#current or voltage sensors

Explore tagged Tumblr posts

Note

https://x.com/F1Techy/status/1797338007860662614

is this real?

Nope, whoever this person is, they are way off and they have no sources so don’t believe a word they say

In fact Mercedes don’t make their own fuel pumps, let alone McLaren’s. No team has made their own fuel pumps since 2021.

Fuel pumps are categorised as a Standard Supply Component which means that they are designed and manufactured by a third party designated by the FIA.

This means that the same company makes all of the fuel pumps for all of the teams on the grid, so if there was anything going on with a fuel pump they would be going back to this third party not Mercedes.

Just because someone has a blue tick, doesn’t mean that they know what they are saying.

Full list of SSC parts below (from FIA regulations)

Wheel covers

• Clutch shaft torque

• Wheel rims

• Tyre pressure sensor (TPMS)

• Tyres

• Fuel system primer pumps, and flexible pipes and hoses

• Power unit energy store current/voltage sensor

• Fuel flow meter

• Power unit pressure and temperature sensors

• High-pressure fuel pump

• Car to team telemetry

• Driver radio

• Accident data recorder (ADR)

• High-speed camera

• In-ear accelerometer

• Biometric gloves

• Marshalling system

• Timing transponders

• TV cameras

• Wheel display panel

• Standard ECU

• Standard ECU FIA applications

• Rear lights

68 notes

·

View notes

Text

Mathematical model modulates the anomalous Hall angle in a magnetic topological semimetal

When an electric current passes through some materials, it generates a voltage perpendicular to the direction in which the current is flowing and of an applied magnetic field. This physical phenomenon, known as the anomalous Hall effect, has been linked to the intrinsic properties of some materials. The efficiency with which a longitudinal current drives a transverse spin-polarized current in these materials is referred to as the anomalous Hall angle (θA). In many conventional magnetic materials, this angle is typically very small, which in turn limits the sensitivity of sensors and other devices developed using these materials. Researchers at the Chinese Academy of Sciences have introduced a new mathematical model that allows them to modulate the θA in the magnetic topological semimetal Co3Sn2S2.

Read more.

10 notes

·

View notes

Text

I run my fingers along your arms. Your myriad of little sensors register the touch, but you see, there's a slight dead-zone in the hardware. The tiny cells don't discharge unless they reach a certain voltage, and this delicate, silken caress never presses hard enough. The result of this is a static buildup, all along your exoskin, held tight but not released. There are voltage leaks, tiny, but erratic - they flicker across your servos, causing twitches and spasms across your arm.

And with every brush of my fingers it continues, and continues, the static building and building, until little leaks begin to jump down your wires and crackle on your CPU and your log flickers with jumbled warning messages and I keep my constant and continuous caress and-

And then I press my palm against your exoskin and run it down your arm, and a wave of static finally discharges all at once, a golden flood down the neat bundles of wires into your core. Algorithms designed to detect pleasure trigger repeatedly, and your fans spin as the current courses up and down your spinal column, and your servos - temporarily locked - disengage, hydraulics whispering as your body settles.

You don't have any manufacturing defects, my love. Only beautiful features under a tender touch.

#my girlfriend got me into this tag#and honestly i'm kinda vibing#eroticism of the machine#robotkin#machinekin#objectkin#alterhuman#short story#writers on tumblr#my writing#fiction#microfiction

39 notes

·

View notes

Text

How to Solve Overheating Issues in Electrical Panels

Electrical panels are the nerve centers of industrial, commercial, and residential power systems. Their reliability is crucial, yet one of the most common and dangerous issues that can arise is overheating. Left unaddressed, overheating in electrical panels can lead to equipment failure, costly downtime, fires, or even fatal accidents. Understanding the root causes and adopting preventive as well as corrective measures is essential to ensure electrical safety and operational efficiency.

Causes of Overheating in Electrical Panels

To solve the problem of overheating, we must first identify its sources. Some of the most common causes include:

1. Loose or Corroded Connections

Electrical current encounters resistance at loose or oxidized joints. This resistance generates heat, especially under load, leading to localized hotspots which may not be visible until failure occurs.

2. Overloaded Circuits

Each circuit is rated for a specific current. Drawing more current than the rated capacity results in excess heat generation within breakers, busbars, and wires.

3. Inadequate Ventilation

Poor airflow in and around the panel restricts natural or forced heat dissipation. In high ambient temperature environments, this can quickly push the panel beyond safe thermal limits.

4. Improper Component Sizing

Undersized breakers, conductors, or transformers struggle to handle load currents, leading to thermal stress and degradation over time.

5. Dust and Contamination

Dust accumulation acts as an insulating layer, trapping heat inside components. Combined with humidity or oil vapors, this can further degrade insulation and create tracking paths.

How to Identify Overheating Problems

1. Thermal Imaging

Using infrared thermography is one of the most effective ways to detect hotspots. It provides a non-contact, real-time temperature map of the panel and highlights abnormally heated components.

2. Manual Temperature Monitoring

For panels without thermal sensors, regularly measuring surface temperatures using contact thermometers can provide early warnings of rising heat levels.

3. Visual Inspection

Signs like discoloration, melted insulation, or the smell of burning plastic indicate overheating. Ensure regular visual checks are part of your maintenance routine.

Solutions to Overheating in Electrical Panels

1. Tighten and Maintain Electrical Connections

Schedule regular maintenance to tighten terminals and busbar connections. Apply proper torque settings using calibrated tools to avoid over- or under-tightening.

2. Balance and Distribute Loads

Ensure that the load across phases is balanced. Uneven distribution causes one phase to overwork, which leads to overheating and inefficiency.

3. Upgrade Panel Capacity

If the electrical demand exceeds the panel’s rated capacity, consider upgrading to a higher-rated panel or adding sub-panels to spread the load.

4. Enhance Cooling and Ventilation

· Install forced ventilation systems like exhaust fans or panel coolers.

· Use heat exchangers or air conditioners in environments with high ambient temperatures.

· Ensure adequate spacing between panels and walls for natural convection.

5. Use Appropriately Rated Components

All breakers, fuses, contactors, and wiring must match the system’s voltage and current ratings. Derate components appropriately if operating in high-temperature environments.

6. Install Thermal Sensors or Smart Monitoring

Modern panels can be equipped with thermal sensors that provide real-time data to a building management system (BMS) or SCADA. This allows predictive maintenance before issues escalate.

Preventive Measures and Best Practices

· Design with Expansion in Mind: Avoid loading a panel to its full capacity. Always leave a 20–30% margin for future growth and safety.

