#ferrite testing

Explore tagged Tumblr posts

Text

Ferrite Testing in Pune: Ensuring Weld Quality and Material Integrity

At Integrated NDE, we provide specialized ferrite testing in Pune, offering reliable and accurate solutions to ensure the quality and integrity of stainless steel welds and other critical components. Ferrite testing is a vital non-destructive testing (NDT) method used to measure the ferrite content in stainless steel welds and castings, ensuring that the material's properties meet industry standards and perform optimally in demanding environments.

Understanding Ferrite Testing

Ferrite is a magnetic phase found in stainless steels, particularly in duplex and austenitic stainless steels. The ferrite content in these materials plays a crucial role in determining their mechanical properties, corrosion resistance, and overall performance. Excessive or insufficient ferrite content can lead to issues such as cracking, reduced toughness, and compromised corrosion resistance. This is where ferrite testing becomes essential.

Our ferrite testing services are designed to accurately measure the ferrite content in stainless steel welds, castings, and components. By determining the ferrite content, we help clients ensure that their materials are suitable for their intended applications, particularly in industries such as oil and gas, chemical processing, and power generation, where material performance is critical.

Ferrite Testing Process

The ferrite testing process involves using specialized equipment, such as a ferrite scope or a magnetic probe, to measure the ferrite content in a sample. The process is non-invasive, meaning it does not damage the material being tested. Our technicians are trained to conduct these tests with precision, ensuring accurate results that are essential for quality control and compliance with industry standards.

For ferrite testing of welds, our team inspects the weld metal and the heat-affected zone (HAZ) to ensure that the ferrite content is within the acceptable range. This is particularly important for stainless steel welds, where the balance between austenite and ferrite phases must be carefully controlled to prevent issues such as hot cracking or reduced corrosion resistance.

Applications of Ferrite Testing

Ferrite testing services are widely used in various industries to ensure the quality and reliability of stainless steel components. In the oil and gas industry, for example, ferrite testing is crucial for components exposed to harsh environments, where both mechanical strength and corrosion resistance are paramount. In the chemical processing industry, maintaining the correct ferrite content is essential to prevent failures in equipment such as reactors, heat exchangers, and piping systems.

In addition to ensuring material performance, ferrite inspection is also used to verify compliance with industry standards, such as the American Society of Mechanical Engineers (ASME) and the American Welding Society (AWS). By conducting thorough ferrite testing, we help our clients meet these stringent standards, ensuring the safety and reliability of their products.

Why Choose Integrated NDE for Ferrite Testing in Pune

At Integrated NDE, we are committed to providing the highest level of service in non-destructive testing in Pune, including ferrite testing. Our experienced team of technicians uses state-of-the-art equipment to deliver accurate and reliable results. We understand the critical importance of ferrite content in stainless steel welds and components, and we work closely with our clients to ensure that their materials meet the required specifications.

In addition to our expertise in ferrite testing, we offer a comprehensive range of NDT services, including ultrasonic testing, radiography, and magnetic particle inspection. This allows us to provide a full suite of testing solutions to meet the diverse needs of our clients across various industries.

When you choose Integrated NDE for your ferrite testing services, you can trust that you are working with a partner who is dedicated to quality, precision, and customer satisfaction. Whether you need to verify the ferrite content in a critical weld or ensure the integrity of a stainless steel component, our team is here to provide the expertise and support you need.

For more information about our ferrite testing in Pune or to schedule a consultation, contact Integrated NDE today. Let us help you ensure the quality and reliability of your materials with our expert ferrite testing and NDT services.

#ferrite testing in pune#ferrite testing services#non destructive testing in Pune#ndt testing#ferrite testing#ferrite inspection#ferrite testing of welds#ferrite testing stainless steel

0 notes

Text

Integrated NDE Solution in Pune: Precision in Ferrite Testing for Austenitic and Duplex Stainless Steels

In the realm of industrial manufacturing and engineering, the integrity and quality of materials are crucial. Non-destructive testing (NDT) methods, such as ferrite testing, play a significant role in ensuring the reliability of materials, especially in critical applications involving austenitic stainless steel and duplex stainless steels. Integrated NDE Solution in Pune excels in providing comprehensive NDT services, with a specialized focus on ferrite testing. This article delves into the intricacies of ferrite testing, highlights its benefits, and explores the cutting-edge services and equipment offered by Integrated NDE Solution.

Understanding Ferrite Testing

Ferrite testing is a non-destructive method used to measure the ferrite content in austenitic and duplex stainless steels. Ferrite content is a critical parameter in determining the mechanical properties, corrosion resistance, and weldability of these materials. The presence of an appropriate amount of ferrite ensures the material’s optimal performance in service environments, particularly in applications involving high temperatures and corrosive media.

Importance of Ferrite Content

Corrosion Resistance: Correct ferrite content enhances the corrosion resistance of stainless steels.

Mechanical Properties: Ferrite influences the toughness and strength of the material.

Weldability: Optimal ferrite levels prevent issues such as hot cracking during welding.

Thermal Stability: Ferrite content affects the material’s behavior under high temperatures.

How Ferrite Testing Works

Ferrite testing typically involves using a ferrite meter or a magnetic induction device to measure the ferrite content in stainless steel materials. The process is straightforward and involves the following steps:

Surface Preparation: The surface of the sample is cleaned to ensure accurate readings.

Calibration: The ferrite meter is calibrated using standard reference materials with known ferrite content.

Measurement: The probe of the ferrite meter is placed on the surface of the sample, and the ferrite content is read directly from the device.

Analysis: The results are analyzed to determine if the ferrite content is within the acceptable range for the specific application.

Benefits of Ferrite Testing

Non-Destructive: Does not damage or alter the sample being tested.

