#automobile PCBA

Explore tagged Tumblr posts

Text

Red Strip LED PCBA Boards for Automobile Brake Systems: Safety and Reliability Engineered in China

In the automotive industry, where safety and durability are non-negotiable, red strip LED PCBA (Printed Circuit Board Assembly) boards have become indispensable components in modern brake systems. These specialized boards power high-visibility brake lights, ensuring clear communication between vehicles and enhancing road safety. Chinese manufacturers, renowned for their precision engineering and cost-efficient production, are driving innovation in this critical sector. This article explores how China’s expertise in automotive-grade LED PCBA technology delivers high-performance solutions for global automakers. Please send PCB files to [email protected] to get a quote now!

The Role of Red Strip LED PCBA Boards in Brake Systems

Red strip LED PCBA boards are integrated into vehicle brake lights, particularly in third brake lights (CHMSL – Center High-Mount Stop Lamps) and rear light clusters. Their primary functions include:

Instant Illumination: LEDs provide rapid response times (<1 ms), crucial for alerting drivers during sudden braking.

High Brightness & Uniformity: Ensure visibility in all weather conditions (e.g., fog, rain, or bright sunlight).

Energy Efficiency: LEDs consume less power compared to traditional incandescent bulbs, reducing strain on vehicle batteries.

Longevity: With lifespans exceeding 50,000 hours, they outlast conventional bulbs, minimizing maintenance needs.

These boards are engineered to meet stringent automotive standards, including resistance to vibration, temperature extremes, and electrical surges.

Why Choose Chinese-Made Red Strip LED PCBA Boards?

China’s automotive electronics sector combines cutting-edge technology with rigorous quality control, making it a trusted partner for global OEMs and Tier-1 suppliers. Here’s why Chinese manufacturers excel:

1. Automotive-Grade Design and Materials

Robust Substrates: Use of high-temperature FR-4, aluminum-core PCBs, or ceramic-filled laminates to withstand engine compartment heat (up to 125°C+).

Premium LEDs: Sourced from top-tier suppliers, offering high luminous intensity (≥1000 mcd) and consistent color temperature (630–660 nm wavelength for pure red).

Protective Coatings: Conformal coatings (silicone, acrylic) guard against moisture, dust, and chemical corrosion.

2. Advanced Manufacturing Processes

Automated SMT Assembly: High-speed pick-and-place machines ensure precise mounting of LEDs, resistors, and drivers.

Reflow Soldering: Optimized profiles prevent thermal stress on components.

Automated Optical Inspection (AOI): Detects soldering defects, misaligned components, or trace imperfections.

3. Compliance with Automotive Standards

Chinese suppliers adhere to critical certifications:

AEC-Q101: Qualification for LED components in automotive environments.

IATF 16949: Quality management for automotive production.

ISO 16750: Compliance for vibration, shock, and temperature resistance.

IP67/IP69K: Dust and water resistance for outdoor durability.

4. Customization for Specific Applications

Flexible Form Factors: Boards tailored to fit curved or compact brake light housings.

Dimming and Control Integration: Compatibility with CAN/LIN bus systems for adaptive brake lighting.

Smart Features: Integration with sensors for fault detection or adaptive brightness based on ambient light.

5. Cost-Effective Scalability

China’s integrated supply chain and economies of scale enable competitive pricing without compromising quality. Bulk production capabilities ensure timely delivery for high-volume automotive orders.

Key Applications in Automotive Brake Systems

Third Brake Lights (CHMSL)

Slim, high-intensity LED strips mounted on rear windshields or spoilers.

Customizable lengths and brightness levels to match vehicle designs.

Rear Light Clusters

Integrated PCBA boards for combined brake/tail/turn signal functions.

Dynamic lighting patterns (e.g., scrolling effects for enhanced visibility).

Advanced Driver Assistance Systems (ADAS)

Synchronization with emergency braking systems to flash lights during rapid deceleration.

Electric and Autonomous Vehicles

Low-power designs compatible with EV battery systems.

Fail-safe circuits for autonomous vehicle communication.

Case Study: Enhancing Safety for a European EV Manufacturer

A leading European electric vehicle brand partnered with a Chinese PCBA supplier to develop a red strip LED brake light system. The design incorporated:

Aluminum-core PCBs for superior heat dissipation in high-density battery compartments.

PWM Dimming Control to adjust brightness based on ambient light, reducing glare for following drivers.

Vibration-Resistant Soldering to endure rough road conditions. The result? A 25% improvement in heat management, 15% energy savings, and compliance with ECE R7 and FMVSS 108 safety standards—showcasing China’s ability to meet global automotive demands.

Quality Assurance and Testing

Chinese manufacturers implement rigorous validation processes:

Thermal Cycling Tests: Expose boards to -40°C to +125°C cycles to simulate extreme climates.

Vibration and Shock Testing: Mimicate road conditions per ISO 16750-3 standards.

Salt Spray Testing: Ensure corrosion resistance for coastal or winter road environments.

Electrical Stress Testing: Validate performance under voltage spikes (e.g., load dump scenarios).

Why Partner with Chinese Suppliers?

End-to-End Solutions: From PCB fabrication to full assembly and testing.

Prototyping Speed: Functional samples delivered in 7–10 days.

Global Logistics Support: Seamless shipping to automotive hubs in Europe, North America, and Asia.

Sustainability Focus: RoHS-compliant materials and energy-efficient production practices.

Conclusion

Red strip LED PCBA boards are vital for modern vehicle safety, and China’s automotive electronics industry is at the forefront of delivering reliable, innovative, and cost-optimized solutions. By leveraging advanced manufacturing technologies, adherence to global standards, and a deep understanding of automotive needs, Chinese suppliers empower automakers to create safer, smarter, and more efficient vehicles.

Drive Safer. Choose Precision. Trust Red Strip LED PCBA Boards from China.

For more, please visit https://hitechcircuits.com/pcb-assembly/.

0 notes

Text

Consumer Electronics Printed Circuit Board Market: Key Growth Drivers in the Global Industry

MARKET INSIGHTS

The global Consumer Electronics Printed Circuit Board Market size was valued at US$ 15.34 billion in 2024 and is projected to reach US$ 24.78 billion by 2032, at a CAGR of 6.9% during the forecast period 2025-2032.

Consumer electronic PCBA (Printed Circuit Board Assembly) boards are integrated circuits used across consumer electronics products to mechanically support and electrically connect components through conductive copper pathways. These boards serve as the backbone of modern electronics, encompassing various types including single-layer, double-layer, and multilayer configurations to accommodate different device complexities.

The market growth is primarily driven by accelerating demand for smart devices, including smartphones, wearables, and IoT-enabled home appliances. While China dominates PCB production with over 50% global market share, emerging 5G infrastructure and AI applications are creating new opportunities across multilayer PCBA segments. Furthermore, leading manufacturers like Jabil and Flex Ltd continue expanding production capacities to meet the growing demand for compact, high-performance electronic assemblies.

