#electromagnetic field sensor unit

Explore tagged Tumblr posts

Text

[ Whistling, Beeping ]

STAR WARS EPISODE II: Attack of the Clones 00:41:13

The note about the Dai Bendu being the origin of the Galactic Republic's Roundel was originally written as "Bendu monks" in 2002's Attack of the Clones Incredible Cross-Sections and in 2007's Complete Cross-Sections. This text was removed, however, in 2018's Complete Vehicles and 2020's Complete Vehicles, New Edition. The Dai Bendu do exist in Canon though, thanks to mentions in Star Wars Outlaws and various DeAgostini reference works.

#Star Wars#Episode II#Attack of the Clones#Wild Space#Kamino system#Kamino#Obi-Wan Kenobi’s Delta-7 Aethersprite#R4-P17#Galactic Roundel#R4-P series#astromech droid#Industrial Automaton#Kuat Systems Engineering#R2 unit#Jedi Order#engine cooling duct outlet#electromagnetic field sensor unit#processor state indicator#secondary holoprojector#Dai Bendu#numerology#the Force

6 notes

·

View notes

Text

New F-16 Electronic Warfare System ‘on Par with Fifth-Gen’ Enters Flight Test

Sept. 4, 2024 | By John A. Tirpak

The F-16’s new electronic warfare suite, the AN/ALQ-257, has begun flight testing after successfully completing ground tests in an anechoic chamber, Northrop Grumman reported.

The Integrated Viper Electronic Warfare Suite, or IVEWS, mounted in a Block 50 F-16, completed an Air Force evaluation in the Joint Preflight Integration of Munitions and Electronic Sensors (J-Prime) facility—an anechoic chamber—last month, Northrop said. That same aircraft has been conducting flight tests for about two weeks, and will soon be joined by a second F-16, a company official said. Northrop is not yet cleared to reveal the location of testing.

Flight testing to validate what was learned in the chamber will take just a few weeks, and an operational assessment will be completed “by the fourth quarter of this year,” said James Conroy, vice president of navigation, targeting, and survivability, in an interview with Air & Space Forces Magazine. Developmental and operational testing should be completed in early 2025, and based on the results, the Air Force will decide future milestones such as when production and deliveries can begin and when the first F-16 unit is expected to be declared operational, he said.

“We’re going fast,” Conroy said, because the Air Force’s F-16s “don’t have this kind of survivability equipment” and need it to be operationally relevant. The system is an all-digital jammer that has been extensively tested to cooperate with and deconflict with the F-16’s new AN/APG-83 Scalable Agile Beam Radar (SABR), an active electronically-scanned array (AESA) radar. The two systems can be used simultaneously, Conroy said. Both are made by Northrop.

The electronic warfare system is capable of detecting, identifying and countering “the most advanced threats” on the battlefield today, Conroy said, and can perform accurate geo-location of emitters with just a single aircraft. The simulations in the chamber were “intense,” he said.

The IVEWS will be internal to the F-16 and will replace the centerline-mounted AN/ALQ-131 self-defense jamming pod, freeing one external station on the fighter for a fuel tank or weapon. The system will use antennas located elsewhere on the fuselage; the outer mold line of the aircraft hasn’t been altered, Conroy said.

He declined to characterize whether the IVEWS is comparable to the Eagle Passive/Active Warning Survivability System (EPAWSS) being mounted on F-15Es and F-15EXs, saying only that that they are “both advanced electronic warfare systems” and can work together.

The IVEWS is intended to provide the F-16 with electronic warfare capabilities “on a par with fifth-generation aircraft, significantly enhancing survivability for operations in contested and congested electromagnetic spectrum environments,” Northrop said. “Its ultra-wideband suite can detect, identify, and counter advanced radio frequency threats, including millimeter wave systems.”

The IVEWS started out as a Middle-Tier Acquisition program to achieve rapidly fielding; it became an Air Force program of record in 2019.

Conroy said the system will be especially helpful in coping with mobile anti-aircraft radars and missiles whose position is unknown at the start of a mission and which may turn on and fire on F-16s when directly overhead or nearby.

To reach this point, the IVEWS has undergone three years of testing, both on the ground and in the air aboard Northrop’s Bombardier CRJ, acting as a surrogate for the F-16 in the Northern Lightning 2021 exercise, Conroy said. It has also been tested at Hill Air Force Base’s F-16 Block 50 avionics system integration laboratory.

In the chamber, the IVEWS was “subjected to accurate representations of complex radio frequency spectrum threats,” Northrop said in a press release. It demonstrated “the ability to detect, identify, and counter advanced radio frequency threats while operating safely with other F-16 systems.”

Conroy said the system could permit the F-16 to remain credible into the 2040s, and is being evaluated by a number of F-16 user countries, particularly those buying the F-16 Block 70. Turkey has signed a letter of agreement selecting the IVEWS for its Block 70s.

@FHaeromedia via X

16 notes

·

View notes

Text

Top Companies Leading the Kinetic Footfall Energy Harvesting Market Revolution

Unleashing the Future of Energy: A New Paradigm in Sustainable Power Generation

The global Kinetic Footfall Energy Harvesting and Security market is undergoing a revolutionary transformation. With an anticipated compound annual growth rate (CAGR) of 54.1% from 2024 to 2031, this sector is poised to redefine how urban ecosystems generate and manage energy. Leveraging advanced technologies like piezoelectric systems, electromagnetic induction, and triboelectric nanogenerators (TENGs), the market is rapidly expanding into diverse applications ranging from smart cities to high-traffic public venues.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40424-global-kinetic-footfall-energy-harvesting-market

Kinetic Footfall Energy Harvesting Market Forecast: Explosive Growth Through 2031

In 2023, the kinetic footfall energy harvesting market was valued at USD 318.78 million, and is projected to surpass USD 630 million by 2031. This exponential growth is driven by increasing global emphasis on sustainable energy, carbon neutrality, and smart infrastructure integration.

Key growth catalysts include:

Expanding urbanization and smart city initiatives

Public and private investment in renewable technologies

Technological advancements in micro-energy generation

Growing demand for decentralized and autonomous energy systems

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40424-global-kinetic-footfall-energy-harvesting-market

Regional Outlook: Strategic Growth Across Global Kinetic Footfall Energy Harvesting Markets

North America

North America is at the forefront of kinetic energy adoption, particularly the United States and Canada, which are investing heavily in smart city infrastructure and sustainable public transportation systems.

Europe

Countries like Germany, UK, and France lead the region with widespread integration in urban transport hubs, commercial complexes, and green building developments.

Asia-Pacific

Emerging economies such as China, India, Japan, and South Korea are driving robust adoption fueled by rapid urban expansion, government-backed clean energy initiatives, and population density.

Middle East and Africa

With increasing focus on renewable energy to reduce dependence on oil, countries like UAE and South Africa are integrating kinetic energy harvesting into new smart city projects.

South America

Nations including Brazil and Chile are gradually adopting these systems within public spaces and transit systems, driven by environmental policies and energy cost reduction strategies.

Technology Landscape: The Core of Energy Harvesting Innovation

Piezoelectric Technology

Piezoelectric systems dominate the market due to their high-frequency responsiveness and compact design, ideal for high-traffic locations such as airports, stadiums, and urban crosswalks. These materials convert pressure from footsteps into electrical energy, which can power lighting, sensors, and low-consumption devices.

Electromagnetic Induction

Utilizing the relative motion between magnetic fields and coils, electromagnetic induction is suitable for moderate foot traffic areas. These systems are reliable, durable, and cost-efficient, particularly in transportation hubs and shopping malls.

Triboelectric Nanogenerators (TENGs)

As a cutting-edge solution, TENGs harness friction-based mechanical movement to generate electricity. With their lightweight, flexible design, TENGs are becoming increasingly prevalent in educational institutions, healthcare facilities, and public walkways.

Application Spectrum: Cross-Sector Adoption Driving Market Momentum

Urban Infrastructure

Smart pavements, energy-harvesting crosswalks, and public lighting systems are transforming cities into self-powered environments, improving operational efficiency while lowering environmental impact.

Commercial Buildings

Integrated energy-harvesting flooring systems are being used to reduce energy bills and achieve sustainability certifications (e.g., LEED, BREEAM).