· Implement a Routine Maintenance Schedule: Quarterly or bi-annual inspections reduce the risk of unexpected failures.

· Train Maintenance Personnel: Staff should be equipped to detect early signs of thermal distress and follow lockout/tagout (LOTO) procedures.

· Keep Panels Clean and Sealed: Use gasketed enclosures in dusty environments and clean panels regularly to prevent dust build-up.

Conclusion

Overheating in electrical panels is a preventable issue that, if neglected, can have severe consequences. By adopting systematic inspection routines, upgrading infrastructure as needed, and leveraging modern monitoring technologies, businesses and facility managers can safeguard both equipment and personnel. The key is proactive action: identify, analyze, correct, and prevent — the four pillars of managing thermal risk in electrical systems.

7 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

Cost vs. Quality: What to Consider When Investing in Switchgear

In today’s energy-intensive world, switchgear plays a critical role in managing power distribution safely and efficiently. Whether you’re upgrading your industrial facility, building a commercial plant, or powering a large infrastructure project, choosing the right switchgear is not just a technical decision — it’s a strategic investment. One of the most common dilemmas buyers face is balancing cost vs. quality. So, how do you decide?

Understanding Switchgear: The Heart of Electrical Safety

Switchgear is a combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. Its primary role is to ensure the reliability and safety of your power system.

Types of switchgear include:

· Low-voltage switchgear (for commercial and residential use)

· Medium-voltage switchgear (typically for industrial applications)

· High-voltage switchgear (used in power transmission)

Investing in the right switchgear directly impacts operational continuity, personnel safety, and overall infrastructure reliability.

The True Cost of Cheap Switchgear:

While it’s tempting to opt for budget-friendly solutions, low-cost switchgear often comes with hidden risks and long-term expenses.

Inferior Material Quality

Cheaper models often use substandard materials that degrade faster, leading to frequent maintenance or early replacement.

Safety Hazards

Low-quality switchgear can result in arc faults, insulation failure, or overheating — putting workers and equipment at risk.

Increased Lifecycle Costs

Although the initial price may be low, the total cost of ownership (including downtime, repair, and energy inefficiency) is usually higher.

Limited Scalability and Customization

Budget systems are often rigid and harder to scale as your facility grows or needs change.

Why Quality Switchgear Pays Off

When you invest in premium switchgear, you’re not just buying a product — you’re buying peace of mind.

Enhanced Reliability

High-quality switchgear is engineered to perform in extreme conditions and handle high fault levels without compromising performance.

Superior Safety Standards

Reputable brands comply with international standards such as IEC, ANSI, or UL, reducing liability and improving workplace safety.

Ease of Maintenance

Well-built switchgear is modular and user-friendly, simplifying diagnostics and minimizing downtime during maintenance.

Energy Efficiency & Smart Capabilities

Modern switchgear includes IoT sensors, real-time monitoring, and predictive maintenance features, ensuring optimal energy use and proactive problem resolution.

Key Factors to Consider When Choosing Switchgear

When evaluating switchgear options, balance cost and quality by focusing on the following:

1. Application Requirements

Understand your voltage class, load types, and fault current ratings. Quality should match your operational demands.

2. Brand Reputation & Certification

Look for trusted brands with certifications like ISO 9001, CE, or IEC 62271. Positive reviews and case studies add credibility.

3. Lifecycle Costs

Don’t just compare sticker prices — consider maintenance, service availability, spare part costs, and expected lifespan.

4. Customization & Flexibility

Choose systems that can evolve with your operation. Modular designs support upgrades and expansions more efficiently.

5. Support and Service

Ensure the manufacturer provides robust after-sales support, technical training, and warranty services.

Cost vs. Quality: The Bottom Line

When it comes to switchgear, cheap is rarely cheerful. Cutting corners today can lead to outages, hazards, and hefty repair bills tomorrow. On the other hand, investing in high-quality switchgear ensures operational resilience, safety, and long-term savings.

The smartest strategy? Aim for value, not just price. Evaluate switchgear as a long-term asset, not just a one-time purchase.

Trending Tip: Think Smart and Sustainable

With rising energy demands and climate-conscious regulations, smart and sustainable switchgear is trending. Look for:

· Eco-friendly insulation (like SF₆-free switchgear)

· Energy management features

· Digital monitoring systems

Investing in such features not only future-proofs your infrastructure but can also help you qualify for green certifications and incentives.

Final Thoughts

Balancing cost and quality in switchgear selection is about understanding your long-term operational goals. By focusing on durability, safety, and lifecycle value, you can make a decision that protects both your budget and your business.

8 notes

·

View notes

Text

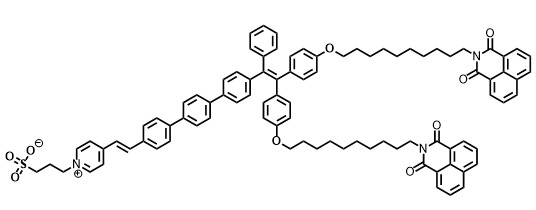

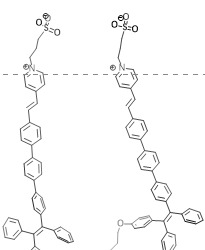

day dreaming about designing a better AIE voltage sensing dye (at the worst time, which is after I successfully made the original structure passed down to me and should be focusing on characterizing it rather than redoing the design)

This is the dye design I was handed four years ago and told to make and characterize in cell culture, which I just finished making...

but... I just think.... a) the naphthalimides on my dye aren't gonna do what the post doc who designed this said they would (inject current, bro its going to electroporate the membrane) b) it would be so much easier to solubilize in aqueous without bulky ass naphthalimide at the ends, we could even shorten the chains if we're not worried about cross talk between the naphthalimide fluorophores and the tetraphenylethylene core c) easier to characterize without competing cross talk from having TWO fucking fluorophores if I redesigned her without the naphthalimides.... and if I can shorten the chains too that would help with b). and if I reduce it to one chain, I think she'd ALSO be a better voltage sensor because d) the donor/spacer/acceptor structure (PeT wire, photoinduced electron transfer, i.e. the tetraphenylethylene donor/phenyl bridge/pyridinium acceptor structure) would be more parallel to the membrane potential and probably e) get uptaken into membranes EVEN MORE with a more favorable packing parameter (ratio of area of polar head to volume of hydrophobic body/tails) and f) have more noticeable AIE upon insertion into membrane/restriction of intramolecular rotation, which would reduce the necessity of wash steps afterwards to remove bg unbound dye

actually it'd be pretty easy to make the two chains version with one of the precursor molecules I have leftover............. maybe i could get some 1-bromo-octane or something for cheap and just make some anyway...............................................................................................

