#delay cost buffer

Explore tagged Tumblr posts

Text

Preserving the Past | How a Construction Estimating Service Supports Historic Renovations

Introduction

Historic renovations are more than just construction projects—they are missions to preserve cultural identity, architectural artistry, and community heritage. These projects come with a unique set of challenges: outdated materials, strict preservation guidelines, and unpredictable structural conditions. In such high-stakes environments, financial planning becomes both critical and complex. A construction estimating service plays a vital role in supporting historic renovations by forecasting costs accurately, managing risk, and aligning preservation goals with budget realities.

Understanding the Complexity of Historic Renovations

Unlike modern construction, historic renovations demand extraordinary attention to detail and sensitivity to architectural authenticity. These projects often require working with fragile materials, replicating century-old craftsmanship, or adhering to national heritage regulations. The unpredictable condition of hidden structural elements and the need for specialized labor can lead to volatile costs. A construction estimating service provides clarity in this uncertainty by mapping out cost implications across every phase.

Specialized Cost Knowledge

One of the greatest advantages of using a construction estimating service for historic renovations is access to cost databases tailored to heritage-specific items. These include antique finishes, custom-milled woodwork, lime plasters, handmade tiles, and restoration-grade hardware. Estimators familiar with historic projects can source these prices from trusted networks and ensure the budget reflects the premium nature of these materials and methods.

Aligning with Preservation Guidelines

Many historic buildings are protected under local or national regulations. Compliance with these standards often restricts what materials and techniques can be used. A construction estimating service collaborates with architects, engineers, and preservation consultants to ensure the estimates conform to these strict guidelines. This collaboration helps prevent costly redesigns or permit delays by aligning costs with conservation requirements early in the planning process.

Uncovering Hidden Costs

Historic buildings often hold surprises behind their walls—rotted timber, outdated wiring, asbestos, or damaged masonry. A skilled construction estimating service anticipates these potential discoveries by adding allowances and contingencies that reflect the probability of encountering such conditions. This proactive approach prevents severe budget overruns later in the project when surprises inevitably surface.

Labor and Craftsmanship

Restoring a heritage building requires more than typical labor. It demands artisans skilled in lost trades—stonemasons, woodcarvers, traditional roofers, and plaster experts. These specialists come at a higher cost and may require additional lead time. Construction estimating services provide realistic labor pricing that accounts for the difficulty of sourcing such talent and the time-intensive nature of their work.

Material Sourcing Challenges

Sourcing authentic or reproduction materials for heritage work is difficult and expensive. Whether it's sourcing reclaimed bricks, custom ironwork, or original glass patterns, these materials are not found in typical supply chains. A construction estimating service includes extended sourcing times, transportation logistics, and potential storage costs in the budget. This ensures no hidden costs creep in due to delays or miscalculations.

Collaboration with Conservation Professionals

In heritage work, conservation architects, archaeologists, and historians may be involved in the approval process. Construction estimating services understand the need to collaborate with these professionals to adjust budgets in real time. As decisions evolve to protect the site’s integrity, the estimator ensures that all changes are reflected in the financial plan, helping the team stay informed and in control.

Supporting Grant and Funding Applications

Many historic renovation projects rely on public grants, tax credits, or nonprofit funding. These applications often require a detailed and credible cost estimate as part of the submission. A professionally prepared estimate from a construction estimating service adds credibility to the project and improves the chances of securing financial support. Their transparent cost breakdowns are also useful in donor reporting and public accountability.

Change Management in Adaptive Reuse

Sometimes historic buildings are being adapted for modern uses—like turning a church into a library or a mill into an office complex. These transformations, known as adaptive reuse, require careful cost integration between old and new. A construction estimating service helps manage this balance by assessing how modern amenities (like elevators or HVAC systems) can be introduced without compromising the building’s character or violating codes.

Conclusion

Historic renovations demand a precise, respectful, and financially grounded approach. They are projects rooted in storytelling and preservation, but also need to meet budgets, deadlines, and regulations. A construction estimating service becomes the financial translator between past and present, ensuring that the beauty and significance of heritage structures are preserved without hidden financial risk. Whether it's a museum, a colonial home, or an art deco theater, accurate cost estimating is the backbone of any successful restoration.

#historic renovation#heritage construction#preservation budget#construction estimating#antique materials cost#old building repair#restoration estimate#cultural preservation#adaptive reuse#construction planning#cost forecasting#conservation rules#budgeting historic sites#heritage grant support#masonry repair cost#estimating consultants#traditional materials pricing#restoration labor cost#AS Estimation & Consultants#construction heritage project#plaster restoration cost#architectural conservation#project cost control#delay cost buffer#funding historic buildings#construction risk#unknown structure costs#estimating historic sites#contractor for heritage#heritage restoration estimates

0 notes

Text

Monaco Grand Prix 2025: The Race That Broke the Grid into Three

Monaco doesn’t usually deliver races to remember — but this year, the street circuit became a strategic battlefield. Between Verstappen’s gamble, Norris’ resilience, Leclerc’s home-soaked determination, and a grid shaken by team tactics, this was anything but your typical Monaco Grand Prix. Here’s what happened beneath the glitz — and beyond the noise.

Lap 1 — Launches, Lockups and Early Drama

Despite missing out on pole by just 0.109s to Norris, Leclerc had the stronger launch off the line. The pair charged toward Turn 1, locked in a race for P1. When Norris locked up both front wheels under braking, a plume of smoke shot into the air — and for a moment, it looked like Leclerc might snatch the lead. But on exit, Norris held firm and clung onto P1.

Behind them, Verstappen chose caution over combat. Perhaps recalling how little room Piastri has offered him in recent wheel-to-wheel battles (see: Jeddah), he backed out of the fight and slotted into P4, leaving Piastri to claim P3.

Further back, the action came thick and fast. Fans seated at the famous Casino Hairpin in Turn 6 were treated to a bold move from Bortoleto, who muscled past Antonelli for P14 — an impressive feat on a track where overtakes, especially at the hairpin, are rare and risky. But it didn’t last. Just two corners later, in Turn 8, Bortoleto went into the barrier, and Antonelli retook the position. The incident triggered the first yellow flag of the race. Though Bortoleto rejoined the race, the Virtual Safety Car was deployed to clear debris from the track. Bearman in P20, Gasly in P17, and Tsunoda in P12 capitalised immediately, diving into the pits to tick off the first of two mandatory stops.

Lap 9 to 19 – Tsunoda Gets Tapped, Lawson Splits the Grid

Gasly’s contact with Tsunoda at the end of lap 8 triggered the second yellow flag of the race. His front-left wheel clipped Tsunoda’s rear-right, snapping the suspension and leaving Gasly without brakes — as he reported over radio. Unable to stop the car, he coasted into the pit lane and retired, inadvertently shutting down any chance for others to use the yellow flag to pit.

But the bigger story was already unfolding further up the road.

By Lap 13, Lawson had built a 12s buffer behind Ocon. While not the largest gap between cars on the grid (that belonged to Bortoleto and Hulkenberg, separated by nearly 13s), Lawson’s gap stood out. Most others were running within 0.4s to 4s of the car ahead. This wasn’t a coincidence — it was the start of a strategic ripple effect that would go on to divide the race.

With Lawson backing up the pack behind him, his teammate Hadjar (running P7) was free to pit with minimal time loss. A stop that typically costs 19 seconds only cost Hadjar about 6s. He boxed from P7 and rejoined in P8. Hamilton, Alonso, and Ocon — running P5 through P7 — followed suit on the next lap, diving into the pit lane without losing track position. All thanks to the breathing room Lawson had engineered.

By Lap 20, the grid had split into three unofficial race groups: the frontrunners in P1–P4 running their own pace; the undercut beneficiaries in P5–P8 cushioned in Lawson’s gap; and the rest of the field stacked up behind Lawson, forced into a traffic train.

Midrace Shakeup — Pit Stops and Position Plays

With the field split by pit strategies, Norris — then race leader — was the first of the frontrunners to dive in, rejoining the track in P4 just behind Verstappen. The move handed the lead temporarily to Leclerc as Piastri was next to pit. The aim was clear: overcut Leclerc before the Monegasque could pit.

But the execution didn’t stick the landing.

