#custom induced draft fan

Explore tagged Tumblr posts

Text

Centrifugal High-Pressure Induced Draft Fan Price and Selection Guide

In industrial production, centrifugal high-pressure induced draft fans are a common type of equipment, widely used in metallurgy, chemical engineering, power and other fields. Its price is influenced by multiple factors, including brand, specification and model, material, and whether customized design is required, etc. Products of well-known brands usually have better quality guarantees, but their prices are also relatively higher. Although the equipment produced by some small and medium-sized enterprises is relatively low in price, it may be slightly inferior in terms of performance and durability. Therefore, when making a choice, it is necessary to comprehensively consider the budget and actual needs.

Selection

Different application scenarios have different demands for centrifugal high-pressure induced draft fans. For instance, the equipment used for mine ventilation needs to have a strong air volume and pressure, while also taking into account the explosion-proof safety performance. For fans used in laboratories or in conjunction with precision instruments, more emphasis is placed on noise control and operational stability. Therefore, before making a purchase, one should clarify their purpose of use and determine the suitable model in combination with the on-site environmental conditions (such as temperature, humidity, dust concentration, etc.).

Precautions

In addition to the initial purchase cost, the maintenance cost for long-term use is equally important. High-quality centrifugal high-pressure induced draft fans often have a higher energy efficiency ratio and can save a large amount of energy costs during daily operation. In addition, good after-sales service is also an indispensable part, as it is related to whether problems that may arise later can be solved in a timely manner. It is recommended to give priority to choosing brand products that offer comprehensive warranty services.

Conclusion

Youdaoplaceholder0 Reasonable assessment of one 's own needs and full understanding of market conditions are the key steps to select cost-effective and practical working requirements of centrifugal high-pressure induced draft fan.

E-mail: [email protected]

0 notes

Text

Boiler ID Fan Manufacturers: Enhancing Efficiency with Essar Air Systems

In industrial boiler systems, efficient air management is crucial for optimal performance. One of the key components in achieving this is the Induced Draft (ID) Fan. As a leading Boiler ID Fan Manufacturer, Essar Air Systems specializes in providing high-performance, energy-efficient, and durable ID fans for various industrial applications.

Understanding Boiler ID Fans

A Boiler ID Fan plays a vital role in maintaining the efficiency of a boiler system by extracting flue gases and ensuring proper combustion. These fans create negative pressure, drawing out hot gases from the furnace and directing them towards the chimney. This process helps maintain controlled combustion and prevents backpressure, thereby optimizing boiler performance.

Why Choose Essar Air Systems for Boiler ID Fans?

1. Superior Engineering & Quality Manufacturing

Essar Air Systems designs and manufactures high-quality Boiler ID Fans using premium materials and advanced engineering techniques. Our fans are built for high efficiency, durability, and low maintenance.

2. Energy Efficiency & Cost-Effective Solutions

Our ID fans are engineered to consume less power while providing maximum output. This results in significant energy savings, reducing operational costs for industries.

3. Customizable Solutions

Every industrial setup is unique, and so are its requirements. We offer custom-designed Boiler ID Fans to meet specific air volume, pressure, and temperature needs.

4. Reliable & Long-Lasting Performance

With precision engineering and stringent quality control, Essar Air Systems ensures that its fans deliver consistent and reliable performance, even under extreme working conditions.

5. Wide Industry Applications

Our Boiler ID Fans cater to various industries, including:

Power Plants

Cement Plants

Steel & Metal Industries

Chemical & Petrochemical Plants

Food Processing Industries

The Essar Air Systems Advantage

Being a reputed Boiler ID Fan Manufacturer in India, Essar Air Systems follows a customer-centric approach. We prioritize efficiency, innovation, and after-sales support, ensuring our clients receive the best value for their investment.

If you are looking for high-performance Boiler ID Fans, trust Essar Air Systems for unmatched quality and reliability. Contact us today to learn more about our products and how we can enhance your industrial operations.

