#cncmaker

Explore tagged Tumblr posts

Video

youtube

MX220 Carves a Fake Mountain on Marble #cnc #cncmilling #cncmaker #mach...

0 notes

Photo

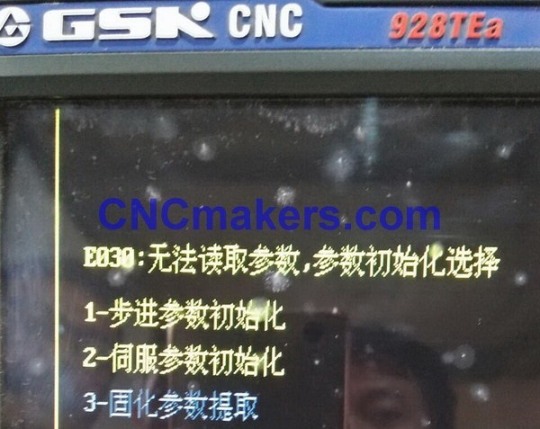

GSK928TEa User: Hello sir, our GSK 928 TEa CNC controller shows E030 error, what should we do? CNCmakers support: The E030 alarm for the GSK928TEa means the mainboard is broken, need to change a new GSK928TEa CNC controller https://paycnc.com/gsk928tea_p0062.html https://www.instagram.com/p/CiRV-6vJ2oV/?igshid=NGJjMDIxMWI=

0 notes

Text

GSK928TEa User:

Hello sir, our GSK 928 TEa CNC controller shows E030 error, what should we do?

CNCmakers support:

The E030 alarm for the GSK928TEa means the mainboard is broken, need to change a new GSK928TEa CNC controller

https://paycnc.com/gsk928tea_p0062.html

0 notes

Photo

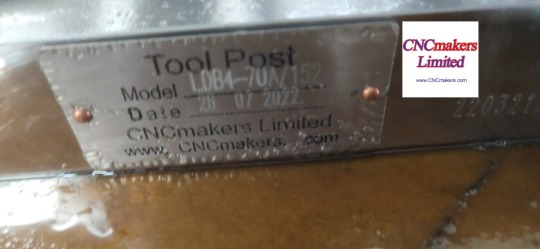

4 position tool turret from CNCmakers https://paycnc.com/c/electric-turret-nc-turret_0365 https://www.instagram.com/p/CgeHw9QJrPu/?igshid=NGJjMDIxMWI=

1 note

·

View note

Text

4 position tool turret from CNCmakers

https://paycnc.com/c/electric-turret-nc-turret_0365

0 notes

Photo

GSK983Ma 423 Alarm with new replaced DA98B-20 The position deviation value of axis Y exceeds +-327687... Speed instruction value of DA converter is beyond +81... Dear Sir, Kindly, we had error 14 on drive DA98B-20 of Y axis, on another cnc machine. So, we replaced the drive by a new one, and entered the parameters as in the old drive. But when we try to run the Y axis, we have alarm 423 on the cnc screen. What could be the problem? The old drive parameters are: Pa01 = 88 Pa05 = 400 Pa06 = 6 Pa07 = 1000 Pa09 = 35 Pa11 = 100 Pa19 = 1 Pa20 = 1 Pa21 = 30 Pa22 = 1 Pa23 = 2500 Pa24 = 100 Pa25 = -50 Pa26 = 200 Pa27 = -300 Pa28 = 500 Pa29 = 2500 Pa30 = 1 Pa32 = 0 Pa36 = 100 Pa37 = -100 Pa38 = 100 (other parameters are as factory setting) CNCmakers Support: New DA98B-20 install on GSK983Ma, need to change PA4=1 https://www.paycnc.com/c/gsk-da98b-ac-servo-driver_0375 https://www.instagram.com/p/CgJZeY2uI8B/?igshid=NGJjMDIxMWI=

0 notes

Text

GSK983Ma 423 Alarm with new replaced DA98B-20

The position deviation value of axis Y exceeds +-327687...

Speed instruction value of DA converter is beyond +81...

Dear Sir,

Kindly, we had error 14 on drive DA98B-20 of Y axis, on another cnc machine.

So, we replaced the drive by a new one, and entered the parameters as in the old drive.

But when we try to run the Y axis, we have alarm 423 on the cnc screen.

What could be the problem?