Though no exact delay was listed, Piastri’s stop was visibly slow — long enough for him to vent his frustration over team radio. He rejoined the race behind Norris, with a noticeable gap between them.

On the very next lap, Leclerc responded.

His Ferrari crew delivered a flawless 2.0-second stop — the fastest of the race — and it paid immediate dividends. Leclerc exited the pit lane and slotted between the two McLarens, reclaiming track position over Piastri and re-establishing himself in P3.

Lap 38 — The Unluckiest Driver Strikes Again

Fernando Alonso was on track for a storybook finish: P6 in Monaco, his highest result since Baku 2024, and his first points of the season. But the moment smoke began trailing from his car, any hope of rewriting his luck vanished. He was instructed to retire the car, and ever the sportsman, Alonso quietly pulled into a slipway to avoid disrupting the race.

His retirement didn’t just end a points run — it echoed his bitter comment after Imola, when he called himself “the unluckiest driver” on the grid. Monaco, it seems, just backed him up.

Lap 44 to 49 — Team Games, Lawson’s Confusion & Russell’s Costly Shortcut

With a coordinated plan, Williams executed a bit of team strategy: Albon in P9 and Sainz in P10 swapped places on Lap 44, giving Sainz clean air to clear his mandatory stops while Albon held up the chasing pack. Once Sainz was done, they would switch back.

But not everyone was clued in. When Sainz began backing the pack up, Liam Lawson radioed in to ask why Sainz was doing that. Ironically, it was for the same reason Lawson had done earlier in the season — a bit of classic strategic clogging.

Now for the drama.

By Lap 49, Russell cut the Nouvelle Chicane while overtaking Albon for P10 — and was immediately under review. Russell claimed he had to bail out to avoid contact after Albon braked earlier than expected. But replays and onboard footage showed no such threat. On Lap 50, he was instructed to give Albon the place back, or there’d be a penalty.

Instead, Russell responded: “I’ll take the penalty.”

This casual defiance — combined with the lack of evidence supporting him — led the stewards to conclude the move was intentional. To send a message, they went beyond the standard 5 or 10-second penalty and handed him a pit lane drive-through penalty. At Monaco, that’s a 20-second time loss, minimum. And it had to be served within three laps, or the penalty would double.

In the end, the shortcut cost him more than a single position — it cost him points, and a whole lot of time.

Lap 50 to 63 — Gaps, Games & the Verstappen Safety Car Gambit

With Norris, Leclerc, Verstappen and Piastri leading the race, it was Piastri who blinked first — pitting and comfortably retaining P4. Leclerc followed at the start of Lap 50 and rejoined in P3, ahead of Piastri. Meanwhile, Norris was instructed to carve out a pit window wide enough to retain P2 once he rejoined the race.

He did exactly that. By the time Norris boxed a few laps later, he had built a 14s buffer — enough to rejoin ahead of Leclerc, slotting into P2 behind Verstappen. Crucially, Verstappen still hadn’t served his second mandatory stop.

In the midfield, drama repeated itself at the Nouvelle Chicane. On Lap 53, Antonelli overtook Albon and claimed P10 by cutting the same corner that got Russell into trouble. This time, track footage showed Antonelli’s rear wheel grazing the wall at the chicane entry, forcing him off track to avoid losing the car. He immediately gave the position back to Albon, and the stewards had no reason for any further action.

By Lap 56, the field had fractured into deeper, distinct segments. But the real canyon was behind Lawson — a 43s gap to Sainz in P9, isolating the top eight entirely. Verstappen, still holding P1, hadn’t boxed again. It became clear Red Bull were gambling on a late safety car. If deployed, it would neutralise the race pace and minimize the time Verstappen lost in the pits — potentially preserving a podium. The hope was that he'd pit and rejoin in P3 with the assistance of the safety car, to avoid pitting without it, which would put him in P4.

Then came the heat.

By Lap 63, Verstappen led Norris by around 1.5 to 2 seconds. Behind them, Leclerc had closed in on Norris — the gap flickering between 0.5 and 1 second. Verstappen later insisted he hadn’t backed Norris into Leclerc on purpose, claiming he was just managing tyres. But the effect was the same: Norris spent the closing laps fending off a fired-up Leclerc, desperate to take at least P2 in his home race.

Caught in Verstappen’s dirty air and with Leclerc breathing down his neck, Norris radioed his team asking for Piastri’s whereabouts — hoping his teammate could put pressure on Leclerc from behind and relieve some of the heat. At that point, Piastri was 4s adrift and told only to stay close, in case any opportunities opened up.

Leclerc, for his part, radioed in that Norris was “making many mistakes” — but frustratingly, he couldn’t make any of them count.

To the End — A Momentous Victory & Fastest Lap to Boot

With just three laps to go, Piastri closed in on the leading trio. Although he was less than a second behind Leclerc in P3, Leclerc’s focus remained firmly fixed on Norris ahead.

By the end of Lap 77, Verstappen finally served his long-delayed second pit stop — a necessary move to avoid disqualification. This effectively unleashed Norris, who claimed the lead.

As the final lap began, the top three — Norris, Leclerc, and Piastri — were separated by just half a second. Norris, now race leader, put his foot down and started pulling away. At Turn 1, he already held an 0.8s advantage over Leclerc.

By the time they reached the Nouvelle Chicane (Turns 10 and 11), Norris had extended his lead to 2.4s. Crossing the finish line, that gap had grown to an impressive 3s — sealed with the fastest lap of the race as the cherry on top.

In the aftermath, it was notable that cars P9 through P17 were lapped twice, with Antonelli, finishing P18, having been lapped three times.

#Box box breakdown#formula 1#f1#monaco gp 2025#ollie bearman#oliver bearman#Lance Stroll#Franco Colapinto#Pierre Gasly#Gabriel Bortoleto#Kimi Antonelli#George Russell#Nico Hulkenberg#Yuki Tsunoda#Carlos Sainz#Alex Albon#Liam Lawson#Esteban Ocon#Lewis Hamilton#Fernando Alonso#Isack Hadjar#Max Verstappen#Oscar Piastri#Charles Leclerc#Lando Norris

20 notes

·

View notes

Text

On Recovering From Disaster

Just before disaster struck with my 68030 homebrew, I had a plan to fork the project and take it in two directions in parallel.

The first would be my minimal Multibasic setup which was running great and was something I would be proud to exhibit at VCFSW '25.

Since that was working well, I didn't want to do anything that might make it not ready for the show. So I had assembled a second main board that I could use with other peripheral cards to continue development. My plan was to rework the memory map to move ROM and I/O addresses to the upper half of the 32-bit address space, which would allow me to use a DRAM card for up to 16MB of contiguous memory starting at address 0 — a perfect setup for running a proper OS

And then I burned up my good mainboard.

I had a spare CPLD on-hand, and I was able to get another 40MHz 68EC040 for cheap. But the 4Mbit SRAM chips are expensive, and I thought that if I was going to be paying for more SRAM, I should get the 12ns parts that would allow me to run RAM with no wait states at 50MHz. Which would require adapter boards, and more pin headers, and would have just driven the cost up even more.

Paralyzed by indecision and the rising cost, I decided to switch gears. I already have the DRAM board I built years ago, I just needed to get it working. And if I'm doing that, I may as well do the work on reorganizing my memory map.

So that's what I did. I made a new branch on my newly cleaned up repository, and set to work. I updated the mainboard bus controller logic to remove the no-longer-needed SRAM control, adjust the ROM address to start at 0x8000,0000, and move the 6850 UART address to 0x8008,0000. This freed up the entire 2GB space between 0x0000,0000 and 0x7FFF,FFFF for the DRAM card to use for main memory (my bus connector layout only allows for up to 16MB main memory, but that's plenty for my purpose).

Next, I needed to build the control logic for my DRAM board. I've done this once before on my Wrap030-ATX project a couple years ago, so I used that logic as a starting point. It … kind-of worked. Sometimes. Maybe.

I was getting random errors all over the place. Sometimes it was able to copy all of ROM into RAM and verify the copy without error, but it would fail when running code from RAM. Sometimes it wouldn't even pass the first two simple tests of writing a longword to RAM and reading it back.