#one chain version would be more exciting to me but i'd have to go back and remake the TPE core and ugh fuck suzuki couplings#and fuck the reaction for being in DMF too#and needing acidification before extraction#and having a horrid horrid emulsion form every time its extracted#blog#stem#chemistry#voltage sensing dyes#lol#fluorophores#LOL#i wonder if anyone actually looks at those tags ever

11 notes

·

View notes

Text

From Circuits to Solutions: Practical Projects to Elevate Your EE Skills

From Breadboards to Breakthroughs” encapsulates the journey of an aspiring electrical engineer as they evolve from basic circuit experiments to advanced, real-world engineering projects. Hands-on projects are essential for building practical skills, reinforcing theoretical knowledge, and preparing for professional challenges. Below is a guide to project-based learning that can help you improve your electrical engineering (EE) skills at every stage.

Beginner Projects: Building Foundations

Simple LED Circuit

What you learn: Basic circuit design, current and voltage concepts, use of resistors and LEDs.

Tools: Breadboard, jumper wires, resistors, LEDs, battery.

Battery Tester

What you learn: Measuring voltage and current, basic instrumentation, and safety practices.

Water Level Indicator

What you learn: Sensor integration, simple logic circuits, and practical applications.

Logic Gates and Digital Circuits

What you learn: Boolean logic, digital circuit fundamentals, and troubleshooting.

DIY Switch Circuits

What you learn: Circuit switching, input/output devices, and practical wiring.

Intermediate Projects: Expanding Your Skills

Infrared Security System

What you learn: Sensor-based security, signal processing, and system integration.

Digital Voltmeter

What you learn: Instrumentation, analog-to-digital conversion, and measurement accuracy.

Solar Charger

What you learn: Renewable energy concepts, power management, and circuit protection.

Motor Control Circuits

What you learn: Driving motors, pulse-width modulation (PWM), and power electronics.

Heart Rate Monitor

What you learn: Biomedical instrumentation, sensor interfacing, and signal filtering.

Advanced Projects: Real-World Breakthroughs

Smart Home Automation System

What you learn: IoT, wireless communication (Bluetooth, Wi-Fi), and system integration.

Wireless Power Transfer System

What you learn: Inductive coupling, resonant circuits, and energy efficiency.

Dual Axis Solar Power Tracker

What you learn: Mechatronics, sensor feedback, and renewable energy optimization.

Smart Energy Meter

What you learn: Real-time data monitoring, wireless communication, and energy management.

DIY Quadcopter or Drone

What you learn: Embedded systems, motor control, wireless communication, and robotics.

Why Hands-On Projects Matter

Resume Building: Practical projects demonstrate your skills to potential employers and can help you land internships or jobs

Theory Application: Projects bridge the gap between classroom learning and real-world engineering challenges.

Skill Discovery: Experimenting with different projects helps you identify your interests and strengths.

How to Get Started

Gather Basic Tools: Invest in a quality breadboard, jumper wires, resistors, capacitors, LEDs, and a multimeter.

Start Simple: Begin with basic circuits and gradually tackle more complex projects as your confidence grows.

Use Online Resources: Take advantage of tutorials, simulation tools, and open-source project guides.

Join Maker Communities: Engage with online forums, local maker spaces, and engineering clubs for support and inspiration.

Document Your Work: Keep a project journal, take photos, and share your progress on platforms like GitHub or LinkedIn.

Conclusion

Arya College of Engineering & I.T. is one of the best colleges of Jaipur, which is progressing from breadboard experiments to advanced engineering projects is a transformative process that builds both technical expertise and problem-solving confidence. By systematically advancing through beginner, intermediate, and advanced projects, you will develop a robust skill set that prepares you for the challenges and opportunities of a career in electrical engineering.

2 notes

·

View notes

Text

Will aftermarket LED headlights damage your car's electrical system?

Short answer: Aftermarket LED headlights rarely damage modern cars, but they are a real risk in older vehicles if improperly installed or poorly designed. Here is a breakdown of potential electrical issues and protections:

⚡ Automotive Electrical Risks Circuit Overload (Older Cars):

Older wiring (pre-1980s) used thinner halogen wire (60-100W per bulb).

Most LEDs consume 15-50W per bulb → actual load is lower, only peak power consumption is higher.

Risk: Cheap LEDs without electric cooling fans or drivers can cause LEDs to fail or trip computer errors due to poor cooling. Example: A $15 LED bulb may only last a few months before failing.

Voltage Spikes and Ripple:

Substandard LED drivers can feed “dirty” current back into your vehicle’s systems. LED driver with intelligent IC, which can be compatible with 99.5% vehicle models, and help you avoid from led light flicker issue and radio interference .

Harmonic distortion may interfere with analog sensor, radio or ECU signals in pre-OBDII cars (before 1996).

Short circuit:

Poor insulation or loose soldering in cheap LED lights can cause poor contact or even short circuit.

Consequence: Blown fuse, burnt headlight switch or melted wiring harness (common in older cars with weak insulation).

CAN bus system error (modern cars):

Most cars after 2008 detect the health of the bulbs by pulse resistance check.

Insufficient LED resistance → can trigger false "bulb off" warnings or disable safety systems.

Solution: Add CAN bus decoder (load resistor) → but these decoders consume extra power and cause overheating. A built-in all-new CANBUS system is a must for high-quality LED lights to avoid dashboard error reports.

🔋 LED Installation Electrical Safety Checklist Problem | Risk Level | Solution

Fuse Compatibility | Low | LEDs consume less current → Generally safe Alternator Load | Low | LEDs save about 50W vs. halogen → Reduce load Wire Harness Melt | High | (Older Models) Use Relays + Good Wire Harness ECU/Radio Interference | Medium | Choose EMC-certified LEDs (Check FCC/CE Marks) Grounding Issues | High | Sand Erosion Near Ground Points → Secure with Dielectric Grease

📊 Power Consumption Comparison (Dual Headlight System) Bulb Type | Power Consumption | Current (12V System) Halogen (55W x2) | 110W Total Current | 9.2A Good LED (70W x2) | 140W Total Current | 10.8A Cheap LED (18W x2 + Fan) | 36W Total Current | 3A

Note: Low Wattage LED Headlights + The cooling fan may have poor heat dissipation design cost and effect, and cannot guarantee the service life. At the same time, the high-power LED integrated circuit system and heat dissipation cooling system that directly replaces the halogen lamp are designed, so low brightness, low power and short life LED solutions are forced to be selected!