Transportation Hubs

Airports, train stations, and metro systems are prime locations for harvesting energy from massive foot traffic, powering LED displays, ticketing systems, and surveillance cameras.

Sports & Entertainment Venues

Stadiums and event spaces employ kinetic floors that convert audience movement into electricity for real-time lighting effects and digital engagement.

Educational Institutions

Universities and schools are early adopters, using kinetic energy to promote environmental awareness and power smart classroom equipment.

Healthcare Facilities

Hospitals utilize harvested energy for emergency lighting, monitoring systems, and automated sanitization devices, especially in off-grid or backup scenarios.

Residential Complexes

Innovative flooring technologies are integrated into lobbies and gyms to contribute to overall building energy efficiency.

Public Spaces

Parks, plazas, and sidewalks are being redesigned to include kinetic harvesting systems that enhance lighting and safety using human activity.

End-User Segmentation: Stakeholders Leading the Green Transition

Municipalities and Governments

Municipal investments are fueling widespread deployment of kinetic energy in public services such as smart street lighting, traffic management, and environmental monitoring systems.

Commercial Enterprises

Retail giants and corporate campuses are integrating footfall energy systems to demonstrate corporate social responsibility and reduce energy expenditure.

Educational Institutions

Adoption is driven by both functional energy benefits and the desire to create interactive, educational demonstrations of sustainability in action.

Healthcare Providers

Hospitals and care centers are embedding these technologies to ensure uninterrupted operation of critical systems in high-traffic zones.

Property Developers

Footfall energy solutions are enhancing property value and contributing to certification targets for net-zero buildings.

Event Organizers

Temporary installations at festivals, marathons, and concerts are enabling energy-independent event management, improving sustainability credentials.

Competitive Landscape: Kinetic Footfall Energy Harvesting Market Leaders and Innovators

The global kinetic footfall energy harvesting marketis shaped by both well-established companies and emerging players offering niche technologies. Leading participants include:

Pavegen – A pioneer in human-powered smart flooring

EnOcean GmbH – Specializing in self-powered IoT sensor solutions

Energy Floors – Creators of interactive kinetic floors for public engagement

Freevolt Technologies Limited – Innovators in RF and kinetic energy hybrid solutions

POWERleap Inc. – Known for energy-generating floor tiles

EnOcean Alliance – A collective promoting interoperability standards for energy harvesting tech

Piezoelectric Technology Inc. – Advanced materials for high-output footfall applications

Voltree Power Inc. – Specializing in alternative renewable sources including kinetic applications

Strategic Outlook: Accelerating Toward Smart, Self-Powered Environments

The global Kinetic Footfall Energy Harvesting and Security market is transitioning from experimental deployment to mainstream integration. With the convergence of urban planning, environmental responsibility, and smart technology, this market will serve as a foundation for decentralized, responsive, and intelligent energy systems of the future.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40424-global-kinetic-footfall-energy-harvesting-market

Conclusion

We are entering a transformative era where energy from human movement is no longer a conceptual novelty but a critical component of sustainable infrastructure. With advanced technology, strategic applications, and unwavering global demand, the kinetic footfall energy harvesting market stands as a cornerstone in the renewable energy revolution. The next generation of smart cities will not just be powered by the sun or wind—but by the very steps we take.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Hi, before I explain my post, I want to say something important.

• What you see my blog has become a major overhaul. And despite the changes, I decided that my 2nd account will be now my artwork blog with a secret twist.

⚠️NEW RULE! (W/ BIGGER TEXT!)⚠️

⚠️ SO PLEASE DO NOT SHARE MY 2nd ACCOUNT TO EVERYONE! THIS SECRECY BLOG OF MINE IS FOR CLOSES FRIENDS ONLY!⚠️

• AND FOR MY CLOSES FRIENDS, DON’T REBLOG IT. INSTEAD, JUST COPY MY LINK AND PASTE IT ON YOUR TUMBLR POST! JUST BE SURE THE IMAGE WILL BE REMOVED AND THE ONLY LEFT WAS THE TEXT.

⚠️ SHARING LINKS, LIKE POSTS, REBLOG POSTS, STEALING MY SNAPSHOT PHOTOS/RECORDED VIDEOS/ARTWORKS (a.k.a. ART THIEVES) OR PLAGIARIZING FROM UNKNOWN TUMBLR STRANGERS WILL IMMEDIATELY BE BLOCKED, RIGHT AWAY!⚠️

😡 WHATEVER YOU DO, DO NOT EVER LIKED & REBLOG MY SECRET POST! THIS IS FOR MY SECRET FRIENDS ONLY, NOT YOU! 😡

Okay? Capiche? Make sense? Good, now back to the post…↓

No #OnThisDay throwback post, only exclusive for super secret blog(s) albeit re-post. Instead, I have this!

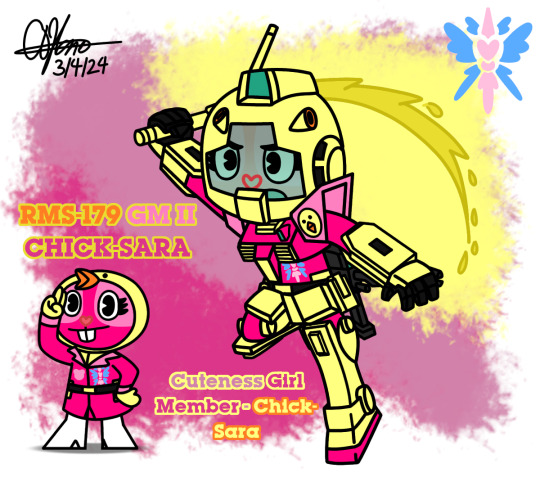

Title: Cuteness Girl Member - Chick-Sara

Hello, April! 🎗️🧩 Here's my "Secret Art Trade" for my good 'ol G-Pal, rafacaz4lisam2k4. 🇬🇹🙂

• I'm still thinking about Ricky's (another rafacaz4lisam2k4's HTF OC) first "Cuteness Mecha Armor", soon. But, in the mean time, let's meet "Chick-Sara" 🐤🐿️, an adorable chipmunk HTF OC (owned by his) in chick's clothing. And by that, I meant the yellow baby chicken (not a female slang word 🙄😒). I was gonna give her a Zeon's armored "Zaku" series ❌, but look how innocent she is that she deserves a Federation's armored "GM" ✔️, instead; "GM II" to be specific. 🤖🙂

BTW: Don't worry, though, there will be more members that will fitted in Zeon's armored Zaku for the selected "Cuteness Members", someday to make balance out. 😉

GM II Chick-Sara Based on the: RMS-179 GM II [CLICK ME!]

Armament(s):

60mm Vulcan Gun • A pair of shell-firing armament built into the helmet. Low offensive power, only used to restrict enemy movement, and lay down a wall of suppressive fire due to their rapid fire capability.

Beam Saber • The beam saber is a small device held in the armor's hands when deployed and is powered by a rechargeable energy capacitor. It emits high-energy Minovsky particles to form a blade-shaped I-field (via manipulation of electromagnetic fields), and then fills this I-field shell with superheated Minovsky particle plasma to produce an effective cutting blade. Like the GM, the GM II has one beam saber stored on its backpack, but features an improved blade generator unit.

BOWA·BR-S-85-C2 Beam Rifle • A portable firearm that shoots out mega particles beams. It has a power rating of 1.9 MW and is powered by a built-in energy CAP system.

BLASH HB-L-07/N-STD Hyper Bazooka • An improved model of the HB-L-03/N-STD Hyper Bazooka with added targeting sensors, increasing its accuracy. The magazine has also been changed to be completely sealed/airtight, and this not only makes exchanging magazine easier, but also protects against debris intrusion, accidental explosion due to being hit, etc. Additionally, no special attention needs to be paid to the weapon during operation as the rigidity of the rib section connecting the carrying handle to the bazooka's rear has been enhanced.

HWF GMG·MG79-90mm Bullpup Machine • The bullpup machine gun was a system weapon developed as a Space/Ground dual-use projectile weapon. Though compact, it has sufficient anti-MS firepower while maintaining accuracy. Its muzzle velocity is increased due to the use of new gunpowder and this enables it to easily penetrate the armor of Zeon's. A box-like sensor system incorporating a video camera and laser sensor is installed at the top, and when this system is used alongside the GM II's targeting system, target acquisition capability is enhanced.