Back to the data sheets to plan out the logic. I drew out a new timing diagram down to 1ns resolution, accounting for the specified propagation time for my CPLDs, and the measured signal delays for my CPU. This gave me the information I needed to build out a new state machine for the DRAM controller. In the process I also caught a few other bugs in my original logic, such as not ensuring the DRAM Write Enable strobe did not get asserted during refresh cycles.

The new state machine worked much better, but I got my timing off a bit. It worked reliably at 16MHz, but not at the intended 25MHz. At least it was working though; I can move forward with 16MHz.

The next thing to do was get my 8-port serial card working with this new setup. Every time the computer tried to access one of the 8 serial ports, it would get a bus error. This was a tough one that had me stuck for a while.

It looked like the serial card was getting addressed and asserting DSACK0# as expected, but I couldn't confirm the signal was making it back to the CPU. Every time I tried to measure the DSACK signals, the probes would increase the line capacitance (I think) too much and cause the whole computer to fail before it even got to the point of trying to address the serial ports.

I have the DSACK signals in a wired-or configuration. The logic on each card connects to the proper DSACK signal via an open-collector buffer, and is able to pull the signal low to signal that card acknowledging the bus cycle. The signal is then pulled back up to +5V by a 1kΩ resistor. This works well enough for small, slow systems, but with long bus wires or lots of chips on the bus, the extra capacitance means it can take a long time for that pull-up resistor to get the signal back up to +5V.

I made a change to my DRAM controller to actively drive the DSACK signals to +5V briefly at the end of a bus cycle before setting the pin to high-impedance. This helps ensure a fast rise time at the end of the cycle so it doesn't disrupt the next bus cycle.

It didn't fix the problem with the serial card, but it did allow me to actual probe the signals live to see what was happening — the Bus Error signal was getting asserted immediately after the CPU addressed the serial card. This didn't make much sense to me. My main board logic will assert Bus Error if no peripherals acknowledge a bus transaction within 64 clock cycles. Nothing should be asserting Bus Error so quickly.

Except … the main board bus controller. My original memory map used the lower half of the address space for the main board, and peripheral cards used the upper half. So my original main board logic was built to assert Bus Error immediately for an unused address in the lower half of the address space. I hadn't properly removed that bit of logic, so it was now asserting Bus Error for any accesses to the upper half of the address space that weren't used by the main board.

The challenges of working on a project after six years. I had forgotten that bit of logic was even there.

With that erroneous Bus Error assertation removed, the machine was finally able to properly load my Multibasic kernel and run BASIC for 8 users again.

At the moment it is running stable at 24MHz on my 25MHz-rated full 68030. It may not be the 50MHz high I was at, but after the frustration and disappointment of the past few weeks, I'm absolutely taking that as a win. 24MHz is incredible.

#mc68030#motorola 68k#motorola 68030#vcfsw#wrap030#retrotech#debugging#troubleshooting#homebrew computing#homebrew computer#retro computing

23 notes

·

View notes

Text

I'm gonna get new ears installed.

It's getting close to 5 am and I can't sleep yet. Part of it is because I just finished work, but part of it is because I'm... Excited? ... Anxious? I'm both happy and sad and a little hopeful but also very fearful.

So, for those not in the know. I'm deaf and have been my whole life. It's not one of those things like I can't hear anything. But a lot of frequencies and sound ranges just don't work well for me. I tried wearing heading aids when I was a kid, but they made things worse. All they did was amplify everything. That made it harder to hear the pieces I had to struggle to hear since it was getting further buried under even more background noise.

For example, if you've ever been to a movie where the sound mixing was off. The dialogue is incomprehensible because the ambient noise is so frickin loud. If you try to turn the volume up, all you hear is more jets and explosions.

Anyway, I've had some issues in class where some professors are very hard to understand but the college wouldn't help me until I had a current diagnosis from an audiologist saying that yeah. I really am just that deaf. In the process of seeing the audiologist though, she was telling me that they have new stuff that can work for people like me. Unlike old hearing aids that amplify all sound, these things have like adaptive sound controls and can amplify specific frequencies on the fly. So in theory it will bring my hearing to similar levels as other people's.

The thing costs $10k... I have decent insurance which drops it down to $6k but it's still a massive expense. I'm going to do it though.

I'm both excited and anxious. If the audiologist is to be believed, I spend a lot of my energy on listening to people speak, then replay it back in my head and soft through the possible similar sounding words and recreate the sentences on my head.

I've always said I do this. I jokingly refer to it as "buffering" because I'm running on a few second delay in conversation. Like imagine those interviews on the news where there's this awkward pause of four to five seconds where the signal gets sent across the world from the asker to the answerer before the other person can respond to it. The doc says this is probably the source of a lot of my frequent migraines and exhaustion and is exacerbating my tinnitus. Basically I'm in like hyper vigilant mode 24/7 constantly trying to pick out the faintest sounds so I can be functional in normal life leading to constant mental fatigue.

Anyway. I don't know how long it will take to actually get the device, and once I get it, the doc said it'll take a while to get adjusted. They're not just going to throw me into the deep end and let me figure it out. The plan is to slowly increase the deadened frequencies until they balance out with the others.

I don't know what this will actually do for me. I've never been able to hear normally so I don't know what it will feel like. I don't know if I will ever get to a normal hearing level. I wonder if this will make it easier out in public. I get overwhelmed in busy places since there are so many sounds which makes it impossible to hear the things I want.

I'm worried that I'll spend all this money and it won't improve anything.

I'm worried that I will get these and it will be everything I wanted.

How long has this tech existed? Could I have had this years ago? How much have I missed by not being able to understand people talking to me.

If I get this will it make a noticable difference in the migraines? In the chronic fatigue? I don't know. I want to be optimistic, but it's hard to even know what to expect.

Anyway. If you want a bit of a glimpse into what it's like being me, give this a listen

youtube

19 notes

·

View notes

Text

System Breach Sunday...! ⭕

#4

Almost instantaneously, as electricity began to trickle in, the build up of pressure seemed to dissipate from Connor’s synthetic nervous system. The supplemental charge was slow, inefficient, unlikely to offer more than a few percentage points per hour if he chose to work while using it—but none of that mattered. The subjective relief that it gave him quite simply overshadowed all practical data. And how could it not—when, for the first time since he’d come out of stasis on the Lieutenant’s kitchen floor, the tension in his shoulders, in his skull, the sharp points behind his eyes finally felt… bearable?

“Connor! There you are!”

The android snapped to attention, turning sharply to face the source of the voice; almost on reflex, he force-closed all irrelevant thought processes. Surveillance systems were quick to settle however, and routed instead to social modules.

Detective Ben Collins strode towards Connor’s desk, steaming mug of coffee in hand. He gave the android a full once-over with a scrutinizing look, but then smiled and nodded, satisfied. “You could set a clock to your arrivals, kid. I was starting to wonder if you’d show!”

Internally, Connor grimaced. Collins was right—he’d arrived to the precinct approximately twenty two minutes later than average. Even after taking into account the distance to the office from Lieutenant Anderson’s home, Connor had not left with adequate time. Ruefully, he suspected that it might not only be his fine motor control that had decalibrated, but his sense of task duration as well. Everything he’d done that morning had taken far longer than it should have.

Appeasement protocols at the ready, Connor opened his mouth to apologize, “I am sorry for any delay my tardiness may have caused, Detective.”

But Collins, still smiling, waved him off. He took a sip of his coffee, “Don’t worry about it, I’m just glad you’re in one piece. You looked like hell last night! Hank take good care of you after you left?”

Unwelcome memories blistered across Connor’s mind’s eye. “Y-yes,” he stammered. Mentally recoiled. It had been a gross oversight not to prepare responses in his social buffer for that sort of question.

>”Who’s at the goddamned door so fuckin’ early?” Hank growled, voice gravelly as he leaned out from his bedroom doorway. “It’s seven in the morning! People are tryin’ to fuckin’ sleep!”

>

>Startled, Connor turned to face the Lieutenant. Appeasement protocols stuttered to life before he could voluntarily cue them, and his system was quick to offer a list of data points garnered from the man’s appearance. Most surprising, was the distinct lack of evidence of alcohol.

>

>”CyberLife has delivered my change of uniform,” Connor began, purposefully benign.