Quick and Accurate: Provides immediate and precise measurements of ferrite content.

Versatile: Applicable to both austenitic and duplex stainless steels.

Portable: Ferrite meters are portable, allowing for on-site testing.

Cost-Effective: Relatively low cost compared to other analytical techniques.

Integrated NDE Solution in Pune: Pioneers in Non-Destructive Testing

Integrated NDE Solution in Pune is a leader in the field of non-destructive testing, offering a broad spectrum of NDT services, including ferrite testing. Their expertise, state-of-the-art equipment, and commitment to quality make them a trusted partner for industries requiring reliable inspection services.

Comprehensive NDT Services Offered

Ferrite Testing

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Visual Inspection (VI)

Industries Served

Integrated NDE Solution in Pune caters to a diverse array of industries, including:

Aerospace: Ensuring the safety and reliability of critical components.

Automotive: Inspecting critical parts to prevent failures.

Construction: Verifying the integrity of structural components.

Oil and Gas: Ensuring the reliability of pipelines and equipment.

Power Generation: Maintaining the integrity of infrastructure components.

Chemical Processing: Ensuring the material integrity in corrosive environments.

Ferrite Testing in Action

Case Study: Power Generation Component Inspection

In the power generation industry, the integrity of components such as pressure vessels and heat exchangers is paramount. Integrated NDE Solution was approached by a leading power plant operator to conduct ferrite testing on critical components made of austenitic stainless steel. The ferrite content was measured to ensure it met the required specifications, preventing issues related to thermal fatigue and corrosion.

Case Study: Duplex Stainless Steel Pipeline Inspection

A major oil and gas company required ferrite testing for duplex stainless steel pipelines to ensure they could withstand the harsh conditions of subsea environments. Integrated NDE Solution employed their advanced ferrite meters to measure the ferrite content accurately. The results confirmed that the pipelines had the optimal ferrite content, ensuring their durability and resistance to stress corrosion cracking.

Advanced Ferrite Testing Equipment

Integrated NDE Solution in Pune utilizes the latest ferrite testing equipment to ensure the highest level of accuracy and reliability in their inspections. Some of the advanced equipment includes:

Ferrite Meters: State-of-the-art devices that provide accurate and repeatable measurements of ferrite content.

Calibration Standards: Reference materials with certified ferrite content used to calibrate ferrite meters for precise readings.

Portable Ferrite Meters: Lightweight and portable meters that allow for convenient on-site testing.

The Role of Certified Technicians

The effectiveness of ferrite testing largely depends on the expertise of the technicians conducting the tests. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their skills and knowledge ensure that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune is dedicated to maintaining the highest standards of quality and safety. They adhere to international standards and best practices, ensuring that all inspections are performed with utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is a top priority. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it’s a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In industries where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in non-destructive testing, particularly in ferrite testing for austenitic and duplex stainless steels. Their dedication to quality, use of advanced technology, and customer-centric approach make them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to set the standard for excellence in non-destructive inspection. Their expertise in ferrite testing and other NDT services is pivotal in industries where safety and reliability are crucial. As technology advances and industries evolve, Integrated NDE Solution remains at the forefront, offering unparalleled service and support to their clients.

In conclusion, for businesses seeking the highest standards in ferrite testing, non-destructive inspection, and comprehensive NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results. Their innovative approach, advanced technology, and unwavering commitment to quality ensure that every inspection meets the stringent requirements of today’s demanding industrial environments.

0 notes

Text

An intimate conversation with - and using - my iPhone 4S demonstrating the losslessest possible audio capture example.

0 notes

Text

Comprehensive Guide to Magnetic Performance Testing

Comprehensive Guide to Magnetic Performance Testing Do you know that the performance of your sintered NdFeB magnets can make or break your high tech applications? Learn the latest techniques to get top quality and reliability. Magnetic Performance Standards How do manufacturers guarantee every NdFeB magnet meets the performance standards? What are the new methods to measure magnetic properties…

#Alnico Magnets#Ceramic Magnets#custom magnet#Custom Magnetic Solutions#FeCrCo#Ferrite Magnets#fluxmeters#Gauss Meter#Heavy Duty Magnets#Iron Chrome Cobalt Magnets#magnet design#Magnetic Applications#magnetic flux#magnetic flux density analysis#Magnetic flux measurement#Magnetic Influence#magnetic moment#magnetic moment testing#Magnetic Solutions#magnetic testing equipment#NdFeB#NdFeB magnets#Neodymium Iron Boron Magnets#Permanent Magnet#Samarium Cobalt Magnets#Sintered NdFeB Magnets#SmCo#Tesla meter#testing magnet

0 notes

Text

On This Day in 1964, the Legendary Lockheed SR-71 Blackbird Flew For the First Time.

December 22, 2019 Military Aviation

A Blackbird takes off from Beale AFB. (Image credit: USAF)

The SR-71 was the first aircraft to feature stealth capabilities.

The Lockheed SR-71 Blackbird flew for the first time on Dec. 22, 1964 at Air Force Plant 42 in Palmdale, California. The first aircraft to enter service was delivered to the 4200th (later, 9th) Strategic Reconnaissance Wing at Beale Air Force Base, California, in January 1966. Throughout its career, that came to an end on Oct. 9, 1999, no SR-71 was reportedly lost nor damaged due to hostile actions: the SR-71 flew above Mach 3 at 85,000 feet, with a reported top speed of Mach 3.4 during flight testing and Mach 3.5 during on an operational sortie while evading a missile over Libya.

Although most historians and experts know it many aviation enthusiasts ignore that the Blackbird can somehow be considered the first stealth aircraft ante litteram.

