smite the valley mages off the face of the earth, of course- a little too effectively.

they did manage to totally wipe out the valley mages, which was their goal! they decimated the mages, as well as literally every other living thing in the biome, their own society, and did a lot of Bad Shit to the environment of the nether as a whole.

because the area and the people were so charged with magic already, the mages weren't just completely killed- instead, they were trapped in the newly-created soul sand, half-alive, with their souls only being released upon the sand being burnt. the valleys are now completely devastated, and you can hear the mages whispering or calling in the distance, sometimes enough to lure an unwary traveler to their death, though this isn't out of malice.

the delta warriors, also killed by the cataclysm, became the wither skeletons and skeletons of the nether. those who were in the valley at the time of the cataclysm became the wither skeletons due to the magic of the area; they spend their eternities protecting the fortresses they built. those who weren't there are the normal skeletons, forever attempting to provide reinforcements for a battle which is long since over.

and the piglins? they were adversely affected by the cataclysm, of course, everything was, and their glory days are past. but they're alive, where the other two are not- despite this extinction-level event, they are still continuing on, essentially the same as they were before. and this continues even through the most major thing that would harm the crimson forests after the cataclysm, that being the introduction of the warped forests.

the warped forests were essentially corruption which crept in just after the cataclysm when the environment was still unsettled; it began to slowly expand, eating away at the crimson forests, and it is also very... weird, as far as the biomes go. it's not really hostile, it won't kill you to enter or anything and there's even some helpful stuff there, but... it is Deeply Wrong. the endermen there are numb and expressionless, like they're sleepwalking. they never really react to stimuli other than being looked in the eye, but sometimes they scream in the distance like they're being tortured.

and, bonus, because i'm not sure whether it's piglin legend or reality but i think it's cool:

each of the biomes has an Entity to it, not quite sentient but enough to have intent, like a manifestation of the ones who used to live there. it's not quite a god, not quite real, but it is there and you can feel it, when you step into its domain.

the basalt delta is a conqueror imprisoned, the warrior who lost. the Entity of the deltas is trapped far beneath the surface, but it is still there, angry and vengeful, straining to get out, and sometimes you can hear it laughing, or the distant echo of the drums of war. the basalt delta is angry. the basalt delta hates you. the basalt delta wants you fucking dead.

the soul sand valleys are asleep. it's not quite dead, nothing with so much power and life could just die like that, but it isn't quite there, either. the valleys are a tragedy of unimaginable scale, and there is murmuring in the distance, never quite close enough to make out.

the nether wastes are dead. they are barren, empty, lifeless; nothing really grows and nothing really lives. the wastes died a long time ago, even before the cataclysm- the only trace of it is in the occasional odd noise, and the way the rock shifts and crumbles at random, unsettled by the fighting which reduced it to nothing.

the crimson forests are the only one left as it was- weaker, tired, but still alive and still awake and still free. the crimson forests do not get involved with wars not their own, do not play with the kind of power that can reduce a civilization to dust. the crimson forest, and its residents, are survivors above all. they will still be there, living, and so will the forests.

the warped forest, on the other hand... the warped forest is not of the nether. the warped forest is a foreigner, come slinking into the gaps left behind and slowly gaining ground, bit by bit. if any of the biomes has a mind, it's this one- the warped forests make odd, terrifying sounds, and the endermen are screaming in the distance or wandering like ghosts, and there is something laughing, low and heavy.

best not to stay too long.

#mc ambiance noises are TERRIFYING and i love them#if anyone wants to know which ones inspired certain stuff just ask#minecraft#minecraft lore#minecraft worldbuilding#minecraft nether#rain chatter

242 notes

·

View notes

Text

Composite Materials in Railways

Introduction to composites and FRPs