#diesel engine noise reduction

Explore tagged Tumblr posts

Text

Noise Reduction Treatment in Drilling Rig Diesel Engine Room

The power system of oil drilling rigs mainly comes from diesel engines. The power of diesel engines is relatively large, generally around 800KW. A set of 5000M drilling rig generally requires 3 diesel engines and a set of 7000M drilling rig generally requires 4 diesel engines. Diesel engines will produce noise when they are working, especially diesel engines used in drilling rigs. Due to their high power and mutual influence, the noise is particularly prominent. The sound of a diesel engine can be heard even in the wild and at great distances.

1. Analysis of noise sources of diesel generator sets

1.1 Aerodynamic noise

During the operation of the diesel unit, the disturbance to the air causes a sound source between the air and the diesel unit to form noise. This kind of noise directly radiates to the outside, specifically including: the noise of the exhaust system, the noise of the air intake system, and the rotation noise of the diesel engine cooling fan.

(1) Exhaust system noise. The most direct noise source of diesel generator sets is the noise generated by the exhaust system. This noise is relatively high in intensity and is about 10~15dB (A) higher than normal engine noise. During the operation of the generator set, high-temperature and high-pressure exhaust gas must be continuously discharged. According to the operating status of the generator set, the exhaust system has two stages of exhaust, namely free exhaust of the generator set and forced exhaust of the generator set. When the exhaust gas from the generator set is discharged from the exhaust valve, it will flow from the exhaust pipe to the muffler, and finally be discharged into the air through the rear exhaust pipe. During the entire exhaust process, a large amount of exhaust noise will be generated, which is also the main source of noise from diesel generator sets. The noise generated during the exhaust process was analyzed and it was found that the composition of the noise source was relatively complex. There are noises caused by the frequency of exhaust operations in the exhaust system per unit time, noise caused by the resonance of exhaust gases in the exhaust pipe, and blowing noise caused by the airflow ejected from the exhaust pipe. The main factors that can affect the noise of the exhaust system of the generator set are: the internal pressure of the engine cylinder, the pipe diameter of the exhaust system, the rated exhaust volume of the generator set, the operating speed and workload of the generator set, etc. Increasing the working load of the generator set or increasing the engine speed will increase the gas flow, resulting in an increase in exhaust noise.

(2) Noise from the air intake system. The noise generated by the air intake system is one of the main noises of the diesel generator set. The main reason for the formation is that the air inlet is continuously opened and closed according to the air intake demand of the generator set, which causes the pressure of the air intake system to continuously change and cause noise. When the intake system is working, a certain pressure pulse is formed in the intake pipe, causing the intake system to produce periodic noise. The audio frequency range of this noise is generally around 200Hz. At the same time, when the air flow enters the inside of the system, it will flow through the air intake pipe, causing the air to be kicked out of the body. This situation will cause high-frequency noise in the engine air intake system. Usually the air flow in the intake pipe is constantly changing, so the frequency band of this noise is also relatively fixed, generally concentrated around 1000Hz. When the noise frequency of the intake cycle and the air column in the intake system reaches consistency, airflow resonance will occur, causing the noise of the intake system to increase. The noise generated by different superchargers in different generator sets is also different. The noise intensity of a turbocharged generator set is obviously different compared to a non-turbocharged generator set. This is due to the relatively high speed of the turbocharged generator set, which causes the engine's air intake system to produce relatively strong airflow due to air cutting, resulting in higher-frequency noise. The frequency distribution range of this noise is generally between 500 and 10000Hz.

1.2 Surface radiated noise

Strictly speaking, it is difficult to distinguish the surface radiation noise of diesel generator sets. Combustion noise is generally caused by the pressure vibration generated by diesel combustion inside the cylinder acting on the mechanical components of the overall cylinder, thereby radiating a certain amount of noise to the outside. During the operation of the generator set, various mechanical components will continue to collide mechanically, thus generating mechanical noise. Usually, when the generator set speed is low, the combustion noise generated is higher than the mechanical noise.

2. Specific construction measures for noise reduction in diesel generator rooms

Use high-efficiency shock-absorbing rubber pads to isolate the unit. This part of the technology is now very mature. After isolation treatment, the vibration on the surface of the unit is effectively isolated.

(2) Perform noise reduction processing on the propagation channel, and install soft damping connections on the exhaust pipe of the generator set to reduce the external radiation of the sound source. According to the principle of muffling, the muffler structure can use a resistive muffler. It uses porous sound-absorbing material - melamine foam, which is arranged in a certain way in the pipe. When the airflow passes through the resistive muffler, the sound waves cause vibrations in the air and small fibers in the pores of the melamine foam. Due to friction and viscous resistance, sound energy is converted into heat energy and absorbed, thus playing a silencing effect.

(3) Each wall of the room is made of multiple layers of noise-reducing materials, including rock wool, sound-absorbing mesh cloth and sound-absorbing mesh board. Adding a sound-absorbing wall to the wall of the generator room inside the machine room can not only reduce the reverberation sound in the machine room while improving the sound insulation effect, but also attenuate the direct transmission of strong noise when it is running to the top.

(4) When designing the air inlet and outlet, the minimum air inlet and outlet volume standards required for normal operation of the unit are fully considered. At the same time, in order to solve the heat dissipation problem in the machine room, the air inlet and the exhaust outlet of the generator set should be set on the same straight line. In addition, the air intake and exhaust openings should be equipped with resistive sheet sound absorbing grilles.

3.Conclusion

The noise from the diesel generator set of oil drilling rigs is the largest noise source at the entire drilling rig site. It has a great impact on environmental protection and does not meet the requirements of the safety and environmental management system (HSE), so it needs to be prevented. This article conducts research on the noise generated by diesel generator sets, and provides specific construction measures for noise reduction in the generator set room, which can provide reference for relevant personnel.

SINOYQX’s oil and gas generator set noise reduction solution

1) Medium and high frequency sound-absorbing module, sound-absorbing melamine foam board

2) Full-range sound-absorbing module, pyramid sound-absorbing melamine foam board

3) Sound absorption and shock absorption module, EPDM composite melamine board

4) Fully customized modules according to noise source

For more information about SINOYQX Melamine Foam, please reach us at [email protected] or voice to us: +86-28-8411-1861.

#melamine foam#noise control#sound-absorbing material#thermal insulation#flame retardant#sound-absorbing foam#noise treatment#diesel engine noise reduction#diesel generator set#porous sound-absorbing materials

0 notes

Text

🌟 Unleash Unstoppable Power with the PS POWER Diesel Generator! 🌟

Looking for a reliable, efficient, and durable power solution? Look no further! The PS POWER Diesel Generator is here to meet all your energy needs, whether for your home, business, or industrial site.

Why Choose PS POWER Diesel Generators?

🔋 High Performance: Our diesel generators are powered by top-of-the-line engines, ensuring consistent and robust power output, even under the heaviest loads.

💰 Fuel Efficiency: Say goodbye to skyrocketing fuel costs! The PS POWER Diesel Generator is designed for optimal fuel consumption, giving you maximum power with minimal expense.

🏗️ Built to Last: With a rugged, corrosion-resistant design, this generator is engineered to withstand the toughest conditions, ensuring reliable performance year after year.

🔇 Whisper-Quiet Operation: Don’t let noise disrupt your environment. Our advanced noise-reduction technology ensures quiet operation, perfect for both urban and remote settings.

🛡️ Safety First: Equipped with comprehensive safety features like automatic shutdown and overload protection, you can trust the PS POWER Diesel Generator to keep you and your equipment safe.

🌍 Eco-Friendly: Committed to protecting our planet, our generators meet stringent environmental standards, minimizing emissions while maximizing efficiency.

Perfect for: 🏠 Home Backup: Keep your household powered during outages. 🏢 Business Continuity: Ensure your operations never skip a beat. 🏗️ Industrial Use: Power heavy machinery with confidence. 🌲 Off-Grid Living: Enjoy reliable power, no matter where you are. More...