HFW-GR·MR82 90mm GM Rifle • A portable, mobile suit-use 90mm rifle built based on the 'system weapon' structure, its effective range and accuracy is superior to the HWF GMG·MG79-90mm machine gun. With the extended barrel, the GM Rifle sees a 15% increase in muzzle velocity, leading to increased armor penetration capability. Additionally, a newly developed caseless cartridge allows for a lightened ammunition load.

YHI YF-MG100 100mm Machine Gun • First utilized by Federation's armor ground forces during the One Year War, its use became less common after the war as the Federation switched to 90mm caliber weaponry. Equipped with a box magazine and folding stock, it has excellent rate of fire and is easy to wield. It utilized a smoothbore type barrel that lacked rifling and has to be replaced after firing 3000 rounds. The weapon could utilize three different types of ammunition: HEAT (High Explosive Anti Tank), APFSDS (Armor-Piercing Fin-Stabilized Discarding-Sabot), and HESH (High Explosive Squash Head), allowing combat units to select the appropriate type to meet operational needs.

Bazooka • A portable, physical projectile-type firearm, this general purpose bazooka was used by the armored Jegan and other Earth Federation Forces' armors. A spare ammunition cartridge is mounted in front of the bazooka's grip, and the weapon is compatible with various types of warhead. Despite the relatively slow speed of the bazooka's projectiles, they have sufficient destructive power to deal critical damages to an armor.

M-120A1 120mm Machine Gun • The same portable firearm used by the Zaku II. It can switch between semi-automatic and automatic fire. Although useless against Luna Titanium Alloy, it can still destroy weaker armor material with multiple shots. It fires 120mm caliber rounds that are stored in a 100-rounds drum magazine.

Harpoon Gun • A projectile weapon designed for amphibious combat. The harpoon gun fires four harpoons one by one in a rotary manner similar to a revolver. The tip of each harpoon is loaded with explosives that detonate once the projectile has penetrated the enemy's armor.

YHI ERRL-TYPE.Doc-04/380mm Rocket Launcher • A portable large rocket launcher meant for armor, it is independently developed by Yashima Heavy Industries for use specifically in 1G environment. Also known as Hyper Bazooka (Ground Type), it has a very versatile design with features that include targeting sensors, etc. It uses a banana-shaped magazine and has a short barrel to facilitate its use in jungle/forested areas. This weapon can utilize a number of different munitions including warheads that deploy stabilizing fins after launch, and this shows that its design took many references from human-sized ground weaponry used in older eras.

YHI YF-RC180 Railcannon • A weapon that uses electromagnetic forces, rather than gunpowder, to fire solid projectiles at very high velocities. Manufactured by Yashima Heavy Industries. This equipment was developed in consideration of the problems that the early beam weapons had decreased power due to attenuation in the atmosphere, and the basic structure is diverted from a battleship's main gun. It was first used by the armor (RGM-79F) Land Combat Type GM.

170mm Cannon • A successor to the 180mm Cannon developed during the early stages of the One Year War. Although the caliber of the shell was reduced to improve handling, its range and power have been increased. The cannon's trigger grip is mounted at the top surface, and a foregrip can be used to stabilize the weapon when in use. Like the 180mm cannon, the 170mm cannon was fed by a magazine: though this time it was underneath the cannon.

BR-87A Beam Rifle • The same beam rifle model as the one used by the Marasai and Hizack. It is powered by a replaceable e-pac and is power rated at 2.2 MW.

FADEGEL RGM-M-Sh-003 Shield • A basic defensive armament used by the Federation's GM type MS. It is composed of a triple honeycomb structure made of Luna Titanium and the surface also has anti-beam coating for defending against beam attacks.

FADEGEL RGM-M-Sh-007 Shield • An improved model of the RGM-M-Sh-003. It has the exact same size as its predecessor, but its material was changed to Titanium-Ceramic composite. Its mount latch was made movable, allowing the shield to be positioned up or down when carried by a Mobile Suit manipulator or mounted on the forearm, increasing its usability.

RGM*S-Sh-WF/S-00109 Shield • The GM II can also use the same forearm-mounted shield as the armor G-Ground Type and GM Ground Type. This small, light shield is constructed of Luna Titanium alloy, and is designed to primarily protect the cockpit and other critical areas. Additionally, it can be used as a close-range striking weapon in C.M.A. (Cuteness Mecha Armor) combat. Furthermore, through lodging the spikes at the tip into the ground, the shield can serve as a free-standing frontal defense. This also allows the mobile suit to use both hands to hold large-caliber weaponry and maintain a stable firing position.

Special Equipment(s)/Features:

Ballute System • An atmospheric entry device designed to be used by a multitude of different mobile suit models. As the mobile suit enters the atmosphere, a bowl-shaped ballute (balloon parachute) deploys to protect it from the friction heat of atmospheric entry. The balloon then detaches, leaving the armor with chest and leg hover units which ease its descent to the ground. If the mobile suit reaches the ground without expending all the fuel in the leg units, these devices can also be used for hovering and high-speed strike missions.

Chick-Sara (HTF OC) - owned by rafacaz4lisam2k4 Armor (Mobile Suit Gundam - Universal Century Timelines) - Gundam series © Bandai Namco Filmworks, Inc. (SUNRISE), Sotsu

2 notes

·

View notes

Text

Fault Analysis of Industrial Pressure Sensors

In modern industrial automation control systems, industrial pressure sensors are used in process sections that require pressure monitoring. They collect signals or serve as feedback signals to monitor and regulate process flows, enabling safe and orderly management and control.

Due to variations in process media characteristics and application conditions, it’s important to analyze the causes of pressure sensor failures by combining an understanding of their measurement principles with actual field usage.

Types of Industrial Pressure Sensors:

Piezoresistive Pressure Transmitter

This type uses semiconductor pressure-sensitive materials. When pressure is applied, the resistivity of the material changes due to the piezoresistive effect, causing a voltage signal proportional to the pressure to be generated in a Wheatstone bridge circuit. This voltage signal reflects the change in pressure.

Capacitive Pressure Transmitter

This type uses a measuring diaphragm and electrodes placed on both sides of insulating plates to form capacitors. The measured medium applies two different pressures through the high- and low-pressure chambers, acting on the isolation diaphragms on either side of the sensing element. The diaphragm deforms depending on the pressure difference, causing changes in capacitance. These changes are converted into signals readable by a controller through oscillation and demodulation circuits.

Inductive Pressure Transmitter

Typically composed of a pointer-type pressure gauge and an electronic remote transmission unit. When pressure causes the Bourdon tube in the gauge to deform, the iron core inside an inductive coil also shifts position, changing the inductance. This inductance change is then converted into a DC current or voltage signal.

Strain Gauge Pressure Transmitter

This type also measures pressure by converting it into a change in resistance. Two strain gauges are glued axially and radially to a strain cylinder using a special adhesive. When the cylinder is compressed, the strain gauges deform, altering their resistance. Unlike the piezoresistive type, the strain gauge method involves a physical change in the shape of the strain material.

Industrial Pressure Sensor Failures

Abnormal Pressure Readings

Abnormal pressure readings are one of the most common faults in industrial pressure sensors. In addition to typical issues such as zero drift and range shift, other potential causes include component failure, sensor malfunction, wiring issues, electromagnetic interference, and problems with the pressure or capillary tubing. Each of these factors should be systematically inspected and ruled out during troubleshooting.

Component Damage

It’s important to consider whether the fault was caused by lightning strikes, overvoltage, incorrect wiring, or cable damage resulting in short circuits or open circuits. If inspection confirms that any electronic components are burnt out or physically damaged, they must be replaced promptly. It’s also critical to check whether the instrument’s grounding system is functioning correctly and carry out any necessary repairs or maintenance.

Special attention should be paid to possible water ingress, which can cause corrosion of internal electronic components. This often results from poor sealing at the cable entry point or aging of the transmitter’s sealing ring. In such cases, damaged components should be replaced, and proper sealing and routine inspection of the transmitter should be ensured.

