#fine bubble diffuser oxygen transfer efficiency

Explore tagged Tumblr posts

Text

PROMO SPECIAL DIFFUSER FINE BUBBLE HUB:(081335353290)

Diffuser fine bubble 10 inci adalah perangkat aerasi yang menghasilkan gelembung kecil secara merata untuk meningkatkan oksigenasi dalam air. Dengan diameter 10 inci, diffuser ini menggunakan teknologi canggih untuk menciptakan gelembung kecil yang memiliki luas permukaan tinggi, memperbaiki pertukaran gas di dalam air. Dengan desainnya yang presisi, diffuser ini mengoptimalkan distribusi gelembung yang halus dan tahan lama, meningkatkan transfer oksigen ke dalam air untuk mendukung kehidupan akuatik dan proses biologis. Dengan kinerja efisien dan pemeliharaan yang mudah, diffuser fine bubble 10 inci merupakan solusi aerasi yang handal dan efektif untuk lingkungan akuatik.

Untuk pembelian bisa anda kunjungi link dibawah ini:

Shopee:https://shopee.co.id/Air-Diffuser-Fine-Bubble-Disc-10-Inch-i.749609936.15280185273?sp_atk=219b75b4-27d6-4b0c-9fad-ac6c0fa4f896&xptdk=219b75b4-27d6-4b0c-9fad-ac6c0fa4f896 Tokopedia:https://www.tokopedia.com/heframid/air-diffuser-fine-bubble-air-disc-10-inch?extParam=src%3Dshop%26whid%3D13549232

Atau bisa hubungi toko kami lewat no:081335353290

diffuser fine bubble,fine bubble tube diffuser,fine bubble air diffuser,fine bubble diffuser design,fine bubble diffuser price

#fine bubble diffuser brands#ceramic disc fine bubble diffuser#cost of fine bubble diffuser#fine bubble diffuser design#fine bubble disc diffuser for wastewater treatment#10 inch fine bubble disc diffuser#disc type fine bubble diffuser#fine bubble diffuser oxygen transfer efficiency#fine bubble diffusers#bubble diffuser

0 notes

Text

The Smart Solution for Modern Wastewater Treatment with a Fine Bubble Tube Diffuser

Water is life, and keeping it clean is everyone’s responsibility. From households to industries, treating water properly ensures a healthier and more sustainable environment. One of the key technologies helping with this process is the fine bubble tube diffuser. Though it may look simply, this device plays a powerful role in cleaning wastewater and enhancing biological treatment processes.

In this blog, let us explore everything you need to know about the bubble tube diffuser — from how it works to its advantages, applications, and how it supports eco-friendly water treatment.

What is a Fine Bubble Tube Diffuser?

A fine bubble tube diffuser is a device used in wastewater treatment plants to add oxygen into the water. It looks like a flexible tube, made from materials such as EPDM or silicone. The tube has many small perforations that release tiny bubbles when air is pumped through.

These fine bubbles are small enough to stay longer in the water. This longer contact time allows for better oxygen transfer, which is essential for breaking down waste and helping bacteria grow in biological treatment systems.

Understanding the Functioning of an Efficient Aeration System

Here is a step-by-step overview of how it works:

Air Supply: Compressed air is delivered from a blower to the diffuser system.

Air Distribution: The air flows into the diffuser tubes lined with slits.

Bubble Formation: Tiny bubbles are released uniformly into the water.

Oxygen Transfer: The small bubbles allow more oxygen to dissolve, helping microorganisms efficiently treat the wastewater.

Because of the uniform distribution and bubble size, the bubble tube diffuser makes aeration much more efficient while consuming less energy.

Major Advantages of Advanced Wastewater Aeration

Using this technology comes with many advantages:

1. High Oxygen Transfer Efficiency

Tiny bubbles have a large surface area, which increases the rate of oxygen absorption. This ensures faster and more effective biological treatment.