MARKET DRIVERS

Proliferation of Smart Devices to Fuel Demand for PCBA Boards

The global consumer electronics market continues to expand at an unprecedented rate, with smart devices driving significant demand for high-quality PCBA boards. Smartphones alone accounted for over 1.4 billion units shipped globally in 2023, each requiring sophisticated multilayer PCBA assemblies. The Internet of Things (IoT) revolution has further accelerated this trend, with projections indicating 30 billion connected devices by 2025. These consumer electronics require increasingly complex PCBA solutions that can handle higher processing speeds while maintaining energy efficiency and compact form factors.

Advancements in 5G Technology Accelerating Market Growth

The global rollout of 5G networks represents a pivotal driver for the PCBA board market, as next-generation devices require completely redesigned circuit architectures. 5G-compatible PCBA boards must accommodate higher frequency ranges (up to 52.6 GHz for mmWave implementations) while minimizing signal loss and electromagnetic interference. Carrier aggregation technologies in modern 5G modems often require up to 40% more complex PCBA designs compared to 4G LTE solutions. This technological shift is prompting manufacturers to invest heavily in advanced production capabilities, particularly for high-frequency laminate materials and precision assembly techniques.

Automotive Electronics Evolution Creating New Demand Streams

The automotive sector’s rapid electrification and digital transformation is generating substantial opportunities for PCBA manufacturers. Modern vehicles now incorporate over 100 electronic control units (ECUs) on average, each containing specialized PCBA solutions. The autonomous vehicle segment particularly demands high-reliability boards capable of withstanding harsh environments while processing massive sensor data streams. Premium electric vehicles may contain PCBA components valued at 3-4 times that of conventional automobiles, creating a high-value growth channel for manufacturers with automotive-grade capabilities.

MARKET RESTRAINTS

Supply Chain Vulnerabilities Constraining Market Expansion

The PCBA industry faces significant challenges from global supply chain disruptions, particularly for critical raw materials. Copper prices have shown 35% volatility year-over-year, directly impacting board production costs. Specialty laminate materials and semiconductor components have experienced lead time extensions up to 52 weeks in some cases, creating production bottlenecks. Geopolitical tensions in key manufacturing regions further exacerbate these challenges, forcing companies to maintain larger inventory buffers that negatively impact working capital efficiency.

Environmental Regulations Increasing Compliance Costs

Stringent environmental regulations, particularly concerning lead-free soldering processes and halogen-free laminates, have significantly increased manufacturing complexity. The Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide now require extensive documentation and testing protocols for each product iteration. Compliance costs for a medium-sized PCBA manufacturer can exceed $500,000 annually, creating substantial barriers to market entry for smaller players. These regulations also necessitate continuous R&D investments to develop alternative materials that meet both performance and environmental requirements.

MARKET CHALLENGES

Miniaturization Demands Outpacing Manufacturing Capabilities

The relentless drive toward smaller, more powerful consumer electronics presents fundamental manufacturing challenges. PCBAs for wearable devices now routinely require trace widths below 50μm and micro-vias under 100μm in diameter, pushing the limits of conventional fabrication techniques. Yield rates for such high-density interconnect (HDI) boards can be 15-20% lower than standard designs, significantly increasing unit costs. This miniaturization trend also demands substantial capital investments in equipment capable of sub-micron precision, with advanced pick-and-place machines often exceeding $500,000 per unit.

Talent Shortage Impacting Technological Advancement

The industry faces a critical shortage of skilled engineers capable of designing and manufacturing next-generation PCBA solutions. Complex RF designs and high-speed digital layouts require specialized expertise that typically takes 5-7 years to develop. The global electronics manufacturing sector currently experiences a 22% vacancy rate for mid-career PCB design engineers, slowing innovation cycles. This skills gap is particularly acute in emerging manufacturing hubs, where educational infrastructure hasn’t kept pace with industry requirements.

MARKET OPPORTUNITIES

AI-Enabled Manufacturing Creating Efficiency Breakthroughs

Artificial intelligence applications in PCBA manufacturing are unlocking unprecedented quality and efficiency improvements. Machine vision systems can now detect assembly defects with 99.98% accuracy, compared to 92% for human inspectors. Predictive maintenance algorithms reduce equipment downtime by 40% in advanced facilities, while AI-optimized panel utilization can decrease material waste by up to 15%. Early adopters of these technologies are gaining significant competitive advantages in both quality consistency and production cost structures.

Emerging Markets Driving Volume Growth

Developing economies represent the next frontier for consumer electronics adoption, creating substantial opportunities for PCBA manufacturers. Smartphone penetration in Southeast Asia and Africa is projected to grow at 8% CAGR through 2030, significantly outpacing mature markets. Local governments are implementing favorable policies to attract electronics manufacturing, including Vietnam’s 10-year tax holidays for high-tech investments. These regions also benefit from younger, tech-savvy populations driving demand for affordable smart devices, creating ideal conditions for volume-focused manufacturing strategies.

CONSUMER ELECTRONIC PCBA BOARD MARKET TRENDS

5G Technology Adoption and High-Density PCBA Demand

The rapid rollout of 5G networks globally is driving significant changes in the consumer electronic PCBA (Printed Circuit Board Assembly) market. As 5G-capable devices require higher frequency and bandwidth performance, manufacturers are shifting toward high-density interconnect (HDI) PCBA boards with advanced materials like low-loss laminates. The global 5G smartphone market is expected to reach over 1.2 billion units by 2025, directly influencing PCBA design requirements. Furthermore, the miniaturization trend in consumer electronics continues to push innovation in multilayer and flexible PCBA solutions, with some manufacturers now offering boards with up to 20+ layers for premium devices.

Other Trends

Automation in PCBA Manufacturing

Consumer electronics manufacturers are increasingly adopting automated surface-mount technology (SMT) lines to improve production efficiency and quality control. This shift is particularly evident in high-volume segments like smartphones and wearables, where precision and consistency are critical. Automated optical inspection (AOI) systems are now being integrated into production lines at a rate exceeding 30% annually, reducing defects by up to 60% compared to manual inspection. As labor costs rise in traditional manufacturing hubs, this automation trend is becoming crucial for maintaining competitiveness.

Sustainability Initiatives Reshaping Materials and Processes

Environmental regulations and consumer preferences are driving significant changes in PCBA materials and manufacturing processes. The European Union’s Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have accelerated the adoption of lead-free soldering and halogen-free laminates. Recent market data shows that over 85% of new PCBA production now complies with RoHS standards, up from just 60% five years ago. Additionally, manufacturers are investing in closed-loop recycling systems for precious metals recovered from PCBA waste, with some achieving recovery rates exceeding 90% for gold and silver.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Invest in Advanced Manufacturing and Strategic Partnerships

The global Consumer Electronic PCBA Board market features a fragmented yet highly competitive landscape dominated by established manufacturers and emerging regional players. Among these, Jabil and Flex Ltd maintain leading positions, owing to their extensive production capabilities and engagements with multinational electronics brands. These Tier-1 manufacturers collectively held approximately 18% of the global market share in 2024, supported by vertically integrated supply chains and investments in high-mix, low-volume (HMLV) manufacturing.

