#cost and estimation in electrical engineering

Explore tagged Tumblr posts

Text

Is Your Estimator Holding You Back? Signs You Need a Pro Estimating Partner.

In the fast-paced world of Australian construction, every dollar counts and every delay matters. Accurate, timely estimating isn’t just a task — it’s the foundation of your project’s success. Yet, many builders and contractors struggle with outdated, in-house estimating practices that slow them down or eat into profits.

So, how do you know if your current estimator is helping or hurting your business?

Here are the red flags to watch out for — and why partnering with a professional estimating team like Estimating Solutions Group (ESG) could be your smartest move this year.

🔴 1. You’re Losing Tenders — Over and Over

If your bids are frequently unsuccessful, the issue might not be your price — it could be your estimate. An overly conservative estimate may push your pricing too high. On the flip side, underestimating can lead to razor-thin margins or losses after project kick-off.

✅ Pro solution: ESG helps you strike the right balance — accurate, competitive estimates backed by years of experience in the Australian market.

⏱️ 2. Your Estimates Take Too Long

Time is money. If you’re waiting days or weeks for your internal team to complete a cost breakdown, you’re already behind the competition.

✅ Pro solution: Estimating Solutions Group offers fast turnaround times, helping you submit tenders quickly and confidently.

💸 3. Your Projects Keep Running Over Budget

Cost overruns often start with poor estimating. Unexpected material costs, underestimated labour, or missed scope items? That’s a sign your estimating process needs a serious upgrade.

✅ Pro solution: ESG uses tried-and-tested systems, local supplier rates, and a deep understanding of real-world construction costs.

📉 4. You Lack In-House Estimating Expertise

Smaller construction businesses often rely on site supervisors or project managers to “figure out” costs. But without dedicated estimating skills, you risk missing key cost factors or compliance details.

✅ Pro solution: With ESG, you tap into a team of dedicated construction estimators with experience across residential, commercial, civil, and infrastructure projects.

🔍 5. You Can’t Scale Because Estimating Is Bottlenecked

Want to take on more projects but are stuck waiting on estimates? That’s a growth killer.

✅ Pro solution: Outsourcing to ESG means you can scale your business without hiring extra internal staff. More projects, less overhead.

🔧 6. You’re Not Using Modern Estimating Tools

Still working from spreadsheets and old templates? Estimating software and digital takeoff tools are game-changers — but not everyone has the time or skills to master them.

✅ Pro solution: ESG uses the latest industry tech for efficient takeoffs, BOQs, and cost analysis — saving you time and reducing risk.

👷 Why Estimating Solutions Group?

With clients across Australia, Estimating Solutions Group delivers:

Accurate, detailed estimates

Competitive pricing strategies

Quick turnarounds (even on complex projects)

Ongoing support across all project stages

Whether you're a residential builder, commercial contractor, or developer, ESG can help you increase profitability, win more tenders, and avoid cost surprises.

🔚 Final Thoughts

If any of these warning signs sound familiar, it's time to consider a smarter approach. Don’t let poor estimating hold you back. Level up your estimating with a trusted partner like ESG — and start building with confidence.

👉 Get in touch with the Estimating Solution Group team today to find out how they can support your next project.

#construction estimating service#outsourcing construction estimating#construction estimating consultants#cost and estimation in electrical engineering#Electrical estimating in melbourne#Electrical estimators in melbourne

0 notes

Text

Green energy is in its heyday.

Renewable energy sources now account for 22% of the nation’s electricity, and solar has skyrocketed eight times over in the last decade. This spring in California, wind, water, and solar power energy sources exceeded expectations, accounting for an average of 61.5 percent of the state's electricity demand across 52 days.

But green energy has a lithium problem. Lithium batteries control more than 90% of the global grid battery storage market.

That’s not just cell phones, laptops, electric toothbrushes, and tools. Scooters, e-bikes, hybrids, and electric vehicles all rely on rechargeable lithium batteries to get going.

Fortunately, this past week, Natron Energy launched its first-ever commercial-scale production of sodium-ion batteries in the U.S.

“Sodium-ion batteries offer a unique alternative to lithium-ion, with higher power, faster recharge, longer lifecycle and a completely safe and stable chemistry,” said Colin Wessells — Natron Founder and Co-CEO — at the kick-off event in Michigan.

The new sodium-ion batteries charge and discharge at rates 10 times faster than lithium-ion, with an estimated lifespan of 50,000 cycles.

Wessells said that using sodium as a primary mineral alternative eliminates industry-wide issues of worker negligence, geopolitical disruption, and the “questionable environmental impacts” inextricably linked to lithium mining.

“The electrification of our economy is dependent on the development and production of new, innovative energy storage solutions,” Wessells said.

Why are sodium batteries a better alternative to lithium?

The birth and death cycle of lithium is shadowed in environmental destruction. The process of extracting lithium pollutes the water, air, and soil, and when it’s eventually discarded, the flammable batteries are prone to bursting into flames and burning out in landfills.

There’s also a human cost. Lithium-ion materials like cobalt and nickel are not only harder to source and procure, but their supply chains are also overwhelmingly attributed to hazardous working conditions and child labor law violations.

Sodium, on the other hand, is estimated to be 1,000 times more abundant in the earth’s crust than lithium.

“Unlike lithium, sodium can be produced from an abundant material: salt,” engineer Casey Crownhart wrote in the MIT Technology Review. “Because the raw ingredients are cheap and widely available, there’s potential for sodium-ion batteries to be significantly less expensive than their lithium-ion counterparts if more companies start making more of them.”

What will these batteries be used for?

Right now, Natron has its focus set on AI models and data storage centers, which consume hefty amounts of energy. In 2023, the MIT Technology Review reported that one AI model can emit more than 626,00 pounds of carbon dioxide equivalent.

“We expect our battery solutions will be used to power the explosive growth in data centers used for Artificial Intelligence,” said Wendell Brooks, co-CEO of Natron.

“With the start of commercial-scale production here in Michigan, we are well-positioned to capitalize on the growing demand for efficient, safe, and reliable battery energy storage.”

The fast-charging energy alternative also has limitless potential on a consumer level, and Natron is eying telecommunications and EV fast-charging once it begins servicing AI data storage centers in June.

On a larger scale, sodium-ion batteries could radically change the manufacturing and production sectors — from housing energy to lower electricity costs in warehouses, to charging backup stations and powering electric vehicles, trucks, forklifts, and so on.

“I founded Natron because we saw climate change as the defining problem of our time,” Wessells said. “We believe batteries have a role to play.”

-via GoodGoodGood, May 3, 2024

--

Note: I wanted to make sure this was legit (scientifically and in general), and I'm happy to report that it really is! x, x, x, x

#batteries#lithium#lithium ion batteries#lithium battery#sodium#clean energy#energy storage#electrochemistry#lithium mining#pollution#human rights#displacement#forced labor#child labor#mining#good news#hope

3K notes

·

View notes

Text

okay because I'm seeing some misinfo, here's the story on the Key Bridge collapse

What was the Key Bridge?

The Francis Scott Key Bridge (also called the Key Bridge, the Beltway Bridge, and the Outer Harbor Crossing) was steel-arch continuous-through-truss bridge spanning the Patapsco River south of the Baltimore Harbor. The bridge took 5 years to build and cost an estimated $145 million ($735 million in today's dollars). The full bridge project (including approaches) was 10.9 miles long, but the stretch over the Patapsco was 1.6 miles long and 4 lanes wide, and comprised a length of I-695, the Baltimore Beltway. It traveled between Hawkins Point and Dundalk, and in addition to the I-895 Harbor Tunnel was the primary way for Marylanders to cross from the Eastern Shore to the West. The bridge carried an estimated 11.5 million vehicles per year. There is a lane for ships to pass under the Key Bridge with enough clearance.

Was it structurally sound?

The bridge received its latest inspection in 2022 and received a 6/9 score, which is considered "fair" by federal standards. There was a concern with one of its columns, which was downgraded from a health index of 77.8 to 65.9, but it is not clear yet if this was one of the columns struck by the ship. In 1980 the bridge was struck by a different cargo ship which destroyed a concrete support structure, but the bridge itself was unharmed. There is as of yet no evidence that the bridge collapsed because of poor condition. Experts say the lesson to be learned is about the size and weight of modern cargo ships, and that the bridge was not to blame. Engineers have noted, however, that the bridge's piers lacked protective devices such as fenders.

What was the ship?