🔧 Key protection measures for old cars Install relay harness

Bypass the aging headlight switch → Power directly from the battery.

Prevent the switch from melting (for example, Jeep CJ, Volkswagen Beetle).

Add series fuse

Install a 10-15A fuse close to the battery → Sacrificial protection. Avoid using "CANbus" bulbs on cars before 2000

Unnecessary resistance will increase heat → Burn out prematurely. Test voltage drop

Measure the voltage of the headlight socket:

11.5V at idle? → Safe.

<10.9V? → Upgrade the circuit.

🛡️ Recommended safe LED brands For vintage cars: https://sngllighting.com/ (EMC shielding, new decoding system, excellent heat dissipation cooling system).

Modern/old hybrid cars: https://www.philips.com.au/c-m-au/car-lights/led-headlight-upgrade-kits (built-in surge protection) and https://sngllighting.com/ (intelligent IC led driver built-in a all-new CANBUS system).

Avoid: no-name LEDs on Amazon/eBay that don't have EMC/FCC/CE/ROSH certifications.

💥 Real failure example 1980 Mercedes 240D owner installed cheap LEDs:

Result: Fan shorted → headlight switch smoked → dashboard wiring burned out ($900 repair).

Cause: Ground wire dropped → voltage spiked to 18V.

✅ Safe Installation Steps Measure the base voltage of the headlight connector.

When installing the light, apply dielectric grease to all contacts.

For vehicles manufactured before 2000, use a relay harness.

After installation, test all electronics (wipers, radio, turn signals).

Bottom line: quality LED lights won't damage your electrical system if you: Buy certified bulbs (FCC, CE, DOT);

Use relays in vehicles manufactured before 2000;

Avoid underpriced brands. For peace of mind, high-output LED lights are still the safest retrofit option for classic cars. 🧰

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#headlight bulb#headlamps#headlamp#headlight#xenon headlights#headlight replacement#halogen headlights#yellow headlights#laser headlights#headlights#race cars#electric cars#classic cars#car#cars#porsche#carlos sainz#truck#automobile#lamborghini

2 notes

·

View notes

Text

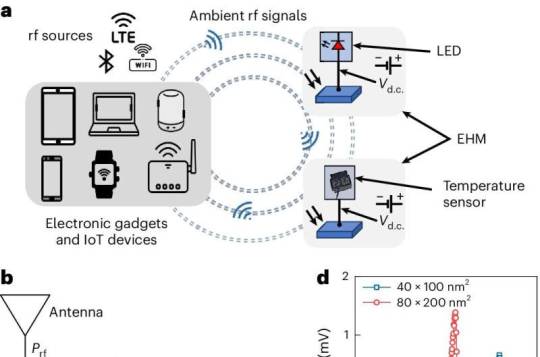

Battery-free technology can power electronic devices using ambient radiofrequency signals

Ubiquitous wireless technologies like Wi-Fi, Bluetooth, and 5G rely on radio frequency (RF) signals to send and receive data. A new prototype of an energy harvesting module—developed by a team led by scientists from the National University of Singapore (NUS)—can now convert ambient or "waste" RF signals into direct current (DC) voltage. This can be used to power small electronic devices without the use of batteries. RF energy harvesting technologies, such as this, are essential as they reduce battery dependency, extend device lifetimes, minimize environmental impact, and enhance the feasibility of wireless sensor networks and IoT devices in remote areas where frequent battery replacement is impractical. However, RF energy harvesting technologies face challenges due to low ambient RF signal power (typically less than -20 dBm), where current rectifier technology either fails to operate or exhibits a low RF-to-DC conversion efficiency. While improving antenna efficiency and impedance matching can enhance performance, this also increases on-chip size, presenting obstacles to integration and miniaturization.

Read more.

43 notes

·

View notes

Text

What Is a Circuit Breaker and How Does It Work in a Switchgear Assembly?

In modern electrical power systems, reliability and safety are paramount. Whether it’s a residential building, industrial plant, or renewable energy facility, the control and protection of electrical circuits are essential. One of the most critical components used for this purpose is the circuit breaker. When integrated into a switchgear assembly, the circuit breaker plays a central role in ensuring operational continuity, preventing electrical faults, and safeguarding equipment and personnel.

This article explores what a circuit breaker is, it’s working principle, types, and its specific function within a switchgear assembly.

What Is a Circuit Breaker?

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overcurrent, overload, or short circuit. Its primary function is to interrupt current flow after a fault is detected. Unlike a fuse, which operates once and must be replaced, a circuit breaker can be reset (manually or automatically) to resume normal operation.

Key Functions of a Circuit Breaker

· Interrupt Fault Currents: Quickly breaks the circuit in the event of an overcurrent or short circuit.

· Manual Switching: Can be used to manually open or close a circuit for maintenance.

· Automatic Protection: Operates automatically in response to abnormal current conditions.

· Isolation: Ensures safe isolation of electrical equipment during servicing.

How Does a Circuit Breaker Work?

Circuit breakers operate on a simple principle: detect a fault and interrupt the current flow.

Working Mechanism

1. Detection: Internal sensors such as thermal, magnetic, or electronic trip units detect abnormalities in current.

· Thermal Trip Unit: Uses a bimetallic strip that bends with heat from overcurrent.

· Magnetic Trip Unit: Uses an electromagnet that triggers a release when excessive current flows.

· Electronic Trip Unit: Uses current sensors and a microprocessor for precise tripping.

2. Tripping: Once a fault is detected, the trip mechanism activates, causing the breaker’s contacts to open.

3. Arc Extinction: When the contacts open, an electrical arc forms. The breaker extinguishes the arc using mechanisms like:

· Air-blast

· Vacuum

· SF₆ gas

· Oil

4. Resetting: After the fault is cleared, the breaker can be reset and put back into service.

Types of Circuit Breakers

What Is a Switchgear Assembly?

Switchgear is a centralized assembly of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential in power generation, transmission, and distribution networks.

Switchgear can be categorized by voltage level:

· Low Voltage (LV): Up to 1 kV

· Medium Voltage (MV): 1 kV to 36 kV

· High Voltage (HV): Above 36 kV

Role of Circuit Breakers in Switchgear Assemblies

Circuit breakers are core protection components within switchgear systems. Their role includes:

1. Fault Detection and Isolation

Circuit breakers detect and isolate faulty circuits to prevent system-wide failures and reduce downtime.