Get in Touch with Us!

For inquiries, reach out to us at Essar Air Systems website for more information.

0 notes

Text

Induced draft fans and forced draft fans from Reitz india are custom designed to serve the needs of various processes in industries like cement, iron & steel, power plants, fertilizers/ chemicals and more. As a top quality Reitz India's PA fans and SA fans, has set a benchmark in delivering superior fans with high quality features and better industrial standards.

0 notes

Text

Livestock manure itself is of good quality and is particularly suitable for the manufacture of organic fertilizers. Organic fertilizer raw materials contain a lot of fiber, provide sufficient nutrients for the survival of microorganisms, and have the role of improving soil structure. However, the production of organic manure must undergo aerobic fermentation, which can remove the odor of livestock and poultry manure. In the process of composting and fermentation of organic fertilizer, many customers choose simple compost turning machine. Before understanding the characteristics of the simple compost turning machine, we first understand the process of pig manure compost fermentation. After solid and liquid separation of pig manure in the pig house, the manure residue, dry and clean feces and bacteria are mixed together. Generally, the water content of the feces after separation by the solid-liquid separator is 50% to 60%, and then the mixed materials are loaded into the woven bag on the packing rack in the fermentation room. The induced draft fan is used to remove moisture from the greenhouse. By adjusting the temperature and humidity, the formation of organic fertilizer is accelerated. Generally, an organic fertilizer can be produced in 25 days.

The advantage of the simple compost turning machine is that it has enough power to turn the pile during operation, which can turn the compost more thoroughly and avoid anaerobic fermentation caused by the less timely turning of the pile. At the same time, it has excellent heating and insulation functions for the fermentation workshop. The disadvantages of the use of simple compost turning machine are high investment costs and difficult mechanical maintenance. The advantages of compost fermentation are small investment, low operating costs and high compost quality. Compost fermentation is mainly used for the production of small and medium-sized commercial organic fertilizers and the harmless treatment of manure in pig farms. However, the disadvantage of compost fermentation is that it occupies a large space and has high labor costs. Huaqiang Heavy Industry provides all kinds of fermentation compost turning machine all year round, welcome to come to consult.

0 notes

Text

ID Fans

Are You Looking for ID Fans Manufacturer in India ?AKJ Industries is a prominent manufacturer and supplier of high-quality ID (Induced Draft) Fans in India. These fans are engineered for efficient air handling, crucial for maintaining optimal combustion in boilers, kilns, and furnaces. Designed for durability and high performance, AKJ Industries’ ID Fans ensure proper exhaust of flue gases and are widely used in power plants, cement plants, and other industrial applications. With a focus on innovation and customer satisfaction, AKJ Industries delivers energy-efficient solutions that meet diverse industrial needs while adhering to stringent quality standards. For more details Contact us@+91-9868621620

0 notes

Text

Keeping Your Cool: The Essential Guide to Cooling Towers

Imagine a giant radiator constantly working behind the scenes to keep your house from overheating. That's basically what a cooling tower does for industrial processes! These remarkable structures play an essential role in various industries by removing excess heat and ensuring smooth operations. But how exactly do they work, and why are they so crucial? Let's dive in and explore the glamorous world of cooling towers!

The Cooling Process Explained

In simple terms, a cooling tower acts as a heat exchanger. Here's a breakdown of the process: Warm Water In: Industrial processes often generate a lot of heat. This hot water is pumped into the cooling tower. Airflow: Powerful fans within the tower create an upward draft of air. Evaporation Magic: As the hot water cascades down technical fillings inside the tower, it comes into contact with the cool air. This contact causes some of the water to evaporate, absorbing heat in the process.

Cooler Water Out: The cooled water is then collected at the bottom of the tower and returned to the industrial process, ready to absorb more heat.

Heat Dispersal: The evaporated water, now in the form of hot, humid air, exits the tower through the top.