The MV Dali is a container ship flying the Singapore flag. It is owned by Grace Ocean Private Ltd. and operated by Synergy Marine Group Ltd. The ship is currently being chartered by Maersk, a Dutch shipping company. It was built in 2015 by Hyundai. The ship is 980 feet long and 157 feet wide. The ship's gross tonnage (its internal volume) is 95,128 tons (190,256,000 pounds). Its deadweight (the weight of cargo it can carry) is 116,851 tons (233,702,000 pounds). The ship was carrying 3,000 containers. The engine is a MAN-B&W 9S90ME putting out 41,480 kilowatts (55,626 horsepower).

Over its lifetime the Dali has been inspected 27 times, and only 2 faults were ever found. On June 27, 2023 the Dali was held in port in Chile due to an issue with the propulsion system. According to an inspector the pressure gauges on the heating system were "unreadable". The fault was fixed before the ship left port.

The Dali is crewed by 22 Indian nationals including 2 maritime pilots.

What happened?

The Dali arrived at the Port of Baltimore on March 23, 2024. At 12:44 AM on March 26, 2024 the Dali left port, beginning its journey to Colombo, Sri Lanka. At 01:26 AM the ship suffered a "complete blackout" and began to drift out of the shipping lane. It is not yet known what caused the electrical failure. The backup generator did not power the propulsion system. At around 01:26 AM the crew of the Dali sent a mayday distress call to the Maryland Department of Transportation (MDOT) informing them of the loss of power and that a collision with the Key Bridge was possible. The anchors were dropped as an emergency measure to attempt to slow or stop the vessel. At the request of one of the pilots traffic flow over the bridge was immediately halted. Black smoke was seen coming from the Dali, which experts believe was the result of the crew managing to restart the power system to regain some maneuvering capability.

At 01:28 AM the Dali, traveling at 8 knots (considered to be a fast speed) collided with a support strut beneath the Key Bridge's metal truss at the southwest end of the bridge. A Baltimore resident said he heard the collision and that it "felt like an earthquake". Emergency teams began receiving 911 calls at 01:30 AM, and the Baltimore Police Department were alerted at 01:35 AM. One of the officers present radioed that he was going to go onto the bridge to alert the construction crew as soon as a second officer arrived, but the bridge collapsed seconds later.

What was the damage?

The Key Bridge has completely collapsed. The metal truss relies on structural tension from the bridge itself to maintain its rigidity. As soon as one of the support columns was destroyed, the rest of the bridge quickly followed.

The damage to the Dali is reported as minimal. The ship was impaled by the bridge's structure above the waterline, but has maintained watertight integrity. The crew has not reported any water contamination from its 1.8 million gallons of marine fuel. 13 containers carrying potentially hazardous material were damaged, and are being inspected by a team of Coast Guard divers. At least 5 vehicles including 3 passenger cars and a cement mixer were detected underwater, but authorities do not believe they were occupied

Who was hurt?

The crew of the Dali reports no casualties, except one crewmember who was hospitalized for minor injuries. There was a crew of 8 construction workers on the Key Bridge filling in potholes. 2 were immediately pulled from the water by rescue crews, with 1 being rushed to emergency care and the other reporting minor injuries and refusing treatment. The hospitalized worker has since been discharged. 1 of those rescued was Mexican. The remaining 6 remain missing. Of those 6, 2 have been identified:

Miguel Luna from El Salvador

Maynor Yassir Suazo Sandoval from Honduras

Of the remaining 4, 2 are Guatemalan nationals. Neither have been identified, but the Guatemalan Foreign Affairs Ministry has stated that they were a 26-year-old from San Luis, Petén, and a 35-year-old from Camotán, Chiquimula. The other 2 are presumed to be Mexican.

Rescue Efforts

The Coast Guard was immediately deployed for search-and-rescue operations. Military Blackhawk helicopters were seen over the river. Rescue efforts were ended at 07:30 PM on March 26, 2024 due to darkness, fog, and cold temperatures. Rear Admiral Shannon Gilreath said "Based on the length of time that we've gone in the search, the extensive search efforts that we put into it, the water temperature -- at this point, we do not believe that we're going to find any of these individuals still alive". Recovery operations resumed at 07:30 AM on March 27, 2024 with all 6 workers presumed dead.

No divers have yet entered the water underneath the bridge. Supervisory Special Agent Brian Hudson of the FBI's Underwater Search and Evidence Response Team said "the debris field is pretty sizable and I know that’s why they’re hesitant to send divers down because some of the debris is still shifting, the heavy weight of the rocks". The FBI has deployed Remotely Operated Vehicles (ROVs) equipped with cameras and SONAR.

Aftermath

At 05:08 AM on March 26, 2024 Transportation Secretary Pete Buttegiege posted on X (formerly Twitter):

"I’ve spoken with Gov. Moore and Mayor Scott to offer USDOT’s support following the vessel strike and collapse of the Francis Scott Key bridge. Rescue efforts remain underway and drivers in the Baltimore area should follow local responder guidance on detours and response."

At 07:30 AM on March 27, 2024 President of the Maryland State Senate Bill Ferguson posted on X (formerly Twitter):

"Over 15,000 in the Balt region rely on daily operations at Port of Baltimore to put food on the table. Today, with Del. @LukeClippinger and colleagues representing Port, we are drafting an emergency bill to provide for income replacement for workers impacted by this travesty."

At around 09:40 AM on March 26, 2024 Maryland Governor Wes Moore and Baltimore Mayor Brandon Scott declared a State of Emergency to take effect at 10:30 AM March 26, 2024, and to last 30 days. Baltimore's Emergency Operations Plan was put into effect.

More than 1,000 personnel from the US Army Corps of Engineers (USACE) have been deployed to assist with clearing the debris and rebuilding efforts. President Joe Biden has pledged that the federal government will pay for the entire reconstruction of the bridge.

Jennifer Homendy, the chair of the National Transportation Safety Board (NTSB) has recovered the Dali's data recorder, and will be inspecting both the Key Bridge and the Dali to determine the cause of the crash and the collapse. She says the investigation could take up to 2 years to complete.

Was it intentional?

According to William DelBagno, head of the FBI's Baltimore field office: "There is no specific or credible information to suggest there are ties to terrorism in this incident".

Secretary of Homeland Security Alejandro Mayorkas said: "There are no indications this was an intentional act".

At least 3 people have been killed in accidents related to ships operated by Synergy in the past 6 years. In 2018 a person on board a Synergy ship in Australia was killed in an accident relating to the vessel's personnel elevator. In 2019 an officer aboard a Synergy vessel in Singapore fell overboard while performing maintenance. In 2023 at least one sailor was killed when a Synergy ship collided with a dredging ship in the Philippines. In the first two cases safety inspectors noted that proper safety procedures had not been adhered to.

Sources

1, 2, 3, 4, 5, 6, 7

#atlas entry#this is still a developing story but all the information herein is accurate and current at time of publishing#baltimore#baltimore bridge collapse#francis scott key bridge#key bridge#I spent an hour collating all this info please give it a reblog

2K notes

·

View notes

Text

“Generative AI uses significant energy and water resources, but companies are generally not reporting details of these uses,” the [Government Accountability Office] said. Things also vary greatly depending on where in the U.S. an AI model is trained. It doesn’t cost the same amount to cool a datacenter in Texas as it does in Oregon. But what the GAO could figure out was startling. “It is not unusual to see new data centers being built with energy needs of 100 to 1000 megawatts, roughly equivalent to powering 80,000 to 800,000 households,” the GAO said. It added that 40 percent of that cost is just cooling the data center, a cost that’s expected to increase as the planet heats up.

[...]

The GAO report also noted that using generative AI as a search engine was far more costly than traditional search methods. “One estimate indicates using generative AI could cost 10 times more than a standard keyword search,” it said. According to the GAO’s estimates, AIs doing 250,000,000 queries a day would use as much electricity as 26,071 U.S. household’s use in a day and 1,100,836 gallons of water.

24 April 2025

153 notes

·

View notes

Text

Tesla’s Wardenclyffe Tower: Built on Sound Math, Undone by Cost and Misunderstanding

Let’s set the record straight—Nikola Tesla’s Wardenclyffe Tower was a high-voltage experimental transmission system grounded in quarter-wave resonance and electrostatic conduction—not Hertzian radiation. And the math behind it? It was solid—just often misunderstood by people applying the wrong physics.

In May 1901, Tesla calculated that to set the Earth into electrical resonance, he needed a quarter-wavelength system with a total conductor length of about 225,000 cm, or 738 feet.