Meanwhile, Chinese firms like Shennan Circuits Company Limited (SCC) and Avary Holding have expanded aggressively, leveraging cost efficiencies and government-backed semiconductor policies. SCC reported consecutive revenue growth above 12% YoY, capitalizing on domestic smartphone manufacturers’ demand for multilayer PCBAs. The company’s recent acquisition of a German PCB fabricator signifies its ambitions in the European automotive electronics segment.

While major players focus on capacity expansions, mid-sized competitors such as Victory Giant Technology (VGT) differentiate through certified quick-turn prototyping services essential for IoT device makers. Notably, VGT partnered with Xiaomi and Oppo to develop high-frequency PCBA solutions for 5G smartphones, demonstrating innovation-driven competition.

Meanwhile, supply chain disruptions prompted firms like Palpilot International to localize production – establishing plants in Mexico and Vietnam to bypass tariff risks. Such strategic realignments reflect the industry’s shift toward regionalization while sustaining just-in-time delivery models.

List of Key Consumer Electronic PCBA Board Companies Profiled

Jabil Inc. (U.S.)

Flex Ltd. (Singapore)

Shenzhen Fastprint Circuit Tech (China)

Kingbrother Electronics (China)

Shennan Circuits Co. Ltd (China)

Avary Holding (Shenzhen) Co. Ltd. (China)

Victory Giant Technology (China)

Aoshikang Technology (China)

Camelot Electronics Technology (China)

Lensuo Technology Development (China)

Segment Analysis:

By Type

Multilayer PCBA Board Segment Dominates Due to Increasing Demand for High-Density Electronics

The market is segmented based on type into:

Single-layer PCBA Board

Double-layer PCBA Board

Multilayer PCBA Board

By Application

Smartphone Segment Holds Maximum Share Owing to Rising Global Smartphone Adoption

The market is segmented based on application into:

Smart Phone

Tablet

Smart Wear

TV Set

Air Conditioner

Others

By Technology

Surface Mount Technology Leads Due to Higher Efficiency and Compact Design Capabilities

The market is segmented based on technology into:

Through-hole Technology

Surface Mount Technology

Mixed Technology

By Material

FR4 Substrate Maintains Dominance as Industry Standard for Consumer Electronics

The market is segmented based on material into:

FR4 Substrate

Flexible Substrate

High-frequency Substrate

Others

Regional Analysis: Consumer Electronic PCBA Board Market

North America The North American PCBA Board market is characterized by high-value, technology-driven demand, particularly for advanced multilayer boards used in premium consumer electronics. The United States accounts for over 85% of regional demand, fueled by strong R&D investment and the presence of tech giants like Apple and Google. While the market faces cost pressures due to labor and material expenses, manufacturers are increasingly adopting automation to maintain competitiveness. Environmental regulations such as RoHS compliance influence material selection, pushing suppliers toward lead-free and halogen-free solutions. Canada’s market is smaller but growing steadily, supported by telecommunications equipment demand.

Europe European PCBA manufacturers focus on high-quality, precision-engineered boards for automotive, industrial, and consumer applications. Germany leads in production capabilities, housing several global EMS providers. The EU’s circular economy action plan drives innovation in recyclable PCB materials and processes. Though labor costs remain high compared to Asia, European manufacturers differentiate through advanced manufacturing techniques and stringent quality control. The UK and France show particular strength in aerospace and defense applications that require specialized PCBA solutions. Brexit-related supply chain disruptions have prompted some reshoring of PCB production within the EU.

Asia-Pacific As the global manufacturing hub for PCBA boards, Asia-Pacific dominates with over 70% of worldwide production capacity. China’s massive electronics ecosystem drives demand for cost-efficient, high-volume PCBs, with Shenzhen serving as a key production cluster. Japanese and Korean manufacturers lead in advanced HDI and flex PCB technologies for premium devices. Rapid urbanization across Southeast Asia is creating new consumer electronics markets, though infrastructure gaps sometimes hinder supply chain efficiency. The region benefits from vertical integration, with many PCB fabricators also offering assembly services. Intense competition keeps margins thin but fosters continuous process optimization.

South America South America’s PCBA market remains modest but developing, primarily serving domestic consumer electronics manufacturers. Brazil accounts for nearly half of regional demand, though economic instability often delays capital investments in PCB manufacturing. Most complex boards are imported from Asia, while local facilities focus on simpler designs. Currency fluctuations impact material procurement costs, causing pricing volatility. Some countries like Argentina are implementing import substitution policies to boost local PCB production, though technological limitations constrain capabilities. The growing middle class is driving demand for affordable smartphones and appliances, creating opportunities for PCB suppliers.

Middle East & Africa This emerging market shows potential as electronics manufacturing gradually expands beyond oil-dependent economies. Israel stands out for its high-tech PCB applications in defense and telecommunications. UAE and Saudi Arabia are investing in technology parks to attract electronics manufacturers, though most PCBs are still imported. Limited local expertise in complex board design and manufacturing hampers development, leading to reliance on foreign partners. South Africa serves as a regional hub, with some capability for basic PCB production. Infrastructure challenges and fragmented supply chains remain barriers, though government initiatives aim to develop local electronics manufacturing ecosystems.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Consumer Electronic PCBA Board markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global market was valued at USD 12.8 billion in 2024 and is projected to reach USD 18.3 billion by 2032, growing at a CAGR of 4.6%.

Segmentation Analysis: Detailed breakdown by product type (single-layer, double-layer, multilayer), application (smartphones, tablets, wearables, home appliances), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific dominates with 68% market share in 2024, led by China’s manufacturing ecosystem.

Competitive Landscape: Profiles of 15 leading manufacturers including Jabil, Flex Ltd, Shenzhen Fastprint, and Shennan Circuits, analyzing their market share (top 5 companies hold 32% share), capacity expansions, and technological partnerships.

Technology Trends: Assessment of HDI boards, flexible PCBs, embedded components, and IoT integration driving innovation. The multilayer PCB segment accounts for 54% revenue share in 2024.

Market Drivers & Restraints: Evaluation of 5G adoption, smart device proliferation, and supply chain localization benefits versus raw material price volatility and geopolitical trade tensions.

Stakeholder Analysis: Strategic insights for PCB fabricators, EMS providers, OEMs, and investors regarding capacity planning, technology roadmaps, and emerging applications like AR/VR devices.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-video-sync-separator-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes_17.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-investments.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/coaxial-panels-market-challenges.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/oled-and-led-automotive-light-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gas-cell-market-demand-for-ai-chips-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-demodulator-ic-market-packaging.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nano-micro-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/single-mode-laser-diode-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/battery-management-system-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/scanning-slit-beam-profiler-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/atomic-oscillator-market-electronics.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/plastic-encapsulated-thermistor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-policy.html

0 notes

Video

youtube

pcb assembly #pcba #pcbassembly #robotics #automobile#smartphone #factor...

