#ZeroDefects

Explore tagged Tumblr posts

Text

What is Zero Defects in Quality Management? - ZQC, Analysis, Plan, Example

Zero defects in quality management is a company plan to ensure that all products leaving their facility are defect-free. Companies can do this through comprehensive planning and vigilant employees constantly looking for errors. Implementing zero defects can be challenging, but the benefits make it worthwhile. This blog post will explore zero-defect and how it can help your business succeed.

Definition

Zero defects is a quality management term that means products and services are released without nonconformities.

The Zero Defect meaning is there are no defects in a given product. This is especially important when dealing with food and other regularly consuming items. To achieve this, companies must have processes that prevent defects from happening in the first place. There are many benefits to achieving zero defects, including improved customer satisfaction, reduced rework, and increased efficiency. Achieving zero defects can be challenging, but it's worth the effort to ensure that the quality standards are well-maintained and the defects are reduced to the possible extent. There are many ways to achieve zero-defect output. For example, you can use statistical process control charts to identify and eliminate the causes of variation in your process. You can also use quality tools such as to cause and effect diagrams, check sheets, Pareto charts, and FMEA (failure mode and effects analysis) to identify and eliminate defects in your product.

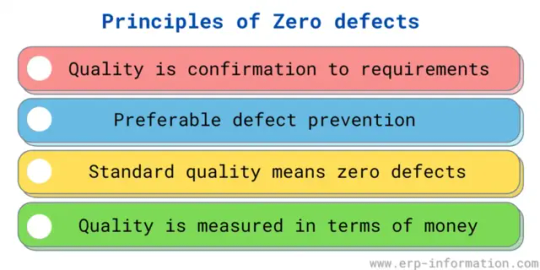

Four important principles of zero defects in quality management

- Quality is important to ensure that all the important factors of production are taken care of, making way for good processes and procedures. - Quality must be given equal importance and must be set right. It doesn't make sense that the company starts with its production and then tries to determine the quality standards. The number of defects detected must be minimal. If not, it will cost a huge amount to the business to set everything right. - Quality is money. To compare the data, the business must ascertain its waste, production, and profits in monetary terms. - The company must keep zero defects as its target and try to reach a state of perfection though it is practically impossible to attain such a state.

Zero defect benefits

It benefits the organization in many ways. Aligns process One of the most significant advantages of this concept is that it tries to align all the required processes precisely. So, it ensures that the firm does not suffer significant damage or loss and thus saves costs. It also leads to waste reduction as it is constantly monitored and controlled. Enhances workers' morale Usually, workers think that some minor mistakes will happen while working. But the zero-defect concept changes this mindset of the workers and encourages them to work without defects. That increases workers' morale. Improves customer relationship Better quality means delighted customers and repeat customers. This end of the day translates to long-term customer relationships and more profits for the company. But the business must be careful that the strict environment created to ensure zero defects does not lead to reduced morale of its employees. Constant improvement must be encouraged, which will sum up living the goal of zero defects.

Disadvantages of Zero Defect

Technically it is difficult to achieve zero defects. There will be a chance of a negative impact on performance because of the time and resources committed to zero defect. It may negatively affect the whole supply chain when the other manufacturer has a different definition of zero defect.

How to adopt Zero Defects?

There are no proven instructions to achieve zero defects. Following are the few guidelines that need to be followed to adopt zero defects

- Identify the quality issues that consume more budget. - Initially, the company must identify the changes to be done in the process by recognizing the proper way to do things. - Understand clearly the needs of customers in terms of quality. Then, try your best to meet it. - The company has to encourage its employees to get quality products by motivating, pledging, challenging, telling the importance of teamwork, and giving rewards. - Create a qualified team for quality improvement. - We know "prevention is better than cure." Therefore, it is better to prevent mistakes by having robust design systems that do not allow you to make mistakes. - Carefully monitor your process so that you can identify the root cause of the defect and take immediate action on it. - Take corrective action to remove the defect causes. - Keep on doing all these things to achieve zero defects.