So Tesla’s tower design had to evolve during construction. In a letter dated September 13, 1901, to architect Stanford White, Tesla wrote: “We cannot build that tower as outlined.” He scaled the visible height down to 200 feet. The final structure—based on photographic evidence and Tesla’s own testimony—stood at approximately 187 feet above ground. To meet the required electrical length, Tesla engineered a system that combined spiral coil geometry, an elevated terminal, a 120-foot vertical shaft extending underground, and radial pipes buried outward for approximately 300 feet. This subterranean network, together with the 187-foot tower and carefully tuned inductance, formed a continuous resonant conductor that matched Tesla’s target of 738 feet. He described this strategy in his 1897 patent (No. 593,138) and expanded on it in his 1900 and 1914 patents, showing how to simulate a longer conductor using high-frequency, resonant components. Even with a reduced visible height, Tesla’s system achieved quarter-wave resonance by completing the rest underground—proving that the tower’s electrical length, not its physical height, was what really mattered.

Tesla calculated his voltages to be around 10 million statvolts (roughly 3.3 billion volts in modern SI), so he had to consider corona discharge and dielectric breakdown. That’s why the terminal was designed with large, smooth spherical surfaces—to minimize electric surface density and reduce energy loss. This was no afterthought; it’s a core feature of his 1914 patent and clearly illustrated in his design sketches.

Now, about that ±16 volt swing across the Earth—what was Tesla talking about?

He modeled the Earth as a conductive sphere with a known electrostatic capacity. Using the relation:

ε × P = C × p

Where:

ε is the terminal’s capacitance (estimated at 1,000 cm)

P is the applied voltage (10⁷ statvolts)

C is the Earth’s capacitance, which Tesla estimated at 5.724 × 10⁸ cm (based on the Earth’s size)

p is the resulting voltage swing across the Earth

Plugging in the numbers gives p ≈ 17.5 volts, which Tesla rounded to ±16 volts. That’s a theoretical 32-volt peak-to-peak swing globally—not a trivial claim, but one rooted in his framework.

Modern recalculations, based on updated geophysical models, suggest a smaller swing—closer to ±7 volts—using a revised Earth capacitance of about 7.1 × 10⁸ cm. But that’s not a knock on Tesla’s math. His original ±16V estimate was fully consistent with the cgs system and the best data available in 1901, where the Earth was treated as a uniformly conductive sphere.

The difference between 7 and 16 volts isn’t about wrong numbers—it’s about evolving assumptions. Tesla wrote the equation. Others just adjusted the inputs. His premise—that the Earth could be set into controlled electrical resonance—still stands. Even if the voltage swing changes. The vision didn’t.

Wouldn't that ±16V swing affect nature or people? Not directly. It wasn’t a shock or discharge—it was a global oscillation in Earth’s electric potential, spread evenly across vast distances. The voltage gradient would be tiny at any given point—far less than what’s generated by everyday static electricity. Unless something was specifically tuned to resonate with Tesla’s system, the swing had no noticeable effect on people, animals, or the environment. It was a theoretical signature of resonance, not a hazard. While some early experiments in Colorado Springs did produce disruptive effects—like sparks from metal objects or spooked horses—those involved untuned, high-voltage discharges during Tesla’s exploratory phase. Wardenclyffe, by contrast, was a refined and carefully grounded system, engineered specifically to minimize leakage, discharge, and unintended effects.

And Tesla wasn’t trying to blast raw power through the ground. He described the system as one that would “ring the Earth like a bell,” using sharp, high-voltage impulses at a resonant frequency to create standing waves. As he put it:

“The secondary circuit increases the amplitude only... the actual power is only that supplied by the primary.” —Tesla, Oct. 15, 1901

Receivers, tuned to the same frequency, could tap into the Earth’s oscillating potential—not by intercepting radiated energy, but by coupling to the Earth’s own motion. That ±16V swing wasn’t a bug—it was the signature of resonance. Tesla’s transmitter generated it by pumping high-frequency, high-voltage impulses into the Earth, causing the surface potential to oscillate globally. That swing wasn’t the energy itself—it acted like a resonant “carrier.” Once the Earth was ringing at the right frequency, Tesla could send sharp impulses through it almost instantly, and tuned receivers could extract energy.

So—was it feasible?

According to Tesla’s own patents and 1916 legal testimony, yes. He accounted for insulation, voltage gradients, tuning, and corona losses. His design didn’t rely on brute force, but on resonant rise and impulse excitation. Tesla even addressed concerns over losses in the Earth—his system treated the planet not as a passive resistor but as an active component of the circuit, capable of sustaining standing waves.

Wardenclyffe wasn’t a failure of science. It was a casualty of cost, politics, and misunderstanding. Tesla’s system wasn’t just about wireless power—it was about turning the entire planet into a resonant electrical system. His use of electrostatics, high-frequency resonance, and spherical terminals was decades ahead of its time—and still worth studying today.

“The present is theirs; the future, for which I really worked, is mine.” —Nikola Tesla

#nikola tesla#science#history#quotes#electricity#wireless#technology#mathematics#math#engineering#power#Wardenclyffe#ahead of his time#ahead of our time

85 notes

·

View notes

Text

You know what really grinds my gears?

Working with people who don't understand how a neural computer works.

Be it some mass ratio optimizing payload engineer, a logistics officer frustrated with the difficulties caused by our team's solutions or just our boss looking for reasons to fire us because they thought our initial cost estimate was "unrealistically high" and are now sorely disappointed at reality, these people are miserable to deal with. On the surface, their complaints make sense; we are seemingly doing a much worse job than everyone else is and anything we come up with creates lots of problems for them. Satisfying all their demands, however, is impossible. With this post I intend to educate my audience on

Neural Computers 101

so that my blog's engineer-heavy audience may understand the inevitable troubles those in my field seemingly summon out of thin air and so that you people will hopefully not bother us quite as much anymore.

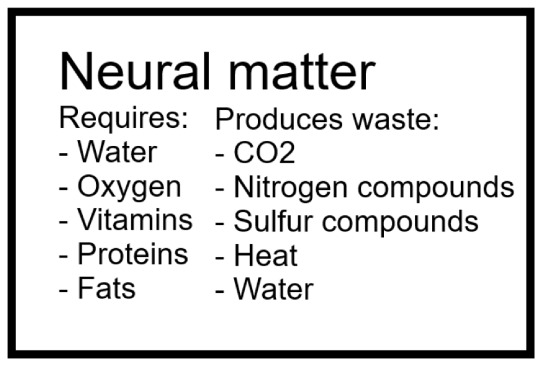

First of all, neural matter is extremely resource heavy. Not by mass, mind you; a BNC of 2 kilograms requires only a few dozen grams of whatever standardized or specialized mix of sustenance is preferred in a single martian day. (I'm not going to bother converting that.) The inconvenient part is the sheer variety in the things they need and the waste products they create.

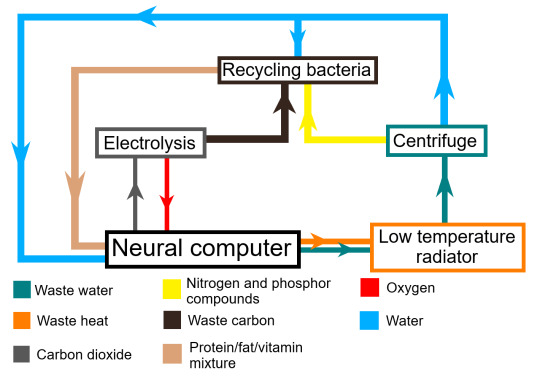

This is just a shortened list, but already it causes problems. If you want to create a self contained system to avoid having to refuel constantly, you will need a lot of mass and a lot of complexity. This is what a typical sustenance diagram for such a system looks like:

(Keep in mind, this diagram doesn't even have electricity drawn in.)

Typically these systems are even more complicated, with redundancies and extra steps. In any case, this is complicated, energy expensive and a nightmare to maintenance crew. I mean, just keeping the bacterial microbiome alive is a lot of effort!

Second of all, neural matter is extremely vulnerable. Most power plant and rocket designers just round away all temperature changes less than 100 K, but neural matter will outright die if its temperature is just a few kelvin off of the typical value. The same goes for a lot of other things - you'll need some serious temperature regulation, shock absorption, radiation shielding (damn it I wish we had access to the same stuff as those madmen in the JMR) and on top of all of that, you need to consider mental instability!

That last one is kind of the biggest pain in the ass for these things - we need to give them a damn game to play whenever they don't have any real work to deal with or they degrade and start to go insane. (Don't worry, I'm not stupid, I know these things aren't actually sentient, I'm just saying that to illustrate the way they work.) It can't even be the same game - you need to design one based on what the NC is designed to do! (Game is a misleading term by the way; it's not like a traditional video game. No graphics - just a set of variables, functions and parameters on a simple circuit board that the NC can influence.)