Sensor failure.

The diaphragm of the diaphragm pressure transmitter will condense on the diaphragm due to the crystallization of the medium, or the medium contains blocky solids that impact the diaphragm for a long time, causing the diaphragm to deform and damage, affecting the measurement.

Line failure.

Line failure is generally internal wiring, which can be checked by measuring resistance and voltage with a multimeter. Perform wiring operations according to the pressure transmitter manual to ensure the correct connection of the line.

Electromagnetic interference.

This type of failure is generally difficult to troubleshoot, but it occurs very frequently. Avoid running the signal cable of the instrument in parallel with the electrical high-voltage signal cable, otherwise it is easy to cause signal interference, resulting in communication errors, inaccurate measurement values, and other problems. The pressure transmitter should also be installed away from locations with strong magnetic/electric fields or strong vibration sources.

Pressure pipe and capillary problems

Pressure pipe problems usually occur due to the characteristics of the medium, non-clean medium, or medium with high viscosity, which causes the pressure pipe to be blocked and cannot feedback the accurate pressure value. Or the pressure pipe leaks due to long-term use, resulting in inaccurate measurement. In this case, the pressure pipe should be replaced in time and regular cleaning and maintenance should be done. Capillary problems may occur due to inaccurate selection of pressure oil temperature resistance. In low temperature conditions, it is necessary to select appropriate pressure oil to avoid the phenomenon of pressure oil solidification due to low temperature. Similarly, it is necessary to pay attention to the high temperature and avoid the pressure oil vaporization.

Abnormal display screen of industrial pressure sensor

(1) The instrument cannot display. First, it is necessary to check whether the voltage at both ends of the instrument is normal. If the voltage is abnormal, it is necessary to check whether the signal circuit is virtual or disconnected;

(2) The instrument display is abnormal. After correct wiring, adjust the pressure within the range of the industrial pressure sensor and observe the changes in the pressure display value to determine whether the display screen is faulty.

If the flow signal output is abnormal, it is necessary to use professional measuring instruments to perform the following inspections:

(1) Check whether the input and output lines of the transmitter are short-circuited, whether the cable is damaged, and whether the component wiring is wrong or reversed;

(2) Measure whether the power supply voltage of the transmitter meets 24 V, and simultaneously check the signal line problem, whether there is interference or voltage attenuation due to long distance. If there is attenuation, consider replacing the thick wire cable to solve it;

(3) It is necessary to confirm whether the range of the instrument and the actual measured value are consistent with the parameters of the acquisition device; whether the acquisition device is intact.

Through the above analysis, common fault problems of industrial pressure sensor can be effectively solved. Of course, the actual fault conditions are varied, and solving the problems also requires specific analysis based on the specific situation, identifying the problem, analyzing the cause and taking corresponding measures.

0 notes

Text

Anechoic Chambers | RF Shield Rooms & RF Absorbers in Europe | DMCRF

In today’s technology-driven world, precision in electromagnetic testing is not optional—it’s essential. That’s why engineers, researchers, and product developers across Europe trust DMC for state-of-the-art anechoicchambers that deliver unmatched accuracy. From RF testing to EMC compliance, DMC has carved a niche with chambers designed to eliminate external noise and internal reflections, providing a controlled environment that ensures test results are reliable, repeatable, and industry-compliant.

What Is an Anechoic Chamber?

An anechoic chamber is a specialized space built to absorb sound or electromagnetic waves, creating a “free-field” environment. This means the chamber is isolated from external interference and internal echo, making it ideal for applications like antenna testing, radar measurements, and electronic interference analysis.

These chambers are designed with wedge-shaped absorbers made from high-performance foam or ferrite, depending on the frequency range. The goal? Simulate open-space conditions without the variables found in real-world environments.

Why DMC Anechoic Chambers Are a Step Ahead

DMC has been delivering custom-engineered anechoicchambers for a wide range of industries, including aerospace, telecom, defense, automotive, and consumer electronics. Their designs are not just scientifically advanced—they’re practical, modular, and scalable.

Here’s why professionals choose DMC:

✅ Tailor-Made Designs: Every chamber is built to your specific frequency range, size constraints, and application goals.

✅ Superior Absorption Materials: Uses premium carbon-loaded foam and ferrite tiles to minimize internal reflections.

✅ Precision Shielding: Each unit features high-grade RF shielding to block external interference.

✅ Modular Build: Easy to install, relocate, or expand as your requirements grow.

✅ Standards Compliance: Built to meet CISPR, IEEE, and MIL-STD guidelines.

✅ Turnkey Service: From design consultation to final installation, DMC manages every step.

✅ Global Support: Reliable after-sales service and maintenance, even after project completion.

Applications of Anechoic Chambers Across Industries

DMC’s anechoicchambers support a wide variety of use cases. Here's how different industries leverage these cutting-edge chambers:

Telecommunications

Testing antennas, 5G devices, routers, and wireless modules

Evaluating signal behavior in a reflection-free zone

Aerospace & Defense

Radar cross-section (RCS) analysis

Secure communication system testing

Military-grade RF equipment development

Automotive

EMC compliance for electric vehicles and onboard systems

Testing radar and LiDAR sensors used in autonomous driving

Consumer Electronics

Bluetooth, Wi-Fi, and smart home devices

Smartphones, tablets, wearables

Each application benefits from the low-noise, zero-reflection environment that DMC chambers consistently deliver.

The Science of Silence: How DMC Builds Anechoic Chambers

What sets DMC apart is their deep technical understanding and ability to execute highly specialized builds. Their chambers are developed in three major formats:

RF Anechoic Chambers: Designed for electromagnetic and radio frequency testing.

Acoustic Anechoic Chambers: Built to absorb sound reflections, ideal for microphone, speaker, or audio system testing.

Hybrid Chambers: A blend of both, for devices that require combined testing.

Key construction elements include:

Wedge Geometry Design: Optimized to absorb targeted frequencies effectively.

High-Density Shielding Panels: Ensures electromagnetic isolation.

Non-Reflective Floors: Options available based on testing type.

Ventilation & Lighting: Carefully engineered not to compromise chamber performance.

DMC’s expert team ensures that each element serves a functional role while maintaining ease of access for operators.

Real-World Benefits of Using Anechoic Chambers

Installing an anechoic chamber might seem like a big investment, but the return in terms of data reliability, reduced product recalls, and faster certification is invaluable.

Key benefits include:

Accurate Measurements: With no reflection or interference, readings are more precise.

Faster R&D Cycles: Get real results in a controlled setting without repeated field tests.

Market Readiness: Speed up compliance testing for CE, FCC, or other regulatory certifications.

Innovation Boost: Focus on innovation without second-guessing your testing environment.

For companies developing cutting-edge technologies, having access to a chamber means staying ahead of the curve.

DMC: Your Trusted Partner in Precision Testing

With years of experience and a long list of successful installations across Europe, DMC isn’t just another supplier—they’re a reliable partner committed to your success. From concept and simulation to installation and service, every DMC project is backed by engineering expertise and a passion for performance.

Their clients include major research institutions, private R&D labs, defense contractors, telecom firms, and automotive manufacturers. Whether you need a small benchtop unit or a large walk-in setup, DMC delivers custom-engineered solutions that exceed expectations.

Final Thoughts

In today’s highly competitive and tech-forward industries, precision is everything. Testing environments must be as advanced as the devices being tested. With DMC’s anechoicchambers, you’re not just getting a room—you’re investing in accuracy, efficiency, and innovation. Whether you're working with wireless tech, radar, or automotive sensors, DMC ensures your results are as clear and interference-free as possible.

Contact us:

Visit: https://dmcrf.eu/

Call: +49 15 23 8483618

0 notes

Text

Global Electromagnetic Grippers Market Trends and Competitive Landscape 2025–2032

The global Electromagnetic Grippers Market size was valued at US$ 167 million in 2024 and is projected to reach US$ 243 million by 2032, at a CAGR of 4.7% during the forecast period 2025-2032. While the vacuum grippers segment is growing faster at 36.2% CAGR, electromagnetic variants remain crucial for ferrous material handling applications.

