#cnc precision testing services

Explore tagged Tumblr posts

Text

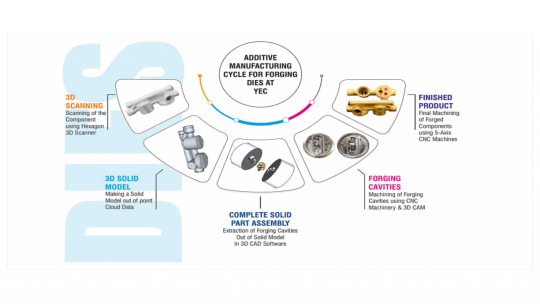

Unveiling the Potential of 3D Scanning in Reverse Engineering

In the realm of engineering innovation, the advent of 3D scanning has revolutionized traditional methodologies. Among its myriad applications, one particularly noteworthy domain is reverse engineering.

Enterprises worldwide are leveraging 3D scanning technologies to dissect and recreate intricate designs, breathing new life into legacy components and machinery. The process involves capturing detailed digital renderings of physical objects, which serve as blueprints for replication or enhancement.

In the heart of technological advancements, Yamunanagar Engineering Cluster stands as a beacon of ingenuity. Employing cutting-edge 3D scanning techniques, the cluster pioneers the restoration and optimization of industrial assets with unparalleled precision and efficiency.

Beyond restoration, 3D scanning facilitates product innovation, enabling engineers to analyze and enhance existing designs swiftly. It expedites prototyping, reduces time-to-market, and fosters a culture of continuous improvement.

As industries evolve, the fusion of 3D scanning reverse engineering propels progress, ushering in a new era of limitless possibilities and unparalleled innovation.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

Premium White Hard PTFE Sheets for Demanding Industrial Applications

Aohong's white hard PTFE sheet stands as a benchmark in high-performance fluoropolymer solutions, delivering exceptional mechanical strength and chemical resistance. Manufactured from 100% virgin PTFE (polytetrafluoroethylene), these rigid fluoropolymer sheets maintain superior dimensional stability across extreme temperatures (-200°C to +260°C), outperforming conventional filled PTFE variants in purity and longevity.

Unmatched Material Properties

Our pure white PTFE sheets exhibit critical advantages:

0.02% deformation under 20MPa compressive load (ASTM D695)

28MPa tensile strength – 40% higher than recycled PTFE blends

60kV/mm dielectric strength (IEC 60243 at 200°C)

Zero moisture absorption – ideal for semiconductor cleanrooms

Microscopic analysis reveals a homogeneous crystalline structure with <0.1% void content, achieved through Aohong's proprietary isostatic pressing technology.

Precision Manufacturing Process

At our ISO 9001:2015-certified Suzhou facility, each sheet undergoes:

Ultra-fine resin filtration (99.99% purity)

Cold compaction at 65MPa for density uniformity

Controlled sintering (375±5°C for 20 hours)

Precision machining to ±0.03mm tolerances

This process yields FDA-compliant white PTFE sheets meeting:

USP Class VI biological safety standards

EU 10/2011 food contact regulations

RoHS 3 Directive compliance

Industrial Applications

Medical Devices

MRI component insulators

Autoclavable surgical tool handles

Food Processing

Non-stick conveyor liners

Dairy equipment gaskets

Semiconductor

Wafer carrier components

Plasma etch chamber liners

Chemical Processing

Hydrofluoric acid tank linings

Chlor-alkali cell seals

Quality Verification

Every production batch includes:

FTIR spectroscopy for molecular integrity checks

DSC analysis confirming 327±2°C melt point

X-ray diffraction testing crystallinity (15-20% range)

100% thickness gauging with laser micrometers

Recent third-party testing demonstrated 300% longer service life versus Chinese Q/YZB standards for PTFE sheets in sulfuric acid exposure.

Customization Options

Aohong provides tailored solutions:

Thicknesses from 0.5mm to 150mm

Anti-static versions (10⁶-10⁹ Ω/sq)

High-wear grades with 15% improved abrasion resistance

FDA white color-stable formulations

Pre-cut blanks for CNC machining

Why Aohong Excels

With 18 years of PTFE specialization, we offer:

12-month performance guarantee

Teflon™-equivalent properties at competitive pricing

Technical support from materials PhDs

Case Study: A Shanghai semiconductor fab reduced particle contamination by 92% after switching to our ultra-clean white PTFE sheets for wafer handling.

Advanced White PTFE Sheet Solutions for Critical Environments Contact Aohong today to request samples or discuss your application requirements. Our engineers combine deep material science expertise with practical experience from 1,200+ successful installations worldwide.

2 notes

·

View notes

Text

Maximize Off-Road Steering Performance with the COMPLETE DANA 60 CROSSOVER & HIGH STEER Kit from East West Offroad (EWO)

When it comes to serious off-road performance, having the right steering geometry can make all the difference between confidently conquering technical terrain and struggling with poor control. For off-road enthusiasts running Dana 60 kingpin axles, the COMPLETE DANA 60 CROSSOVER & HIGH STEER kit from East West Offroad (EWO) offers a bulletproof upgrade engineered to handle the harshest conditions the trail throws your way.

This blog will dive into why this high steer kit is a must-have for lifted trucks and custom builds across the USA, what’s included, and how it transforms your vehicle’s capability—both on the trail and beyond.

Why High Steer Matters for Dana 60 Setups

Stock steering geometry wasn’t designed for aggressive off-road use. Once you lift your rig and add oversized tires, factory components begin to fall short. You’ll often deal with:

Severe bump steer

Steering linkage that’s vulnerable to rocks and debris

Tie rod angles that compromise articulation

Unstable or vague steering input

A crossover and high steer system fixes these issues by repositioning critical components higher above the axle and giving you proper angles for drag links and tie rods. The result? Smoother, safer, and more controlled off-road handling.

Built for Strength: What’s in the COMPLETE DANA 60 HIGH STEER Kit?

The team at East West Offroad (EWO) doesn’t just build components—they engineer full-system upgrades built for the abuse of real-world off-roading. Their COMPLETE DANA 60 CROSSOVER & HIGH STEER kit is designed specifically for Dana 60 kingpin axles, one of the most trusted platforms in heavy-duty off-road applications.