And lastly, neural computers are complicated. Dear Olympus are they complicated. There are so so many ways to build them, and the process of deriving which one to use is extremely difficult. You can't blame the NC team for an inappropriate computer if the damn specifications keep changing every week!

There's the always-on, calculation-heavy, simple and slow Pennington circuits, the iconic Gobbs cycle (Bloody love that thing!), the Anesuki thinknet and its derivatives, the Klenowicz for those insane venusians and so so many more frameworks for both ANCs and BNCs. Oh yeah, by the way, the acronyms ANC and BNC actually don't stand for Advanced and Basic Neural Computer respectively. They stand for Type A Neural Computer and Type B Neural Computer. It comes from that revolutionary paper written by Anesuki.

12 notes

·

View notes

Text

U.S. Approves Foreign Military Sale for South Korean F-15K Upgrade

The State Department has approved the possible sale of components that will allow South Korea to upgrade its F-15K Slam Eagle fleet to a configuration similar to the F-15EX Eagle II.

Stefano D'Urso

F-15K upgrade

The U.S. State Department has approved on Nov.19, 2024, a possible Foreign Military Sale (FMS) to the Republic of Korea of components that will allow the upgrade of the country’s F-15K Slam Eagle fleet. The package, which has an estimated cost of $6.2 billion, follows the decision in 2022 to launch an upgrade program for the aircraft.

The State Department has approved the possible sale of components that will allow South Korea to upgrade its F-15K Slam Eagle fleet to a configuration similar to the F-15EX Eagle II.The F-15KThe new capabilities

The Slam Eagles are the mainstay of the Republic of Korea Air Force’s (ROKAF) multirole missions, with a particular ‘heavy hitting’ long-range strike role. According to the available data, the country operates 59 F-15Ks out of 61 which were initially fielded in 2005. In 2022, the Defense Acquisition Program Administration (DAPA) approved the launch of an upgrade program planned to run from 2024 to 2034.

In particular, the Defense Security Cooperation Agency’s (DSCA) FMS notice says a number of components were requested for the upgrade, including 96 Advanced Display Core Processor II (ADCP II) mission system computers, 70 AN/APG-82(v)1 Active Electronically Scanned Arrays (AESA) radars, seventy 70 AN/ALQ-250 Eagle Passive Active Warning Survivability System (EPAWSS) electronic warfare (EW) suites and 70 AN/AAR-57 Common Missile Warning Systems (CMWS).

In addition to these, South Korea will also get modifications and maintenance support, aircraft components and spares, consumables, training aids and the entire support package commonly associated with FMS. It is interesting to note that the notice also includes aerial refueling support and aircraft ferry support, so it is possible that at least the initial aircraft will be ferried to the United States for the modifications before the rest are modified in country.

A ROKAF F-15K Slam Eagle drops two GBU-31 JDAM bombs with BLU-109 warhead. (Image credit: ROKAF)

The components included in the possible sale will allow the ROKAF to upgrade its entire fleet of F-15Ks to a configuration similar to the new F-15EX Eagle II currently being delivered to the U.S. Air Force. Interestingly, the Korean configuration will also include the CMWS, currently not installed on the EX, so the F-15K will also require some structural modifications to add the blisters on each side of the canopy rail where the sensors are installed.

“This proposed sale will improve the Republic of Korea’s capability to meet current and future threats by increasing its critical air defence capability to deter aggression in the region and to ensure interoperability with US forces,” says the DSCA in the official notice.

The upgrade of the F-15K is part of a broader modernization of the ROKAF’s fighter fleet. In fact, the service is also upgrading its KF-16s Block 52 to the V configuration, integrating a new AESA radar, mission computer, self-protection suite, with works expected to be completed by 2025. These programs complement the acquisition of the F-35 Lightning II and the KF-21 Boramae.

Ulchi Freedom Shield 24

A ROKAF F-15K Slam Eagle, assigned to the 11th Fighter Wing at Daegu Air Base, takes off for a mission on Aug. 20, 2024. (Image credit: ROKAF)

The F-15K

The F-15K is a variant of the F-15E Strike Eagle built for the Republic of Korea Air Force’s (ROKAF) with almost half of the components manufactured locally. The aircraft emerged as the winner of the F-X fighter program against the Rafale, Typhoon and Su-35 in 2002, resulting in an order for 40 F-15s equipped with General Electric F110-129 engines. In 2005, a second order for 21 aircraft equipped with Pratt & Whitney F100-PW-229 engines was signed.

The Slam Eagle name is derived from the F-15K’s capability to employ the AGM-84H SLAM-ER standoff cruise missiles, with the Taurus KEPD 350K being another weapon exclusive to the ROKAF jet. The F-15K is employed as a fully multi-role aircraft and is considered ad one of the key assets of the Korean armed forces.

With the aircraft averaging an age of 16 years and expected to be in service until 2060, the Defense Acquisition Program Administration (DAPA) launched in 2022 an upgrade program for the F-15Ks. The upgrade, expected to run from 2024 to 2034, is committed to strengthening the mission capabilities and survivability of the jet.

The F-15K currently equips three squadrons at Daegu Air Base, in the southeast of the country. Although based far from the demilitarized zone (DMZ), the F-15K with its SLAM-ER and KEPD 350 missiles can still hit strategic targets deep behind North Korean borders.

An F-15K releases a Taurus KEPD 350K cruise missile. (Image credit: ROKAF)

The new capabilities

It is not yet clear if the F-15K will receive a new cockpit, since its configuration will be similar to the Eagle II. In fact, the F-15EX has a full glass cockpit equipped with a 10×19-inch touch-screen multifunction color display and JHMCS II both in the front and rear cockpit, Low Profile HUD in the front, stand-by display and dedicated engine, fuel and hydraulics display, in addition to the standard caution/warning lights, switches and Hands On Throttle-And-Stick (HOTAS) control.

Either way, the systems will be powered by the Advanced Display Core Processor II, reportedly the fastest mission computer ever installed on a fighter jet, and the Operational Flight Program Suite 9.1X, a customized variant of the Suite 9 used on the F-15C and F-15E, designed to ensure full interoperability of the new aircraft with the “legacy Eagles”.

The F-15K will be equipped with the new AN/APG-82(V)1 Active Electronically Scanned Array (AESA) radar. The radar, which has been developed from the APG-63(V)3 AESA radar of the F-15C and the APG-79 AESA radar of the F/A-18E/F, allows to simultaneously detect, identify and track multiple air and surface targets at longer ranges compared to mechanical radars, facilitating persistent target observation and information sharing for a better decision-making process.

F-15K upgrade

A ROKAF F-15K Slam Eagle takes off for a night mission during the Pitch Black 2024 exercise. (Image credit: Australian Defense Force)

The AN/ALQ-250 EPAWSS will provide full-spectrum EW capabilities, including radar warning, geolocation, situational awareness, and self-protection to the F-15. Chaff and flares capacity will be increased by 50%, with four more dispensers added in the EPAWSS fairings behind the tail fins (two for each fairing), for a total of 12 dispenser housing 360 cartridges.

EPAWSS is fully integrated with radar warning, geo-location and increased chaff and flare capability to detect and defeat surface and airborne threats in signal-dense and highly contested environments. Because of this, the system enables freedom of maneuver and deeper penetration into battlespaces protected by modern integrated air defense systems.

The AN/AAR-57 CMWS is an ultra-violet based missile warning system, part of an integrated IR countermeasures suite utilizing five sensors to display accurate threat location and dispense decoys/countermeasures. Although CMWS was initially fielded in 2005, BAE Systems continuously customized the algorithms to adapt to new threats and CMWS has now reached Generation 3.

@TheAviationist.com

21 notes

·

View notes

Text

Excerpt from this story from Anthropocene Magazine:

U.S. states can decarbonize on their own for about the same price as a federal-led effort to reduce emissions by the same amount, according to a new study. The findings underline that a “coalition of the willing” could not bring the country to net-zero emissions on its own. But they also represent a hopeful vision of how climate action in the U.S. could continue despite Trump Administration rollbacks.

The Biden Administration pursued ambitious decarbonization policies via the Inflation Reduction Act and other initiatives, while the Trump Administration has taken a very different approach to climate policy. The situation highlights the volatility of national-level climate action in the United States, even as the American public broadly supports developing alternative energy sources, and urgent action is needed to avoid locking in fossil fuels with new infrastructure.

