#diffuser machine manufacturers

Explore tagged Tumblr posts

Text

Many people new to the world of essential and aromatic oils are curious about the different methods of diffusing these oils in their home or business. Two of the most popular ways of diffusing essential oils are by using a reed diffuser or an electric oil diffuser. While both types of diffusers get the job done, they also each have their distinct pros and cons. That’s why we wanted to write a full guide to the benefits and drawbacks of each scenting method.

By the end of this article, you’ll be able to decide whether a reed diffuser or an electric oil diffuser is the best fit for scenting your home or business. Before we get started though, let’s make sure we’re clear on the key differences between reed diffusers and electric oil diffusers.

WHAT IS A REED DIFFUSER?

Reed diffusers feature a fragrance oil and base solution mixed together inside of a glass bottle with a narrow neck. Rattan reeds or sticks are then inserted to the liquid, and left sticking out from the bottle. These reeds absorb the fragrant liquid from inside the bottle and diffuse it into the air of the room. A reed diffuser continues to release scent throughout the lifespan of the reeds and fragrance oil in the bottle.

WHAT IS AN ELECTRIC OIL DIFFUSER?

As the name implies, electric oil diffusers still diffuse essential oils into the air, but don’t feature any reeds, and are instead powered by electricity. Unlike reed diffusers, there are several different types of electric oil diffusers on the market.

#diffuser machine#diffuser machine fragrance#diffuser machine learning#diffuser machine price#diffuser machine near me#diffuser machine kuwait#diffuser machine - dr large#diffuser machine for hair#diffuser machine dubai#diffuser machine manufacturers#diffuser machine - dr mini#dr scent diffuser machine#best home diffuser machine#hotel scent diffuser machine#hotel diffuser machine#home diffuser machine#smart scent diffuser machine#smell diffuser machine#oil diffuser machine#ds eco diffuser machine#aroma diffuser machine#scent diffuser machine#aroma scent diffuser machine#home unit 101 aroma diffuser machine#scent machine#scent machines for homes#scent machine for hvac#scent machine for business#best home scent machines#best scent machine

4 notes

·

View notes

Text

Alright I can't finish this all in one sitting, but here's at least a bit of.... something? A word vomit? A prelude to smut about the eroticism of the machine? For all you robot, mecha, and spaceship fuckers out there. @k1nky-r0b0t-g1rl that means you

Pappy always said that manufacturing biological transportation was nothing knew. I mean, shit, humanity's been breeding horses for how long? To him, not much was novel about what was going on in the shipyards way out by Neptune when I was a kid.

But Pappy didn't know a lot of things. And he certainly didn't meet Roseanna.

The Federation Navy had experimented with biologics for decades. The idea was to create self regenerating ships- something to interface with the hull, move the new titanium plates and particulates into place, have a living, growing mass interfacing with the steel so that the ship didn't have to head all the way back to the yards to patch up after every dogfight.

The first generation... worked. With a full time crew, that is. Full time people on deck jabbin the rigid, chitonous interface with the hull full of growth hormones to get them to set just right. Full time onboard bioengineers to compute what signaling cocktail ya need to hit 'em with to get it to grow back right. Skilled onboard technicians to shave back the chitin when it tried to overgrow the titanium, and slap some new cells in to seed the process in heavily damaged areas. Less input material, less time in the yards, but far more manpower. Great for a Federation cruiser on deep space peacekeeping missions. Far too complex for small craft. Right?

Until some bastard put brains in 'em.

Well. A lotta suits would say that they weren't brains. They were a diffuse network of sensory neurons and ganglia, living inside the body of the ship, integrating signals from a skin of alloyed metal and fibrous protein, calculating power draw too and from various components, and integrating with the mechanical and electrical components of the ship to precisely manage the "wound healing" process of the vessel. And of course, it just so happened that one of those ganglia was larger and more complex than the rest of them, and it just so happened that the computer interfaces with this ganglia exhibit complex, thinking behaviors on the level of human cognition, and it just so happens that most pilots and navigators reported them developing their own personalities.....

But of course, the Navy didn't want anyone to have some kind of pesky empathy in the way of their operations. And they certainly didn't want anyone side eyeing the rate at which they disposed of the damn things, and let them suffer and rot after disposal. So as far as the official record was concerned, they didn't have brains.

Like most people in the belt, I found Rosie on a... unsponsored field trip to the Neptune scrap yards. She wasn't a ship then. She wasn't much of anything. Not much more than a vat with the central ganglia and just barely enough of the stem cells needed to regrow a network. But I took her all the same. Brains were valuable. Few pilots outside the Navy had them back then. Nowadays, a black market for "brain seeds", a cocktail of neuronal stem cells and enough structural stem cells to grow your own into the chassis of your ship. They were pumpin' em out, and leaving them to die. It was cruel. They may be vehicles, but they're a livin' being too.

But I digress. I'd never do that to Roseanna. I make sure she gets proper care. And for a good, proper, working ship? That includes some good, proper work.

The asteroid we were docked in was one of my usuals- good bars, nice temp quarters, nice views of the rock's orbiting twin, and a spacious hanger for Rosie to rest in. The chasiss I had imprinted Roseanna to was a 40-meter light skipper, with some adjustments for handling deep space trips. It was pretty much the smallest thing you could actually use to live and work for long periods of time, but it got the job done. The angular design made the entire ship look like a wedge, or the blade of a bulky dagger. It didn't hurt that each bottom edge was fortified with a sharpened titanium blade, turning the entire sides of the ship into axe-like rams.

Those would probably come in handy today.

I approached Roseanna on the catwalk above her, marveling her alloyed scales. I could almost see her shudder in anticipation as my footsteps vibrated through the air above her. I took the steps down, and hit the trigger to open her top hatch.

When the news got out of the Navy scuffling with a rebelling mining station, an electric air raced across the station. Some went about their day as normal. Some resigned themselves to picking at the leftovers after the dust had settled. And some, like me, knew that they could get the finest pickings.

I strapped in to the pilot's seat like it was an old boot.

"Welcome, Captain Victoria."

Rosie could talk, but more often than not, she chose not to. But she understood me just fine. Most of our communication took place using her three prerecorded lines- her welcome statement, affirmative, and negative- as well as the tiny screen showing a small, emoticon face. Many pilots chose to give their ships an elaborate render, but Rosie preferred it this way. It was the first face I gave her, from somewhere out of the scrap heaps, and she refused any offer I made to upgrade. Secretly, I was overjoyed. To me, that was her face. That was her voice. And it was beautiful to see her true self through them.

I brushed my hands across her paneling. Across the switches, the hydraulic controls for the plasma fuel, the steering, the boosts, the comms channels. The thing with biologics was that you were still the pilot. For whatever reason, they hadn't quite gotten to the point where the brains could take over their own piloting. My personal opinion was just that their personalities lacked the ambition to. But whatever reason that was, the best pilots were still the ones that knew both their ship, and the ship's brain. And me and Rosie? We knew each other well.

As my fingers touched the brushed aluminum controls, rimmed with chitinous layers rooting them into the ship, I could feel the walls around me holding their invisible breath. "Do you know what we're doing today, Rosie?"

Her tiny panel flickered on. ...?

"We got a scrap run."

^_^

:)

^_^

Her panel flicked between various expressions of excitement. My finger quivered on the main power, holding for a moment before flicking it on. The primary electronics of the ship hummed to life, and what Rosie controlled pulsed with it. My hands moved across the main functional panels- main hydraulic plasma valve, exhaust ports open, and finally, flicking the switch the start the plasma burner.

My hands gripped the steering. The hanger's airlock doors opened in front of me. My neck length hair started to float as the station's gravity shut off. I hit the switch to unlatch from the supports above. For a moment, we hang there. The dull crackle of the idling plasma burner is the only sound that resonates through Rosie's hull.

Go time.

I punch the boost.

#eroticism of the machine#robot girl#mecha girl#spaceship girl#the fuck do I even tag this LOL#yall gotta tag this and make sure it gets to the right spaces for me okay

280 notes

·

View notes

Text

Biologics, chapter 0.5

Hello, hello! I finally have added a significant amount to my story, Biologics, resulting in a total of ~4400 words. Not a whole ton, I know, but unfortunately life gets to ya. It isn't quite where I want it to be to consider a proper chapter one, but I feel like there's enough written for me to post. General warning that this is intended to heavily lean into the theme of "eroticism of the machine", so if that doesn't appeal to you, you've been warned. It does, however, have many general sci fi worldbuilding elements, so I hope it has a somewhat broad appeal!