2 notes

·

View notes

Text

Understanding Diesel Generator Exhaust Silencer: Different Types and Sound Ratings

There is a common idea that diesel generators are noisy. It cannot be denied that diesel gensets produce more noise than other kinds of power generators, which could be a nuisance for residents around. Luckily, there are many ways to make the generators quieter. An exhaust silencer can effectively reduce noise and exhaust emissions produced during combustion. Read on and learn about different types of diesel generator exhaust silencers and the silencer sound ratings.

What is a diesel generator exhaust silencer?

A diesel generator exhaust silencer is a device for reducing diesel engine noise emission. It is inevitable that all internal combustion engines produce noise, more or less. The noise level will largely vary depending on diesel engine type. Diesel generators are powered by a diesel engine, which is an internal combustion engine that runs on diesel fuel. The operation of an internal combustion engine produces distinct pulses of exhaust gas that exit through the exhaust pipes and the muffler. Sound is a pressure wave formed from pulses of alternating high and low pressure air. Exhaust silencers are installed within the exhaust system of diesel engines. They allow the passage of exhaust gasses while restricting the transmission of sound.

What are the types of diesel generator exhaust silencers?

Diesel generator exhaust silencers come in different designs that vary depending on their size and shape, the way they work and a few other features. Commonly, the silencers are in cylinder, disc, and rectangle shapes, with inlets and outlets able to be located on both sides, both ends or one side and one end to work with your system. The three basic types are:

Reactive silencer

The internal construction consists of a maximum of three chambers connected by a tube. The exhaust noise created bounces between different chambers and reactive silencers mute sound by bouncing it around inside one or multiple chambers. This type of generator silencer is commonly used for low to mid-level noise reduction.

Absorptive silencers

The internal construction consists of fiberglass or E glass insulation. The exhaust noise is reduced as it flows through the insulation. This type of generator silencer has a greater sound attenuation rating and is typically used to reduce high frequency sound waves.

Combination silencers

As the name implies, this type of silencer combines the construction of the reactive and absorptive silencers. Combination silencers are typically made from a metal chamber with absorption material fitted inside. They can be used to reduce mid, low and high-frequency sounds.

The three basic designs mentioned above offer several different generator silencers that you can choose to meet your requirements. Which type of diesel generator exhaust silencer is right for you? It will depend on the model of your generator and the level of noise reduction you require. The following options are the type of silencers you can choose from:

Cylindrical silencers

Cylindrical silencers can be mounted horizontally or vertically, making them a great option for generators of various different models. They are the most common used type of silencers and can be utilized in both inside and outside applications. Additionally, these silencers are relatively affordable and especially suitable for budget-minded shoppers.

Low-profile silencers

Low-profile silencers are available in various shapes such as rectangular, oval, and round. They typically have a higher sound reduction rating than other types and commonly used in diesel generators located in sound attenuated enclosures. Please note that these silencers must meet the National Fire Protection Association (NFPA) guidelines. The downside of low-profile silencers is that they are more expensive compared to other options and may require more frequent maintenance.

Emission control silencers

Emission control silencers work by reducing the amount of noise generated by the engine. They absorb the noise and then redirect it away from the engine. Certain models of these silencers come with the ability to control the vibrations as well. The Environmental Protection Agency (EPA) regulates emissions for generators that supply main power to a facility. Emission control silencers can help filter emissions for better environmental control and to stay in compliance with local or EPA regulations. They are typically used in industrial settings where noise emissions need controlling.

Sound attenuation silencers

Sound attenuation silencers are specially designed to reduce the overall noise created by the diesel generator engine. These silencers absorb and dissipate the noise before it has a chance to reach the outside world. Diesel generators used in residential areas usually come in this type of silencer.

Hybrid silencers

Hybrid silencers combine both emission control and sound attenuation into one unit. These silencers are commonly used in places where both emission and noise reduction are strict requirements.

Sound ratings of diesel generator silencers

Sound pressure is measured in decibels (dB). A-weighted decibel (dBA or dB(A)) is an expression of the relative loudness of sounds as perceived by the human ear. Diesel generators with noise ratings are measured in dBA. Typically, noise ratings increase along with the power and size of the generator. For generators, a silencer does the same job that a muffler handles for engines in automotive and construction applications. Diesel generator exhaust silencers also come with a sound rating and they are divided into various grades.

Initially, the silencer ratings were divided into four basic grades: industrial, commercial, residential, and hospital grades. They were considered the industry standard in silencer manufacturing. During this period, the amount of sound reduction for grade varied between manufacturers. The Electrical Generating Systems Association (EGSA) came up with a rating guide that provided consistent silencer ratings for any manufacturer belonging to the association. The result was eight classes of ratings from Class 1 up to Class 8:

Industrial Grade – Exhaust noise reduction of 15 to 20 dBA

Residential Grade – Exhaust noise reduction 20 to 25 dBA

Critical Grade – Exhaust noise reduction of 25 to 32 dBA

Super Critical Grade – Exhaust noise reduction 30 to 38 dBA

Hospital Grade – Exhaust noise reduction of 35 to 42 dBA

Hospital Plus Grade – Exhaust noise reduction of 35 to 50 dBA

Extreme Grade – Exhaust noise reduction of 40 to 55 dBA

Super Extreme Grade – Exhaust noise reduction of 45 to 60 dBA

Manufacturers of generator silencers typically focus production on the grade and style combinations that customers demand the most.

All noise emitted by an engine does not specifically come from the exhaust system. In addition to the diesel generator exhaust silencer, there are many other ways to keep your generator quieter, such as moving the generator further away, using acoustic barriers like generator canopies and enclosures, installing acoustic wall panels, positioning anti-vibration mounts underneath the generator, using attenuators, etc.

Get a silent diesel generator today

If you are looking for a generator with exhaust silencer or other acoustic dampening devices, contact Dingbo Power today. We are a professional manufacture of diesel generator sets with almost 20 years experience in the industry. We offer a variety of silent type diesel gensets that can meet your needs. Feel free to contact us with any questions, concerns, or inquiries to learn more about the products & services we provide.

2 notes

·

View notes

Text

5 Reasons to Buy a Fully Electric Wheel Loader

If you're in the construction or mining business, or perhaps looking to take your farm up a notch, you've most likely come across a wheel loader or two. Now, imagine a fully electric version of this massive machinery. Too futuristic, you reckon? Well, not anymore. Fully electric wheel loaders are the future, and here’s why you should be excited about them.

Environmentally Friendly Operation

With electric wheel loaders, say goodbye to all those nasty exhaust fumes. These beasts come emission-free, which means:

Cleaner air for you and your workers.

A massive reduction in carbon footprint.

Contributing to a sustainable and greener planet.

2. Quiet as a Wallaby at Dawn

Electric machinery, unlike their diesel counterparts, are far quieter. What does this mean for you?

Less noise pollution – a bonus for worksites near residential areas.

Happier, less stressed-out neighbours.

Workers can communicate easily without yelling over a roaring engine.

3. Significant Cost Savings in the Long Run

Though the initial investment might be higher, electric wheel loaders can lead to significant savings in the long run.

No more pouring dollars into diesel.

Reduced maintenance costs. Electric motors have fewer moving parts, meaning fewer things can go wrong.

Potential for government incentives for going green.

4. No Worries about Fuel Supply

Are you sick of those days when there's a sudden spike in diesel prices or there's an unpredictable shortage? With electric wheel loaders:

You can charge them up using renewable energy sources, like solar or wind.

No need to fret about the fluctuating fuel market.

Your operations won't be halted by external fuel issues.

5. Improves Work Efficiency

A fully electric wheel loader isn't just about environmental benefits or savings. It can seriously boost your work efficiency. How, you ask?

Instant torque from electric motors ensures rapid and smooth operations.

Consistent power delivery without the lag often experienced in diesel engines.

Less downtime, thanks to reduced maintenance needs.

In Conclusion

Navigating our way into the future, it's clear that our choices now have lasting impacts. Machines like the fully electric wheel loader don't just signify progress in tech but also our commitment to a greener tomorrow. Batt Mobile Equipment has got your back. Because it's not just about moving forward, it's about making sure we're heading in the right direction. Cheers to a sustainable journey ahead!