>

>”Oh, goody,” the Lieutenant rolled his eyes, “If only you’d stop bleeding into them.”

>

>”...I will do my best, Lieutenant. I will only need a few minutes to get ready. What time would you like to leave for the precinct this morning?”

>

>The man scoffed, loudly. “Leave? Are you out of your plastic mind? You have any idea how much sleep your little bender cost me last night?”

>

>Connor opened his mouth, primed to apologize, but forced his jaw to close.

>

>The Lieutenant continued, regardless, “You’re on your fuckin’ own. Until you get a lead on that case of yours, I’m not leaving this damn house.”

>

>Connor flinched as the bedroom door slammed.

>

>”...Very well, Lieutenant.”

“Lieutenant Anderson will be arriving sometime later. He had… other matters to attend to,” Connor supplied, deflecting as best he could. The cut in his right arm twinged, pinching sharply, and he couldn’t help but draw it closer to his chest. Realizing what he’d done, Connor wanted to pull his left arm in as well, to balance his posture and remain inconspicuous—but the cord at his wrist felt suddenly like a tether, a restraint.

Seemingly unfazed, Collins gave the android a pitying look, “Other matters… I’m sure he does.” After another sip of coffee and shake of his head however, Ben offered Connor a conspiratorial grin, “Wait here, I’ve got something for you.”

Quickly, but not so fast as to spill his cup, Collins strode towards his desk, some dozen feet away. He plucked a small evidence bag from beside his terminal, then returned to Connor.

“We found this stashed in the last room on that motel’s second floor,” Ben started, showing Connor the evidence bag. Inside was a small, well worn notebook. “No RA9 graffiti or shrines like the other deviants. Just this, a few android repair kits, and a busted mirror in the bathroom. Real freaky stuff.”

#whew! trying to get into the groove of writing again after surgery last week#finally off pain meds lmao#this is the beginning of a scene i've had planned for a while now that's not at all in the original#super excited for it! and also the relationship arc between connor and hank that seems to have written itself into the rewrite 👀#after the knife scene in the last chapter connor's stopped calling hank by his first name T_T#love when shit just writes itself!#System Breach Sunday#System Breach rewrite#dbh#dbh fic#my fic#detroit become human#detroit become human connor#connor rk800#dbh connor#system breach saturday

7 notes

·

View notes

Text

How Do I Make a Renovation Plan?

Thinking about a home renovation? Whether you're sprucing up your living space, prepping a rental property, or making a house feel like home, one thing’s certain—planning is everything. A well-thought-out renovation can add serious value to your property, improve functionality, and make your home more enjoyable. But where do you start?

If you’re in Lake County, IL, working with a reputable remodeling company like Waldron Construction can make the process smoother. But before you pick up the phone, let’s break down a solid renovation plan.

Define Your Goals

Renovations aren’t just about aesthetics—they’re about solving problems and improving your lifestyle. The clearer you are about what you want, the easier the entire process will be.

Ask yourself:

Are you remodeling for comfort, functionality, or resale value?

Do you want a quick refresh or a full-scale transformation?

Are there specific pain points in your home that drive you crazy?

For example, if your kitchen feels cramped, do you want to knock down a wall or simply add more storage? If you're flipping a house, are you focused on high-ROI upgrades like kitchens and bathrooms, or is curb appeal your top priority?

If accessibility is a concern (think aging-in-place modifications), features like wider doorways, zero-threshold showers, and smart home tech should be on your radar.

Set a Realistic Budget

You’ve probably heard the saying: Renovations always cost more than expected. It’s true. Unexpected issues—like hidden water damage or outdated wiring—can pop up and inflate your costs. That’s why adding a 10-20% contingency buffer is smart.

When creating your budget, consider:

Labor Costs – Skilled professionals are worth every penny.

Materials – High-end finishes cost more, but sometimes a mid-range alternative gives the same look at a fraction of the price.

Permits & Inspections – Local codes may require permits, and those fees add up.

Temporary Living Arrangements – If you’re doing a full home remodel, will you need to stay elsewhere?

Be honest about what you can afford. Stretching your budget too thin can leave you with unfinished projects or rushed, low-quality work.

Create a Prioritized Wish List

We all want the dream home, but let’s be real—not every renovation is essential. To avoid blowing your budget, split your list into must-haves and nice-to-haves.

Must-Haves (Essentials):

Structural repairs (foundation, roof, electrical, plumbing)

Functional improvements (fixing layout issues, adding storage)

Safety upgrades (railings, non-slip flooring, accessibility features)

Nice-to-Haves (Luxuries):

High-end finishes (marble countertops, custom cabinetry)

Smart home upgrades (automated lighting, heated floors)

Outdoor living enhancements (fire pits, built-in grills)

If you have a strict budget, prioritize the essentials first. You can always phase in cosmetic upgrades later.

Find the Right Professionals

DIY can be tempting, especially with all the YouTube tutorials out there. But unless you’re an experienced contractor, major renovations are best left to the pros.

A licensed contractor ensures:

Compliance with local building codes

Proper permits and inspections

Professional-grade craftsmanship

Liability coverage in case something goes wrong

If you’re in Lake County, IL, Waldron Construction has a stellar reputation for home remodeling and renovations. Their team can guide you through the process, ensuring your vision becomes a reality—without the usual headaches.

Get a Timeline

Renovations rarely go exactly as planned. Weather, supply chain delays, and hidden structural issues can all throw a wrench in your timeline.

A realistic schedule should include:

Planning & Design – 2-4 weeks

Permits & Approvals – 2-6 weeks (depends on local regulations)

Demolition & Prep Work – 1-2 weeks

Construction Phase – Varies based on scope (can be 4-12+ weeks)

Finishing Touches & Inspections – 1-2 weeks

If you need your home ready by a certain date (e.g., before the holidays or a major event), plan for some buffer time.

Choose the Right Materials & Finishes

Material selection can make or break your project. Sure, that high-end quartz countertop looks amazing, but is it worth stretching your budget?

Consider:

Durability: Will it hold up to daily wear and tear?

Maintenance: Does it require special cleaning or upkeep?

Availability: Is there a long wait time for materials to arrive?

Resale Value: Will it boost your home's marketability?

For Budget-Conscious Homeowners:

Luxury vinyl plank (LVP) flooring looks like hardwood but costs less.

Prefabricated cabinets are more affordable than custom-built ones.

Quartz countertops mimic marble but are lower maintenance.

For High-End Renovations:

Custom millwork and cabinetry

Natural stone countertops

Smart home integrations

Plan for the Disruptions

Even small renovations can turn your home into a construction zone. Be prepared for:

Dust & Noise – Cover furniture, seal off rooms, and consider earplugs.

Limited Access to Spaces – If it’s a kitchen remodel, set up a temporary meal prep area.

Scheduling Adjustments – Contractors might need to come early or work late to stay on track.

If you're renovating multiple areas, tackle one space at a time instead of gutting everything at once.

Inspections & Final Walkthrough

Before considering the project finished, do a detailed walkthrough with your contractor. Look for:

Unfinished paint touch-ups

Cabinet doors and drawers that don’t close properly

Flooring or tile imperfections

Any last-minute adjustments needed

Don’t be afraid to ask for fixes—it’s your home, and you should be 100% happy with the results.

Ready to Get Started?

A well-planned renovation doesn’t just add beauty—it improves functionality, comfort, and even home value. Whether updating a single room or doing a full-scale remodel, the key is planning and working with the right team.

If you're in Lake County, IL, let Waldron Construction bring your vision to life. With expert craftsmanship and personalized service, they’ll help you create a beautiful and functional home.

Call Waldron Construction today at (224) 788-9173 to discuss your renovation plans!

2 notes

·

View notes

Text

https://www.wsj.com/articles/rafah-evacuation-israel-biden-administration-antony-blinken-jake-sullivan-hamas-3e3c85f7

By: The Editorial Board

Published: May 22, 2024

Remember Rafah? For months, the Biden Administration bitterly opposed an Israeli invasion of Hamas’s last stronghold in Gaza. The mantra was that Israel had “no credible plan” to evacuate the city’s 1.3 million civilians. Yet the Israelis went ahead anyway, and two weeks later they have safely evacuated an estimated 950,000 people.