Here’s what this author explained in a past article titled Well Before The SR-72 Was Conceived, The Iconic SR-71 Blackbird Proved “Speed Is The Real Stealth”:

Ezoic

The Blackbird was the first aircraft to feature stealth capabilities: a special paint that contained iron ferrites and absorbed radar energy instead of returning it to the sender was used for SR-71’s wings, tail and fuselage. The reduced RCS (Radar Cross Section) made any reaction to an SR-71 overflight almost useless: the aircraft was so fast that once the radar detected it, the SAM battery’s guidance system was not able to compute the right parameters for a successful kill. Moreover, the range and bearing of the SR-71 was also denied to the enemy by jamming the radars with the use of the sophisticated electronic countermeasures (ECM) that equipped by the Blackbird.

However, in spite of its radar-evading features, what made the SR-71 almost impossible to intercept, were its incredible flight characteristics: it was able to fly at 3.5 Mach at 88,000 feet. The aircraft could climb higher than that and according to some sources the Blackbird could reach 120,000 feet and above. At that altitude, Soviet SAMs would have been unable to maneuver to hit an SR-71: the air is so thin that any maneuvering capability of a missile is practically nonexistent, as explained by the former Blackbird pilot Col. Richard H. Graham in his book “SR-71 The Complete Illustrated History of THE BLACKBIRD The World’s Highest , Fastest Plane.”

In 2012 a DARPA statement stated that America was gradually losing the “strategic advantage” that its stealth warplanes had long provided, as other countries’ stealth and counter-stealth capabilities continued to improve. For this reason, “speed is the new stealth” is a slogan that accompanied the unveiling of the SR-72 in 2013. However, the SR-71’s story is a proof that speed has always been the key to stealth.

Not only did SAMs fail to catch the Blackbird but even the fastest Soviet fighter jets, including the MiG-31 Foxhound, lacked the necessary speed to reach the SR-71.

The last flight of an SR-71 took place on Oct. 9, 1999, during the Edwards AFB Open House Airshow. Fourteen years later, in 2013, Lockheed Martin’s Skunk Works, the legendary division that designed airplanes which represented a giant leap for their times such as the F-104, the U-2, the Blackbird family or the F-117A stealth fighter jet, revealed the existence of a sort of SR-71 replacement: a Hypersonic intelligence, surveillance and reconnaissance (ISR) and strike aircraft dubbed SR-72, designed for Mach 6.

The first concept artwork of the SR-72 released by Lockheed Martin in 2013.

On Sept. 27, 2017, Aviation Week reporter Guy Norris scooped the story about the landing of a mysterious, unidentified new aircraft at U.S. Air Force Plant 42 Production Flight Test Facility in Palmdale California.

“According to information provided to Aviation Week, one such [SR-72] technology demonstrator, believed to be an unmanned subscale aircraft, was observed flying into the U.S. Air Force’s Plant 42 at Palmdale, where Skunk Works is headquartered. The vehicle, which was noted landing in the early hours at an unspecified date in late July, was seen with two T-38 escorts. Lockheed Martin declined to comment directly on the sighting.”

Ezoic

In February 2018, Lockheed Martin, pushed back on reports of the SR-72’s development stating that no SR-72 had been produced. In November last year, Lockheed Martin stated that a prototype of the SR-72 was scheduled to fly by 2025. A sort-of SR-72 aircraft (or something inspired to it) is flown by Maverick (Tom Cruise) in “Top Gun: Maverick”, the sequel of the famous 1980s aviation movie.

Once operational the hypersonic strike aircraft will be able to fly about twice as fast as its predecessor. To date, the Mach 3+ SR-71 Blackbird remains the fastest, manned air-breathing aircraft ever produced.

About David Cenciotti

David Cenciotti is a journalist based in Rome, Italy. He is the Founder and Editor of “The Aviationist”, one of the world’s most famous and read military aviation blogs. Since 1996, he has written for major worldwide magazines, including Air Forces Monthly, Combat Aircraft, and many others, covering aviation, defense, war, industry, intelligence, crime and cyberwar. He has reported from the U.S., Europe, Australia and Syria, and flown several combat planes with different air forces. He is a former 2nd Lt. of the Italian Air Force, a private pilot and a graduate in Computer Engineering. He has written five books and contributed to many more ones.

@theaviationist via X

27 notes

·

View notes

Text

Pic 1: The forced perspective I needed to make Ferrite's arm gun look big enough

Pic 2 & 3: Test renders - figuring out posing and lighting

Pic 4: Final pose, to be edited in clip studio

Pic 5: Edited final render, on card without effect text

5 notes

·

View notes

Text

Ductile to Brittle Transition Temperature

Of the two general types of fracture (ductile or brittle), not all materials fall neatly into one category or the other. Some materials experience what is known as the ductile to brittle transition temperature, or DBTT. Ferritic steels in particular, among other BCC metals, have two failure modes, switching from ductile failure at higher temperatures to brittle failure at lower ones. While the transition is perhaps more well known in metals, it can occur in other materials such as polymers and ceramics as well. Different forms of impact testing are used to determine the temperature.

Sources/Further Reading: (Image source - 2016 fracture mechanics book chapter) (YENA Engineering) (ASAMS) (nuclear-power.com) (UNSW) (2023 article) (Instron)

#Materials Science#Science#Ductility#Brittleness#Materials failure#Deformation mechanisms#Temperature#FailureFriday#2024Daily

9 notes

·

View notes

Text

How Binding Wire and TMT Bars Create the Backbone of Modern Construction

A steel pipe company that produces components knows something essential about modern-day building practices: the invisible elements regularly determine a shape's integrity. While concrete might also seem like the hero of creation tasks, the fact is it's a ways more complicated. The fusion of binding twine and reinforcement bars creates the hidden framework that allows concrete structures to face up to the test of time.