Zero Defects Examples

One of the most famous zero defects examples comes from Henry Ford, who says, "Quality is Job 1." Ford implemented rigorous quality control measures at his factories to produce cars free of defects. This helped him gain a reputation for producing high-quality products and staying ahead of his competition. Other zero defects examples include Japanese companies such as Toyota and Honda, known for their high-quality standards and attention to detail. These companies have become world leaders in manufacturing because they produce products that meet or exceed the expectations of their customers.

FAQs

What is Zero Quality Control (ZQC)?ZQC is a Japanese philosophy and management principle that aims to eliminate waste in the production process. In addition, the goal is to achieve "zero defects" or products free of errors and meet customer requirements. ZQC has been credited with helping to make the Japanese manufacturing industry one of the most efficient in the world. Toyota, in particular, is well-known for its implementation of Zero Quality Control, which has helped it become the largest automaker in the world.What is Zero Defect Plan?Zero Defect Plan, also known as the zero-defect program, is an organizational philosophy that aims to reduce the number of defects in new products or processes. In other words, this is a commitment from the company to its customers that all goods will reach them without defects or "defectives." While it has widely been applied in many industries, some aspects of the plan are controversial. For example, while some contend that quality by design is vital for prevention work, others assert that zero-defect calls for new designs that are impossible to foresee premature faults beforehand. Furthermore, some indications are related to its implementation difficulty and lack of traceability. Due to these reasons, many companies abandon zero-defect strategies since their results did not meet expectations.What is zero-defect manufacturing?Zero defect manufacturing is a quality philosophy that seeks to eliminate all product defects and is usually aimed at reducing the amount of rework or scrap that results from producing defective products. The goal is to have every product manufactured to meet the customer's quality requirements without defects. This generally requires a rigorous process of inspection and testing to catch any problems before they reach the customer. It can also require steps such as Design for Manufacturing (DFM) and Design for Assembly (DFA), making it easier and cheaper to produce high-quality products.What is the philosophy of zero defects?The philosophy of Zero Defects is based on the idea that a systematic process can improve any product by eliminating all defects. Zero defects mean you have no errors, accidents, or wasted time or money. It's about creating a process that eliminates anything that could go wrong - at any stage of the life cycle - before it becomes an issue for someone else.How to do the Zero Defect analysis?Zero defect analysis is a quality assurance methodology applied to any process to identify and eliminate defects. It relies on breaking down the cycle into smaller steps to examine each step for potential faults. You want to take care of any problems before they cause you to have low-quality products or errors. So if you find a problem, fix it right away.

Conclusion

Quality management is a process of reducing the number of defective products. Achieving zero defects in quality management requires continuous improvement, changes, and commitment from all levels of an organization. Organizations should better understand their customers' needs to design processes that produce better-quality goods or services. It's also essential to have systems that help identify problems before they become severe enough to result in damages or consumer complaints. This way, organizations will avoid costly errors that could jeopardize reputation and profitability over time. You will also like: - Advanced Product Quality Planning (APQP) – A Comprehensive Guide to the Process - What is the Delivery Performance? - What is an Acceptable Quality Level? - What is Customer Service Level? - Output Control Read the full article

0 notes

Text

Tired of defects slowing down your production line or impacting product quality?

Meet DefectGuard by Brightpoint AI – an advanced defect detection solution built to help manufacturing and production teams achieve faster inspections, accurate results, and streamlined quality control.

Here’s how DefectGuard adds value to your operations:

1. Automated Inspection – AI-powered tools and machine vision automatically inspect products for defects, increasing both speed and consistency.

2. Real-time Monitoring – Instantly detects issues during production or development, enabling immediate correction and reducing waste or rework.

3. High Accuracy & Precision – Identifies even the smallest or hidden defects, significantly lowering false positives and false negatives.