Electromagnetic grippers are industrial automation components that use controlled magnetic fields to securely grasp ferrous materials without physical contact. These devices operate through precisely engineered coils that generate temporary electromagnetic fields when energized, enabling efficient material handling in manufacturing, logistics, and robotic applications. Key variants include permanent magnet, electro-permanent magnet, and switched electromagnet types.

The market growth is primarily driven by increasing automation in automotive manufacturing and expanding e-commerce logistics operations. Asia Pacific dominates with 60% market share due to concentrated manufacturing activity, while North America and Europe account for 15% and 19% respectively. Recent technological advancements include smart grippers with integrated sensors from companies like SMC and Zimmer, enhancing precision in Industry 4.0 applications. Major players are expanding their portfolios through strategic partnerships, such as FIPA’s 2023 collaboration with a Japanese robotics firm to develop next-generation magnetic handling solutions.

Get Full Report with trend analysis, growth forecasts, and Future strategies : https://semiconductorinsight.com/report/electromagnetic-grippers-market/

Segment Analysis:

By Type

Electromechanical-driven Vacuum Grippers Segment Leads Due to Enhanced Precision and Efficiency in Industrial Automation

The market is segmented based on type into:

Compressed Air-type Vacuum Grippers

Electromechanical-driven Vacuum Grippers

By Application

Manufacturing Segment Dominates with High Utilization in Assembly Lines and Material Handling

The market is segmented based on application into:

Manufacturing

Logistics

Others

By End User

Industrial Automation Sector Holds Significant Share Due to Rising Demand for Smart Manufacturing Solutions

The market is segmented based on end user into:

Automotive

Electronics

Aerospace

Food Processing

Others

Regional Analysis: Electromagnetic Grippers Market

North America The North American electromagnetic grippers market benefits from advanced manufacturing automation and significant investments in Industry 4.0 technologies. The United States dominates regional demand due to its robust automotive and aerospace sectors where magnetic grippers are widely used for material handling. Automotive OEMs and Tier-1 suppliers account for approximately 42% of regional demand, driven by the need for precision handling of ferrous components. Canada shows steady growth with increasing adoption in metal fabrication industries. Strict workplace safety regulations (OSHA standards) further propel the market as electromagnetic grippers reduce manual handling risks. However, high initial costs and limited applicability to non-ferrous materials restrain wider adoption.

Europe Europe represents a mature market characterized by stringent industrial safety standards and strong automation adoption across Germany, France, and Italy. Germany alone contributes nearly 35% of regional revenue due to its concentrated manufacturing base. The market benefits from EU directives promoting worker safety and energy-efficient automation solutions. Scandinavian countries lead in innovative applications, particularly in heavy industries like shipbuilding and wind turbine manufacturing. While Western Europe shows steady growth, Eastern European markets are catching up with increasing FDI in automotive manufacturing hubs. The region faces challenges from the gradual phasing out of traditional manufacturing processes in favor of more versatile robotic systems.

Asia-Pacific As the largest and fastest-growing market, Asia-Pacific is expected to maintain over 50% global market share through 2030. China’s dominance stems from its massive electronics and automotive sectors, where electromagnetic grippers streamline production lines. Japan and South Korea follow closely with advanced robotics integration in precision manufacturing. India emerges as a high-growth market with its “Make in India” initiative boosting industrial automation. Southeast Asian nations show increasing adoption in electronics assembly. While cost sensitivity drives demand for entry-level solutions, regional manufacturers are increasingly investing in smart grippers with IoT capabilities to enhance Industry 4.0 readiness.

South America The South American market remains relatively small but shows potential in Brazil’s automotive sector and Argentina’s agricultural equipment manufacturing. Economic instability and limited industrial automation budgets constrain market growth, with many manufacturers preferring mechanical alternatives. However, mining equipment applications present niche opportunities for heavy-duty electromagnetic grippers. The lack of local manufacturing necessitates imports, making grippers cost-prohibitive for smaller operations. Recent trade agreements could improve access to advanced automation technologies if economic conditions stabilize.

Middle East & Africa This region demonstrates uneven growth patterns, with Gulf Cooperation Council (GCC) countries leading in automation adoption for oil/gas and construction equipment manufacturing. South Africa shows moderate demand from mining and automotive sectors. Infrastructure limitations and reliance on oil revenues create market volatility. While the UAE invests heavily in smart manufacturing initiatives, wider regional adoption lags due to limited technical expertise and preference for traditional material handling methods. Future growth hinges on economic diversification efforts and increasing foreign manufacturing investments in special economic zones.

MARKET OPPORTUNITIES

Emerging Applications in Renewable Energy Sector

The rapid expansion of renewable energy infrastructure is creating new application opportunities for electromagnetic gripping technology. Wind turbine manufacturing presents particularly promising prospects, as electromagnetic grippers demonstrate superior performance in handling large ferrous components throughout the production process. Industry projections suggest the renewable energy sector could account for over 15% of electromagnetic gripper sales within the next five years.

Advancements in Smart Gripping Technologies

The integration of IoT capabilities and predictive maintenance features into electromagnetic grippers is opening new market segments. These intelligent systems can monitor their own performance, predict maintenance needs, and optimize gripping parameters automatically. Manufacturers introducing these enhanced models report 30-40% reductions in unplanned downtime, making them attractive for mission-critical operations.

Furthermore, ongoing material science innovations are expected to expand the range of compatible workpieces, potentially addressing one of the technology’s traditional limitations.

ELECTROMAGNETIC GRIPPERS MARKET TRENDS

Automation and Industry 4.0 Driving Adoption of Electromagnetic Grippers

The rapid advancement of industrial automation and the widespread adoption of Industry 4.0 principles are significantly boosting the demand for electromagnetic grippers. These devices, capable of handling ferrous materials with high precision and reliability, have become indispensable in smart factories. Unlike traditional mechanical grippers, electromagnetic variants eliminate physical wear and tear while maintaining strong holding forces – up to 15 N/cm² in modern models. The growing shift toward contactless gripping solutions across automotive and electronics manufacturing further accelerates market expansion. Major industrial robot manufacturers are increasingly integrating electromagnetic grippers into collaborative robot (cobot) systems, creating new growth avenues.

Other Trends

Logistics Automation Boom

Automated warehouses and material handling systems are driving substantial demand for electromagnetic grippers in logistics applications. With the global warehouse automation market projected to grow at 14% CAGR, the need for reliable ferrous material handling solutions has intensified. Electromagnetic grippers offer distinct advantages in palletizing, sorting, and transfer operations – particularly where rapid switching between objects is required. Recent innovations in power-efficient electromagnets that consume 30-40% less energy than conventional models are making them more viable for continuous operation in distribution centers.

Technological Advancements in Magnetic Systems

The electromagnetic gripper market is witnessing remarkable improvements in core technologies. Next-generation models feature self-regulating magnetic circuits that automatically adjust holding force based on load requirements, significantly improving energy efficiency. Development of hybrid systems combining permanent and electromagnetic elements allows for fail-safe operation – critical in aerospace and medical device manufacturing applications. The introduction of smart grippers with embedded sensors provides real-time feedback on grip status and part positioning, enabling better integration with automated quality control systems. These innovations are helping overcome traditional limitations like heat generation and inconsistent performance with uneven surfaces.

COMPETITIVE LANDSCAPE

Key Industry Players

Manufacturers Focus on Technological Advancements to Gain Competitive Edge

The global electromagnetic grippers market features a moderately fragmented landscape, with established automation solution providers competing alongside specialized magnetic technology firms. SMC Corporation emerges as a dominant player, leveraging its extensive distribution network and diversified portfolio across pneumatic and electromagnetic handling solutions. The company’s stronghold in Asia-Pacific, which accounts for approximately 60% of global demand, reinforces its market leadership position.

FIPA GmbH and PHD Inc. have demonstrated significant growth in the industrial automation segment, particularly through their customized gripper solutions for automotive manufacturing. These companies benefit from rising adoption in automotive production lines, where electromagnetic grippers enable precise handling of metal components without surface contact.

Notably, several mid-sized players are gaining traction through niche specialization. Braillon Magnetics has carved a strong position in heavy-load applications, while Zimmer Group focuses on high-precision solutions for electronics manufacturing. Such strategic positioning allows these companies to compete effectively against larger conglomerates in specific application segments.