When employees pour concrete around a carefully built skeleton of metal rebars, they may be collaborating in a production method that has revolutionized structure and infrastructure improvement globally. But how precisely does this system paint, and why is the connection between binding wire and substances from TMT bar manufacturers so essential?

The Critical Role of Binding Wire

Binding wires serves as the unsung hero of this creation symphony. This especially thin, malleable cord performs the essential feature of securing reinforcement bars in their designed positions before concrete placement. When construction people tie rebar grids or cages, binding wire ensures that the reinforcement continues the right spacing and alignment all through the concrete pour.

Proper positioning is non-negotiable due to the fact that the effectiveness of reinforcement relies absolutely on unique placement in the concrete matrix. Even minor displacement can considerably lessen structural capacity and sturdiness. This is in which the relationship among binding twine and materials from TMT bar producers will become crucial.

The Science Behind TMT Bar Manufacturing

TMT (thermo-mechanically treated) bars constitute a widespread development in reinforcement technology. Unlike traditional steel bars, products from TMT bar manufacturers go through a complicated production system concerning managed heating, speedy quenching of the surface layer, and self-tempering of the center as residual warmth flows outward.

This method creates a completely unique micro structure: a sturdy outer layer with martensite formation providing high yield strength and a ductile ferrite-pearlite center that ensures flexibility and weldability.

The Binding Process: Where Precision Meets Craftsmanship

The connection among binding wire and reinforcement from TMT bar producers requires both technical information and practiced talent. Workers usually use specialized tools known as rebar stages to create steady connections at intersection points. The binding pattern follows engineer-specific requirements, with different styles (parent-8, saddle, or wrap-and-twist ties) used depending on structural demands.

Binding cord itself is available in several sorts, with black annealed wire being the most not unusual for popular packages. For specialized tasks, galvanized or PVC-coated binding wire prevents corrosion in aggressive environments. A legit steel pipe business enterprise regularly components the entire range wished for numerous programs.

Industry Integration: From Manufacturing to Construction

The journey from uncooked fabric to finished shape demonstrates extremely good supply chain integration. A steel pipe agency that still materials binding cord and collaborates with TMT bar producers represents an evolution closer to incorporated cloth answers that make sure compatibility and performance.

This delivery chain integration matters because inconsistencies among reinforcement elements can create unexpected weaknesses. When materials come from assets with coordinated pleasant requirements, builders gain confidence in long-term structural overall performance.

Looking Forward: Innovation in Reinforcement Technology

The binding cord and TMT bar production industries retain evolving collectively. Recent improvements consist of self-connecting reinforcement systems that reduce binding cord requirements, corrosion-resistant alloys for severe environments, and digital tracking technology that files reinforcement placement for fine guarantee.

For developers and contractors, staying knowledgeable about these improvements through relationships with a complete metallic pipe company gives competitive benefits in terms of creation efficiency and structural performance.

Final Thoughts

The next time you walk past a production web page or input a concrete construction, don't forget that beneath the gray floor lies a cautiously orchestrated community of materials operating in harmony—concrete, TMT bars, and binding twine growing systems that define our built environment.

#binding wire#TMT bars#construction materials#structural strength#building materials#steel reinforcement#construction basics#TMT bar price#wire for construction#construction wire#steel binding wire#durability#modern construction#building foundations#TMT bars use#construction steel#construction industry#TMT bar quality#steel bars#wire for reinforcement#building projects

1 note

·

View note

Text

Technician testing a magnetic core memory module¹ at the Industrial Electronics Division of Mullard Limited, Balham, London (April 5, 1969). Invented in 1949 by MIT computer engineer Jay Forrester, these memories consisted of very small ferrite rings strung together into a complex mesh of sensing wires designed for reading or writing binary information, they were the predominant form of random-access computer memory for 20 years between about 1955 and 1975.

4 notes

·

View notes

Text

Expert Ferrite Testing in Pune by Integrated NDE Solution

Ferrite testing is crucial for assessing the quality and performance of materials, especially in industries where stainless steels and welds are extensively used. Integrated NDE, located in Pune, offers specialized ferrite testing services that ensure the reliability and durability of these materials.

Importance of Ferrite Testing

Ferrite content in austenitic stainless steel and duplex stainless steel significantly impacts their mechanical properties and corrosion resistance. High ferrite levels can lead to brittleness, while low levels can cause cracking. Therefore, precise ferrite testing is essential to maintain the balance required for optimal material performance.

Advanced Ferrite Testing Techniques

Integrated NDE employs state-of-the-art techniques for ferrite testing in Pune, utilizing both portable and stationary instruments to measure the ferrite content accurately. Our methods are designed to deliver quick and reliable results, ensuring that materials meet the stringent standards required for their applications.

Ferrite Testing of Welds

Welds in stainless steel structures are critical points that require thorough inspection. Ferrite testing of welds ensures that the weld metal has the appropriate ferrite content to avoid issues such as cracking and brittleness. Integrated NDE provides detailed ferrite inspection services for welds, helping clients maintain the integrity of their welded structures.

Applications in Various Industries

Our ferrite testing services cater to a wide range of industries, including:

Petrochemical and Chemical Industries: Ensuring the materials can withstand corrosive environments.

Oil and Gas: Verifying the quality of materials used in pipelines and refineries.

Construction: Assessing the integrity of stainless steel structures.

Power Generation: Testing materials used in critical components of power plants.

Non-Destructive Testing in Pune

Integrated NDE is a leader in non-destructive testing in Pune, offering a comprehensive suite of NDT testing services. Ferrite testing is a part of our extensive NDT capabilities, ensuring that clients receive accurate and reliable data without compromising the integrity of their materials.

Why Choose Integrated NDE?