Types of Cooling Towers: There are two main types of cooling towers, each with its own advantages:

Natural Draft Cooling Towers: These towers rely on the natural rising of hot air to create the upward draft. They are typically large, hyperboloid-shaped structures and are well-suited for applications where energy efficiency is a priority.

Induced Draft Cooling Towers: These towers use fans to generate the airflow, making them more compact and efficient in hotter climates. They are commonly used in industrial settings.

Why are Cooling Towers Important?

Cooling towers are important for several reasons: Maintaining Optimal Temperatures: In many industries, like power generation or chemical processing, accurate temperature control is essential. Cooling towers control equipment from overheating, ensuring efficient operation and preventing breakdowns. Energy Efficiency: By removing heat, cooling towers allow industrial operations to reuse the cooled water, reducing the need for constant water replacement. This translates to significant water conservation and energy savings. Environmental Impact: Overheated industrial processes can release excess heat into the environment. Cooling towers help mitigate this by transferring heat to the atmosphere through controlled evaporation.

Veda Engineering: Your Partner in Cooling Solutions When it comes to reliable and efficient cooling tower solutions, Veda Engineering stands out as a leading Cooling Tower Manufacturer. With a proven track record and a commitment to innovation, they offer a wide range of cooling towers to suit diverse industrial needs. Here's what sets Veda Engineering apart: Cutting-Edge Technology: They collaborate with leading manufacturers to provide access to state-of-the-art cooling tower designs that prioritize efficiency and sustainability. Quality and Durability: Their cooling towers are built with the highest quality materials and engineering practices, ensuring long-lasting performance and minimal maintenance requirements. Excellent Service: Veda Engineering provides comprehensive after-sales support, ensuring your cooling tower operates smoothly for years to come.

Conclusion Cooling towers are the silent heroes of many industries, keeping processes cool and efficient. By understanding their role and the expertise of leading manufacturers like Veda Engineering, you can ensure your operations run smoothly and sustainably. If you're looking for a reliable cooling tower solution, look no further than Veda Engineering. Their commitment to quality, innovation, and customer service makes them a trusted partner for all your industrial cooling needs.

0 notes

Text

Exporter of Flash Dryer in Cameroon

Drytech Engineering Systems is Exporter of Flash Dryer in Cameroon. We are Manufacturer, Supplier, and Exporter of Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, and Dust Collector Systems. Drytech Engineering System is Flash Dryer Manufacturer in Ahmedabad, Gujarat, India. Our flash dryer system is an inexpensive solution to drying powders and granular materials, and is designed for high moisture materials with a constant-rate drying zone and can use higher gas temperatures, versus other dryer types because the material retention time is very short. Our Flash Dryer offers rapid drying for a wide range of materials. Working Process: The drying chamber receives the heated thermal medium, generating a swirling airflow combined with mechanical agitation for efficient drying. A feeder introduces the wet material into the chamber, where it undergoes pulverization and drying via stirring and vortex flow. At the top of the chamber, a particle-size classifier separates fine powder meeting drying standards, which the separator collects. The classifier retains larger particles, subjecting them to further pulverization and drying until they meet the required standards. The induced draft fan expels clean exhaust gas, completing the drying process. Why Choose a Reputable Flash Dryer Manufacturer? High-Quality Equipment Technical Support Customization Options Innovative Solutions Drytech Engineering Systems is Exporter of Flash Dryer in Cameroon and including locations like Yaounde, Douala, Garoua, Kousseri, Bamenda, Maroua, Ngaoundere, Bafoussam, Mokolo, Buea, Ebolowa, Kribi, Bertoua, Loum, Limbe, Foumban, Kumba, Nkongsamba, Mbouda, Edea, Dschang, Yagoua, Sangmelima, Banyo, Obala, Meiganga, Guider, Tiko, Kaele, Bafia, Wum, Kumbo, Nkoteng, Bafang, Mbalmayo, Tibati, Bangangte, Figuil, Batouri, Nanga-Eboko, Mbanga, Eseka, Penja, Mbandjock, Garoua Boulai, Manjo, Touboro, Mora, Muyuka, Yoko, Pitoa, Fontem, Lagdo, Belabo, Babanki, Kontcha, Belabo, Makenene, Bibemi, Guefigue, Ambam, Poli, Makari, Yabassi, Tignere, Njinikom, Figuil, Bogo, Maga, Dizangue, Yoko. For detailed information and inquiries, please feel free to contact us. Read the full article