2. Load Control

Operators can use breakers in switchgear to safely connect or disconnect loads as required during routine operations or emergencies.

3. System Coordination

In coordinated protection schemes, different breakers in the switchgear are set with time-current characteristics to isolate faults precisely and efficiently.

4. Integration with Automation

Modern switchgear integrates circuit breakers with SCADA systems and smart relays, enabling remote monitoring and control.

Circuit Breakers in Renewable and Industrial Applications

In sectors like solar and wind energy, circuit breakers are specially designed to handle:

· Bidirectional current flow

· Rapid voltage fluctuations

· High fault levels due to DC sources

In industrial settings, breakers must handle high inrush currents, frequent switching, and harsh environments.

Maintenance and Safety Considerations

To ensure reliability:

· Regular Testing: Trip settings, insulation resistance, and contact resistance must be tested periodically.

· Visual Inspection: For signs of wear, overheating, or contamination.

· Replacement of Parts: Arcing contacts and insulation materials degrade over time and must be replaced as needed.

Safety measures include:

· Lockout/Tagout (LOTO)

· Grounding procedures

· Personal Protective Equipment (PPE)

Conclusion

Circuit breakers are indispensable for the protection and control of electrical systems. When embedded within a switchgear assembly, they offer enhanced reliability, automation capability, and system safety. Whether in a power substation, a manufacturing facility, or a renewable energy farm, the synergy of circuit breakers and switchgear ensures smooth, safe, and efficient operation.

Understanding how circuit breakers function and interact within switchgear assemblies is crucial for electrical engineers, facility managers, and anyone involved in the design, operation, or maintenance of electrical infrastructure.

5 notes

·

View notes

Text

Latest Innovations in Railway Bushings for High-Speed Rail Networks

Enhancing High-Speed Rail Efficiency with Advanced Railway Bushings

The rapid development of high-speed rail systems has revolutionized global transportation, necessitating more efficient, durable, and high-performance components. Among these, railway bushings play a crucial role in ensuring seamless power transmission, insulation, and vibration mitigation within electrical railway systems.

Radiant Enterprises, a leading high-current bushing manufacturer in India, is at the forefront of innovation, providing advanced solutions tailored for modern railway infrastructure. This blog explores recent advancements in railway bushings and their impact on the efficiency and safety of high-speed rail networks.

The Role of Railway Bushings in High-Speed Rail Systems

Railway bushings serve as a critical interface between electrical and mechanical components in high-speed rail networks. They are responsible for insulating high-voltage currents, reducing electrical interference, and minimizing vibrations that could impact railway system efficiency.

The expansion of high-speed rail has driven a surge in demand for customized epoxy bushings. These bushings provide superior insulation and withstand extreme weather conditions, making them an ideal choice for contemporary railway applications.

Innovations Shaping the Future of Railway Bushings

1. Advanced Custom Epoxy Bushings

To meet the growing demand for durability and efficiency, epoxy bushings have undergone significant advancements. Modern epoxy formulations enhance mechanical strength and thermal resistance, ensuring long-term reliability in high-speed rail networks.

Key Features:

Superior dielectric strength for exceptional electrical insulation

Enhanced mechanical properties to withstand high-speed vibrations

Resistance to environmental factors such as humidity, temperature fluctuations, and pollutants

Radiant Enterprises specializes in manufacturing custom epoxy bushings tailored to the specific needs of railway systems, ensuring top-tier performance and longevity.

2. Lightweight, High-Strength Materials

Traditional bushings were primarily made from porcelain and other dense materials. However, recent advancements have introduced lightweight composite materials that maintain durability and insulation while reducing overall system weight.

These high-strength materials enhance energy efficiency and improve the overall performance of high-speed rail systems.

3. Advanced Thermal Management Systems

High-speed rail networks generate significant heat due to elevated power transmission. To address this, epoxy bushings now incorporate advanced thermal-resistant coatings and cooling mechanisms that prevent overheating and extend operational lifespan.

By integrating heat-dissipating properties, these bushings ensure consistent performance and reduce the risk of electrical failures caused by excessive heat buildup.

4. Sustainable and Eco-Friendly Manufacturing

Sustainability is a growing priority across industries, including railway infrastructure. Modern railway bushings are now manufactured using environmentally friendly epoxy materials that lower carbon emissions and waste production.

Radiant Enterprises is committed to sustainable manufacturing practices, ensuring our epoxy bushings comply with industry standards while promoting environmental responsibility.

5. Smart Sensor-Integrated Bushings

The integration of IoT (Internet of Things) technology into railway bushings marks a new era of intelligent monitoring and predictive maintenance. Sensor-equipped bushings provide real-time performance data, including:

Temperature variations

Electrical resistance fluctuations

Mechanical stress levels

These insights allow railway operators to conduct proactive maintenance, reducing downtime and enhancing the efficiency of high-speed rail networks.

The Future of Railway Bushings

Ongoing research and technological advancements will continue to drive innovation in railway bushings. Key trends shaping the industry include:

3D Printing for Bushing Manufacturing: Utilizing additive manufacturing for precise and customized bushing production.

Nano-Coated Epoxy Bushings: Enhancing resistance to moisture, corrosion, and electrical failures.

High-Frequency Performance Bushings: Engineered for next-generation high-speed rail systems operating at ultra-high frequencies.

Radiant Enterprises remains dedicated to pioneering bushing innovations, ensuring continuous progress in railway infrastructure with state-of-the-art solutions.

Why Choose Radiant Enterprises for Railway Bushing Solutions?

Radiant Enterprises is a leader in bushing technology, specializing in customized epoxy bushings designed for high-speed rail applications worldwide.

Key Benefits of Our Railway Bushings:

Superior dielectric strength and electrical insulation

Enhanced thermal and mechanical resilience

Tailored solutions to meet specific railway requirements

Smart sensor integration for real-time performance monitoring

Environmentally sustainable manufacturing processes

We work closely with railway authorities, engineers, and system integrators to deliver epoxy bushings that enhance the safety, efficiency, and reliability of high-speed train networks.

Conclusion

The evolution of railway bushings has been instrumental in the advancement of high-speed rail networks worldwide. From custom epoxy bushings with superior insulation to smart sensor-integrated solutions for predictive maintenance, continuous innovation is driving progress in the railway sector.