Expertise: Our team of experienced professionals is proficient in advanced ferrite testing techniques.

Precision: We use cutting-edge technology to deliver precise and reliable results.

Comprehensive Services: From ferrite testing stainless steel to detailed ferrite inspection, we cover all aspects of ferrite content analysis.

Client-Centric Approach: We tailor our services to meet the specific needs of our clients, ensuring their complete satisfaction.

Conclusion

Integrated NDE's ferrite testing services in Pune are designed to provide accurate and reliable analysis of ferrite content in stainless steels and welds. Our advanced techniques and experienced professionals ensure that materials meet the required standards, enhancing their performance and longevity. Trust Integrated NDE for all your ferrite testing and NDT testing needs in Pune, and ensure the integrity and reliability of your critical materials.

For more information about our services and to schedule a consultation, visit our Ferrite Testing page.

#ferrite testing in pune#ferrite testing services#non destructive testing in Pune#ndt testing#ferrite testing#ferrite inspection#ferrite testing of welds#ferrite testing stainless steel

0 notes

Text

RF Chambers | DMCRF

High-Performance RF Chambers for Precise Testing. Looking for reliable RF (Radio Frequency) chambers for electromagnetic compatibility (EMC), antenna testing, or wireless device validation? DMC RF offers state-of-the-art RF shielded chambers designed for accuracy, durability, and superior performance.

Our RF test chambers are used in industries such as:

✔ Telecommunications (5G, IoT, Wi-Fi testing)

✔ Aerospace & Defense (radar, avionics, military comms)

✔ Automotive (connected cars, EV systems)

✔ Consumer Electronics (smartphones, wearables, IoT devices)

Why Choose Our RF Chambers?

✅ Customizable Designs – Tailored to meet specific testing requirements (size, frequency range, shielding effectiveness).

✅ High Shielding Effectiveness – Ensures minimal interference for accurate test results.

Sturdy Construction: Long-term dependability is ensured by the use of premium materials.

✅ Compliance with Global Standards – Meets FCC, CE, MIL-STD, and ISO regulations.

✅Expert Support: From design to installation, our team ensures seamless integration.

Applications of Our RF Chambers

EMC/EMI Testing – Ensure devices meet electromagnetic compatibility standards.

The Complete Guide to RF Chambers: Technology, Applications, and Selection Criteria

Introduction to RF Chambers

Radio Frequency (RF) chambers, also known as shielded enclosures or Anechoic Chambers, are specialized testing environments designed to control electromagnetic interference (EMI) and ensure accurate measurement of radio frequency signals. At DMC RF (https://www.dmcrf.com/), we understand the critical role these chambers play in today's wireless technology landscape.

RF chambers create isolated electromagnetic environments that allow engineers and researchers to:

Conduct precise measurements without external interference

Test device emissions and immunity

Validate wireless communication performance

Ensure regulatory compliance

Understanding RF Chamber Technology

Basic Principles of Operation

RF chambers work on two fundamental principles:

Shielding: Blocks external electromagnetic waves from entering

Absorption: Minimizes internal reflections for accurate measurements

The effectiveness of an RF chamber is measured by its:

Shielding effectiveness (typically 60-120 dB)

Frequency range (from kHz to mmWave)

Field uniformity (for immunity testing)

Key Components

Several layers of conductive materials, usually copper or steel, make up a shielding enclosure.

Absorber Materials: Pyramid foam, ferrite tiles, or hybrid absorbers

Filtered Penetrations: For power and signal lines

Access Systems: RF-tight doors and interlock mechanisms

RF chambers remain essential tools for ensuring the reliability and compliance of modern wireless technologies. Whether you're developing next-generation 5G devices, automotive radar systems, or medical IoT solutions, having the right RF testing environment is crucial.

Antenna & OTA Testing – Measure radiation patterns and signal strength.

Contact Us:

Phone No : +1 (613) 915 5533

Website : https://www.dmcrf.com/

0 notes

Text

Optimising EMI Management in PCB Design: Best Practices for Reliable Performance

Electromagnetic interference (EMI) is a critical concern in modern electronics design. As devices become faster, more compact, and more interconnected, effective EMI management in PCB (Printed Circuit Board) design is essential to ensure product reliability, compliance with regulatory standards, and optimal performance.

This article explores the causes of EMI in PCB design, its effects, and proven strategies to optimise EMI management from the early design stages.

What Is EMI in PCB Design?

EMI refers to unwanted electromagnetic energy that disrupts the normal operation of an electronic circuit. In PCB design, EMI can originate from internal sources (such as high-speed digital signals, switching power supplies) or external sources (such as RF transmitters or nearby electronics).

Common issues caused by EMI include:

Signal integrity degradation

Increased error rates in data transmission

Interference with other devices

Product failure or malfunction

Causes of EMI in PCBs

Understanding the sources of EMI is the first step toward mitigation. Key causes include:

Poor grounding and return paths

High-speed signal transitions

Unshielded components and cables

Inadequate trace layout and spacing

Improper power distribution design

Strategies for Optimising EMI Management

1. Implement a Solid Ground Plane

A continuous ground plane minimizes impedance and provides an effective return path for high-frequency signals. Avoid splitting the ground plane, as this can create unwanted loops that radiate EMI.

2. Use Controlled Impedance Traces

High-speed signals should be routed using controlled impedance techniques. Differential pairs and matched trace lengths help reduce signal reflection and crosstalk.

3. Minimise Loop Areas

The loop area between a signal and its return path should be kept as small as possible. Larger loops act like antennas, increasing the potential for EMI emission.

4. Apply Proper Decoupling

Use decoupling capacitors close to power pins to suppress noise and stabilise voltage levels. Select capacitors with the right values and low equivalent series resistance (ESR).

