#ansys software

Explore tagged Tumblr posts

Text

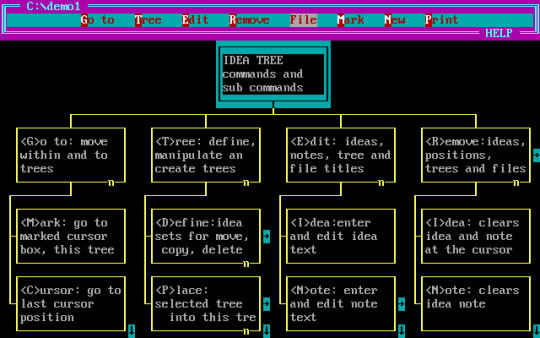

Idea Tree (DOS, Mountain House Publishing, ~1989)

You can run it in your browser here.

#internet archive#in-browser#dos#old software#vintage software#text mode#ansi#ansi art#1989#1980s#80s

14 notes

·

View notes

Text

Apparently the best way to get ansys working is to play The Offspring to it

0 notes

Text

Discover the Synopsys stock price forecast for 2025–2029, with insights into financial performance, AI-driven growth, and investment tips. #Synopsys #SNPS #SNPSstock #stockpriceforecast #EDAsoftware #semiconductorIP #AIchipdesign #stockinvestment #financialperformance #Ansysacquisition #sharebuyback

#AI chip design#Ansys acquisition#Best semiconductor stocks to buy#EDA software#Financial performance#Investment#Investment Insights#Is Synopsys a good investment#semiconductor IP#share buyback#SNPS#SNPS stock#SNPS stock analysis 2025–2029#Stock Forecast#Stock Insights#stock investment#Stock Price Forecast#Synopsys#Synopsys AI-driven chip design#Synopsys Ansys acquisition impact#Synopsys financial performance 2024#Synopsys share buyback program#Synopsys stock#Synopsys stock buy or sell#Synopsys stock price forecast 2025#Synopsys stock price target 2025

0 notes

Text

0 notes

Text

From Design to Deployment: How Switchgear Systems Are Built

In the modern world of electrical engineering, switchgear systems play a critical role in ensuring the safe distribution and control of electrical power. From substations and factories to commercial buildings and critical infrastructure, switchgear is the silent guardian that protects equipment, ensures safety, and minimizes power failures.

But have you ever wondered what goes on behind the scenes, from the idea to the actual installation? Let’s dive into the full journey — from design to deployment — of how a switchgear system is built.

Step 1: Requirement Analysis and Load Study

Every switchgear project begins with requirement analysis. This includes:

Understanding the electrical load requirements

Calculating voltage levels, short-circuit ratings, and operating current

Identifying environmental conditions: indoor, outdoor, temperature, humidity

Reviewing applicable industry standards like IEC, ANSI, or DEWA regulations (especially in UAE)

This stage helps engineers determine whether the project needs low voltage (LV), medium voltage (MV), or high voltage (HV) switchgear.

Step 2: Conceptual Design & Engineering

Once the requirements are clear, the conceptual design begins.

Selection of switchgear type (air insulated, gas insulated, metal-enclosed, metal-clad, etc.)

Deciding on protection devices: MCCBs, ACBs, relays, CTs, VTs, and fuses

Creating single-line diagrams (SLDs) and layout drawings

Choosing the busbar material (copper or aluminum), insulation type, and earthing arrangements

Software like AutoCAD, EPLAN, and ETAP are commonly used for precise engineering drawings and simulations.

Step 3: Manufacturing & Fabrication

This is where the physical structure comes to life.

Sheet metal is cut, punched, and bent to form the panel enclosures

Powder coating or galvanizing is done for corrosion protection

Assembly of circuit breakers, contactors, protection relays, meters, etc.

Internal wiring is installed according to the schematic

Every switchgear panel is built with precision and must undergo quality control checks at each stage.

Step 4: Factory Testing (FAT)

Before deployment, every switchgear unit undergoes Factory Acceptance Testing (FAT) to ensure it meets technical and safety standards.

Typical FAT includes:

High-voltage insulation testing

Continuity and phase sequence testing

Functionality check of all protection relays and interlocks

Mechanical operations of breakers and switches

Thermal imaging to detect hotspots

Only after passing FAT, the switchgear is cleared for shipping.