2 notes

·

View notes

Text

The Environmental Impact of Diesel Dredge Operation

Diesel dredge equipment is essential for maintaining navigable waterways, supporting marine construction, and executing large-scale sediment removal. However, as with any industrial machinery, diesel dredge operations come with a set of environmental challenges that must be addressed. At Mudcat Dredge, we recognize the growing demand for sustainability in the industrial equipment and machinery sector. Understanding the environmental footprint of diesel dredging is the first step toward adopting smarter, cleaner, and more responsible practices.

Air Emissions Remaining a Diesel Dredge Concern

Diesel dredge equipment is powered by internal combustion engines that emit significant amounts of greenhouse gases such as CO₂ and nitrogen oxides (NOx). These pollutants contribute to both local air pollution and global climate change. In marine and coastal settings where air circulation may be limited, such emissions can linger, affecting nearby ecosystems and human populations. Over time, reliance on outdated diesel dredge engines can lead to cumulative environmental damage.

Diesel Dredge Operations Stir Up Sediment Layers

One of the major concerns with diesel dredge activity is the resuspension of sediment from riverbeds or seabeds. When sediments are disturbed, they often release pollutants—such as heavy metals, nutrients, or organic toxins—back into the water. This clouding effect reduces visibility, disrupts aquatic life, and can temporarily alter the pH and oxygen levels of the surrounding water. In sensitive habitats, even short-term dredging can create long-lasting ecological consequences.

Diesel Dredge Machines Contribute to Underwater Noise

Diesel-powered dredging equipment produces consistent low-frequency noise that travels efficiently through water. For marine species—especially those relying on echolocation or sound-based communication—this type of underwater noise can be extremely disruptive. Dolphins, whales, and various fish species have shown avoidance behavior and stress responses when exposed to diesel dredge noise. Sound-muffling modifications and scheduling dredge operations during low-activity marine periods can help lessen the acoustic footprint.

Fuel Leaks Pose Risks to Water Ecosystems

Despite improvements in hydraulic and fuel systems, diesel dredge equipment still carries the risk of oil, diesel, or hydraulic fluid leaks. These leaks may enter the water directly or contaminate surrounding land that later drains into marine environments. Even small spills can cause harm to fish, birds, and vegetation. Regular maintenance and proactive inspection schedules are critical in preventing such contamination. Operators must also have immediate spill response procedures in place.

Diesel Dredge Equipment Impacts Benthic Habitats

Benthic zones—the areas at the bottom of water bodies—are often home to diverse ecosystems, including mollusks, crustaceans, and vegetation. Diesel dredge operations can disrupt these sensitive habitats, displacing organisms and altering nutrient cycles. In some cases, dredging destroys entire microhabitats that take years to regenerate. Responsible dredging involves careful mapping of these zones, choosing equipment with precise excavation capabilities, and following environmental regulations that limit dredging in ecologically critical areas.

Diesel Dredge Units Require Energy-Efficient Upgrades

The traditional diesel dredge setup often runs at full power, consuming fuel even during periods of low productivity. This inefficiency leads to increased emissions and higher operational costs. Newer dredging technologies, such as variable engine controls, load-sensing hydraulics, and automated idle-reduction systems, allow for more efficient fuel usage. At Mudcat Dredge, we advocate for integrating such innovations to extend machine life and minimize environmental harm.

Regulations Are Reshaping Diesel Dredge Practices

Governments and environmental agencies are introducing stricter regulations for diesel dredge operations, especially in protected or high-traffic marine zones. These policies cover emissions, noise levels, sediment disposal methods, and equipment maintenance protocols. Compliance is no longer optional—it’s a fundamental part of operating responsibly in today’s industrial landscape. At Mudcat Dredge, staying ahead of regulatory changes means constantly evolving our product designs and support systems.

Conclusion

The environmental impact of diesel dredge operations is complex, but not insurmountable. With greater awareness, modern engineering, and a commitment to sustainability, it's possible to minimize the ecological footprint of dredging while still achieving vital infrastructure goals. At Mudcat Dredge, we believe that diesel dredge equipment can evolve into cleaner, safer tools through innovation and responsible use.

0 notes

Text

Rubber Mountings for DG Sets - Control Vibration the Smart Way

In industrial setups, diesel generator (DG) sets are crucial for uninterrupted power. However, one common issue across industries is vibration. These vibrations can cause damage to the generator frame, building structure, and nearby machinery. This is where rubber mountings for DG sets play an important role.

What Are Rubber Mountings?

Rubber mountings are flexible components installed between the DG set and the floor or base. They help absorb and dampen vibrations during operation. Unlike rigid supports, these mountings provide cushioning to reduce shocks and improve machine stability.

Why DG Sets Need Rubber Mountings

Constant vibrations from DG sets can lead to:

Loosening of bolts and parts

Noise pollution in the facility

Cracks in the base or flooring

Reduced performance and lifespan of the DG set

Using rubber shock mountings reduces all of the above risks, ensuring efficient, quieter, and longer-lasting operation.

Benefits of Rubber Mountings for DG Sets:

Vibration Isolation: Minimizes transmission of vibration to the floor or nearby structures.

Noise Reduction: Decreases ambient noise levels, making the working environment safer.

Better Equipment Life: Reduces stress on engine components, increasing longevity.

Cost Efficiency: Lowers maintenance needs and downtime.

Where Are Rubber Mountings Used?

Factories and manufacturing units

Hospitals and data centers

Commercial buildings and malls

Telecom towers and infrastructure projects

At Resistoflex, our rubber mountings are designed for Indian industrial needs. They are tested under real-world loads and conditions to deliver consistent performance.

👉 Explore rubber mountings for DG sets

Blog 2: Expansion Joints for Pipelines – The Backbone of Industrial Fluid Movement

In large industrial facilities, pipelines are everywhere—carrying water, chemicals, steam, or gases. But what happens when these pipes expand, contract, or vibrate due to temperature or pressure changes? The answer lies in using expansion joints for pipelines.

What Are Expansion Joints?

Expansion joints (also known as flexible joints or compensators) are installed in pipelines to absorb movements caused by:

Thermal expansion and contraction

Vibrations from pumps or compressors

Ground movement or seismic activity

Misalignment between connected equipment

Types of Expansion Joints:

Rubber Expansion Joints – Flexible and corrosion-resistant, ideal for water and chemical pipelines.

Metallic Expansion Joints – Used in high-pressure or high-temperature environments.

Key Benefits:

Protects Equipment: Prevents cracks or leaks in pipelines.

Absorbs Movement: Handles thermal stress and mechanical shifts.

Reduces Vibrations: Minimizes damage from pulsation or pump startup.

Saves Maintenance Costs: Reduces chances of system failure.

Industries That Use Expansion Joints:

Power plants

Chemical and fertilizer industries

Oil and gas

Water treatment and plumbing

Resistoflex provides premium-quality rubber expansion joints for pipelines designed to work in tough Indian conditions.

👉 Discover expansion joint solutions

0 notes

Text

Drive in Style with the New Range Rover Velar – Land Rover Bangalore Deals Inside

If you appreciate modern luxury, advanced technology, and effortless performance, then let us introduce you to the SUV that ticks every box—the Range Rover Velar. Here at Land Rover Bangalore, we’re thrilled to showcase this stunning vehicle, which is turning heads across the city and redefining what it means to drive in style.

Whether you're a seasoned executive who demands refined travel or a new car buyer stepping up to the world of premium SUVs, the Range Rover Velar offers a blend of sophistication and versatility that few can match. Its sleek, reductive design speaks volumes – it's minimal, clean, and undeniably elegant. The flush door handles, floating roofline, and signature LED lights make a lasting first impression, no matter where the Velar takes you.

A Cabin Designed for You

Step inside, and you’ll feel an immediate sense of calm. The cabin of the Range Rover Velar is crafted with premium materials, including optional Windsor leather and sustainable alternatives. The dual touchscreen Pivi Pro infotainment system, ambient lighting, and noise insulation create a space where luxury meets comfort and convenience.