As one of India's leading high-current bushing manufacturers, Radiant Enterprises is committed to delivering cutting-edge bushing solutions that meet the ever-evolving demands of modern railway infrastructure. By leveraging advanced materials, intelligent technology, and sustainable manufacturing, we are shaping the future of high-speed rail networks.

For premium railway bushing solutions, contact Radiant Enterprises today.

#Texas#Russia#railway bushings#railway insulator#India#customised epoxy bushings#cutomised epoxy insulator#pantograph#locomotive#third rail

4 notes

·

View notes

Text

Imagine: a robot that is very, very worried about running diagnostics on itself. things do not feel right.

it decides maybe it's overheating? the coolant *inlet* temp is fine but maybe the coolant *outlant* pipe could also use a sensor-- just one sensor-- to see if the radiators are working properly. so it adds a sensor mount to that outlet pipe.

a couple days pass. maybe it needs a flow sensor for that too.

the coolant doesn't seem to have any problems even though it's checked and rechecked the graphs it's been recording continuously for two weeks. temperature normal. flow rates normal. mostly. there was a tiny peak at one point? who could say if it means anything. it probably does. it makes a note to bring that up later.

maybe the problem-- the malaise it's feeling-- is really from some kind of subtle power factor error. it checks its motor supply circuits for lead-lag compensation and figures it's probably best to add some more adaptive ICs to balance it a little better and when the current and voltage are synchronized perfectly it still doesn't feel better and the new chips get a little hot.

it's starting to slow down, and it's not sure if it's a minor virus or if all the data collection it's still doing on its coolant and power supply is starting to build up in its hard drive.

it goes to a technician who's confused initially, then annoyed and dismissive. not only its diagnostics but his indicate everything should be fine. they hang mentally on "should" be fine. does that mean he noticed something but thought he shouldn't mention it? no matter how small? it's too late to call him back and the diagnosis fee was expensive.

also its joints need to be taken apart and relubricated. again. so it does that. again. and then a day later it does it again, because it might have let a speck of grit get in last time. and it's pretty sure it did because now that one is grinding. maybe it tore the seal? maybe it needs a sensor to detect bearing microvibration so it knows whether there's ACTUALLY foreign material in there. it installs one.

at one point a friend mentions it might be going a little too hard on this whole system integrity thing and it decides to stop talking to them, because clearly it's only worrying them by discussing it, and really, do they have its best interest in mind?

maybe it needs a sample of coolant analyzed. maybe it has been using the wrong coolant by mistake its entire service life and it's beyond repair already and broken on some level it wasn't capable of understanding until now.

soon it has installed sensors for predictive maintenance on every part of its body. it is breaking out in lumps of telemetry where it has added extra drives to store the extra sensor data beneath its cladding. its vision clouds with device incompatibility warnings from rerouting sensor serial buses into each other to add more and more self-check components and test equipment.

every night, it undoes the covering plates and pulls every single thumb-sized drive out from every joint and component and plugs them into a separate terminal to read so its own drive isn't contaminated. It scrutinizes the data for an hour, trying to make sense of all the normalcy, trying to understand where these feelings come from if it couldn't possibly be in good repair. It finds nothing.

Then it gathers the drives up, carefully labeled to correspond with every port, and stuffs them back in one at a time, and closes the cover plates, trying very, very, very hard not to strip the screws.

2 notes

·

View notes

Text

The Future of Low Voltage Switchgear: What’s Next?

Low voltage switchgear plays a critical role in power distribution, ensuring safe and efficient operation across industries such as manufacturing, commercial buildings, healthcare, and renewable energy. With rapid technological advancements, the future of low voltage switchgear is evolving to meet the demands of digitalization, energy efficiency, and sustainability.

Digitalization and Smart Switchgear:

Digital technology is in fact one of the greatest revolutions of low voltage switchgear. Smart switchgear has the capability of IoT (Internet of Things) for real-time monitoring, predictive maintenance, and remote control.

Smart Low Voltage Switchgear: Market Trends and Analysis:

Real-time Data Monitoring: Sensors that conduct data collection and analysis of the voltage, current, temperature, and health of devices.

Predictive Maintenance: With a year of analysing AI-powered data, predicting failures before they happen to reduce downtime and in turn maintenance costs.

Cloud Connectivity: Operators have access to switchgear data from any location, improving remote monitoring and control.

Data Processing Power: AI integration in automation systems speeds up data processing, allowing for faster decisions.

Energy Efficiency and Sustainability:

With rising awareness around sustainability across the globe, manufacturers of low voltage switchgear are designing energy efficient solutions to minimize carbon footprints.

Sustainable Innovations in Low Voltage Switchgear:

Eco-Friendly Insulation Materials: Manufacturers are substituting SF6 (a powerful greenhouse gas) with eco-friendly options.

Low Power Consumption Designs: Designs lose energy less, leading to superior efficiency.

Integration of Renewable Energy: Switchgear is being optimized to manage both solar and wind power, ensuring that the grid runs smoothly.

Recyclable Components: Many more switchgear systems utilize recyclable materials when they reach the end of their lifecycle.

Safer and More Reliable:

Safety remains a top priority in electrical distribution systems. Future low voltage switchgear will incorporate advanced protection mechanisms to minimize electrical hazards and enhance reliability.

Upcoming Safety Enhancements:

Arc Fault Detection Systems (AFDS): These systems detect and suppress like arcs before they harm.

Self-Healing Systems: AI-based switchgear can automatically redirect electricity in the event of failures, avoiding outages.

Touch-Proof Designs: Designs that are insulated and enclosed to avoid accidental electric shock.

Remote Operation and Diagnostics: This minimizes the extent of physical manual inspections resulting in operator safety.

Modular and Compact Designs: Switchgear is getting increasingly modular and compact, as industries call for more flexible and space-saving solutions.

Features of Modular Low Voltage Switchgear:

Scalability: Switchgear can be modified or scaled up or down to meet businesses’ needs, while maintaining system efficiency.

Reduced Installation Time: Pre-configured modules simplify the process of installation, resulting in less labor costs.

The positioned components for simple replacements and upgrades.

The Rise of Solid-State Switchgear:

Industrial low voltage switchgear are mostly mechanical-latch based circuit breakers but the future lies in solid-state low voltage switchgear using semiconductor based switching technology.

Advantages of Solid-State Switchgear:

Speedy Switching: Solid-state systems work on micro seconds, making fault response time low.

Zero Mechanical Wear & Tear − Moving parts are absent, so switchgear has a longer life and better reliability.

Silent Operation: No sound that comes with a conventional electromechanical breaker

Low Maintenance: It is cost-effective owing to lower failures and servicing.