So yes, if you already read the first snippet, that's going to be mostly a one to one repeat with some grammatical adjustments. Feel free to scroll down until you get to the new stuff. Flow-wise, there just wasn't a good place to break between the two sections.

Look at me rambling. And I wonder why I can't get any of this stuff done. Anyways, here it is!

Biologics

Pappy always said that manufacturing biological transportation was nothing knew. I mean, shit, humanity's been breeding horses for how long? To him, not much was novel about what was going on in the shipyards way out by Neptune when I was a kid.

But Pappy didn't know a lot of things. And he certainly didn't meet Roseanna.

The Federation Navy had experimented with Biologics for decades. The idea was to create self regenerating ships- organic matter that interfaced with the hull, moving new titanium plates and patches into place down to microscopic precision. If you had a living, growing mass interfacing with steel, a ship didn't have to head all the way back to the yards to patch up after every dogfight.

The first generation... worked. With a full time crew, that is. Full time people on deck jabbin the rigid, chitonous matrix full of growth hormones to get them to set just right. Full time onboard bioengineers to compute what signaling cocktail ya need to hit 'em with to get it to grow back right. Skilled onboard technicians to shave back the chitin when it tried to overgrow the titanium, and slap some new cells in to seed the process in heavily damaged areas. Less input material, less time in the yards, but far more manpower. Great for a Federation cruiser on deep space peacekeeping missions. Far too complex for small craft. Right?

Until some bastard put brains in 'em.

Well. A lotta suits would say that they weren't brains. They were a diffuse network of sensory neurons and ganglia, living inside the body of the ship, integrating signals from a skin of alloyed metal and fibrous protein, calculating power draw too and from various components, integrated with the mechanical and electrical components of the ship to precisely manage the "wound healing" process of the vessel. And of course, it just so happened that one of those ganglia was larger and more complex than the rest of them, and it just so happened that the computer interfaces with this ganglia exhibit complex, thinking behaviors on the level of human cognition, and it just so happens that most pilots and navigators reported them developing their own personalities.....

But of course, the Navy didn't want anyone to have some kind of pesky empathy in the way of their operations. And they certainly didn't want anyone side eyeing the rate at which they disposed of the damn things, just to let them suffer and rot. So as far as the official record was concerned, they weren't brains. But I knew different.

Like most people in the belt, I found Rosie on an... unsponsored field trip to the Neptune scrap yards. She wasn't a ship then. She wasn't much of anything. Not much more than a vat with the central ganglia and just barely enough of the stem cells needed to regrow a network. But I took her all the same. Brains were valuable. Few pilots outside the Navy had them back then. Nowadays, a black market for "brain seeds", a cocktail of neuronal stem cells and enough structural stem cells to grow your own into the chassis of your ship, was thriving. The Navy was pumpin' em out, and leaving them to die. It was cruel. Sometimes, being scavenged and resold was a kinder fate. But more often, some nasty piece of work would pick them up eventually, and treat them like just another goddamn ship. They may be vehicles, but they're a livin' being too.

I digress. I'd never do that to Roseanna. I make sure she gets proper care. And for a good, proper, working ship? That includes some good, proper work.

The asteroid we were docked in was one of my usuals- good bars, nice temp quarters, nice views of the rock's orbiting twin, and a spacious hanger for Rosie to rest in. The chassis I had imprinted Roseanna to was a 40-meter light skipper, with some adjustments for handling deep space trips, as well as some... personal touches. It was pretty much the smallest thing you could actually use to live in and work for long periods of time, but it got the job done. The angular design made the entire ship look like a wedge, or the blade of a bulky dagger. It didn't hurt that each bottom edge was fortified with a sharpened titanium blade, turning the entire sides of the ship into axe-like rams.

Those would probably come in handy today.

I approached Roseanna on the catwalk above her, marveling her alloyed scales. I could almost see her shudder in anticipation as my footsteps vibrated through the air above her. I took the steps down, and hit the trigger to open her top hatch.

When the news got out of the Navy scuffling with a rebelling mining station, an electric air raced across the station. Some went about their day as normal. Some resigned themselves to picking at the leftovers after the dust had settled. And some, like me, knew that they could get the finest pickings.

I slipped into the pilot's seat like it was an old boot.

"Welcome, Captain Victoria."

Rosie could talk, but more often than not, she chose not to. But she understood me just fine. Most of our communication took place using her three prerecorded lines- her welcome statement, affirmative, and negative- as well as a tiny screen showing a small, emoticon face. Many pilots chose to give their ships an elaborate render, but Rosie preferred it this way. It was the first face I gave her, from somewhere out of the scrap heaps, and she refused any offer I made to upgrade. Hell, she even had a hi-res screen for external cameras and comms, but she refused to interface directly with it. Secretly, I was overjoyed. To me, the little pixelated screen was her face. That was her voice. And it was beautiful to see her true self through them.

I brushed my hands across her paneling. Across the switches, the hydraulic controls for the plasma fuel, the steering, the boosts, the comms channels. The thing with Biologics was that you were still the pilot. For whatever reason, they hadn't quite gotten to the point where the brains could take over their own piloting. My personal opinion was just that their personalities lacked the ambition to. Cuz they certainly could take over some ships functions directly, and had the skill to do complex mechanical and electrical tasks. The Navy never let 'em drive, though, and most pilots didn't even know they could give them the ability to control any of the ships functions directly. But with a little help, a little bit of solid engineering, and a pilot that knew their ship... well, you could do a lot. And me and Rosie? We knew each other well. Over the years, I'd added some nice things for her, and she loved using them to help me out.

As my fingers touched the brushed aluminum controls, rimmed with chitinous layers affixing them to the ship, I could feel the walls around me holding their invisible breath. "Do you know what we're doing today, Rosie?"

Her tiny panel flickered on.

[...?]

"We got a scrap run."

[ ^_^]

[ :) ]

[ ^_^ ]

Her panel flicked between various expressions of excitement. My finger quivered on the main power, holding for a moment before flicking it on. The primary electronics of the ship hummed to life, and the parts Rosie controlled pulsed with it. My hands moved across the main functional panels- main hydraulic plasma valve, exhaust ports open, and finally, flicking the switch the start the plasma burner.

My hands gripped the steering. The hanger's airlock doors opened in front of me. My neck length hair started to float as the station's gravity shut off. I hit the switch to unlatch from the supports above. For a moment, we hang there. The dull crackle of the idling plasma burner is the only sound that resonates through Rosie's hull.

Go time. I punch the boost.

The station shakes. Rosie was never a subtle one.

The mechanics are deafened.

The crowd of spectators are deafened.

The other pilots in the hanger are deafened.

But me? The vibrations of Rosie's hull shuddering under me was the sweetest symphony my ears ever had the pleasure of hearing. As we shot out of that hanger, I found myself involuntarily humming a high note, harmonizing with the sweet rumble of my baby's acceleration as we shoot out into the inky, black expanse of space. The twin asteroids shot by us as we disappeared, leaving only the faint blue plasma trail from our engines.

My hand is firm on the boost, weathered hands tightly gripping the bar of the accelerator. I remember installing this thing in her- it was an aftermarket adjustment, not included in the usual light skipper chassis. Gently stripping away the back of her chassis, caressing her insides as I rooted the paneling, firmly attaching the tanks and burners on her insides... these hands had taken great pleasure in that. Bested only, of course, by the first time I had felt the thing roar to life.

And what a feeling it was. Rosie's entire chassis, biological and mechanical, shuddering under my grasp. The grip of my calloused hands on the boost controls, tight and sweaty around the ridged grip of the horizontal bar. The noises she made, as if to shout in glee and wild abandon at being unchained and let loose into the eternal field of space, as she was made to do. The gentle touch of her skin on my back, my body pressed in contact with the small fraction of hers that was my seat. I glanced down at her face panel.