Whether you're navigating Bangalore’s busy business corridors or cruising down the highway for a weekend escape, the Velar provides a commanding view of the road and an intuitive and powerful driving experience. Its advanced driver assistance features and adaptive dynamics ensure a smooth, confident ride every time.

Performance with Purpose

Under the hood, the Range Rover Velar offers a range of powerful engine options, including the refined 2.0L petrol and diesel variants, as well as the punchier 3.0L mild-hybrid versions. Whichever you choose, expect responsive acceleration and fuel efficiency wrapped in sheer driving pleasure. It’s the perfect combination of performance and elegance – built for Indian roads with British engineering.

Explore Velar On-Road Price in Bangalore

We know that pricing plays a big role in choosing your dream car. That’s why at Land Rover Bangalore, we offer transparent pricing and personalised consultations to help you make the best decision. The Range Rover Velar price starts at a competitive point for its segment, and we provide exclusive finance options, corporate plans, and limited-time benefits to make your purchase even more rewarding.

Curious about the Velar on-road price in Bangalore? Reach out to us, and we’ll provide a detailed quote that includes RTO, insurance, registration, and any current offers applicable. You’ll be surprised how attainable driving a Velar can be with the right guidance and support.

Visit Land Rover Bangalore Today

If you're ready to upgrade your driving experience, we invite you to visit our showroom and explore the Range Rover Velar in person. Our expert team at Land Rover Bangalore will walk you through its features, take you on a personalised test drive, and help you with a tailor-made ownership plan.

Luxury, performance, and unmistakable style – the Range Rover Velar is the SUV you’ve been waiting for. And the best part? It’s right here, waiting for you at Land Rover Bangalore. Let’s begin your journey in true Land Rover fashion – powerful, poised, and unforgettable.

Your new chapter starts with the Velar. Come drive it today.

0 notes

Text

Transforming Operations: Electric Vehicles in Industrial Settings

The global push toward decarbonization and operational efficiency is reshaping the industrial landscape, and at the heart of this transformation is the Electric Industrial Vehicles Market. Once dominated by fossil-fuel-driven machines, warehouses, ports, and manufacturing facilities are increasingly shifting toward electrically powered alternatives. These vehicles, ranging from forklifts and tow tractors to container handlers and automated guided vehicles (AGVs), are now crucial in driving cleaner, quieter, and more cost-effective industrial operations.

Electric industrial vehicles (EIVs) operate using rechargeable batteries or advanced electric drive systems instead of internal combustion engines. These vehicles offer numerous benefits, including reduced operational costs, lower emissions, minimal noise pollution, and reduced maintenance needs. As global industries continue to align with environmental, social, and governance (ESG) goals, the adoption of electric vehicles within the industrial sector is expected to skyrocket over the coming decade.

Request for sample copy of this report- https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86483

Electric Industrial Vehicles Market Outlook 2035

The industry was valued at US$ 23.3 Bn in 2024. The global electric industrial vehicles market is estimated to grow at a CAGR of 8.2% from 2025 to 2035 and reach US$ 55.5 Bn by the end of 2035.

This significant growth projection is attributed to the rapid pace of industrial electrification, robust investments in clean technology, and the expansion of smart warehouses and green manufacturing units across North America, Europe, and Asia Pacific.

Market Dynamics and Growth Drivers

The market is primarily driven by four converging trends: environmental regulations, cost optimization, technological advancements, and changing consumer preferences.

Environmental Compliance and Emissions Reduction: Governments around the world are enforcing stricter emissions standards across industrial sectors. Regulatory frameworks such as the EU’s Green Deal and the U.S. Clean Air Act are encouraging companies to adopt electric alternatives in industrial operations to reduce their carbon footprint.

Operational Cost Efficiency: Electric industrial vehicles have lower fuel and maintenance costs over their lifetime compared to diesel or gas-powered machines. Lithium-ion batteries, in particular, provide faster charging times and longer service intervals, reducing total cost of ownership.

Technological Advancements: Innovations in battery technologies—such as lithium-ion phosphate (LFP), solid-state batteries, and fast-charging systems—are making electric industrial vehicles more viable and powerful. Simultaneously, digital technologies such as IoT, fleet telematics, and AI-based vehicle control systems are improving safety and productivity.

Growing Demand from E-commerce and Logistics Sectors: With the rapid rise of e-commerce, warehouse automation and high-efficiency material handling have become more critical than ever. Electric forklifts and AGVs are ideal solutions for indoor environments, as they produce no emissions and are safe for confined spaces.

Analysis of Key Players in Electric Industrial Vehicles Market

The market is characterized by the presence of global giants who are leveraging both innovation and scale to maintain competitive advantages.

Toyota Material Handling leads the market with its extensive portfolio of electric forklifts and pallet trucks known for durability and energy efficiency.

Jungheinrich AG is recognized for pioneering lithium-ion battery integration in industrial vehicles, offering compact designs and superior performance.

Crown Equipment Corporation emphasizes energy-efficient solutions, including regenerative braking systems and smart energy storage.

Kion Group AG (parent company of Linde Material Handling and STILL) focuses on high-end technology integration, offering intelligent control systems for fleet management and automation.

Mitsubishi Logisnext is actively investing in the expansion of its eco-friendly vehicle lineup to increase its footprint in global markets.

These companies are heavily investing in R&D to enhance their offerings in terms of battery range, load capacity, autonomous features, and safety systems. Their strategic moves reflect the growing demand for sustainability, flexibility, and innovation across industries.

Anhui Forklift Group Corporation Ltd., Clark Material Handling Company, DOOSAN BOBCAT KOREA, EP Equipment Co., Ltd., Hangcha Group Co., Ltd., Hyster-Yale Materials Handling, Inc., JCB (J C Bamford Excavators Ltd.), Komatsu Ltd., Konecranes Plc, and Manitou Group are some of the other key electric industrial vehicles market players who contribute to the market’s diversity and innovation.

Each of these players has been profiled in the electric industrial vehicles market report based on parameters such as company overview, financial overview, business strategies, product portfolio, business segments, and recent developments.

Key Market Developments in Electric Industrial Vehicles Market

May 2024: Toyota Industries Corporation announced a major expansion in electric forklift manufacturing with a US$ 100 Mn investment in a new production facility in Indiana, U.S. This facility will focus on next-generation electric vehicles powered by advanced battery systems, signaling Toyota’s commitment to local production and sustainability.

April 2023: EP Equipment unveiled a new range of heavy-duty electric forklifts equipped with reinforced chassis and advanced lithium-ion batteries. These models are designed for ports, distribution centers, and manufacturing hubs requiring robust lifting capacities and extended duty cycles.

April 2023: Anhui Forklift Group launched multiple new electric forklift models featuring state-of-the-art battery technology with fast-charging capabilities and ergonomic controls. This development underscores the company’s push into high-performance and smart vehicle segments.

These developments showcase the dynamism of the market and how manufacturers are focusing on innovation, localization, and green technology to stay competitive.

Regional Insights

North America and Europe currently lead the global electric industrial vehicles market due to strong environmental regulations and the presence of leading OEMs and logistics providers. In North America, the U.S. dominates due to rapid warehouse automation and aggressive sustainability goals set by corporations like Amazon, Walmart, and FedEx.

Asia Pacific, particularly China, India, and Japan, is projected to witness the fastest growth during the forecast period. China, with its strong manufacturing base and government incentives for electric mobility, remains a key growth engine. India is emerging as a new hub for low-cost manufacturing of electric industrial equipment due to the "Make in India" initiative and rising e-commerce.

Opportunities and Future Outlook

Looking forward, the electric industrial vehicles market is poised to undergo a major transformation, offering immense opportunities for value creation.

Autonomous Electric Vehicles: Integration of autonomous technologies is becoming mainstream in warehouse and industrial settings. Electric AGVs and self-driving forklifts are expected to gain more traction due to their ability to work 24/7, reducing labor costs and human errors.

Battery-as-a-Service (BaaS): The high upfront cost of batteries can be offset through subscription-based battery services. This model is gaining popularity among logistics and rental fleet companies.