🔧 Kit Includes:

Driver and passenger high steer arms, CNC-machined from premium billet steel

Heavy-duty tie rod and drag link assemblies

High-strength Grade 8 hardware

All required spacers and bushings for seamless integration

Clear, step-by-step installation instructions

Each piece is built to handle lifted suspensions, 40”+ tires, and the extreme flexing that comes with trail abuse. Whether you're crawling rocks in Moab or tackling backcountry forest trails, this kit delivers control you can rely on.

➡️ Explore full specs and order now

Why Choose East West Offroad (EWO)?

In a sea of generic aftermarket suppliers, East West Offroad sets itself apart with a commitment to quality, customer service, and performance. Here’s why American off-roaders trust them:

✅ Made in the USA – Precision machining with American steel ✅ Trail-Tested – Components are field-proven by real-world drivers ✅ Customer-Focused – Responsive support before, during, and after purchase ✅ Installation Support – Clear documentation and tech support from actual off-roaders

EWO is more than a brand—it’s a community of fabricators, engineers, and drivers who understand what your build needs to thrive in extreme conditions.

Top Benefits of the COMPLETE Dana 60 High Steer System

1. Enhanced Ground Clearance

The high steer arms lift steering linkage above the axle centerline—away from rocks, logs, and trail hazards that can bend or break your stock components.

2. Eliminate Bump Steer

Poor geometry causes your tires to steer themselves every time the suspension moves. This kit realigns your steering to eliminate dangerous bump steer, especially critical on high-speed or uneven trails.

3. Increased Suspension Travel

With improved articulation and less binding in the linkage, your suspension can move freely, allowing for better traction and control on rough or uneven terrain.

4. Reliable Steering Response

Expect firm, consistent steering input across all conditions. Whether you’re in deep mud or navigating off-camber climbs, your vehicle will respond like it should.

5. Extended Component Lifespan

Better angles mean less strain on joints and linkages, reducing the risk of premature failure and increasing the lifespan of your entire steering system.

Real-World Testimonials from Hardcore Off-Roaders

🗣 “I run 42s on my Dana 60 and was constantly worried about bending the stock tie rod. Since switching to the EWO high steer setup, I haven’t had a single issue.” – Greg M., Utah

🗣 “Install was straightforward, and everything fit perfectly. My Jeep finally drives like it should after the lift. 10/10 Lisa T., Colorado

🗣 “High-quality parts and top-notch support. This is the real deal for anyone serious about their off-road rig.” – Derek H., Texas

Who Is This Kit For?

If you meet any of the following criteria, this kit is designed for you:

You drive a GM, Chevy, Jeep, or custom vehicle with Dana 60 kingpin axles

You’ve lifted your rig or installed long-travel suspension

You run larger-than-stock tires

You go off-road regularly and demand consistent, reliable steering performance

Whether you're building a competition crawler or a weekend trail warrior, this upgrade is an investment in control, safety, and longevity.

Final Thoughts: Don’t Let Steering Hold You Back

In off-roading, every component matters—but your steering system is the one connection between your hands and the terrain. Don’t trust it to worn-out stock geometry or cheap offshore parts.

Upgrade to the COMPLETE DANA 60 CROSSOVER & HIGH STEER system from East West Offroad (EWO) and drive with confidence, no matter where the trail leads.

👉 Order yours today from East West Offroad and join the thousands of off-roaders across the USA who trust EWO for battle-ready performance.

🔗 Complete Dana 60 Crossover & High Steer Kit – Order Now

#Dana 60 Crossover Steering Kit#Dana 60 High Steer Kit#Dana 60 Crossover#Dana 60 high Steer#Dana 60 Kingpin Crossover#Dana 60 High Steer Arms#Dana 60 Steering Arms

1 note

·

View note

Text

Precision Sheet Metal Manufacturing: Future Directions in the Industry

As the global market grows and evolves, the demand for product customization has intensified. Many leading companies are concentrating on their core areas—brand management, product design, and marketing—while outsourcing non-core functions to specialized manufacturing service providers. This strategy has fostered the emergence of manufacturing service companies, such as Foxconn and Flextronics, which are now prominent players in the global manufacturing landscape.

Precision metal components have become indispensable in these outsourced products, playing a crucial role in both the aesthetics and functionality of end products. With rising precision requirements, manufacturing service providers are increasingly specializing in precision manufacturing, leveraging their technological and cost advantages. Even industry giants like Foxconn and Flextronics rely on these specialized firms for manufacturing and technical support, thereby enhancing their overall competitiveness and shaping China's precision metal manufacturing sector.

One key area of focus within this industry is precision sheet metal manufacturing, which is essential for delivering high-quality, accurate metal components. This process utilizes CNC and sheet metal technologies, employing various cold-working techniques such as cutting, stamping, bending, welding, riveting, assembling, and forming to process thin metal sheets (typically less than 6mm thick) to meet stringent customer requirements for product accuracy and functionality.

Compared to traditional sheet metal manufacturing, precision sheet metal fabrication offers several distinct advantages:

High Precision Requirements for Downstream Industries Precision sheet metal services cater to high-tech sectors such as telecommunications, aerospace, solar energy, and semiconductors, where precision is critical. For instance, the accuracy of communication base station antennas directly affects signal transmission and reception, while solar power systems require precise metal components to ensure optimal light concentration and photoelectric conversion efficiency. For example, a 300-watt solar panel demands a backplate thickness tolerance within 0.5% and no deformation under 4000-volt high-pressure tests. Additionally, these industries impose stringent requirements on the visual quality of products, including color consistency and smoothness of lines.

Need for High-Precision Equipment and Molds Precision manufacturing demands advanced equipment, such as flexible manufacturing systems, CNC punching machines, CNC bending machines, friction welding equipment, and robots for assembly and welding. The automation and precision of these devices ensure the accuracy of sheet metal products. For example, CNC punching machines can maintain a forming error of ±1.5mm for plates measuring 1.1m x 1.4m. Mold accuracy is also crucial, typically requiring precision within microns (0.01mm).