0 notes

Text

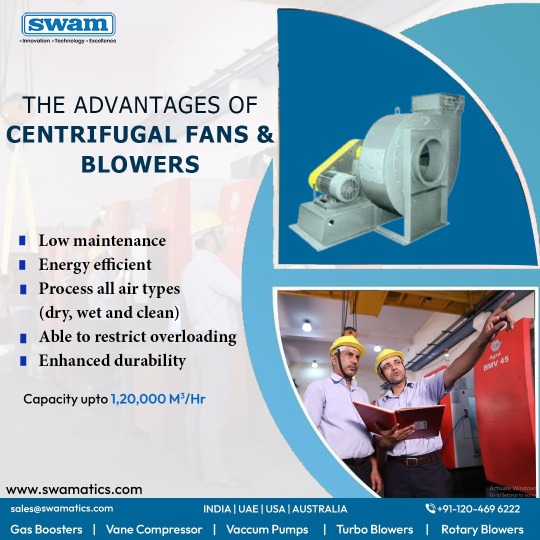

Swam offers a wide range of centrifugal fans that fulfill the requirements of many leading industries. They can handle higher pressures and volumes of air, making them more suitable for diverse processes. The Fans generally are of high quality welded construction and consist of Impeller assembly, spiral housing and suction and discharge nozzles. The impellers, depending on the application and the pressure, have the backward curved or straight radial blades and are intended to handle dust laden, corrosive or hot gases, are manufactured out of properly selected anti-corrosive, wear and heat resistant materials.

Distinctive features of centrifugal fans:

Wide selection of fans to meet customer process requirements

Heavy duty and rugged design for lasting performance

Smooth vibration free operation

Wide choice of materials of construction and sealing systems

Suitable for corrosive, abrassive, hazardous application

For most process industries; Cement, Power, Chemical, Steel & Mining Swam fans are used for: Ventilation & air circulation, Induced draft & dust collection, Cooling and combustion air & Exhausting or Boosting Gases etc.

For more details, reach out to us at:

🌐http://www.swamatics.com/

📲+91-120-4696222

#manufacturer#supplier#centrifugalfans#centrifugalblowers#Compressors#blowers#industrialblowers#SwamPneumatics#swam#swamatics

1 note

·

View note

Text

Are you looking for Induced Draft Fans Manufacturer in India

Induced Draft Fans Manufacturer From Faridabad, India:

“VENTILAIR INDIA PVT.LTD.” offers High efficiency induced draft fans with Mild Steel and Stainless Steel construction. Our Fans are suitable for even toughest of the Industrial conditions and are used in various industries such as boiler, chemical, dust collection, pharma, marine, packaging, etc.

Ventilair India has vast experience as an induced draft Fan manufacturer, supplier & exporter. Our fans are widely used by manufacturers of boilers, furnaces, dust collection, and ovens with their equipment. All the impellers are statically and dynamically balanced on the machine. A balancing and fan performance certificate is provided along with the blower. Ventilair makes Induced Draft Fan and Forced Draft Fan are designed to run at high efficiency thereby giving considerable power savings to our customers.