The old drive parameters are:

Pa01 = 88

Pa05 = 400

Pa06 = 6

Pa07 = 1000

Pa09 = 35

Pa11 = 100

Pa19 = 1

Pa20 = 1

Pa21 = 30

Pa22 = 1

Pa23 = 2500

Pa24 = 100

Pa25 = -50

Pa26 = 200

Pa27 = -300

Pa28 = 500

Pa29 = 2500

Pa30 = 1

Pa32 = 0

Pa36 = 100

Pa37 = -100

Pa38 = 100

(other parameters are as factory setting)

CNCmakers Support:

New DA98B-20 install on GSK983Ma, need to change PA4=1

https://www.paycnc.com/c/gsk-da98b-ac-servo-driver_0375

0 notes

Photo

GSK983Ma 423 Alarm with new replaced DA98B-20 The position deviation value of axis Y exceeds +-327687... Speed instruction value of DA converter is beyond +81... Dear Sir, Kindly, we had error 14 on drive DA98B-20 of Y axis, on another cnc machine. So, we replaced the drive by a new one, and entered the parameters as in the old drive. But when we try to run the Y axis, we have alarm 423 on the cnc screen. What could be the problem? The old drive parameters are: Pa01 = 88 Pa05 = 400 Pa06 = 6 Pa07 = 1000 Pa09 = 35 Pa11 = 100 Pa19 = 1 Pa20 = 1 Pa21 = 30 Pa22 = 1 Pa23 = 2500 Pa24 = 100 Pa25 = -50 Pa26 = 200 Pa27 = -300 Pa28 = 500 Pa29 = 2500 Pa30 = 1 Pa32 = 0 Pa36 = 100 Pa37 = -100 Pa38 = 100 (other parameters are as factory setting) CNCmakers Support: New DA98B-20 install on GSK983Ma, need to change PA4=1 https://www.paycnc.com/c/gsk-da98b-ac-servo-driver_0375 https://www.instagram.com/p/CfDR0w1vn9b/?igshid=NGJjMDIxMWI=

0 notes

Text

GSK983Ma 423 Alarm with new replaced DA98B-20

The position deviation value of axis Y exceeds +-327687...

Speed instruction value of DA converter is beyond +81...

Dear Sir,

Kindly, we had error 14 on drive DA98B-20 of Y axis, on another cnc machine.

So, we replaced the drive by a new one, and entered the parameters as in the old drive.

But when we try to run the Y axis, we have alarm 423 on the cnc screen.

What could be the problem?

The old drive parameters are:

Pa01 = 88

Pa05 = 400

Pa06 = 6

Pa07 = 1000

Pa09 = 35

Pa11 = 100

Pa19 = 1

Pa20 = 1

Pa21 = 30

Pa22 = 1

Pa23 = 2500

Pa24 = 100

Pa25 = -50

Pa26 = 200

Pa27 = -300

Pa28 = 500

Pa29 = 2500

Pa30 = 1

Pa32 = 0

Pa36 = 100

Pa37 = -100

Pa38 = 100

(other parameters are as factory setting)

CNCmakers Support:

New DA98B-20 install on GSK983Ma, need to change PA4=1

https://www.paycnc.com/c/gsk-da98b-ac-servo-driver_0375

0 notes

Photo

Ready To Receive Receiving GSK928TEII GSK928TEII User: Dear CNCmakers, Why I push all button CNC ready receiving, we are transferring data from PC to GSK928TEII with RS232 cable, the screen shows:Ready To Receive Receiving. But there is no any response when I press any buttons. For input program transfer use rs232 I push edit than R than all button status receiving Ussualy I must write number program first This is the first time use rs232 Maybe I wrong procedure? CNCmakers Support: For input program transfer use rs232 I push edit than R than all button status receiving. If unplug the RS232 cable still the same. Then please check if there is any wet inside the controller If it is not wet, then it could be the mainboard problem https://www.paycnc.com/gsk928tea_p0062.html https://www.instagram.com/p/CezstvTJsaV/?igshid=NGJjMDIxMWI=

0 notes

Text

Ready To Receive Receiving GSK928TEII

GSK928TEII User:

Dear CNCmakers, Why I push all button CNC ready receiving, we are transferring data from PC to GSK928TEII with RS232 cable, the screen shows:Ready To Receive Receiving. But there is no any response when I press any buttons.

For input program transfer use rs232 I push edit than R than all button status receiving

Ussualy I must write number program first

This is the first time use rs232

Maybe I wrong procedure?

CNCmakers Support:

For input program transfer use rs232 I push edit than R than all button status receiving.