Enter “climate federalism,” a concept that casts U.S. states as laboratories not just of democracy but of climate action. In theory, this bottom-up approach might be more effective and durable than top-down action. In the new study, researchers sketch out what it might look like in practice.

“Ultimately the most important takeaway here is that state-led action can achieve substantial emission reductions, even without federal support, but that the world looks very different from one where there is federal coordination,” says study team member Jeremiah Johnson, an environmental engineer at North Carolina State University. “This has some important implications, not just for those states that choose to participate, but also for those who don’t.”

Johnson and his colleagues identified 23 U.S. states that are most likely to pursue net-zero emissions by 2050, based on the number of climate policies currently on the books as well as their overall political leanings. They fed publicly available energy system data into a computer model to estimate the cost of decarbonization and predict the green technologies that the states would likely turn to in their efforts.

Action by this group of states could reduce U.S. greenhouse gas emissions by about 46% by 2050, the researchers report in the journal Nature Communications. The researchers then used the same model to explore what federally coordinated action to reduce national emissions by the same amount would look like.

Federal led climate action would be about 0.7% cheaper than state action, the researchers found. “We were surprised [the state-led] emissions reductions would be achieved at costs comparable to federal actions,” Johnson says. Since only about half of U.S. states were expected to pursue net-zero emissions, “we expected to see this considerably push up the costs of achieving deep decarbonization.”

However, the mix of green technologies that would be used in a state-led decarbonization effort would be different from the federally coordinated one. The state-led effort would lean heavily on green manufacturing technologies to decarbonize industry, while the federal approach would rely more on clean energy such as solar and wind power.

The net-zero states would likely rely on electrification to reduce emissions from transportation and industry, as well as direct air capture to neutralize residual emissions. They might also purchase more electricity from neighboring states, leading to the potential for “emissions leakage.” In the state-led scenario, “we observed substantial new electricity exports from the Great Plains states into the Upper Midwest while those exporting states increased fossil fuel-based use,” Johnson says. “This would undercut the efforts of net-zero states unless their policies are designed to address this.”

The state-led scenario also leaves some cost-effective mitigation opportunities on the table, such as bioenergy with carbon capture and storage in the Southeastern United States, where states are unlikely to pursue decarbonization without federal action. Still, if state-led action is the only option, this can lead to substantial progress on climate, the study shows.

8 notes

·

View notes

Text

LETTERS FROM AN AMERICAN

January 1, 2025

Heather Cox Richardson

Jan 01, 2025

Twenty-five years ago today, Americans—along with the rest of the world—woke up to a new century date…and to the discovery that the years of work computer programmers had put in to stop what was known as the Y2K bug from crashing airplanes, shutting down hospitals, and making payments systems inoperable had worked.

When programmers began their work with the first wave of commercial computers in the 1960s, computer memory was expensive, so they used a two-digit format for dates, using just the years in the century, rather than using the four digits that would be necessary otherwise—78, for example, rather than 1978. This worked fine until the century changed.

As the turn of the twenty-first century approached, computer engineers realized that computers might interpret 00 as 1900 rather than 2000 or fail to recognize it at all, causing programs that, by then, handled routine maintenance, safety checks, transportation, finance, and so on, to fail. According to scholar Olivia Bosch, governments recognized that government services, as well as security and the law, could be disrupted by the glitch. They knew that the public must have confidence that world systems would survive, and the United States and the United Kingdom, where at the time computers were more widespread than they were elsewhere, emphasized transparency about how governments, companies, and programmers were handling the problem. They backed the World Bank and the United Nations in their work to help developing countries fix their own Y2K issues.

Meanwhile, people who were already worried about the coming of a new century began to fear that the end of the world was coming. In late 1996, evangelical Christian believers saw the Virgin Mary in the windows of an office building near Clearwater, Florida, and some thought the image was a sign of the end times. Leaders fed that fear, some appearing to hope that the secular government they hated would fall, some appreciating the profit to be made from their warnings. Popular televangelist Pat Robertson ran headlines like “The Year 2000—A Date with Disaster.”

Fears reached far beyond the evangelical community. Newspaper tabloids ran headlines that convinced some worried people to start stockpiling food and preparing for societal collapse: “JANUARY 1, 2000: THE DAY THE EARTH WILL STAND STILL!” one tabloid read. “ALL BANKS WILL FAIL. FOOD SUPPLIES WILL BE DEPLETED! ELECTRICITY WILL BE CUT OFF! THE STOCK MARKET WILL CRASH! VEHICLES USING COMPUTER CHIPS WILL STOP DEAD! TELEPHONES WILL CEASE TO FUNCTION! DOMINO EFFECT WILL CAUSE A WORLDWIDE DEPRESSION!”

In fact, the fix turned out to be simple—programmers developed updated systems that recognized a four-digit date—but implementing it meant that hardware and software had to be adjusted to become Y2K compliant, and they had to be ready by midnight on December 31, 1999. Technology teams worked for years, racing to meet the deadline at a cost that researchers estimate to have been $300–$600 billion. The head of the Federal Aviation Administration at the time, Jane Garvey, told NPR in 1998 that the air traffic control system had twenty-three million lines of code that had to be fixed.

President Bill Clinton’s 1999 budget had described fixing the Y2K bug as “the single largest technology management challenge in history,” but on December 14 of that year, President Bill Clinton announced that according to the Office of Management and Budget, 99.9% of the government's mission-critical computer systems were ready for 2000. In May 1997, only 21% had been ready. “[W]e have done our job, we have met the deadline, and we have done it well below cost projections,” Clinton said.

Indeed, the fix worked. Despite the dark warnings, the programmers had done their job, and the clocks changed with little disruption. “2000,” the Wilmington, Delaware, News Journal’s headline read. “World rejoices; Y2K bug is quiet.”

Crises get a lot of attention, but the quiet work of fixing them gets less. And if that work ends the crisis that got all the attention, the success itself makes people think there was never a crisis to begin with. In the aftermath of the Y2K problem, people began to treat it as a joke, but as technology forecaster Paul Saffo emphasized, “The Y2K crisis didn’t happen precisely because people started preparing for it over a decade in advance. And the general public who was busy stocking up on supplies and stuff just didn’t have a sense that the programmers were on the job.”

As of midnight last night, a five-year contract ended that had allowed Russia to export natural gas to Europe by way of a pipeline running through Ukraine. Ukraine president Volodymyr Zelensky warned that he would not renew the contract, which permitted more than $6 billion a year to flow to cash-strapped Russia. European governments said they had plenty of time to prepare and that they have found alternative sources to meet the needs of their people.

Today, President Joe Biden issued a statement marking the day that the new, lower cap on seniors’ out-of-pocket spending on prescription drugs goes into effect. The Inflation Reduction Act, negotiated over two years and passed with Democratic votes alone, enabled the government to negotiate with pharmaceutical companies over drug prices and phased in out-of-pocket spending caps for seniors. In 2024 the cap was $3,400; it’s now $2,000.

As we launch ourselves into 2025, one of the key issues of the new year will be whether Americans care that the U.S. government does the hard, slow work of governing and, if it does, who benefits.

Happy New Year, everyone.

LETTERS FROM AN AMERICAN

HEATHER COX RICHARDSON

#Con Man#Mike Luckovich#Letters From An American#heather cox richardson#history#American History#Y2K#do your job#the work of government#Inflation Reduction Act#technology management#the hard slow work of governing

14 notes

·

View notes

Text

Why do headlights dim when a car engine is turned on?

Headlights dimming when you start the car’s engine is usually normal, but it can also signal an underlying electrical issue. Here’s why it happens and when to be concerned:

1. Normal Behavior: Momentary Dimming During Engine Startup

Cause: When you turn the key (or push the start button), the starter motor draws a massive surge of power (150–300+ amps) from the battery. This temporarily drops the battery voltage (from ~12.6V to 9–10V), reducing power to the headlights.

Duration: Dimming lasts 1–2 seconds while the engine cranks. Lights should brighten once the alternator begins charging (~14V).

Typical in: Older vehicles, cars with weaker batteries, or halogen headlights (LEDs are less affected due to lower power draw).

2. Abnormal Dimming: Persistent or Severe Voltage Drop If headlights stay dim after the engine starts or dim while driving, it indicates a problem:

Common Causes

Weak or Failing Battery: • A degraded battery can’t maintain voltage under load. • Test: Check battery voltage (engine off: <12.4V = weak; running: <13.5V = alternator issue).