Fleet Electrification Programs: Companies worldwide are developing comprehensive fleet electrification plans. As a result, demand for end-to-end electrification solutions, including vehicles, charging infrastructure, and software platforms, is expected to grow.

Conclusion

The Electric Industrial Vehicles Market is at a critical juncture, driven by sustainability demands, cost savings, and technological progress. As industries shift toward green operations, the adoption of electric vehicles in warehouses, factories, ports, and construction sites is no longer optional—it’s a necessity. With a projected valuation of US$ 55.5 Bn by 2035, the market offers significant opportunities for manufacturers, technology providers, and investors.

Companies that continue to innovate, adapt to regional demands, and focus on durability, automation, and sustainability will lead the next era of industrial mobility.

0 notes

Text

Construction Electric Vehicle Market Drivers Shaping Sustainable Innovation and Green Equipment Transformation Globally

The construction electric vehicle market is experiencing a profound shift as environmental sustainability and regulatory compliance take center stage. Once dominated by diesel-powered machines known for high emissions and operating noise, the sector is now witnessing a surge in the adoption of electric vehicles (EVs) tailored specifically for construction applications. This transition is fueled by several key drivers that are changing how construction companies invest in machinery and how governments incentivize green innovations.

1. Rising Environmental Concerns and Emission Regulations

A primary driver of growth in the construction electric vehicle market is the rising global concern over carbon emissions and their impact on climate change. Construction activities are significant contributors to greenhouse gas emissions, primarily through the use of fossil-fueled heavy machinery. In response, regulatory bodies in Europe, North America, and parts of Asia-Pacific have introduced stringent emissions standards for off-road construction equipment.

These regulations are prompting construction firms to look for cleaner alternatives, and electric vehicles present an ideal solution. Unlike diesel-powered machines, electric construction vehicles emit no tailpipe pollutants and reduce overall carbon footprint on job sites.

2. Government Incentives and Policy Support

Many national and regional governments are actively encouraging the adoption of electric construction vehicles by offering financial incentives, tax rebates, and subsidies. These incentives not only lower the upfront cost of electric machinery but also accelerate research and development in the segment. Additionally, governments are investing in infrastructure upgrades to support EV charging capabilities on construction sites, which has further eased operational concerns for contractors.

Furthermore, public construction tenders increasingly prioritize companies that demonstrate sustainability in their equipment and practices. As a result, firms investing in electric construction vehicles are better positioned to win government contracts and enhance their competitive edge.

3. Technological Advancements in Battery and Charging Systems

Battery technology has seen substantial improvements in recent years, with higher energy density, faster charging capabilities, and longer life cycles becoming the norm. These advancements are critical in construction applications, where vehicle uptime is crucial for productivity.

Modern electric construction vehicles can now operate for extended periods on a single charge and are equipped with fast-charging technology that minimizes downtime. In addition, smart energy management systems and predictive maintenance tools have improved operational efficiency, making electric options more attractive than ever.

4. Lower Operational and Maintenance Costs

Electric construction vehicles offer a compelling long-term value proposition due to their lower operating and maintenance costs. Since they have fewer moving parts compared to internal combustion engine (ICE) machines, they require less maintenance and experience fewer mechanical failures. Additionally, the cost of electricity is generally more stable and affordable compared to diesel fuel.

Contractors are increasingly recognizing the total cost of ownership (TCO) benefits of electric machinery, especially in urban and indoor projects where emissions and noise restrictions are stringent. These economic incentives are accelerating the shift toward electric fleets.

5. Noise Reduction for Urban and Sensitive Environments

Construction projects in urban areas or near residential neighborhoods often face noise restrictions. Electric vehicles operate much more quietly than diesel-powered alternatives, making them ideal for these sensitive environments. Reduced noise pollution not only ensures compliance with local regulations but also enhances worker comfort and safety on site.

For indoor construction or projects conducted during off-hours, electric vehicles enable smoother operations without causing disturbances to surrounding communities or facilities. This practical advantage is increasingly becoming a deciding factor in equipment purchasing decisions.

6. Corporate Sustainability Goals and ESG Commitments

Many construction companies are aligning their operations with environmental, social, and governance (ESG) principles to meet stakeholder expectations and investor requirements. Fleet electrification is a visible and impactful step in achieving corporate sustainability goals.

By adopting electric vehicles, construction firms demonstrate their commitment to reducing carbon footprints, which can improve their brand reputation, attract eco-conscious clients, and gain access to ESG-focused funding opportunities. This strategic alignment between sustainability and business growth is acting as a major catalyst for electric vehicle adoption in the sector.

7. Global Construction Market Expansion

The ongoing expansion of the global construction industry, especially in emerging economies, is opening up new opportunities for electric vehicle integration. As developing nations invest in infrastructure while facing rising pollution levels, electric construction equipment becomes an attractive option to balance development with environmental responsibility.

Manufacturers are now offering electric solutions tailored for varying market needs, from compact urban machines to heavy-duty equipment for large-scale infrastructure projects. This product diversity supports adoption across a wide range of applications and geographic locations.

In conclusion, the construction electric vehicle market is being propelled by a combination of regulatory pressures, economic benefits, and environmental responsibility. As technology continues to advance and support infrastructure improves, electric construction vehicles are becoming a practical and profitable choice for contractors worldwide. The cumulative impact of these market drivers is setting the stage for a cleaner, quieter, and more efficient future in construction.

#ConstructionEVMarket#ElectricConstructionVehicles#GreenConstruction#SustainableConstruction#EVinConstruction

0 notes

Text

Diesel vs. Spark‑Ignited Engines: Which Is Best for Your Application?

When you're selecting the right engine, especially for industrial, agricultural, marine, or generator applications, the choice between diesel (compression‑ignition) and spark‑ignited (typically gasoline/petrol) engines is pivotal. Engines, Inc. — via their Engines Power brand — offers top-quality diesel and spark‑ignited engines tailored for critical power needs across multiple sectors. Let’s break down the key aspects to determine which engine type is best suited for your specific needs.

1. Fundamentals of Combustion

Diesel Engines (Compression‑Ignition, CI)

Invented by Rudolf Diesel in the late 19th century, diesel engines rely on compression ignition—only air is compressed at high ratios (typically 15:1 to 23:1), producing sufficient temperature to ignite injected fuel. This leads to several advantages:

High thermal efficiency: Diesel engines convert a greater percentage of fuel into useful work—up to 43% in automotive, 45% in heavy trucks, and even 55% in low-speed marine engines.

Torque performance: Diesel engines generate substantial low-end torque, ideal for heavy loads.

Lean‑burn operation: The lean-air-fuel mixture improves efficiency and reduces fuel waste.

Spark‑Ignited Engines (SI)

These engines rely on spark plugs to ignite a premixed air-fuel blend. Typical compression ratios are lower—9:1 to 12:1 . While they don’t reach the efficiency of diesels, spark‑ignited engines offer benefits in:

Simplicity and cost: Generally cheaper to build and maintain.

Flexibility of fuel types: Run on gasoline, ethanol, LPG, CNG, and even hydrogen

Quieter operation: Less noise and vibration compared to the diesel “clatter.”

2. Efficiency & Fuel Economy

Diesel’s Edge

Diesel’s high compression ratios yield superior thermodynamic efficiency. For instance, the largest marine diesels reach around 55% efficiency, while typical passenger-car diesels hit about 43% . EnginesPower highlights diesel’s suitability in applications demanding long runtimes, high load, and fuel economy, such as:

Generators (prime & standby)

Marine propulsion

Industrial and agricultural machinery

Spark‑Ignited Tradeoffs

Spark‑ignited engines suffer from two key losses:

Thermal limits: Lower compression ratios translate to slower burn and more energy wasted as heat.

Pumping losses: Throttled air intake reduces volumetric efficiency .

However, advancements like direct injection, turbocharging, and variable valve timing (VVT) have significantly improved gasoline engine efficiency in recent years.

3. Torque & Power Delivery

Diesel Strength

Diesel engines shine in torque output:

High torque at low RPMs is common, making them ideal for heavy-duty tasks like hauling, plowing, or powering industrial equipment.