Focus on Accurate Unfolding Processes Precision sheet metal manufacturing utilizes cutting-edge tools like laser cutters and CNC bending machines, revolutionizing traditional processing methods. Traditionally, sheets were roughly unfolded before bending, then resized and further processed, leading to inefficiencies and material waste. In contrast, precision sheet metal fabrication involves precise unfolding, cutting all shapes, holes, and slots before bending, which enhances efficiency and quality but demands higher precision in unfolding diagrams.

High-Quality Production Environment A high-quality production environment is essential for ensuring the reliability and stability of precision sheet metal products. Precision equipment is sensitive to temperature changes, which can affect device accuracy and, consequently, product quality. Furthermore, downstream industries like telecommunications and solar energy require strict controls on carbon emissions, airborne dust levels, and equipment insulation to ensure stable operation of the final products.

As a professional in the field, I believe that the evolution of precision sheet metal manufacturing reflects broader trends in the industry. The increasing demand for high precision, coupled with advancements in technology, is driving the sector towards greater specialization and innovation. This focus on precision not only enhances product quality but also strengthens the competitive edge of manufacturing service providers globally.

#CNCmachining#CNCmanufacturing#PrecisionMachining#CNCtechnology#MachineShop#CustomMachining#CNCparts#MetalFabrication#CNCengineering

1 note

·

View note

Text

CNC Prototyping Services For Precision Manufacturing

CNC Prototyping is a particular and reliable method for growing useful prototypes using pc-managed machining. It allows fast production of components from metals, plastics or composites, best for testing layout, in shape, and characteristic. CNC prototyping guarantees high accuracy, rapid turnaround and helps iterative product improvement before mass manufacturing.

0 notes

Text

Crafting Nature: Metal Artistry in Fabrication

The Art of Metal Fabrication

Metal fabrication is a transformative craft, blending raw materials with human ingenuity to create structures that stand the test of time. From industrial components to artistic installations, the process involves cutting, bending, and assembling metals like steel and aluminium to form intricate designs or robust frameworks. Among these creations, the steel tree ring stands out as a symbol of both strength and beauty, embodying the fusion of nature-inspired aesthetics with modern engineering. This circular motif, often crafted to encircle trees or serve as a decorative element, showcases the precision and creativity inherent in metalwork. Fabrication shops, especially those specializing in aluminium, have become vital hubs for such innovative designs, offering customized solutions for both practical and artistic needs.

The Rise of Aluminium Fabrication

The demand for lightweight, durable, and corrosion-resistant materials has propelled aluminium into the spotlight of modern fabrication. Unlike heavier metals, aluminium offers versatility, making it ideal for everything from architectural facades to intricate sculptures. For those seeking aluminium fabrication near me, local workshops provide tailored services, crafting everything from structural components to bespoke art pieces. These shops employ advanced techniques like welding, laser cutting, and CNC machining to shape aluminium with precision. The result is a material that balances functionality with aesthetic appeal, perfect for outdoor installations like tree rings or garden features that require both durability and a sleek, modern look. Local fabrication services ensure that clients can collaborate closely with artisans to bring their visions to life.

The Symbolism of the Steel Tree Ring

A steel tree ring is more than a decorative piece; it carries profound symbolism. Often encircling the base of a tree, it represents protection, growth, and the harmonious blend of nature and human craftsmanship. Fabricators craft these rings using high-grade steel, chosen for its strength and ability to withstand harsh weather conditions. The process begins with designing a ring that complements the tree’s natural form, followed by cutting and welding the steel into a seamless circle. Some designs incorporate intricate patterns or engravings, transforming the ring into a piece of art. The steel tree ring serves as a testament to the skill of metalworkers, who balance structural integrity with creative expression, ensuring the piece enhances its natural surroundings while standing as a durable, long-lasting feature.

Why Choose Local Fabrication Services?

Searching for aluminium fabrication near me often leads to discovering skilled artisans in one’s community. Local fabrication shops offer several advantages, including personalized service, quick turnaround times, and the ability to oversee the project from concept to completion. These workshops are equipped to handle a range of projects, from small decorative items to large structural components. Aluminium’s lightweight nature makes it a preferred choice for clients looking to create portable or easily installed pieces, such as garden art or architectural accents. By working with local fabricators, clients can ensure their projects align with their vision while supporting skilled tradespeople who contribute to the community’s creative and economic vitality.

The Fabrication Process Unveiled

The journey from raw metal to a finished piece like a steel tree ring involves multiple stages, each requiring precision and expertise. It begins with design, where artisans collaborate with clients to sketch out ideas, often using software to create detailed blueprints. Next comes material selection—steel for strength, aluminium for versatility. Cutting techniques, such as plasma or laser cutting, shape the metal, while bending and forming create the desired contours. Welding and assembly bring the pieces together, and finishing touches like polishing or powder coating enhance durability and appearance. For a steel tree ring, the process might involve curving steel bands into perfect circles, welding them securely, and adding decorative elements like etched patterns. Similarly, aluminium fabrication follows a parallel path, with an emphasis on leveraging the metal’s malleability to achieve sleek, modern designs.

Blending Art and Functionality

Metal fabrication transcends mere utility, often blurring the line between art and engineering. A steel tree ring, for example, serves a practical purpose by protecting a tree’s base from damage while adding an artistic flourish to a garden or park. Similarly, aluminium components crafted in local shops can elevate a building’s exterior or create stunning outdoor sculptures. The ability to customize these pieces allows fabricators to cater to diverse needs, whether it’s a homeowner seeking a unique garden feature or a business requiring structural components. The interplay of form and function is what makes metal fabrication so compelling, as artisans transform raw materials into pieces that are both useful and visually striking.

Sustainability in Metal Fabrication

Sustainability is increasingly shaping the world of metal fabrication. Both steel and aluminium are highly recyclable, making them eco-friendly choices for projects like tree rings or architectural elements. Local fabrication shops often prioritize sustainable practices, such as recycling scrap metal and using energy-efficient equipment. By choosing aluminium fabrication near me, clients can reduce the carbon footprint associated with transporting materials, while supporting businesses that prioritize environmental responsibility. Steel tree rings, with their durability, also contribute to sustainability by reducing the need for frequent replacements. This focus on eco-conscious practices ensures that metal fabrication not only meets aesthetic and functional needs but also aligns with a growing commitment to preserving the planet.