5. Shielding and Filtering

Shield critical sections of the PCB with metal enclosures or ground planes. Use ferrite beads and EMI filters at key entry/exit points to block high-frequency noise.

6. Route Signals Thoughtfully

Keep high-speed traces short and direct.

Avoid 90-degree trace angles, as they increase EMI emission.

Separate analog and digital signals and isolate noisy components.

7. Use Stack-Up Optimisation

A well-planned multilayer PCB stack-up can improve EMI performance by sandwiching signal layers between ground or power planes, reducing radiated emissions.

EMI Testing and Compliance

Even with careful design, testing is essential. Conduct pre-compliance testing during prototyping using EMI test equipment or services. Ensure your product complies with standards like:

FCC (USA)

CISPR (Europe/International)

MIL-STD-461 (Military equipment)

0 notes

Text

ASTM A240 UNS S32760 Sheet, Super Duplex Zeron 100 Steel Sheet

ASTM A240 UNS S32760 Sheet, also known as Super Duplex Zeron 100 Steel Sheet, is a premium-grade stainless steel product known for its excellent strength, corrosion resistance, and durability. It is a highly alloyed super duplex stainless steel with a mixed microstructure of austenite and ferrite. This structure provides exceptional mechanical properties, including high tensile strength and impact toughness, even at sub-zero temperatures.

UNS S32760 sheets are widely used in aggressive environments, especially in offshore and marine industries, chemical processing plants, desalination plants, and oil & gas industries. These sheets offer superior resistance to pitting, crevice corrosion, and chloride stress corrosion cracking, making them ideal for use in environments containing high chloride levels.

Super Duplex Zeron 100 contains significant amounts of chromium, molybdenum, and tungsten, which enhance its corrosion resistance. It also includes copper to improve resistance to sulfuric acid. The high strength of this material allows for thinner sections and lighter structures compared to standard austenitic stainless steels.

These sheets are produced according to ASTM A240 specifications, ensuring quality, consistency, and suitability for pressure vessels and structural applications. They are available in various thicknesses, widths, and lengths, and can be customized to meet specific project requirements.

Whether you are looking for a durable material for critical offshore platforms or chemical tanks, ASTM A240 UNS S32760 Super Duplex Sheets offer long-lasting performance and cost-efficiency. Their low maintenance requirements and excellent weldability make them a popular choice among engineers and fabricators.

If you're sourcing Super Duplex Zeron 100 Sheets, ensure that the supplier offers mill test certificates, third-party inspection, and timely delivery to meet project schedules.

0 notes

Text

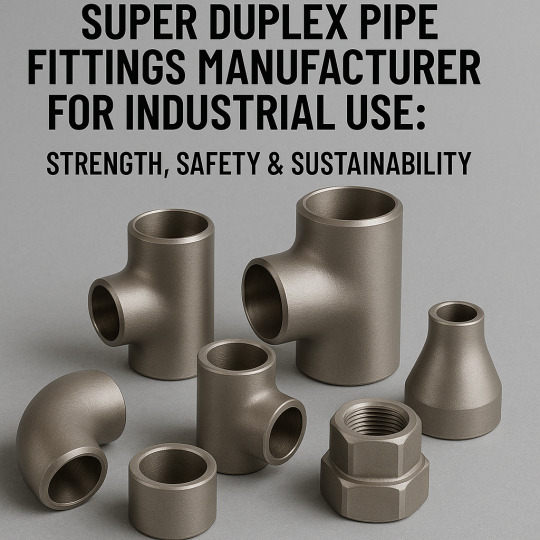

Super Duplex Pipe Fittings Manufacturer for Industrial Use: Strength, Safety & Sustainability

In the demanding world of industrial operations, the reliability of piping systems is non-negotiable. Whether in oil refineries, chemical plants, marine environments, or desalination facilities, the infrastructure must withstand extreme pressures, corrosive substances, and high temperatures. One material that consistently meets and exceeds these challenges is Super Duplex Stainless Steel — and with it, the need for a trusted Super Duplex pipe fittings manufacturer for industrial use becomes essential.

What Makes Super Duplex Steel So Unique?

Super Duplex stainless steel offers a perfect balance of strength and corrosion resistance. Composed of a dual-phase microstructure (austenitic and ferritic), it outperforms standard stainless steels and Duplex grades in critical industrial environments. This unique composition ensures:

High mechanical strength

Superior corrosion resistance (especially to chlorides)

Excellent weldability and fatigue resistance

Cost-effectiveness through longevity and reduced maintenance

These properties make Super Duplex pipe fittings ideal for use in highly corrosive and high-pressure systems — especially in industries where failure is not an option.

Applications of Super Duplex Pipe Fittings in Industrial Sectors

Super Duplex fittings are widely used across industries including:

Oil & Gas (onshore and offshore)

Petrochemical and Chemical Processing

Marine & Shipbuilding

Desalination Plants

Power Generation

Pulp & Paper

In these settings, fittings must perform under extreme operating conditions. Super Duplex pipe fittings ensure system integrity, reducing the risk of leaks, cracks, and corrosion-related failures.

Why Choosing the Right Manufacturer Matters

Not all fittings are created equal. For performance to match specification, selecting a reputed Super Duplex pipe fittings manufacturer for industrial use is crucial. A quality-focused manufacturer ensures:

Precision machining and dimensional accuracy

Certification to international standards (ASTM, ASME, NORSOK, etc.)

Full traceability and quality documentation

Testing for pressure, corrosion, and durability

By sourcing from a reliable manufacturer, industries gain peace of mind knowing that each fitting is engineered for long-term performance and safety.