[ :| ]

[ :D ]

[ :| ]

[ :D ]

[ :| ]

[ :D ]

[ :| ]

[ :D ]

My humming gave way to a chuckle, and then a wholehearted, exhilarated laugh. Someone was enjoying herself. The flickering faces on her panel reminded me of the happily panting station dogs back on Mars.

But as much as I would like this to just be a joyride, I had promised Rosie a scrap run. And the pickings were looking good. I glanced down at the nav. I was intentionally headed at a slightly indirect angle- Rosie's boost was her main attractive feature (both as a ship, and as a working partner), and the extra leeway I had in travel time let me strategize a bit more. I doubted we would be the first people there, but I figured we could get in before the main rush. The only trouble was darting in and grabbing something right from under the noses of the first locusts. The scrap field in question included a disabled heavy mining freighter, a goliath of the ship larger than some of the asteroids it made supply runs between. I assumed that most other scavengers would be approaching directly from our station, and the other stations in its proximity. With Rosie's boost, we could overshoot, hook around, and put the freighter in between us and the guns of the more violent craft. Rosie has no long range weapons of any kind- not only would they slow down her miraculous speed, but she didn't like them. I tried installing a small plasma cannon once, and she expressed immense distaste. Maybe they were too brutish for her, or maybe she didn't like the way they felt inside her, burdening her with pressure from the inside that didn't befit the delicate touches I usually graced her with. Rosie loved speed, precision, elegance, and stealth above all else. It's just the kind of ship she was.

That's not to say she was a pacifist, or defenseless. Quite the contrary. She just prefers a more... personal touch.

The navicom beeped at me. We'd reached the point where we needed to make that hook. My bare feet gently swept across the titanium flooring to the steering pedals. My right hand delicately gripped the steering joystick, while my left eased its grip on the boost accelerator.

"Ready for this, darling?"

[ >:) ]

I slammed the steering to the left, and Rosie gleefully complied. The wide bank of the turn as we rotated and soared through the sea of stars twisted my body in its inertia, compressing me further into her. As the angle straightened out to the proper heading, I punched the boost again, and Rosie roared forward.

Slowly, our target came into sight. Damn. This thing had taken some serious damage. Mining freighters typically weren't heavily armored- their only job was to get material from point A to B- but this one had clearly been through some serious modifications. Modifications that now lay in ruin. Titanium plating was scattered in a field around the core of the freighter. I couldn't quite tell what was stuff left behind by the battle, and what was the result of shoddy craftmanship- but it didn't matter. What did matter was that the entire thing had been split almost in half, and the scattered cargo that was leaking out. Cargo that most likely included half the weapon supplies of this little rebel faction. Would fetch a pretty penny, to the right buyer. And hell, if it was just gonna sit here unclaimed...

Ah shit. It wasn't gonna sit here unclaimed. Despite my best efforts, it looks like we weren't the first ones here. A larger scavenger gang had already arrived, and it looks like it was one of the ones I knew- Augustus and his lot. Most likely, they'd be after the weapons intact, one more thing to use to shakedown the scattered independent stations I always flitted between. He would not be happy to see me n Rosie here. What he called his "fleet" was a single, mid-sized carrier ship, about half the size of the freighter we were looting, and the dozen or so scout fighters and strip mining crafts he had looted from the Navy and various corps, and one Biologic that he called his. I respect that part, to be honest. What I don't respect is him immediately turning around and using that charge every goddamn station his ever-increasing "protection fees". Not to mention my personal disdain for the way he treated his ship. Didn't even give her a damn name. I digress. But any chance to loot something from under that slimebag's nose was a win in my book. I knew he wasn't gonna make it easy, though.

Welp. That's what our positioning was for. The side facing us was the main starboard face, and like the rest of the ship, it was peppered in small holes and gashes. Seems like the main damage had happened from the other side, and a few cables and scaffolds on the starboard just barely kept the two rear cargo compartments clinging to the front.

"Alright Rosie, time to creep it in slow. Be quiet, now, don't want them picking up a plasma surge"

[ :| ]

Ha. That was her "my lips are sealed" face. She's having fun with this already.

I cut the booster, coasting closer and closer to the bust open vessel. I eased the reverse thrusters ever so slightly, my fingers gently stroking the dual brake levers, lightly teasing at them to wait until we were as close as I thought we could be without attracted attention.......... before slamming both sides back towards me. For just one, crucial moment.

The goal here was to approximately match the speed and trajectory of a floating piece of titanium plating. Rosie's frontal blades were essentially that, anyways, so all they would see is a somewhat more angular piece of rubble. Hopefully they hadn't seen that same piece of rubble screaming out of travel speed, but I was cautious enough with my distances that I didn't think that was a problem. And they hadn't seen me yet. Once we were close enough to the freighter itself, we were blocked from their raw sightline, and Rosie was running quiet enough to not tip off any of their energy sensors.

But there was still no guarantee. Rosie, however, had no shortage of tricks. Something that she and I had developed together was a nice little bit of snooping. Well cared for and well trained, a Biologic brain had the problem solving of a human, and the computational power of a machine. But them together, and you've got a perfect decoder. And I happened to know that Augustus used an encrypted local frequency to keep his

"Alright Rosie, thinkin you can eavesdrop a little?"

Affirmative.

[...]

[...]

[...]

[...]

[...]

[...]

[..!]

:D

My comms crackled to life. "...7 heavy cannons in center-front portside bay, 3 replacement fighter hatchs...."

The comms crackled back and forth, with each pilot giving updates to what they were finding in their own little segment that they were slicing apart. Occasionally, I saw Augustus or the fighters flick between the slicing ships, overseeing their progress on the port bays. Good. Let them focus on the other side for now. Slowly, the fleet was overshadowed by the freighter. We made it. I released my breath- shit, didn't realize I was holding it- and took a better look at what we were dealing with. It looked as if the scattered debris field had mostly been the remnants of the hull, as well as light weapons for small craft and even infantry. They would fetch some small change, sure, but Rosie's cargo capacity was small. Packing efficiency was the name of the game. I saw the gash that it had all been flooding out of on this side- the entire freighter was covered in them- and peered inside. And ho boy, did my heart flutter.

Heavy cannons.

Jump-graded travel boosters.

Raw, precious metals.

And, hidden in the back corner, seemingly bolted into the wall.... a brain.

We'd hit jackpot, and potentially rescued a poor ship from abandonment, or worse.

"Alright Rosie. Time to get to work."

Affirmative.

And here was another lil something that made Rosie special- her manipulation arms . She always preferred that delicate touch, and wanted to interact with the world in a tactile, real way. So we worked on it. Together. I was tired of taking spacewalks to grab small pieces of scrap, or using the entire goddamn cargo bay on a piece that only had a tiny core, or scraps of precious metals inside. So we needed something that could pluck apart our finds. Do some light disassembly in the field, extract what was valuable, and load it in with the most packing efficiency possible. So I gave her arms- snake like appendages, coiled up in her cargo bay, with thousands of points of articulation. At first, I tried to make some kind of control system that I could use from the cockpit. But Rosie had a different idea. At her urged, I jacked them directly into the same sensory and motor systems that let her grip onto, position, and repair her hull. And by god, it worked.

When I showed her off the first time, no one had ever seen anything like it. Because there was nothing like it. A ship taking real mechanical control, over something so precise and delicate, was something that only a deeply intelligent, deeply skilled ship, with complex decision making and tactile movement could do.

And I was goddamn proud of her.

Every time she deployed them, I watched awe. Rosie gave a face of determination, and sinuous, metallic, tentacle-like appendages slid out in a bundle from the cargo bay opening on her underside. Each one was headed off by a different attachment- a precision laser cutter, a simple three-pointed grabbing claw, a drill, a tiny buzzsaw, camera that let me see what was going on, and more. Each one could be swapped out, depending on the task at hand. With eight of them slithering out from her cargo bay, though, there was usually something for everything. They extended out as a single bouquet, down through the hole of the cargo compartment, and split apart once inside. Each arm got to work.

Her observation monitor flickered on, giving me a view from the camera arm. I would've liked to get the brain out first, but two heavy cannons and a booster blocking the way anyways. We'd cut through that, picking off the energy cores and precious metals in the circuits as we go, and work our way towards the back. Rosie seemed to like the plan as well. My only job was to watch the comms, and watch the sensors.