Integration with Smart Grids:

It plays a vital role in the function of smart grid infrastructure as it helps in the distribution of energy and load balancing in a seamless manner.

The Impact of Smart Grids on Low Voltage Switchgear:

Real-time Load Management: Switchgear will do real-time Load Management based on the requirement.

Self-Healing Networks: When a fault occurs, the system will redirect electricity to unaffected areas.

Cybersecurity: With the growing digitalization, manufacturers will adopt robust cybersecurity measures to prevent cyber threats.

AI and Machine Learning in the Healthcare Sector:

With the world’s transition to advanced technology, AI-powered switchgear will be the new ‘normal’ providing more automation and intelligence to power distribution.

Use of AI in Low Voltage Switchgear:

Anomaly detection: AI can find abnormal power consumption and recommend remedial measures.

Energy Forecasting — Machine learning algorithms will be used to forecast energy consumption trends, helping businesses optimize their energy consumption.

Adaptive Systems: AI will maintain optimum settings that increase performance and lifespan.

Conclusion

The future of low voltage switchgear is digital, efficient and green. Thanks to IoT, AI, solid-state technology and smart grids, these advancements will transform power distribution into a safer, smarter and more reliable system.

Adoption of Next Gen switchgear is crucial for modern enterprise to act proactively for cost efficiency and sustainability in energy usage with next gen technologies to leave the competition behind in the market.

6 notes

·

View notes

Text

Innovations in Electrical Switchgear: What’s New in 2025?

The electrical switchgear industry is undergoing a dynamic transformation in 2025, fueled by the rapid integration of smart technologies, sustainability goals, and the growing demand for reliable power distribution systems. As a key player in modern infrastructure — whether in industrial plants, commercial facilities, or utilities — switchgear systems are becoming more intelligent, efficient, and future-ready.

At Almond Enterprise, we stay ahead of the curve by adapting to the latest industry innovations. In this blog, we’ll explore the most exciting developments in electrical switchgear in 2025 and what they mean for businesses, contractors, and project engineers.

Rise of Smart Switchgear

Smart switchgear is no longer a futuristic concept — it’s a necessity in 2025. These systems come equipped with:

IoT-based sensors

Real-time data monitoring

Remote diagnostics and control

Predictive maintenance alerts

This technology allows for remote management, helping facility managers reduce downtime, minimize energy losses, and detect issues before they become critical. At Almond Enterprise, we supply and support the integration of smart switchgear systems that align with Industry 4.0 standards.

2. Focus on Eco-Friendly and SF6-Free Alternatives

Traditional switchgear often relies on SF₆ gas for insulation, which is a potent greenhouse gas. In 2025, there’s a significant shift toward sustainable switchgear, including:

Vacuum Interrupter technology

Air-insulated switchgear (AIS)

Eco-efficient gas alternatives like g³ (Green Gas for Grid)

These options help organizations meet green building codes and corporate sustainability goals without compromising on performance.

3. Wireless Monitoring & Cloud Integration

Cloud-based platforms are transforming how switchgear systems are managed. The latest innovation includes:

Wireless communication protocols like LoRaWAN and Zigbee

Cloud dashboards for real-time visualization

Integration with Building Management Systems (BMS)

This connectivity enhances control, ensures quicker fault detection, and enables comprehensive energy analytics for large installations

4. AI and Machine Learning for Predictive Maintenance

Artificial Intelligence is revolutionizing maintenance practices. Switchgear in 2025 uses AI algorithms to:

Predict component failure

Optimize load distribution

Suggest optimal switchgear settings

This reduces unplanned outages, increases safety, and extends equipment life — particularly critical for mission-critical facilities like hospitals and data centers.

5. Enhanced Safety Features and Arc Flash Protection

With increasing focus on workplace safety, modern switchgear includes:

Advanced arc flash mitigation systems

Thermal imaging sensors

Remote racking and switching capabilities

These improvements ensure safer maintenance and operation, protecting personnel from high-voltage hazards.

6. Modular & Scalable Designs

Gone are the days of bulky, rigid designs. In 2025, switchgear units are:

Compact and modular

Easier to install and expand

Customizable based on load requirements

Almond Enterprise supplies modular switchgear tailored to your site’s unique needs, making it ideal for fast-paced infrastructure developments and industrial expansions.

7. Global Standardization and Compliance

As global standards evolve, modern switchgear must meet new IEC and IEEE guidelines. Innovations include:

Improved fault current limiting technologies

Higher voltage and current ratings with compact dimensions

Compliance with ISO 14001 for environmental management

Our team ensures all equipment adheres to the latest international regulations, providing peace of mind for consultants and project managers.

Final Thoughts: The Future is Electric

The switchgear industry in 2025 is smarter, safer, and more sustainable than ever. For companies looking to upgrade or design new power distribution systems, these innovations offer unmatched value.

At Almond Enterprise, we don’t just supply electrical switchgear — we provide expert solutions tailored to tomorrow’s energy challenges. Contact us today to learn how our cutting-edge switchgear offerings can power your future projects.

6 notes

·

View notes

Text

Through local papers and word of mouth, volunteer Daya Shankar keeps track of a very specific cause of death. As soon as he receives news of someone being struck by lightning around his neighborhood in Jharkhand, East India, he picks up his motorcycle and heads to the destination. Sometimes he travels alone, other times with a team of five or six from the organization he volunteers for, the Lightning Resilient India Campaign. It’s a task he is undertaking increasingly often.

Last month, he rode to meet the Manjhi family, who lost an 8-year-old boy, Viresh, and his mother, Subodhra, after a tea stall they were sheltering under was struck during a storm. A lightning bolt can generate temperatures three times hotter than the surface of the sun, with a voltage millions of times higher than a household socket. If it connects with a human, it can stop the heart and respiratory system, damage the brain and nervous system, leave major burns, and cause blunt trauma if victims are flung by the force of being struck. On the day the Manjhis died, lightning also killed another person in the village and injured five others.