0 notes

Video

youtube

Smart City & Security & Home & Smart Central Control Panel in GLOBAL SOU...

Do you also like to Experience the Future of Life Technology Products?

Come to our booth: 5J02 Exhibition Dates: 11-14 October, 2024 Exhibition Address: Asia-World Expo Hong Kong

Website:https://www.teejoin.com/

TEEJOIN will show you the list of products you need for the future of your home.

Smart Home : Smart Switch: UK, US, Euro, Smart WiFi switches with customised Zigeeb protocol and Graffiti module support Alex. Intelligent door locks: our intelligent door locks can support, NFC, WiFi and APP control, fingerprint identification, traditional key unlocking and so on. Intelligent curtains: using our self-developed high-brush motor intelligent curtain pulley set, support for curtains and windows Other important components: Smart bulbs, LED light strips, Candle Light, Smart lights, Wi-Fi light strip, Zigbee 3.0 Gateway, Kseries Home security Sensor, Smart Doorbell, Indoor Camera, Outdoor Camera, Smart Centre Screen & Smart Centre Controls Panel

Smart City & Security : Face Recognition & Palmprint Recognition,Intelligent Positioning Navigation, Car Navigation Screens and Personnel Health Locator etc.

All you need to do is provide your ideas and our team will assist you with one-stop product management services from product design, prototyping, moulding, CNC machining, PCBA to the formation of new products.

#smarthome #smartswitch #gpstracker #smartlock #iot #teejoin #smartdoorlock #Intelligentcurtains #smartcurtains #smartcity #homesecurity #homeautomationprojects #HousingDesign #homedesign #healthylifestyle #smartlights #ledlightstrips #Zigbee #Gateway #Gatewa #SmartDoorbell #IndoorCamera #OutdoorCamera #SmartCentreScreen #SmartCentreControlsPanel #hongkong #hk #exhibitions #automobile #smartdisplay #futuretech #futuretechnology #futurehouse #wifilife

#youtube#smart home devices#Smart Home#smart home automation#smart home technology#SmartSwitch#smart door lock

0 notes

Text

3C Electronics Industry Solution

3C Electronics Industry Solution

Not in time and errors in manual loading is a huge challenge in production line adaptation and flexible manufacturing in electronics industry! IPLUSMOBOT intelligent factory logistics solutions recognize the change in material supply and demand immediately and intelligent mobile robot fleets self-organize and self-adapt on demand to improve the throughput and output, reducing the overall cost of logistics in the factory.

Typical Solution Scenarios

3C Electronics

Electronics device and element manufacturing workshop | Communication equipment and computer manufacturing workshop

Robotics Electronics

PCBA/SMT Manufacturing Workshop

Fast Consumer Moving Goods

Automobile Electronics Assembly Workshop

3pl Mobile3C Electronic Assembly Workshop

Cases

Warehouse Robotics in Supply Chain

How AMR Helps the World-Leading Manufacturers of Consumption Electronic Products Raise the Productivity

ChallengeIn one of its world largest manufacturing factories, manual feed trolleys are used by the customer to transport materials between the production line side warehouse and each assembly line. Th...

0 notes

Text

Brief introduction of flex pcb manufacturing proces

The development of flexible PCB manufacturing technology is very rapid, and it is widely used in systems such as communication, industrial control, aerospace, and automobiles. Therefore, it is of great practical significance to understand the flexible single-sided, double-sided and multilayer pcb boards and rigid-flexible multilayer board processes.

Process characteristics of flexible PCB manufacturing. From the structural analysis of the flexible PCB board, the biggest feature of the substrate used in the flexible board is that it is composed of a thin film, which is not only small in size and light in weight, but secondly, the substrate can be bent and folded at will and can develop into a three-dimensional space. It greatly improves the flexibility and freedom of circuit design and mechanical structure design, and can give full play to the functional characteristics of printed circuint boards. The third is that the flexible PCB can be wired in three directions (that is, X, Y, Z directions) to greatly reduce the interface connection points, avoid wire connection errors, and improve the reliability and stability of the electronic PCB board. Collectively speaking, the biggest process characteristics of flexible pcb boards: in any geometry electronic equipment that rigid printed pcb boards cannot be installed: greatly shorten the connection distance, so that many wire connection points are reduced on the flexible PCB board. In addition to these aspects, there are more important functional characteristics, that is, more devices can be installed or mounted on the pcb. Become a more fully-functional flexible board, showing greater advantages: due to the the materials performance difference and the process performance of the flexible board are also different. The principle is to meet the technical requirements of the electrical performance of the device, ensure that it can withstand all kinds of hot and cold shocks during the processing process, and keep the processing performance of the substrate unchanged

With the increasing requirements for high-performance flexible circuit boards, the selection of appropriate high-performance raw materials is particularly important to ensure the stability of the manufactured PCB products.

According to the design requirements, the manufacturing process of the flexible pcb board is carried out between the laminations if there is a need for buried holes. The surface of the circuit pattern should be protected against oxidation. This is the main process of flexible pcb board. The key point of the flexible board process is to first consider the feasibility of the substrate processing process. At the same time, the processing technology of the flexible pcb board is similar to that of the rigid pcb substrate. In order to reduce the amount of shrinkage as much as possible and avoid nonlinear deformation, the following principles should be considered: 1. During pannel, after the graphics are analyzed by the process, the shrinkage caused by each part of the graphics can be complemented as much as possible. 2. Through the puzzle, the entire substrate is transformed into a linear shape. 3. When positioning, a set of data or a basic layer should be selected as the positioning standard to improve the positioning accuracy of the multilayer flexible pcb board. 4. Strictly control the temperature and humidity of the measurement chamber. 5 During the production process, it must be ensured that the boards cannot be joined together. 6. To ensure the consistency of the production of single-piece flexible PCBs, strictly implement each link to ensure the high quality and high precision of the flexible pcb. During the quality control of flexible pcb board operation, it is more difficult to manufacture than rigid multilayer pcb board.

FASTPCBA strictly controls the manufacturing each process of flexible circuit board to provide customers with more reliable PCBA products.