I watched the camera as the petite tools of the arms excised and picked apart the titanium shell of the first heavy cannon. Her tools- the delicate 'fingers' of her arms- picked, pulled, tugged, and gently gripped every necessary notch, every joined titanium plate that needed to be undone, ever scrap of precious material. Firm, yet precise. Strong, yet never breaking or mishandling a single piece of cargo. As Rosie worked, my eyes darted across the energy sensors. I could see blips firing off as the ships on the other side of the freighter as the slicing ships worked and flitted between their stations from the other side. The comms crackled with their reports to Augustus- they seemed to be moving back and forth to the main carrier to drop off their hauls. It seemed like they had a lot to go through- we'd have plenty of time.

On the camera view, I could see a grabbing claw retracting back through the cargo bay. The first cannon had the back section cleanly excised from the massive barrel and chassis, leaving a path for the tools to get to the booster. The precious energy cell was sliding its way back into Rosie's cargo bay. God damn. She was quick with that. The laser cutter and saw were already making short work of the booster, too. We'd get to the brain in no time.

The chatter on the other line continued. We were still safe, but Augustus' crew had made more progress than I had hoped. Once the slicers had picked apart the port, they'd loop around to the starboard. We had to grab what we could as fast as we can- but I knew neither me or Rosie was gonna leave without that brain. Rosie gracefully sliced the fuel cell and ignition from the plasma burner, leaving the bracketing and vents behind. The second heavy cannon was soon to follow. Each cut through each piece had left a winding path towards the back of the chamber, allowing a physical path to what I had seen just barely poking through: a container for a genuine ship's brain. Rosie slid her camera arm in for a closer look.

The brain was bolted into the chassis of the ship, as well as some containers of growth factor. Seemed like the intent was to grow her in to this freighter. That was certainly an ambitious task, but if they knew what they were doing, it would be well worth it. A self-repairing, intelligent hauler as large as this one would be the heart and soul of resistance movements everywhere, supplying every backwater mining station or moon that longed to be free. Unfortunately, the brave and principled can still be stupid, and these chucklefucks had no idea what they were doing. Slapped in a random cargo bay, desperately trying to get growth out from there with no proper imprinting guidance... shame. If they'd've found me before running into the Navy, I might've helped them out. But at least now, we could give her a better life. I knew a lot of good, caring pilots that would take loving care of a fine ship like her.

From what I could tell, we were still safe from Augustus. Based on what I was hearing on the comms, each slicer was working on its last cargo hold subsection, and after that, they'd be poking around this side. We had to get this brain and get out.

Tenderly, her claw arm gripped the top of the brain's chamber, as her other fingers started working on the rivets. A saw would bust through part of the titanium bracket holding the chamber down, and when it got too close to the container itself, laser cutters took over, delicately slicing off each affixation point one by one. Rosie worked in a clockwise direction, first working down the three riveting points on the right, sawing off the bottom bracket, and then working up the rivets on the left.

C'mon Rosie. You got this. Just need the top plate....

"Finishing up there, slicer 5T?"

Shit. That was Augustus on the comms.

"Sure thing boss. Just gotta get this load to central. Mind if someone takes a peek on the other side for parasites before I get there?"

Shit.

"Sure thing. Fighter 3A, get your ass in gear and make a full pass of the ship."

An energy spike pinged on my sensor panels as the fighter revved up a booster.

"Gotcha boss. Starting at aft segment."

Shitshitshitshitshitshitshitshitshitshitshit

We still had a sliver of time before we were seen. They'd wanna get a good pass everywhere- there were ships far stealthier than us out there. But it was minutes at most. We had to finish up.

"Rosie, how're we doing there? You done?"

Negative.

[ ;( ]

"Fuck. Rosie, we gotta get outta here."

Affirmative. Affirmative. Affirmative. Affirmative.

Rosie-speak for "I know, I know, I know"

My eyes were fixed to the scanner and my cockpit windows for a visual, but I spared one moment to check Rosie's cam. She was finishing sawing through the top bracket. Just a little more....

"Aft clear, moving to starboard cargo bays."

The brain snapped off of the hull, and Rosie's claws were zipping it back to her cargo bay. I revved the engines into standby. The arms tenderly guided it through the path we had cleared, and out through the hole in the hull. We might be able to barely slip away without them knowing.....

I looked up through the cockpit, just as the dinged-up, formerly Navy fighter showed itself from behind a piece of debris. It froze for a moment, and then lined its nose to face me. Cannon ports shifted open, and slowly took aim.

"Well shit, Augustus, you're gonna wanna see this. Get your ass over here, I'm switching to public comms."

I heard slight fuzz as he switched his channel.

"Alright, leech, I'll keep this simple. You have thirty seconds to relinquish your haul before you join the debris."

For a single, cold moment, I swear I made eye contact with him through our cockpits.

#writing#sierra writes#biologics#robotfucker#eroticism of the machine#story#sci fi story#scifi#scifi story

92 notes

·

View notes

Text

Generative AI and Predictive AI: Comparing Two Powerful Technologies

Artificial Intelligence (AI) is transforming industries at an unprecedented pace. Among the many AI advancements, Generative AI and Predictive AI stand out as two of the most impactful technologies. While both leverage AI to process and analyze data, they serve vastly different purposes. This article will break down their definitions, how they work, key differences, applications, and their potential future impact. Generative AI Training

What is Generative AI?

Generative AI is a branch of artificial intelligence that focuses on creating new content, data, or outputs. It learns from vast amounts of data and uses that knowledge to generate original text, images, audio, and even videos.

How Generative AI Works

Generative AI models rely on advanced machine learning techniques like deep learning and neural networks. Some well-known Generative AI models include:

GPT (Generative Pre-trained Transformer): Creates human-like text, used in chatbots and content generation.

DALL·E: Generates realistic and artistic images from text descriptions.

Stable Diffusion: Produces high-quality AI-generated images. Gen AI Online Training

Applications of Generative AI

Generative AI is widely used across various industries, including:

Content Creation: Writing articles, blog posts, scripts, and marketing copy.

Art and Design: Generating artwork, illustrations, and design elements.

Healthcare: Assisting in drug discovery and medical imaging.

Gaming and Entertainment: Creating characters, music, and even entire game worlds. Generative AI Training

What is Predictive AI?

Predictive AI, also known as predictive analytics, is an AI-powered technology designed to analyze past data and make future predictions. It uses statistical algorithms and machine learning to forecast outcomes based on patterns in historical data. Gen AI Online Training

How Predictive AI Works

Predictive AI models function using:

Machine Learning Algorithms: Such as regression analysis, decision trees, and neural networks.

Data Mining: Extracting meaningful patterns from structured and unstructured data.

Big Data Analytics: Processing large datasets to uncover trends and make predictions.

Applications of Predictive AI

Predictive AI is highly valuable in industries that rely on forecasting, including:

Finance: Stock market analysis, fraud detection, and risk assessment.

Healthcare: Predicting disease outbreaks and patient diagnoses.

Retail: Demand forecasting and personalized recommendations.

Manufacturing: Predictive maintenance to prevent equipment failures.

Generative AI vs Predictive AI: Key Differences

While both technologies utilize AI and machine learning, they serve distinct purposes. Here’s a comparison:

Feature

Generative AI

Predictive AI

Purpose

Creates new content and data

Predicts future outcomes based on past data

Core Function

Content generation

Data forecasting

Examples

ChatGPT, DALL·E, Stable Diffusion

Forecasting tools, fraud detection, medical diagnosis

Industries

Media, Art, Marketing, Gaming

Finance, Healthcare, Retail, Manufacturing

Data Usage

Learns from datasets to generate new outputs

Analyzes historical data to predict trends

The Future of Generative AI and Predictive AI

Both Generative AI and Predictive AI will continue to evolve and shape various industries. Some potential future developments include:

Enhanced Creativity: Generative AI will produce even more realistic and sophisticated content.

Improved Accuracy: Predictive AI will refine its forecasting capabilities with better data and algorithms.

AI Synergy: The combination of both technologies could lead to AI systems that generate solutions while predicting their outcomes.