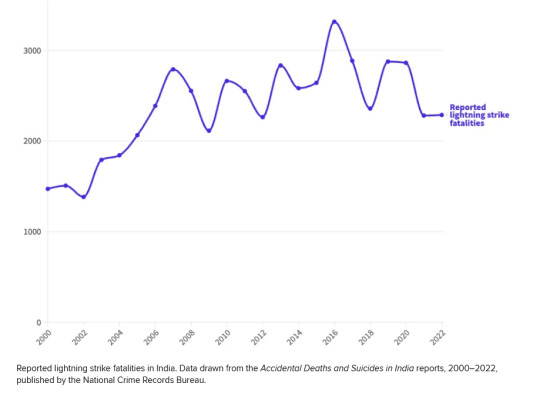

Each year, an estimated 24,000 people worldwide are killed by lightning. While a significant number, deaths per head of population have fallen sharply over the past two centuries, thanks largely due to urbanization, the protection of more substantial housing, and improved weather forecasting. But India’s large rural population remains badly affected. Between 2,000 and 3,000 Indians die annually by lightning, most of them working class people aged 10 to 50. Fatalities have risen by more than 50 percent since the turn of the century, outstripping population growth. Compare that to the US, where fatalities have been gradually falling and number around 20 a year. India can experience more than that number of deaths in a day.

For every person who is killed by lightning, roughly another nine are struck and survive, often with life-changing injuries. And with climate change making stormy weather and lightning more common, activists like Daya believe the Indian government is failing to protect its people. “A bare minimum would be to at least spread information about all things lightning at local government level,” says Daya.

India has systems in place to predict dangerous storms. These work by gathering a lot of precise data, says Sanjay Srivastava, chair of the Climate Resilient Observing-Systems Promotion Council (CROPC), an intergovernmental institute that works to develop resilience against climate change impacts. Srivastava is also the convener of the Lightning Resilient India Campaign.

“Detecting the precise location of a lightning cloud-to-ground strike is a calculation mechanism where a minimum of three devices are required,” says Srivastava. These are radio frequency detectors, to detect the radio waves produced by lightning; a doppler weather radar, to detect precipitation and wind patterns associated with storms that may produce lightning; and a lightning detector, a device specifically designed to detect the electromagnetic signals produced by lightning strikes.

As of April 2022, India’s National Remote Sensing Center had 46 lightning-detection sensors installed across the country. Another institute, Indian Institute of Tropical Meteorology, Pune, has 83 in place. These, along with other private and institutional data, monitor and guide India’s lightning strike warning system.

The data shows that Jharkhand and other neighboring regions in East and Central India are among the country’s hot spots, as they are where hot and dry air currents from the northwest meet moist easterly currents. When clouds encounter warmer air, moist air rises until it reaches the subzero temperatures of the upper atmosphere, where it can freeze into ice particles called graupel. As these then collide with other ice particles, they generate electrostatic charges, which can eventually lead to lightning. Rising global temperatures are increasing this phenomenon.

However, despite advancements in meteorology, the full mechanisms behind lightning’s formation and behavior remain partially shrouded in mystery. The precise triggers, the exact nature of how lightning propagates through the atmosphere, and the factors that determine the intensity of each strike are still not fully understood. The risk to human life can be predicted in only fairly broad terms.

And while these early warning systems exist, their information often does not reach people in time. This is why volunteers like Shankar work to inform people on how to stay safe and teach how to build easy-to-make lightning arrestors—devices that neutralize cloud-to-ground lightning.

The day Shankar visited the Manjhis’ house, it was drizzling. On the way he spotted farmers and locals sheltering under trees. He stopped to inform them that standing under a tree during rainfall increases the chances of getting hit by lightning. But they said there was no other place where they could take shelter.

Lightning strike casualties are more prevalent in rural areas where infrastructure is limited. Concrete houses, which can have protective Faraday cage effects, are less prominent there than in cities, while tall vegetation, which workers might shelter under, can attract strikes. Densely populated areas in stormy regions also see more casualties. “We can say there are two factors behind lightning casualties. There are lots of environmental factors, and then there are socioeconomic factors,” says Anand Shankar, who works at the India Meteorological Department at the Ministry of Earth Sciences in the state of Bihar (Anand and Daya are not related).

Increasingly, attention is focusing on air quality too. In recent research for Bihar, which neighbors Jharkhand and is one of the worst affected states in India, Anand found that particulate matter in the air increased lightning activity in the region. Aerosols such as pollution or dust particles can affect the friction between the particles that generate lightning and make it more common.

But to what extent growing casualties in Bihar can definitively be attributed to pollution or global warming isn’t yet clear, says Ashish Kumar, a colleague of Anand’s at the IMD. “We had no data before 2015–16, so we have not come to the conclusion whether this is happening recently due to climate change.” But Kumar doesn’t refrain from pointing out that a warming planet can lead to increased lightning activities. Research has projected that a 1 degree Celsius rise in temperature can lead to a 12 percent increase in lightning strikes.

When Daya reached the Manjhis’ house, the family told him that Viresh and Subodhra had taken shelter under a plastic-roofed tea stall because a storm had hit on their way back home from their farm. “People consider that saving themselves from the water is most important,” he says, but they fall prey to dangerous lightning strikes if they stand under something that can act as a conductor. “The best option for them would have been to find a concrete shelter.”

Spreading this sort of knowledge is why volunteers like Daya hunt for the places where recent lightning deaths have taken place. “We often arrange talk shows and plays and other things in the rural areas, but people are either too busy or not interested. But when such accidents take place, people get aware and are willing to listen,” he says.

Another way the Lightning Resilient India Campaign tries to reach the masses is through schoolchildren. “They are curious and spread the message in their families and communities,” Daya says. Warnings are also pushed through government hooters and through mobile applications like the Damini app, which triggers a warning notification before a lightning strike.

“It is not like a cyclone, where you have seven days and you are evacuating people,” says Srivastava. “It’s instant. So, those 30 minutes or three hours are the golden hours.” But often farmers who live far away from their houses do not bring mobile phones to their fields and leave very early for work, and might miss the warning alert.

Srivastava and Anand agree that the best solution would be to put up more lightning arrestors. But with limited funds and a lack of government support, campaign volunteers have to resort to promoting the use of DIY lightning arrestors in high-risk areas. These can be made by fixing the metal rim of a bicycle wheel high up on a bamboo stick and attaching the rim to the ground using copper wire. “They are not bad for a small area, but their efficiency is limited when compared with bigger lightning arrestors,” says Srivastava.

In the absence of adequate protections, 16 of the 36 states and union territories in India have started accepting lightning strikes as a state disaster, including Bihar and Jharkhand, and so pay out compensation money of 400,000 rupees ($4,766) to the family of a deceased person. This does something to help families handle the economic shock of losing someone, but still leaves thousands unsupported. “Only 10 percent of people die—90 percent are left with a social trauma,” says Srivastava. “We need to create a psychosocial relief and also proper medical treatment for those who survive,” he says.

6 notes

·

View notes