#flexible PCB manufacturin#multilayer pcb boards#flexible PCB board#single-piece flexible PCBs#pcb assembly

1 note

·

View note

Photo

We maintain international standards in our EMS Manufacturing India Processes. We are one of the best Electronics Manufacturing Services company in India that cover Automobile, Energy, Defence and Avionics, Telecom, and Medical Industries

To know more visit - https://eitpl.com/electronic-manufacturing-services/

Or

Call us @+919650274009

Emai - [email protected]

#OEM #ODM #PCBA #pcbassembly #EMS #pcbfabrication #boxbuildassembly #pcbprototype #electronicsmanufacturing #manufacturing #electronics #PCB #pcbuild #pcbdesign #technology #industrial #india #qualityproducts #quality #smtassembly #SMT #leaders #electronicsmanufacturingservices #pcbmanufacturing

0 notes

Text

Features of industrial endoscopes

Industrial endoscope is a visual inspection instrument, which is mainly used to detect whether there are defects or failures in instruments and equipment, to avoid fatigue work of instruments and equipment, damage to equipment parts, and to ensure the normal operation of instruments and equipment while ensuring the use of equipment. life. At present, industrial endoscopes are widely used in automobile manufacturing and maintenance, aerospace, petrochemical, electric power, industrial machinery and other fields. So what are the characteristics of industrial endoscopes?

Robust and durable: Industrial video endoscope cables and mirror rods are basically made of metal. The camera adopts a scratch-resistant and oil-resistant glass shell, precision mold injection molding, and some parts are made of stainless steel to ensure the product is durable, waterproof, wear-resistant, and corrosion-resistant, improving the durability in harsh environments.

Advanced technology: The electronic endoscope adopts the latest transistor CCD camera and high-brightness LED light source technology, the video image is bright, the display image is clear, the color is vivid, and the resolution is high.

Simple operation: equipped with an external rechargeable battery and a portable high-definition color LCD display, which greatly facilitates long-term outdoor use, and can be equipped with a special video capture card for real-time capture, which can be achieved with one key. It can be connected to a monitor or display to display the inspection image in real time and with high definition.

Strong Liquid Resistance: From the distal probe to the handpiece, industrial video endoscopes are highly water resistant and have excellent resistance to minerals, synthetic lubricants, jet fuel, kerosene, gasoline and diesel.

Economical and practical: Industrial electronic endoscopes are cost-effective and value for money. This model is highly competitive in the market in terms of price and performance. It is your first choice for pipeline video inspection, precision instrument inspection, etc.

Shenzhen HenGal Innovative Technology Co., Ltd. is a professional endoscope manufacturer. We have made significant achievements in both medical and industrial areas. In the medical field, we mainly produce and sell camera modules and PCBA parts. Products are used in respiratory endoscopy, bronchoscopy, ENT endoscopy, biliary endoscopy, urological endoscopy, gastrointestinal endoscopy, etc. In the industrial field, we have developed a variety of handheld endoscope series, which are sold well in the market. If you are interested in our products, please contact us as soon as possible.

0 notes

Text

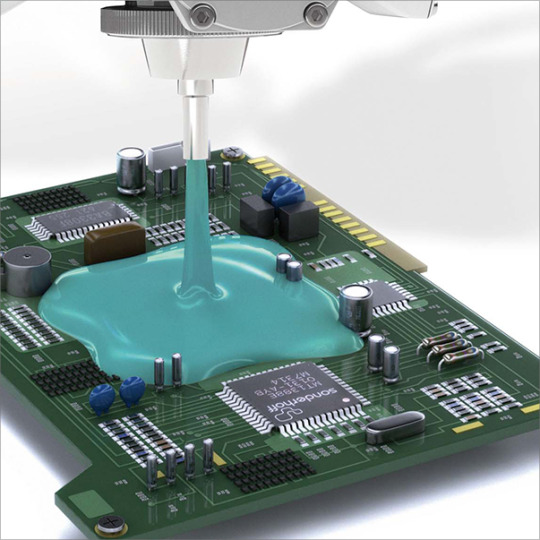

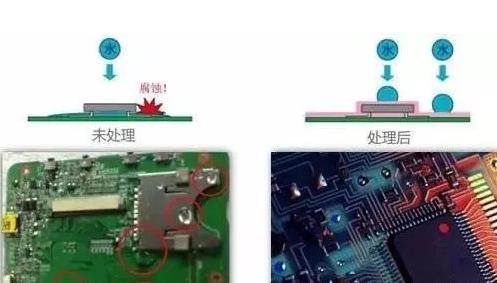

Points of Brushing PCBA Potting Material (1)

https://www.grande-pcba.com/common-problems-and-requirements-of-brushing-pcba-potting-material/As the size of the electronic components of the PCBA circuit board is getting smaller and smaller, and the density is getting higher and higher; The influence on PCBA is also increasing, so we put forward higher requirements for the reliability of PCBA of electronic products. PCBA circuit board three-proof potting material can effectively achieve the protection effects of insulation, moisture-proof, anti-leakage, shock-proof, dust-proof, anti-salt spray, etc. Thereby improving the reliability of the circuit board, increasing its safety factor, and effectively delaying the service life.

Application of Potting Material

PCBA circuit board potting material is widely used in high-tech fields, such as high-end circuit boards in automobiles, home appliances, military electronics, aerospace, medical electronics, etc., which can improve product quality of PCBA circuit boards and effectively reduce rework.

In addition, the rise of emerging industries, the widespread use of electric vehicle charging piles, and unmanned aircraft have further expanded the use of conformal paint. At present, it has become a major trend to apply conformal paint on PCBA for protection.

Function of Potting Material

The potting material is used to protect PCBA circuit boards and related equipment from environmental erosion, whose function is mainly to improve the reliability of products, especially in harsh operating environments.

The potting material protects electronics from external elements such as extreme heat, humidity, moisture and dust. It also protects electronics from internal factors such as corrosion, whisker growth and short circuits within the system. In short, the potting material is equivalent to an insulating layer, which ensures that different components can operate normally and avoids premature failure of the PCB.

Operating requirements for brushing PCBA potting material

Brushing potting material should be carried out in a separate room, but it cannot be completely sealed, which must have good ventilation facilities.

Smoking, eating and drinking are prohibited in the operation room, and alcoholic beverages are not allowed before operating.

Wear masks or gas masks, rubber gloves, chemical protective glasses and other protective equipment during operation to avoid harm to the body. This also depends on the potting material products selected. If it is a benzene-containing product, you should pay great attention to protection. And fire protection, and if it is a TIS-NM environmentally friendly potting material product, the safety is much higher, and there is no risk of burning.

After the work is completed, the used utensils should be cleaned in time, the tools and equipments should be sorted and tested, and the containers with potting material should be tightly covered.

The workplace should be clean and dust-free, no dust flying, and no unrelated personnel should be allowed to enter.

Tools and equipments should be fully grounded, and electrostatic protection measures should be taken.

Do not overlap the PCBA during operation; And the PCB board should be placed horizontally.

Before each batch of raw materials is used, a small sample curing test (3-5PCS) should be done.

Clean and bake the board. Dust, moisture and oil must be removed from the surface of the object to be coated so that the potting material is able to fully exert its protective effect. Thorough cleaning ensures that corrosive residues are completely removed and that the conformal coating adheres well to the board surface. Baking conditions: 60°C, 10-20 minutes, it is better to apply while hot after taking it out of the oven.