The Future of Custom Metalwork

As technology advances, so does the potential for metal fabrication. Innovations like 3D printing and automated CNC systems are expanding the possibilities for creating intricate designs, such as highly detailed steel tree rings or complex aluminium structures. These advancements allow fabricators to push the boundaries of creativity, producing pieces that were once unimaginable. For those searching for aluminium fabrication near me, the future promises even greater customization, with digital tools enabling precise, client-driven designs. The combination of traditional craftsmanship and modern technology ensures that metal fabrication will continue to evolve, offering new ways to blend art, functionality, and sustainability.

0 notes

Text

Stainless Steel Investment Castings

MS Machining delivers high‑precision stainless steel investment castings tailored for demanding industrial standards, utilizing its CAST 300 series to pour premium stainless steel alloys that conform to AMS, MIL, Federal, and ASTM specifications. Leveraging the time‑tested lost‑wax investment casting technique, the process begins with an intricate wax pattern that is enclosed in a refractory ceramic shell. Once dewaxed, molten stainless steel is poured, creating complex geometries with exceptional dimensional accuracy and fine surface finishes, often eliminating extensive secondary machining. MS Machining’s expertise in stainless steel alloys ensures robust corrosion resistance, mechanical strength, and versatility across applications, from aerospace components to medical, food‑processing, and defense parts. The company’s integrated approach seamlessly combines precision casting with optional CNC milling, heat treatment, and finishing services, offering clients turnkey solutions with tight tolerances and fast turnaround. With rigorous quality control, MS Machining supports both prototype runs and full‑scale production, delivering high‑integrity parts with traceable documentation. Whether you require intricate valve bodies, marine fittings, or surgical instruments, their comprehensive capability in stainless steel investment castings guarantees reliable performance, minimal lead times, and compliance with stringent industry standards—making MS Machining a trusted partner for precision components that demand excellence.

0 notes

Text

Fabrication of Heavy Engineering Equipment – Precision Solutions by Intra Group

The Fabrication of Heavy Engineering Equipment is a critical process in the manufacturing industry, requiring expertise, precision, and advanced technology to deliver robust and efficient machinery. From cement plants and material handling systems to construction equipment and industrial machinery, every sector demands high-quality fabricated components to ensure seamless operations and maximum productivity.

Intra Group – Leaders in Heavy Engineering Equipment Fabrication

At Intra Group, we specialise in the fabrication of heavy engineering equipment for diverse industries across India and abroad. With decades of manufacturing experience and state-of-the-art infrastructure, we provide customised fabrication solutions that align with client specifications and international standards.

Our Fabrication Capabilities Include:

Cement Plant Equipment FabricationKilns, silos, clinker coolers, storage tanks, and cement mill components.

Construction Equipment FabricationMixers, batching plants, paver block plants, and wall panel plants.

Industrial Heavy FabricationPressure vessels, steel structures, conveyors, and bulk material handling equipment.

Precision CNC Machining & WeldingUsing high-precision CNC machines, robotic welding, and advanced assembly techniques to deliver dimensionally accurate and durable components.

Why Choose Intra Group for Heavy Engineering Fabrication?

Decades of Expertise – Over 40 years of experience in fabrication and manufacturing. Advanced Infrastructure – Modern fabrication workshops equipped with CNC plasma cutting, heavy-duty rolling, welding, and machining facilities. Quality Assurance – Strict multi-level quality inspections to ensure each product meets IS and international standards. Timely Delivery – Commitment to timelines, ensuring seamless project execution for clients. Custom Solutions – Tailor-made fabrication services based on your engineering drawings and operational needs.

Applications of Our Heavy Engineering Fabrication Services

Cement and concrete plants Construction equipment manufacturers Industrial processing units Material handling systems Steel plants and prefabricated structures

Intra Group – Your Reliable Partner for Fabrication of Heavy Engineering Equipment

With a reputation for excellence, innovation, and client-focused solutions, Intra Group has become a trusted partner for top construction and industrial companies in India. We combine engineering expertise with advanced fabrication technologies to deliver equipment that stands the test of time.

Contact Us Today

Looking for reliable services in the Fabrication of Heavy Engineering Equipment? Visit Intra Group – Fabrication of Heavy Engineering Equipment to explore our projects, manufacturing capabilities, and customised solutions. Partner with Intra Group to enhance your production efficiency and operational excellence.

0 notes

Text

How to Choose the Right Automobile Spare Parts Manufacturer for Your Business

Choosing the right automobile spare parts manufacturer is one of the most critical decisions an automotive business can make. Whether you are an OEM (Original Equipment Manufacturer), a distributor, or a service center, your operations, customer satisfaction, and profitability heavily rely on the quality and reliability of the spare parts you offer.

With an ever-expanding global automobile industry, the market is flooded with manufacturers promising top-tier products at competitive prices. However, not all deliver on their commitments. Some may fall short in consistency, while others may lack adequate support, customization, or logistical capabilities.

In this blog, we will walk you through a structured and comprehensive guide to help you identify and partner with the right automobile spare parts manufacturer that aligns with your business goals, quality expectations, and market needs.

Why Choosing the Right Manufacturer Matters

The automobile spare parts industry plays a pivotal role in vehicle maintenance, repairs, and aftermarket servicing. Substandard parts not only compromise vehicle performance and safety but can also damage the reputation of your business. Here's why your manufacturer selection is crucial:

Product quality impacts brand credibility.

Timely delivery ensures operational continuity.

Compliance and certifications affect legal adherence.

Cost-effectiveness influences margins and pricing strategy.

A trusted partnership leads to long-term business sustainability

Step-by-Step Guide to Choosing the Right Manufacturer

1. Define Your Specific Requirements

Before approaching any manufacturer, outline your specific needs. This includes:

Types of spare parts needed (engine parts, suspension, braking systems, filters, etc.)

Volume requirements (bulk orders or small batches)

Technical specifications (material grade, precision levels, etc.)

Customization needs (branding, packaging, exclusive designs)

Target pricing and your acceptable margin range

By understanding what you need, you reduce the risk of mismatches and streamline communication with potential manufacturers.