4. Data Logging & Reporting – Captures every defect instance for reporting, trend analysis, and root cause identification – fueling continuous improvement.

Integration with Production Systems – Seamlessly fits into your existing manufacturing or software pipelines, reducing manual intervention and enabling automatic feedback for efficiency.

Whether you're in textiles, Metal & Steel, Wood, food & beverage, Package Handling, automotive, or electronics, DefectGuard adapts to your needs and delivers high-impact results.

Let’s help you build defect-free, data-driven operations with the power of AI.

Learn more: https://www.defectguard.ai/

#DefectDetection #AIforManufacturing #SmartQualityControl #DefectGuard #BrightpointAI #MachineVision #IndustrialAI #ZeroDefects #AIInnovation #ManufacturingEfficiency #ProductionMonitoring

0 notes

Text

Our best-selling Zero Defect BB Cushion in 21 Light Beige is back! With long-lasting wear and a natural finish, it evens out skin tone and smooths texture effortlessly. 💜

#Prislynshop #ZeroDefect #BBCushion #CushionFoundation #Cushion #MakeupCushion #KBeauty #Heynature #Makeup

0 notes

Text

Medical parts rejected? 🚫 Our 5-axis QC insanity: Eliminating burrs smaller than cells! 🔍 #MedicalMachining #ZeroDefects #LifeSavingCNC

1 note

·

View note

Video

youtube

"Revolutionize Alloy Wheel Repair with Triple-Sensor CNC Mastery! 🔧✨ #SmartMachining #Industry4"

Description: Discover the future of wheel restoration! Our automated CNC lathe for alloy wheel repair integrates 3 advanced detection systems: contact probe for precision mapping, tool-tip sensing for real-time adjustments, and laser scanning for micron-level accuracy. Perfect for flawless rim refurbishment, this machine slashes downtime by 50% while delivering showroom-quality finishes. Ideal for automotive workshops seeking #Industry40 efficiency, #ZeroDefect machining, and #SustainableManufacturing. Boost productivity with #CNCInnovation and redefine precision in #WheelRepairTech! 🚗💡

Tags: #CNCMachining #AlloyWheelRestoration #LaserScanning #AutomotiveTech #PrecisionEngineering #SmartFactory #ContactProbe #ToolTipDetection #ManufacturingSolutions #DIYAutoRepair

1 note

·

View note

Text

🚗 Jeet Cars Exclusive Offer! 🚗 CORLLA ALTIS 1.8 VL 70K KM ONLY 2017 🚘 Car Details: - Make: Toyota altis - Variant: 1.8 vl - Year: 09 Feb 2017 - Owner: 1st -colour: champagne - Kilometers: 70000 - reg no:MH02EK5537 - Fuel: petrol - Insurance: 5 FEB 2025 - Transmission: AUTOMATIC - Price: please inquire - 1. CAR IS IMMACULATE CONDITION WITH SET OF 2KEY. 2. LESS DRIVEN WITH COMPLETE SERVICE HISTORY 3. SUPER SILENT DRIVE QUALITY. 4. .ZERO DEFFECT CONDITION WITH NO FAULT CODES NOT A SINGLE PENNY WORK REQUIRED IN THE CAR. - Thank you for your interest in our car photos. It was great connecting with you! - We have more options available. - Visit us at our office or share your contact details for more information on our stock and address. 📍 Location: Beside Vijay Sales and Gold Gym, Bhabola Road, Vasai (Virar), Vasai West, 401201 📞 Contact & WhatsApp: 8698888048 / 7408571271 #CarDeals #UsedCarSale #Altis1_8VL #PetrolCar #CarForSale #FirstOwner #ToyotaAltis #2017Model #ImmaculateCondition #LuxuryCars #AutomaticTransmission #ZeroDefect #ServiceHistory