Air throttling is unnecessary; engine power is controlled by adjusting fuel injection, ensuring efficient torque management en.wikipedia.org+4en.wikipedia.org+4enginespower.com+4.

Spark‑Ignited Dynamics

SI engines offer:

Higher peak power per liter due to higher RPM limits.

Faster throttle response, suitable for applications requiring quick speed changes.

Lower torque compared to diesel at low RPMs, often compensated by turbocharging.

4. Durability & Maintenance

Diesel Durability

Built to withstand high compression, diesel engines are robust and ideal where longevity is critical. Yet they require:

Precision fuel injection systems

Periodic maintenance of systems like turbochargers, EGR, and DPF modules due to soot buildup

SI Simplicity

Gasoline engines are:

Simpler to maintain

Cheaper parts and services

Less complex emissions control systems, making them ideal for smaller applications where ease of maintenance is key.

5. Emissions & Environmental Compliance

Diesel Challenges & Solutions

Diesel engines emit NOₓ and particulate matter, but modern systems mitigate this with:

Exhaust Gas Recirculation (EGR) to lower combustion temperatures

Diesel Particulate Filters (DPFs)

Selective Catalytic Reduction (SCR) using urea

Spark‑Ignited Control

SI engines also produce pollutants but:

Catalytic converters and oxygen sensors help manage CO, HC, and NOₓ

EGR use reduces NOₓ and enhances efficiency

6. Cost & Total Cost of Ownership (TCO)

Diesel: Higher Initial, Lower Cycle

Upside: Strong fuel economy, long engine life, lower fuel consumption.

Downside: Higher upfront cost and more expensive repairs.

Spark‑Ignited: Economical Entry

Upside: Lower purchase cost, less complex maintenance.

Downside: Higher fuel consumption and shorter lifespan under heavy use.

7. Typical Applications

Engine Type -Diesel

Heavy‑duty trucks, industrial generators, agricultural/marine equipment

Engine Type - Spark‑Ignited

Light-duty vehicles, portable generators, small machinery, residential use

Engines Power offers both:

Diesel for prime/standby generators, marine propulsion, drivetrain components, repower solutions

Spark‑Ignited for lighter OEM, industrial, and agricultural applications seeking simpler, less emission-intensive engines .

8. Emerging Technologies

HCCI and Advanced Combustion

Homogeneous Charge Compression Ignition (HCCI) combines diesel’s compression ignition with gasoline-like premixed charge for cleaner combustion . Though not commercially mainstream, it's a promising hybrid approach that could reshape future engine choices.

Variable Valve Timing & Advanced Fuel

VVT and direct injection in gasoline engines improve fuel efficiency and emissions.

Diesel also benefits from common-rail injection and variable geometry turbochargers to boost performance .

9. Final Decision: Diesel or Spark‑Ignited?

Here’s a practical selection guide:

Choose Diesel if you need:

Long runtime and heavy-load capability

Exceptional fuel economy

Robustness and longevity

Applications in remote, off-grid, marine, or industrial settings

Choose Spark‑Ignited if you need:

Low upfront costs and easier maintenance

Light to medium-duty use

Less stringent emissions requirements

Versatility in fuel type for residential or small commercial use

10. Why EnginesPower?

Engines, Inc. (EnginesPower) offers:

Specialist diesel and spark‑ignited power units, tailored for OEM, marine, agricultural, and industrial sectors

Services such as customization, testing, dynamometer validation, and service support for both engine types

Global supply, including Tier-compliant diesel for export .

Service infrastructure: 24-hour support, nationwide dealer network, engine rebuilding, and prototyping enginespower.com.

In Summary

Diesel engines: High efficiency, torque, and endurance—ideal for heavy-duty, long-run operations.

Spark‑ignited engines: Lower cost, simpler maintenance—fit for smaller scale, flexible use.

Your ideal engine depends on workload, fuel economics, emission regulations, and budget. EnginesPower’s comprehensive diesel and spark-ignited engine offerings, backed by robust service and engineering support, ensure you get the right solution for your needs enginespower.com

#diesel engine solutions#diesel engine services in odessa#diesel parts#diesel engine solution#diesel engine#kohler engine#baton rouge#san antonio tx#new orleans#diesel engine odessa#diesel engine service#diesel engine repair#Diesel Engine

0 notes

Text

Beyond Power Outages: Maximizing Uptime with UAE-Made Diesel Generators

In the dynamic and ambitious landscape of the United Arab Emirates, where innovation and relentless progress define the very fabric of industry and commerce, the concept of "uptime" is paramount. Beyond simply avoiding power outages, businesses across sectors — from manufacturing and construction to healthcare and telecommunications — recognize that continuous, reliable power is the lifeblood of their operations. Downtime, even for a few minutes, can translate into significant financial losses, compromised productivity, missed deadlines, and a damaged reputation. This critical need for uninterrupted power has spotlighted the crucial role of robust, high-quality diesel generators, particularly those manufactured right here in the UAE.

The Strategic Advantage of Local Manufacturing

The decision to invest in a diesel generator is a strategic one, aimed at safeguarding operational continuity. However, the choice of manufacturer is equally pivotal. Opting for diesel generator manufacturers in UAE offers distinct advantages that go beyond immediate purchase. Local manufacturing ensures that the generators are designed and built to withstand the specific environmental challenges of the region, including extreme temperatures and dust. This localization also often means readily available spare parts, swift technical support, and accessible maintenance services, all of which are crucial for minimizing potential downtime. A locally manufactured generator isn't just a product; it's a commitment to regional operational excellence and resilience.

Furthermore, proximity to the manufacturer fosters stronger relationships, allowing for customized solutions tailored to specific industry needs. Whether it's a highly specialized power requirement for a data center or a rugged unit for a remote construction site, local manufacturers can offer bespoke configurations and rapid deployment, a flexibility often unmatched by international counterparts. This localized expertise contributes significantly to maximizing the uptime of critical operations.

Unleashing Uptime: Benefits of UAE-Made Diesel Generators

The benefits of utilizing UAE-made diesel generators for maximizing uptime are multi-faceted. Firstly, engineered for endurance: these generators are built to perform reliably in the demanding climate of the UAE. Their robust construction and high-quality components ensure consistent power delivery even under continuous, heavy loads. This inherent durability means fewer breakdowns and prolonged operational life, directly contributing to superior uptime.

Secondly, swift support and service: a key advantage of local sourcing is the ease of access to factory-trained technicians and genuine spare parts. In the event of an issue, response times are significantly reduced, minimizing the duration of any potential power interruption. Regular preventative maintenance, facilitated by local presence, ensures that generators operate at peak efficiency, proactively averting issues that could lead to downtime. This localized support network is invaluable for businesses where every minute of operation counts.

Thirdly, customization and integration: UAE manufacturers often provide greater flexibility in terms of customizing generator sets to meet specific application requirements. This can include specialized enclosures for noise reduction, advanced control panels for seamless integration with existing power management systems, or fuel tanks designed for extended run times. Tailored solutions ensure that the generator fits perfectly into your operational ecosystem, enhancing overall reliability and optimizing performance for maximum uptime.

Essential Tips for Sustained Performance

To truly maximize uptime with your UAE-made diesel generator, adherence to best practices in operation and maintenance is non-negotiable.

Regular Preventative Maintenance: This is the cornerstone of reliability. Implement a strict maintenance schedule, including oil changes, filter replacements (fuel, air, oil), coolant checks, and battery inspections. Partner with your chosen manufacturer or an authorized service provider for professional maintenance to ensure all critical components are routinely checked and serviced.

Load Bank Testing: Periodically test your generator under full or near-full load. This simulates real-world operating conditions, burning off unburnt fuel residues and ensuring all systems function optimally. This practice is vital for confirming the generator's readiness for an actual power outage and helps identify potential weaknesses before they cause a failure.

Fuel Management: Diesel fuel quality is crucial. Ensure clean, fresh fuel is always used and stored properly to prevent contamination and degradation. Regular fuel polishing might be necessary for extended storage to prevent microbial growth and sediment buildup.

Environmental Control: While UAE-made generators are built for the local climate, ensuring proper ventilation, temperature control, and protection from excessive dust and moisture will significantly extend the life and reliability of the unit.