2. Evaluate Manufacturing Capabilities

Not every manufacturer has the machinery, workforce, and expertise to produce all types of automotive components. Look into:

Production technology (CNC machines, robotics, casting methods)

In-house testing and quality assurance setups

Design & prototyping services

Automation and scalability for large volumes

Material sourcing and traceability

A capable manufacturer can deliver consistent results over time and adjust production based on your growing needs.

3. Assess Quality Standards and Certifications

Quality assurance is non-negotiable in the auto industry. Spare parts must meet safety, durability, and performance standards.

Look for manufacturers that adhere to:

International Quality Certifications such as ISO 9001, IATF 16949, or relevant automotive standards.

Standard operating procedures (SOPs) for every production stage.

Batch-wise testing reports and quality audits.

Traceability systems to identify parts throughout the supply chain.

You can even ask for a sample production run or site visit to evaluate how rigorously quality checks are enforced.

4. Check for Product Range and Specialization

Some manufacturers offer a vast product catalog, while others specialize in particular categories. Depending on your needs, decide whether:

You want a single manufacturer for all components or

You’d rather work with specialized vendors for critical systems

Working with a manufacturer who specializes in your required parts ensures better performance and technical understanding.

Additionally, inquire if they can develop new parts or replicate parts from your existing catalog. This flexibility can be a huge advantage.

5. Investigate Track Record and Experience

Experience speaks volumes. While new players can be innovative, seasoned manufacturers offer:

Proven stability

Problem-solving capability

Customer references and testimonials

Adaptability to market fluctuations

Research how long they’ve been in business and their journey so far. Have they scaled up operations over the years? Are they known for consistency and ethical practices?

You can also ask for a portfolio of previous collaborations without mentioning client names to evaluate their domain knowledge.

6. Evaluate Logistics and Supply Chain Strength

Efficient logistics are as important as production quality. A manufacturer might produce excellent parts but fail in timely delivery, causing project delays on your end.

Check for:

Inventory management capabilities

Warehousing options for buffer stock

Lead times and delivery frequency

Geographical proximity of logistics cost is a concern

Their relationship with freight carriers or logistics providers

Some manufacturers even offer Just-In-Time (JIT) deliveries or consignment models for long-term contracts. This can significantly optimize your inventory handling.

7. Analyze Communication and Support

Business is a relationship. Transparent and proactive communication lays the foundation for a long-term partnership.

Pay attention to:

Response time to queries

Language proficiency

Technical understanding of your specifications

Clarity in documentation and quotation

Post-sales support including replacements, returns, or recalls

When communication flows smoothly, your entire supply chain functions without hiccups.

8. Price Competitiveness vs. Value Delivered

Price is important but it shouldn’t be the only deciding factor. Low-cost parts that compromise performance can cost more in the long run due to:

Returns and replacements

Loss of customer trust

Legal issues due to non-compliance

Instead, focus on value for money. This includes:

Durability and warranty

Service life of parts

Packaging and branding options

Customization support

Negotiate pricing based on long-term volume and forecasted growth rather than focusing on one-off rates.

9. Assess Innovation and R&D Focus

The automobile industry is constantly evolving with new materials, emission norms, electric vehicles, and smart systems.

Choose a manufacturer who is future-ready and invests in:

Research & development

Upgradation of machines and tools

Employee training

Participation in technology expos or industry seminars

This forward-thinking approach ensures they can meet your evolving needs and stay compliant with changing regulations.

10. Start with a Trial Partnership

Once you’ve shortlisted a few automobile spare parts manufacturers, consider starting with a small volume order or a pilot batch. This allows you to:

Evaluate the product quality in real use

Test their delivery timelines

Monitor communication and support behavior

Fine-tune product specs and expectations

Only after a successful trial run should you commit to a long-term, bulk-order partnership.

Advantages of Working with the Right Manufacturer

Once you’ve locked in the right partner, the benefits are enormous:

Consistent product quality

Improved supply chain efficiency

Higher customer satisfaction

Cost control and better profit margins

Opportunities for co-development and product innovation

Scalability for future growth

It essentially becomes a win-win relationship where both parties benefit from aligned goals and transparent operations.

The Future of Spare Parts Manufacturing

The automobile industry is undergoing a revolution. With electric vehicles, autonomous driving systems, and AI-based diagnostics entering the mainstream, manufacturers too are evolving rapidly.

Tomorrow’s top automobile spare parts manufacturers will not just supply parts, they'll deliver smart solutions, real-time inventory updates, predictive maintenance data, and customized components using 3D printing or additive manufacturing.

Being early in choosing such innovative partners will give your business a long-term edge in both capability and market reach.

Final Thoughts

Choosing the right automobile spare parts manufacturer is more than a procurement task; it's a strategic business decision. It influences your brand reliability, customer satisfaction, and overall operational success.

Take your time to assess, communicate, test, and validate every partnership. Ask the right questions. Demand transparency. And above all, ensure that your supplier is ready to grow with you, not just supply to you.

Looking for a Trusted Spare Parts Manufacturing Partner?

Get in touch with Ace Forge, the reliable name in quality, consistency, and delivery. Visit https://www.aceforge.in/ to know more details.

Partner with Ace Forge Today – Where Precision Meets Performance.

1 note

·

View note

Text

Inspection Equipment Testing Services: Your Precision and Safety Experts

In industries, the growing competition requires optimum equipment operations that mark the paramount importance of precision and safety. This inspection equipment plays a crucial role in maintaining quality standards and preventing potential hazards avoiding any business disruption. For this reason, Inspection equipment testing services are essential for any business domain heavily dependent on machinery to ensure the accuracy and reliability of these tools.

We involve comprehensive quality checks and evaluation of various inspection tools, such as gauges, meters, scanners, and analysers, to verify their accuracy and functionality. These services are typically performed by specialized technicians who follow stringent testing protocols to test equipment on various parameters critical for the production process.

Importance of Inspection Equipment Testing Services:

Quality Assurance: Precise inspection equipment is crucial for maintaining product quality and process efficiency. It allows regular testing that guarantees that measurements will be accurate and consistent.

Safety Compliance: Industries like manufacturing, aerospace, and healthcare rely on inspection equipment for safety and compliance with best business practices. The correct functioning of devices through inspection reduces the risk of accidents and largely ensures adherence to regulations.

