#boiler cost to replace

Explore tagged Tumblr posts

Text

The Ultimate Guide to Hydro Jetting in Verona, NJ

If you're a homeowner in Verona, NJ dealing with stubborn clogs and slow drainage issues, hydro jetting might be the solution you've been looking for. Hydro jetting is a powerful and effective method of clearing out tough blockages in your plumbing system using high-pressure water. In this comprehensive guide, we'll explore everything you need to know about hydro jetting Verona NJ.

First and foremost, let's dive into how hydro jetting works. During a hydro jetting service, a professional plumber will use a specialized machine that blasts water at high pressure through your pipes. This intense force clears away any buildup of grease, hair, soap scum, or other debris that may be causing blockages in your plumbing system. Unlike traditional methods like snaking or chemical drain cleaners, hydro jetting provides a thorough cleaning that can help prevent future clogs.

One of the biggest advantages of hydro jetting is its effectiveness in removing even the toughest blockages. Whether you're dealing with a simple clog or a more serious issue like tree roots infiltrating your pipes, hydro jetting can break through the obstruction and restore proper flow to your plumbing system. This makes it an ideal solution for homeowners in Verona, NJ who are experiencing recurring drainage problems.

Furthermore, hydro jetting Irvington nj is a safe and environmentally friendly option for clearing out your pipes. Since it relies on water pressure rather than harsh chemicals, there's no risk of damaging your pipes or harming the environment with toxic substances. This makes hydro jetting a sustainable choice for maintaining your plumbing system while also promoting long-term health and safety for your household.

In addition to its cleaning power and eco-friendly benefits, hydro jetting can also help improve the overall efficiency of your plumbing system. By removing built-up residue and obstructions from your pipes, water can flow more freely and smoothly throughout your home. This can lead to better water pressure, reduced instances of clogs, and improved longevity for your plumbing fixtures.

Conclusion: In conclusion, if you're dealing with stubborn clogs or slow drainage issues in Verona, NJ, consider scheduling a hydro jetting service to clear out your pipes effectively and efficiently. With its powerful cleaning capabilities, eco-friendly approach, and ability to improve overall plumbing efficiency, hydro jetting is an excellent choice for homeowners looking to tackle tough blockages head-on. Contact a reputable plumber in Verona today to learn more about how hydro jetting can benefit your home's plumbing system!

#plumbing services#boiler repairs#boiler repair service#water heating repair#nj sewer cleaning service#repairing services#boiler repair services#plumbing hydro jet north bergen nj#hydro jetting verona nj#boiler cost to replace#sewer cameras inspection hackettstown nj#pipe jetting company newark nj

0 notes

Text

How Much Does a Boiler Repair Cost in London? A Homeowner’s Guide

If your boiler has stopped working or is showing signs of trouble, your first question is likely: “How much will this cost to fix?” Boiler repair prices can vary depending on the issue, boiler type, and your location—but we’ve broken it down to give you a clear idea of what to expect in London.

Average Boiler Repair Costs in London

Here’s what most homeowners in London pay for common boiler issues:

Minor repair (sensor replacement, pressure adjustment): £90–£150

Mid-level repair (pump, valve, or diverter replacement): £150–£300

Major repair (PCB board, fan, or heat exchanger): £300–£500

Emergency call-outs (evening/weekend): Add £50–£100

At Boiler Repair Experts London, we always provide clear, upfront pricing—no hidden charges.

What Factors Affect the Cost?

Not every repair costs the same. Here are the main factors that affect your final bill:

Boiler make and model: Premium brands like Worcester Bosch or Vaillant may have more expensive parts

Age of your boiler: Older boilers may need harder-to-find parts or extra labor

Type of fault: Simple sensor issues cost less than replacing a faulty heat exchanger

Time of day: Evening, weekend, or emergency services may cost slightly more

Access and setup: Boilers in tight cupboards or flats with limited access can add labor time

We always inspect and quote before beginning work so you know exactly what to expect.

When Is It Better to Replace Than Repair?

If your boiler is over 12 years old, out of warranty, and the repair will cost more than £400, it might be worth considering a replacement. A new, energy-efficient boiler could lower your bills and come with up to 10 years warranty.

We’ll always advise you honestly if a repair isn’t cost-effective—and offer a free quote for installation if needed.

How to Avoid Surprise Costs

To avoid unexpected boiler problems and high repair bills, consider:

Annual servicing to keep your system in good condition

Magnetic filters to prevent sludge build-up

Boiler cover plans that include parts and labor

Regular bleeding of radiators and pressure checks

Prevention is always cheaper than an emergency repair.

Book a Local Expert, Not a Call Center

At Boiler Repair Experts London, we’re a local, independent team—not a call center. That means:

Direct communication with Gas Safe engineers

Same-day appointments in Central, North, South, East & West London

Honest pricing and experienced diagnostics

Repairs for Ideal, Baxi, Vaillant, Worcester Bosch, Glow-worm, and more

Book Your Boiler Repair in London Today

Don’t get caught out by surprise costs. Call us now for an accurate quote and same-day service.

Call: 020 8050 2945 Website: www.boilerrepairexpertslondon.co.uk

#boiler repair cost london#how much is boiler service#boiler price guide#london boiler call out fees#boiler parts replacement cost#gas engineer quote london#boiler repair vs replacement#cheap boiler fix near me#same day boiler engineer#emergency boiler repair price

0 notes

Text

Birtish Gas New Boiler: Cost, Installation & Replacement Guide

If you're considering a gas boiler replacement in 2025, you're probably wondering about the new boiler cost and whether it's worth the investment. With rising energy prices and efficiency improvements, upgrading to a new boiler can save you money in the long run. In this guide, we’ll break down the costs, factors that affect pricing, and how to get the best deals���especially with British Gas new boiler options.

How Much Does a New Boiler Cost in 2025?

The cost of a new boiler depends on several factors, including the type of boiler, installation complexity, and your location. Here’s a rough estimate:

Combi Boiler – £1,500 to £3,500

System Boiler – £1,800 to £4,000

Conventional Boiler – £2,000 to £4,500

Additional costs may include installation fees, smart thermostats, and radiators if upgrades are needed.

Factors That Affect New Boiler Prices

Boiler Type – Combi boilers are generally more affordable than system or conventional boilers.

Brand & Efficiency – Premium brands like Worcester Bosch, Vaillant, and British Gas boilers often cost more but offer better efficiency.