Features of Induced Draft Fans:-

1. Less Power Consumption

2. High Impeller Life

3. Less Maintenance

4. Low noise

5. High Bearing Life

6. Good after sales service

About Us:

Our team of skilled professionals keeps a strict vigil on the manufacturing process to make sure that only faultless products reach our esteemed customers.Established in the year 1988 in Faridabad (Haryana, India), “Ventilair India Private Limited” is amongst the leading Manufacturers and Exporters of a wide variety of air pollution control systems and equipments. Our product range includes Air Cooling System,

Visit Us: Induced Draft Fans Manufacturer

Contact Information:

No. 11/7, Mile Stone, Mathura Road, Faridabad - 121003, Haryana, India

+91 9971026641

0 notes

Text

Teral stands at the forefront of Induced Draft Fan manufacturing in India, renowned for establishing industry benchmarks in both quality and performance. With an unwavering dedication to innovation and unwavering customer-centricity, Teral has cemented its position as the foremost authority in this domain. Their production facilities, staffed by proficient experts, guarantee the creation of inducement draft fans that excel in efficiency and reliability. Be it for industrial applications, HVAC systems, or power generation plants, Teral's product range consistently delivers the ultimate in airflow and cooling solutions. When it comes to Induced Draft Fan manufacturing in India, Teral stands unrivaled in excellence.

0 notes

Text

https://www.blowers-fans.com/forced-draft-fan.html

Teral stands at the forefront of Induced Draft Fan manufacturing in India, renowned for establishing industry benchmarks in both quality and performance. With an unwavering dedication to innovation and unwavering customer-centricity, Teral has cemented its position as the foremost authority in this domain. Their production facilities, staffed by proficient experts, guarantee the creation of inducement draft fans that excel in efficiency and reliability. Be it for industrial applications, HVAC systems, or power generation plants, Teral's product range consistently delivers the ultimate in airflow and cooling solutions. When it comes to Induced Draft Fan manufacturing in India, Teral stands unrivaled in excellence.

0 notes

Text

Boiler ID Fan Manufacturers: Enhancing Efficiency and Performance

Boiler ID (Induced Draft) fans play a crucial role in maintaining the efficiency and performance of industrial boilers. These fans help in extracting flue gases, ensuring proper combustion, and maintaining the required air pressure inside the boiler. Finding reliable Boiler ID fan manufacturers is essential for industries to achieve optimal operational efficiency and meet environmental regulations.

What is a Boiler ID Fan?

A Boiler ID fan is an induced draft fan that extracts hot flue gases from the boiler and discharges them into the atmosphere through a chimney. Unlike FD (Forced Draft) fans, which push air into the system, ID fans create a negative pressure that ensures the removal of exhaust gases, preventing backpressure and improving combustion efficiency.

Key Features of High-Quality Boiler ID Fans

High Efficiency – Designed to consume less energy while delivering maximum airflow.

Durability – Constructed with corrosion-resistant and heat-resistant materials.

Low Noise & Vibration – Advanced balancing techniques reduce operational noise.

Custom Design Options – Available in different sizes and configurations based on industrial requirements.

Compliance with Environmental Standards – Helps industries meet pollution control norms.

Applications of Boiler ID Fans

Boiler ID fans are used in various industries, including:

Power Plants – Essential for handling large volumes of flue gases.

Cement Industry – Helps remove hot gases and dust from kilns.

Steel Industry – Assists in maintaining proper airflow in furnaces.

Chemical Plants – Ensures safe disposal of harmful gases.

How to Choose the Best Boiler ID Fan Manufacturer?

When selecting a Boiler ID fan manufacturer, consider the following factors:

1. Experience and Reputation

Choose manufacturers with years of expertise in designing and supplying industrial fans. Look for positive customer reviews and successful project references.

2. Quality and Certifications

Ensure the manufacturer follows international standards like ISO and provides high-quality materials for long-term reliability.

3. Customization and Technical Support

A good manufacturer offers customized solutions tailored to your specific industrial needs and provides excellent after-sales support.

4. Competitive Pricing

Compare prices from multiple manufacturers while ensuring that quality is not compromised.