Cost Efficiency: Faulty inspection equipment can lead to flawed products, production downtime, and rework costs that can significantly hamper business image. Leveraging Inspection equipment testing services prevent these issues by detecting problems early, saving both time and money.

Data Integrity: Inspection equipment often generates crucial data that plays an important role in decision-making. If these instruments are inaccurate, it can lead to incorrect data conclusions which can be avoided by regular testing safeguards.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

ABP Powers: A Trusted Name Among Servo Stabilizer Suppliers

In an increasingly electrified and digital world, maintaining consistent voltage supply is vital for the smooth operation of electronic and industrial equipment. Power fluctuations, surges, and voltage drops can severely damage sensitive machinery and disrupt business continuity. To combat these issues, voltage stabilizers have become essential. Leading the way in this field is ABP Powers, one of India’s most reliable servo stabilizer suppliers, known for quality, innovation, and performance.

Who is ABP Powers?

ABP Powers is a well-established player in the power conditioning and backup solutions market. With years of expertise and a deep understanding of the electrical ecosystem, the company has carved a niche for itself in manufacturing high-performance voltage stabilizers, UPS systems, and other power control devices. Among the many servo stabilizer suppliers in the market, ABP Powers stands out for its robust product range, technical excellence, and customer-centric approach.

What Are Servo Stabilizers?

Servo voltage stabilizers are advanced power regulation devices that maintain a constant voltage level, ensuring that connected equipment receives a steady and optimal power supply. Unlike conventional stabilizers, servo stabilizers operate with a motor-controlled stabilization system, offering greater accuracy and reliability. These are particularly useful for sensitive industrial and commercial applications, such as CNC machines, printing equipment, medical instruments, and telecom systems.

ABP Powers’ Servo Stabilizers: Engineered for Excellence

ABP Powers designs and manufactures a comprehensive range of servo voltage stabilizers for single-phase and three-phase systems. These stabilizers are engineered to handle high input voltage fluctuations, ensuring that critical systems operate efficiently and without interruption.

Here’s what makes ABP Powers a leading choice among servo stabilizer suppliers:

Wide Input Voltage Range: Their stabilizers are built to perform efficiently even in areas with extreme voltage variations, making them suitable for both urban and rural settings.

Digital Control Panels: ABP stabilizers are equipped with digital microprocessor-based control systems that enhance precision, monitoring, and control.

Heavy-Duty Build Quality: Constructed with durable materials and premium-grade components, ABP stabilizers are designed for longevity, with minimal maintenance requirements.

Custom Configurations: The company offers tailor-made solutions to meet the specific needs of different industries, whether it's a manufacturing unit, hospital, school, or IT facility.

Energy Efficiency: ABP Powers' servo stabilizers not only protect equipment but also help reduce energy wastage by ensuring optimal voltage supply, contributing to cost savings and sustainability.

Why Choose ABP Powers Over Other Servo Stabilizer Suppliers?

ABP Powers doesn’t just manufacture products—they deliver solutions. Unlike generic servo stabilizer suppliers, ABP provides end-to-end support, including site inspection, load analysis, system recommendation, installation, and after-sales service. Their team of engineers works closely with clients to understand their requirements and provide the most suitable voltage regulation system.

Additionally, ABP Powers backs its products with excellent warranties and prompt service support, ensuring peace of mind for customers. Their service network spans across major Indian cities and is continuously expanding, enabling timely maintenance and technical assistance.

Commitment to Quality and Compliance

Quality is at the core of ABP Powers’ operations. All products undergo rigorous testing and adhere to national and international standards for safety, performance, and durability. The company continuously invests in research and development to stay ahead in the rapidly evolving energy management sector.

Visit: - https://www.abpups.com/servo-voltage-stabilizer-dealers.html

0 notes

Text

Why 3D CAD Modeling Services Are Essential for Modern Product Design

In the ever-evolving world of product design, speed, precision, and innovation are the key pillars that drive success. Whether you're designing a consumer gadget, a complex mechanical component, or a next-generation vehicle part, you can no longer rely on 2D sketches or outdated tools. Enter 3D CAD modeling services—a game-changer for modern product development.

From idea to prototype and beyond, 3D modeling has become the standard for engineers, designers, and manufacturers worldwide. But why is it so essential? Let’s dive into the major reasons 3D CAD modeling is not just useful, but vital in today’s design landscape.

1. Enhanced Visualization of Designs

3D CAD models bring your ideas to life in a visual, interactive way. Instead of flat drawings, you get detailed, realistic models that can be viewed from every angle. This helps clients, stakeholders, and team members understand the product better—before it’s ever built.

A designer can rotate the object, zoom in to inspect details, and even simulate its behavior under stress—all before creating a prototype.

2. Precision and Accuracy

Modern products demand a level of precision that manual sketches and 2D CAD simply can't match. With 3D CAD modeling services, dimensions, tolerances, and surface details can be controlled to the smallest degree. This is especially important in industries like aerospace, automotive, and healthcare, where even a minor miscalculation can lead to failure.

3. Faster Design Iteration

Need to tweak a design? Want to test multiple concepts before choosing the best one? 3D modeling makes it easy to revise, compare, and improve your product. Changes that once took days now take hours or minutes, accelerating the product development cycle significantly.

4. Better Collaboration Across Teams

Whether you’re working with engineers, marketers, or manufacturers, 3D models create a common visual language everyone can understand. Teams can collaborate in real-time, share files across platforms, and spot potential issues early in the design process. That means fewer delays and smoother production workflows.

5. Simulation and Stress Testing

One of the biggest benefits of 3D modeling in mechanical engineering is the ability to simulate how a product behaves under real-world conditions. Engineers can analyze stress, vibration, thermal dynamics, and other factors—reducing the need for multiple physical prototypes and saving both time and money.

For example, if you're designing a vehicle component, you can simulate how it reacts to high speeds or harsh environments—ensuring it meets both performance and safety standards.

6. Support for Regulatory Compliance

In regions like Australia, compliance with strict technical and safety regulations is non-negotiable���especially in industries such as automotive. 3D CAD modeling helps you meet these standards by ensuring every component is designed and tested with precision.

When it comes to vehicle compliance Australia demands, 3D models allow for detailed reporting, performance analysis, and accurate documentation—making certification easier and faster.