2. Reduced Energy Costs

Less air is needed to maintain proper oxygen levels, which means reduced power consumption. Over time, this makes the system very cost-effective.

3. Uniform Airflow

The tube design allows air to spread evenly in the tank, preventing untreated zones or “dead spots.”

4. Strong and Durable

Made with resistant materials like EPDM and silicone, these diffusers last long, even in tough chemical or temperature conditions.

5. Low Maintenance

The system resists fouling and clogging, so maintenance needs are minimal. Regular inspections once or twice a year are usually enough.

Where Are Diffusers Used?

These diffusers are widely used in various areas, such as:

Municipal sewage treatment plants

Industrial wastewater systems

Aquaculture farms and fish tanks

Food and beverage processing units

Chemical manufacturing facilities

Ponds, oxidation ditches, and lagoons

No matter the industry, the fine bubble tube diffuser can be adjusted to meet specific needs, making it a flexible solution for different water treatment challenges.

Selecting the Right Diffuser for Your System

To choose the best system, keep the following points in mind:

Material: Go for high-quality EPDM or silicone for durability.

Tube Length: Depends on your tank size — longer tubes cover more area.

Bubble Size: Bubbles between 1–3 mm offers the best oxygen transfer.

Installation Type: Choose a model that is easy to set up or remove.

Airflow Capacity: Ensure the diffuser can handle the required air supply.

Consulting with a water treatment expert or supplier will help you select the most efficient for your needs.

Positive Environmental and Operational Impact

A fine bubble tube diffuser system not only helps reduce energy consumption but also supports environmental protection. By using less power and offering higher oxygen efficiency, these systems help improve water quality before it is released into the environment.

This means faster treatment, better bacterial activity, and lower operational expenses — making it a smart choice for both small- and large-scale systems.

Frequently Asked Questions (FAQs)

Q1: How long does a fine bubble tube diffuser last? With regular checks and cleaning, they typically last 5–8 years.

Q2: Can I use it in my old water treatment tank? Yes, they are easy to retrofit into existing systems without much alteration.

Q3: Are they safe for saltwater or chemical exposure? Yes, especially if you choose silicone membranes, which are highly resistant.

Q4: Do they need regular cleaning? Not frequently. Most only require an annual or semi-annual inspection depending on water quality.

Q5: Can they be used in deep tanks? Yes, they perform well at different depths, if the blower supplies the necessary air pressure.

Conclusion:

When it comes to modern wastewater treatment, the fine bubble tube diffuser stands out as a reliable, affordable, and eco-friendly choice. Its ability to improve oxygen transfer, lower energy use, and require minimal maintenance makes it ideal for a range of industries.

If you are looking for expert solutions and high-quality aeration systems, Titan Aeration Company is known for delivering durable and efficient technologies designed to meet today’s treatment demands.

Visit here for more details: https://www.titanaeration.com/flexible-hose-retrievable-system.html

0 notes

Text

Best Water Aeration System in Faridabad

A water aeration system is a crucial technology designed to enhance the oxygen levels in water bodies such as ponds, lakes, reservoirs, and wastewater treatment facilities. By introducing air into the water, these systems promote the exchange of gases, increasing dissolved oxygen (DO) levels essential for aquatic life and the breakdown of organic matter. Aeration can be achieved through various methods, including surface aeration, where water is agitated at the surface to facilitate oxygen transfer, and subsurface aeration, which involves diffusing air bubbles at the bottom of the water body to promote vertical mixing and oxygen distribution. This process not only supports aerobic organisms but also helps in preventing the release of harmful gases like hydrogen sulfide and methane from sediments. The benefits of implementing a water aeration system are multifaceted. In aquatic ecosystems, adequate oxygen levels are vital for the survival of fish and beneficial microorganisms. Aeration helps in reducing the accumulation of organic sludge, controlling algae growth by limiting nutrient availability, and eliminating foul odors caused by anaerobic decomposition. In wastewater treatment, aeration facilitates the aerobic digestion of pollutants, enhancing the efficiency of biological treatment processes. Moreover, consistent aeration can prevent thermal stratification in water bodies, ensuring uniform temperature and oxygen distribution, which is essential for maintaining a balanced aquatic environment Selecting the appropriate aeration system depends on factors such as the size and depth of the water body, the specific water quality issues present, and the desired outcomes. For instance, fine bubble diffusers are highly efficient in oxygen transfer and are suitable for deeper water bodies, while surface aerators are effective for shallow ponds. Regular monitoring and maintenance of these systems are essential to ensure optimal performance and to adapt to changing environmental conditions. By investing in a suitable water aeration system, stakeholders can significantly improve water quality, support aquatic life, and enhance the overall health of aquatic ecosystems