If unplug the RS232 cable still the same. Then please check if there is any wet inside the controller

If it is not wet, then it could be the mainboard problem

https://www.paycnc.com/gsk928tea_p0062.html

0 notes

Photo

Input power of CNC retrofit kit GSK218MC CNC Retrofit kit User: Hi, we are retrofitting your system on our machine and have some questions for power supply. Please see attached image. 1. What is the pinout for R, S and T connections marked in photo? 2. 3 phase transformer converting down to 220V is needed? 3. Is it possible to run the system from 1phase power supply? If yes - could you provide connection diagram? CNCmakers Support: 1. What is the pinout for R, S and T connections marked in photo? R S T are input power 220V/3 phases 2. 3 phase transformer converting down to 220V is needed? Yes, needed. 3. Is it possible to run the system from 1phase power supply? If yes - could you provide connection diagram? Can not run the system from 1phase power supply. http://cncmakers.com/cnc/controllers/CNC_Controller_System/CNC_Retrofit_Package.html https://www.instagram.com/p/CeiZ6rYOkyq/?igshid=NGJjMDIxMWI=

0 notes

Text

Input power of CNC retrofit kit

GSK218MC CNC Retrofit kit User:

Hi, we are retrofitting your system on our machine and have some questions for power supply. Please see attached image.

1. What is the pinout for R, S and T connections marked in photo?

2. 3 phase transformer converting down to 220V is needed?

3. Is it possible to run the system from 1phase power supply? If yes - could you provide connection diagram?

CNCmakers Support:

1. What is the pinout for R, S and T connections marked in photo?

R S T are input power 220V/3 phases

2. 3 phase transformer converting down to 220V is needed?

Yes, needed.

3. Is it possible to run the system from 1phase power supply? If yes - could you provide connection diagram?

Can not run the system from 1phase power supply.

http://cncmakers.com/cnc/controllers/CNC_Controller_System/CNC_Retrofit_Package.html

0 notes

Photo

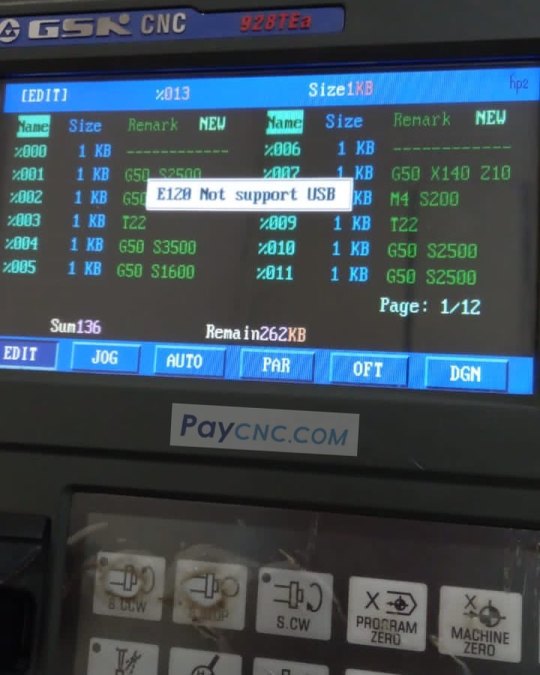

GSK 928TEa User: Hello sir, there is alarm on GSK928TEa CNC controller E120 Not Support USB How can we solve this problem? CNCmakers Support: Please try another USB flash GSK 928TEa User: We have tried 7 different USB, but still the same problem. CNCmakers Support: It has to be FAT32, and the size must be smaller than 8G. GSK 928TEa User: Okay, thank you sir. https://www.paycnc.com/gsk928tea_p0062.html https://www.instagram.com/p/CePh6f3vFRc/?igshid=NGJjMDIxMWI=

0 notes

Text

GSK 928TEa User:

Hello sir, there is alarm on GSK928TEa CNC controller

E120 Not Support USB

How can we solve this problem?

CNCmakers Support:

Please try another USB flash

GSK 928TEa User:

We have tried 7 different USB, but still the same problem.

CNCmakers Support:

It has to be FAT32, and the size must be smaller than 8G.

GSK 928TEa User:

Okay, thank you sir.

https://www.paycnc.com/gsk928tea_p0062.html

0 notes

Photo

KND CNC controller K1TB3-AS LCD Display screen https://paycnc.com/knd-k1tb3-as-lcd-dispay-screen_p6754.html https://www.instagram.com/cncmakers/p/CZGL9RTJnQt/?utm_medium=tumblr

0 notes