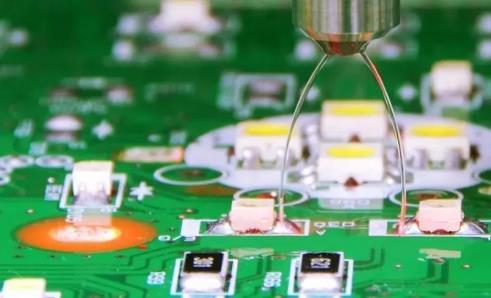

When brushing, the board should be placed as flat as possible. There should be no dew after brushing. The brushing should be flat and there should be no exposed parts. It is appropriate between 0.1-0.3mm.

Before brushing and spraying, ensure that the diluted product is fully agitated and left for 2 hours before brushing or spraying. Using a high quality natural fiber brush, lightly brush and dip at room temperature. If a machine is used, the viscosity of the paint should be measured (with a viscosity agent or flow cup), and a diluent can be used to adjust the viscosity.

The circuit board assembly should be immersed in the paint tank vertically. The connector should not be immersed unless carefully covered, and the circuit board should be immersed for 1 minute until the bubbles disappear, and then slowly taken out. A uniform film will be formed on the surface of the circuit board. Most of the paint residue should be allowed to flow from the board back to the immersion filmer. TFCF has different coating requirements. The immersion speed of circuit boards or components should not be too fast to avoid excessive bubbles.

When using it again after dipping, if there is crusting on the surface, remove the skin and continue to use it.

After brushing, lay it flat on the bracket and prepare to cure. The method that needs to be heated is to accelerate the curing of the potting material. If the potting material surface is uneven or contains air bubbles, curing in a high temperature oven should be left at room temperature for an additional time to allow the solvent to flash out.

Technical requirements for brushing PCBA potting material

The potting material protection must be tested, qualified and thoroughly cleaned before PCB Assembly.

The brush used should be kept clean, and it is forbidden to use it for other operations; When applying the potting material to the brush, be careful not to drip into the components that do not need to be coated; And the brush should be cleaned with thinner after use.

The coating layer should be transparent and cover the PCB board and components evenly, with uniform color and consistency.

The process steps are: Brushing A surface → A Surface Drying → Brushing B surface → Curing At Room Temperature

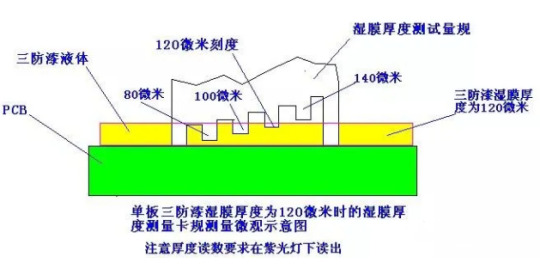

Spraying thickness: Spraying thickness is 0.1mm—0.3mm (dry film thickness is generally 30-100UM)

All coating operations should be carried out under the conditions of not lower than 16°C and relative humidity lower than 75%. As a composite material, PCB will absorb moisture. If it is not dehumidified, the potting material cannot fully protect it. Pre-drying and vacuum drying can remove most of the moisture.

Thickness Test Method:

1. Dry film thickness measuring tool: A. Micrometer (IPC-CC-830B); B. Dry film thickness gauge (iron base)

2. Wet film thickness measurement: The thickness of the wet film can be obtained by the wet film thickness gauge, and then the thickness of the dry film can be calculated by the proportion of the solid content of the glue.

Many circuit boards undergo cross-sectional inspection after selective coating to ensure potting material coverage and thickness are met.

https://www.grande-pcba.com/common-problems-and-requirements-of-brushing-pcba-potting-material/

0 notes

Text

Power PCBA Board

https://www.hx-technology.com/power-pcba-board.html

As a professional PCBA supplier, HX Technology is committed to providing high-quality power PCBA board services. The product services cover industrial controller, medical equipment, telecommunications equipment, environmental protection equipment, instrumentation, security systems, and other fields. HX Technology’s power PCBA boards are exported to Europe and North America. With experienced, senior, stringent, and principled work styles, we aim to provide our customers with the best PCBA board and good service feeling.

Application of Electronics PCBA

Electronic PCBA is mainly used in computer motherboard mouse board, graphics cards, office equipment, printers, copiers, shakers, all kinds of chargers, calculators, digital cameras, radios, TV motherboards, limited TV amplifiers, cell phones, washing machines, electronic scales, telephones, LED lamps, etc., and in the application of home appliances: air conditioners, refrigerators, stereos, MP3; used in industrial equipment In industrial equipment: GPS, automobile, instrumentation, medical instruments, aircraft, military weapons, missiles, satellites, etc.

Process of manufacturing PCBA board

The manufacturing of the PCBA board is divided into two parts. One part is the manufacturing of the PCB itself. The other part is the soldering of the components. Only after soldering components, the PCB can achieve its function and value. The process of welding components on the PCB, called PCBA, namely printed circuit board assembly, which is the empty PCB after SMT, and then after the entire process of DIP plug-in.

PCBA circuit board Professionals

HX Technology is the leading PCBA circuit board provider. We offer your PCBA circuit board requirements. We will give you comprehensive expertise and quality assurance of PCBA circuit board products.

Popular PCB Assembly Services

0 notes

Text

X-Ray SMD Reel Counter

Microfocus X-ray inspection is widely used in LED/automobile/aerospace/EMS etc field and become a necessity for modern PCBA inspection.

The X-ray reel counter machines produced by Seamark have the characteristics of high performance, cost-effectiveness, long lifespan, user-friendly software, simple maintenance, high definition inspection image with special tilt which make our machines can meet different category products inspection needs.

Besides standard X-ray component counter, we also provide customized solutions to meet your special inspection requirements.

Welcome to order!

Offline Reel Counter

Seamark's 2D X-ray inspection machine adopts a closed microfocus X-ray tube with voltage 90KV, 110KV,130KV, which meet different product inspection technical requirements.

Online Reel Counter

X-Ray counting machine, also known as SMD components counter. The equipment adopts the principle of photoelectric sensing and uses the corresponding relationship between the guide hole of the carrier and the components to accurately determine the number of SMD parts.

https://www.seamarkzm.com/products/x-ray-smd-reel-counter/

1 note

·

View note

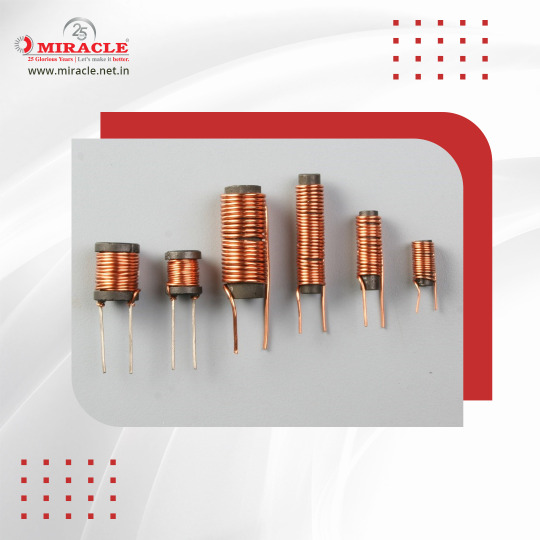

Photo

Miracle is suppling in large quantity all kinds of filter coils used by PCBA Manufacturers & SMPS Manufacturers. With our experience in winding for last 25 years we can meet customer quality demands & on-time supply demands. Miracle is working with many prestigious company who are into EMS manufacturing worldwide.