For More Details Click Here: https://www.indiantradebird.com/product/water-aeration-system

0 notes

Text

Comparative Energy Consumption of Circumferential Aeration Aerator in Wastewater Treatment

In the context of wastewater treatment, the selection of an aeration system is a critical decision that significantly impacts both the operational costs and the environmental footprint of the treatment process. The Circumferential Aeration Aerator, with its distinct design, has been a subject of interest for its potential energy efficiency. This article aims to provide a comprehensive comparison of the energy consumption of Circumferential Aeration Aerators with other aeration devices, examining their performance in various scenarios.

The Circumferential Aeration Aerator is a type of surface aerator that is designed to distribute air evenly across the entire cross-section of aeration basins, promoting efficient oxygen transfer and mixing. This design is intended to optimize the oxygenation process, which is essential for the aerobic decomposition of organic matter in wastewater. The energy consumption of such a system is a crucial factor in determining its overall efficiency and cost-effectiveness.

When comparing the energy consumption of a Circumferential Aeration Aerator with other aeration devices, such as fine bubble diffusers or mechanical surface aerators, several factors must be taken into account. These include the oxygen transfer efficiency, the power input per unit of oxygen transferred, and the operational conditions of the wastewater treatment plant.

The Circumferential Aeration Aerator, due to its even distribution of air, tends to have a higher oxygen transfer efficiency compared to some other aeration systems. This efficiency translates into lower energy consumption per unit of oxygen transferred, making it an attractive option for energy-sensitive applications. Studies have shown that the Circumferential Aeration Aerator can achieve oxygen transfer efficiencies that are competitive with, and in some cases good to, those of fine bubble diffusers, which are known for their high efficiency but can be more energy-intensive.

However, the energy consumption of the Circumferential Aeration Aerator is not solely determined by its oxygen transfer efficiency. The power input required to operate the system is also a significant factor. The Circumferential Aeration Aerator, being a mechanical system, requires less power per unit of oxygen transferred compared to some other mechanical aerators. This is due to its design, which allows for a more direct and efficient use of energy to move air into the wastewater.

In terms of operational conditions, the Circumferential Aeration Aerator can be more versatile than other systems. It can be easily adjusted to accommodate changes in the volume of wastewater or the required oxygen levels, which can cause further energy savings. This adaptability is particularly important in treatment plants that experience fluctuating influent loads or seasonal variations in oxygen demand.

Despite these advantages, the Circumferential Aeration Aerator is not without its challenges. Maintenance costs and the need for regular inspection to ensure the integrity of the aeration system can add to the operational expenses. However, with proper maintenance and management, these costs can be reduced, and the long-term energy savings can make the Circumferential Aeration Aerator a more economical choice.

In conclusion, the Circumferential Aeration Aerator offers a competitive energy consumption profile when compared to other aeration devices. Its high oxygen transfer efficiency, lower power input requirements, and adaptability to varying operational conditions make it a strong contender for wastewater treatment plants seeking to optimize their energy usage. As environmental concerns and energy costs continue to rise, the Circumferential Aeration Aerator's energy efficiency becomes an increasingly important consideration in the selection of aeration technologies for wastewater treatment.