Step 5: Transportation & Site Installation

Transportation must be handled with care to avoid damage to components. At the site:

Panels are unloaded and moved to their final location

Cabling and bus duct connections are established

Earthing systems are connected

Environmental sealing is done if installed outdoors or in dusty environments

Step 6: Commissioning & Site Acceptance Testing (SAT)

This final stage ensures the switchgear is ready for live operation.

Final checks and Site Acceptance Tests (SAT) are performed

System integration is tested with other components like transformers, UPS, and generators

Load tests and trial runs are conducted

Commissioning report is generated, and documentation is handed over to the client

Conclusion

From idea to execution, the journey of building a switchgear system is highly technical, safety-driven, and precision-based. Whether you’re in power generation, industrial automation, or commercial construction, understanding this process ensures you choose the right system for your needs.

7 notes

·

View notes

Text

let’s dispel once and for all the fiction that mechanical keyswitches are good. They aren’t that much better than the alternatives.

More earnestly: the number one benefit of mechanical keyswitches is that they grant a designer an extraordinary degree of latitude when it comes to the structure and design of a keyboard. Unless you really highly value clickiness the majority of their features can be matched by high quality rubber domes from any decent keyboard manufacturer.

Their real strength is that you can pick consistent, reliable switches and put them anywhere you want in 3D space and just run wires to them to make a unique 1 of 1 keyboard that perfectly fits you, and you can easily stick a microcontroller with custom firmware in there to implement whatever features you want.

I got a Logitech ergo rubber dome today and it feels great, the biggest issue is that I wish it didn’t have a numpad and I wish it had more thumb buttons so that they could do more work. And of course I would! That’s what my homemade custom mechanical split keyboard looks like! I could make that to exact specs with some wood tools and a laser cut sheet of brass for the switchplate, whereas this Logitech is a miracle made of over a dozen unique injection moulded parts with an overall mould cost probably exceeding USD 50k!

I would love to have exactly the perfect high end rubber dome mass-produced keyboard of my dreams, but no one makes it, and that’s, reasonable, I have very specific dreams, but I have never understood bog standard layout mechanicals. You could be having a much better time with something with nicer switches!

Sorely tempted to figure out if I can physically hack off the numpad here and sneakily hot-glue some kailh choc switches to the wristrest as thumb keys. At the moment I'm just putting my trackball square on top of the numpad which works fine. I'll print a cap for it later. This is going to end up at Gainful Employment Location not home. At the very least I want to see if there's a way to distinguish the two spacebars in software and use some clever hacks to make them behave as enter/backspace/both.

ISO enter keys were sent by the devil but I don't really have a lot of good options unless I want to import ANSI keyboards.

15 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Note

About the post you recently reblogged...

I do rate Carlos high and like him but the race engineer or automotive engineer allegations need to stop. Already being an F1 driver is a life-long investment into understanding many things and honing your skills. Your driving skills.

This is a very complicated team sport and engineering sport, and I think people really downplay just how much engineering work there is behind the cars. Make Carlos use ANSYS software to model the structure of a car, make Carlos run a CFD simulation and analysis, make him generate iso-surfaces in the X velocity and then identify wake regions/flow separation and THEN make him come up with modifications within the regulations that help reduce drag 🙄. And all the shit I'm saying is like the most most basic part that we are taught in a bachelor's mechanical engineering degree. I could not even begin to think or imagine what actual f1 engineers do.

So, please, this man who is a good driver does not need to, nor does he understand the car like the engineers on the williams factory do. He understands it in a different way, and his feedback is very valuable, sure. But god, please, he isn't designing that car. Why can't people understand??

And no he's not creating better strategies. What drivers see and know as they drive is a very very small percentage of all the information the pitwall and strategist have. And even if he was fed that info, he'd have to be a genius to parse all that out. People (rightly) complain about Norris' engineer Will giving him almost a riddle to chose what Tyre he wants, can't imagine what giving a driver ALL the info the team is considering would look like. They wouldn't even have the time 💀.

Sorry my rant is over but this pisses me off badly. The way people will overstate the role of the driver for both positive and negative agendas is such a pet peeve of mine.

I have no recollection of what post i reblogged but yeah, you’re so valid 😅

2 notes

·

View notes

Text

You hear about video game development?