Please send us your requirements at [email protected] & enable us to be your partner fr your requirements for special transformers & CT’s.

Application: Medical, Aerospace, Automobile, Instrumentation, Lighting Industry

For more information, visit: https://www.miracle.net.in/

#InductorCoilManufacturerinIndia#ToroidaltransformerinIndia#TransformermanufacturerinIndia#MedicalIsolationTransformerinIndia#MiracleElectronics

0 notes

Text

UV LED products begin to land in the global market

Since the outbreak of the epidemic, research and technical projects related to UVLED have been emerging in an endless stream at home and abroad, and they have also successfully used UVLED in various scenarios: the appearance of UV disinfection robots in Pittsburgh International Airport and Amazon supermarket in the United States; the use of UVLED disinfection in Metro and bus by the Metropolitan Transportation Agency (MTA) in New York; and the introduction of UVLED refrigerators and UVLED by various electrical appliance enterprises Water dispenser and other products. And the heaviest of them is the recently released high-power sterilization UVC LED lamp by atomicblue, a Texas led company. The novel coronavirus can be eliminated by sterilizing N95 masks and steel surfaces after the National Institutes of Health conducted high quality laboratory tests. Last week, the global Lighting Association issued guidelines for the safe use of UVC disinfection equipment to regulate the safe use of UVC equipment. This week, the lighting Europe also announced that it fully recognized the latest UV-C safety guidelines issued by the global Lighting Association (GLA) in May, and called on all EU Member States to ensure that UV-C products can be continuously put into the EU market. Company dynamics - a survey of internal and external changes of enterprises Recently, Gree and Guoxing optoelectronics have launched a "virus Hunter" air purifier, which can effectively kill 99.9% of new coronavirus in specific environment. ● the Bluetooth Technology Alliance (SIG) and diia, the global Dali Alliance for the lighting and sensor industry, announced a partnership aimed at accelerating the adoption of IOT enabled commercial lighting systems. This cooperation will make it possible to deploy qualified dali-2 equipment and intelligent d4i lighting equipment as well as qualified Bluetooth grid intelligent lighting control network. ● gecurrent recently plans to expand its smart lighting business in Canada by adding two agents in Ontario, omnilumen technical products and gslighting group. According to Optotech, 18.37 billion visible light, UV and IRLED chips are expected to be shipped in 2020, up 25% year on year. * Liqing announced that its revenue in May 2020 would be 327 million NT dollars (the same below), a decrease of 7.39% compared with the same period last year. The accumulated revenue from January to may in 2020 decreased by 22% to 1.355 billion yuan. Li Qing said that the average productivity rate of the main production bases in Shanghai and Dongguan remained at 85%, which also helped to stabilize the revenue of more than 300 million yuan in May. From April 29, 2020 to the date of announcement disclosure, the company has received a total of 3.9453 million yuan of various government subsidies related to income. Recently, jinlaite announced that it plans to invest 51 million yuan to establish a joint venture with easie (China) Environmental Protection Technology Co., Ltd. to develop the market of environmental health electrical appliances. A few days ago, zhaochi shares disclosed on the investor interaction platform that the company would participate in 618 promotion activities through online platforms such as Jingdong and tmall, and would also sell on Jingdong, tmall and Aiguang platforms through live delivery. Recently, Tailong lighting answered the question on the investor interaction platform that some products of the company have adopted miniled, and the company will continue to increase R & D investment and reserve corresponding technologies. This year, the Shenzhen Municipal Bureau of Education issued the standard guidelines for equipment and facilities allocation of compulsory education schools in Shenzhen and the standard guidelines for equipment and facilities allocation of ordinary high schools in Shenzhen, which once again specified the requirements for classroom lighting, and required the blackboard lighting to be hung 1500mm above the blackboard to ensure that the light source was directly on the blackboard. According to the website of the Central Commission for Discipline Inspection and the State Supervision Commission, at present, China Electronics Technology (Shanxi) silicon carbide material industrial base has achieved mass production of 4-inch wafers, and 6-inch high-purity semi insulating silicon carbide single crystal substrate has also started engineering verification, providing customers with a small batch of product trial. It is expected that the industrial application will reach the international level by the end of the year. Cutting edge: capture the technical direction of the industry Recently, Lianjing intelligent, a wholly-owned subsidiary of Jingke electronics, has developed and designed a vehicle borne sterilization module scheme for the interior of automobiles in conjunction with domestic first-line engine manufacturers. The module adopts PCBA circuit design scheme independently developed by United crystal intelligence, combined with the design of four UVC and UVA light sources in 270nm wave band of Jingke electronics, and combines the sterilization effect of UVC with the strong penetration ability of UVA, resulting in higher sterilization rate and better effect. Cooper Lighting Solutions announced the launch of a fast, effective and optimized sterilization solution. Its reliable UV sterilization technology will help create a safe environment in retail stores, workplaces, public toilets and catering services. Urban starlight -- the latest development of lighting application It is reported that Daxing airport expressway has been running for nearly one year since it was officially opened on July 1, 2019. Since its opening, the "intelligent street lamp" on the expressway has saved about 400000 kwh of electricity, with an overall energy saving rate of 30%. ● at the end of June, 132 multi-functional smart poles on the Qianwan No.1 road in Shenzhen will replace the original ordinary street lamps and realize the lighting of the whole line. Qianhai's multi-functional smart street lamp is one of the first two pilot projects in Shenzhen.

0 notes

Text

SMT Electronic Product Manufacturer

Under the trend of electronic applications such as smart technology, multimedia, and networking, SMT technology has emerged. With the development of various disciplines, SMT developed and popularized rapidly in the 1990s and became the mainstream of electronic assembly technology. It not only changes the traditional concept of electronic circuit board assembly, but also has an absolute advantage in PCB assembly technology with its high density, high speed, and standardization.

It has played an important role in promoting the development of contemporary electronic information industry, and has become one of the indispensable technologies for manufacturing modern electronic products. At present, it has been saturated in various fields of aviation, medical, automobile, military industry, national defense, telecommunications, household appliances, lighting and other industries, and has a wide range of applications.