Market consolidation appears imminent as major players expand through acquisitions and partnerships. Recent industry movements include SMC’s 2023 acquisition of a German automation specialist, strengthening its European foothold. Meanwhile, Asian manufacturers like DH-Robotics are investing heavily in R&D to develop energy-efficient grippers with embedded IoT capabilities, anticipating future smart factory requirements.

List of Key Electromagnetic Gripper Companies Profiled

SMC Corporation (Japan)

FIPA GmbH (Germany)

PHD Inc. (U.S.)

Compact Automation (U.S.)

Niryo (France)

HitBot (China)

HVR MAG (U.S.)

DH-Robotics (China)

Femag Engineering Machinery (Germany)

Binar Handling (Netherlands)

Braillon Magnetics (France)

Pascal Corporation (Japan)

Zimmer Group (Germany)

Smaat Techniques (India)

Pietro Fiorentini (Italy)

Learn more about Competitive Analysis, and Forecast of Global Electromagnetic Grippers Market : https://semiconductorinsight.com/download-sample-report/?product_id=103032

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Electromagnetic Grippers Market?

-> Electromagnetic Grippers Market size was valued at US$ 167 million in 2024 and is projected to reach US$ 243 million by 2032, at a CAGR of 4.7% during the forecast period 2025-2032.

Which key companies operate in Global Electromagnetic Grippers Market?

-> Key players include SMC, FIPA, Zimmer, Braillon Magnetics, HVR MAG, and PHD, among others.

What are the key growth drivers?

-> Key growth drivers include rising automation in manufacturing, expansion of logistics infrastructure, and demand for contactless material handling solutions.

Which region dominates the market?

-> Asia-Pacific holds the largest market share (60%), driven by manufacturing growth in China and Japan.

What are the emerging trends?

-> Emerging trends include smart grippers with IoT connectivity, energy-efficient designs, and hybrid gripper systems combining multiple technologies.

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 +91 8087992013 [email protected]

0 notes

Text

Handheld Counter IED Market Size, Share & Trends Analysis Report 2025–2033

The global handheld counter IED market size was estimated at USD 3.25 billion in 2024 and is projected to reach USD 5.39 billion by 2033, growing at a CAGR of 6.0% from 2025 to 2033. This growth is largely driven by the increasing prevalence of global insurgencies and asymmetric warfare, which have heightened the need for portable threat detection solutions.

The rise in asymmetric conflicts and insurgency-driven violence has notably boosted the demand for handheld counter-IED systems. Non-state groups and terrorist organizations are increasingly using low-cost, improvised explosive devices to target military personnel and civilians alike. These threats are especially common in unstable regions such as the Middle East, South Asia, and parts of Africa, where military forces frequently encounter unpredictable and dangerous IED attacks.

In response, governments and military forces are focusing on equipping their personnel with rapid-deployment, portable detection tools. Handheld counter-IED devices enable users to quickly scan suspicious objects, vehicles, and areas in real time, which helps reduce reaction times and enhances safety for troops and civilians operating in high-risk environments.

Key Market Trends & Insights:

• In 2024, North America held a significant portion of the handheld counter-IED market, accounting for 38.1% of the total global market share. Within this region, the United States stood out as the dominant player in the handheld counter-IED industry, maintaining a leading position throughout the year.

• When looking at the market by product type, the portable detectors segment emerged as the largest contributor, capturing 47.6% of the market share in 2024. This highlights the preference and demand for easily transportable devices that can be deployed quickly in various field conditions.

• Regarding detection technologies, the electromagnetic field detection segment led the market by holding the largest share in 2024. This technology is favored for its effectiveness in identifying hidden explosive devices through the detection of disturbances in electromagnetic fields.

• By application, the military sector dominated the handheld counter-IED market in 2024, underscoring the critical role these systems play in defense operations to counteract threats posed by improvised explosive devices on the battlefield.

Order a free sample PDF of the Handheld Counter IED Market Intelligence Study, published by Grand View Research.

Market Size & Forecast:

• 2024 Market Size: USD 3.25 Billion

• 2033 Projected Market Size: USD 5.39 Billion

• CAGR (2025-2033): 6.0%

• North America: Largest market in 2024

• Asia Pacific: Fastest market in 2024

Key Companies & Market Share Insights:

Several key companies are leading the handheld counter-IED market, including Chemring Group PLC, L3Harris Technologies Inc., Smiths Detection, FLIR Systems, and others. To strengthen their competitive position and broaden their market presence, these major players are actively engaging in strategic initiatives such as mergers, acquisitions, and forming partnerships with defense contractors, law enforcement agencies, and research institutions. These collaborations allow companies to advance their technological offerings by integrating features like multi-sensor systems, AI-powered threat analysis, and real-time communication capabilities into their handheld devices.

Chemring Group PLC is a notable participant in the handheld counter-IED market, providing sophisticated explosive detection and electronic countermeasure technologies designed specifically for defense and security purposes. With a strong background in military-grade sensing solutions, Chemring’s handheld devices are engineered to identify a broad spectrum of threats, including buried improvised explosive devices (IEDs), command-wire triggered devices, and pressure plate triggers.

L3Harris Technologies Inc. distinguishes itself in the handheld counter-IED market through its cutting-edge sensor fusion and portable detection technologies. Drawing on its extensive expertise in aerospace, defense, and tactical communications, L3Harris offers compact, high-sensitivity handheld products such as the Fido series, which facilitate quick and precise detection of trace explosives, thereby enhancing operational effectiveness in threat environments.

Key Players

• L3Harris Technologies, Inc.

• Chemring Group PLC

• Smiths Detection

• FLIR Systems

• Raytheon Technologies

• Lockheed Martin Corporation

• Northrop Grumman Corporation

• Thales Group

• BAE Systems PLC

• Elbit Systems Ltd

Explore Horizon Databook – The world's most expansive market intelligence platform developed by Grand View Research.

Conclusion:

The handheld counter-IED market is experiencing strong growth driven by increasing global insurgency and asymmetric warfare. Rising threats from improvised explosive devices used by non-state actors and terrorists are prompting governments and armed forces to prioritize portable, rapid-response detection technologies. Advances in sensor integration, AI, and real-time communication are enhancing the effectiveness of handheld counter-IED systems, supporting improved safety and operational efficiency in volatile regions.

#Handheld Counter IED Market#Handheld Counter IED Market Size#Handheld Counter IED Market Share#Handheld Counter IED Market Analysis

0 notes

Text

RF Shielded Microwave Chambers |DMCRF

In today’s fast-paced world of wireless communication and electronic product development, achieving precision in RF and EMC testing is non-negotiable. That’s why RF Shielded Microwave Chambers have become a critical part of modern test infrastructure. At DMCRF, we specialize in providing top-quality RF Chambers Microwave solutions tailored to meet diverse industry standards. As trusted RF Chamber Manufacturers, our products are engineered to offer unmatched performance, shielding effectiveness, and reliability.

What Are RF Shielded Microwave Chambers?

RF Shielded Microwave Chambers are specialized enclosures designed to isolate electromagnetic signals from external interference. These chambers are commonly used in testing environments to evaluate the performance of electronic devices under various radio frequency conditions. Their shielding capability ensures that no external signal can interfere with the testing process, thereby maintaining the accuracy and consistency of test results.

These chambers are widely used in industries such as aerospace, defense, telecommunications, medical devices, and automotive electronics where EMI (Electromagnetic Interference) control is paramount.

Importance of RF Chambers Microwave in Modern Testing

As electronic devices become smaller, faster, and more integrated, the challenges of RF interference continue to grow. This is where RF Chambers Microwave play a crucial role

Accurate EMC & RF Testing: These chambers create a controlled testing environment, free from external RF noise.

Product Certification: Compliance with international standards (like FCC, CE, MIL-STD) often requires device testing inside RF shielded chambers.

R&D and Prototyping: Engineers and designers rely on microwave chambers during product development to analyze performance and troubleshoot interference issues.

At DMCRF, our RF shielded microwave chambers are meticulously designed to handle such advanced testing requirements with high precision.

Why Choose DMCRF as Your RF Chamber Manufacturer?