Well. I wouldn't say I expected such a catastrophic implosion from Unity.

Now, I can't say that I didn't laugh at the situation. It's a hilariously terrible case of bad management coming up with bad ideas in desperation. But it's also a somewhat scary indication of the sorry state of the industry.

Unity controls about 40% of the engine marketshare (according to a linkedin post I found anyway). Unity dominates the engine scene by a large margin, followed by Unreal at around 30% and Cryengine by around 5%. Unity forms such a large part of the entire game development industry, that it's difficult to really even understand just how much they control the concept of games as a whole!

Most people are jumping to some paid alternatives, like the aforementioned Unreal and, to a lesser extent, Game Maker, but my suggestion is this: don't!

Within the last decade, all-encompassing closed super game engines have become less of a side venture and more of an expectation. Back in the 2000s, there were a few engines like this, mostly amateur ones. Game engines were less creation stations and more of a loose collection of middleware and tools. Purchasing the rights to the engine meant that you also got the responsibility of also tying the engine into something resembling a game yourself. I feel like this art has been lost.

Game engines nowadays are more of a purchase of a passing right to use and incredibly specific, closed set of tools. You don't get to define the tools, and you don't get to really own the tools. It's yet another example of the tradition of the games industry fucking over the customers, and the customers just going with it. Because of this, while Unreal got some free dunks on Twitter for this, I can assure you Epic is planning something equally terrible as Unity's PR faux pas, and it'll come into to play in about 3 years when everyone's just accepted that Unity sometimes financially screws you over.

But, game developers are indeed developers. They know software, and they can learn to make new software.

If you're a game dev and still reading this, I'd recommend taking a peek beyond the curtains of corporate cockfighting, into the realm of DIY game engines. It's a… somewhat janky world full of strange characters with unusual ideas on how much time it's acceptable to spend not working on a game, but it's also a place where you're not being sat on by fatcats.

Just as game engines have progressed in the past 20 years, so have libraries, middleware and resources for independents. Making your own engine isn't just picking up ANSI C and toiling for a year in software rendering hell. Open tools like Pygame, Monogame, LÖVE and Cocos2D (among many, many others) are far beyond just simple rendering libraries and border on being game engines sometimes. The difference is, these tools are open source, and they do not restrict you with what you can do with them.

There are several games you may have played made using these frameworks. Streets of Rage 4 (MonoGame), Celeste (MonoGame), Fez (XNA, aka. MonoGame), Miitomo (Cocos2D), Geometry Dash (Cocos2D)… I got tired of looking up more. There are a lot of games.

The future which I hope to see for game developers is one where you have a large assortment of simple tools you can pick. Level editors, asset converters, entity systems, all small chunks of a game engine you could drop into your own project to slowly build up your own collection of workflows to make games your own way, completely independent of any larger forces on the market.

The support for these frameworks is still somewhat barren compared to Unity, but I believe, that if more people jump to alternatives like this, more tools, tutorials and middleware built for them would start showing up. This is how Unity also got its start, about 15 years ago. You also really don't need all the power in the world to make your simple 2D Megaman clones. The fog created by the monolithic engines we have now have obscured just how simple the building blocks for your favourite games can really be.

It just takes some bravery and willingness to learn a new way to approach making games, but I think the outcome is worth it, even just for you.

21 notes

·

View notes

Text

Additive Manufacturing Market Size, Anticipating Growth Prospects from 2034

The world additive manufacturing market stands at US$ 26.79 billion in 2024 according to a fresh study released by Fact.MR, a market research and competitive intelligence firm. Global sales of additive manufacturing solutions are anticipated to grow ahead at 21.6% CAGR during 2024-2034.

More companies these days are likely to sustainable production practices because of their positive impacts on the environment. Compared to conventional production, additive manufacturing offers a number of environmental benefits. Energy and waste reduction are two significant benefits of additive manufacturing technologies over conventional production processes. Additive manufacturing eliminates the use of extra materials required for production with greater efficiency.

3D printing is chosen as the most advanced and latest manufacturing method. This technology is gaining popularity and capable of replacing conventional manufacturing methods in a number of end-use sectors. Medical, electronics, aerospace, defense, and other sectors are willing to embrace these additive manufacturing methods. Advances in electronics manufacturing are expected to result in more automation, and, in turn, additive manufacturing technologies.