Conclusion

Boiler ID fans are vital components in industrial processes, ensuring efficient combustion and emission control. Choosing a reliable Boiler ID fan manufacturer can enhance operational efficiency, reduce downtime, and ensure compliance with environmental norms. Whether you operate a power plant, cement factory, or chemical plant, investing in a high-quality Boiler ID fan is a crucial decision for sustainable operations.

If you are looking for the best Boiler ID fan manufacturers in India, consider companies that offer premium quality, customization, and excellent customer support. Contact a trusted supplier today to get the best solution for your industry.

0 notes

Text

Reitzindia Industrial centrifugal blowers are custom designed to serve the needs of various processes in industries like cement, iron & steel, power plants, fertilizers/ chemicals and more. As a top quality Induced draft fans and forced draft fans from Reitz India, has set a benchmark in delivering superior fans with high quality features and better industrial standards.

0 notes

Text

Livestock manure itself is of good quality and is particularly suitable for the manufacture of organic fertilizers. Organic fertilizer raw materials contain a lot of fiber, provide sufficient nutrients for the survival of microorganisms, and have the role of improving soil structure. However, the production of organic manure must undergo aerobic fermentation, which can remove the odor of livestock and poultry manure. In the process of composting and fermentation of organic fertilizer, many customers choose simple compost turning machine. Before understanding the characteristics of the simple compost turning machine, we first understand the process of pig manure compost fermentation. After solid and liquid separation of pig manure in the pig house, the manure residue, dry and clean feces and bacteria are mixed together. Generally, the water content of the feces after separation by the solid-liquid separator is 50% to 60%, and then the mixed materials are loaded into the woven bag on the packing rack in the fermentation room. The induced draft fan is used to remove moisture from the greenhouse. By adjusting the temperature and humidity, the formation of organic fertilizer is accelerated. Generally, an organic fertilizer can be produced in 25 days.

The advantage of the simple compost turning machine is that it has enough power to turn the pile during operation, which can turn the compost more thoroughly and avoid anaerobic fermentation caused by the less timely turning of the pile. At the same time, it has excellent heating and insulation functions for the fermentation workshop. The disadvantages of the use of simple compost turning machine are high investment costs and difficult mechanical maintenance. The advantages of compost fermentation are small investment, low operating costs and high compost quality. Compost fermentation is mainly used for the production of small and medium-sized commercial organic fertilizers and the harmless treatment of manure in pig farms. However, the disadvantage of compost fermentation is that it occupies a large space and has high labor costs. Huaqiang Heavy Industry provides all kinds of fermentation compost turning machine all year round, welcome to come to consult.