This was supposed to be impossible. Rafah became a red line for Mr. Biden on the logic that there was no way to conduct a major operation with all those civilians present. That was the justification for the President’s arms embargo. “We’re walking away from Israel’s ability to wage war in those areas,” he said.

Even as the evacuation got under way, Secretary of State Antony Blinken repeated that Israel had “no credible plan.” National security adviser Jake Sullivan added, “We still believe it would be a mistake to launch a major military operation into the heart of Rafah.” When the evacuation began to work, the Biden team moved on to criticizing Israeli readiness for the “day after” the main fighting, as if success in Rafah were a foregone conclusion.

Finally on Tuesday, the Administration claimed credit. “It���s fair to say that the Israelis have updated their plans. They’ve incorporated many of the concerns that we have expressed,” a senior U.S. official told reporters. He also said the Rafah operation might create “opportunities for getting the hostage deal back on track.”

The maneuvering has costs. “This Administration never supports anything we do until we do it,” a senior Israeli official told us early this month. To win Mr. Biden’s consent, the Israelis first had to advance and succeed. But the delay his opposition caused has dragged out the war to all but Hamas’s detriment.

Rafah remains critical to any day-after plan, since nothing can work if Hamas governs territory with military battalions and controls the Egyptian border. Israel has already discovered 50 tunnels crossing from Rafah into Egypt for smuggling. Once troops finish clearing a buffer zone along the border, Israel can cut off Hamas from Egypt, a key to strangling whatever insurgency may follow.

It’s reasonable to ask what force will control Gaza in the future. But no one else will fight and die to defeat Hamas for Israel, or even to resist it as a civilian power. Certainly not the feeble Palestinian Authority, which wants a power-sharing deal with Hamas in Gaza because otherwise it knows it would be slaughtered.

Though Israeli liberals won’t like to hear it, Israel probably will need to fill the vacuum in Gaza for a time. Though Israeli right-wingers won’t like to hear it, the purpose would be to make way for local governance. The politics, there and here, explain why it has been easier to pretend there’s no plan at all.

==

Apparently, evacuating 950,000 people before conducting a military operation is somehow a "genocide."

It's worth pointing out that the Exodus in the bible involved upwards of two million people. Obviously, this was fiction, but here's a mass migration on a comparable scale, and while the fictional one gets written into a holy book, the real world one goes largely unacknowledged.

#rafah#moral corruption#israel#IDF#Israel Defence Forces#palestine#pro palestine#hamas#pro hamas#hamas supporters#gaza genocide#palestinian genocide#genocide#evacuation#rafah evacuation#exterminate hamas#religion is a mental illness

19 notes

·

View notes

Text

Reliable and Affordable Navette Aéroport Orly Roissy Shuttle

Traveling between airports can often be one of the most stressful parts of a journey, especially when tight schedules and heavy luggage are involved. For those flying in or out of Paris, the need for a reliable and efficient Navette aeroport Orly Roissy service has never been greater. Whether you are a frequent flyer or visiting Paris for the first time, a dependable shuttle service connecting Orly and Roissy Charles de Gaulle (CDG) airports can save you time, stress, and money.

In this post, we’ll explore everything you need to know about the Navette aeroport Orly Roissy service, from what it is, to why it’s a smarter alternative to taxis or public transport, and how to make the most of your airport transfer.

Why Choose a Navette Aéroport Orly Roissy?

Paris has two major international airports: Orly Airport (ORY) and Charles de Gaulle Airport (CDG), commonly known as Roissy. These two airports are about 40 kilometers (25 miles) apart, and transferring between them can take anywhere from 45 minutes to over 90 minutes, depending on traffic and transportation method.

Here’s why choosing a Navette aeroport Orly Roissy is the best option for this journey:

Direct Transfer: No need to worry about switching trains or buses with your luggage. The shuttle takes you directly from one airport to the other.

Comfort and Convenience: Enjoy a comfortable ride in a modern, air-conditioned vehicle with professional drivers.

Punctuality: Shuttle services operate on a reliable schedule and track your flight to adjust for delays.

Fixed Pricing: Unlike taxis, you know the price before you book, helping you manage your travel budget.

Safety and Peace of Mind: Especially important for international travelers unfamiliar with the local transport system.

How Long Does the Shuttle Take?

The transfer time between Orly and Roissy CDG can vary depending on traffic conditions. On average, a Navette aeroport Orly Roissy service takes around 60 to 90 minutes. Morning and evening rush hours in Paris may increase travel time, so it’s always a good idea to allow some buffer time if you have a connecting flight.

Most shuttle services operate throughout the day and evening, with availability that matches incoming and outgoing flight schedules.

What Are the Shuttle Options Available?

There are generally three types of shuttles you can choose from:

Private Shuttle: Ideal for individuals or groups who want a dedicated vehicle. This is the most flexible and comfortable option.

Shared Shuttle: A cost-effective choice where you share the ride with other passengers headed in the same direction. Pickup times and routes may be slightly adjusted based on others' schedules.

Luxury or Business Class Shuttle: For those looking for a more premium experience with added amenities such as Wi-Fi, refreshments, and extra luggage space.

Booking Your Navette Aéroport Orly Roissy

Booking a Navette aeroport Orly Roissy in advance is strongly recommended, especially during peak travel seasons. Many services offer online booking, allowing you to select your pickup and drop-off locations, number of passengers, and flight details.

Here's what to expect during the booking process:

Enter your travel dates and flight details.

Choose your preferred type of shuttle (private, shared, or luxury).

Receive a booking confirmation with all the details and contact information.

Some services offer mobile apps or SMS notifications for live updates.

What to Expect on the Day of Transfer

On the day of your transfer, you’ll receive clear instructions on where to meet your driver, whether it's at an arrival terminal or a designated shuttle pickup point. Drivers are usually courteous and speak basic English, ensuring a smooth and professional experience.

If you’re arriving in Paris, your driver will typically wait for you with a name sign, assist with luggage, and guide you to the vehicle. For departures, the shuttle will arrive at the scheduled time to pick you up from the terminal or nearby hotel.

Cost of Navette Aéroport Orly Roissy

Pricing varies based on the shuttle type and the number of passengers. On average:

Private Shuttle: €70–€120

Shared Shuttle: €30–€50 per person

Luxury Shuttle: €100–€150

Most companies offer discounts for round-trip bookings, multiple passengers, or early reservations.

Who Should Use the Orly to Roissy Shuttle?

The Navette aeroport Orly Roissy service is suitable for:

International travelers with connecting flights between the two airports

Families or groups traveling with children and luggage

Business travelers with time-sensitive schedules

Elderly passengers who prefer door-to-door service

Tourists who want a hassle-free transfer

No matter your reason for travel, the shuttle offers a practical solution tailored to your needs.

About Navettes Aéroports

At Navettes Aéroports, we understand how important smooth airport transfers are for your journey. Our fleet of reliable shuttles, experienced drivers, and 24/7 customer service ensure a seamless transfer between Orly and Roissy. Whether you’re heading to your next flight or just arriving in Paris, our commitment is to make your travel simple, safe, and stress-free.

Final Thoughts

Traveling between Paris Orly and Roissy CDG airports doesn’t have to be a headache. With a trusted Navette aeroport Orly Roissy service, you can move between terminals comfortably, on time, and without unnecessary hassle. Avoid the complications of public transportation or the unpredictability of Paris traffic with a service designed for convenience and peace of mind.

Booking in advance, choosing the right shuttle type, and knowing what to expect will make your airport transfer experience one less thing to worry about. Whether for business or pleasure, start or end your journey the right way—with a reliable shuttle transfer.