0 notes

Text

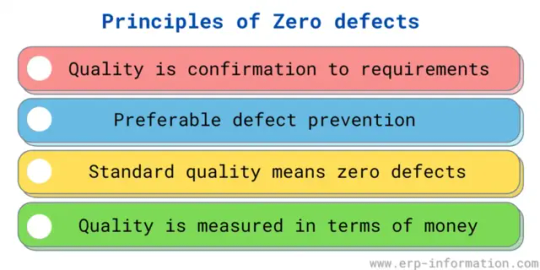

ZED Certification Process

Reach us! 022-42200900 www.icsasian.com [email protected]

#ZeroDefect #certification

0 notes

Photo

Interesting webinair to understand the Toyota mindset and continuous improvement. #asksensei #leanproduction #busbar #improvement #zerodefects https://www.instagram.com/p/CHFGOOypvlg/?igshid=6z3ivqkepa7x

0 notes

Text

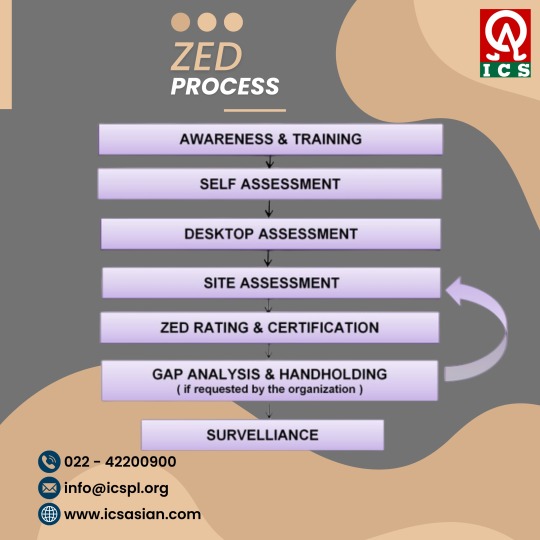

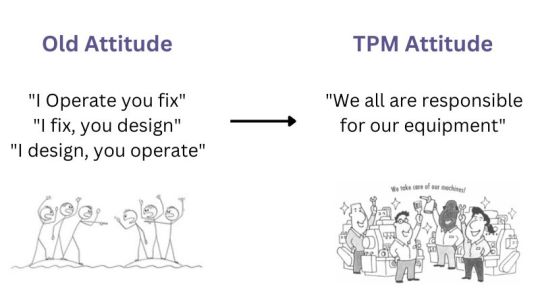

Why do companies choose TPM approach ?

Before the TPM approach operator only uses the machine and the maintenance person is responsible for daily maintenance due to which maintenance people don't get enough time for preventive maintenance but after TPM they can Produce and Product in Less time, Less cost, Zero loss without affecting the quality of the product by involving satisfied employees.

TPM is a culture that focuses on improving the effectiveness of the plant, equipment and process through the empowerment of people to achieve perfect production.