Get Free Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9254

Key Takeaway from Market Study

The international additive manufacturing industry is valued at US$ 26.79 billion in the year 2024.

Global additive manufacturing technologies demand is to value at US$ 189.34 billion as of the year 2034.

The market is estimated to grow with a productive CAGR of 21.6% during 2024 to 2034.

North America will dominate with a share of 29.1% in the world's additive manufacturing industry as of the year 2034.

China's demand for additive manufacturing technologies is expected to grow at 22.4% CAGR between 2024 and 2034.

Canada's market is expected to be US$ 9.26 billion by the end of 2034.

The medical sector is expected to have 22.1% of the total market revenue worldwide by 2034.

"Growing usage of additive manufacturing methods across various industries, such as aerospace and defense, to create intricate parts and light-weight components is anticipated to be one of the major growth drivers," provides a Fact.MR analyst.

Browse Full Report: https://www.factmr.com/report/additive-manufacturing-market

Key Market Players

Renishaw Plc.,

Wipro Limited,

Materialise,

ANSYS, Inc.,

Evonik,

Siemens Industry Software Inc.,

Stratasys Ltd.,

General Electric,

Xerox Corporation,

AMFG,

Mazak Corporation,

American Additive Manufacturing LLC,

Optomec are leading additive manufacturing solution providers.

Growing Adoption of Additive Manufacturing in Automotive Sector

Demand for additive manufacturing solutions in the automotive industry is forecasted to grow at 23% CAGR and reach a market value of US$ 27.64 billion by the end of 2034. Increased adoption of additive manufacturing methods is responsible for the simplification of the supply chain, speeding up prototyping, making customization easier, and allowing the manufacture of lightweight parts.

More Valuable Insights on Offer

Fact.MR, in its new offering, presents an unbiased analysis of the additive manufacturing market, presenting historical demand data for 2018 to 2023 and forecast statistics for 2024 to 2034.

The study divulges essential insights into the market based on product type (hardware, material, software), technology (power bed fusion, direct energy deposition, material jetting, material extrusion, photopolymerization), and application (medical, automotive, aerospace & defense, consumer electronics, architecture, industrial equipment, education & research institutions), across six major regions of the world (North America, Europe, East Asia, Latin America, South Asia & Oceania, and MEA).

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Apparently the best way to get ansys working is to play The Offspring to it

0 notes

Text

Greetings, fellow mechanical engineering enthusiasts and aspiring Ansys aficionados! Today, we embark on a journey through the intricate world of Ansys theory, delving deep into complex problem-solving techniques that are pivotal for mastering this powerful simulation software. Our expert has meticulously crafted a comprehensive solution to a master-level Ansys theory question, designed to sharpen your understanding and equip you with the skills needed to excel in your mechanical engineering assignments.

Understanding Finite Element Analysis in Ansys

Finite Element Analysis (FEA) lies at the heart of Ansys, enabling engineers to simulate and analyze the behavior of structures and mechanical systems under various conditions. To truly harness the capabilities of Ansys, one must grasp the fundamentals of FEA, including mesh generation, boundary conditions, material properties, and solving techniques.

Master-Level Ansys Question:

Question:

A cantilever beam is subjected to a concentrated load at its free end. Using Ansys, determine the deflection at the free end of the beam.

Solution:

To solve this problem using Ansys, we first need to create a finite element model of the cantilever beam. This involves defining the geometry of the beam, assigning material properties, meshing the structure, and applying boundary conditions.

Geometry and Meshing: We start by creating a 3D model of the cantilever beam in Ansys DesignModeler. Define the dimensions of the beam and create a solid model.

Material Properties: Specify the material properties of the beam, including Young's modulus and Poisson's ratio, to accurately represent its behavior under loading conditions.

Mesh Generation: Generate a mesh on the beam using Ansys Meshing. Ensure that the mesh is refined enough to capture the stress variations accurately, especially near the point of loading.

Boundary Conditions: Apply boundary conditions to mimic the physical constraints of the problem. For a cantilever beam, fix the base of the beam to restrict its movement and apply the concentrated load at the free end.

Solution: Once the model is set up, solve for the deflection using Ansys Mechanical. The software will calculate the deformation of the beam under the applied load, providing us with the desired deflection at the free end.