0 notes

Text

Wind Turbine Blade Inspection Services Market Size, Market Trends & Strategic Outlook

Global Wind Turbine Blade Inspection Services Market Overview The global wind turbine blade inspection services market is currently valued at approximately USD 6.25–7 billion in 2023–24. Industry analysts forecast robust growth, reaching between USD 11.2–11.5 billion by 2028–2030, reflecting a CAGR in the range of 9.4–12.2% over the next 5–10 years citeturn0search2turn0search6turn0search7. Key growth drivers include the rapid buildout of onshore and offshore wind farms, aging blade stock in need of inspection, tightening regulatory mandates, and technological progress in inspection services. The rise of drones, UAVs, remote monitoring platforms, AI-enabled analytics, and predictive maintenance solutions is steadily shifting the market toward digitization and automation citeturn0search2turn0search8. Global Wind Turbine Blade Inspection Services Market Dynamics Drivers: Expansion of wind capacity globally (117–125 GW annually), strict blade integrity requirements for longer blades and offshore installations, and sustainability‑focused asset management citeturn0search12turn0search8. Restraints: High capital outlay for advanced sensors, NDT tools, autonomous drones; uneven regulatory regimes; and persistent global shortage of trained inspection personnel citeturn0search1turn0search8. Opportunities: Surge in offshore wind requiring specialized inspection; AI‑driven damage analytics; integration of IoT/cloud telemetry; digital twins for predictive scheduling; growing interest in eco‑friendly, recyclable blade materials citeturn0search0turn0search5turn0search11. Influence of technology & regulation: Governments and international standard bodies are mandating more frequent blade assessments, while tech breakthroughs—such as remote diagnostics and big‑data analytics—allow for lower O&M costs, higher uptime, and strengthened safety and compliance profiles. Download Full PDF Sample Copy of Global Wind Turbine Blade Inspection Services Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=455362&utm_source=PR-News&utm_medium=353 Global Wind Turbine Blade Inspection Services Market Trends and Innovations Drone & UAV automation: Autonomous flight, high‑res LIDAR/thermography, orbit/MPC flight plans enabling non‑intrusive inspections; some systems embedded with browser‑based damage‑analysis dashboards citeturn0search5turn0reddit22turn0reddit24. AI/ML analytics: Computer vision algorithms spotting micro‑cracks, leading‑edge erosion, delamination, streamlining repair cycles and reducing human error citeturn0search1turn0search8. Digital twin integration: Virtual replicas of blade structures, fed by continuous sensor data, improving predictive maintenance and lifecycle planning citeturn0search2turn0search7. Collaborative ventures: Partnerships like BAM–LATODA thermography/AI alliance and Voodin–Senvion timber‑blade initiative illustrate the move toward interdisciplinary innovation citeturn0search2turn0reddit14turn0search11. Sustainable materials trend: Fully recyclable wooden blades under development (e.g., laminated veneer lumber, >50 m length), reducing end‑of‑life waste and inspection complexity citeturn0reddit14turn0reddit18. Global Wind Turbine Blade Inspection Services Market Challenges and Solutions Despite strong momentum, the market faces several roadblocks: High technology costs: Capital-intensive equipment limits adoption among smaller operators. Solution: Offer inspection-as-a-service leasing models or shared‑asset cooperative platforms. Labor shortage: Skilled inspectors are scarce. Solution: Invest in remote‑pilot training, inter‑company programs, and certification initiatives to upskill drone and NDT personnel. Supply chain disruptions: Delays in sensor, drone, or parts supply hinder operations. Solution: Onshore regional logistics hubs and cross‑sector partnerships can buffer procurement risk. Global Wind Turbine Blade Inspection Services Market Future Outlook

Looking ahead to 2030 and beyond, the market is poised to nearly double in size, hitting up to USD 15 billion by 2032–33 at a sustainable CAGR of ~10–11% citeturn0search8turn0search6turn0search3. Key growth catalysts will be: Offshore wind boom: Projects in Europe, North America, and Asia require frequent remote inspection due to high-capex exposure. Larger and longer blades: UL film-scale composites demand advanced NDT and AI monitoring to maintain integrity. Regulatory push: Stronger environmental and health & safety laws will enforce more rigorous, documented inspection regimes. Industry consolidation: Collaborations between OEMs, software providers, and maintenance firms will speed tech adoption. Sustainability integration: Circular materials like timber blades will gain inspector attention, and blade end-of-life reuse strategies will drive service innovation. In summary, the wind turbine blade inspection services market is evolving toward a digitally driven, sustainable, and regulation-aligned future—where drones, AI, IoT and collaborative innovation unlock new value for operators, OEMs, and service providers. Key Players in the Global Wind Turbine Blade Inspection Services Market Global Wind Turbine Blade Inspection Services Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. Schneider Electric SE ABB Ltd. Vestas Wind Systems A/S Siemens Gamesa Renewable Energy SGS SA (Société Générale de Surveillance SA) LM WIND POWER UL International GmbH DNV AS Mistras Group Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=455362&utm_source=PR-News&utm_medium=353 Global Wind Turbine Blade Inspection Services Market Segments Analysis and Regional Economic Significance The Global Wind Turbine Blade Inspection Services Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The Global Wind Turbine Blade Inspection Services Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/wind-turbine-blade-inspection-services-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies. We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise

in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/last-mile-delivery-by-drones-market/ https://www.verifiedmarketresearch.com/ko/product/ultrasound-skin-tightening-devices-market/ https://www.verifiedmarketresearch.com/ko/product/construction-and-mining-equipment-market/ https://www.verifiedmarketresearch.com/ko/product/environmental-water-testing-market/ https://www.verifiedmarketresearch.com/ko/product/ai-in-precision-aquaculture-monitoring-and-control-market/

0 notes

Text

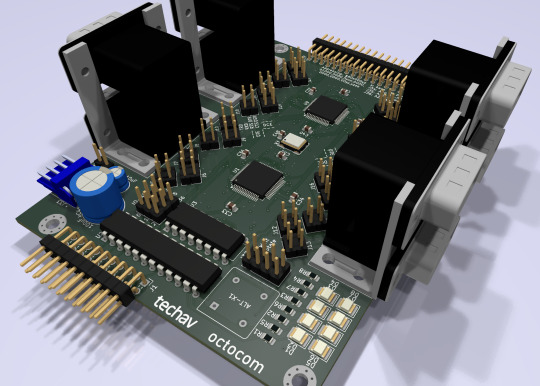

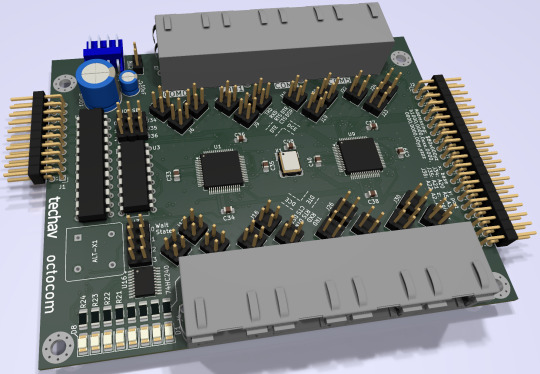

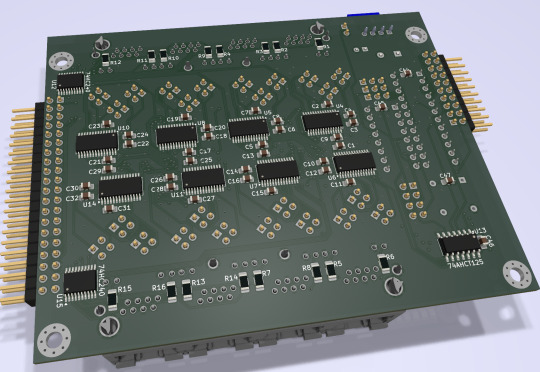

Sharing a Computer with More Friends

A few months ago I built an I/O expansion board for my homebrew 68030 project with a 4-port serial card to go with it, and got BASIC running for four simultaneous users. It worked, but not as well as I had hoped. I wanted to be able to run two of those serial cards to support 8 total users, but it had proven unstable enough that with just the one card I had to slow down the whole system to 8MHz.

So I designed a new serial card.

I had previously been running this computer without any issues at 32MHz with a mezzanine card with FPU & IDE as well as a video card. The main board by itself can clear 56MHz. Having to go all the way down to 8MHz just didn't sit well with me. I want this machine to run as fast as possible for its 8 users.

I put extra time into reviewing worst-case timing for all components and graphing out how signals would propagate. The 16C554 quad UARTs I'm designing around are modern parts that can handle pretty fast bus speeds themselves — easily up to 50MHz with no wait states on the 68030 bus — assuming all the glue logic can get out of the way fast enough.

Signal propagation delays add up quickly.