Conclusion

Understanding Generative AI vs Predictive AI is crucial as both technologies are revolutionizing industries in different ways. Generative AI is transforming creative fields, while Predictive AI is optimizing decision-making and forecasting. As AI continues to evolve, businesses and individuals can leverage both technologies to enhance innovation and efficiency.

Visualpath is the Leading and Best Institute for learning in Hyderabad. We provide Generative AI Online Training Course. You will get the best course at an affordable cost.

Call on – +91-7032290546

Visit: https://www.visualpath.in/online-gen-ai-training.html

#GenAI Training#Generative AI Training#Generative AI Course in Hyderabad#Gen AI Training in Hyderabad#Gen AI Online Training#GenAI Course in Hyderabad#Generative AI Course Training in Chennai#Generative AI Course Training in Bangalore#Best Generative AI Training in India#Generative AI Courses Online#Generative AI Training Institute Hyderabad#Generative AI Training in Ameerpet

1 note

·

View note

Text

The issue is "AI" is a branding term, largely riding off of science fiction talking about futuristic more-intuitive tooling. There is not a clear definition for what it is because it's not a technical term.

There are specific techniques and systems like LLMs (large language models) and diffusion models to generate images and the like, but it's not cleanly separated from other technology, that's absolutely true. It's also that predecessor systems also scraped training material without consent.

The primary difference here is in scale, in the sense of the quality of generated outputs being good enough that spambots and techbros and whoever use it, and in the sense that the general public is aware of these tools and they're not just used by the more technical, which have combined to create a new revolution in shitty practices.

Anyways I still maintain that the use of "AI" (and "algorithm") as general terms meant to apply this specific kind of thing is basically an exercise in the public attempting to understand the harm from these shitty practices but only being given branding material to understand what this shit even is.

Like, whether something is "AI", in the sense of "artificial intelligence", is very subjective. Is Siri "AI"? Is Eliza "AI"? Is a machine-learning model that assists with, idk, color correction "AI"? What about a conventional procedural algorithm with no data training?

Remember, a lot of companies "use AI" but it could just be they're calling systems they're already using "AI" to make investors happy, or on the other end that they're feeding into the ChatGPT API for no reason! What they mean is intentionally unclear.

And the other thing too is "algorithm" is used in the same kind of way. I actually differentiate between capital-A "Algorithms" and lowercase-a algorithms.

The latter is simply the computer science definition, an algorithm is a procedure. Sorting names in a phonebook uses a sorting algorithm. A flowchart is an algorithm. A recipe is an algorithm.

The other is the use usually found in the media and less technical discussions, where they use capital-A "Algorithm" to refer to shitty profit-oriented blackbox systems, usually some kind of content recommendation or rating system. Because I think these things are deserving of criticism I'm fine making a sub-definition for them to neatly separate the concepts.

My overall point is that language in describing these shitty practices is important, but also very difficult because the primary drivers of the terminology and language here are the marketeers and capitalists trying to profit off this manufactured "boom".

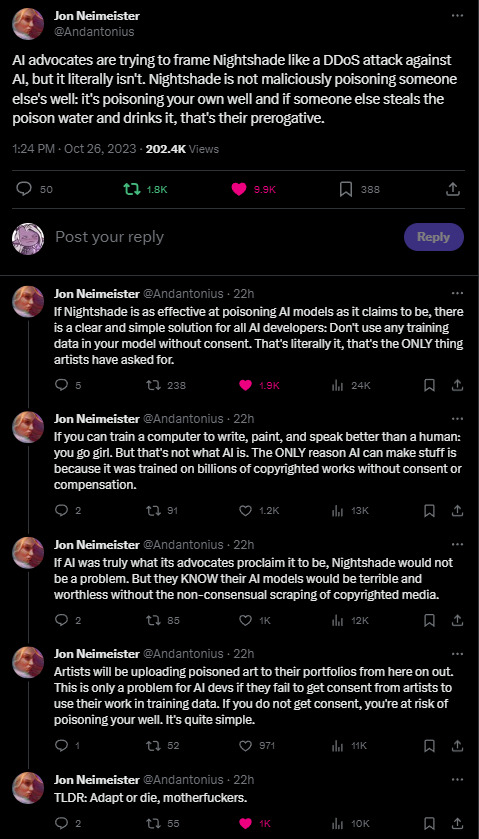

I just have to share this beautiful thread on twitter about AI and Nightshade. AI bros can suck it.

17K notes

·

View notes

Text

Is Perforated Metal Sustainable? Exploring Diamond Perforated Metals

What Are Diamond Perforated Metals?

Diamond perforated metals are sheets of metal, typically steel, aluminum, or stainless steel, punctuated with a pattern of diamond-shaped holes. These perforations are created through a mechanical process that punches holes into the metal, resulting in a lightweight yet durable material. The diamond pattern is not only aesthetically pleasing but also functional, offering strength and versatility. Companies like Huijin produce such materials for various applications, including industrial enclosures and architectural facades.

The sustainability of diamond perforated metals begins with their material composition. Metals like aluminum and steel are highly recyclable, and the perforation process does not compromise their recyclability. This inherent property makes diamond perforated metals a promising candidate for sustainable design and construction.

Manufacturing Process of Diamond Perforated Metals

The production of diamond perforated metals involves punching or stamping metal sheets with precision machinery. This process is efficient, producing minimal waste since the removed material (the punched-out sections) can often be recycled. Modern manufacturing techniques further enhance sustainability by optimizing energy use and reducing emissions. For instance, advanced CNC machines allow for precise perforations, minimizing material loss and ensuring consistency in the diamond pattern.

Moreover, the durability of diamond perforated metals contributes to their sustainability. Their resistance to corrosion, especially in stainless steel or coated variants, ensures a long lifespan, reducing the need for frequent replacements and conserving resources over time.

Environmental Benefits of Diamond Perforated Metals

Recyclability and Circular Economy

One of the primary reasons diamond perforated metals are considered sustainable is their recyclability. Metals like aluminum and steel can be recycled indefinitely without losing their properties. According to the Aluminum Association, nearly 75% of all aluminum ever produced is still in use today, highlighting the material’s role in a circular economy. Diamond perforated metals, being made from these materials, support this cycle by allowing end-of-life products to be melted down and repurposed into new sheets or other metal products.

The recycling process for diamond perforated metals is also energy-efficient compared to producing virgin metal. Recycling aluminum, for example, uses 95% less energy than primary production, significantly reducing the carbon footprint.

Energy Efficiency in Applications

Diamond perforated metals contribute to energy efficiency in both industrial and architectural applications. In industrial settings, they are often used as filters or enclosures, allowing for optimal airflow and reducing the energy required for ventilation systems. In architectural applications, diamond perforated metals are employed as building facades or shading systems. These facades can reduce solar heat gain, lowering the energy needed for cooling buildings, especially in hot climates.

For instance, a diamond perforated metal facade can act as a passive solar control system, diffusing sunlight while maintaining natural ventilation. This reduces reliance on air conditioning, leading to lower energy consumption and greenhouse gas emissions.

Reduced Material Waste

The perforation process for diamond perforated metals is designed to maximize material efficiency. The diamond pattern allows for a high open area (the percentage of the sheet that is perforated), which reduces the amount of raw material needed while maintaining structural integrity. This efficiency translates to less resource extraction and lower environmental impact during production.

Applications of Diamond Perforated Metals in Sustainable Design

Industrial Uses

In industrial contexts, diamond perforated metals are valued for their strength and versatility. They are commonly used as walkways, platforms, and enclosures in factories and construction sites. Their perforated design allows for drainage and ventilation, enhancing safety and functionality. The durability of diamond perforated metals ensures they withstand harsh environments, reducing maintenance and replacement costs.

From a sustainability perspective, these applications benefit from the material’s longevity and recyclability. For example, a diamond perforated metal walkway in a factory can last decades, and when it reaches the end of its life, it can be recycled into new metal products, minimizing waste.

Architectural Applications

In architecture, diamond perforated metals are increasingly popular for their aesthetic and functional qualities. They are used as building facades, ceiling systems, and decorative fences, adding both style and sustainability to designs. The diamond pattern creates a visually striking effect while allowing for light and air penetration, which enhances occupant comfort and reduces energy use.