Post-Processing: Analyze the results obtained from Ansys Mechanical to gain insights into the behavior of the beam. Visualize the deformation using contour plots and extract the deflection at the free end for further analysis.

Conclusion: In this blog post, we've tackled a master-level Ansys theory question, demonstrating the application of Finite Element Analysis in solving complex mechanical engineering problems. By mastering these fundamental principles and techniques, you'll be well-equipped to tackle challenging assignments and projects with confidence. Remember, for expert assistance in solving your Ansys assignments, look no further than mechanicalengineeringassignmenthelp.com. Solve your Ansys assignment and elevate your mechanical engineering journey today!

Stay curious, stay innovative, and keep exploring the limitless possibilities of Ansys!

4 notes

·

View notes

Text

#Indian Institute of Technology Hyderabad (IITH)#Software#engineering#electronicsnews#technologynews#ansys

0 notes

Text

have to learn whole new CAD software till next thursday so i can start my mini project. like i already know solidworks and ansys but still.... my professor is like no, noobs already know that, you gotta know better 😭😭😭

1 note

·

View note

Text

This Week in Rust 513

Hello and welcome to another issue of This Week in Rust! Rust is a programming language empowering everyone to build reliable and efficient software. This is a weekly summary of its progress and community. Want something mentioned? Tag us at @ThisWeekInRust on Twitter or @ThisWeekinRust on mastodon.social, or send us a pull request. Want to get involved? We love contributions.

This Week in Rust is openly developed on GitHub and archives can be viewed at this-week-in-rust.org. If you find any errors in this week's issue, please submit a PR.

Updates from Rust Community

Official

Announcing Rust 1.72.1

Foundation

Announcing the Rust Foundation’s Associate Membership with OpenSSF

Project/Tooling Updates

This month in Servo: upcoming events, new browser UI, and more!

Pagefind v1.0.0 — Stable static search at scale

Open sourcing the Grafbase Engine

Announcing Arroyo 0.6.0

rust-analyzer changelog #199

rumqttd 0.18.0

Observations/Thoughts

Stability without stressing the !@#! out

The State of Async Rust

NFS > FUSE: Why We Built our own NFS Server in Rust

Breaking Tradition: Why Rust Might Be Your Best First Language

The Embedded Rust ESP Development Ecosystem

Sifting through crates.io for malware with OSSF Package Analysis

Choosing a more optimal String type

Changing the rules of Rust

Follow up to "Changing the rules of Rust"

When Zig Outshines Rust - Memory Efficient Enum Arrays

Three years of Bevy

Should I Rust or should I go?

[audio] What's New in Rust 1.68 and 1.69

[audio] Pitching Rust to decision-makers, with Joel Marcey

Rust Walkthroughs

🤗 Calling Hugging Face models from Rust

Rust Cross-Compilation With GitHub Actions

tuify your clap CLI apps and make them more interactive

Enhancing ClickHouse's Geospatial Support

[video] All Rust string types explained

Research

A Grounded Conceptual Model for Ownership Types in Rust

Debugging Trait Errors as Logic Programs

REVIS: An Error Visualization Tool for Rust

Miscellaneous

JetBrains, You're scaring me. The Rust plugin deprecation situation.

Crate of the Week

This week's crate is RustQuant, a crate for quantitative finance.

Thanks to avhz for the self-suggestion!

Please submit your suggestions and votes for next week!

Call for Participation

Always wanted to contribute to open-source projects but did not know where to start? Every week we highlight some tasks from the Rust community for you to pick and get started!

Some of these tasks may also have mentors available, visit the task page for more information.

r3bl_rs_utils - [tuify] Use nice ANSI symbols instead of ">" to decorate what row is currently selected

r3bl_rs_utils - [all] Use nu shell scripts (not just or fish) and add Github Actions to build & test on mac & linux

r3bl_rs_utils - [tuify] Use offscreen buffer from r3bl_tui to make repaints smooth

Ockam - make building of ockam_app create behind a feature flag

Ockam - Use the Terminal to print out RPC response instead of printlns

Hyperswitch - add domain type for client secret

Hyperswitch - separate payments_session from payments core

Hyperswitch - move redis key creation to a common module

If you are a Rust project owner and are looking for contributors, please submit tasks here.