My first draft schematic used discrete 74-series logic for chip selection, signal decoding, timing, etc. At slower bus speeds this wouldn't have been a problem. But I want this thing to run as fast as possible. By the time critical signals had made it through all those logic gates, I was looking at already being well into one wait state by the time the UART would see a 50MHz bus cycle begin.

I needed something faster. I was also running low on space on the board for all the components I needed. The obvious answer was programmable logic. I settled on the ATF22V10 as a good compromise of speed, size, availability, and programmability. It's available in DIP with gate delays down to 7ns. Where discrete gates were necessary, I selected the fastest parts I could. The final design I came up with showed a worst case timing that would only need one wait state at 50MHz and none for anything slower.

It ended up being a tight fit, but I was able to make it work on a 4-layer board within the same footprint of my main board, putting some components on the back side. (It may look like a bunch of empty space, but there's actually a lot going on running full RS232 with handshaking for 8 ports).

New problem. I had blown my budget for the project. As much as I love those stacked DE9 connectors, they're expensive. And there's no getting around the $10 pricetag for each of those quad UARTs. Even using parts on-hand where possible, I was looking at a hefty Mouser order.

[jbevren] suggested using ganged RJ45 connectors with the Cisco pinout instead of stacked DE9, to save space & cut costs. [Chartreuse] suggested buffering the TTL serial TX/RX signals to drive the LEDs that are frequently included on PCB-mount RJ45 connectors. Both great ideas. I was able to cut 20% off my parts order and add some nice diagnostic lights to the design.

Two weeks later, I received five new PCBs straight from China. I of course wasted no time setting into starting to assemble one.

I really set myself up for a challenge on this one. I learned to solder some 25 years ago and have done countless projects in that time. But I think this might be the most compact, most heavily populated, most surface mount board I've ever assembled myself. (There are 56 size 0805 (that's 2x1.2mm) capacitors alone!)

After a few hours soldering, I had enough assembled to test the first serial port. If the first port worked then the other three on that chip should work too, and there's a great chance the other chip would work as well.

And it did work! After some poking around with the oscilloscope to make sure nothing was amiss, I started up the computer and it ran just fine at 8MHz.

And at 16MHz.

And at 25MHz.

And at 32MHz.

And at 40MHz.

And almost at 50MHz!

Remember what I said about my timing graphs showing one wait state for 50MHz? The computer actually booted up and ran just fine at 50MHz. The problem was when I tried typing in a BASIC program certain letters were getting switched around, and try as I might, BASIC just refused to 'RQN' my program. It was pretty consistently losing bit 3, likely from that signal having to travel just a tiny bit farther than the others. A problem that will probably be resolved with an extra wait state.

Good enough for a first test! A few hours more and I finished assembling the card.

I did have some problems with cleaning up flux off the board, and I had to touch up a few weak solder joints, but so far everything seems to be working. I've updated my little multi-user kernel to run all 8 users from this new card and it's running stable at 40MHz.

I need to update my logic on the 22V10 to fix a bug in the wait state generator. I would love to see this thing actually running at 50MHz — a 25% overclock for the 40MHz CPU I am currently running. I also want to expand my little kernel program to add some new features like the ability to configure the console serial ports and maybe even load programs from disk.

I hope to bring this machine with a collection of terminals and modems this June to VCF Southwest 2025 for an interactive exhibit that can be dialed into from other exhibits at the show.

#wrap030#multi-user BASIC#EhBASIC#homebrew computer#motorola 68030#68030#mc68030#motorola 68k#vcfsw#vcfsw2025#Retrocomputing#rtc#retrotech crew

31 notes

·

View notes

Text

Common Mistakes to Avoid When Purchasing Industrial Steel and Wire

When it comes to construction, manufacturing, or heavy-duty engineering projects, purchasing the right industrial steel and wire is critical. These materials are the backbone of structural integrity, electrical conductivity, and component durability. However, despite their significance, many businesses and buyers make critical mistakes during the procurement process. These oversights can lead to operational delays, safety risks, and financial losses.

In this blog, we’ll explore the most common mistakes to avoid when buying industrial steel and wire—and how to make smarter, more efficient decisions that serve both your budget and your business goals.

Ignoring Material Specifications

One of the most common mistakes is purchasing steel or wire without checking the exact specifications. Not all steel grades or wire types are created equal. Some may be ideal for tensile strength, while others offer corrosion resistance or formability. For example:

Carbon steel is strong but may rust without coatings.

Stainless steel resists corrosion but is more expensive.

Galvanized wire is coated for outdoor use, whereas annealed wire is better for flexibility.

Failing to match the material to your project’s requirements can lead to performance issues and even structural failure. Always consult with engineers or materials specialists before making a purchase.

Overlooking Compliance and Certification

When buying industrial steel and wire, it's vital to ensure the products meet industry standards and safety regulations. Materials should come with certifications such as:

ASTM (American Society for Testing and Materials)

ISO (International Organization for Standardization)

BIS (Bureau of Indian Standards)

Purchasing uncertified products might save money in the short term, but it exposes your company to legal liabilities and quality risks. Insist on documentation that verifies the origin, grade, and treatment of the materials.

Choosing Price Over Quality

While cost is an important factor, opting for the cheapest option can lead to major setbacks. Low-quality steel and wire can:

Corrode faster

Have weak tensile strength

Deform or break under stress

These problems often lead to higher maintenance costs, replacement expenses, or operational downtimes. Investing in quality materials upfront ensures long-term value, reliability, and safety.

Not Verifying Supplier Reputation

A reputable supplier is just as important as the product itself. Many buyers make the mistake of selecting vendors based solely on price or availability without checking:

How long the supplier has been in business

Reviews and references

Delivery history and customer service

Their quality control measures

Purchasing from unverified sources increases the risk of receiving substandard or counterfeit products. Always research suppliers, request samples if needed, and read customer reviews to ensure you're partnering with a trustworthy company.

Failing to Consider Project Lead Times

Another common mistake is underestimating how long it takes to source, process, and deliver industrial steel and wire. Custom cuts, coatings, or large quantities can take weeks or even months to fulfill. Buyers often order too late, putting projects at risk of costly delays.

To avoid this, work closely with suppliers to understand lead times and maintain a buffer in your project schedule. It's wise to place orders well in advance, especially for large or specialized projects.

Disregarding Storage and Handling Needs

Even the highest quality steel and wire can become damaged due to poor storage and handling. Materials that are stored in humid environments may rust, and improper stacking can cause warping or bending. When making a purchase:

Ask about packaging and delivery methods

Ensure you have adequate storage facilities

Train staff on how to handle and move materials safely

Neglecting these factors can quickly turn a good purchase into a costly mistake.

Not Factoring in Future Requirements

Buying only for immediate needs is short-sighted. Businesses often make the mistake of not forecasting future demand, which can lead to inconsistent supply, missed discounts for bulk orders, or rushed procurement during peak seasons.

Consider future projects, potential expansions, and reorder needs when placing your order. Some suppliers offer contracts or inventory management services to help ensure a steady flow of materials.

Skipping Technical Consultation

Every application has unique technical requirements. For example, wire used in fencing needs flexibility and weather resistance, while wire for electronics must be highly conductive. Unfortunately, buyers sometimes skip consulting with a technical expert, leading to unsuitable choices.

Don’t hesitate to engage with engineers or experienced suppliers who can provide insight into which product is best suited for your application. Their guidance can help you avoid trial-and-error purchases.

Underestimating Logistics Costs

Logistics are often an afterthought during the purchasing process. Industrial steel and wire are heavy and bulky, which means shipping and handling can be a significant part of the total cost. Buyers who fail to account for this may go over budget.

Ask about shipping rates, freight insurance, and delivery timelines. If possible, choose a local or regional supplier to reduce transport costs and ensure faster delivery.

Neglecting After-Sales Support

Finally, buyers often overlook the importance of after-sales support. Issues can arise after delivery—such as quantity discrepancies, material defects, or documentation problems. A supplier who offers responsive support can save time and reduce stress.

Ensure your supplier provides easy communication channels and stands behind their products with return policies or replacement guarantees.

Final Thoughts

Purchasing industrial steel and wire isn’t just a transactional decision—it’s a strategic one. The quality, reliability, and appropriateness of these materials can make or break your project’s success. By avoiding these common mistakes, you can ensure better performance, reduced costs, and long-term satisfaction.