Faulty Alternator: • Worn brushes, bad diodes, or a loose belt reduce charging capacity. • Symptom: Lights dim when using accessories (AC, heated seats).

Corroded or Loose Connections: • Corrosion on battery terminals, ground straps, or headlight wiring increases resistance, causing voltage drop.

Overloaded Electrical System: • Aftermarket upgrades (amplifiers, light bars) strain the alternator.

3. How to Diagnose

Test the Battery: • Use a multimeter to check voltage (engine off: 12.6V ideal; engine running: 13.5–14.5V). • Load-test the battery at an auto parts store.

Inspect the Alternator: • Rev the engine to 2,000 RPM while monitoring voltage (should stay steady at ~14V).

Check Wiring: • Clean battery terminals with baking soda/water and a wire brush. • Trace ground connections (engine block to chassis) for corrosion.

Reduce Load: • Disconnect aftermarket electronics to see if dimming stops.

4. Solutions

Replace the Battery: Opt for a higher CCA (Cold Cranking Amps) rating if you live in a cold climate.

Repair/Replace Alternator: Rebuild or upgrade to a high-output alternator if needed.

Upgrade Wiring: Replace corroded cables or install a headlight relay harness to reduce voltage drop.

Switch to LEDs: LED bulbs draw less power and are less affected by voltage fluctuations.

When to Worry

Lights stay dim even after the engine starts.

Flickering or random brightness changes while driving.

Battery warning light appears on the dashboard.

Cost Estimates Fix Cost Range Battery replacement $100–$300 Alternator repair/replace $200–$600 Wiring harness upgrade $50–$150 (DIY) LED bulb conversion $40–$200

Key Takeaway: Brief dimming during startup is normal, but persistent dimming means your electrical system needs attention. Address issues early to avoid being stranded with a dead battery! 🔧🔋

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#car culture#race cars#cars#classic cars#car#suv#porsche#truck#supercar#automobile#car light#battery#engine starts#vehicle#futuristic#engineering#headlight bulb#headlamps#headlamp#headlight

4 notes

·

View notes

Text

Best Books and Study Plan for Junior Engineer Aspirants"

The Junior Engineers (JE) Exam is a competitive exam performed by diverse authorities agencies in India to recruit engineering diploma holders into technical positions. This examination gives young engineers a prestigious opportunity to begin their careers in public region corporations like CPWD, MES, Railways, and various kingdom power and water forums. With based boom, task security, and government benefits, JE posts are a dream for lots aspiring engineers.

Junior engineer exam syllabus

Types of Junior Engineer Exams

Several bodies conduct JE recruitment. The most commonplace ones encompass:

Central government exam for posts in CPWD, MES, BRO, and many others.

For Civil, Mechanical, and Electrical engineers.

RRB JE (Railway Recruitment Board – Junior Engineer):

Recruitment for Indian Railways.

Includes Civil, Mechanical, Electrical, Electronics, and IT.

State PSC JE Exams:

Conducted by using nation public carrier commissions.

Recruitment for PWD, WRD, or different nation departments.

PSUs and Other Boards:

Some PSUs and energy boards (like UPPCL, TANGEDCO) conduct their own JE exams.

Eligibility Criteria

Though the criteria vary barely from employer to company, the overall necessities are:

1. Educational Qualification:

Minimum: 3-12 months Diploma in Engineering (Civil / Electrical / Mechanical / Electronics / IT).

Some businesses allow B.E./B.Tech holders as properly.

2. Age Limit:

Usually among 18 to 32 years (varies for one-of-a-kind exams).

Relaxation furnished to SC/ST/OBC/PWD as in line with rules.

3. Nationality:

Must be a citizen of India.

Other standards may additionally encompass Tibetan refugees or human beings of Indian origin from certain nations.

Exam Pattern

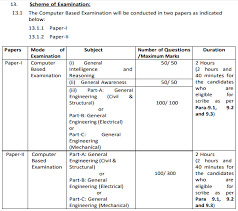

The JE examination commonly accommodates stages:

1. Paper 1 – Objective (Computer Based Test):

General Intelligence & Reasoning – 50 marks

General Awareness – 50 marks

General Engineering (Civil / Electrical / Mechanical) – one hundred marks

Total: two hundred marks

Time: 2 hours

2. Paper 2 – Subjective (Written):

In-intensity engineering questions primarily based on circulate

Total: 300 marks

Time: 2 hours

Note: RRB JE consists of CBT 1, CBT 2, and every now and then Document Verification or Medical Examination.

Syllabus Overview

A. General Intelligence & Reasoning

Analogies, Similarities, Spatial Visualization

Problem Solving, Decision Making

Verbal and Non-Verbal Reasoning

Coding-Decoding, Series, Puzzles

B. General Awareness

Current Affairs, India and its Neighbours

History, Culture, Geography, Polity

Economy, Science and Technology

C. General Engineering Subjects

i. Civil Engineering:

Building Materials, Surveying, Soil Mechanics

Hydraulics, Irrigation Engineering

RCC and Steel Design, Estimating and Costing

ii. Electrical Engineering:

Circuit Theory, Measurement

Electrical Machines, Generation and Transmission

Utilization of Electrical Energy, Basics of Electronics

iii. Mechanical Engineering:

Thermodynamics, Power Engineering

Fluid Mechanics, Theory of Machines

Strength of Materials, Production Engineering

Preparation Tips

1. Understand the Syllabus

Before you start, analyze the whole syllabus. SSC and RRB each offer specified syllabi. Focus in your engineering subject because it incorporates the most marks.

2. Choose Standard Books

For Civil: S. Chand, R.S. Khurmi, and Previous Year Papers

For Mechanical: R.S. Khurmi, Made Easy Notes

For Electrical: J.B. Gupta, Electrical Technology via B.L. Theraja

three. Make a Study Plan

Divide your training into daily or weekly desires. Allocate greater time to your technical situation whilst maintaining every day practice in reasoning and modern affairs.

Four. Practice Previous Year Papers

Solving final 5–10 years' papers is extremely beneficial to understand exam developments and recurring subjects.

Five. Take Mock Tests

Appear for on line or offline mock tests frequently. Analyze your weak areas and revise for that reason.

6. Stay Updated with Current Affairs

Read newspapers, observe monthly magazines like Pratiyogita Darpan, and use modern-day affairs apps.

Career Growth after Selection

Once selected as a Junior Engineer, the profession trajectory is stable and promising:

Promotion Ladder:

Junior Engineer (JE)

Senior Section Engineer / Assistant Engineer

Executive Engineer

Superintending Engineer

Chief Engineer

Benefits:

Central or State Government pay (Level 6 pay matrix or equal)

DA, HRA, Medical, Pension, and other perks

Fixed working hours

Opportunity to work on public infrastructure and country wide improvement

Challenges of the Role

Although being a JE gives activity protection and prestige, it additionally involves demanding situations including:

Field Work: Site inspections, discipline supervision, venture tracking.

Deadlines: Infrastructure or electrical work comes with tight closing dates.

Transfers: Especially in railways or countrywide departments, postings can also change.

Salary Structure

The earnings for a JE varies relying on the department:

Basic Pay: ₹35,400 (Level 6)

In-hand Salary: ₹forty two,000–₹50,000 approx. (inclusive of allowances)

Other blessings: LTC, scientific, organization coverage, and so on.

#Junior engineer exam syllabus#college students#school students#online classes#offline institute classes

2 notes

·

View notes

Text

Best Courses to Study in Australia for Indian Students with High ROI.

Why Australia is a Top Study Abroad Destination in 2025

Australia continues to rank among the top destinations for Indian students seeking world-class education, global career opportunities, and a multicultural lifestyle. With over 100,000 Indian students currently studying in Australia, the trend is fueled by high employability, quality institutions, and welcoming immigration policies. This blog provides a complete study guide in Australia for Indian students, focusing on the top courses offering the highest return on investment (ROI) in 2025.