Installation Complexity – Replacing an old boiler with the same type is cheaper than a complete system overhaul.

Government Grants – Some homeowners may qualify for boiler upgrade schemes, reducing costs.

Gas Boiler Replacement: Is It Worth It?

Replacing an old, inefficient boiler with a modern one can:

✅ Reduce energy bills by up to 30%

✅ Improve home heating efficiency

✅ Lower carbon emissions

✅ Increase property value

British Gas New Boiler: What Are the Options?

British Gas offers a range of new boiler installation services, including:

Fixed-price quotes with no hidden costs

Finance options to spread the cost

Expert installation and aftercare

How to Get the Best Boiler Deals in 2025

Compare multiple quotes from different suppliers

Check for government incentives and grants

Consider flexible financing options for affordability

Final Thoughts

A new boiler is a significant investment, but with the right choice, you can enjoy lower energy bills and a warmer home. If you're looking for a reliable gas boiler replacement, consider getting a British Gas new boiler or exploring other top brands to find the best fit for your needs.

0 notes

Text

I can be laughably inconsistant in how I portray Electra’s build besides “somewhat to very short and denser than you’d expect”. On one hand, it makes sense for an electric train to be very lean because they notably don’t “store” anything fuel-wise irl (unless they have a battery or are a dual-mode electo-diesel). On the other hand, it’s a running joke that Americanized versions of European engines have to be waaaay heavier than the originals for crashworthiness reasons (other countries just have better signaling/fewer road crossings to begin with) so modern-day Electra being heftier checks out. Also not immune to making stupid jokes about how electric locos often have issues with being too light irl and making them heavier can be a GREAT thing for freight service since it reduces wheelslip and lets them pull more.

#i’m blanking on what model it was but I swear there was some passenger-oriented one that was a flop#and they replaced the heating boiler with fucking concrete when they were switched to freight service to make up for the weight#i know the cursed “slugs” tend to get weighed down with it to make up fot having their diesel prime movers removed#diesel loco rebuilds/repurposing get cursed so fast my fav is a railroad in mexico going full frankenstein with various parts#one of my beefs with canon is that most poor rinky dink railroads use like 50s-era diesel locos#steam is only really used in places with VERY low labor costs and a ton of burnable solid fuel (coal mines or sugarcane farms)#a gp9 winning the big race against an E-unit because the final round is backwards would be hilarious though#because that’s why roadswitchers replaced them irl and ratty old roadswitchers are the state bird of dinky shortlines

0 notes

Text

Best Combi Boiler Prices in Centre England: Your Ultimate Guide for 2024

Choosing the right combi boiler can be a daunting task, especially with the myriad of options available in the market. If you’re in Centre England and on the hunt for the best combi boiler prices, you’ve come to the right place. In this guide, we’ll walk you through everything you need to know about finding the best combi boiler for your home in 2024.

Why Choose a Combi Boiler?

Combi boilers, short for combination boilers, are highly efficient and compact systems that provide both heating and hot water directly from the boiler. Unlike traditional boilers, there’s no need for a separate hot water cylinder or cold water storage tank, making them perfect for homes with limited space.

Benefits of Combi Boilers:

Space Saving: No need for bulky tanks.

Energy Efficient: Provides hot water on demand, reducing energy wastage.

Cost-Effective: Lower installation and maintenance costs compared to traditional systems.

Best Combi Boilers in 2024

When it comes to choosing the best combi boiler in 2024, several brands and models stand out due to their efficiency, reliability, and customer satisfaction. Here are some top contenders:

1. Worcester Bosch Greenstar i Series

Renowned for their reliability and performance, the Worcester Bosch Greenstar i Series continues to be a favourite among homeowners in Centre England. These boilers are not only energy-efficient but also come with a range of smart features, including programmable thermostats and compatibility with smart home systems.

2. Vaillant ecoTEC Plus

The Vaillant ecoTEC Plus is another top choice for 2024. It’s known for its high efficiency and robust build quality. This model also offers excellent control over your heating and hot water, ensuring you only use what you need, thus saving on energy bills.

3. Ideal Logic Max

Ideal Boilers have made a name for themselves with their Logic Max range. These boilers are compact, reliable, and come with a lengthy warranty. They are perfect for smaller homes where space is at a premium but performance is still a priority.

Factors to Consider When Choosing a Combi Boiler

Selecting the right combi boiler involves considering several factors to ensure it meets your specific needs. Here are some crucial aspects to keep in mind:

1. Boiler Size and Output

The size and output of the boiler should match the heating and hot water demands of your home. An undersized boiler won’t meet your needs efficiently, while an oversized one could lead to unnecessary energy consumption.

2. Energy Efficiency

Look for boilers with high efficiency ratings. Modern combi boilers come with an ErP rating, and an A-rated boiler is the most efficient, helping you save on energy bills and reduce your carbon footprint.

3. Installation and Maintenance Costs

Consider the installation costs and the availability of local engineers for regular maintenance. Some brands may offer extended warranties or service packages which can be beneficial in the long run.

4. Smart Controls and Features

Modern combi boilers often come with smart controls that can be integrated with home automation systems. These features provide greater control over your heating, making it easier to manage and optimize energy use.

Finding the Best Combi Boiler Prices in Centre England

Now that you know what to look for, how do you find the best combi boiler prices in Centre England? Here are some tips:

1. Compare Quotes

Get quotes from multiple suppliers and installers. This will give you a better idea of the market rate and help you find the best deal. Don’t forget to check if the quoted price includes installation and VAT.

2. Look for Deals and Discounts

Keep an eye out for seasonal promotions, discounts, or cashback offers from manufacturers and suppliers. These can significantly reduce your overall expenditure.

3. Check Online Reviews

Read online reviews and ratings from other homeowners in Centre England. This can provide insights into the performance and reliability of different boiler models and the quality of service from installers.

4. Consider Financing Options

Some companies offer financing options, allowing you to spread the cost of your new boiler over several months or years. This can be particularly useful if you’re on a tight budget.

Conclusion

Investing in the best combi boiler is crucial for ensuring your home stays warm and your energy bills remain manageable. By considering the factors outlined above and doing thorough research, you can find the best combi boiler prices in Centre England that suit your needs and budget.

For more information and to explore a wide range of combi boilers, visit Smart Heating Hub Ltd. Our experts are here to help you make an informed decision and ensure you get the best value for your investment.

#Best Combi Boiler Prices#Best Combi Boilers 2024#Best Combi Boiler in Centre England#Affordable Combi Boilers#Energy Efficient Combi Boilers#Top Combi Boiler Brands#Worcester Bosch Combi Boilers#Vaillant Combi Boilers#Ideal Logic Max Boilers#Combi Boiler Installation#Combi Boiler Deals#Combi Boiler Discounts#Combi Boiler Reviews#Compare Combi Boilers#Cheap Combi Boilers#High Efficiency Combi Boilers#Smart Combi Boilers#Compact Combi Boilers#Reliable Combi Boilers#Combi Boiler Maintenance#Best Heating Systems#Modern Combi Boilers#Centre England Heating Solutions#Home Heating Tips#Boiler Financing Options#Combi Boiler Warranty#How to Choose a Combi Boiler#Best Boilers for Small Homes#Boiler Replacement Costs#Eco-Friendly Boilers

0 notes

Text

ZARAHEATİNG - DEVASA+

Zara Heating: Professional Boiler Services for Your Comfort

When it comes to ensuring the warmth and efficiency of your home, Zara Heating stands out as the go-to solution for all your boiler needs. Specializing in boiler service cost, replacement, and repair, our team of experts is dedicated to providing top-notch services that guarantee your home's comfort and safety.

Boiler Service Excellence: Quality and Affordability

At Zara Heating, we understand the importance of regular boiler service in maintaining its optimal performance. Our skilled technicians offer thorough and efficient boiler service to ensure that your heating system operates at its best. We prioritize both quality and affordability, aiming to provide cost-effective solutions without compromising on the excellence of our services.

Boiler Replacement: Upgrading Your Comfort

If your boiler is showing signs of wear and tear or if you're considering upgrading to a more energy-efficient model, Zara Heating is here to assist you. Our boiler replacement services are designed to seamlessly integrate advanced and efficient heating systems into your home, enhancing both comfort and energy savings.

Expert Boiler Repair: Swift Solutions for Peace of Mind

Experiencing issues with your boiler? Zara Heating specializes in prompt and reliable boiler repair. Our team of experienced technicians can quickly diagnose and resolve any boiler-related problems, ensuring that your heating system operates smoothly. Trust us to bring warmth and peace of mind back to your home.

Worcester Boiler Flashing Blue Light: Understanding and Resolving Issues

The sight of a Worcester boiler flashing a blue light can be perplexing, but worry not – Zara Heating has the expertise to understand and resolve such issues. Our technicians are well-versed in diagnosing Worcester boiler problems, including blue light flashes, and providing effective solutions to get your system back on track.

Why Choose Zara Heating?

Professionalism: Our team consists of skilled professionals dedicated to delivering high-quality boiler services.

Affordability: We believe in fair pricing without compromising on the excellence of our services.

Reliability: Count on us for reliable and prompt boiler repairs, replacements, and servicing.

Expertise: With extensive experience, we specialize in addressing specific boiler issues, including Worcester boiler complications.

Choose Zara Heating for all your boiler service needs. Your comfort is our priority, and we're committed to providing services that ensure your home stays warm and welcoming. Contact us today at ZaraHeating.co.uk for professional boiler solutions tailored to your requirements.

706 notes

·

View notes

Text

Attn UK followers

If you're struggling with food and bills or need to fix or replace something essential like a boiler, you can apply for help from your local council. This does not affect your benefits as it's not handled by the DWP and does not count as income.

This is for upcoming and current costs. As always, if you are in debt, work out what you can afford after rent, bills and food and then call and set up a payment plan for that amount.

Please reblog because I'm seeing a lot of people struggling already and it will get worse over winter

946 notes

·

View notes

Text

Half time with our calendar and this is the perfect moment to introduce you to a lady who shows the interface of Age of Sail and Age of Steam. She is generally regarded as the start of the Age of Steam and yet she still has both elements. But who am I talking about ? - The HMS Warrior

More about her history here:

HMS WARRIOR was built as part of Britain’s response to concerns over France’s maritime ambitions which included the building of LA GLOIRE, a powerful ironclad which was the most advanced warship of its day. WARRIOR was commissioned on 1 August 1861 and at that time unquestionably ruled the seas. Her main guns, engines and boilers were contained within an armoured wrought iron hull and she could be driven by both steam and sail. This combination meant that she could outrun and outgun any ship afloat and she never fired a shot in anger – the classic deterrent.

During the first commission her main role was to lead the Channel Squadron. On 22 November 1864 she paid off for her first major refit at Portsmouth Dockyard during which the ship was comprehensively refurbished. She was also completely re-armed with 7” and 8” muzzle loaded rifled guns. However, in the American Civil War the success of the Monitor was to have a dramatic effect on naval thinking and WARRIOR’s role as ‘Monarch of the Seas’ was to be very short-lived.

She re-commissioned in July 1867 and re-joined the Channel Fleet. The second commission was rather less interesting than the first as she was no longer regarded as the most powerful warship afloat and faded from the limelight. The second commission ended in 1871 and she then spent four years in refit at Portsmouth being fitted with improved boilers, steam power for the forward capstan and a new poop deck to accommodate an Admiral. On completion in 1875 she became part of the First Reserve Fleet where she was to remain until paying at Portsmouth on 31 May 1883.

After periods as a depot ship and part of HMS VERNON she was paid off in 1924. She was then converted for use as a floating oil jetty and in 1929 was towed to Pembroke Dock where she was to remain for the next 50 years. In 1967 the campaign to restore WARRIOR started and prominent in this was Sir John Smith who formed the Manifold Trust. A committee chaired by the Duke of Edinburgh met in 1968 to discuss her future and from this emerged the Maritime Trust. When Pembroke Dock closed in 1978 the Manifold Trust agreed to underwrite the cost of restoration and the ship was handed over to the Maritime Trust in 1979.

In 1983 ownership was transferred to the Ship’s Preservation Trust which became the Warrior Preservation Trust in 1983. Although the hull was very sound the rest of the ship was in a poor state. The task which was part restoration and part re-building needed vast resources not only of money (£8M) but also of skill, patience and endurance. The 8 year restoration programme at Hartlepool transformed her into one of the world’s most important historic warships and in 1987 she returned to Portsmouth where she is now moored in the Historic Dockyard.

A planned preservation programme is in place for the ship and over the years she has been dry-docked twice, and the upper deck, (£725K provided by the Heritage Lottery Fund), all three fighting tops and half moons and the stern gallery have been replaced.

#naval history#naval artifacts#hms warrior#19th century#age of sail#age of steam#tall ship#day 12#advent calendar

130 notes

·

View notes

Text

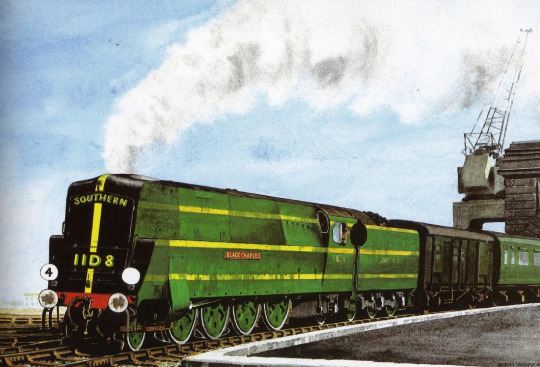

Bulleid's Proposed Locomotives

So it turns out Bulleid had so many of his designs dropped for one reason or another, and since I can't stick with a single project for more than a few seconds, I wrote up histories for all of them!

Enjoy the ramblings of a madman who spent a good long while finding free number slots for them.

Southern Railway Warship Class

The Southern Railway was the most financially successful of the "Big Four", but this was largely based on investment in suburban and main line electrification. After the successful introduction of the SR Schools class in 1930, the railway had lagged behind the others in terms of modernizing its aging fleet of steam locomotives, as they were more focused on Electrification. Following the retirement of the general manager of the Southern Railway Sir Herbert Walker and Richard Maunsell the Chief Mechanical Engineer (CME) in 1937, their successors considered that the time had come to change this situation. In March 1938 the new general manager Gilbert Szlumper authorized Oliver Bulleid, Maunsell's replacement, to prepare designs for twenty express passenger locomotives. The deteriorating international situation prior to the Second World War was an additional factor in this decision.

Originally, Bulleid had wanted a 4-8-2 Mountain Type, but the Civil Engineering department had resisted this based on size and weight, so a 2-8-2 was chosen instead. Bulleid had worked with Gresley on his P2 2-8-2 express engines, so he already had some background knowledge, especially with the P2’s problems and ideas on how to solve them. Of course, due to the war, they were classified as heavy mixed-traffic engines to get around wartime regulations.

They were built with high-pressure 280 PSI boilers and three 18inx26in cylinders, as well as being the first engines to use Bulleid’s chain-driven valve gear, though the middle cylinder had to be inclined steeply to clear the first driven axle. The boiler was partly welded to save on cost, and the inner firebox was made of steel. The Southern had no facilities to build these boilers, so it was subcontracted to the North British Locomotive Co., as well as Beyer Peacock. They were also fitted with Bulleid’s Air-Smooth Casing. Unlike later designs that utilized this, the casing on the Warships both served their function purpose as labor saving as well as being able to be passed off as some sort of streamlining. How Bulleid got that one through during the war is a mystery! The Warship’s were also the first to use Bulleid’s Firth-Brown Wheels.

10 of these engines were constructed in 1940. More were set to be produced, but once again, the Civil Engineering Department expressed their discomfort at such a large engine running at high speeds with only a single pony-truck in front, despite other engines of a similar design getting on fine elsewhere. This would lead Bulleid to designing and building 30 of his well-known Merchant Navy Class 4-6-2s.

They were named after Warships as a way to increase morale, with 11D1 being officially named “Dreadnought” in April 1940. They performed well in service, hauling heavy passenger and express goods, though the Chain-Driven valve gear was sensitive and required high maintenance, as well as the oil-bath having leaking problems, contributing to wheel-slips(Though the extra wheel helped negate this as well). The casing, while it did save on labor during cleaning, and the more streamlined appearance helped with publicity, it made maintenance hard to carry out. Surprisingly, thanks to their different front ends, they never really experienced drifting smoke like Bulleid’s Pacifics.

All 10 of the engines would be passed into British Railways, numbered 37001-37010, where their duties mostly stayed the same. 11D8 “Black Charles'' took part in the 1948 locomotive exchange trials, where it was compared to LMS Duchess pacifics and LNER A4’s and A2/2s, where it performed favorably, though the chain driven valve gear and its oil bath still caused headaches. After the Crewkerne incident, BR chose a rebuilding program of any engines that still used Bulleid’s Chain Driven motion, however, as the Warships had required far less modifications that the Pacifics, they were on the bottom of the list in the rebuilding program. In the end, only 37003 “Triumph”, 37009 “Warspite”, and 37010 “Exeter” were rebuilt in 1956, 1957, and 1959.

Despite their status as a class with very few engines, all ten would survive until the end of southern steam, going between 1965-1966.

Two are preserved, both being rescued from Barry Scrapyard in Wales. These examples are Class Pioneer 11D1 “Dreadnought”, as well as 11D3 “Triumph”.

Stats

Power Classification - 8MT

Built - 1940 to 1941

Boiler Pressure - 280 PSI

Cylinders (3) - 18in x 26in

Wheels (Driven) - 6ft 2in

Wheels (Leading) - 3ft 1in

Wheels (Trailing) - 3ft 7in

Wheels (Tender) 3ft 7in

Tractive Effort - 40,640 lbf

Total Length - 74ft 8in

Fleet

11D1 (37001) - Dreadnought

11D2 (37002) - Anson

11D3 (37003) - Triumph

11D4 (37004) - Vanguard

11D5 (37005) - Ark Royal

11D6 (37006) - Audacity

11D7 (37007) - Valiant

11D8 (37008) - Black Charles

11D9 (37009) - Warspite

11D10 (37010) - Exeter

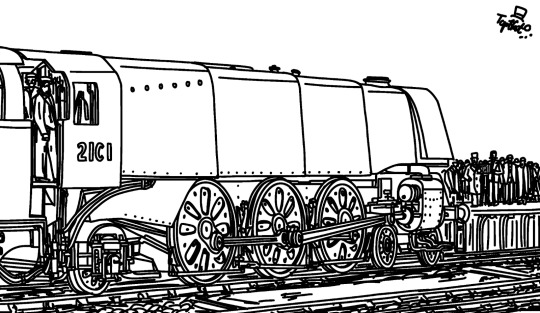

Southern Railway Prototype Light Pacific

(Pic by Sttophat on twitter)

In 1941, Bulleid had introduced his Warship Mikado's and Merchant Navy Pacific's to become the main motive power for the Southern Railway’s Express passenger trains, though while they performed well, they were restricted by their weight, especially since the condition of the rails were hampered by the Second World War. Initially, trains on the lighter sections were handled by the Q1 0-6-0 freight engines and other, older engines, but they couldn’t handle the faster trains that were anticipated after the war. There was also the planned electrification of certain areas after the war, so the new design also needed to handle freight traffic as well, fast enough to not impede electric services.

What was decided on in the end was a downsized version of the Merchant Navy’s, fitted with the same design theory of the Q1’s to create a “Light Pacific”. The Locomotive was completed in 1942 alongside the Q1’s, and was trialed for a short time before entering service. It was deemed a success, and numbered 21C201. It was powerful enough to handle fast, heavy trains, as well as having an extremely light axle loading for a pacific at 16.5 Tons, enabling it to be used on almost every part of the UK Network as a whole. However, Bulleid decided to go with a different approach, creating simply a downsized Merchant Navy with no Q1 elements. This would increase the axle load, though this wasn’t much of an issue, as the Battle of Britain and West Country Class Light Pacifics still had a high enough route availability for the work they were assigned. Thus, the “Q1 Light Pacific'' would remain a one-off.

During the war, No.21C201 would actually travel a fair amount, and would regularly venture out of Southern territory, its light axle-load coming in handy. After the war however, it would mostly stay in the South. Performance-wise, it seemed to inherit all of the good qualities from the Q1’s and the pacific’s. The light-weight was already a plus, coupled with a great, free-steaming boiler and additions that made the driver and fireman’s life easier. However, it also inherited the bad aspects as well. The chain-driven valve gear was a well-known headache on bulleid locomotives, but there was also the issue that its light-weight caused. The regular Light Pacifics had trouble starting heavy trains thanks to their weight, but No.21C201 had it worse, especially with the well-known issues with the oil bath the valve gear was situated in. The light weight would also affect braking power as well, making unfitted trains harder to stop, a trait inherited from the Q1’s.

No.21C201 (Now Renumbered 34000) was not considered for rebuilding like the other Bulleid Pacifics due to its one-off status. It would be given a general repair in 1960 before spending the rest of its life at Nine-Elms, mainly working express and semi-fast goods trains and the occasional passenger turn during peak period and summer excursions. It was withdrawn from service in 1966 and broken up at Eastleigh.

Stats

Power Classification - 6MT

Built - 1942

Wheels (Driven) - 6ft 2in

Wheels (Leading) 3ft 1in

Wheels (Trailing) - 3ft 7in

Wheels (Tender) - 3ft 7in

Boiler Pressure - 250 psi

Cylinders (3) - 16.5in x 24in

Tractive Effort - 28,145lbf

Total Built - 1

Southern Railway L1 Class

Bulleid designed these locomotives during the Second World War, but construction didn’t begin until 1946. They shared many components with Bulleid’s Q1 0-6-0 goods engines, and were essentially the Q1’s with an Air-Smoothed Casing and a bigger boiler (though the firebox was identical with that of a Q1’s).

Twelve of these engines would be constructed between 1946 and 1948, with the final 3 being built by British Railways. They were originally numbered 22C1 to 22C12, though they were renumbered in 1949 to 36101 to 36112. They were originally meant for short distance goods and passenger services, though they never really found their footing in this role. The passenger trains that usually necessitated big tank engines were already being handled by electric engines, and everything else usually required smaller and lighter engines, which meant that, despite inheriting the power and efficiency of the Q1, the added weight and size meant that they were barred from where they could be most effective. The goods work they were meant for were also in the care of both Q1’s and Maunsell’s Q Class, as well as the many N class moguls already in service. In the end they spent their time hopping from shed-to-shed before settling on ex-LSWR territory, and even venturing into Western Region territory.

They were withdrawn between 1962-1964. Only one survives, 22C9 (36109) on the Bluebell Railway.

Stats

Power Classification - 5F 4P

Built - 1946 to 1948

Boiler Pressure - 230 PSI

Cylinders (2) - 19in x 26in

Wheels (Driven) - 5ft 1in

Wheels (Bogies) - 3ft 1in

Tractive Effort - 30,080 lbf

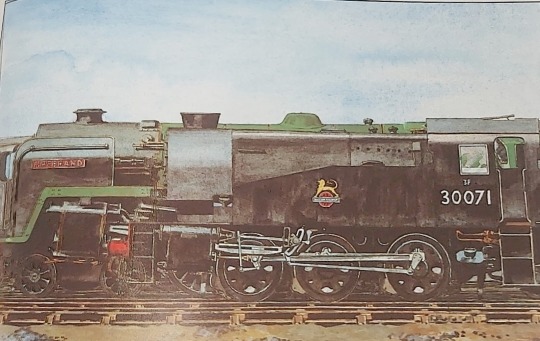

Southern Railway Dock Class

After the Second World War, many of the Southern Railway’s shunters (mainly those at Southampton) inherited from pre-grouping companies were worn out and needed overhauling. As such, Bulleid opted to replace them outright with his own design of 0-6-0T, with a short wheelbase of 10 feet to enable it to negotiate the tight curves. Like many of Bulleid’s designs, he equipped it with a relatively high boiler pressure.

Six would enter service in 1946, and while a total of 18 were planned, this would never come to be, as Eastleigh works was not in a position to build new locomotives with the backlog from the war. In the end, the southern found it cheaper to purchase ex-USATC S100 dock shunters, as they fulfilled most of the requirements needed.

They were numbered C201 to C206, and were renumbered to 30071 to 30076 in British Railways days. The first, 30071, was built with the Idaglass boiler lagging and casing as used in the Q1 class, while the other 5 were built with conventional boiler lagging and tanks. 30071 would be rebuilt like the others in 1953.

The class would lead uninteresting lives as dock shunters in Southampton and Dover until their withdrawal between 1961-1962. One was initially purchased for preservation but the deal fell through. None are preserved.

Stats

Power Classification - 3F

Built - 1946

Boiler Pressure - 220 PSI

Cylinders (2) - 16in x 24in

Wheels (Driven) - 4ft 6in

Tractive Effort - 21,276 lbf

#oliver bulleid#what-if engines#train#I have way more of these if you guys want to see them#or maybe I'll just do it anyways lol

54 notes

·

View notes

Text

3-4% more efficient

Today I was talking to the guy who is installing my new gas-powered heating system. The system he's replacing is also gas-powered and about 15 years old. He said that the council were spending a lot more money on some parts to increase efficiency by only 3-4%, and that was bad and a waste of money.

My dude.

MY DUDE.

We are so good at things powered by fossil fuels, which are extremely inefficient. An increase of 3-4% over 15 years when we are already really good with fossil fuels,

is quite a LOT actually?

And like,

Imagine if we could increase the efficiency of every fossil-fuel-powered thing on Earth by 3-4%. We still haven't stopped increasing our CO2 output as a species, but imagine if we increased the efficiency of everything powered by fossil fuels, by 3-4%. That would be HUGE. That would make a big dent in the CO2 graph.

And it's not like there is one machine that powers everything in the world, so we can't do that. The ONLY way we can do that, is by upgrading machines when they break.

We have to improve each individual machine,

on the whole planet,

by 3-4%.

And that costs MONEYYYYYYY.

I think probably money *is* quite important.

But.

I think maybe if anything could be considered more important than money, it's human life and wellbeing.

I think one might argue that since humans made money and almost all humans use and need money to maintain their health and quality of life,

that ensuring human life and wellbeing might well be the MAIN! PURPOSE! OF MONEY!

Five people in the UK died in Storm Bert in November 2024 (last month), and those storms are being exacerbated by climate change. How much of a life am I taking every time I heat my home, because it's powered by gas? I asked for an air source heat pump system but the guy doing the pre-installation assessment said that's not available.

It is so much cheaper to prevent climate change than to undo its effects.

Those five people who died in the most recent storm are dead. They paid taxes that are replacing boilers so that the storms that killed them are slowed down by 3-4%. If our boilers hadn't been replaced by more efficient models 15 years ago, more than five people might be dead now. If (when) we manage to start reducing the amount of CO2 in the atmosphere, those five people will still be dead.

We can spend £1 now or £10, £100, £1,000 later, plus a bunch of dead. people. People who will be dead.

Imagine thinking 3-4% more efficient of anything was no big deal and not worth it. (Let alone something that exhales poison.)

I would throw that stupid gas boiler into the sun if I could. But then....... I would be very cold. I'm so angry.

13 notes

·

View notes

Text

So, I think I have PMDD and I can't afford to get a diagnosis but I've been having some tenderness down around there, absolutely zero tolerance for That Guy, and this just happened:

One of That Guy's work friends (the one I don't like) is currently stationed overseas and sent him a giant, .5lb chocolate bar from Norway.

It arrived melted and then reformed into a blob at one end of the bag.

I decided I'd boil the chocolate in the wrapper since I'd seen that a lot online and don't have a double boiler nor do I have two pans that would fit well enough to work as one, mix it up well, and then pour the melted chocolate into some silicone molds I have.

It was going great until I tried to move the large chunk of solid chocolate down into the melted portion.

The end of the wrapper split open dumping all of the chocolate into the water, destroying it.

I felt bad so I went online and ordered him a replacement bar of chocolate and the damn thing cost about $35.

He said don't do that, it's just chocolate, but I know he was disappointed in me for ruining it.

I kept feeling worse and worse and seriously considered going upstairs and shooting myself.

That is not said lightly or as a joke. It was a very serious consideration.

I think I'm going to have my period soon.

5 notes

·

View notes

Text

Free Boiler Upgrade

Free Boiler Upgrade: Stay Warm and Save Money This Winter

With rising energy costs and harsh British winters, many homeowners are looking for ways to reduce heating bills while making their homes more comfortable. The Free Boiler Upgrade scheme is here to help! Thanks to the ECO4 Government Grant, eligible homeowners can now have their old, inefficient boiler replaced with a brand-new, energy-efficient boiler — completely free of charge.

What Is the Free Boiler Upgrade?

The Free Boiler Upgrade is part of the ECO4 Government Grant, a scheme aimed at reducing energy usage and tackling fuel poverty across the UK. Under this initiative, eligible households can have their old boiler replaced with an A-rated model — at no cost.

Why Get a New Boiler?

✅ Lower Energy Bills: New boilers operate more efficiently, using less gas and reducing your heating costs. ✅ Better Heating: Enjoy a warmer, more comfortable home throughout the winter. ✅ Environmentally Friendly: Reduce your carbon footprint with an A-rated, eco-friendly boiler. ✅ Hassle-Free Installation: The scheme covers the cost of the boiler and its installation.

Who is Eligible?

To qualify for the Free Boiler Upgrade, you must:

Be a homeowner in the UK.

Receive certain benefits (e.g., Universal Credit, Tax Credits, etc.).

Have an old, inefficient boiler (typically over 10–15 years old).

👉 Not sure if you qualify? It's quick and easy to check your eligibility online.

How to Apply for a Free Boiler Upgrade?

Applying is simple and only takes a few moments:

Visit freeboilerupgrade.com

Check your Eligibility by submitting your details.

Get Approved and book an installation date.

Enjoy a New, Energy-efficient Boiler and lower energy bills!

What If You're Not Eligible?

If you’re not eligible for a free boiler, don’t worry! You can still benefit from our referral programme:

✅ Refer a Friend and earn up to £200 per eligible lead. ✅ There’s no limit — help as many friends and family as you want!

Stay Connected!

For more information, tips, and the latest news about Free Boiler Upgrades, follow us on Instagram:

👉 Instagram: Free Boiler Upgrade

Don’t Wait — Apply Today!

With rising energy prices and cold temperatures, now is the best time to upgrade your boiler and save money. The Free Boiler Upgrade scheme is available for a limited time and on a first-come, first-served basis.

👉 Check if you qualify for a FREE boiler upgrade today! Visit: freeboilerupgrade.com Call: +44 7375 868046

Stay warm, save money, and help the planet — one boiler at a time!

2 notes

·

View notes

Text

Pioneer Plumbing & Heating, Vancouvers Best Plumbing Service

Pioneer Plumbing & Heating Inc, Vancouvers Preferred Plumbing Company

When your shower goes cold suddenly or an unexpected ceiling stain reveals a hidden leak, you quickly understand the importance of having a local plumber you can trust or heating professional stationed nearby. Most homeowners don’t think twice about their plumbing and heating, until an issue disrupts the status quo. That’s why finding a reputable plumbing contractor is beneficial.

The Importance of Employing Nearby Plumbing and Heating Professionals

Employing a local plumbing contractor has it's benefits. A local plumber is accustomed to the specific difficulties homes in the area run into, in contrast to a large national chain. In colder places, plumbers familiar with the local climate often advise insulation for exposed water lines to avoid freezing plumbing, an expensive problem during winter. While a large plumbing company might miss that detail, a local specialist will always be well prepared for it.

Hometown contractors depend upon their reputation and testimonials, which frequently means they’re committed to furnishing outstanding service. To them, you are a lot more than a job, you’re part of the community.

Important Services Each Home owner Must Watch for

1. Emergency Plumbing Problems: Plumbing problems always seem to develop at the worst possible time. When a pipe breaks, a toilet overflows, or a water heater stops working, timely action is important. We provide emergency plumbing services with quick response times.

2. Boiler and Furnace Upkeep: . Anual furnace check-ups can recognize issues such as carbon monoxide gas leakage or defective components before they escalate.

3. b Clogged drains and backed up sewer lines are a lot more than irritations, they often cause costly water damage. Our methods, like hydro jetting, effectively remove tough clogs while guarding your plumbing from harm.

4. Water Heater Replacement and Repair: From instant hot water to conventional models, our heating prossionals can diagnose hot water issues, recommend the right water heater for your home, and ensure safe replacement.

5. Planned Maintenance Packages: One of the best ways to steer clear of plumbing and heating situations is through routine maintenance. Inquire right now about our general maintenance packages. They come with seasonal checkups, and https://lanetnay620.bravesites.com/entries/general/Pioneer-Plumbing-Heating---Drains--Vancouvers-Favorite-Plumbing-Company priority service, which implies difficulties are avoided cost effectively.

Save Money and Regular Check-ups

Preventative care doesn’t just keep your systems running smoothly, this also saves you money. Keeping your furnace in good condition minimizes energy use helping reduce your utility expenses. Routine plumbing checks can spot minor leaks early on, preventing them from turning into costly problems you would rather not face.

youtube

Put Your Money into Long Lasting Comfort and Worry Free Living

Your home represents your most valuable resource. By partnering with a dependable local plumbing, you are also safe guarding that commitment, you are also ensuring your family's comfort and safety year round. Pioneer Plumbing, Heating, and Drain Services is a top-rated plumbing contractor serving the Vancouver area. Contact us today for a free quotation, you’ll be glad you did.

Pioneer Plumbing, Heating and Drains 626 Kingsway Vancouver, BC V5T 3K4 (604) 872-4946 https://w

2 notes

·

View notes

Text

Overdue Maintenance

The Spine x OC (Atlas)

Cw: slight angst and mentions of past mistreatment of a sentient mechanical being.

Atlas's gears whirr and creak as he shifts to sit on the metal table in Peter Walter VI's lab. He doesn't have anything against the Walters and their work is proudly displayed by the other mechanical beings in the Manor, but that doesn't stop him from being nervous about this.

The Spine had convinced him, finally, after several years of officially dating, to let one of the Walters do some maintenance and maybe an upgrade or two for him.

The Spine slips his hand into Atlas' smaller one and gives a reassuring squeeze. "I'll be here the whole time, I promise," he says, offering a kind smile. Atlas nods and squeezes his hand back. He's still nervous but he can make it through one maintenance with his boyfriend by his side. He'd have booked it into a dark corner by now if Spine wasn't standing right next to him.

Six pulls up a rolling table with some tools on it, much smaller than the automaton is used to seeing. "Ready to begin?" Six asks and Atlas glances him over, noting the thick rubber gloves and leather apron, likely in case his core causes issue.

"Sure, but remember my clauses," he sighs steam, figure crouched where he sits. Peter nods, "Of course, it's important that you agree to all this." Atlas nods, venting steam.

He'd agreed, as long as he doesn't have to go into stasis, they run everything they do by him before they do it and the Spine has to remain at all costs. If any of these weren't followed, he'd walk out and wouldn't return for anything anytime soon.

Peter motions to his shirt and hat and Atlas takes both off easily, ignoring the creaking of his joints as he does. He puts his stuff on the table beside him and releases the hydraulic locks that keeps his chest plate shut. They hiss and the hatch moves just an inch open, steam steadily rolling from inside it.

"Thank you. I'm just going to assess the damage for now, I'll tell you when I want to do anything else," Six says, sounding almost too formal as he gets a little pen light and carefully opens the hatch. Atlas' grip on The Spine's hand increases but Spine just offers him another smile.

Atlas is all clockwork and ball joints, which limits his movements from time to time but he's learned to live with it. He's sure his insides are a rusted, oily mess, but Six seems undeterred. "Can you slow your boiler and bellows down? The whole cavity is flooded with heat and steam," Six asks, pulling his hands out.

Atlas nods, filling his bellows to their full capacity before exhaling all the steam, which allows his boiler to slow considerably. If he slows things any more than that, he'd fall into stasis, so he balanced on the line.

The Spine moved to hold onto Atlas' shoulder with his free hand, not daring to look too closely at the mechanisms that make up his partner. "You're doing great, darling," he says, voice gentle and calming. He gets another hand squeeze as an answer, since Atlas' can't make his voicebox work at the moment from stress.

It didn't escape either automaton that Six paused for a few minutes as he investigated with the pen light. Then he takes a step back and rummages in a nearby cupboard.

"So, your systems are heavily outdated, but I'd need a lot more time than we have today, to figure out how to best update them, for now, I'm just going to replace some parts and clean the excess oil out. How's that sound?" He tacks the last part on, but either way, Atlas appreciates it.

Atlas nods as his answer, working hard to keep his boiler and bellows slow and steady. He looks to Spine, who still smiles reassuringly, and gets a gentle pat on the shoulder as answer.

The Walter bots trust the Peters, but Atlas can't stop memories flooding into his peripheral vision. Dark labs with glowing, green pipes lining the walls, large, rusted tools and a burn-damaged face leering down at him. He shakes his head to clear himself of the images and finds Six back in his personal space. It takes everything in him to not jump.

"Let's start with the slipping gears. They've worn down over time, so I'm just going to take them out and put new gears in their place," Six explains, a box of gears rattling where he puts it on the table. Atlas nods again, trying to relax his shoulders. Of course he knew about the slipping gears, but they caught every third or fourth tooth and he still ran just fine, so he hadn't given it much thought, even if it hurts almost constantly.

"Worthless thing keeps breaking down! One of these days it'll just have to go until it stops, we can't afford all this shit!" Ignatius barks at his nephew, the teenager barely knows which tools to pull out but he's adept at tuning out his uncle.