About Krueger

At Krueger, we understand the complexity and importance of sourcing the right steel and wire products. With decades of experience and a reputation for quality, we offer industry-compliant materials, technical guidance, and dependable support. Whether you're looking for standard grades or customized solutions, Krueger is your trusted partner in industrial materials.

1 note

·

View note

Text

How Do You Deal with Remodeling Stress?

Remodeling your home should be exciting—new floors, fresh cabinets, that dream kitchen you’ve always wanted. But let’s be real: it can also feel like a never-ending cycle of decisions, delays, and dust. Whether you're upgrading your kitchen, finishing your basement, or tackling a full-scale renovation, the process can be overwhelming. So how do you keep your sanity intact? Here’s a breakdown of what to expect, how to manage stress, and ways to make your remodeling experience smoother.

The Emotional Rollercoaster of Remodeling

You start with excitement. You’ve picked your colors, scouted Pinterest for inspiration, and can practically see yourself cooking in your brand-new kitchen. But then, reality kicks in—backordered materials, unexpected costs, and workers walking through your home at 7 a.m. Suddenly, you're wondering if it was all a mistake.

This is normal. Remodeling isn't just a physical process—it’s an emotional one. You’re making big decisions about your home, which can feel personal and, at times, overwhelming. But with the right mindset (and a little preparation), you can keep stress levels in check.

Plan Like a Pro

Let’s be honest: something will go wrong. Maybe the wrong tile gets delivered. Maybe your bathroom vanity takes weeks longer than expected. The key is preparing for these hiccups instead of letting them derail you.

Here’s what helps:

Pad Your Budget. Hidden costs pop up, whether it’s plumbing surprises or last-minute design tweaks. A good rule of thumb? Set aside at least 10-20% extra.

Give Yourself Time. Contractors give estimates, but weather, shipping delays, and unexpected repairs can add time. Mentally add a buffer to your timeline.

Make Key Decisions Early. Picking out cabinets, flooring, and fixtures ahead of time prevents last-minute scrambles (and the stress that comes with them).

Have a Backup Plan. Remodeling your kitchen? Think about how you’ll cook without it—maybe a temporary setup in another room with a microwave and toaster oven.

Keep the Chaos Under Control

Remodeling means your home becomes a construction zone. Tools everywhere, plastic sheets draped over furniture, and a fine layer of dust settling on everything. It’s frustrating, but there are ways to keep the mess manageable:

Protect What You Can. Cover furniture, seal off rooms not being worked on, and consider moving valuables out of high-traffic areas.

Clean as You Go. A quick vacuum at the end of each day keeps the dust from becoming unbearable.

Designate a ‘Calm Zone.’ Whether it’s your bedroom or a cozy corner, have a spot that remains untouched—somewhere to escape the chaos.

Communication is Everything

Ever played the game where one person whispers a message, and by the end, it’s completely different? That’s what happens when homeowners and contractors don’t communicate clearly. Misunderstandings can lead to stress, wasted time, and costly mistakes.

Here’s how to keep everyone on the same page:

Have a Main Point of Contact. Whether it’s your general contractor or project manager, know who to turn to with questions or concerns.

Use Visuals. A picture is worth a thousand words. Show your contractor exactly what you want instead of trying to describe it.

Ask Questions. If something seems off, speak up! It’s easier to fix an issue early than redo work later.

Managing Stress

No matter how well you plan, remodeling can still feel stressful. But a few simple habits can make a big difference:

Take Breaks. Step away from the project when you need to. Go for a walk, grab a coffee, or spend time in a part of the house that’s not under construction.

Keep the End Goal in Mind. It’s easy to get stuck on the daily frustrations, but remind yourself why you started—your dream home is on the other side of this.

Celebrate Small Wins. Did the countertops finally get installed? Did the bathroom tile turn out perfect? Acknowledge progress to keep yourself motivated.

When to Call in the Experts

DIY sounds great until you're knee-deep in a project and realize you’re in over your head. Some projects—like installing Pella windows, specialty flooring, or water filtration systems—are best left to professionals.

If you're in Lake County, IL, Waldron Construction specializes in kitchen remodeling, bathroom renovations, basement finishing, and custom millwork. Whether you're upgrading your home or building from scratch, their expert team can handle everything from architecture to interior design.

Ready to Remodel Without the Stress?

A well-planned remodel should bring joy, not headaches. Whether tackling a small renovation or a full home overhaul, a little preparation and the right team make all the difference.

If you're in Antioch, Illinois, and need experienced kitchen and bath remodelers, call Waldron Construction at (224) 788-9173. Their team will handle the hard work so you can focus on enjoying your newly transformed space.

0 notes

Text

Erosion Control 101: Using Rip Rap and Seawalls Together

Florida’s coastline is beautiful—but it comes with a cost. If you own waterfront property in places like Marco Island, Naples, or Bonita Springs, shoreline erosion is a real threat. Without proper protection, your land can slowly wash away with every storm, tide, or boat wake.

That’s why more homeowners are turning to a dual defense system: seawalls paired with rip rap. This combo is a proven strategy used by marine construction experts like SeaBee General Contractor to safeguard property from erosion while maintaining a natural look.

Let’s break it down.

🌊 What Is a Seawall?

A seawall is a solid structure—usually made from concrete, vinyl, or composite panels—built parallel to the shoreline. It acts as a first line of defense, blocking waves and tides from directly hitting the land.

Benefits of seawalls:

Stops soil loss and shoreline collapse

Provides a clean, defined edge to your property

Increases long-term property value

With proper maintenance, lasts decades

But seawalls alone aren’t always enough, especially in high-impact zones or where the ground is unstable. That’s where rip rap comes in.

🪨 What Is Rip Rap?

Rip rap is a layer of large, loose rocks placed along the shoreline or around structures like seawalls, docks, and bridge supports. The rocks absorb and slow down wave energy before it can hit the shore—or your seawall.

Why use rip rap?

Natural-looking erosion control

Reduces direct water pressure on seawalls

Adds an extra buffer zone between water and soil

Helps prevent undermining of the seawall foundation

🛡 Why Combining Rip Rap and Seawalls Works Best

When used together, rip rap and seawalls form a layered defense against erosion:

Rip rap disperses wave energy, lowering the force that reaches your seawall.

The seawall holds the land in place, preventing soil washout.

Together, they protect both the surface and foundation of your shoreline.

Think of rip rap as the cushion and the seawall as the shield. One helps the other last longer.

📍 Where This Matters Most in Florida

Coastal areas like Marco Island, Naples, Estero, Golden Gate, and Bonita Springs are especially vulnerable to erosion due to:

Frequent storms

High tides

Boating activity

Sandy or silty soil types

If you live or own property in any of these areas, investing in erosion control is not optional—it’s essential.

At SeaBee General Contractor, we’ve seen firsthand the damage caused when shoreline protection is delayed or ignored. We’ve also seen how our combined rip rap and seawall installations keep properties safe year after year.

💡 What to Expect When You Hire SeaBee

When you work with us, here’s what we provide:

Custom site evaluation for your shoreline conditions

Licensed marine construction with proven results

High-quality rip rap placement

Durable seawall installation or repairs

Compliance with local environmental and permitting regulations

We don’t just build—we protect your investment for the long haul.

📍 SeaBee General Contractor – Marco Island’s Marine Construction Experts

Business Address: 933 N Collier Blvd Marco Island, FL 34145

Phone: (239) 642-0116 Website: https://www.seabeemarineconstruction.com

We proudly serve Marco Island, Naples, Golden Gate, Bonita Springs, Estero, and the surrounding communities throughout Collier and Lee Counties.

🛠 Ready to Protect Your Shoreline?

If you’re worried about erosion—or just want to make sure your current setup is solid—SeaBee General Contractor is here to help. We’ll evaluate your shoreline and build a customized erosion control plan using rip rap, seawalls, or both.

👉 Call us today at (239) 642-0116 or visit seabeemarineconstruction.com to schedule your free consultation.

Don’t wait until the next storm takes your land—protect your waterfront now.

1 note

·

View note

Text

Why Lead Time Matters in the Spice Business and How We Keep Ours Short