Top Reasons to Study in Australia for Indian Students

Globally ranked universities like the University of Melbourne, ANU, and UNSW

Post-study work visas for up to 4 years

Pathways to Permanent Residency (PR)

Industry-relevant, skill-based courses

High graduate employability

Scholarships and financial support for Indian students

High ROI Courses for Indian Students in Australia

1. Information Technology and Computer Science

Why It’s Worth It:

Booming tech industry in cities like Sydney and Melbourne

Strong demand for software developers, AI specialists, and cybersecurity analysts

Excellent PR pathways via the Skilled Occupation List (SOL)

Career Opportunities:

Software Developer

Cloud Engineer

Cybersecurity Analyst

Average Salary: AUD 70,000 – 120,000

2. Engineering (Civil, Mechanical, Electrical, Mining)

Why It’s Worth It:

High demand for engineers in infrastructure, renewable energy, and mining

PR-friendly occupations

Hands-on, accredited programs (Engineers Australia recognition)

Career Paths:

Civil Engineer

Structural Engineer

Renewable Energy Consultant

Average Salary: AUD 75,000 – 130,000

3. Health Sciences & Nursing

Why It’s Worth It:

Acute shortage of skilled healthcare workers

Strong employment growth projected until 2030

Offers direct PR routes for nursing graduates

Career Opportunities:

Registered Nurse

Public Health Officer

Physiotherapist

Average Salary: AUD 65,000 – 110,000

4. Business Analytics and Data Science

Why It’s Worth It:

High demand across sectors (banking, retail, healthcare)

Versatile career paths with global appeal

STEM classification supports extended post-study work visa

Career Options:

Data Analyst

Business Intelligence Consultant

Data Scientist

Average Salary: AUD 85,000 – 130,000

5. Accounting and Finance

Why It’s Worth It:

Consistent job demand across Australia

Accredited courses (CPA Australia, CA ANZ)

Opens doors to roles in multinational firms

Career Opportunities:

Chartered Accountant

Financial Analyst

Auditor

Average Salary: AUD 70,000 – 115,000

6. Education and Teaching

Why It’s Worth It:

Australia’s school system seeks qualified teachers, especially in regional areas

Included in the Medium and Long-term Strategic Skills List (MLTSSL)

Roles After Graduation:

Primary School Teacher

Early Childhood Educator

Secondary School Teacher

Average Salary: AUD 65,000 – 100,000

7. Architecture and Construction Management

Why It’s Worth It:

Australia’s urban expansion and infrastructure projects

Recognized qualifications with global applicability

Popular Careers:

Architect

Project Manager

Construction Estimator

Average Salary: AUD 70,000 – 120,000

Cost of Education in Australia (2025)

Course Type

Average Annual Tuition (AUD)

UG Courses

20,000 – 45,000

PG Courses

22,000 – 50,000

MBA

40,000 – 80,000

Scholarships Available for Indian Students

Australia Awards Scholarships – Fully funded by the Australian government

Destination Australia Scholarships – Regional study scholarships worth AUD 15,000

University-Specific Grants – E.g., Monash International Merit Scholarship, University of Sydney International Scholarships

Post-Study Work Rights and PR Pathways

Australia allows international students to work up to 20 hours per week during semesters and full-time during breaks. Graduates can apply for a Temporary Graduate visa (subclass 485), offering work rights for 2–4 years depending on qualification and location.

PR Pathways via:

General Skilled Migration (GSM)

Employer-Sponsored Visas

Regional Migration Programs

How Eduvisor Can Help You Study in Australia

Navigating the Australian education system, choosing the right course, and applying for visas can be overwhelming. That’s where Eduvisor, a trusted study abroad consultant in India, steps in. Eduvisor offers personalized counseling, university shortlisting, scholarship assistance, SOP writing, and complete visa support — tailored for Indian students planning to study in Australia.

Final Thoughts

Choosing a high-ROI course in Australia is more than just picking a subject — it’s about aligning your passion with global trends. With the right guidance and planning, Australia can be your gateway to a successful international career. Use this study guide in Australia for Indian students as your blueprint for 2025 and beyond.

Ready to begin your journey? Let Eduvisor turn your study abroad dream into reality.

FAQs

Q1. What are the most affordable courses to study in Australia? A: Vocational Education & Training (VET) courses, TAFE programs, and regional university degrees are often more budget-friendly.

Q2. Is PR easy after studying in Australia? A: Courses on the SOL and MLTSSL lists (like IT, Nursing, Engineering) make it easier to qualify for PR.

Q3. How do I find scholarships to study in Australia? A: Government sites, university portals, and expert consultants like Eduvisor can help you explore scholarships based on merit, need, and region.

2 notes

·

View notes

Text

DIY Auto Repairs: Parts Every Car Owner Should Know About

Because sometimes the only thing standing between you and a $500 repair bill is a $30 part and some confidence.

Listen, we've all been there. That moment when your car makes a noise it definitely shouldn't be making, and your stomach drops thinking about how much the repair shop is about to charge you. But here's a little secret from someone who used to be terrified of looking under the hood: many car repairs are actually doable yourself, if you just know the basics.

The Gateway Parts (AKA Your DIY Starter Pack)

Before you dive into the deep end of auto repair, these parts are your beginner-friendly introduction:

Air Filters - Literally just pop open a plastic box, take out the dirty accordion-looking thing, put in the clean one. Shops charge $25+ for this 2-minute job.

Wiper Blades - Those streaky windshield marks aren't just annoying—they're dangerous in heavy rain. Most auto parts stores will even install new ones for free if you buy them there.

Headlight Bulbs - Why pay someone $50 to unscrew a bulb? Most cars take less than 15 minutes to swap these out.

Batteries - With a simple wrench and the ability to tell positive from negative, you can save serious cash here. Pro tip: take a picture of the connections before disconnecting anything.

The Money-Saving Middle Ground

Ready to level up? These parts might seem intimidating at first, but they're actually pretty manageable:

Brake Pads - I'm not saying brake work is super easy, but it's mostly just removing wheels, unscrewing a few things, and putting new pads where the worn ones were. The satisfaction of doing this yourself is chef's kiss.

Spark Plugs - With a special socket and a little patience, you can bring your engine back to life when it's running rough. Just replace one at a time so you don't mix up the wires.

Oil and Filter - Yes, getting under the car is involved, but a basic oil change is basically "unscrew plug, drain goop, replace filter, add new goop." The first time takes an hour, but you'll get it down to 20 minutes eventually.

Sensors - Modern cars have sensors for EVERYTHING. Oxygen sensors, mass airflow sensors, coolant temp sensors... they can cost hundreds to replace at shops, but often they're just a connector and a bolt.

The "Proceed With Caution" Parts

These repairs can save you serious money but require more research and patience:

Alternator - This electricity-generating wizard isn't actually that complicated to replace, but it can be buried in an annoying location depending on your car model.

Starter - When your car won't start and makes a clicking noise, this is often the culprit. Replacing it is often just a matter of disconnecting the battery, removing a few bolts, and swapping in a new one.

Thermostat - This little temperature-regulating valve is responsible for a surprising number of overheating issues. Replacing it can be messy (coolant everywhere!) but not difficult.

Fuel Pump - Located in your gas tank, this isn't the most convenient part to reach, but if you're facing a $700 repair bill, suddenly dropping your gas tank doesn't seem so bad.

Resources That Won't Make Your Eyes Glaze Over

YouTube Channels Worth Your Time:

ChrisFix (seriously, this guy explains things better than most college professors)

Scotty Kilmer (opinionated but incredibly knowledgeable)

EricTheCarGuy (detailed walkthroughs for common repairs)

Apps That Actually Help:

Repair Pal (get fair estimates before you start)

Torque Pro (connects to your car's computer to tell you what's wrong)

Car Parts (compare prices across different stores)

The Parts You Should Leave to the Pros

Sometimes, DIY isn't worth it. Here's when to wave the white flag:

Anything involving the airbag system (unless you enjoy danger)

Timing belt/chain replacement (one tiny mistake = engine death)

Transmission rebuilds (just... no)

Engine mounts (awkward angles + supporting engine weight = potential disaster)

Parting Thoughts (See What I Did There?)

The auto repair industry has an incentive to keep you intimidated and dependent. But with a repair manual, some basic tools, and the confidence to try, you'd be amazed what you can fix on your own.

The first time I changed my own brake pads, I saved $220 and gained something more valuable: the knowledge that I could figure things out myself. Now my go-to response to car trouble isn't panic—it's curiosity.

What auto repair are you most intimidated by? Drop a comment below and maybe we can demystify it together.

#CarRepair #DIY #AutoParts #SaveMoney #CarMaintenace #CarTips #Automotive

#auto parts and accessories#auto parts store#autopart#autopartsbusiness#autopartscatalog#autopartssales

2 notes

·

View notes

Text

Study in Lithuania from Bangladesh 2025

Explore top universities, affordable tuition, and a seamless visa process to study in Lithuania. Start your journey today with Graduate Track!

Lithuania offers rich academic opportunities, an affordable living cost, and a high-quality education system, making it an attractive destination for students from Bangladesh. With globally recognized universities, English-taught programs, and excellent post-graduation prospects, Lithuania has become a preferred choice for international students.