As one of the leading RF Chamber Manufacturers, DMCRF brings decades of experience and innovation to the field of microwave chamber technology. Here’s what sets us apart:

1. Custom Engineering Solutions

We understand that every project has unique challenges. Whether you require a compact bench-top chamber or a large walk-in microwave test facility, DMCRF offers tailor-made solutions built to your exact specifications.

2. Superior Shielding Effectiveness

Our chambers deliver exceptional shielding levels across a broad frequency range. We use state-of-the-art materials and manufacturing processes to ensure minimal signal leakage and optimal test reliability.

3. Compliance & Certification

All our microwave RF chambers comply with international EMC and RF testing standards, making your product certification process smoother and faster.

4. Support & Integration

From design consultation to final installation, DMCRF offers complete end-to-end support. Our team works closely with your engineers to ensure seamless integration with existing test setups and instruments.

Applications of RF Shielded Microwave Chambers

Microwave RF chambers are not limited to one industry. Here are some major use cases where DMCRF’s solutions make a difference:

Wireless Communication Devices: Testing antennas, routers, mobile phones, and IoT devices for performance under RF load.

Automotive Systems: Verifying electronic control units (ECUs) and sensors for EMI resilience.

Medical Electronics: Ensuring patient safety by testing pacemakers, infusion pumps, and other sensitive equipment.

Defense and Aerospace: Testing radar systems, communication modules, and navigation devices in highly controlled environments.

Consumer Electronics: Pre-compliance and functional testing of laptops, smart devices, and wearables.

Technological Features of DMCRF Chambers

At DMCRF, our RF Chambers Microwave are equipped with advanced features that support the latest testing demands:

Modular Design: Easy to assemble, expand, or reconfigure.

Honeycomb Waveguide Vents: Provide ventilation while maintaining shielding integrity.

RF Absorbers: Minimize internal reflections for anechoic testing.

Filtered Power and Data Lines: Ensure power and signal integrity during tests.

Anechoic Foam Lining: Optional upgrades for high-frequency and OTA testing environments.

What to Consider When Choosing an RF Shielded Microwave Chamber

Before purchasing an RF chamber, consider the following factors:

Frequency Range Requirements: Ensure the chamber can shield against all relevant frequencies.

Chamber Size: Choose a size that accommodates your devices and test setup comfortably.

Shielding Performance: Higher dB ratings offer better isolation.

Connectivity Needs: Consider filtered ports, RF connectors, and internal power options.

Budget vs. Customization: Decide between off-the-shelf and custom-built chambers based on your budget and test needs.

DMCRF’s team is always ready to guide you through these decisions with expert advice.

Sustainability & Quality Standards

DMCRF is committed to quality, sustainability, and ethical manufacturing. Our RF chamber production follows strict quality control protocols to ensure consistent performance. We also use eco-friendly materials wherever possible and adopt energy-efficient processes in our manufacturing facilities.

Conclusion: Invest in Performance with DMCRF

Whether you're in product development, certification, or academic research, having the right testing environment is vital. RF Chambers Microwave from DMCRF are designed to provide the perfect balance of isolation, functionality, and reliability. As trusted RF Chamber Manufacturers, we bring a deep understanding of RF shielding technology and a dedication to customer success.

By partnering with DMCRF, you’re not just buying a chamber — you’re investing in a future-proof testing solution built for precision, performance, and peace of mind.

Visit Us: https://www.dmcrf.com/

Call Us :+1(613) 915 5533

0 notes

Text

Quantum Qubit Networks Future of Computing & Communication

Modern technology uses “qubit networks” to describe interconnected systems with “qubits” as key components. Even though “Qubit Network” is used in many technological domains, quantum qubit networks are vital for quantum computing and sensing. The most well-known and current research centres on them. These quantum-based networks do complex tasks beyond traditional computers.

Quantum Qubit Network Architectures and Capabilities

The architecture of interconnected qubits in quantum qubit networks affects their performance. Researchers are studying how topologies affect a system's ability to maintain quantum coherence and provide valuable functionality for sensitive sensing and powerful information processing. This field struggles with environmental decoherence, or the loss of quantum information.

Superconducting Qubit Networks for Sensing and Processing

Superconducting circuits, especially flux qubit circuits, can enable reliable and scalable quantum technologies. Recent research show that qubit arrangement considerably influences their ability to process information and detect magnetic fields.

Effect of Network Topology Research on superconducting flux-qubit networks' linear and cross-shaped designs is crucial. Research shows that cross-shaped networks are more magnetic flux-responsive than linear arrays. The “network effect” and cooperative interactions between core and peripheral qubits in the network cause this enhancement, not merely adding qubits.

The cross-shaped array's connection design is crucial for collective behaviour that boosts sensitivity. Topology impacts magnetic response through qubit inductive coupling.

Computer Methods and Design Criteria

Researchers employed advanced computational methods to study how qubit arrangement affects magnetic response in these networks. Instead of manufacturing devices, accurate diagonalisation was used to model the networks' energy levels and responses to external stimuli.

Linear response theory and exact diagonalisation were employed to characterise dynamic activity, revealing the networks' processing and detection capability. This computational technique explores the design space, finds ideal configurations, and establishes quantitative design criteria for function-oriented superconducting quantum circuits.

Two-purpose: Reservoir Computing and Quantum Sensing Topologically constructed networks are powerful information processors and sensitive electromagnetic sensors.

Quantum sensing: By carefully managing the qubit structure, researchers can increase the system's ability to detect weak electromagnetic signals. Compared to simpler designs, these networks detect external magnetic fields better.

These networks perform well for reservoir computing, which allows direct data analysis in addition to sensing. One physical device can process and detect signal information. By using these qubit arrays' complicated, high-dimensional dynamics to compute directly in the sensor, signal reconstruction and problem-solving are conceivable without additional processing units.

This integration could lead to smaller, more effective quantum devices that solve difficult problems in materials research and medical diagnostics by speeding quantum information processing. Modelling these systems allows rapid prototyping and optimisation, speeding up quantum technology development.

Photon-Linked Qubit Networks

Photonically linked qubit networks, which enable quantum networking, are another key research field. Distributing pairs of entangled qubits among remote quantum processing nodes does this.

Mechanism and Improvement: Each node in these networks uses photon-interacting communication qubits to transfer quantum data. Cavity Quantum Electrodynamics (CQED) increases qubit-photon interactions, enabling advanced protocols.

Performance Advantages: Researchers are studying these protocols' speed and fidelity in relation to the photonic degree of freedom employed to transport quantum information and crucial device parameters. Strong-coupling protocols in photonically coupled qubit networks can increase distribution rates by 30-75% while maintaining high fidelities (around $\mathcal{F}\gtrsim99%$) compared to two-photon interference methods. This suggests a high-performance quantum communication method.

Other “Qubit Network” Companies

Because “Qubit Network” is employed in non-quantum contexts, there may be ambiguity.

Qubit (QBT) coin: QBT coin is a separate digital asset, unlike quantum qubit networks. Qubit (QBT), its native cryptocurrency, has a one billion coin limit that cannot be increased. Some sources report 0 QBT circulating supplies, while others report 1 billion. On March 26, a new airdrop would give users daily mining money on the Qubit Network mainnet, expected to launch in Q2 2025. Qubit's (QBT) market value is $6,311,345 and its price fluctuates at $0.0001978 USD.

IT company Qubit Networks

The company “Qubit Networks” provides networking, security, and managed IT services. Their products include:

Networking: providing switching, routing, and reliable wireless technologies to move data rapidly, efficiently, and safely.

Network security involves developing secure networks and providing the knowledge and resources to safeguard digital assets and network environments.

Server/Storage: handling data storage, backup, and archiving and servers that provide resources, data, and services.

Premium Support: 24/7 support to enhance network efficiency and reduce customer costs.

In conclusion, quantum qubit networks, which are necessary for quantum sensing and information processing, dominate the scientific debate, even though “Qubit Networks” can also refer to an IT service provider or a cryptocurrency. Topological design is crucial for superconducting and photonically coupled quantum networks to improve efficiency and enable integrated quantum technologies.