7. Streamlined Manufacturing and Prototyping

Modern manufacturing methods—like CNC machining, injection molding, and 3D printing—rely heavily on digital 3D models. By using CAD-based outputs, manufacturers can program machines with pinpoint accuracy, reducing waste and ensuring consistent quality.

Whether you’re developing a consumer product or an industrial machine part, having a 3D model means smoother handoffs from design to production.

Final Thoughts

From concept to completion, 3D CAD modeling stands as the backbone of efficient, innovative, and high-quality product design. It enables teams to visualize ideas, simulate real-world performance, ensure compliance, and streamline the manufacturing process—all while saving time and resources.

If you're serious about staying competitive in today’s fast-paced design world, 3D CAD modeling services are not just an option—they're a necessity.

Whether you're working on complex machinery, consumer tech, or components tied to vehicle compliance Australia standards, leveraging 3D design is your path to precision and performance.

So the next time you start a new design, remember: good ideas start on paper, but great products come to life in 3D.

0 notes

Text

Why 3D CAD Modeling Services Are Essential for Modern Product Design

In the ever-evolving world of product design, speed, precision, and innovation are the key pillars that drive success. Whether you're designing a consumer gadget, a complex mechanical component, or a next-generation vehicle part, you can no longer rely on 2D sketches or outdated tools. Enter 3D CAD modeling services—a game-changer for modern product development.

From idea to prototype and beyond, 3D modeling has become the standard for engineers, designers, and manufacturers worldwide. But why is it so essential? Let’s dive into the major reasons 3D CAD modeling is not just useful, but vital in today’s design landscape.

1. Enhanced Visualization of Designs

3D CAD models bring your ideas to life in a visual, interactive way. Instead of flat drawings, you get detailed, realistic models that can be viewed from every angle. This helps clients, stakeholders, and team members understand the product better—before it’s ever built.

A designer can rotate the object, zoom in to inspect details, and even simulate its behavior under stress—all before creating a prototype.

2. Precision and Accuracy

Modern products demand a level of precision that manual sketches and 2D CAD simply can't match. With 3D CAD modeling services, dimensions, tolerances, and surface details can be controlled to the smallest degree. This is especially important in industries like aerospace, automotive, and healthcare, where even a minor miscalculation can lead to failure.

3. Faster Design Iteration

Need to tweak a design? Want to test multiple concepts before choosing the best one? 3D modeling makes it easy to revise, compare, and improve your product. Changes that once took days now take hours or minutes, accelerating the product development cycle significantly.

4. Better Collaboration Across Teams

Whether you’re working with engineers, marketers, or manufacturers, 3D models create a common visual language everyone can understand. Teams can collaborate in real-time, share files across platforms, and spot potential issues early in the design process. That means fewer delays and smoother production workflows.

5. Simulation and Stress Testing

One of the biggest benefits of 3D modeling in mechanical engineering is the ability to simulate how a product behaves under real-world conditions. Engineers can analyze stress, vibration, thermal dynamics, and other factors—reducing the need for multiple physical prototypes and saving both time and money.

For example, if you're designing a vehicle component, you can simulate how it reacts to high speeds or harsh environments—ensuring it meets both performance and safety standards.

6. Support for Regulatory Compliance

In regions like Australia, compliance with strict technical and safety regulations is non-negotiable—especially in industries such as automotive. 3D CAD modeling helps you meet these standards by ensuring every component is designed and tested with precision.

When it comes to vehicle compliance Australia demands, 3D models allow for detailed reporting, performance analysis, and accurate documentation—making certification easier and faster.

7. Streamlined Manufacturing and Prototyping

Modern manufacturing methods—like CNC machining, injection molding, and 3D printing—rely heavily on digital 3D models. By using CAD-based outputs, manufacturers can program machines with pinpoint accuracy, reducing waste and ensuring consistent quality.

Whether you’re developing a consumer product or an industrial machine part, having a 3D model means smoother handoffs from design to production.

Final Thoughts

From concept to completion, 3D CAD modeling stands as the backbone of efficient, innovative, and high-quality product design. It enables teams to visualize ideas, simulate real-world performance, ensure compliance, and streamline the manufacturing process—all while saving time and resources.

If you're serious about staying competitive in today’s fast-paced design world, 3D CAD modeling services are not just an option—they're a necessity.

Whether you're working on complex machinery, consumer tech, or components tied to vehicle compliance Australia standards, leveraging 3D design is your path to precision and performance.

So the next time you start a new design, remember: good ideas start on paper, but great products come to life in 3D.

0 notes

Text

Leading PCB Manufacturers in India – Spotlight on Vaishnavi Electronics

The rapid expansion of India’s electronics industry has fueled the growing demand for high-quality printed circuit boards (PCBs). From consumer electronics and automotive systems to medical devices and industrial machinery, PCBs form the backbone of virtually every electronic product. In this competitive landscape, Vaishnavi Electronics has emerged as one of the leading PCB manufacturers in India, offering reliable, cost-effective, and customized PCB solutions across multiple industries.

PCBs are essential for providing electrical connectivity and mechanical support to electronic components. Whether in a simple home appliance or a complex communication system, a well-designed and well-manufactured PCB ensures stable performance and long-lasting operation. The Indian market has seen a significant rise in demand for both basic and advanced PCBs, including single-sided, double-sided, multilayer, and metal-clad variants. Companies like Vaishnavi Electronics are playing a crucial role in fulfilling this need by delivering products that meet both domestic and international standards.

Vaishnavi Electronics brings years of expertise in PCB manufacturing and a strong focus on quality, innovation, and customer satisfaction. The company offers a comprehensive range of PCB types, including single-layer PCBs for basic applications, double-layer PCBs for more complex circuits, and metal-clad PCBs designed for high thermal performance. Their manufacturing capabilities are backed by modern machinery, skilled technicians, and rigorous quality control processes, ensuring each board is reliable and precise.

What sets Vaishnavi Electronics apart is its ability to provide end-to-end PCB manufacturing services. From initial design consultation and prototyping to full-scale production and final testing, the company supports clients through every stage of the product development process. Their in-house team of engineers works closely with clients to understand specific requirements, suggest design improvements, and optimize layouts for better manufacturability and performance.