This blog provides extensive knowledge on the courses you can study, how to apply, the average cost of tuition fees, steps to apply for a Lithuanian student visa from Dhaka, Sylhet, Chittagong and estimated living expenses.

Available Courses to Study in Lithuania Lithuania offers a diverse range of academic programs across various fields, making it a great destination for international students. Many universities provide English-taught programs, especially at the Bachelor’s, Master’s, and PhD levels. Here are some of the most popular courses for international students:

Business & Management Business Administration International Business Marketing & Digital Marketing Finance & Accounting Supply Chain Management Engineering & Technology Civil Engineering Mechanical Engineering Electrical & Electronics Engineering Renewable Energy & Environmental Engineering Artificial Intelligence & Robotics Information Technology (IT) & Computer Science Software Engineering Data Science & Big Data Analytics Cybersecurity Computer Science & AI Game Development Health & Medical Sciences Medicine Dentistry Nursing Pharmacy Public Health Social Sciences & Humanities Psychology International Relations Political Science Sociology Law Arts & Design Graphic Design Interior Design Visual Arts Music & Performing Arts Fashion Design Tourism & Hospitality Management Hotel & Restaurant Management Travel & Tourism Event Management Many Lithuanian universities collaborate with European institutions, offering Erasmus+ exchange programs, internships, and research opportunities.

Top Universities to Study in Lithuania Lithuania is home to several high-ranking universities that offer globally recognized degrees and a variety of English-taught programs. Here are some of the top universities in Lithuania for international students:

Vilnius University (VU) The oldest and largest university in Lithuania. Ranked among the top universities in Europe. Offers programs in Business, IT, Law, Medicine, and more. Strong research facilities and international collaborations.

Kaunas University of Technology (KTU) Best for Engineering, IT, and Business studies. Strong industry partnerships and innovation-driven education. Member of many international academic networks. Affordable tuition fees with scholarship options.

Vytautas Magnus University (VMU) Popular for Humanities, Social Sciences, and Arts. Offers flexible study programs and interdisciplinary courses. Active in student exchange programs like Erasmus+. Research-focused with international collaborations.

Vilnius Gediminas Technical University (VILNIUS TECH) Specializes in Engineering, Architecture, and IT. Strong focus on research, innovation, and technology. Provides students with internship and work opportunities. Has a modern campus with state-of-the-art facilities.

Lithuanian University of Health Sciences (LSMU) Best for Medicine, Dentistry, Nursing, and Pharmacy. Recognized by WHO and other medical organizations. Provides clinical training at affiliated hospitals. High acceptance rate for international medical students.

ISM University of Management and Economics One of the top universities for Business and Economics. Has strong industry connections for internships and placements. Offers globally recognized business degrees. Partnered with leading universities worldwide. These universities offer world-class education with affordable tuition fees, making Lithuania an attractive destination for Bangladeshi students.

Lithuanian Student Visa Processing Agency in Dhaka & Sylhet Applying for a Lithuanian student visa from Bangladesh requires expert guidance to ensure a smooth and hassle-free process. Graduate Track is the official student visa agency of Lithuania in Bangladesh, which specializes in helping students secure admission to top Lithuanian universities and obtain their visas successfully.

With offices in Dhaka and Sylhet, Graduate Track provides end-to-end support, including university selection, application processing, document preparation, visa assistance, and pre-departure guidance. If you’re planning to study in Lithuania, Graduate Track is your reliable partner to make the journey seamless and stress-free.

Admission Process to Study in Lithuania The application process for studying in Lithuania involves several steps:

⭐ Choose a Program and University The first step is to select a university and program that aligns with your academic background and career goals. Lithuania offers a variety of English-taught courses in fields like Business, Engineering, IT, and Health Sciences.

⭐ Check Admission Requirements Each program has specific admission requirements, including academic qualifications, English language proficiency tests (IELTS/TOEFL), and other essential documents. Some universities may also require additional entrance exams or interviews.

⭐ Prepare Documents Commonly required documents for Lithuanian student visa from Bangladesh include:

✅ Completed application form ✅ Certified academic transcripts and certificates ✅ Passport-sized photograph ✅ Copy of passport ✅ Proof of English proficiency (IELTS/TOEFL) ✅ Statement of Purpose (SOP) ✅ Letters of Recommendation ✅ CV/Resume (if required) ⭐ Submit Your Application You can apply directly through Graduate Track, the official Lithuanian student visa processing agency in Bangladesh.

⭐ Pay Application Fees Application fees vary by university but typically range between €50 – €150.

⭐ Entrance Exams or Interviews Some universities may conduct online interviews or entrance exams, particularly for competitive courses like Medicine and Engineering.

⭐ Receive Admission Letter Once your application is accepted, you will receive an offer letter from the university. This document is essential for your student visa application.

⭐ Where to submit Lithuanian visa application in Bangladesh? Once all your documents are ready submit your category D visa in Dhaka VFS Sweden visa application centre. Bangladeshi students no longer need to go India for Lithuanian student visa. VFS Sweden application centre located at Gulshan 2. Connect with our advisor for admission and visa support.

Average Tuition Fees in Lithuania Tuition fees at higher education institutions in Lithuania vary based on the university, chosen study program, and academic level. On average, the cost of studying in Lithuania is:

Program Level Fees in Euro Fees in USD Fees in BDT Bachelor Studies 1500 – 3000 EUR 1300 USD 171,628.32 BDT Master Studies 2300 – 4000 EUR 2300 USD 303,650.11 BDT PhD Studies 8400 EUR 8400 USD 1,108,983 BDT Living Cost of Lithuania Lithuania is a budget-friendly destination for international students. Here’s a breakdown of typical monthly living costs:

EUR USD BDT 535.80 EUR 580.60 USD 70,758.22 BDT Here’s How Graduate Track Can Assist You: Personalized Consultation: We provide expert guidance on the Lithuanian student visa process, ensuring you meet all requirements and submit the necessary documents for a successful application.

University Admission Support: Our team assists you in securing admission to top universities in Lithuania, helping you choose the right program based on your academic background and career goals.

Comprehensive Visa Assistance: Whether it’s filling out application forms, preparing documents, or visa interview support, Graduate Track is here to make the process smooth and stress-free.

Local Offices in Dhaka & Sylhet: With offices in both Dhaka and Sylhet, you can visit us anytime for expert assistance and personalized services.

Don’t let visa challenges hold you back. Your pathway to studying in Lithuania is in safe hands with the Graduate Track. Contact us today to begin your journey.

Conclusion Lithuania has become an increasingly popular destination for Bangladeshi students due to its high-quality education system, affordable tuition fees, and diverse academic opportunities. With globally recognized universities, a range of English-taught programs, and a smooth visa process, Lithuania offers a great environment for international students to pursue their higher education.

If you are planning to study in Lithuania, expert guidance can make the application and visa process easier. Graduate Track is the official student visa agency of Lithuania in Bangladesh with its experienced team and offices in Dhaka and Sylhet and is here to assist you at every step—from university admission to visa processing.

Start your journey to studying in Lithuania today with the Graduate Track and take a step closer to achieving your academic and career goals.

4 notes

·

View notes

Text

Trimble SysQue vs MSuite in BIM

Both Trimble SysQue and MSUITE play crucial roles in the modern BIM (Building Information Modeling) ecosystem. While they are designed for distinct purposes, they often complement each other in streamlining workflows for MEP (Mechanical, Electrical, Plumbing) contractors and construction professionals. Let’s talk about both the tools individaully.

What is Trimble SysQue?

Trimble SysQue is primarily a Revit-based solution that enhances the BIM modeling services process by enabling the creation of fabrication-ready designs. Its strength lies in its precision and accuracy, achieved through the integration of manufacturer-specific data into BIM models. This ensures that every component designed using SysQue matches real-world specifications, making it ideal for prefabrication workflows. For example, when designing ductwork or piping systems, SysQue allows users to specify dimensions, materials, and components directly sourced from manufacturers. This level of detail not only reduces errors during construction but also ensures compatibility during the prefabrication and installation phases. SysQue is particularly useful for teams focused on creating detailed designs within Autodesk Revit, as it seamlessly integrates into this widely used platform.

How Trimble SysQue Enhances Revit Workflows for Fabrication-Ready Models

Trimble SysQue is a powerful tool that enhances Revit workflows, specifically tailored for the fabrication-ready MEP modeling (Mechanical, Electrical, and Plumbing) systems. It allows users to directly create and manage fabrication-level models within Revit, streamlining the transition from design to fabrication. Here’s how SysQue integrates with Revit and the advantages it offers for precise modeling: