#ethylene detection

Explore tagged Tumblr posts

Text

youtube

#Portable colorimetric sensor#Fe nanozyme#surface-active sites#artificially ripened fruits#VOC detection#ethylene detection#calcium carbide#food safety#ripeness detection#porous nanozyme#colorimetric changes#fruit quality#sensor array#portable device#on-site testing#chemical analysis#volatile organic compounds#nano-technology#agriculture innovation#food inspection.#Youtube

0 notes

Text

The evolution of life may have its origins in outer space

Astronomers find signs of complex organic molecules – precursors to sugars and amino acids – in a planet-forming disc.

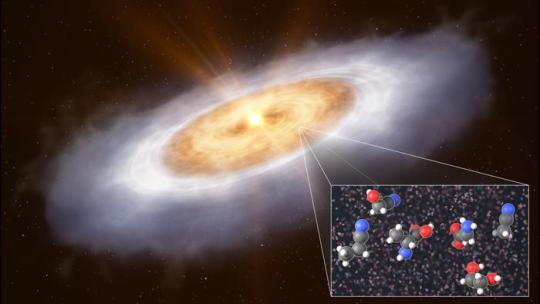

Using the Atacama Large Millimeter/submillimeter Array (ALMA), a team of astronomers led by Abubakar Fadul from the Max Planck Institute for Astronomy (MPIA) has discovered complex organic molecules – including the first tentative detection of ethylene glycol and glycolonitrile – in the protoplanetary disc of the outbursting protostar V883 Orionis. These compounds are considered precursors to the building blocks of life. Comparing different cosmic environments reveals that the abundance and complexity of such molecules increase from star-forming regions to fully evolved planetary systems. This suggests that the seeds of life are assembled in space and are widespread. The findings were published in the Astrophysical Journal Letters today.

Astronomers have discovered complex organic molecules (COMs) in various locations associated with planet and star formation before. COMs are molecules with more than five atoms, at least one of which is carbon. Many of them are considered building blocks of life, such as amino acids and nucleic acids or their precursors. The discovery of 17 COMs in the protoplanetary disc of V883 Orionis, including ethylene glycol and glycolonitrile, provides a long-sought puzzle piece in the evolution of such molecules between the stages preceding and following the formation of stars and their planet-forming discs. Glycolonitrile is a precursor of the amino acids glycine and alanine, as well as the nucleobase adenine.

The assembly of prebiotic molecules begins in interstellar space

“Our finding points to a straight line of chemical enrichment and increasing complexity between interstellar clouds and fully evolved planetary systems.” – Abubakar Fadul, MPIA

The transition from a cold protostar to a young star surrounded by a disc of dust and gas is accompanied by a violent phase of shocked gas, intense radiation and rapid gas ejection.

Such energetic processes might destroy most of the complex chemistry assembled during the previous stages. Therefore, scientists had laid out a so-called ‘reset’ scenario, in which most of the chemical compounds required to evolve into life would have to be reproduced in circumstellar discs while forming comets, asteroids, and planets.

“Now it appears the opposite is true,” MPIA scientist and co-author Kamber Schwarz points out. “Our results suggest that protoplanetary discs inherit complex molecules from earlier stages, and the formation of complex molecules can continue during the protoplanetary disc stage.” Indeed, the period between the energetic protostellar phase and the establishment of a protoplanetary disk would, on its own, be too short for COMs to form in detectable amounts.

As a result, the conditions that predefine biological processes may be widespread rather than being restricted to individual planetary systems.

Astronomers have found the simplest organic molecules, such as methanol, in dense regions of dust and gas that predate the formation of stars. Under favourable conditions, they may even contain complex compounds comprising ethylene glycol, one of the species now discovered in V883 Orionis. “We recently found ethylene glycol could form by UV irradiation of ethanolamine, a molecule that was recently discovered in space,” adds Tushar Suhasaria, a co-author and the head of MPIA’s Origins of Life Lab. “This finding supports the idea that ethylene glycol could form in those environments but also in later stages of molecular evolution, where UV irradiation is dominant.”

More evolved agents crucial to biology, such as amino acids, sugars, and nucleobases that make up DNA and RNA, are present in asteroids, meteorites, and comets within the Solar System.

Buried in ice – resurfaced by stars

The chemical reactions that synthesize those COMs occur under cold conditions, preferably on icy dust grains that later coagulate to form larger objects. Hidden in those mixtures of rock, dust, and ice, they usually remain undetected. Accessing those molecules is only possible either by digging for them with space probes or by external heating, which evaporates the ice.

In the Solar System, the Sun heats comets, resulting in impressive tails of gas and dust, or comas, essentially gaseous envelopes that surround the cometary nuclei. This way, spectroscopy – the rainbow-like dissection of light – may pick up the emissions of freed molecules. Those spectral fingerprints help astronomers to identify the molecules previously buried in ice.

A similar heating process is occurring in the V883 Orionis system. The central star is still growing by accumulating gas from the surrounding disc until it eventually ignites the fusion fire in its core. During those growth periods, the infalling gas heats up and produces intense outbursts of radiation. “These outbursts are strong enough to heat the surrounding disc as far as otherwise icy environments, releasing the chemicals we have detected,” explains Fadul.

“Complex molecules, including ethylene glycol and glycolonitrile, radiate at radio frequencies. ALMA is perfectly suited to detect those signals,” says Schwarz. The MPIA astronomers were awarded access to this radio interferometer through the European Southern Observatory (ESO), which operates it in the Chilean Atacama Desert at an altitude of 5,000 metres. ALMA enabled the astronomers to pinpoint the V883 Orionis system and search for faint spectral signatures, which ultimately led to the detections.

Further challenges ahead

“While this result is exciting, we still haven't disentangled all the signatures we found in our spectra,” says Schwarz. “Higher resolution data will confirm the detections of ethylene glycol and glycolonitril and maybe even reveal more complex chemicals we simply haven't identified yet.”

“Perhaps we also need to look at other regions of the electromagnetic spectrum to find even more evolved molecules,” Fadul points out. “Who knows what else we might discover?”

IMAGE: This artist’s impression shows the planet-forming disc around the star V883 Orionis. In the outermost part of the disc, volatile gases are frozen out as ice, which contains complex organic molecules. An outburst of energy from the star heats the inner disc to a temperature that evaporates the ice and releases the complex molecules, enabling astronomers to detect it. The inset image shows the chemical structure of complex organic molecules detected and presumed in the protoplanetary disc (from left to right): propionitrile (ethyl cyanide), glycolonitrile, alanine, glycine, ethylene glycol, and acetonitrile (methyl cyanide). Credit ESO/L. Calçada/T. Müller (MPIA/HdA)

6 notes

·

View notes

Text

It's foolish to think that Putin isn't orgasmic over what the Trump administration has been doing to screw America.

Trump and his co-president Elon Musk have now targeted the EPA for revenge and retribution.

Trump, Musk move to oust EPA staff in the Great Lakes region, including dozens responsible for protecting drinking water for 30 million in U.S. and Canada

Trump purged dozens of career officials in the Chicago office during his first term. His latest attempt to cull the workforce is led by billionaire Elon Musk, whose companies Tesla and SpaceX have been fined by the EPA for multiple violations of environmental laws. “Elon Musk wants to turn EPA into every polluter’s ally,” U.S. Sen. Edward Markey, a Massachusetts Democrat, said Thursday at a rally in front of the agency’s headquarters. “He wants to take environmental cops off the beat.” History suggests Musk and scores of other polluters are going to catch a break during the next four years. Water pollution cases filed by the EPA in the Great Lakes region declined during each of the first three years Trump was president, according to an analysis of agency records by the nonprofit Environmental Law and Policy Center. Meanwhile, the number of chronic violators of the Clean Water Act in the heavily industrialized states skyrocketed under Trump, who as a candidate in 2016 vowed to abolish the EPA. [ ... ] More than 8 million people in Illinois get their drinking water from a utility where at least one PFAS has been detected, a 2022 Chicago Tribune investigation found. The discovery of high levels of ethylene oxide pollution led to the closure of a sterilization plant in southwest suburban Willowbrook and prompted a state law requiring another facility in north suburban Waukegan to dramatically reduce emissions.

Trump feels it's his right to make life easy for polluters who have given him and other far right Republicans huge campaign contributions.

States like Illinois can step up enforcement. But they don't have the reach and resources of the federal government. Be prepared to get sicker over the next few years.

#epa#the environment#water pollution#pfas#illinois#the great lakes#donald trump#elon musk#maga#republicans#make america sick again#vladimir putin#trump is a russian asset#traitor trump#владимир путин#путин хуйло#путлер#трамп - путинский пудель#дональд трамп#трамп хуйло

12 notes

·

View notes

Text

Extend the Life of Your Roof with These Pro Commercial Repair Tips

youtube

When it comes to managing a commercial property, few elements are as critical as the integrity of the roof. Your roof is the first line of defense against the elements, protecting your structure, equipment, and employees from damage. At Lancaster Roofing, we understand the vital role that a well-maintained roof plays in the success and safety of your business. That’s why we specialize in timely, professional, and long-lasting commercial roof repair services tailored to your specific needs.

Why Commercial Roof Repair Should Be a Priority Unlike residential properties, commercial buildings often have flat or low-slope roofs, which require specialized materials and systems. These roofing systems are susceptible to unique problems—ponding water, membrane tears, punctures from foot traffic, or weather-related damage—that need expert attention.

Ignoring even small signs of wear and tear can lead to major issues down the road. Water infiltration, mold growth, energy inefficiency, and structural damage can escalate quickly if not addressed. That’s why business owners should consider routine inspections and prompt commercial roof repair to avoid costly repairs and unplanned downtime.

Signs You May Need Commercial Roof Repair Early detection is key. If you spot any of the following signs, it may be time to call Lancaster Roofing:

Water stains on interior ceilings or walls

Ponding water on the roof surface

Blistering or bubbling in the roofing membrane

Cracks, splits, or visible tears

Loose flashing or metal panels

Sudden spikes in energy bills due to insulation failure

Even if these issues seem minor, they can quickly worsen under heavy rainfall or temperature fluctuations. A proactive repair approach can extend the lifespan of your roof and save thousands in potential damage.

Our Expert Commercial Roof Repair Process At Lancaster Roofing, we take pride in delivering precision and professionalism in every project. Here’s how our commercial roof repair process works:

Inspection and Assessment We start with a comprehensive inspection to identify the root cause of the issue. Our experienced technicians evaluate every component of your roofing system—from the membrane and flashing to the insulation and drainage.

Customized Repair Plan Once the problem areas are diagnosed, we provide a detailed report and discuss the most cost-effective repair options with you. Whether it's a localized patch, seam resealing, or replacement of damaged sections, we tailor the solution to your specific needs and budget.

Efficient, Non-Disruptive Repairs We understand that business must go on. Our team works efficiently and professionally, minimizing disruptions to your daily operations. We use top-quality materials and proven techniques to ensure long-term durability.

Post-Repair Inspection and Maintenance Tips After the repair, we conduct a follow-up inspection to confirm everything is sealed and secure. We’ll also provide maintenance recommendations to help you prevent future problems and keep your roof in peak condition.

Serving All Types of Commercial Roofing Systems At Lancaster Roofing, we’re experienced in handling repairs for a wide range of commercial roofing systems, including:

TPO (Thermoplastic Polyolefin)

EPDM (Ethylene Propylene Diene Monomer)

PVC Roofing

Built-Up Roofing (BUR)

Modified Bitumen

Metal Roofing Systems

No matter what type of roof your property has, our technicians are trained to identify problems quickly and provide reliable, lasting solutions.

The Cost of Delaying Repairs Some business owners hesitate to schedule a repair due to cost concerns, but postponing necessary roof work can be far more expensive in the long run. A small leak can lead to insulation saturation, interior damage, or even structural issues. Emergency repairs and water damage restoration are significantly more costly than proactive commercial roof repair.

Additionally, insurance claims for roofing issues are often denied if the damage is deemed to be the result of neglect. Regular maintenance and prompt repairs help protect your investment and ensure compliance with your warranty and insurance policies.

Why Choose Lancaster Roofing? Choosing the right roofing partner makes all the difference. At Lancaster Roofing, we offer:

Licensed and Insured Roofing Professionals

Decades of Commercial Roofing Experience

High-Quality Materials from Trusted Manufacturers

Fast Turnaround and Emergency Repair Services

Honest Pricing and Transparent Estimates

Customer Satisfaction Guarantee

We’ve built our reputation on integrity, craftsmanship, and customer service. Whether you manage an office building, retail center, warehouse, or industrial facility, we’re the team to trust when your roof needs repair.

Protect Your Business with Expert Roof Repair Your commercial roof does more than keep the rain out—it protects your assets, supports your operations, and ensures safety for everyone inside. Don’t wait until a minor issue becomes a major problem. Call Lancaster Roofing today to schedule a professional inspection or to request a free estimate for your commercial roof repair needs.

#commercial metal roofing#commercial metal roof repair#commercial roof repair#commercial roofing#commercial roofing companies#commercial roofing contractor#Youtube

2 notes

·

View notes

Text

Leak Detection and Repair Market Size, Anticipating Growth Prospects from 2032

The leak detection and repair market was valued at US$ 18.22 billion in 2022 and is projected to grow at a CAGR of 4.1% during the forecast period from 2022 to 2032, reaching an estimated US$ 27.23 billion by 2032.

Key Drivers of Market Demand for Leak Detection and Repair

The increasing adoption of machine learning and Artificial Intelligence (AI) is significantly enhancing leak detection and repair (LDAR) capabilities. Many gas emission monitoring companies are leveraging AI-driven algorithms to detect leaks more efficiently by analyzing satellite imagery and ground-level data. These advanced technologies help operators identify patterns and trends over time, enabling data-driven decision-making.

As a result, oil and gas companies are progressively replacing traditional LDAR systems with technologically advanced solutions. Additionally, venture capital firms are actively investing in companies specializing in AI-based LDAR technologies, further fueling market growth and innovation.

𝐅𝐨𝐫 𝐦𝐨𝐫𝐞 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐢𝐧𝐭𝐨 𝐭𝐡𝐞 𝐌𝐚𝐫𝐤𝐞𝐭, 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐨𝐟 𝐭𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.factmr.com/connectus/sample?flag=S&rep_id=7094

Country-wise Analysis

The United States holds a dominant position in the leak detection and repair (LDAR) market, accounting for 54% of the total market share. This growth is largely driven by stringent government regulations, including mandatory leak detection systems for hazardous liquid pipelines as per U.S. pipeline leak detection regulations.

Additionally, strong government support for the oil and gas sector is fueling industrial expansion, increasing the demand for advanced LDAR solutions. Government subsidies further contribute to the market’s growth, reinforcing the need for efficient leak detection and repair systems across the industry.

Category-wise Insights

The handheld gas detectors segment holds the largest share of the global leak detection and repair (LDAR) market, accounting for over 36% of total revenue. These detectors are widely adopted in the oil and gas sector due to their fast and reliable detection capabilities, compact and lightweight design, and ease of use. They are utilized for detecting various gases, including methanol, carbon dioxide, ammonia, and methane. The rising production of natural gas, along with increasing trade in oil and gas products, continues to drive demand for handheld gas detectors.

The market is segmented into handheld gas detectors, UAV-based detectors, vehicle-based detectors, and manned aircraft detectors. Among these, the UAV-based detectors segment is expected to register the highest CAGR during the forecast period. The ability of UAV-based detectors to navigate hazardous areas enhances safety and operational efficiency, making them increasingly valuable for oil and gas companies. These detectors are used to identify gases such as benzene, ethanol, heptane, octane, and methane, further fueling their adoption in the industry.

Competitive Landscape

The leak detection and repair (LDAR) market is highly competitive, with key players focusing on product innovation, strategic mergers, and acquisitions to strengthen their market presence. Leading companies are expanding their production capacities and global reach to capitalize on opportunities in emerging economies.

In August 2021, Southern California Gas Company (SoCalGas) signed a $12 million agreement with Bridger Photonics, Inc. to enhance methane detection. SoCalGas is utilizing Bridger’s Gas Mapping LiDAR technology to identify, locate, and measure methane emissions across its distribution network.

In June 2021, Clean Air Engineering, Inc. entered into a channel partnership with Picarro. This collaboration integrates Picarro’s industry-leading ethylene oxide (EO) monitoring technology with CleanAir’s advanced services, providing industrial clients with cutting-edge EO measurement and monitoring solutions.

Such strategic initiatives continue to drive advancements in LDAR technologies, ensuring enhanced efficiency and regulatory compliance across industries.

Key Market Segments Covered in Leak Detection and Repair Industry Research

By Component :

Equipment

Services

By Product :

Handheld Gas Detectors

UAV-based Detectors

Vehicle-based Detectors

Manned Aircraft Detectors

By Technology :

Volatile Organic Compounds (VOC) Analyzer

Optical Gas Imaging (OGI)

Laser Absorption Spectroscopy

Ambient/Mobile Leak Monitoring

Acoustic Leak Detection

Audio-Visual-Olfactory Inspection

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Choosing the Right Commercial Roofing Near Nebraska: What You Need to Know

When it comes to protecting your commercial property, the roof plays a critical role. For business owners and property managers near Nebraska, investing in the right commercial roofing solution is essential to ensure long-term durability, energy efficiency, and weather resistance. From unpredictable Midwest storms to harsh winters and sweltering summers, your commercial roof must withstand a variety of environmental challenges.

One of the first considerations when selecting a roofing system is the type of material that best suits your building and budget. Options like TPO (Thermoplastic Olefin), EPDM (Ethylene Propylene Diene Monomer), and modified bitumen are commonly used in commercial settings. Each has its own strengths: TPO is known for its energy efficiency and heat-reflective properties, EPDM is durable and highly weather-resistant, while modified bitumen offers excellent waterproofing and longevity. A professional contractor can assess your building’s specific needs and help guide you to the most effective solution.

Another factor to consider is proper installation. Even the highest-quality roofing materials can fail if not installed correctly. That’s why working with experienced, certified commercial roofers in the Nebraska region is crucial. Look for companies that have a solid track record, strong customer reviews, and a portfolio of completed projects. Hiring local professionals also ensures they are familiar with Nebraska’s building codes, climate conditions, and industry best practices.

In addition to new installations, ongoing maintenance is vital for maximizing the lifespan of your commercial roof. Regular inspections can help detect minor issues—such as ponding water, membrane damage, or flashing deterioration—before they turn into costly repairs. Many roofing companies offer preventative maintenance programs designed to keep your system in top shape year-round, which is a smart investment for any business owner.

Energy efficiency is also a growing concern for commercial properties, and your roofing choice can significantly influence your building’s thermal performance. Reflective roofing systems can reduce cooling costs during hot Nebraska summers, contributing to a lower energy bill and a more sustainable business operation. Some materials are even eligible for ENERGY STAR® ratings and potential tax incentives, further enhancing their value.

If you're searching for reliable commercial roofing near Nebraska, choose a contractor that offers a full spectrum of services—from inspections and repairs to complete roof replacements. The right team will provide transparent quotes, honest timelines, and high-quality workmanship. Whether you own a warehouse, retail store, office building, or industrial facility, your roof deserves expert attention.

In conclusion, your commercial roof is a major investment that directly impacts your business’s bottom line. By choosing the right materials, hiring skilled professionals, and staying proactive with maintenance, you can extend the life of your roof and avoid unexpected costs. Nebraska’s climate can be tough, but with the right approach, your commercial roof can stay strong and secure for decades to come.

0 notes

Text

Understanding the Role of DTPA & EC Scan in Bangalore

Introduction

If your doctor has advised a kidney function test, a DTPA & EC Scan in Bangalore might be the right option. These scans help assess how well your kidneys are working.

What Is a DTPA & EC Scan?

DTPA (Diethylene Triamine Pentaacetic Acid) and EC (Ethylene Dicysteine) scans are nuclear medicine tests. A DTPA & EC Scan in Bangalore is used to measure kidney filtration, drainage, and structure.

Why You Might Need a DTPA & EC Scan in Bangalore

Check kidney function before surgery

Monitor kidney diseases

Detect blockages or obstructions

Evaluate post-transplant kidney performance

Procedure Overview

The DTPA & EC Scan in Bangalore involves a small injection of a radioactive tracer. Imaging follows, which is completely painless and safe.

Conclusion

A DTPA & EC Scan in Bangalore https://kiranpetct.com/dtpa-scan-in-bangalore/ provides accurate insights into kidney health and helps doctors plan appropriate treatments.

0 notes

Text

How often do flat roofs need to be replaced?

Flat roofs are a practical choice for many Omaha homeowners and businesses due to their modern look and efficient design. However, understanding how often flat roofs need to be replaced is vital for protecting your property and avoiding unexpected repair costs. In this guide, we’ll explore factors that impact a flat roof's lifespan, signs of wear and tear, and tips to extend its life, helping you make informed decisions about replacement.

What Is the Average Lifespan of a Flat Roof?

The lifespan of a flat roof depends largely on the materials used, installation quality, maintenance, and weather conditions. Here’s a breakdown of the most common flat roofing materials and how long they typically last:

EPDM (Ethylene Propylene Diene Monomer): This synthetic rubber membrane is highly durable, with an expected lifespan of up to 30 years or more when maintained properly.

TPO (Thermoplastic Olefin): A popular option for energy efficiency, TPO roofs last between 20 and 30 years.

Modified Bitumen: A mix of asphalt and rubber compounds, these roofs generally last around 20 years.

Built-Up Roofing (BUR): Known for its multi-layered design, BUR roofs typically last 20–25 years.

PVC (Polyvinyl Chloride): With proper care, PVC flat roofs can endure for 20–30 years.

While these estimates provide a guideline, factors like extreme weather conditions, poor maintenance, or substandard installation can shorten a roof’s lifespan.

Factors That Influence Flat Roof Longevity

Several factors play a role in determining how long your flat roof will last:

1. Climate Conditions

Omaha’s weather poses unique challenges for flat roofs. Extreme heat during summer causes materials to expand, while freezing winters can lead to contraction. This constant expansion and contraction may weaken the roofing material over time.

2. Maintenance Practices

Regular inspections and proactive repairs are key to extending the life of your roof. Ignoring small issues, such as cracks or ponding water, can lead to larger problems that compromise your roof’s integrity.

3. Installation Quality

Proper installation ensures that the roofing system is durable and watertight. Hiring a professional roofing contractor with experience in flat roof installations reduces the risk of premature failures.

4. Roof Usage

Flat roofs are sometimes used as outdoor spaces or for HVAC system placement. Excessive foot traffic or equipment weight can put strain on the roof, reducing its lifespan.

Signs Your Flat Roof May Need to Be Replaced

Knowing when it’s time to replace your flat roof can save you from costly damage to your property. Here are the most common warning signs:

Persistent Leaks: If you notice frequent leaks despite repairs, it’s a strong indication that your roof is nearing the end of its life.

Ponding Water: Standing water after rainfall can accelerate deterioration and lead to structural issues.

Visible Damage: Cracks, blisters, or bubbles in the roofing material often signal underlying problems that might require replacement.

Frequent Repairs: When repairs become a regular occurrence, investing in a new roof may be more cost-effective.

Sagging Areas: A sagging roof could indicate compromised structural support and should be addressed immediately.

How to Extend the Life of Your Flat Roof

Proper maintenance is key to maximizing the lifespan of your flat roof. Follow these tips to keep your roof in top condition:

1. Schedule Regular Inspections

Perform semi-annual roof inspections, especially after extreme weather events. Early detection of small issues can prevent them from becoming major problems.

2. Keep Drains and Gutters Clear

Flat roofs are more prone to water pooling, so maintaining proper drainage is crucial. Clear out debris from gutters and downspouts to prevent blockages.

3. Repair Minor Damage Promptly

Fix cracks, leaks, or tears as soon as you notice them. Delaying repairs can allow damage to worsen, leading to more extensive (and expensive) problems.

4. Apply Protective Coatings

Consider adding a reflective or waterproof coating to your roof. These coatings can shield the surface from UV rays, prevent water penetration, and extend its life.

5. Work with a Professional

Regular maintenance from a trusted Omaha roofing contractor can help identify potential issues and provide solutions to prolong your roof’s lifespan.

When Is It Time to Replace Your Flat Roof?

Despite regular maintenance, every roof will eventually need to be replaced. Here are some guidelines to help you decide when replacement is necessary:

Your roof is approaching or has exceeded its expected lifespan.

Damage is extensive, such as large areas with blisters, cracks, or sagging.

Repairs are no longer effective or cost-efficient.

Persistent leaks are causing damage to your property.

Choosing the Right Roofing Material for Replacement

When replacing a flat roof, it’s important to select a material that fits your budget, climate, and building needs. Here’s a quick comparison to help you decide:

EPDM: Best for longevity and durability.

TPO: Ideal for energy efficiency and eco-friendliness.

Modified Bitumen: A cost-effective option with decent durability.

BUR: Excellent for waterproofing and durability.

PVC: Great for durability and chemical resistance, making it a popular choice for commercial properties.

Consult a professional roofing contractor in Omaha to determine which option suits your property.

Benefits of Replacing Your Flat Roof

Investing in a new flat roof comes with several advantages:

Improved energy efficiency, leading to lower utility bills.

Enhanced property value and curb appeal.

Better protection against leaks and structural damage.

Reduced maintenance costs with a more durable roofing system.

Conclusion

Flat roofs require regular care and timely replacement to protect your property effectively. Factors like material type, maintenance, and Omaha’s climate all play a role in determining how often replacement is needed. By staying proactive with inspections, addressing repairs promptly, and working with a reliable roofing contractor, you can extend the life of your flat roof and make the most of your investment.

If you’re in Omaha and considering a flat roof replacement, our team is here to help. Contact us today for expert advice, high-quality materials, and professional installation tailored to your needs. Don’t wait to ensure your property is safe and secure—schedule a consultation now!

0 notes

Text

Drainback Systems with Advanced Freeze Protection for Solar Water Heating

Drainback systems are a popular and effective solution for solar water heating in cold climates. These systems use a gravity-driven flow to circulate heat transfer fluid between the solar collectors and the storage tank. One of the main advantages of drainback systems is their freeze protection, which helps prevent damage to the system in cold weather by ensuring that the heat transfer fluid is not exposed to freezing temperatures. Advanced freeze protection features in these systems further enhance their ability to operate reliably in winter conditions, providing a highly durable and low-maintenance solution for solar water heating.

Here’s an overview of drainback systems, how they work, and the advanced freeze protection mechanisms that make them ideal for cold climates.

1. How Drainback Systems Work

A. Basic Principle

Drainback systems are designed to automatically drain the heat transfer fluid from the solar collectors when the system is not actively heating water. This is especially useful in freezing conditions, as it prevents the fluid from being exposed to low temperatures in the collectors or pipes.

Fluid Circulation: The system circulates the heat transfer fluid (usually water or an anti-freeze solution) through the solar collectors during sunny periods. The heated fluid rises to the storage tank, where the heat is transferred to the water.

Gravity-Driven Flow: Unlike active solar systems that use pumps, drainback systems use gravity and natural convection to circulate the fluid between the collectors and the tank. When the system is not in use (e.g., during the night or when temperatures drop), the fluid naturally drains back into the storage tank.

B. Fluid Drainage for Freeze Protection

Automatic Drainback: When the system is off, the drainback valve opens, and the heat transfer fluid flows back into the storage tank, leaving the collectors and pipes empty. This ensures that no fluid remains in the system, preventing it from freezing inside the collectors or pipes.

Drainage in Freezing Conditions: The automatic drainage function of the system protects the collectors from freezing damage. If temperatures drop below freezing, the system drains the fluid before it has a chance to freeze, ensuring that the system remains intact and operational.

2. Advanced Freeze Protection Features in Drainback Systems

While basic drainback systems provide effective freeze protection, modern systems are equipped with advanced freeze protection mechanisms that enhance the system’s resilience to extreme cold. These advanced features are designed to provide an extra layer of protection to ensure that the system operates efficiently in freezing conditions.

A. Temperature Sensors for Freeze Detection

Smart Temperature Monitoring: Advanced drainback systems often come with temperature sensors placed in key components of the system, such as the solar collectors, the storage tank, and the fluid lines. These sensors continuously monitor the temperature of the fluid and the system components.

Automatic Freeze Protection Activation: When the system detects that the temperature is approaching freezing levels, the smart control system automatically activates the freeze protection features, such as draining the fluid from the collectors or turning on a backup heating element.

B. Antifreeze Protection Systems

Anti-Freeze Solutions: In regions with extremely cold weather, anti-freeze solutions (e.g., propylene glycol or ethylene glycol) are often used in conjunction with drainback systems. These solutions lower the freezing point of the circulating fluid, allowing it to remain in liquid form even in very low temperatures.

Dynamic Fluid Adjustment: Some drainback systems can automatically adjust the concentration of the anti-freeze solution based on the weather conditions. This helps ensure that the fluid remains in liquid form even during the coldest months of the year.

C. Thermal Buffering and Heat Retention

Insulated Pipes and Storage Tanks: In cold climates, insulating the pipes and storage tank is crucial for preventing heat loss and ensuring that the fluid remains at an optimal temperature. Advanced drainback systems use high-performance insulation materials around pipes and tanks to minimize heat loss.

Thermal Mass in Tanks: Some drainback systems incorporate thermal mass in the storage tank, which helps store excess heat during sunny periods and release it when solar radiation is insufficient. This feature is especially useful in cold weather, as it allows the system to continue providing hot water for longer periods without relying heavily on backup heating.

3. Automatic Drainback Valves and Smart Control Systems

A. Automated Drainback Valves

Function: In a drainback system, the drainback valve automatically opens and closes based on the system's operation. When the system is active, the valve remains closed, allowing the heat transfer fluid to circulate through the collectors. When the system is idle (such as at night or during freezing conditions), the valve opens, allowing the fluid to drain back into the storage tank.

Fail-Safe Mechanism: The drainback valve is designed to operate with a fail-safe mechanism that ensures proper drainage during periods of inactivity. If the valve malfunctions, the system’s smart control system can activate backup protection measures to prevent freeze damage.

B. Smart Control Systems

Freeze Protection Monitoring: Smart control systems are equipped with temperature sensors and programmable settings that allow the system to monitor and adjust operation based on real-time conditions. When cold temperatures are detected, the system can automatically activate freeze protection measures, such as:

Draining the fluid from the collectors.

Activating the backup heating system to maintain water temperature.

Closing the drainback valve when needed to ensure that the system is properly protected.

Predictive Freeze Protection: Some smart systems use weather forecasts and historical temperature data to predict freeze events in advance. This predictive capability ensures that the system is prepared for extreme cold conditions before they occur, preventing potential damage and reducing the risk of costly repairs.

4. Hybrid Systems and Backup Heating Integration

A. Integration with Backup Heating

Hybrid Design: Drainback systems can be integrated into hybrid solar water heating systems, where a conventional backup heating system (e.g., gas, electric, or heat pump) is used to maintain water temperature during extended cloudy periods, snow accumulation, or extremely low temperatures.

Automatic Switching: The smart control system automatically switches between the solar system and backup heating based on temperature and energy availability. This ensures that the system can always provide hot water, even during prolonged periods of low solar radiation.

B. Heat Pump Backup Systems

Heat Pump Integration: In some systems, heat pumps are integrated with drainback systems to provide a highly efficient backup heating solution. Heat pumps work by transferring heat from the air or ground to the water, providing an energy-efficient method of maintaining hot water when solar energy is insufficient.

5. Benefits of Drainback Systems with Advanced Freeze Protection

A. Improved Durability and Longevity

Freeze Protection: The primary advantage of drainback systems with advanced freeze protection is their ability to prevent freeze damage to the system. By ensuring that no fluid is left in the collectors or pipes during freezing conditions, these systems maintain the integrity of the components and significantly extend the lifespan of the system.

B. Reduced Maintenance Costs

Low Maintenance: Since drainback systems are passive and have fewer mechanical parts than active solar systems, they require less maintenance overall. The advanced freeze protection features, such as automated drainage and freeze detection, help minimize the risk of costly repairs due to freezing or snow accumulation.

C. High Efficiency and Reliability

Optimized Efficiency: With the ability to adjust to varying weather conditions, smart control systems optimize the performance of the drainback system, ensuring high efficiency and reliability even in cold weather.

Reliable Hot Water Supply: The combination of solar energy and backup heating ensures that a reliable supply of hot water is available year-round, even in regions with harsh winters.

Drainback systems with advanced freeze protection offer a reliable, energy-efficient, and low-maintenance solution for solar water heating in cold climates. By integrating features like automatic drainage, smart control systems, anti-freeze solutions, and hybrid heating, these systems ensure optimal performance, minimize freeze damage, and provide a continuous supply of hot water throughout the year. Their ability to handle the challenges posed by freezing temperatures, snow accumulation, and low solar radiation makes them an ideal choice for residential, commercial, and industrial applications in colder regions. For more info contact Solar Water Heater Supplier in UAE or call us at +971 4 2522966.

#solar heater#solar water heater#solar water heater supplier#solar water heater supplier in uae#solar water heater supplier in dubai

0 notes

Text

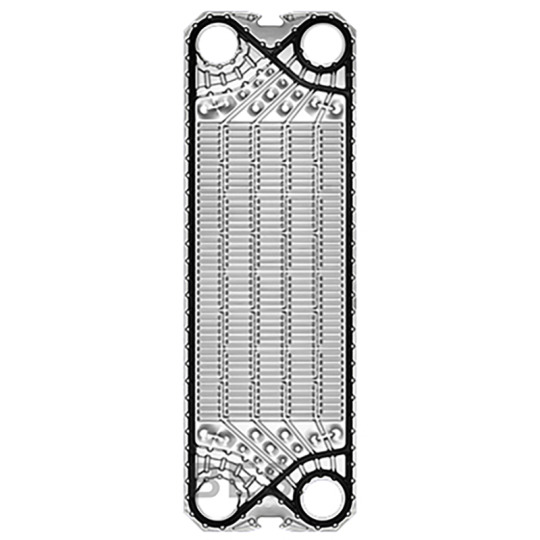

Top-Rated Guide to Fischer PHE Gaskets & Plates: Everything You Need to Know

When it comes to high-efficiency thermal systems, Fischer PHE Gaskets & Plates stand out as a trusted solution for maintaining heat exchanger integrity. PHEs, or Plate Heat Exchangers, are the backbone of thermal energy transfer in industries ranging from HVAC to pharmaceuticals. And without quality gaskets and plates, these systems can falter fast.

What Are Plate Heat Exchangers (PHEs)?

Plate Heat Exchangers work by transferring heat between two fluids using metal plates. These plates are sandwiched with gaskets to form flow channels, optimizing surface area contact and improving energy efficiency. It’s an ingenious solution that’s been engineered for both small-scale systems and industrial giants.

About Fischer and Their Expertise

Fischer is a reputable name in the field of heat exchange components. Known for their rigorous quality controls, superior materials, and long-lasting performance, Fischer PHE gaskets and plates have earned global trust. Whether for original equipment or replacement parts, Fischer products maintain performance in even the harshest industrial environments.

Types of Fischer PHE Gaskets

Gaskets are critical to sealing and guiding fluids inside a heat exchanger. Fischer offers a variety of elastomeric compounds to suit different chemical, temperature, and pressure requirements.

NBR Gaskets

Nitrile Butadiene Rubber (NBR) gaskets are ideal for applications involving oil, grease, or hydrocarbons. They offer good resistance to wear and pressure but aren't suitable for high-temperature processes.

EPDM Gaskets

Ethylene Propylene Diene Monomer (EPDM) gaskets provide excellent resistance to water, steam, and most chemicals. Their flexibility and temperature tolerance make them a go-to option in food and beverage industries.

Viton Gaskets

For applications requiring superior chemical resistance and high-temperature stability, Viton gaskets from Fischer provide unmatched durability. They’re perfect for chemical processing and pharmaceutical applications.

Design and Features of Fischer PHE Plates

The plate design directly impacts a heat exchanger's performance. Fischer plates are engineered for optimal heat transfer and low-pressure drops.

Chevron Pattern & Heat Transfer Efficiency

Most Fischer plates feature a chevron corrugation pattern, which increases turbulence and enhances heat transfer. This pattern helps maintain a thin boundary layer on the surface, resulting in higher thermal efficiency.

Material Composition (SS316, Titanium, etc.)

Fischer uses a variety of materials such as stainless steel (SS304/SS316), Titanium, and Hastelloy to meet the demands of different corrosive environments. These materials ensure the longevity and efficiency of the plates even under aggressive conditions.

How Gaskets and Plates Work Together

The synergy between gaskets and plates is essential for maintaining the functionality of a PHE.

The Sealing Mechanism

Gaskets are placed in a groove around each plate, effectively sealing the fluid inside. Their job is not only to prevent leaks but also to direct the flow through alternate channels.

Thermal Efficiency & Flow Dynamics

Proper alignment of gaskets and plates ensures optimal flow dynamics, minimizing dead zones and maximizing heat exchange surface area.

Frequently Asked Questions (FAQs) on Fischer PHE Gaskets & Plates

1. How often should Fischer PHE gaskets be replaced?

The replacement frequency depends on operating conditions, such as temperature, pressure, and fluid type. However, a general rule is every 2 to 5 years for industrial systems. Regular inspection can help detect signs of wear, hardening, or cracking.

2. Are Fischer gaskets compatible with other heat exchanger brands?

Yes, Fischer manufactures aftermarket gaskets that are compatible with various OEM models like Alfa Laval, GEA, Tranter, and others. Always confirm compatibility with your specific model before purchase.

3. What’s the difference between OEM and aftermarket Fischer gaskets?

OEM gaskets are made by the original equipment manufacturer, while aftermarket gaskets like those from Fischer are designed to match or exceed OEM specifications. Fischer gaskets often provide cost-effective alternatives without compromising performance or durability.

4. How do I identify the correct plate or gasket model?

Check the nameplate of your PHE unit for the model and serial number. Fischer or your supplier can then match that information to the correct gasket and plate design using a compatibility chart or software.

5. Can I reuse Fischer PHE gaskets after disassembly?

It is generally not recommended. Most gaskets are glued and lose sealing integrity once removed. Reusing gaskets can lead to leaks or contamination, especially in high-pressure or hygienic systems.

6. Do Fischer plates come with food-grade certifications?

Yes, Fischer offers FDA-approved and CE-certified plates and gaskets suitable for food and beverage applications. Be sure to request certified versions if you’re operating in regulated environments.

Conclusion

Choosing high-quality gaskets and plates is essential for maintaining the performance, efficiency, and safety of your plate heat exchanger system. Fischer PHE Gaskets & Plates provide a reliable solution backed by technical expertise and durable materials. Whether you're maintaining an HVAC system or a pharmaceutical process line, Fischer's components help keep operations running smoothly, reduce energy consumption, and extend equipment life.

With global availability, OEM compatibility, and stringent quality standards, Fischer has positioned itself as a top-tier provider in the heat exchanger market. Always consult with professionals when selecting or replacing your components to ensure optimal compatibility and long-term value.

0 notes

Text

Membrane Roofs - How They Stay in Place

Wondering what keeps a membrane roof from blowing off in a storm? Knowing how membrane roofing systems are fastened or adhered to your structure will keep you from stressing over your roof when severe weather strikes.

newimageroofingatlanta.com gathered essential information about membrane roofing types, benefits, drawbacks, adherence methods, and maintenance programs.

Membrane Roofing Systems

Each membrane roofing type offers distinct advantages and drawbacks based on material composition, climate suitability, cost, and installation requirements.

1. EPDM (Ethylene Propylene Diene Monomer)

Benefits:

Highly resistant to UV radiation and ozone

Performs well in both hot and cold temperatures

Easy to install and maintain

Flexible and long-lasting

Drawbacks:

Black color absorbs heat, which can increase cooling costs

Vulnerable to punctures from sharp objects

May shrink over time if not installed properly

2. TPO (Thermoplastic Polyolefin)

Benefits:

White reflective surface reduces energy costs

Resistant to mold, tears, and punctures

Heat-weldable seams create a waterproof bond

Lightweight and environmentally friendly

Drawbacks:

Durability can vary depending on the manufacturer’s quality

Newer material, so long-term performance is still under review

It can become brittle in cold weather if improperly installed

3. PVC (Polyvinyl Chloride)

Benefits:

Excellent chemical and grease resistance

Welded seams provide superior waterproofing

High reflectivity helps reduce heat buildup

Proven track record in commercial applications

Drawbacks:

More expensive than EPDM and TPO

It can become brittle over time in colder climates

Environmental concerns regarding plasticizers used during manufacturing

4. Modified Bitumen

Benefits:

Durable and puncture-resistant

Easy to repair with torches or adhesives

Ideal for roofs with heavy foot traffic

Good resistance to temperature extremes

Drawbacks:

Installation often requires open flame or hot asphalt

Less flexible than single-ply systems

Shorter lifespan compared to EPDM or PVC

How Membrane Roofs Stay in Place

Membrane roofs, often used on flat or low-slope roofs, remain secure through specific installation methods engineered to resist wind uplift and external forces. The method chosen depends on the membrane, climate, building structure, and budget. Below are the most common techniques:

1. Mechanical Fastening

This method involves physically anchoring the membrane to the roof deck using screws and metal plates. Fasteners are placed at regular intervals, typically within membrane seams, which are then overlapped to hide and protect them.

Advantages:

Cost-effective

Fast installation

Suitable for various temperatures and weather conditions

Limitations:

Higher potential for air infiltration

It can be extremely noisy during strong winds

It may require more maintenance at seams and fastener points

2. Full Adhesion

In a fully adhered system, installers apply contact adhesive to both the membrane and substrate, creating a continuous and secure bond across the entire roof surface.

Advantages:

Excellent resistance to wind uplift

Watertight seals reduce leaks

Enhances energy efficiency by minimizing air pockets

Limitations:

Requires dry, clean conditions for proper bonding

More expensive than mechanically fastened systems

Adhesive application may extend installation time

3. Ballasted Installation

Ballasted systems involve laying the membrane loosely over the insulation and securing it with heavy materials (gravel, pavers, or river stones). The weight holds the membrane in place and shields it from weather and UV rays.

Advantages:

Simple and fast to install

Very durable with added thermal mass

Easily removable for repairs or roof access

Limitations:

Adds significant weight to the structure

It can be difficult to detect leaks beneath the ballast

Not ideal for high-wind zones or buildings with low load capacity

Additional Membrane Reinforcement Methods

Besides the principal anchoring methods, membrane roofs include several features that enhance their longevity and resistance to uplift and leaks:

Seam Sealing: Seams are critical points in roofing. For TPO and PVC, seams are heat-welded; for EPDM, seams are bonded using rubber adhesive or seam tape. Proper sealing ensures waterproofing and structural integrity.

Flashing: Flashing around roof edges, vents, drains, and penetrations forms a continuous barrier against water intrusion and wind damage.

Edge Reinforcement: Fasteners are often added along roof perimeters and penetrations to secure vulnerable areas and improve resistance during storms or high winds.

Preventing Leaks with Roof Maintenance

Commercial membrane flat roofs are straightforward but still require attention at times. Regular inspections and proactive maintenance can prevent costly damage and extend the lifespan of the entire roof system.

New Image Roofing Atlanta offers commercial roof maintenance programs designed to:

Identify early signs of wear or damage around boots, seals, and flashing

Reapply or repair flashing and sealants

Clear debris that could cause pooling/ponding water

Document roof conditions for warranty and insurance purposes

Schedule preventative maintenance to avoid unplanned downtime or repairs

A well-maintained roof can last significantly longer, and proactive care reduces emergency service costs.

Key Considerations for Adhering Membrane Roofing

Selecting the correct method for adhering membrane roofing systems to substrates depends on multiple variables assessed during planning and design.

1. Roof Structure and Load Capacity:

Not every building can handle the weight added by a ballasted system. Before installation, engineers must evaluate whether the structure can support the chosen method.

2. Climate Conditions:

Regions with high winds or extreme weather require stronger adherence methods, like fully adhered or mechanically fastened systems. Ballasted systems may not be ideal for areas that experience hurricanes.

3. Energy Efficiency Goals:

White membranes (TPO and PVC) reflect sunlight and reduce heat gain, which contributes to energy savings. Fully adhered systems offer better insulation performance by eliminating air gaps.

4. Installation Environment:

Fully adhered roofs require specific temperature and moisture conditions for adhesives to cure properly. Mechanical fastening may be a better choice in colder or damp climates.

5. Maintenance and Accessibility:

If the roof requires frequent access, a ballasted or mechanically fastened system may be easier to inspect and maintain. Fully adhered roofs are best for minimal foot traffic to preserve membrane integrity.

Careful evaluation of these factors ensures not only proper installation but also long-term durability and performance.

Keeping Your Membrane Roof in Place

In this article, you discovered essential information about commercial membrane roofing types (benefits and drawbacks), adherence methods, and maintenance programs.

Membrane roofing systems provide long-lasting, weather-resistant protection when selected and installed. Whether choosing mechanical fastening, full adhesion, or ballast, each method plays a key role in ensuring roof stability.

Failure to understand how secure membrane roofing systems are will leave you paranoid about your roof every time the wind blows.

Sources: panamacity.gov/DocumentCenter/View/3187/3533_en_VersiFleece_PVC_FullyAdhered_System_Sheet?bidId= nps.gov/crps/tps/roofingexhibit/roofingtoday.htm hud.gov/sites/dfiles/OCHCO/documents/1037L.pdf

New Image Roofing Atlanta

2020 Howell Mill Rd NW Suite 232 Atlanta, GA30318 (404) 680-0041

To see the original version of this article, visit https://www.newimageroofingatlanta.com/membrane-roofs-how-they-stay-in-place/

#atlanta commercial roofer#commercial roofer atlanta ga#commercial roofing atlanta#flat roof#low slope roof#commercial roofer#emergency roof repair#Ballasted Membrane Roof#Fully Adhered Membrane Roof#Mechanically Fastened Membrane Roof

1 note

·

View note

Text

Boost Fruit Shelf Life with Smart Ethylene & CO₂ Monitoring

Why Gas Monitoring Is Essential in Fruit Ripening

Post-harvest fruit losses are a serious concern for producers and distributors. A major cause? Poor control over ripening gases like ethylene and carbon dioxide. Without real-time monitoring, inconsistent ripening, early spoilage, and major financial losses are inevitable.

Smart ethylene and CO₂ gas monitoring systems, like those offered by ESEGAS, ensure precise environmental control in ripening chambers—leading to better fruit quality, longer shelf life, and fewer losses.

Ethylene: The Ripening Trigger That Needs Precision

Ethylene is the key hormone that controls ripening in climacteric fruits like bananas, avocados, and mangoes. While it’s essential for color and sweetness, too much ethylene or uneven exposure can cause fruit to ripen unevenly, decay early, or lose visual appeal.

ESEGAS ethylene sensors use advanced photoacoustic or electrochemical technologies to provide real-time, continuous data on gas levels inside ripening rooms. This ensures that fruit is exposed to the right amount of ethylene at the right time—improving uniformity and avoiding unnecessary spoilage.

“Precise ethylene control helps every piece of fruit ripen evenly—no more color mismatch or waste.”

CO₂: The Hidden Factor in Controlled Ripening

While ethylene triggers ripening, carbon dioxide (CO₂) helps manage and delay it. When used correctly, CO₂ can slow down ethylene activity, giving operators the ability to control ripening schedules—which is essential for logistics and market timing.

ESEGAS CO₂ analyzers use non-dispersive infrared (NDIR) technology, ideal for detecting subtle gas shifts. This is important because too much CO₂ can lead to off-flavors and tissue breakdown. Proper CO₂ management also prevents mold and microbial growth in high-humidity environments.

Why Choose ESEGAS Sensors?

ESEGAS sensors are built for the real-world challenges of fruit storage—high humidity, fluctuating temperatures, and gas stratification. Their analyzers offer:

High-accuracy detection at low ppm levels

Fast response time for real-time adjustments

Smart calibration and self-diagnostics

Durability in harsh, moist conditions

With IoT-ready features and multiple output options (Modbus, 4–20 mA, RS485), they’re easy to integrate into existing systems.

“With ESEGAS, your ripening room becomes a data-driven environment—responsive, efficient, and reliable.”

Sensor Placement & Maintenance: Small Steps, Big Impact

Correct sensor placement and care are key to getting accurate data. Install sensors at fruit height, away from fans or direct gas jets. In larger chambers, use multiple sensors to avoid blind spots.

ESEGAS sensors offer easy calibration, protective filters, and firmware updates to maintain long-term accuracy.

Conclusion: Ripen Smarter with ESEGAS

Whether you manage bananas, mangoes, or tomatoes, the key to successful ripening lies in gas control. ESEGAS ethylene and CO₂ sensors empower you to maintain perfect ripening conditions, reduce losses, and deliver consistently high-quality produce to market.

0 notes

Text

Weatherford Roofing Contractors

Weatherford, Texas, is a city where tradition meets growth, and where the weather can be both a friend and a foe to homes and businesses. With intense heat in the summer, unpredictable hailstorms in the spring, and occasional winter freezes, roofs in Weatherford are under constant stress. For this reason, homeowners and commercial property managers alike often rely on the skills and knowledge of experienced Weatherford roofing contractors to maintain the safety, value, and longevity of their buildings.

The importance of roofing goes beyond appearances—it plays a crucial role in energy efficiency, structural integrity, and overall comfort. Working with reliable professionals ensures that roofs can stand up to the test of time, storms, and shifting temperatures that define the North Central Texas region.

The Role of Weatherford Roofing Contractors

The services provided by Weatherford roofing contractors are comprehensive. They handle everything from minor repairs to complete roof replacements, and their work is vital in helping property owners protect their investment. Contractors are trained to assess a roof’s condition, recommend the best course of action, and execute repairs or installations using proper techniques and quality materials.

One of the most important jobs a roofing contractor performs is identifying hidden issues. A roof may appear to be in decent shape from ground level, but underlying problems—such as water intrusion, mold, or structural decay—can be missed without a professional inspection. Roofing contractors use specialized tools and techniques to detect these issues early, preventing them from developing into costly disasters.

Types of Roofing Systems in Weatherford

Given Weatherford’s diverse mix of historic homes, new developments, commercial buildings, and ranch-style properties, roofing contractors must be well-versed in various types of roofing systems. The most commonly used materials include:

Asphalt Shingles Asphalt shingles are popular across Texas due to their affordability and availability. Weatherford roofing contractors install these shingles on many residential properties because they provide good protection against heat and rain. They also come in various styles and colors, allowing homeowners to match their roof with the architectural character of their home.

Metal Roofing Metal roofing is gaining popularity due to its durability and energy-efficient properties. It reflects solar heat, reducing cooling costs in the scorching summer months. Roofing contractors often recommend metal roofs to rural properties or large homes where longevity is a priority. Metal roofs can last 40–70 years with proper installation and maintenance.

Tile Roofing Tile roofs, particularly those made from clay or concrete, are valued for their aesthetic appeal and long lifespan. They’re also ideal for homes with a Mediterranean or Southwestern architectural style. Though heavier than other roofing types, tile roofs offer excellent insulation and resistance to the elements—benefits that contractors take into consideration when assessing installation feasibility.

Flat Roofing Systems Commercial buildings in Weatherford frequently feature flat or low-slope roofs. Contractors install and maintain systems such as modified bitumen, TPO (thermoplastic polyolefin), and EPDM (ethylene propylene diene terpolymer) to ensure water drainage and weather resistance. These systems require specialized knowledge for proper installation and ongoing maintenance.

Storm Damage and Emergency Repairs

Weatherford roofing contractors are often busiest following a storm. Hailstorms, high winds, and falling debris can wreak havoc on even the best-constructed roofs. After severe weather, contractors provide emergency tarping and quick repairs to prevent further damage from rain or wind exposure.

Contractors in Weatherford are skilled in storm damage assessments and can identify impact points that might not be visible to an untrained eye. Their documentation and reporting often help property owners navigate insurance claims, ensuring fair compensation for repairs or replacement.

Timely response is crucial. Delaying roof repairs after a storm can result in leaks, mold growth, and interior damage. Experienced contractors understand the urgency and offer prompt service to restore safety and security to the building.

Roof Inspections and Maintenance

Preventative maintenance is one of the most effective ways to extend the life of a roof. Weatherford roofing contractors offer routine inspections, especially after seasonal changes or storms. These inspections identify early signs of wear, such as cracked shingles, loose flashing, or deteriorating sealants.

Contractors provide maintenance services that include cleaning gutters, sealing joints, reinforcing flashing, and replacing damaged materials. These proactive measures save property owners from expensive repairs down the line and ensure the roof remains in top condition.

New Roof Installation and Replacement

When a roof reaches the end of its lifespan or suffers irreparable damage, Weatherford roofing contractors guide clients through the roof replacement process. This includes helping select the right material, ensuring compliance with building codes, and executing the installation safely and efficiently.

Contractors also consider local climate conditions, sun exposure, slope design, and drainage when recommending a new roofing system. Their goal is to create a long-lasting structure that improves both the functionality and curb appeal of the property.

Energy efficiency is also a major consideration. Modern roofing materials are often designed to reflect heat and improve insulation, which helps reduce energy costs. Contractors help clients evaluate these options and determine the best return on investment based on their needs and budget.

Gutters, Ventilation, and Add-Ons

While the roof is the main feature, Weatherford roofing contractors also handle related systems such as gutters and ventilation. Proper drainage prevents water buildup, which can weaken the foundation and siding. Well-designed ventilation helps reduce moisture and heat buildup in the attic, protecting the roof deck and shingles from premature aging.

Some contractors also offer solar panel mounting, skylight installation, and insulation upgrades as part of their service packages. These add-ons increase home value, improve energy efficiency, and enhance natural lighting, all while requiring professional integration with the roof structure.

Safety Standards and Licensing

Roofing is inherently dangerous work, especially on steep slopes or during extreme weather conditions. Professional Weatherford roofing contractors prioritize safety for both their crew and the property owner. They use fall protection equipment, follow OSHA guidelines, and take measures to secure the worksite during installation or repairs.

Additionally, reputable contractors in the area are licensed, bonded, and insured. This protects homeowners from liability and ensures the work meets both industry and municipal standards. Contractors also stay updated on local building codes and permit requirements, helping projects avoid unnecessary delays or legal issues.

Why Roofing Matters in Weatherford

The importance of roofing in Weatherford goes beyond protection. It’s a symbol of stability, a barrier against the ever-changing Texas climate, and a key factor in maintaining the value of a property. With a trusted contractor, property owners can make informed decisions that serve their long-term interests.

Roofs are not just passive elements of construction—they're working systems designed to manage temperature, moisture, airflow, and external impact. Contractors ensure these systems are functioning as intended, contributing to a safer and more energy-efficient living environment.

Conclusion

Whether dealing with storm recovery, upgrading to more energy-efficient materials, or planning for long-term property maintenance, working with professional Weatherford roofing contractors is essential. These skilled experts understand the unique demands of the region and provide the craftsmanship needed to keep homes and businesses protected year-round.

For anyone seeking reliability, performance, and peace of mind under their roof, Weatherford roofing contractors offer the experience and solutions to deliver results that last.

1 note

·

View note

Text

Cost-Effective Solutions for Common Flat Rooftop Issues

Introduction

Flat rooftops have become increasingly popular among homeowners and businesses alike, especially in urban areas where space is at a premium. While they offer unique advantages like additional outdoor space, ease of installation, and cost-effectiveness, they are not without their issues. From leaks to drainage problems, flat roofs can be a source of frustration. However, understanding common flat rooftop issues and exploring cost-effective solutions can save you time, money, and headaches. In this article, we’ll dive deep into the challenges faced by flat rooftops and provide you with practical solutions to keep your roof in top shape.

Cost-Effective Solutions for Common Flat Rooftop Issues

Flat roofs, despite their sleek appearance and modern appeal, come with a host of potential problems that can develop over time. Here we’ll explore some of the most common issues and how you can tackle them effectively without breaking the bank.

Understanding Flat Roofs What are Flat Roofs?

A flat roof is a type of roofing system that is nearly level in contrast to the many types of sloped roofs. They are often used in commercial buildings but are becoming increasingly popular for residential homes as well.

Types of Flat Roof Systems Built-Up Roofing (BUR) Consists of multiple layers of tar and gravel. Modified Bitumen A single-ply membrane that is easy to install. EPDM (Ethylene Propylene Diene Monomer) A synthetic rubber membrane known for its durability. TPO (Thermoplastic Olefin) A blend of rubber and plastic that is energy-efficient. Common Flat Rooftop Issues 1. Water Ponding

Water ponding occurs when water accumulates on the roof surface due to improper drainage or a lack of slope. This can lead to leaks and structural damage over time.

Solutions for Water Ponding Install Additional Drainage: Ensure your drainage systems are adequate. Create Slopes: Adding slight slopes can minimize standing water. 2. Roof Leaks

Leaks are perhaps the most dreaded issue among flat rooftops. They can stem https://www.southernroofingsystems.com/commercial/pvc-roofing/foley-alabama from various sources such as damaged membranes or faulty seams.

Solutions for Roof Leaks Routine Inspections: Regular inspections help detect early signs of wear. Emergency Roof Leak Repair Services: If you notice a leak, contact licensed roofing contractors immediately. 3. Poor Installation Practices

A poorly installed roof can lead to numerous problems down the line including leaks and structural failures.

Solutions for Installation Issues Hire Certified Roofing Contractors: Always choose experienced professionals for installations. 4. Membrane Damage

Membrane damage due to UV rays or harsh weather conditions can compromise your roof's integrity.

Solutions for Membrane Damage Roof Me

1 note

·

View note

Text

From Red Plenty by Patrick Spufford

"The Unified System: 1970"

A cell. A lung cell. Tobacco smoke swirls by in the spired and foliated channel the cell faces. Its job is to take in oxygen from breath and keep out everything else, and on the whole it does well filtering the usual impurities in air: but this is not a designed mechanism, put together for a function by conscious plan, it is a dumb iteraion of all the features which have proved by trial and error to serve lung cells well in the past. The past did not include deliberately-breathed smoke. We could count an amazing number of different chemicals in the blue-grey vapour snaking through the tissue, altogether too many of which the cell does not know how to exclude. Formaldehyde, acetaldehyde, catechol, isoprene, ethylene oxide, nitric oxide, nitrosamine, the aromatic amines — not to mention the quinones, the semiquinones, the hydroquinones, a whole fanily of polycyclic aromatic hydrocarbons. We are watching for one of these last. Here it comes now, a drifting, tumbling molecule of benzopyrene. It sails into the cell's bulging curtain wall of fats and sticks there, like an insect caught in glue; then, worse, is dragged through, because the fat curtain is spiked here and there by receptors, and one of these has the benzopyrene in its grip. The receptor winches the benzopyrene through the curtain, hand over hand, atom over atom, wrapping it as it comes in a fold of the curtain, and then closing the fold behind it, so that when it reaches the inside, a little fatty envelope buds off from the inner wall of the cell with the benzopyrene sealed inside it. And floats free, into the warm liquid workspace where the body builds its proteins.

But it's all right. The cell has no specific defence against benzopyrene, but it is not defenceless. It has the powerful standard equipment all mammalian cells deploy when foreign bodies turn up where they're not supposed to. The package of fat is a flag, a label, an alert. Detecting it, up comes an enzyme to metabolise the contents. The enzyme munchs the benzopyrene into pieces of epoxide which other bits of the cellular machinery can flush safely away.

This has happened over and over again, every time Sergei Alexeyevich Lebedev lights a cigarette. There are billions of cells in the lungs. Lebedev has smoked thousands of unfiltered Kazbek a day for fifty years. So this has happened thousands of billions of times.

***

Another lung cell. The machines that Lebedev has made all build up their complicated behaviours from absolutely predictable little events, from valves and then transistors turning on and off. Definitely on; definitely off. Without any shading of degree. Without any ambiguity. The machine that makes Lebedev is different. The base layer of its behaviour, from which all the rest emerges, is various and multiple and uncertain. There is no binary simplicity. There is the slow bubble of many chemical reactions all happening at once, each continuing until a task is mostly done, probably done, done enough to satisfy a program which was itself only whittled out of randomness just well enough to get by. The enzyme’s destruction of benzopyrene, for example, only flushes most of it away. A fraction of the epoxides react again with the enzyme and become diol epoxides. That’s what’s happened here; instead of nice, inert, detoxified molecules, we have a version of the same thing which is lacking one electron on one of its atoms, and which consequently yearns to stick to any other molecule which will share an electron with it. The diol epoxides are aggressive gloop. Aggressive? One electron’s worth of electric charge doesn’t tow a molecule very fast through the soupy interior of a cell: it doesn’t send the diol epoxides streaming along at the speed of light like the electrons in a vacuum tube. But it does exert a tiny, persistent pull on them. It draws them along towards molecules they might stick to. It draws them everywhere in the cell, and so it draws some of them towards the cell nucleus, which has another wall of fats around it, but unfortunately is designed to let molecules rather like the diol epoxides in and out on the cell’s ordinary business. The hungry, electron-seeking blob of gloop slips through, and there in front of it are floating twenty-three pairs of tempting targets: the huge, fat, friendly, electron-rich chromosomes of human DNA.

No one in the world in 1970 understands in any detail how they work, and the ignorance is particularly bad in the Soviet Union, thanks to Lysenko. But the chromosomes work whether they are understood or not. The gloop drifts in; and at any and every point along the endless coiled helix where it happens to make contact, the gloop locks on. Where it jostles forward with its missing electron to embrace one of the DNA’s electrons, there’s a little chemical reaction, and the electron in question bonds to both the DNA and the gloop. The gloop is now an ‘adduct’, glued to the helix. But the helix is changed too, by having the blob of tobacco residue stuck to it. At the position where the adduct sits, the information in the DNA has been corrupted. Instead of the G, T, C or A that should be there, in the four-letter alphabet of the genome, it reads as one of the other letters instead. The adduct has written an error into the code.

But it’s all right. In the vast majority of positions along the genome where goo might attach itself at random, altering one letter won’t produce any significant mutation, even if the alteration lasts. The genome is Lebedev’s software, but unlike software written by humans, it is not a set of procedures packed end-to-end, all of which at least purport to do something. It is a jumble of legacy code spread out in fragments through a whole voluminous library of nonsense. Almost always, a random change of letter will either hit some existing nonsense, or turn some sense into new nonsense. And because the chromosomes come in pairs, with a version of every chromosome contributed by Lebedev’s mother floating there opposite a version from his father, if some sense on the version on one side turns to nonsense, the equivalent piece on the other version will go on making sense just fine. Dangerous mutations usually only happen in the rare cases where sense is accidentally turned into different sense. Which is not what has happened here. Here, the arriving molecule has glued itself where it makes no difference at all.

This has happened billions of times.

***

Another lung cell. The soft rainfall of gloop onto Lebedev’s DNA continues. By chance, this particular sticky drop in the statistical rain is one of the small minority that is going to land somewhere that matters. By chance, it is falling onto a stretch of code on Chromosome number 11 which scientists will know later as the gene ras, or hRas. The electrophile noses in; it suckers on; the guanine (G) it has suckered onto on the helix now reads, for all intents and purposes, as cytosine (C). And this time, it happens that changing G to C creates sense, not nonsense, in the code. Ras with a C in it at this specific position is a viable and functional piece of software. But much more of a change is in prospect than there would be if someone substituted a new programme for the one that was supposed to be running in a computer. Human-made software is only an informational ghost, temporarily given possession of the machine and allowed to change 0s to 1s and vice versa. The software of humans, on the other hand, actually builds the hardware it runs on. It creates the machine. So a mutation in the code means a mutation in the body too, if the error endures.

Ras is one of the genes that control cell growth and cell division. In adults, it switches on and off periodically to govern the normal cycle of the cell’s existence. You wouldn’t want it switched on all the time. Foetuses in the womb run ras continually to generate all the new tissue that the Build-A-Human program demands when a human is being first assembled. Otherwise, cell multiplication must happen when, and only when, the body part the cell is in needs a new cell. But it’s the switch that has been altered by having C where G used to be in this mutant version of ras. C instead of G at this one particular point jams the ras gene at ‘on’ – throws the lever for unstoppable growth, and then breaks the lever.