Customization is one of the core strengths of Vaishnavi Electronics. They offer a wide range of materials, board thicknesses, copper weights, and surface finishes to suit different applications and budgets. Whether a customer needs PCBs for LED lighting, industrial automation, medical instruments, or power electronics, the company delivers solutions that are both technically sound and cost-effective.

The company’s manufacturing unit is equipped with advanced production and inspection tools such as CNC drilling machines, automated solder mask printers, and high-precision testers. This enables them to meet tight tolerances and deliver consistent quality across small and large production runs. Their focus on continuous improvement and investment in modern technologies has helped them stay ahead in an ever-evolving market.

Apart from technical excellence, Vaishnavi Electronics also prioritizes timely delivery and responsive customer service. They understand the importance of speed in the electronics industry and strive to reduce lead times without compromising quality. Their flexible approach allows them to accommodate urgent orders, design changes, and volume fluctuations, which is a critical advantage for clients in fast-paced markets.

Environmental responsibility is another key pillar of Vaishnavi Electronics' operations. The company adheres to eco-friendly practices by minimizing chemical waste, recycling production materials, and using RoHS-compliant components. This commitment to sustainability not only meets regulatory standards but also aligns with the global shift toward greener electronics manufacturing.

India is fast becoming a global hub for electronics manufacturing, and PCB producers like Vaishnavi Electronics are central to this growth. By combining technical knowledge, modern infrastructure, and a client-focused approach, the company has earned the trust of customers both in India and abroad.

Conclusion: For businesses seeking a dependable and innovative PCB manufacturers in India, Vaishnavi Electronics offers unmatched quality, flexibility, and support. Their ability to deliver customized solutions across industries makes them a standout name in the Indian PCB manufacturing sector. As the demand for smart and efficient electronic systems continues to grow, Vaishnavi Electronics remains a key contributor to India’s electronics manufacturing success story.

Visit:- https://www.vaishnavielectronics.co.in/pcb.html

0 notes

Text

Boosting Efficiency with the Right Production Tool: A Complete Guide

In today's competitive business landscape, efficiency, quality, and speed are more important than ever. Whether you're in manufacturing, media, or software development, the tools you use have a direct impact on productivity. That’s where a production tool comes into play.

A production tool refers to any equipment, software, or resource used in the creation or manufacturing of a product. These tools are essential for turning raw materials or concepts into finished goods or services. They help streamline operations, reduce errors, and improve consistency.

But what exactly are production tools? And how do they help different industries? Let’s explore.

What is a Production Tool?

A production tool is any tool, machine, software, or system used to support the production process. These tools help in manufacturing, assembling, editing, designing, or delivering a final product.

Depending on the industry, a production tool can be:

Mechanical: Like a welding machine or CNC machine in manufacturing.

Digital: Like video editing software or CAD (Computer-Aided Design) tools.

Process-related: Like ERP (Enterprise Resource Planning) systems or scheduling software.

Regardless of type, the goal of a production tool is to make production faster, easier, and more accurate.

Importance of Production Tools in Various Industries

1. Manufacturing

In factories and workshops, production tools include cutting machines, molds, dies, and assembly robots. These tools improve speed and precision, reduce waste, and lower production costs.

2. Media & Entertainment

For content creators, production tools like cameras, microphones, and editing software (e.g., Adobe Premiere Pro, Final Cut Pro) are essential for creating high-quality videos, music, or animations.

3. Construction

Tools such as drills, saws, measuring devices, and planning software help construction teams build efficiently and safely.

4. Software Development

Developers use production tools like code editors, testing frameworks, version control systems (like Git), and deployment tools to build and maintain software efficiently.

5. Food & Beverage

Mixers, ovens, packaging machines, and quality control software help maintain consistency and meet hygiene standards.

Benefits of Using the Right Production Tool

Using the right tools can completely transform your workflow. Here are some key benefits:

Increased Productivity: Automating repetitive tasks saves time and boosts output.

Improved Accuracy: Precision tools reduce errors and improve the quality of the final product.

Cost Efficiency: Better tools reduce material waste and labor costs.

Consistency: Tools ensure the same result every time, which is vital for brand trust and customer satisfaction.

Safety: Modern production tools come with safety features to protect workers and minimize risks.

Choosing the Right Production Tool

When selecting a production tool, consider these key factors:

Purpose: What task will the tool perform?

Scalability: Will the tool grow with your production demands?

Ease of Use: Is it user-friendly, or will it require extensive training?

Maintenance & Support: Can it be easily maintained, and is support available?

Cost: Does it fit your budget and offer good return on investment?

Investing in high-quality tools may seem expensive initially but often pays off in the long run through better efficiency and fewer problems.

Latest Trends in Production Tools

AI-Powered Tools: Artificial intelligence is being integrated into production tools to make smarter decisions, predict issues, and improve performance.

Cloud-Based Software: From video editing to ERP systems, cloud tools allow for real-time collaboration and remote access.

3D Printing: Revolutionizing manufacturing, 3D printers allow for rapid prototyping and on-demand production.

IoT (Internet of Things): Smart production tools connected via the internet provide real-time data, helping optimize production processes.

Final Thoughts

A production tool is more than just a piece of equipment or software—it’s an investment in your business's future. The right tools empower teams to work smarter, reduce mistakes, and deliver better results faster.

Whether you're a small startup or a large enterprise, understanding your production needs and equipping your team with the right tools is key to staying ahead in the market. As technology evolves, staying updated with the latest tools and innovations can give your business a strong competitive edge.

So, if you’re looking to improve workflow, reduce costs, and scale efficiently, start by evaluating your current tools and identifying where upgrades could make a big difference.

FAQs About Production Tools

Q1: What is the difference between a production tool and a production process? A: A production tool is a machine or software used to perform specific tasks during production. A production process refers to the full sequence of steps taken to manufacture or deliver a product.

Q2: Can small businesses afford advanced production tools? A: Yes. Many modern tools come in scalable and affordable versions, making it easier for small businesses to access high-quality production tools without breaking the bank.

Q3: Are digital production tools better than manual ones? A: Digital tools often offer greater speed, accuracy, and automation. However, manual tools still have value in certain industries and applications. The best choice depends on your specific needs and budget.

Visit Us : https://www.cheefatt.com/categories

0 notes