Updates from the Rust Project

342 pull requests were merged in the last week

#[diagnostic::on_unimplemented] without filters

repr(transparent): it's fine if the one non-1-ZST field is a ZST

accept additional user-defined syntax classes in fenced code blocks

add explicit_predicates_of to SMIR

add i686-pc-windows-gnullvm triple

add diagnostic for raw identifiers in format string

add source type for invalid bool casts

cache reachable_set on disk

canonicalize effect vars in new solver

change unsafe_op_in_unsafe_fn to be warn-by-default from edition 2024

closure field capturing: don't depend on alignment of packed fields

consistently pass ty::Const through valtrees

coverage: simplify internal representation of debug types

disabled socketpair for Vita

enable varargs support for AAPCS calling convention

extend rustc -Zls

fallback effects even if types also fallback

fix std::primitive doc: homogenous → homogeneous

fix the error message for #![feature(no_coverage)]

fix: return early when has tainted in mir pass

improve Span in smir

improve PadAdapter::write_char

improve invalid let expression handling

inspect: closer to proof trees for coherence

llvm-wrapper: adapt for LLVM API changes

make .rmeta file in dep-info have correct name (lib prefix)

make ty::Const debug printing less verbose

make useless_ptr_null_checks smarter about some std functions

move required_consts check to general post-mono-check function

only suggest turbofish in patterns if we may recover

properly consider binder vars in HasTypeFlagsVisitor

read from non-scalar constants and statics in dataflow const-prop

remove verbose_generic_activity_with_arg

remove assert that checks type equality

resolve: mark binding is determined after all macros had been expanded

rework no_coverage to coverage(off)

small wins for formatting-related code

some ConstValue refactoring

some inspect improvements

treat host effect params as erased in codegen

turn custom code classes in docs into warning

visit ExprField for lint levels

store a index per dep node kind

stabilize the Saturating type

stabilize const_transmute_copy

make Debug impl for ascii::Char match that of char

add minmax{,_by,_by_key} functions to core::cmp

specialize count for range iterators

impl Step for IP addresses

add implementation for thread::sleep_until

cargo: cli: Add '-n' to dry-run

cargo: pkgid: Allow incomplete versions when unambigious

cargo: doc: differentiate defaults for split-debuginfo

cargo: stabilize credential-process and registry-auth

cargo: emit a warning for credential-alias shadowing

cargo: generalise suggestion on abiguous spec

cargo: limit cargo add feature print

cargo: prerelease candidates error message

cargo: consolidate clap/shell styles

cargo: use RegistryOrIndex enum to replace two booleans

rustfmt: Style help like cargo nightly

clippy: ignore #[doc(hidden)] functions in clippy doc lints

clippy: reuse rustdoc's doc comment handling in Clippy

clippy: extra_unused_type_parameters: Fix edge case FP for parameters in where bounds

clippy: filter_map_bool_then: include multiple derefs from adjustments

clippy: len_without_is_empty: follow type alias to find inherent is_empty method

clippy: used_underscore_bindings: respect lint levels on the binding definition

clippy: useless_conversion: don't lint if type parameter has unsatisfiable bounds for .into_iter() receiver

clippy: fix FP of let_unit_value on async fn args

clippy: fix ICE by u64::try_from(<u128>)

clippy: trigger transmute_null_to_fn on chain of casts

clippy: fix filter_map_bool_then with a bool reference

clippy: ignore closures for some type lints

clippy: ignore span's parents in collect_ast_format_args/find_format_args

clippy: add redundant_as_str lint

clippy: add extra byref checking for the guard's local

clippy: new unnecessary_map_on_constructor lint

clippy: new lint: path_ends_with_ext

clippy: split needless_borrow into two lints

rust-analyzer: field shorthand overwritten in promote local to const assist

rust-analyzer: don't skip closure captures after let-else

rust-analyzer: fix lens location "above_whole_item" breaking lenses

rust-analyzer: temporarily skip decl check in derive expansions

rust-analyzer: prefer stable paths over unstable ones in import path calculation

Rust Compiler Performance Triage

A pretty quiet week, with relatively few statistically significant changes, though some good improvements to a number of benchmarks, particularly in cycle counts rather than instructions.