Benefits of Super Duplex Fittings in Industrial Use

Extended Service Life: Ideal for long-term operations in aggressive environments

Reduced Maintenance Costs: Thanks to high corrosion resistance

Improved System Safety: Lower risk of failure under mechanical or thermal stress

High ROI: Durable materials lead to fewer replacements and lower lifecycle costs

Conclusion

For industries operating in critical conditions, material reliability can be the difference between smooth operations and costly shutdowns. Super Duplex pipe fittings are a powerful solution that delivers unmatched strength and corrosion resistance — making them indispensable in modern industrial infrastructure. Partnering with a trusted manufacturer ensures you're not just buying components, but investing in long-term operational success.

LPF is a globally recognized manufacturer and supplier of high-performance pipe fittings made from Super Duplex and other specialized alloys. With a commitment to engineering excellence, rigorous quality control, and client-focused service, LPF continues to support some of the world's most demanding industries with reliable and efficient piping solutions.

#super duplex fittings#china#india#duplex & super duplex fittings#Super Duplex pipe fittings#Super Duplex Pipe Fittings manufacturer for Industrial use

0 notes

Text

RF Filter - RFI EMC Filter

In an era where electronic devices dominate industrial, medical, and commercial applications, maintaining clean and stable power is more critical than ever. Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) can severely disrupt sensitive equipment, leading to malfunctions, data corruption, and even system failures. This is where RFI EMC Filters come into play—providing essential protection by filtering out unwanted noise and ensuring compliance with global Electromagnetic Compatibility (EMC) standards.

At DMC RF, we specialize in manufacturing high-performance EMI/RFI power line filters, including the RFI EMC Filter 5 to 300 AMP (FCL-66, -660 Series), RFI EMC Filters 25 to 200 AMP (DMC FCL-11, -110, -14, -140, -1 Series), and a wide range of RFI EMC Filter Accessories (FCL-55, -66, -660 Series). Our filters are designed to meet the most stringent industry requirements, ensuring optimal performance and reliability.

Understanding EMI, RFI, and EMC Filters

What is EMI and RFI?

EMI (Electromagnetic Interference): Unwanted disturbances caused by electromagnetic radiation from external sources, affecting electronic circuits.

RFI (Radio Frequency Interference): A subset of EMI, specifically caused by high-frequency signals that disrupt communication and electronic systems.

Why Are EMC Filters Necessary?

Modern electronic devices must comply with EMC regulations (FCC, CISPR, IEC) to ensure they neither emit excessive interference nor are susceptible to external noise. RFI EMC Filters suppress conducted and radiated emissions, protecting both the equipment and surrounding devices from interference.

How Do RFI EMC Filters Work?

These filters use a combination of inductors (chokes), capacitors, and ferrite cores to:

Block high-frequency noise from entering or exiting a device.

Allow clean power to pass through without disruption.

Reduce electromagnetic emissions to meet regulatory standards.

DMC RF’s High-Performance RFI EMC Filters

1. RFI EMC Filter 5 to 300 AMP (FCL-66, -660 Series)

Designed for high-power industrial applications, this series ensures robust noise suppression in demanding environments.

Key Features:

Current Range: 5A to 300A

Voltage Rating: Up to 660V

High Attenuation: Effective noise reduction across a broad frequency spectrum

Rugged Construction: Built to withstand harsh industrial conditions

Compliance: Meets CISPR, EN 55011, and MIL-STD-461 standards

Applications:

✔ Industrial motor drives & servo systems ✔ Medical imaging & diagnostic equipment ✔ Renewable energy inverters & solar power systems ✔ Data centers & telecom infrastructure

2. RFI EMC Filters 25 to 200 AMP (DMC FCL-11, -110, -14, -140, -1 Series)

Ideal for medium-power applications, these filters provide reliable EMI suppression for commercial and industrial equipment.

Key Features:

Current Range: 25A to 200A

High Efficiency: Minimizes conducted and radiated interference

Flexible Mounting Options: Panel or chassis mounting available

Compact Design: Space-saving without compromising performance

Applications:

✔ CNC machines & robotics ✔ Power supplies & UPS systems ✔ HVAC & refrigeration units ✔ Laboratory & test equipment

3. RFI EMC Filter Accessories (FCL-55, -66, -660 Series)

To ensure seamless integration, DMC RF offers a range of compatible accessories, including:

Available Accessories:

Mounting brackets & hardware for secure installation

Shielded enclosures for enhanced EMI protection

Terminal connectors & cable glands

Customizable solutions for specialized applications

Why RFI EMC Filters Are Essential for Your Industry

1. Industrial Automation & Machinery

Prevents interference in PLC systems, servo drives, and robotics.

Ensures smooth operation of CNC machines and conveyor systems.

2. Medical & Healthcare Equipment

Protects sensitive MRI machines, X-ray systems, and patient monitors from noise.

Ensures compliance with medical EMC standards (IEC 60601).

3. Telecommunications & Data Centers

Reduces signal distortion in 5G infrastructure, servers, and networking equipment.

Enhances data integrity and transmission reliability.

4. Renewable Energy Systems

Filters noise from solar inverters, wind turbines, and battery storage systems.

Improves efficiency and lifespan of power electronics.

Choosing the Right RFI EMC Filter

Factors to Consider:

Current & Voltage Ratings – Match the filter to your system’s power requirements.

Attenuation Level – Ensure sufficient noise suppression for your application.

Mounting Style – Panel-mount, chassis-mount, or DIN rail options.

Regulatory Compliance – Check for FCC, CE, CISPR, and UL certifications.

Environmental Conditions – Consider temperature, humidity, and vibration resistance.

Why Choose DMC RF?

✔ Industry-Leading Quality – Rigorously tested for performance & durability. ✔ Wide Range of Options – From 5A to 300A, covering all industrial needs. ✔ Global Compliance – Meets international EMC/EMI standards. ✔ Expert Technical Support – Assistance in selecting the right filter for your application.