Training and Awareness: Ensure that your operational staff are adequately trained on the basic operation, monitoring, and emergency procedures related to the diesel generator. Early detection of anomalies can prevent minor issues from escalating into major downtime events. Also Read: Why Choose a Diesel Generator in UAE for Your Power Needs?

Conclusion: Your Guide to Uninterrupted Operations

In a region that never stops, ensuring uninterrupted operations is a strategic imperative for businesses aiming for sustained growth and competitiveness. UAE-made diesel generators offer a compelling proposition: engineered for resilience, backed by accessible local support, and customizable to precise needs. They represent a significant investment in operational continuity, providing the unwavering power that translates directly into maximized uptime. By adopting a proactive approach to selection, installation, and maintenance, businesses can transform potential vulnerabilities into robust strengths, allowing them to focus on their core objectives with absolute confidence.

For expert solutions and unparalleled quality in diesel power generation, consider partnering with FG Wilson Engineering FZE. We are dedicated to providing robust, reliable generators engineered to meet the demanding needs of the UAE's diverse industries, ensuring your operations experience pure confidence and maximized uptime. Contact us today to discuss your power requirements.

0 notes

Text

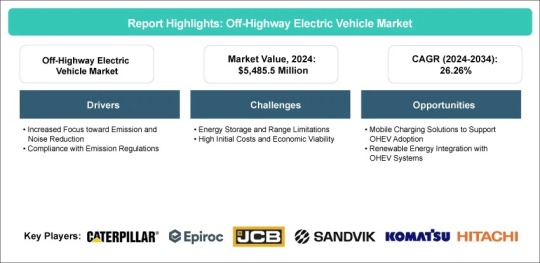

Off-Highway Electric Vehicle Market | BIS Research

The off-highway electric vehicle (OHEV) market has been gaining momentum as construction, agriculture, and mining industries increasingly adopt electric-powered machinery, including excavators, loaders, tractors, and mining trucks. These cars, which have historically been propelled by diesel engines, have resulted in significant maintenance costs, heavy emissions, and noise pollution. By lowering greenhouse gas emissions, increasing energy efficiency, and boosting workplace safety, the move toward electrification allays these worries. The adoption of OHEVs is being accelerated by advancements in battery technology and robust legislative support, which positions them as a crucial element of sustainable industrial operations. These cars provide major environmental advantages together with long-term financial reductions through reduced operating and maintenance expenses. The market for off-highway electric vehicles is expected to increase significantly as enterprises place a higher priority on sustainability, assisting in the global shift to cleaner, more effective industrial processes.

What is the expected CAGR of the off-highway electric vehicle market over the next decade?

The off-highway electric vehicle market is projected to grow at a robust CAGR of 26.26% from 2024 to 2034, driven by sustainability goals and technological advancements. It is expected to rise from $5,485.5 million in 2024 to $56,483.7 million by 2034.

Industrial Impact

The off-highway electric vehicle (OHEV) market is significantly impacting industries such as construction, agriculture, and mining by transforming traditional operational practices. The adoption of OHEVs reduces dependence on fossil fuels, leading to a decrease in greenhouse gas emissions and contributing to cleaner, more sustainable industrial operations. These cars also provide long-term financial advantages for companies by consuming less gasoline and requiring less maintenance, which lowers operating expenses. Additionally, by lowering noise levels and enhancing operator comfort, electric vehicles' quiet and effective operation improves workplace safety. OHEVs offer a practical option for businesses looking to meet environmental regulations while increasing productivity as regulatory constraints on emissions increase. Innovation in battery technology and charging infrastructure is being encouraged by the market's expansion, which is reinforcing the trend toward cleaner, more effective industrial processes. Heavy-duty machinery and industrial mobility are about to undergo a transformation due to the growing integration of OHEVs.

Who are the leading manufacturers in the off-highway electric vehicle market?

By Application • Construction • Mining • Agriculture • Others

Construction to Lead the Market.

By Propulsion Type• Battery Electric Vehicles (BEVs) • Hybrid Electric Vehicles (HEVs)

Hybrid Electric Vehicles to Lead the Market.

By Vehicle Type• Excavators • Trucks • Loaders

Excavators to Lead the Market.

By Region• North America • Europe • Asia-Pacific • Rest-of-the-World

North America Region to Lead the Market.

Recent developments

In August 2024, Fortescue Metals partnered with Liebherr Mining to develop and validate a fully integrated autonomous haulage solution (AHS) at the Christmas Creek mine. This system, which includes a fleet management system, an onboard autonomy kit for the Liebherr T 264 truck, and a high-precision machine guidance system, will coordinate diverse autonomous vehicles. The initiative aims to support Fortescue Metal’s goal of zero Scope 1 and 2 emissions by 2030 and will eventually be available globally as part of Liebherr Group’s expanding technology portfolio.

In July 2024, Eleo, a Yanmar company, launched a new range of modular battery packs for off-highway applications. These packs are designed for low-volume, high-diversity vehicles and offer a scalable voltage range (50V to 720V) and up to 90 kW of continuous power, with flexible integration, easy serviceability, and industry-standard protocols.

In January 2024, Caterpillar partnered with CRH to introduce electric off-highway trucks, contributing to the decarbonization of the construction sector.

In December 2022, Nidec announced a $715 million investment to establish an electric motor manufacturing plant in Mexico, strengthening the region’s supply chain for electrified vehicles. In early 2022, John Deere expanded its battery production capacity by over 2 GWh through Kreisel Electric, reinforcing the push for electrified off-highway equipment.

Key Market Players

AB Volvo

PristenBully

Hitachi Construction Machinery Co., Ltd.

Caterpillar

CNH Industrial N.V.

Epiroc AB

Deere & Company

Unlock Bespoke Analysis: Request Customized Insights to Fuel Your Success in the Market!

Want deep information on Automotive Vertical. Click Here!

Conclusion

The off-highway electric vehicle market is set for transformative growth, fueled by the global shift toward cleaner energy, regulatory pressures, and technological advancements in electrification. The market is growing quickly across industries like mining, construction, and agriculture as major players like AB Volvo, Caterpillar, and Hitachi Construction Machinery spur innovation. Electric off-highway vehicle adoption positions the market as a pillar of the future of heavy-duty transportation and industrial mobility by lowering long-term costs, improving operational efficiency, and supporting environmental goals.

#Off-Highway Electric Vehicle Market#Off-Highway Electric Vehicle Industry#Off-Highway Electric Vehicle Report

0 notes

Text

Technical Parameters of 500KW Yuchai Diesel Generator Set

The 500kW Yuchai generator set of Guangxi Dingbo Power has the advantages of long service life, low fuel consumption, strong power, long-term continuous use, and emergency backup power supply (applied in petrochemical, railway, municipal engineering, industrial and mining enterprises, hotels and other fields. It can also provide customers with multifunctional generator sets such as self starting, automation, noise reduction and environmental protection, and mobile power stations).