Triage done by @simulacrum. Revision range: 7e0261e7ea..af78bae

3 Regressions, 3 Improvements, 2 Mixed; 2 of them in rollups

56 artifact comparisons made in total

Full report here

Approved RFCs

Changes to Rust follow the Rust RFC (request for comments) process. These are the RFCs that were approved for implementation this week:

No RFCs were approved this week.

Final Comment Period

Every week, the team announces the 'final comment period' for RFCs and key PRs which are reaching a decision. Express your opinions now.

RFCs

[disposition: merge] RFC: Unicode and escape codes in literals

Tracking Issues & PRs

[disposition: merge] stabilize combining +bundle and +whole-archive link modifiers

[disposition: merge] Stabilize impl_trait_projections

[disposition: merge] Tracking Issue for option_as_slice

[disposition: merge] Amend style guide section for formatting where clauses in type aliases

[disposition: merge] Add allow-by-default lint for unit bindings

New and Updated RFCs

[new] RFC: Remove implicit features in a new edition

[new] RFC: const functions in traits

Call for Testing

An important step for RFC implementation is for people to experiment with the implementation and give feedback, especially before stabilization. The following RFCs would benefit from user testing before moving forward:

No RFCs issued a call for testing this week.

If you are a feature implementer and would like your RFC to appear on the above list, add the new call-for-testing label to your RFC along with a comment providing testing instructions and/or guidance on which aspect(s) of the feature need testing.

Upcoming Events

Rusty Events between 2023-09-20 - 2023-10-18 🦀

Virtual

2023-09-20 | Virtual (Cardiff, UK)| Rust and C++ Cardiff

SurrealDB for Rustaceans

2023-09-20 | Virtual (Vancouver, BC, CA) | Vancouver Rust

Nightly Night: Generators

2023-09-21 | Virtual (Charlottesville, NC, US) | Charlottesville Rust Meetup

Crafting Interpreters in Rust Collaboratively

2023-09-21 | Virtual (Cologne, DE) | Cologne AWS User Group #AWSUGCGN

AWS User Group Cologne - September Edition: Stefan Willenbrock: Developer Preview: Discovering Rust on AWS

2023-09-21 | Virtual (Linz, AT) | Rust Linz

Rust Meetup Linz - 33rd Edition

2023-09-21 | Virtual (Stuttgart, DE) | Rust Community Stuttgart

Rust-Meetup

2023-09-25 | Virtual (Dublin, IE) | Rust Dublin

How we built the SurrealDB Python client in Rust.

2023-09-26 | Virtual (Berlin, DE) | OpenTechSchool Berlin

Rust Hack and Learn | Mirror

2023-09-26 | Virtual (Dallas, TX, US) | Dallas Rust

Last Tuesday

2023-09-26 | Virtual (Melbourne, VIC, AU) | Rust Melbourne

(Hybrid - online & in person) September 2023 Rust Melbourne Meetup

2023-10-03 | Virtual (Buffalo, NY, US) | Buffalo Rust Meetup

Buffalo Rust User Group, First Tuesdays

2023-10-04 | Virtual (Stuttgart, DE) | Rust Community Stuttgart

Rust-Meetup

2023-10-04 | Virtual (Various) | Ferrous Systems

A Decade of Rust with Ferrous Systems

2023-10-05 | Virtual (Charlottesville, NC, US) | Charlottesville Rust Meetup

Crafting Interpreters in Rust Collaboratively

2023-10-07 | Virtual (Kampala, UG) | Rust Circle Kampala

Rust Circle Meetup: Mentorship (First Saturday)

2023-10-10 | Virtual (Berlin, DE) | OpenTechSchool Berlin

Rust Hack and Learn | Mirror

2023-10-10 | Virtual (Dallas, TX, US) | Dallas Rust

Second Tuesday

2023-10-11| Virtual (Boulder, CO, US) | Boulder Elixir and Rust

Monthly Meetup

2023-10-11 - 2023-10-13 | Virtual (Brussels, BE) | EuroRust

EuroRust 2023

2023-10-12 | Virtual (Nuremberg, DE) | Rust Nuremberg

Rust Nürnberg online

2023-10-18 | Virtual (Vancouver, BC, CA) | Vancouver Rust

Rust Study/Hack/Hang-out

Asia

2023-09-25 | Singapore, SG | Metacamp - Web3 Blockchain Community

Introduction to Rust

2023-09-26 | Singapore, SG | Rust Singapore

SG Rustaceans! Updated - Singapore First Rust Meetup!