SMT surface mount technology includes three major production processes: solder paste printing, component placement, and reflow soldering. Product quality is the core of all manufacturing companies, it is like the cornerstone of high-rise buildings, achieving the pinnacle of enterprises.

Among them, the surface mountain of solder paste printing quality has the biggest impact. According to industry evaluation and analysis, PCB design and feed quality problems excluded, more than 60% of assembly defects are caused by poverty. Therefore, the quality of solder paste printing is improved. Particularly important.

First of all, for the popularization of the basic knowledge of SMT for electronics manufacturing employees, the electronics factory clearly stated that the entire PCBA production process is not easy. I hope you can understand it at a glance and clearly remember the production line is divided into sections and stations.

With the development of electronic products in short, small, light, thin, etc., the wide application of chip components such as 0201, 1005 and fine pitch devices such as SOIC, QFP, BGA and CSP has also put forward the solder paste printing process and equipment Higher requirements.

To meet the requirements of micro and lead-free processes to prevent defects after reflow, we must understand the printing process requirements, the basic knowledge of solder paste, printing parameter settings and its inherent principles, the correct use of solder paste, and good printing process control. Effectively control and improve the quality of solder paste printing.

The well-known analysis of paste manufacturers in the industry: As electronic products develop in the direction of shorter, smaller, lighter, and thinner, the triggering of the structure of the package is smaller, thinner, faster, more convenient and more reliable. Under this market trend, 01005 devices are smaller than 0201 devices, and 0.35MM pitch chips are being promoted and applied, which means that the difficulty of SMT assembly will increase significantly. The miniaturization of the size and spacing of the pads will significantly reduce the difficulties of solder paste, tin and solder paste. Now the 4th powder 01005 equipment and the solder paste 0.35 mm microchip printing will be difficult to meet the demand, how to improve the quality and improve the reliability of solder joints The performance of solder paste applications puts forward new requirements, and the choice of a new generation of finer powder-No. 5 solder paste will become an industry trend.

Merchants in the industry also generally recognize that for products with good soldering and long-term reliability, the first thing to pay attention to is solder paste printing. In production, it is not only necessary to master and use solder paste printing technology, but also to be able to analyze the causes of problems and apply improvement measures to production practices.

FASTPCBA select the best high-quality material suppliers to ensure our products' quality,with purchasing good solder paste such as senju,alpha,loctite etc. Everything we have done is for the benefit of ourcustomers.

0 notes

Text

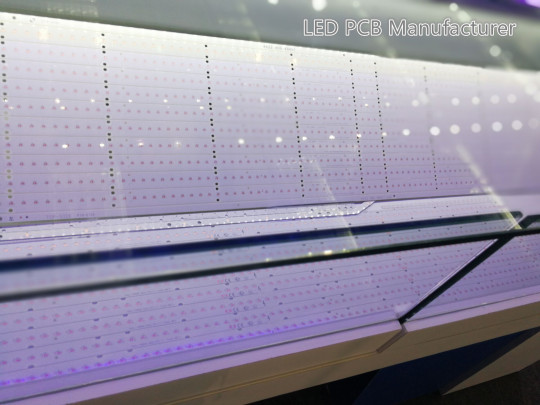

LED PCB

China’s rapid development in semiconductor, China quickly became the world’s largest LED PCB manufacturing country, in the metal circuit board industry, there have also been a lot of exciting news, we believe there will be a higher development in 2018.

There are many types of LED Light ,for example,like some as following: 1.LED light box 2.LED light bar 3.LED work light 4.LED panel light 5.LED down light 6.LED Tube light 7.LED Bulb light 8.LED Strip light 9.LED lamp light 10.LED Spot Light

LED pcb Application: 1. Audio equipment: input, output amplifier, balanced amplifier, audio amplifier, preamplifier, power amplifier, etc. 2.Power equipment, switching regulator “DC/AC converter” SW regulator, etc. 3.Communication electronic equipment: high frequency increase ” filtering electrical” transmitting circuit. 4.Office automation equipment, motor drives, etc. 5.Automobile, electronic regulator “igniter” power controller, etc. 6.Computer: CPU board “diskette drive” power supply device, etc. 7.Power module, inverter “solid relay” rectifier bridge, etc.

KingSong is professionally manufacturing LED PCB,we don’t sell LED Lamp.but we strongly support for LED industry,including production and sales of PCB, PCBA complete product processing, sales, and so on.We can offer all kinds of LED PCB product,for High Power LED of the Aluminum base PCB, Copper base PCB,Ceramic base PCB, for low-power LED of the FR4 PCB, High Temperature PCB. As the Aluminum base PCB of good thermal performance, High-Power LED products most commonly used Aluminum Base PCB.

0 notes

Text

The scope of use of industrial endoscopes

Industrial endoscopes are mainly used in automobiles, aero-engines, pipelines, mechanical parts, etc., which can realize non-destructive testing without disassembling or destroying the assembly and stopping the operation of the equipment, and are widely used in aviation, automobiles, ships, electrical, chemical , electricity, gas, atomic energy, civil construction and other modern core industries. So do you know the scope of application of industrial endoscopes?

1. Weld surface defect inspection. Check the welding quality such as cracks on the surface of the weld, lack of penetration and weld leakage.

2. Intracavity inspection. Check for surface cracks, peeling, pulling wires, scratches, pits, bumps, spots, corrosion and other defects.

3. Status check. When certain products (such as worm gear pumps, engines, etc.) work, endoscopy is carried out according to the items specified in the technical requirements.

4. Assembly inspection. When there is a requirement and need, use an industrial video endoscope to check the assembly quality; after the assembly or a certain process is completed, check whether the assembly position of each component meets the requirements of the drawings or technical conditions; whether there are assembly defects.

5. Excess inspection. Check the product cavity for residual swarf, foreign matter and other excesses.

Due to its special size design, the industrial endoscope allows us to observe the internal surface structure or working state of the object easily and accurately without destroying the surface of the detected object.

Industrial endoscopes can be used for inspection and observation of high temperature, toxic, nuclear radiation and places that cannot be directly observed by the human eye. They are mainly used in automobiles, aircraft engines, pipelines, mechanical parts, etc. Non-destructive testing can be realized when the operation is stopped. On the other hand, the industrial endoscope can also be connected with a camera, a video camera or an electronic computer to form a photographing, imaging and image processing system, so as to monitor, record, store and map the field of view objects. Image analysis. Provides a good guarantee for diagnosis and treatment.

Shenzhen HenGal Innovative Technology Co., Ltd. is a professional endoscope manufacturer. The company has been focusing on the design and application of endoscopic imaging systems since 2011. We have a strong R&D team that provides services including appearance design, mechanical structure design, electronic hardware and firmware development, trial production and small batch production. In the industrial field, we have developed a variety of handheld endoscope series, which are sold well in the market. In the medical field, we mainly produce and sell camera modules and PCBA parts. If you are interested in our products, please contact me over there.

0 notes