In today’s electrically noisy environment, RFI EMC Filters are indispensable for ensuring the reliable operation of sensitive electronic systems. Whether you need a 5A filter for small devices or a 300A industrial-grade solution, DMC RF provides high-performance, compliant, and durable filters tailored to your needs.

By integrating DMC RF’s EMI/RFI power line filters, you can reduce downtime, improve efficiency, and meet global EMC standards with confidence. Contact us now to find the perfect filter solution for your application!

Contact US :

Phone Number : +1(613) 915 5533

Website: https://www.dmcrf.com/emi-rfi-power-line-filters/

1 note

·

View note

Text

Duplex Fasteners Manufacturer, Supplier & Exporter in India Introduction

In challenging environments where both strength and corrosion resistance are crucial, duplex fasteners offer a superior solution. Manufactured from duplex stainless steel, these fasteners combine the qualities of austenitic and ferritic steels making them highly durable, cost-effective, and reliable.

These fasteners are manufactured using duplex stainless steel, which is a microstructure consisting of approximately equal parts of austenite and ferrite. This unique composition offers the benefits of both microstructures, making duplex fasteners a preferred choice in industries such as oil & gas, petrochemical, marine, construction, and more.

Ananka Fasteners is a trusted manufacturer of premium Duplex Fasteners in India, providing an extensive range of high-strength, corrosion-resistant fasteners in various grades, dimensions, and specifications for demanding industrial applications.

What are Duplex Fasteners?

Duplex fasteners include bolts, nuts, washers, studs, threaded rods, and screws made from duplex stainless steel. These fasteners offer:

High mechanical strength (almost double that of standard austenitic stainless steel)

Good weldability and formability

High fatigue strength and toughness

Grades of Duplex Stainless Steel Used

Ananka Fasteners manufactures duplex fasteners using the following popular grades:

Types of Duplex Fasteners We Manufacture

1. Duplex Bolts

Hex Head Bolts

Heavy Hex Bolts

Flange Bolts

U Bolts

Carriage Bolts

Stud Bolts

2. Duplex Nuts

Hex Nuts

Heavy Hex Nuts

Lock Nuts

Dome Nuts

Coupling Nuts

3. Duplex Washers

Plain Washers

Spring Washers

Lock Washers

Flat Washers

4. Duplex Screws

Machine Screws

Self-tapping Screws

Socket Head Cap Screws

Wood Screws

5. Duplex Threaded Rods & Studs

Fully Threaded Rods

Double-end Studs

Tap-end Studs

Duplex Fasteners Specifications & Standards

We manufacture duplex fasteners according to the following international standards:

ASTM A276 / A479 – Stainless steel bars and rods

ASTM A193 / A194 – Bolting Materials for High Temperature or Pressure Service

ASME B18.2.1, B18.2.2, B18.3 – Dimensional Standards

DIN, ISO, JIS, BS – Global Fastening Standards

Applications of Duplex Fasteners

Offshore Oil & Gas Rigs

Chemical Processing Equipment

Desalination Plants

Marine and Shipbuilding

Heat Exchangers and Condensers

Power Generation and Energy Sectors

Structural Components in Buildings & Bridges

Why Choose Ananka Fasteners for Duplex Fasteners?

In-House Manufacturing Facility

We operate a state-of-the-art manufacturing plant in Vasai, Maharashtra, equipped with modern machinery and quality control labs.

Strict Quality Control

Every fastener is tested for tensile strength, hardness, corrosion resistance, and dimensional accuracy before dispatch.

Custom Solutions

From non-standard sizes to specialized coatings (PTFE, Zinc, Hot Dip Galvanized), we offer tailor-made solutions for your project needs.

Global Export Network

We supply duplex fasteners to countries across Europe, the Middle East, Asia, Africa, and the Americas, ensuring timely delivery and complete documentation support.

Packaging & Delivery

Packaging: Wooden boxes, HDPE bags, bubble wraps, or as per customer request.

Delivery: Domestic and international shipping with clear markings, heat numbers, and traceability.

Conclusion

If you're looking for a reliable Duplex Fasteners Manufacturer, Ananka Fasteners is your trusted partner. Our premium quality, commitment to precision engineering, and vast export experience make us the first choice for businesses worldwide. Whether it's a complex offshore application or a structural requirement, our duplex fasteners are engineered to perform flawlessly in harsh environments.

FAQs – Duplex Fasteners

Q1. What’s the difference between Duplex and Super Duplex Fasteners?

Super Duplex fasteners contain elevated levels of chromium, molybdenum, and nitrogen, delivering superior strength and enhanced corrosion resistance compared to standard duplex grades.

Q2. Are duplex fasteners magnetic?

Yes, duplex stainless steels have a ferritic structure that makes them slightly magnetic, unlike austenitic stainless steels.

Q3. Can duplex fasteners withstand seawater?

Yes, especially Super Duplex grades like S32750 and S32760 are highly resistant to seawater corrosion.

Q4. Do you provide test certificates for duplex fasteners?

Absolutely. We provide EN 10204 3.1 / 3.2 certification, third-party inspection reports, and all relevant material test reports.

Q5. What coatings are available for duplex fasteners?

We offer coatings like PTFE, Xylan, Zinc, Hot Dip Galvanized, and custom finishes on request.

#Duplex#DuplexFasteners#Duplex2205Bolts#SuperDuplexFasteners#DuplexFastenersManufacturer#OffshoreFasteners#MarineFasteners#OilAndGasBolts#AnankaFasteners#IndiaManufacturer#GlobalExporter#Blog#Articles#tumblr blog#blogs#tumblr

0 notes