0 notes

Text

NBA 2K24 PC review: A crash course in alienating your fanbase

Every year's releases are discussed in comparison to their predecessors. This is especially relevant to yearly sports championships. Is this merely a rehash of the previous game with upgraded rosters, one could wonder? Like NBA 2K23 and 2K22 before it, NBA 2K24 is a last-gen PC game. In reality, NBA 2K24 on PC doesn't even need to be compared to its PS5 and Xbox Series counterparts to demonstrate how terrible the experience it provides is. This is largely due to the performance bug that has afflicted several games in 2023. I tried to go in with an open mind and enjoy myself as much as possible. This is my job, after all, and you need that mindset in times of hardship, like having to go through NBA 2K24‘s constant crashing on PC. Only those who have endured this dark fate know the feeling of getting punched in the gut each time you start developing thoughts of having fun. Yet, there is fun to be had, theoretically speaking. Gameplay Actually playing basketball in NBA 2K24 is rather pleasant. Animations are fluid and realistic. Moving around the court, dribbling, and shooting feels natural relative to the athletes’ statures and abilities. Playing good defense is possible but is beaten by good offense, as it should be. The AI doesn’t appear to be brainless, though I did yell on a couple of occasions when I had a guy running toward the basket on an open break just to have him fade away to the three-point line as soon as I passed the ball. Other than the crashes, I didn’t experience any glitches or overpowered or broken mechanics. The one gripe I have is that pulling off an excellent release on Hall of Fame difficulty is nigh on impossible, especially with unfamiliar shot releases, but, you know, gaming journalist difficulty and all that. All in all, NBA 2K24 is good for a game of basketball. But we all know there’s more to it than that. MyCAREER MyCAREER is where you go to live out your NBA dreams. Creating your MyPLAYER gives you all the usual facial and body customization options, plus a face scan for extra immersion. That’s ripped away by you selecting which team you get drafted by rather than the other way around. I understand the choice of giving players the option to hoop for their favorite team right away, but in exchange, we’re left with no pre-NBA experience at all—no draft combine, no team workouts, and obviously no draft. Instead, you get dropped straight into the Neighborhood, where you’re be presented with frequent quests, and I’m using that word very lightly. Completing these quests is a decent early source of VC, but that’s it. They’re given by random, unvoiced characters, tasking you with challenges in areas of the Neighborhood. You can freely roam the Neighborhood and play numerous offline and online formats with friends or strangers on the internet. They are mostly fun, but beware that playing online formats without a pre-made party can result in tear-inducing wait times. There’s not much of a story going on, but I’m not a fan of needlessly bloated stories in basketball games anyway, so found the Neighborhood to be a refreshing playground for when you’re not in NBA matches. It’s a smart choice to avoid another cringe-inducing story like some recent NBA 2K entries. You also have your NBA career to worry about. There isn’t too much to it, really. You play league games and gradually progress your character’s stats, popularity, and endorsements. It’s a simple system and that’s why I appreciate it. I just like playing basketball in my basketball game. The pace of progression is solid, despite what was said in previews of the game. I was instantly averaging a double-double with my 60 OVR center, including online games, and leveled up quite a bit for each play session. We are the instant gratification generation, but that’s not video games’ problem to solve. MyTEAM Collecting collectibles for your collection, the game mode. MyTEAM is seemingly centered around building a strong team to compete with, but in actuality, it’s a completionist’s wet dream and worst nightmare all at once. There are many, and I mean many different collections to complete—players, different versions of the same players, team logos, uniforms, court floors, and arenas (yes, they are separated), shoes, and other trinkets. The list is seemingly endless, and that’s the whole point. If you don’t obsess over bringing every single collection to its completion, there is fun to be had in the numerous single-player and multiplayer modes in MyTEAM. Some of them overlap with stuff you can do in MyCAREER, but you’re not playing with a MyPLAYER, so it’s different enough. In NBA 2K24, all VC you obtain, through the extent of your skills or the depth of your wallet, is shared between MyCAREER and MyTEAM. This also affects Season Passes. Even if you prefer one mode to the other, you could use both for acquiring capital that you can then spend in your preferred mode. This is a player-friendly mechanic that allows for more freedom of choice on what you wish to play and when, so I’m all for it. Mamba Moments We’ve seen similar modes in the past. In Mamba Moments, you get to play seven legendary games from Kobe Bryant’s career. You’re given three objectives to complete in each game to match Kobe’s real-life performance. You even get trophies and achievements for it. I have a soft spot for these kinds of NBA 2K game modes, so its addition gets an approving nod from me. It’s a touching tribute to the Mamba. MyLEAGUE This is an ideal time to out myself as a nerd who primarily plays MyLEAGUE. I just love seeing how the league’s history develops and NBA 2K24’s MyLEAGUE scratches that itch. You can play yourself or run a franchise as its General Manager in MyGM, for decades or select a single-season experience in the NBA or WNBA, or play through a playoff bracket of your design. It’s also possible to play with standard teams and rosters or customize the league to your liking. There are options for everyone and there’s nothing better a game can provide its players. Just look at my Jacksonville Celtics for proof. And yes, I did pick Derrick White specifically for this pic. Sorry Derrick, that Heat playoff loss and now this. Performance If you came in reading the title and were looking for confirmation bias against the calamity that is NBA 2K24, you might be wondering what I’m on about, as I’ve been mostly positive throughout. I firmly stand behind the claim that NBA 2K24 is a decent to good basketball game. If you are able to play it. I have never persisted through such poor game performance in my entire life. That’s partially because I wouldn’t willingly slam my head against a wall in my spare time, and I didn’t review any of 2023’s trainwrecks, God bless. Then again, if NBA 2K24 wasn’t so poorly optimized for PC, I would have played rather than persisted and fully enjoyed it rather than almost enjoyed it. Crash is in the title and crashes are in the game. I didn’t count the exact number, because I didn’t think I’d need to, but NBA 2K24 must have crashed at least a dozen times, including three times in the same match. It crashed in regular Play Now games, it crashed in the Neighborhood, it crashed during a MyTEAM challenge, it crashed in the MyGM menu. There was no safe space for me anywhere in this game, the crash was always there, lurking and waiting to take all enjoyment out of my playing session. All this coupled with the stripped-back narrative and lack of cross-play between PC and current-gen consoles shows the PC player base is being left behind, yet again by NBA 2K. Conclusion NBA 2K24’s PC port left me emotionally scarred, like a morbid master torturing its victim by giving it minor amounts of fun before stripping it all away. I didn’t develop Stockholm syndrome, but I can see that there’s something decent buried deep underneath all of the performance issues, which aren’t exclusive to PC and old-gen, by the way. PC players are rightfully angry that they’re still stuck behind current-gen consoles. Despite offering some fun matches, NBA 2K24 does plenty enough to deserve its mediocre rating. Read the full article