For more-

2 notes

·

View notes

Photo

Mengapa sih Saya Mengkonsumsi SOP / SALMON OVARY PEPTIDE ? Saya kan sudah sehat ? Saya kan ada Olahraga ? Saya kan ga ada Masalah kesehatan? Saya kan udah ini..... Saya kan udah itu.... . . Mungkin pernyataan ini paling sering di pertanyakan ya ? . . FYI : Setiap hari nya , jutaan bahkan triliyunan sel dalam tubuh manusia itu bermatian , dan di gantikan dengan yang baru , dan Masalah terbesar nya adalah DISAAT TUBUH MANUSIA MEMASUKI Usia 18-20 Tahun keatas KEMAMPUAN Stemcell tubuh kita utk memperbarui sel sel akan berkurang ditambah lagi seiring dengan USIA yg terus bertambah & Faktor Gaya Hidup . . . SOP memiliki 3 Patent Manfaat yang di akui oleh 3 Negara ( Japan - Korea - China ) , Patent manfaat adalah Sesuatu Yang pasti TERJADI dalam tubuh kita. Khasiat SOP di buktikan melalui 3 patent yg sudah melalui clinical study bertahun2 ; 1. REGENERASI SEL ( JP - 3946238 ) 2. Peningkatan fungsi pembuluh darah ( JP - 39446239 ) 3. Peningkatan Kualitas Kulit ( JP - 3899116 ) . . Jadi Jelas ya , Saat kita memasukkan Salmon Ovary peptide ke dalam tubuh kita , Tubuh kita akan kembali Mengaktifkan " STEMCELL " dalam Tubuh kita yang sudah tidur / berkurang fungsinya AGAR DAPAT MELAKSANAKAN fungsi nya sebagai mana mestinya yaitu MEMPERBAIKI SEL2 YANG RUSAK , sehingga tubuh dapat Melakukan SELF HEALING . Jadi yang sudah sehat akan semakin sehat , dan lebih terjaga kesehatannya..... Dan bagi yg Kurang Sehat ya tentunya akan merasa lebih sehat........ . . . #afclifescience #Sop100plus #madeinJapan #Natural #JapanNoCompromise #Zerodefect (at Semarang, Indonesia) https://www.instagram.com/p/CEBubJmHq1k/?igshid=6uzi0thiwxfv

0 notes

Photo

7 degrees in NYC calls for some Napa Cab! This is by ZD Wines locates on the Silverado Trail in Napa Valley, California. • • The 2015 Cabernet is a blend of organic vineyards from the best parts of Napa, hand-harvested and fermented separately in stainless steel, aged in American oak for 10 months. The barrels are tasted, selected then blended together and further aged in barrel for 14 months. Medium to full-bodied, well-balanced with smooth tannin and acidity. Go find some! • • #zdwines #cabernetsauvignon #napavalley #napacab #organicwine #zerodefect #50thanniversary #wine #vino #winelovers #winetasting #wineoclock #winelife #winetime #winenight #wines #wineo #wineporn #winenot #winestagram #sommelier #redwine #winewednesday #wineoftheday #ワイン #nyc (at New York, New York) https://www.instagram.com/p/Buq4qGmnoSi/?utm_source=ig_tumblr_share&igshid=m1m46uwqy7vf

#zdwines#cabernetsauvignon#napavalley#napacab#organicwine#zerodefect#50thanniversary#wine#vino#winelovers#winetasting#wineoclock#winelife#winetime#winenight#wines#wineo#wineporn#winenot#winestagram#sommelier#redwine#winewednesday#wineoftheday#ワイン#nyc

0 notes

Text

Las fiestas de Navidad están a la vuelta de la esquina. Faltan apenas unas pocas semanas y tu aun no tienes tu regalo. ¿Típico, verdad?

Piensas en regalarle algo original, nunca visto, algo que le sorprenda… pero en ocasiones un regalo clásico puede hacer muchas más ilusión que algo inesperado.

Por eso, hoy te proponemos la siguiente idea: regálale ropa interior. Si, ya sabemos que es un típico regalo junto con las colonias y los perfumes, pero hazme caso. Puede ser el regalo perfecto si sabes donde elegir.

Como sabéis, en este blog nos encanta todo lo que tenga que ver con la artesanía. Por ello, os vamos a proponer 2 webs donde podéis adquirir lencería hecha artesanalmente.

Diseño 2

Ropa interior hecha totalmente a mano. Con una trayectoria de más de 35 años comenzaron creando una bata de punto artesanal y se dieron cuenta de que no existía este tipo de productos en el mercado. La acogida de este productos fue muy satisfactoria y significó el comienzo de nuevos diseños de batas siempre teniendo en cuenta la moda y las tendencias.

Poco a poco su gama de productos fue aumentando a los camisones cortos y largos, pijamas, bailarinas y zapatillas de noche. Otros productos que se han adoptado recientemente son la lencería a medida, tallas grandes y ajuares para novia. Todas sus prendas están fabricadas en talleres en España.