Parameters of 500KW Yuchai generator set

Unit model DB-500GF frequency 50 Hz

Unit power 500 KW output voltage 400/230 V

Diesel engine power 572 KW, power factor 0.8 (lag)

Output capacity 625 KVA unit size 3320 * 1400 * 1780mm

Output current 900 A, unit net weight 3840 kg

500KW Yuchai Generator Set - Diesel Engine Parameters

Model YC6TD780L-D20 Rated speed 1500 r/min

Number of cylinders: 6, maximum output power: 572 KW

Cylinder arrangement: L-type fuel specification and grade: China 0 # (light diesel)

Cylinder diameter/stroke 152 * 180 mm, fuel consumption ≤ 200 g/kw. h

Cylinder total volume 10.8 L lubricating oil specification, grade API-CD or above

Compression ratio 15.0:1, maximum lubricating oil temperature 54 L

Intake method: Boost, intercooled, maximum lubricating oil temperature 121 ℃

Speed regulation method: Electronic speed regulation with maximum oil consumption of 0.24 L/h

The temperature range of the thermostat is 82-93 (℃), and the maximum exhaust temperature is 405/410 ℃

Maximum allowable back pressure 10 KPa, intake resistance 2.5 kPa

Cooling method: Closed cycle water-cooled exhaust volume 21.927 L/S

500KW Yuchai Generator Set - Generator Parameters

Model KCI-500 excitation method brushless self-excited

Voltage adjustment range ≥ ± 5% Voltage control mode AVR

Steady state voltage regulation rate ± 0.5% Transient voltage regulation rate ± 15%

Steady state frequency adjustment rate ≤ 1%, frequency stabilization time ≤ 3S

Temperature rise H ℃, overcurrent 3-5 le ≥ 5S

Insulation level H, overload capacity 3-5, ≥ 5S

Protection level IP22, short-circuit current 3 times for 2 seconds

Efficiency 92.4% Short circuit capability 3 times 2 seconds

The telephone interference coefficient (THF) is less than 2%, TIF<50 cooling method self cooling

Standard configuration

Jet internal combustion engine (diesel); Guangxi Yuchai Engine Co., Ltd. (National Joint Guarantee)

AC synchronous generator (single bearing); KCI Generator (National Joint Guarantee)

Suitable for environments ranging from 40 ℃ to 50 ℃, including radiator tanks, belt driven cooling fans, and fan safety shields;

Power generation output air switch, standard control screen;

Unit steel shared base (including: Unit composite damping rubber pad);

Dry air filter, fuel filter, lubricating oil filter, starter motor, equipped with self charging generator;

Start the battery and the battery starting connection cable;

Industrial 90dB muffler and standard components for connection;

Molded case circuit breaker;

Thickened plastic film packaging;

Random data: original technical documents of diesel engines and generators, generator set manuals, test reports, etc.

Optional configuration

Silent unit (cabinet)

Vehicle mounted mobile power supply vehicle

Silent mobile power station (container trailer)

Mobile trailer type power station (container trailer)

Unit control screen with "three remote" function

ATS automatic load conversion cabinet

Self protection and self starting unit control screen

Fully automatic cabinet merging

Split type daily fuel tank, integrated base fuel tank

Battery floating charger

Dingbo Power was founded in 1974 and is one of the earliest manufacturers of generators and diesel generator sets in China. If you want get more information, please feel free to send email to [email protected] we will pay highly attention on your question.

0 notes

Text

Cork Rubber Sheet VS Neoprene

Cork Rubber Sheet vs Neoprene: Which Material Offers Better Soundproofing and Vibration Damping?

The Core of the Debate

Let’s cut through the noise—literally. If you’ve ever tried to soundproof a home studio or dampen industrial machinery vibrations, you’ve stumbled into the cork-vs-neoprene warzone. These materials aren’t just competitors—they’re ideological opposites: one born from forests, the other from petrochemical labs.

Cork’s Organic Advantage

Cork Rubber Sheet

Cork rubber sheet, harvested from cork oak trees, leverages its honeycomb-like cellular structure to trap sound waves mid-flight. In a Guangzhou music studio retrofit, cork panels reduced mid-frequency echo by 34%, proving its worth in acoustic-sensitive spaces. But let’s not romanticize nature—cork crumbles when exposed to oil spills or sustained heat above 60°C. Try lining a motorcycle engine with it, and you’ll witness a biodegradable disaster.

Products | Hongwo Sealing Sheet

Neoprene’s Synthetic Muscle

Neoprene thrives where cork falters. Its chloroprene backbone laughs at oil, chemicals, and temperatures up to 120°C. At a Jiangsu shipyard, neoprene gaskets suppressed diesel engine vibrations by 41%, outperforming cork in grimy, high-heat environments. But here’s the rub: producing neoprene guzzles energy and spews greenhouse gases—a dirty secret behind its industrial dominance.

The Verdict: Context is King

For eco-warriors insulating a nursery? Cork’s sustainability and mid-range damping win. For factories battling grease and grind? Neoprene’s brute resilience reigns. Hybrid approaches—like layering cork over neoprene in mixed-use buildings—are stealing the spotlight in 2025’s green construction codes.

Silence Isn’t Golden—It’s Strategic

Neither material is perfect, but their rivalry fuels innovation. As cities like Shenzhen mandate noise reduction in new infrastructure, the choice between cork and neoprene isn’t technical—it’s philosophical. Will you side with the forests or the refineries? The answer echoes louder than any decibel reading.

Industrial Sealing Sheet Support And Inquiries

0 notes

Text

Why Do Contractors Prefer Electric Dredge for Urban Projects?

The rise of electric dredge systems in city projects and the reasons contractors can’t get enough of them. These machines deliver zero on-site emissions, drastically lower noise, and precise controls that traditional diesel units struggle to match. Urban waterways and tight harbours demand compact, eco-friendly equipment, and an electric dredge checks all the boxes. With fewer parts to maintain and simpler operation, crews spend more time digging and less time servicing. Contractors also find it easier to secure permits and satisfy community concerns around pollution.

How Does Electric Dredge Reduce Emissions on Urban Waterway Sites?

On busy city waterways, Electric Dredge controlling emissions is essential to project success. Contractors rely on electric dredge units because they produce zero exhaust on site. Graeham Watts - Realtor highlights that this feature allows crews to work near residential zones without violating air quality rules. Local authorities often impose strict limits on diesel-powered equipment, but electric dredge operation side steps those concerns. Cleaner air benefits the community and reduces risk of permit delays. As a result, urban teams can maintain steady progress without environmental hassles.

Electric Dredge Offers Quieter Operation for City Projects

Noise is a major challenge on urban sites, where nearby offices and homes suffer from construction. Electric dredge models run much quieter than traditional engines, cutting sound levels by up to 70 percent. This allows contractors to schedule early morning or evening digs without triggering complaints. Graeham Watts - Realtor notes that reduced noise speeds approvals and fosters good relations with local residents. For city projects aiming to keep neighbours happy and operations smooth, quiet electric dredge technology is a clear advantage.

Cost Efficiency of Electric Dredge in Long-Term Urban Use

Budget constraints drive many urban projects to look for long-term savings. Electric dredge machines offer lower energy costs compared to diesel fuel, translating into significant reductions in operating expenses. With fewer mechanical parts and simpler systems, maintenance is quicker and less frequent. Graeham Watts - Realtor reports that contractors see a 20 percent cut in service bills over diesel counterparts. These cost benefits, combined with potential grants for green equipment, make electric dredge investment a smart choice for projects balancing tight budgets and high performance demands.

Compact Design of Electric Dredge Suits Tight Urban Spaces

Space is limited in city channels and harbours, where tight turns and narrow passages can stall progress. Electric dredge units come in compact designs tailored for urban waterways. Their smaller footprints allow easy access through locks, under bridges, and alongside docks. Graeham Watts - Realtor mentions that some manufacturers even offer modular attachments for quick assembly on site. The compact electric dredge fits areas where larger machines can’t venture, maintaining project momentum and avoiding costly site modifications. This agility keeps urban schedules on track.

Maintenance Simplicity Makes Electric Dredge Ideal for Contractors

Downtime on city contracts can be costly, so easy upkeep matters. Electric dredge systems have fewer moving parts than diesel engines, eliminating components like fuel injectors and exhaust filters. This simplicity means routine checks take less time, spare parts are more accessible, and repairs are straightforward. Graeham Watts - Realtor emphasizes that contractors report faster turnaround on preventive maintenance, resulting in more billable hours. In the fast-paced urban environment where every minute counts, the streamlined maintenance of an electric dredge keeps projects moving and budgets intact.

Electric Dredge Technological Advances Significantly Improve Project Precision

Technological progress has boosted the appeal of electric dredge systems in urban works. Advanced controls and remote monitoring allow operators to adjust suction power and excavation depth with precision. Graeham Watts - Realtor points out that modern electric dredges can integrate with GPS and data analytics, optimizing dig patterns and reducing material waste. Automated safety features, such as emergency shutdowns, protect both crew and infrastructure. These smart enhancements ensure that contractors can meet tight project specifications without sacrificing efficiency or safety.

Environmental Compliance Driven by Electric Dredge Adoption in Cities