2023-10-03 | Taipei, TW | WebAssembly and Rust Meetup (Wasm Empowering AI)

WebAssembly Meetup (Wasm Empowering AI) in Taipei

Europe

2023-09-21 | Aarhus, DK | Rust Aarhus

Rust Aarhus - Rust and Talk at Concordium

2023-09-21 | Bern, CH | Rust Bern

Rust Bern Meetup #3 2023 🦀

2023-09-28 | Berlin, DE | React Berlin

React Berlin September Meetup: Creating Videos with React & Remotion & More: Integrating Rust with React Native – Gheorghe Pinzaru

2023-09-28 | Madrid, ES | MadRust

Primer evento Post COVID: ¡Cervezas MadRust!

2023-09-28 | Paris, FR | Paris Scala User Group (PSUG)

PSUG #114 Comparons Scala et Rust

2023-09-30 | Saint Petersburg, RU | Rust Saint Petersburg meetups

Rust Community Meetup: A tale about how I tried to make my Blitz Basic - Vitaly; How to use nix to build projects on Rust – Danil; Getting to know tower middleware. General overview – Mikhail

2023-10-10 | Berlin, DE | OpenTechSchool Berlin

Rust Hack and Learn

2023-10-12 | Reading, UK | Reading Rust Workshop

Reading Rust Meetup at Browns

2023-10-17 | Leipzig, DE | Rust - Modern Systems Programming in Leipzig

SIMD in Rust

North America

2023-09-21 | Lehi, UT, US | Utah Rust

A Cargo Preview w/Ed Page, A Cargo Team Member

2023-09-21 | Mountain View, CA, US | Mountain View Rust Meetup

Rust Meetup at Hacker Dojo

2023-09-21 | Nashville, TN, US | Music City Rust Developers

Rust on the web! Get started with Leptos

2023-09-26 | Mountain View, CA, US | Rust Breakfast & Learn

Rust: snacks & learn

2023-09-26 | Pasadena, CA, US | Pasadena Thursday Go/Rust

Monthly Rust group

2023-09-27 | Austin, TX, US | Rust ATX

Rust Lunch - Fareground

2023-09-28 | Boulder, CO, US | Solid State Depot - The Boulder Makerspace

Rust and ROS for Robotics + Happy Hour

2023-10-11 | Boulder, CO, US | Boulder Rust Meetup

First Meetup - Demo Day and Office Hours

2023-10-12 | Lehi, UT, US | Utah Rust

The Actor Model: Fearless Concurrency, Made Easy w/Chris Mena

2023-10-17 | San Francisco, CA, US | San Francisco Rust Study Group

Rust Hacking in Person

Oceania

2023-09-26 | Canberra, ACT, AU | Rust Canberra

September Meetup

2023-09-26 | Melbourne, VIC, AU | Rust Melbourne

(Hybrid - online & in person) September 2023 Rust Melbourne Meetup

2023-09-28 | Brisbane, QLD, AU | Rust Brisbane

September Meetup

If you are running a Rust event please add it to the calendar to get it mentioned here. Please remember to add a link to the event too. Email the Rust Community Team for access.

Jobs

Please see the latest Who's Hiring thread on r/rust

Quote of the Week

This is the first programming language I've learned that makes it so easy to make test cases! It's actually a pleasure to implement them.

– 0xMB on rust-users

Thanks to Moy2010 for the suggestion!

Please submit quotes and vote for next week!

This Week in Rust is edited by: nellshamrell, llogiq, cdmistman, ericseppanen, extrawurst, andrewpollack, U007D, kolharsam, joelmarcey, mariannegoldin, bennyvasquez.

Email list hosting is sponsored by The Rust Foundation

Discuss on r/rust

2 notes

·

View notes

Text

I am a fan of Ada (programming language)

This is a re-post to help new comers to find important resources. Ada is a good first language to learn because what is learned increases comprehension of programming in general and translates well into other languages. Ada is used for systems that must not fail, such as flight systems, trains, medical equipment, etc., but most jobs will require another language, so either way Ada will benefit you. Here is the list mentioned above that will help you getting started. Also, if you care to buy a book, look for the author John Barnes. His latest book on Ada should accelerate your understanding if you already know some level of programming

3 notes

·

View notes