0 notes

Text

Which is located in the lower roller

Raymond mill in the use of the process, there should be a fixed personnel responsible for the care, the operator must have a certain level of technology. Which is located in the lower roller, roller blade and turn the course of the same material is fed between shoveling throwing ring roll mill to form a litter layer, layer of the material generated by the rotation of the roller outward pressure to squeeze the material crushed, so as to achieve the purpose flour..Raymond mill will be broken into large lumps of raw materials needed to feed size, by the bucket elevator to transport materials to the storage silo, and then sent to a host of grinding chamber evenly by the electromagnetic vibrating feeder, material into the grinding chamber between the grinding roller and grinding China High-pressure Centrifugal Fans Company ring, after grinding powder will flow from the fan to the analysis machine grading achieve the required fineness of powder with the airflow through the pipe into the large cyclone collector, carried separate collection, and then discharged through the discharge is finished.

Raymond Mill before installing the operating personnel must carry out the necessary technical training to understand the principle of Raymond mill performance, familiar rules. Precautions for the Raymond Mill powder machine properly, the device should be developed, "the safe operation of equipment maintenance system" can ensure the long-term safe operation of the Raymond mill, and have the necessary maintenance tools and grease and corresponding accessories. Materials are crushed to the desired particle size, the whole structure is Raymond mill by the host, analysis machine, plumbing fixtures, air blower.Raymond mill after a period of use, maintenance should be carried. Host operation, the blade system has played a very important role.

While the ring roller mill blade repair and replacement of wearing parts such treatment, grinding roller device before and after use of the connecting bolt nuts should be carefully examined to see if there is loosening, whether to add a little grease.Raymond mill grinding roller device to use more than 500 hours or so to replace the roller, the roller kit for rolling bearings must be cleaned, damaged parts should be replaced, fuel pumps and tools can be used to manually grease gun.

Hoist the material sent by the hopper, then by vibrating feeder will feed into Raymond uniform continuous grinding powder machine host indoor, because the centrifugal force, roller swing outward rotation, the squeeze on grinding ring, between the shovel blade materials to the roller and grinding ring rolling mill rolls by fine grinding to achieve the purpose of the material after grinding with circulating air blower being brought into the analysis machine for sorting , fine through coarse material regrinding, qualified powder into the air waste cyclone powder collector through the powder discharge pipe, is finished. Raymond mill needs to be equipped with the user, hoist, electromagnetic vibrating feeder, electric motors and other components

0 notes