Son productos de una alta calidad y se diferencian por sus diseños originales y sus materiales. La comodidad y la sofisticación es lo que prima en sus diseños y pueden ser un regalo único y preciado.

Aquí abajo os dejamos la web donde podéis encontrarles: http://www.diseno2.com/

También tenéis las fotografías de sus productos.

Zero defects

Hace casi un siglo, en 1920, nacía en España una pequeña empresa de moda íntima con el objetivo de fabricar ropa interior perfecta.

Sus productos están hechos con materiales únicos y tejidos de alta calidad como el algodón egipcio, el hilo de escocia o el hilo de soja. El proceso de producción además se realiza de una manera totalmente artesanal. Esto hace que cada prenda sea única y tenga una comodidad y una calidad excepcional.

Entre sus colecciones se podréis encontrar ropa interior tanto femenina como masculina. Desde camisetas interiores, bragas, boxers, culottes o tangas todo se realiza con un cuidado máximo. Son prendas para ponerse todos los días, cómodas y confortables.

La calidad de sus materiales harán que se convierta en el regalo perfecto. Hecho con mimo y cariño. Aquí os dejamos el link a su página web: https://www.zdzerodefects.com/

Espero que os haya gustado el post y que os sirva para daros una idea más para hacer los mejores regalos. ¡Hasta el próximo post!

Lencería: una buena opción para estas fiestas Las fiestas de Navidad están a la vuelta de la esquina. Faltan apenas unas pocas semanas y tu aun no tienes tu regalo.

0 notes

Text

🚗 Jeet Cars Exclusive Offer! 🚗 CHEVROLET CRUZ VCDI LTZ 50K KM ONLY NEW CONDITION WITH SUNROOF 🚘 Car Details: - Make: CRUZ - Variant: vcdi ltz - Year: 18 oct 2014 - Owner: 1st -colour: grey - Kilometers: 50000 - reg no:MH02DS1620 - Fuel: Diesel - Insurance: expired - Transmission: automatic - Price: please inquire 1. CAR IS IMMACULATE CONDITION WITH SET OF 2KEY. 2. LESS DRIVEN WITH COMPLETE SERVICE HISTORY 3. SUPER SILENT DRIVE QUALITY. 4. .ZERO DEFFECT CONDITION WITH NO FAULT CODES NOT A SINGLE PENNY WORK REQUIRED IN THE CAR. - Thank you for your interest in our car photos. It was great connecting with you! - We have more options available. - Visit us at our office or share your contact details for more information on our stock and address. 📍 Location: Beside Vijay Sales and Gold Gym, Bhabola Road, Vasai (Virar), Vasai West, 401201 📞 Contact & WhatsApp: 8698888048 / 7408571271 #FirstOwner #2014Model #CarDetails #GreyCruz #ChevroletCruz #DieselCar #AutomaticTransmission #ZeroDefect #LuxuryCars #CarDeals #UsedCarSale #ServiceHistory #ImmaculateCondition #LowMileage #SunroofCar #VasaiWest #CarForSale #PreOwnedCars

0 notes

Text

ZED Certification Process

Reach us! 022-42200900 www.icsasian.com [email protected]

#ZeroDefect #certification

0 notes

Photo

The #WorldConsumerRightsDay is celebrated every year on March 15. The day marked to raise awareness about a consumer's rights and needs. The #WorldConsumerRightsDay is observed to demand that the rights of all consumers are respected and protected, and to protest against market abuses and social injustices From this day forward, Ci3 promises to be worthy of your trust. Our services will always be #ZeroDefect, so that your experience will always be perfect. And for more details about Ci3, visit us at https://www.ci3.ae. You may also email us at [email protected]. #ci3 #ci3software #ERPsolution #humanresource #finance #inventory #clinic #sales #AIsolution #scalable #flexible #costeffective #streamlineprocess #collaborative #dubai #uaebusiness #SaudiArabia #isalamabad #usa #manhattan #newyork #consumerrightsday #consumerday

0 notes