For example, a diamond perforated metal facade on a commercial building can reduce the need for artificial lighting by allowing natural light to filter through while providing shade. This balance of aesthetics and functionality makes diamond perforated metals a favorite among architects seeking sustainable solutions.

Challenges to Sustainability

While diamond perforated metals offer numerous environmental benefits, there are challenges to consider. The initial production of metals, particularly steel, can be energy-intensive and produce significant carbon emissions. Although recycling mitigates this impact, the mining and refining of raw materials remain resource-heavy processes.

Additionally, the sustainability of diamond perforated metals depends on proper end-of-life management. If not recycled, these materials could end up in landfills, negating their environmental benefits. Encouraging robust recycling infrastructure and responsible disposal practices is essential to maximizing their sustainability.

Mitigating Environmental Impact

To address these challenges, manufacturers are adopting greener practices. For instance, using renewable energy sources in metal production can reduce the carbon footprint of diamond perforated metals. Additionally, coatings that enhance corrosion resistance can extend the material’s lifespan, further reducing environmental impact.

Designers and architects can also contribute by specifying recycled metals for diamond perforated metal projects. By prioritizing materials with a high recycled content, they can support the circular economy and reduce demand for virgin resources.

Future Prospects for Diamond Perforated Metals

The future of diamond perforated metals in sustainable design looks promising. Advances in manufacturing technology, such as laser cutting and additive manufacturing, are making production even more efficient and precise. These innovations could further reduce waste and energy use, enhancing the sustainability of diamond perforated metals.

Moreover, as green building standards like LEED (Leadership in Energy and Environmental Design) gain traction, the demand for sustainable materials like diamond perforated metals is likely to grow. Their ability to combine functionality, durability, and recyclability positions them as a key player in the transition to a more sustainable built environment.

Integration with Smart Technologies

Emerging technologies, such as smart facades that adjust perforations based on environmental conditions, could elevate the sustainability of diamond perforated metals. These systems could optimize light and heat transmission in real time, further reducing energy consumption in buildings. While still in development, such innovations highlight the potential for diamond perforated metals to evolve in response to sustainability demands.

Conclusion

Diamond perforated metals offer a compelling case for sustainability, thanks to their recyclability, durability, and energy-efficient applications. From industrial walkways to architectural facades, they provide versatile solutions that balance functionality and environmental responsibility. While challenges like energy-intensive production and end-of-life management remain, ongoing innovations and responsible practices are addressing these issues. As the demand for sustainable materials grows, diamond perforated metals are poised to play a significant role in shaping a greener future.

#asexual#easter#margot robbie#michael cera#donald trump#artists on tumblr#across the spiderverse#barbie#rwby#ryan gosling

1 note

·

View note

Text

Maximizing Quality in Ophthalmic Lines with Eye Dropper Bottle Inspection Systems

Pharmaceutical packaging lines today are being redefined by smart automation. Among the most critical upgrades is the use of Eye Dropper Bottle Inspection Systems. These systems ensure real-time, non-contact, high-speed inspection of eye drop bottles—where even the smallest visual defect can compromise product integrity and regulatory compliance.

The Role of Vision Inspection in Ophthalmic Production

Eye drop bottles present unique inspection challenges. Being small, transparent or semi-transparent, and filled with sterile content, they require detailed inspection of critical areas like: - Bottle fill level - Cap alignment and closure - Dropper nozzle presence - Body scratches, smudges or discoloration A dedicated Eye Dropper Bottle Inspection System uses AI-powered vision to monitor all these aspects at once, in real time, on high-speed lines.

How the Eye Dropper Bottle Inspection System Works

1. Bottles enter via a synchronised conveyor system. 2. They pass through lighting and camera modules. 3. Multi-angle industrial cameras scan each bottle for structural and cosmetic defects. 4. Vision software compares images with quality standards using AI and predefined rules. 5. Rejected bottles are instantly removed using a pneumatic arm or air-jet mechanism. 6. Accepted bottles proceed to final packaging without interruption.

Components That Power the System

- Stainless steel conveyor with starwheel feed - High-speed machine vision cameras (top, side, fill level view) - LED lighting modules with optical diffusers - AI-enabled inspection software with parameter tuning - Auto-reject mechanism - HMI for live monitoring, access control, and reports - SCADA/Network integration options

Why Leading Manufacturers Choose Optomech

Optomech’s Eye Dropper Bottle Inspection System is trusted by India's top injectable manufacturers, especially those producing ophthalmic and nasal dropper lines. Key reasons our clients prefer Optomech: - Simple integration into existing packaging lines - Customizable inspection criteria for different bottle sizes and cap designs - Real-time report generation with rejection reasons - Minimal maintenance and fast remote service support With decades of experience and reliable field support, Optomech ensures zero compromise on inspection accuracy or machine uptime.

Key Benefits at a Glance

- Zero sampling: every bottle is inspected - High throughput: up to 400 bottles per minute - Lower QC manpower cost - Real-time decision making and traceability - Reduced product recall risk

Conclusion: Drive Efficiency with Eye Dropper Bottle Inspection Systems

Eye Dropper Bottle Inspection Systems are the new standard for quality in ophthalmic packaging. As compliance standards get stricter and competition grows, vision inspection is becoming essential—not optional. Optomech’s solution offers speed, precision, and long-term support—helping you deliver safer, cleaner, and defect-free packaging. 📩 Book a demo: [email protected] | 🌐 https://www.optomech.in/eye-dropper-bottle-inspection/

0 notes

Link

#AI-AugmentedProduction#automationintegration#DigitalThreadImplementation#MROEvolution#precision-manufacturing#regionalinnovation#SkillsTransformation#workforcedevelopment

0 notes

Text

Discover the perfect scent machine for your home or office. Indulge in an aromatic experience that creates a welcoming atmosphere and promotes well-being.

#diffuser machine#diffuser machine fragrance#diffuser machine learning#diffuser machine price#diffuser machine near me#diffuser machine kuwait#diffuser machine - dr large#diffuser machine for hair#diffuser machine dubai#diffuser machine manufacturers#diffuser machine - dr mini#dr scent diffuser machine#best home diffuser machine#hotel scent diffuser machine#hotel diffuser machine#home diffuser machine#smart scent diffuser machine#smell diffuser machine#oil diffuser machine#ds eco diffuser machine#aroma diffuser machine#scent diffuser machine#aroma scent diffuser machine#home unit 101 aroma diffuser machine#scent machine#scent machines for homes#scent machine for hvac#scent machine for business#best home scent machines#best scent machine

1 note

·

View note

Text

How to Keep Wellness Spaces Clean and Serene for Daily Yoga at Home

How to Keep Wellness Spaces Clean and Serene for Daily Yoga at Home

Yoga is not just an exercise; it’s a holistic practice that nurtures the body, mind, and spirit. For many practitioners, the space where they practice yoga plays a crucial role in their experience. A clean, serene wellness space at home helps cultivate calmness, focus, and mindfulness—making each session more meaningful and restorative.

However, maintaining such a space, especially in a busy household, can be challenging. Dust, clutter, and distractions can disrupt the peaceful atmosphere essential for yoga practice. To help you create and maintain a tranquil yoga environment at home, here are practical tips and strategies to keep your wellness space clean and serene for daily practice.

1. Choose the Right Space for Your Yoga Practice

Creating a wellness space starts with selecting the right spot in your home. Ideally, this area should be quiet, well-ventilated, and free from heavy foot traffic.

Natural Light and Airflow: A room or corner with plenty of natural light boosts energy and positivity. Fresh air circulation keeps the space feeling vibrant and prevents stuffiness.

Minimal Distractions: Pick a location away from televisions, loud noises, and busy household activities.

Adequate Space: Ensure there is enough room for your mat and movement without feeling cramped.

Once you have your spot, you can begin to personalize and maintain it to support your yoga journey.

2. Declutter Regularly for Mental Clarity

Clutter disrupts the calm and invites distraction. A cluttered wellness space can unconsciously add to mental clutter during practice.

Keep Only Essentials: Store only yoga props, mats, blocks, straps, and cushions in the space. Remove unrelated items to keep the area visually clean.