Ignatius jabs wiring into the ports behind his ears to keep him lucid. He's not allowed to sleep while they do this and the wires keep his mind sharp. Sean, Ignatius' nephew, straps down his arms, shoulders, neck and ankles to the table with metal cuffs. They learned the hard way that he struggles when they start pulling tubing and cogs.

Peter is gentle, is the first thing Atlas notices when he comes back to the present. Six is carefully unscrewing stripped bolts and screws, doesn't jostle anything when he removes the old gears and places shiny, new ones in their stead. The new gears are cold, shocking his system slightly. That's likely what pulled him out of his memories.

"Okay, gears are all good. Next is tubing. There's a couple oil lines that have slow leaks and need to be replaced," Six voices again and Atlas is momentarily confused by the airy and gentle tone when he was expecting venom and harsh words. Peter isn't a Becile, so why was Atlas expecting the same cruelty from him? He didn't know and couldn't quite place it.

His wiring and pieces lay splayed out over the table, wire endings burning where they come into contact with the lead work surface, oil slowly draining to where his feet lay. He's vivisected and cold, core working overtime because the wires behind his ears won't let him drift into stasis.

Ignatius jabs his hands into his open stomach, scratching around and pulling oil lines out until they are splayed like his wiring. His hands ball into fists, but he can't do anything besides listen to oil drip from the broken lines like blood.

Drip drip drip...

Six clamps the lines before he cuts them, working carefully. None of his insides are out, except for the singular oil line that's gently held between deft fingers. He replaces it smoothly and quickly, welding the lines so they don't break off again and fastening them into place so they can't be jostled and damaged as easily.

Six has an old scrap cloth that he sticks into the lower part of his stomach, wiping away excess oil and debris from the years. For some reason Atlas finds himself feeling lighter, in a good way.

"And lastly, some wires have rusted to dust. I'll need to replace those, then we can oil your joints and be done for the day," Six says, gentle and cheery. He looks like he enjoys the simplicity of maintaining them, like it's a pleasure and not just his job.

Atlas rests ever so slightly back against The Spine's chest. When had he moved to stand behind him? He was holding both of Atlas' hands in his own. Doesn't matter, his attention needs to stay on what Six is doing, for everyone's safety.

"Still doing okay?" The Spine asks, voice radiating comfort. Atlas hums his answer, finally getting his voicebox to work in some capacity.

"Clean up this crap and run the startup sequence!" Ignatius orders his nephew before storming out of the lab, tools clanking where they fall and door slamming behind him. He's clearly in a shitty mood today and taking it out on everyone else.

Atlas' eyes track Sean's movements as he goes about cleaning the oil and extra parts and putting away the tools they'd needed. It takes a couple minutes, but when Sean sees he's being tracked, he stops moving.

"Blink twice if you want the radio," he says simply, voice rough from disuse and a lingering deaf accent. Atlas doesn't look past the offer and blinks twice before his eyes stop following Sean's movements.

The radio turns on and Atlas focusses solely on the host's voice and the music that follows. He doesn't hum or sing or even speak, but now at least he has some solace from the fire still ravaging his oil lines and wires. If he didn't know any better, he'd assume Ignatius enjoys causing him pain.

"And we're all done," Six says with a smile. Atlas nods and moves more upright to shut his chest plate. "I do want to see you again sometime in the future in regards to your voicebox, but we agreed to a slow pace with these repairs." He rambles on, turning to wipe down his tools and hands.

Atlas let's the hydraulic locks settle into place with a hiss and allows his boiler to pick up a little speed. Six swings around on a spinny chair, looking for all the world like an excited child. "So, how are you feeling?" He asks, bouncing his knee.

Atlas takes stock, noting all the new components and how much smoother everything runs. He also realises, for the first time since his creation, he isn't in pain after maintenance. He rolls some of his joints to test them and finds it's the easiest he's moved since the 80's.

"Good, actually. Thanks Peter," his voice is still a little shaky but he's stable and thinks he can now understand why the Walter bots look forward to maintenance and upgrades.

The Spine holds his shirt up for him and he slides his arms into it, allowing his silver partner to help him with the collar. The Spine plops his old conductor hat on his head and leans down for a quick peck on the lips. "Wasn't so bad after all?"

"Not nearly as bad as I'd been expecting, Love," Atlas answers, taking the hand The Spine offers to help him up from the table. He hasn't run this well since his creation and he's still not over the foreign feeling of painlessness.

The Spine leads him out of the lab so they can go watch a movie, something low maintenance after the stress he'd seen dimming his boyfriend's green eyes during the procedures earlier.

When they were out of sight and hearing range, Six made his way down to the archives and pulled out blueprints from the stacks of handwritten information. The name 'Rabbit' followed by the year 'Upgrades, 1950' is at the top as a label. He puts it on a flat surface nearby and goes over the details. His suspicions were correct, Atlas' inner workings were a near perfect copy of Rabbit's old design. He doesn't know whether to be worried about that or not, yet.

#atlas#spg oc#spg the spine#steam powered giraffe#steam powered giraffe oc#peter walter six#spg six#atlas spg

2 notes

·

View notes

Text

#Best Combi Boiler Prices#Best Combi Boilers 2024#Best Combi Boiler in Centre England#Affordable Combi Boilers#Energy Efficient Combi Boilers#Top Combi Boiler Brands#Worcester Bosch Combi Boilers#Vaillant Combi Boilers#Ideal Logic Max Boilers#Combi Boiler Installation#Combi Boiler Deals#Combi Boiler Discounts#Combi Boiler Reviews#Compare Combi Boilers#Cheap Combi Boilers#High Efficiency Combi Boilers#Smart Combi Boilers#Compact Combi Boilers#Reliable Combi Boilers#Combi Boiler Maintenance#Best Heating Systems#Modern Combi Boilers#Centre England Heating Solutions#Home Heating Tips#Boiler Financing Options#Combi Boiler Warranty#How to Choose a Combi Boiler#Best Boilers for Small Homes#Boiler Replacement Costs#Eco-Friendly Boilers

0 notes

Text

“The problem is that we’re just not moving fast enough to replace gas boilers with heat pumps,” Possible says. “To speed this up and make this easier for people, we need heat pumps to be cheaper than gas boilers.”

The way that charges are added to household energy bills in Britain makes electricity more expensive compared to gas. This makes it harder than it should be for people to get off the fossil fuel, the charity argues.

10 notes

·

View notes