Power: 0.75KW Oxygen generating capacity: ≥1.35kgO2/h Power efficiency: 1.2kg02/hkW Pumping capacity: ≥7,200m3/h Wave-making strength: 50mm Amplitude Wave Action Range (Diameter)≥70m Impeller speed: Φ1580900mm Dimensions: 34rpm Weight: 53kg Farming coverage: 4669m2

0 notes

Text

Welcome to Gasion Airtec Pvt. Ltd, where we specialize in providing top-quality fine bubble diffusers for aeration and oxygenation needs. Our fine bubble diffusers are designed to deliver exceptional performance and efficiency in various applications, including wastewater treatment plants, aquaculture systems, and industrial processes.

What sets our Fine Bubble Diffusers apart is their innovative design, engineered to produce a high volume of small bubbles that maximize the surface area for oxygen transfer. This results in superior oxygenation of water bodies, promoting the growth of beneficial microorganisms and enhancing overall water quality.

0 notes

Text

What Is the Ideal Aeration Setup for Shrimp Nursery, Shrimp Hatchery, and Shrimp Grow-Out Ponds?

In shrimp aquaculture, effective aeration plays a critical role in ensuring optimal growth, survival, and overall health of the shrimp. Different stages of shrimp farming—nursery, hatchery, and grow-out ponds—require specific aeration setups tailored to their unique needs.

A reliable brand like AirOxi offers cutting-edge aeration solutions to meet these requirements, helping farmers improve water quality, maintain oxygen levels, and achieve better yields. In this blog, we’ll explore the ideal aeration setups for shrimp nurseries, hatcheries, and grow-out ponds, highlight the key requirements of a good aeration system, and identify the differences between these setups.

The Importance of Aeration in Shrimp Farming

Aeration systems are vital for:

Maintaining Dissolved Oxygen (DO): Adequate oxygen levels are crucial for shrimp health and survival.

Improving Water Quality: Aerators facilitate the breakdown of organic waste and prevent harmful ammonia buildup.

Preventing Stratification: Aeration ensures uniform water quality by mixing oxygen throughout the water column.

Enhancing Growth: Proper oxygen levels reduce stress and improve shrimp feed conversion rates.

Each stage of shrimp farming—nursery, hatchery, and grow-out—has distinct aeration requirements, making a tailored approach essential.

1. Aeration Setup for Shrimp Nursery

Shrimp nurseries are compact, high-density systems where post-larvae (PL) are reared before being transferred to grow-out ponds. The confined space and higher stocking densities create a greater demand for dissolved oxygen and waste management.

Key Features of an Ideal Aeration System for Nurseries:

Effective Oxygen Transfer: Shrimp nurseries require fine bubble diffusers, such as Low Pressure AirOxi Tubes, which produce micro-bubbles to enhance oxygen transfer efficiency .

Proper Water Movement: Water circulation is critical to prevent the buildup of waste and ensure uniform oxygen levels. Combining airlift systems or paddlewheel aerators with fine bubble aerators achieves optimal results.

Compact and Durable Design: Nurseries are usually smaller in size, making compact aeration systems like AirOxi Tubes ideal for maximizing efficiency without occupying too much space.

Real-Time Monitoring: Integrating oxygen sensors into the aeration setup allows farmers to maintain optimal oxygen levels consistently.

Biosecurity and Maintenance: Aeration systems should minimize water surface agitation to reduce pathogen spread and be easy to clean and maintain for biosecurity.

2. Aeration Setup for Shrimp Hatchery

Shrimp hatcheries are controlled systems focused on producing larval stages, including nauplii, zoea, and mysis. Hatcheries require precise control of water quality and aeration intensity to support the delicate larvae.

Key Features of an Ideal Aeration System for Hatcheries:

Gentle Aeration: Hatcheries need low-intensity aeration to avoid damaging the fragile larvae. Equipment like AirOxi Disc Diffusers and Oxygen Concentrators and Ceramic Plates offers gentle oxygenation with minimal turbulence.