#QuantumQubitNetworks#QubitNetworks#Qubit#SuperconductingQubitNetwork#QuantumSensing#Photons#QubitNetworksLinkedviaPhotons#technology#technews#technologynews#news#technologytrends#govindhtech

0 notes

Text

Thank You, R2

STAR WARS EPISODE II: Attack of the Clones 00:35:07

#Star Wars#Episode II#Attack of the Clones#Jendirian Valley#unidentified freighter tramper#unidentified Ishi Tib#orichalc#Naboo crest headdress#Gondrin Upal#Anakin Skywalker#Senator Padmé Amidala#Thousand Moons#young matron's dress#R2-D2#electromagnetic field sensor unit#serving arm compartment#periscope compartment#durasteel

4 notes

·

View notes

Text

The Rise of Eco-Friendly UPS Systems in the Batteryless Era

The global batteryless storage solutions market is poised for explosive growth over the next decade, with its valuation projected to soar from US$ 540.0 Mn in 2023 to US$ 9.2 Bn by 2034, expanding at a remarkable CAGR of 29.6% from 2024 to 2034. As the world accelerates toward sustainable energy solutions and IoT-driven innovations, batteryless technologies are becoming a key enabler in shaping the future of power storage.

Market Introduction: A Shift from Batteries to Harvested Energy

Batteryless storage solutions eliminate the need for traditional batteries by harvesting energy from environmental sources—such as light, motion, temperature gradients, and radio frequencies. The harvested energy is stored in capacitors and used to power ultra-low-power devices, especially modern microcontrollers used in IoT and sensor-based applications.

These solutions are pivotal in wireless sensor networks (WSNs) and other systems where battery replacement is not feasible or environmentally sustainable. From consumer electronics and healthcare to industrial automation and smart buildings, batteryless solutions offer unmatched flexibility and environmental advantages.

Analyst Viewpoint: The Role of IoT and Green Energy

Analysts agree that the rapid adoption of the Internet of Things (IoT) is a prime driver of market expansion. Batteryless IoT devices powered by supercapacitors are in high demand, particularly in industries seeking long-term, low-maintenance, and eco-friendly energy solutions.

Additionally, the growing demand for eco-friendly uninterruptible power supply (UPS) systems is reshaping energy backup infrastructures. Unlike conventional battery-based UPS systems, fuel-cell powered and supercapacitor-based batteryless UPS units offer superior reliability, lower maintenance, and enhanced sustainability.

Key Market Drivers

1. IoT Proliferation Fuels Demand

IoT applications across industries—especially manufacturing, healthcare, and smart infrastructure—require efficient, low-power, and maintenance-free energy sources. Batteryless energy storage systems (ESS) fit this need by enabling continuous power to connected devices with minimal environmental impact.

2. Surge in Demand for Eco-Friendly UPS Systems

As environmental concerns around lithium-ion battery production rise, businesses are transitioning toward green UPS alternatives. Fuel cells and supercapacitors are increasingly favored for their clean energy credentials and long lifespans, particularly in industrial and commercial sectors where power continuity is critical.

3. Growth in Wireless Power Transfer (WPT) Adoption

Batteryless solutions align perfectly with wireless power transfer technologies, where power is transmitted using electromagnetic fields. This is opening new frontiers in portable medical devices and consumer gadgets, expanding the application range of batteryless storage.

Supercapacitors: The Backbone of Batteryless Power

Supercapacitors are emerging as a cornerstone technology within this market. Known for their long cycling lifetimes, fast charging capabilities, and high power outputs, supercapacitors can serve as primary energy storage units in batteryless systems, especially when paired with solar energy as a backup source.

With applications in renewable energy integration, grid stability, and transportation, supercapacitor-based ESS are being integrated into advanced systems to improve resilience and energy efficiency.

Regional Outlook: Asia Pacific Leads the Charge

Asia Pacific is the dominant region in the global batteryless storage solutions market, accounting for the largest market share in 2023. This leadership is attributed to the region's:

According to energy consumption forecasts, combined primary energy use in the Indian subcontinent, Southeast Asia, and Sub-Saharan Africa is projected to increase from 115,000 petajoules in 2023 to nearly 194,000 petajoules by 2050, underlining the need for sustainable ESS such as batteryless systems.

Competitive Landscape: Innovation is Key

Leading players in the batteryless storage solutions market are heavily investing in modular, plug-and-play architectures compatible with RFID, solar, and kinetic energy harvesting. They are also focusing on integrating multi-protocol wireless connectivity, including Bluetooth LE 5.4 and sub-GHz radios, into their systems.

Notable Industry Developments:

Major players include:

These companies are driving innovation by enhancing energy efficiency, expanding product portfolios, and developing next-generation chipsets for battery-free designs.

Outlook: The Batteryless Future is Now

As environmental awareness grows and the demand for sustainable and maintenance-free energy storage surges, batteryless storage solutions are becoming a mainstream choice. With the rise of smart cities, renewable energy, and connected ecosystems, the future of power lies in battery-free, efficient, and reliable solutions.

Backed by robust technological advancements and strong industry momentum, the global batteryless storage solutions market is on a high-growth trajectory—poised to transform how the world stores and uses energy.

0 notes

Text

5 Surprising Uses of Copper Coils You Didn't Know About

When we hear the term copper coil, most of us instantly think of its traditional use in electrical wiring or industrial applications. However, copper coils have a wide range of applications beyond just wires and power transformers. From your kitchen appliances to the healthcare industry, copper coils play an essential yet often overlooked role in modern technology.

In this blog, we’ll explore five surprising uses of copper coils that go beyond the obvious. Whether you’re a manufacturer, engineer, or just curious about industrial innovations, this article will open your eyes to the versatility of copper coils.

1. Koprex: Delivering Innovation with Copper Coils in Heat Exchangers

Koprex, a trusted name in the metal industry, has been supplying high-quality copper coils for use in heat exchangers across HVAC and refrigeration industries. What makes these coils stand out is their excellent thermal conductivity, corrosion resistance, and durability. These copper coils are used in air conditioners, water heaters, and refrigeration units to transfer heat effectively.

While people usually associate copper pipes with plumbing, the copper coil’s coiled structure makes it ideal for compact and efficient heat transfer systems. With the rise in demand for energy-efficient appliances, companies like Koprex are playing a vital role in pushing sustainable solutions forward.

2. Copper Coils in Medical Devices

It might surprise you to know that copper coils are widely used in the healthcare sector. Copper has natural antimicrobial properties, making it ideal for use in medical environments. In MRI machines, coils made from copper are used for the precise transmission of radio frequency signals.

Not just that, copper coils are also being used in electromagnetic therapy devices and bio-medical sensors. These devices help in the treatment of joint pain, wound healing, and other chronic conditions. The flexibility and conductivity of copper coils make them suitable for intricate designs in medical tools.

3. Renewable Energy – Solar Water Heaters

With India's growing focus on renewable energy, the use of copper coils in solar water heaters has seen a significant boost. Copper is the preferred metal because it conducts heat faster than most other metals, making solar water heating systems more efficient.

The coiled structure allows more surface area to absorb sunlight and transfer the heat to the water. Especially in areas with good sunlight like Rajasthan, Gujarat, and Maharashtra, these systems are now being installed in homes, schools, and commercial buildings. It's a silent contributor to India’s green energy mission.

4. Induction Heating Systems

You might’ve seen induction cooktops in modern kitchens – sleek, stylish, and super quick. But do you know what's inside making it work? A copper coil. These coils generate a magnetic field when electric current passes through them, which then heats up the metal vessel directly placed over the cooktop.

This technology is not just limited to the kitchen. Industrial induction heating systems use copper coils to heat metals during manufacturing processes like forging, brazing, or metal hardening. The ability of copper to carry high-frequency current efficiently makes it the ideal choice for such systems.

5. Automotive Industry – Electric Vehicles and More

With the rise of electric vehicles (EVs) in India, another unique use of copper coils has gained attention. These coils are used in the motors and battery management systems of EVs. Since copper ensures minimal energy loss and maximum conductivity, it's a key material for efficient electric drivetrains.

Not just in EVs, but in traditional automotive systems as well, copper coils are used in ignition systems, fuel pumps, and air conditioning units. As more Indian manufacturers move toward clean mobility, the demand for copper coils is bound to rise.

Final Words: Why It Matters