Storage Solutions: Use shelves, baskets, or bins to neatly organize smaller items. Label containers if helpful.

Daily Quick Tidy: Spend 5 minutes each day putting away props and wiping surfaces to maintain order.

Decluttering not only keeps the space tidy but also signals to your mind that this area is dedicated to peace and focus.

3. Establish a Cleaning Routine Tailored for Yoga Spaces

Yoga spaces require gentle but effective cleaning methods to preserve a hygienic and inviting environment.

Mat Care: Yoga mats are the foundation of your practice. Clean your mat regularly with a mild solution of water and gentle soap or a specially formulated yoga mat spray. Wipe down after each use to prevent sweat and bacteria buildup.

Floor and Surfaces: Vacuum or sweep floors regularly to remove dust and dirt. Mop with natural cleaning solutions to avoid harsh chemical residues.

Props and Cushions: Wash fabric props, bolsters, and cushions as per manufacturer instructions. For wooden or foam props, wipe with a damp cloth and allow them to air dry.

Consistency in cleaning maintains both hygiene and the fresh energy of the wellness space.

4. Use Natural Elements to Enhance Serenity

Incorporating natural elements can deepen the sense of tranquility in your yoga space.

Plants: Indoor plants like snake plants, pothos, or peace lilies improve air quality and add calming greenery.

Aromatherapy: Use essential oils such as lavender, eucalyptus, or sandalwood via diffusers or candles to create a soothing atmosphere.

Natural Materials: Choose mats, blankets, and props made from natural fibers like cotton, jute, or cork to keep the space earth-friendly and warm.

These touches connect you to nature, enhancing mindfulness during practice.

5. Control Noise and Light to Foster Focus

Sound and lighting profoundly affect your yoga experience. Managing these elements helps keep your space serene.

Noise Reduction: Use thick curtains, rugs, or wall hangings to absorb sound. Consider white noise machines or soft music to mask distracting sounds.

Adjustable Lighting: Dimmer switches or soft lamps allow you to tailor light intensity depending on the practice time and mood.

Natural Light: Whenever possible, practice during daylight to harness natural rhythms.

Optimizing your space’s sensory environment supports relaxation and concentration.

6. Keep Air Quality High for Energy and Comfort

Fresh, clean air is vital during yoga to support breathing exercises (pranayama) and overall wellbeing.

Ventilation: Open windows regularly to refresh the air.

Air Purifiers: Consider investing in an air purifier with HEPA filters to remove dust, pollen, and allergens.

Avoid Strong Scents: Steer clear of synthetic fragrances that can irritate the respiratory system; opt for natural options instead.

Good air quality promotes ease of breath and vitality during practice.

7. Mindful Use of Technology in Your Yoga Space

Technology can be both helpful and disruptive. When used mindfully, it can enhance your practice.

Limit Devices: Keep phones, computers, and televisions out of the immediate yoga area to avoid distractions.

Use Guided Apps Wisely: If using yoga apps or videos, position devices so they don’t dominate your space. Use headphones to prevent sound from disturbing others.

Silent Mode: Set devices to silent or “Do Not Disturb” during practice time to maintain focus.

Balancing tech use maintains the purity of your yoga environment.

8. Personalize Your Space with Intention

Your wellness space should reflect your personality and yoga journey to inspire you every day.

Incorporate Meaningful Items: Add meaningful art, spiritual symbols, or photographs that inspire peace and motivation.

Create an Altar or Sacred Spot: Even a small shelf with candles, crystals, or incense can create a focal point for meditation and intention-setting.

Rotate Décor Seasonally: Refresh your space with seasonal elements like flowers or colors to keep it inviting.

A personalized space invites deeper connection and joy in your practice.

9. Maintain Mindful Habits to Preserve Serenity

Beyond physical cleaning, cultivating mindful habits reinforces the serenity of your yoga space.

Shoes Off: Keep shoes outside or at the entrance to prevent dirt.

Respect the Space: Treat the area as a sanctuary, encouraging all family members to honor its cleanliness.

Set Intentions: Begin each practice with a moment of gratitude or intention-setting to reinforce the sacredness of your space.

These practices help your space remain a refuge amidst daily chaos.

10. Troubleshooting Common Challenges

Even with the best intentions, busy households can introduce challenges.

Pets: Keep pet hair at bay by regular grooming and vacuuming. Consider pet-free zones during practice.

Small Spaces: Use foldable mats and multi-purpose props that can be stored compactly.

Time Constraints: If daily cleaning is difficult, schedule weekly deep cleans and quick daily tidies.

Adapt your strategies to fit your lifestyle while keeping your space functional and serene.

Conclusion

Your wellness space is an extension of your yoga practice. By creating and maintaining a clean, organized, and serene environment, you enhance not only your physical workouts but also your mental clarity and emotional balance. With simple habits like decluttering regularly, cleaning mats and props, incorporating natural elements, and cultivating mindful routines, you can ensure your home yoga space remains a sanctuary where body, mind, and spirit align each day.

By investing in this space with care and intention, you deepen your yoga journey and invite greater peace and wellness into your everyday life.

+1 813 838 2810

cleaning services zephyrhills cleaning services zephyrhills florida house cleaning zephyrhills fl house cleaning services zephyrhills commercial cleaning services zephyrhills zephyrhills maid service home cleaning services zephyrhills housekeeping zephyrhills office cleaning zephyrhills commercial cleaning services dade city cleaning services dade city housekeeping dade city

#housecleaningservice#usa#housecleaningservices#dadecitymx#wesleychapel#dadecity#dadecityflorida#wesleychapelfl#wesleychapelmoms#wesleychapelnails

0 notes

Text

Transform Your Ride with a Stunning Jaguar XF Body Kit

For car enthusiasts and luxury vehicle owners, aesthetics and performance often go hand in hand. When it comes to enhancing the style and street presence of a premium sedan like the Jaguar XF, nothing delivers a visual impact quite like a Jaguar XF body kit. Designed to elevate the appearance and aerodynamics of the car, a well-crafted body kit can completely transform the XF into a sleek, aggressive, and head-turning machine that stands apart from the rest.

The Jaguar XF is already known for its refined design, blending British elegance with modern performance. However, for those looking to personalize their vehicle and make a bold statement, a body kit offers the perfect solution. A body kit typically includes components like front and rear bumpers, side skirts, spoilers, and sometimes fender flares or diffusers. These pieces work together to give the car a sportier profile and improved airflow dynamics, which can also subtly enhance performance by reducing drag and increasing downforce.

Installing a Jaguar XF body kit is not just about aesthetics; it also allows owners to express their unique style and make their vehicle truly one of a kind. Whether you prefer a more aggressive, race-inspired look or a clean and understated elegance, there are numerous kit designs available to suit different tastes. Manufacturers often offer body kits in durable materials like polyurethane, fiberglass, or carbon fiber, each with its own benefits. Carbon fiber kits, for example, are extremely lightweight and favored in high-performance circles, while polyurethane kits offer more flexibility and resistance to damage.

In addition to improving the vehicle’s visual appeal, body kits can also complement other modifications, such as custom wheels, lowered suspension, or upgraded exhaust systems. When all these elements are harmonized, the Jaguar XF takes on a cohesive, powerful appearance that reflects its performance potential. For car owners who participate in shows or meets, a body kit can be the centerpiece of a build that garners attention and admiration.

Choosing the right body kit involves careful consideration of quality, fitment, and compatibility with the specific year and model of your Jaguar XF. Poorly fitting kits can cause installation headaches and diminish the overall look. That’s why it’s recommended to invest in kits from reputable brands or custom fabricators who specialize in luxury vehicle enhancements. Professional installation is also advisable to ensure seamless integration with the vehicle’s existing design.

In conclusion, enhancing your car with a Jaguar XF body kit is one of the most effective ways to improve both form and function. It offers a dramatic upgrade in style, provides aerodynamic benefits, and reflects a personal commitment to craftsmanship and detail. Whether you're aiming to turn heads on the street or simply want your Jaguar XF to better reflect your personality, a body kit delivers a transformation that speaks volumes without saying a word.

0 notes

Text

Aluminum Homogenizing Furnace: Optimizing Microstructure for Superior Performance

In the aluminum processing industry, achieving uniform material properties is essential to ensure performance, durability, and machinability. One critical process used to enhance the internal structure of aluminum billets and ingots is homogenization. At the core of this process is the Aluminum Homogenizing Furnace, a specialized heat treatment system designed to improve alloy distribution and prepare aluminum for further processing.

What is an Aluminum Homogenizing Furnace?

An Aluminum Homogenizing Furnace is an industrial furnace used to heat aluminum castings (mainly billets or ingots) to high, controlled temperatures and then allow them to cool at a specific rate. This thermal cycle helps eliminate chemical segregation that occurs during solidification and redistributes alloying elements such as magnesium, silicon, or copper more uniformly across the billet structure.

The result is a more consistent microstructure that enhances mechanical properties and minimizes defects during extrusion or rolling.

Purpose of Homogenization

During casting, aluminum billets solidify unevenly, causing segregation of alloying elements between the center and the outer regions. This non-uniformity can lead to:

Poor mechanical strength

Uneven extrusion behavior

Cracks or surface defects

Homogenization eliminates these issues by:

Reducing segregation of alloying elements

Softening the billet for easier deformation

Enhancing dimensional accuracy during forming

Improving surface finish and tool life

Typical Homogenizing Cycle

Heating Phase: The billets are heated slowly to a homogenizing temperature, typically between 500°C to 600°C, depending on the alloy.

Soaking Phase: The material is held at this temperature for several hours to allow diffusion and alloy redistribution.

Cooling Phase: Controlled cooling (air, furnace, or forced convection) helps prevent internal stresses and maintain the improved structure.

Key Features of an Aluminum Homogenizing Furnace

Uniform Temperature Distribution: Ensures that all billets or ingots receive equal thermal treatment.

High-Performance Insulation: Minimizes heat loss and improves energy efficiency.

Precision Controls: Advanced PLC or SCADA systems manage temperature ramping, soak times, and cooling cycles.

Custom Tray and Racking Systems: Designed to hold large loads of billets while ensuring airflow and uniform treatment.

Cooling Chambers: Integrated or standalone cooling zones for controlled cooling processes.

Types of Aluminum Homogenizing Furnaces

Batch Homogenizing Furnace: Ideal for small-to-medium production quantities with flexibility in alloy types.

Continuous Homogenizing Furnace: Designed for large-scale, automated production with high throughput.

Combination Systems: Integrated with cooling tunnels or quenching chambers to streamline the process.

Applications Across Industries

Extrusion Plants: Homogenized billets lead to smoother extrusion with minimal die wear.

Automotive Sector: Ensures uniform strength and surface finish in vehicle components.

Aerospace Industry: Demands high structural integrity and alloy consistency for critical parts.

Building & Construction: Supplies reliable aluminum profiles for windows, doors, and facades.

Conclusion

The Aluminum Homogenizing Furnace is a vital tool for modern aluminum manufacturers seeking to optimize the performance of their billets or ingots before downstream processing. By enhancing internal consistency and reducing material defects, this furnace ensures that the aluminum products meet the highest standards of quality and reliability.

Investing in a high-efficiency, precision-controlled homogenizing furnace can significantly boost productivity, reduce scrap rates, and improve final product quality in any aluminum processing facility.

0 notes

Text

Shaping Tomorrow's World: The Limitless Potential of Plastic Extrusion Profiles

Trending Topic: In an era driven by innovation and sustainability, the demand for versatile, cost-effective, and environmentally conscious materials is soaring. Plastic extrusion profiles are at the forefront of this movement, offering tailored solutions across a vast spectrum of industries. Their ability to be customized into intricate shapes with specific properties is making them a hot topic for engineers, designers, and manufacturers alike.

Unlocking Design Freedom Through Plastic Extrusion

At its core, plastic extrusion involves forcing molten plastic through a die to create a continuous shape with a defined cross-section. This seemingly simple process unlocks a world of design possibilities:

Complex Geometries: Intricate and unconventional shapes that would be difficult or costly to achieve with other methods are readily produced through extrusion.

Customization is Key: Profiles can be tailored to exact specifications, incorporating features like interlocking mechanisms, channels, grooves, and varying wall thicknesses.

Multi-Material Extrusion: Advanced techniques allow for the co-extrusion of different plastics with varying properties within a single profile, offering enhanced functionality and aesthetics.

Color and Texture Integration: Pigments and surface textures can be seamlessly incorporated during the extrusion process, eliminating the need for secondary finishing.

Why Plastic Extrusion Profiles Are Gaining Momentum

The increasing adoption of plastic extrusion profiles is fueled by a compelling combination of benefits:

Cost-Effectiveness: For high-volume production, extrusion often proves to be a significantly more economical manufacturing method compared to processes like molding or machining.

Durability and Longevity: Engineered plastics offer excellent resistance to weathering, chemicals, impact, and wear, ensuring long-lasting performance in diverse environments.

Lightweighting Solutions: Replacing heavier traditional materials like metal or wood with lightweight plastic profiles contributes to energy efficiency in transportation and ease of handling in construction.

Sustainability Initiatives: The ability to utilize recycled plastics in the extrusion process aligns with growing sustainability goals and reduces waste.

Versatile Material Selection: A wide array of thermoplastic polymers, each with unique properties, can be used in extrusion, allowing for precise tailoring to specific application requirements.

The Ubiquitous Applications of Plastic Extrusion Profiles

From the mundane to the cutting-edge, plastic extrusion profiles are integral to numerous industries:

Construction: Window and door frames, seals, siding, pipes, cable management, and architectural trims.

Automotive: Interior and exterior trims, weather stripping, seals, hoses, and cable conduits.

Furniture: Edging, frames, drawer slides, and decorative elements.

Lighting: Diffusers, housings, and structural components for LED fixtures.

Medical: Tubing, profiles for medical devices, and components for diagnostic equipment.

Retail: Display fixtures, shelving supports, signage, and point-of-sale materials.

Electronics: Wire management channels, housings for electronic devices, and insulation components.

Agriculture: Irrigation pipes, greenhouse structures, and fencing components.

PARKNONWOVEN: Enabling Innovation Across Industries with Advanced Non-Wovens

While PARKNONWOVEN's core expertise lies in non-woven materials, their high-quality products play a vital supporting role in industries that heavily utilize plastic extrusion profiles. Their engineered non-wovens contribute to:

Sealing and Gasketing: Providing compressible and durable non-woven materials used in seals and gaskets within extruded profiles.

Reinforcement and Lamination: Offering non-woven fabrics that can be laminated with extruded profiles to enhance strength, dimensional stability, or provide specific surface properties.

Filtration within Extruded Systems: Supplying non-woven filter media for air and fluid filtration systems integrated into extruded components.

Surface Protection During Manufacturing and Transport: Providing protective non-woven layers to prevent damage to delicate extruded surfaces.

The Synergy of Materials: Shaping a Brighter Future

Plastic extrusion profiles offer a powerful pathway to create customized and efficient components across countless applications. While PARKNONWOVEN focuses on the unique advantages of non-woven materials, their high-quality products often work in tandem with extruded plastics, creating synergistic solutions that drive innovation and efficiency across diverse industries. By understanding the capabilities of both material types, manufacturers can unlock even greater potential for shaping a more sustainable and technologically advanced future.

[email protected] 0124-4816111 Corporate Office: Park Non Woven Pvt. Ltd., Gurugram, HR

#pet acoustic panel#non woven battery gaunlets#breather fabric#fiber glass felt#compressor felt#light weight insulation#plastic extrusion profile#high efficiency media#pp + pet felt#lint free wipes

0 notes

Text

Hemodialysis Market 2025: Regional Forecasts and Market Segmentation

Executive Overview: Expanding Horizons in Hemodialysis Solutions

The global hemodialysis market is undergoing rapid transformation, characterized by technological advancement, increasing prevalence of end-stage renal disease (ESRD), and growing preference for home-based treatment modalities. hemodialysis market projected to expand from USD 75.9 billion in 2022 to USD 113.4 billion by 2031 at a CAGR of 5.6%, this market presents substantial opportunities for manufacturers, healthcare providers, and stakeholders across all regions.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40464-global-hemodialysis-market

Hemodialysis Market Segmentation Analysis