Maintaining Pristine Water Quality: Since larvae are highly sensitive to water conditions, aerators must prevent stratification and encourage the breakdown of organic waste while avoiding excessive water agitation.

Energy-Efficient Solutions: Hatchery systems often operate continuously, making energy-efficient aeration solutions, such as AirOxi Regenerative Blowers, an excellent choice to minimize operational costs.

Precise Control Mechanisms: Oxygen and pH levels must be monitored and controlled meticulously using sensors and automated systems.

Customizable Designs: Hatchery aeration systems should be easily adjustable to accommodate different larval stages and densities.

3. Aeration Setup for Shrimp Grow-Out Ponds

Grow-out ponds are larger, open systems where shrimp are reared to market size. These systems require robust aeration to handle larger water volumes, manage waste, and maintain optimal environmental conditions.

Key Features of an Ideal Aeration System for Grow-Out Ponds:

High Oxygen Demand: Grow-out ponds require higher oxygen levels to sustain the larger biomass. Paddlewheel aerators cannot provide the aeration required. Hence it is best to use them for only water movement and use fine bubble aeration using High Efficiency AirOxi Tubes to ensure sufficient oxygen distribution throughout the pond.

Strategic Oxygen Distribution: Aeration tubes must be placed strategically to avoid dead zones and ensure uniform oxygen levels, particularly during peak feeding times.

Effective Waste Management: Bottom aerators, such as AirOxi Tubes, help maintain a clean pond bed by breaking down organic waste and preventing its accumulation.

Scalability and Adaptability: As grow-out ponds are large-scale systems, aeration setups must be scalable and adaptable to changes in stocking densities and environmental conditions.

Durability and Longevity: Grow-out ponds are exposed to outdoor conditions, so aeration equipment must be durable and resistant to environmental wear and tear.

Key Differences Between Nursery, Hatchery, and Grow-Out Pond Aeration

Parameter

Nursery

Hatchery

Grow-Out Pond

System Size

Small and compact

Small, indoor

Large and open

Oxygen Demand

High

Moderate, controlled

High, varying with biomass

Aeration Intensity

Moderate

Gentle

Strong

Equipment Type

AirOxi low pressure tubes

Ceramic plates

Root Blower with High Efficiency tubes

Water Movement

Controlled

Minimal turbulence

Strong circulation

Main Points for a Good Aeration Setup

To achieve an efficient and effective aeration setup, ensure the following:

High Oxygen Transfer Efficiency: Aerators should provide sufficient oxygen to meet shrimp demand.

Uniform Distribution: Proper placement ensures consistent oxygen levels throughout the water body.

Energy Efficiency: Aeration equipment, such as those from AirOxi, should minimize energy consumption while delivering optimal performance.

Durability: Use equipment made from long-lasting materials that can withstand operational stress.

Scalability and Customization: Systems should be adaptable to changes in pond size or stocking density.

Ease of Maintenance: Choose aeration products that are easy to install and maintain, such as AirOxi Tubes and diffusers.

Monitoring and Automation: Oxygen sensors and automated controllers help maintain optimal DO levels in real-time.

Why Choose AirOxi for Aeration?

AirOxi offers state-of-the-art aeration solutions designed to meet the specific needs of shrimp farmers. Here’s why AirOxi stands out:

Versatile Product Range: From Low pressure tubes to fine bubble diffusers to sub surface aerators, AirOxi caters to every stage of shrimp farming.

Durable and Reliable: AirOxi products are made with high-quality materials to ensure long-term durability.

Energy Efficiency: Designed to reduce energy consumption, AirOxi products are cost-effective for large-scale operations.

Expert Support: AirOxi provides customized solutions and consultation to optimize aeration systems for maximum efficiency.

Proven Results: Farmers worldwide trust AirOxi products for their reliability and superior performance.

Learn more about AirOxi’s innovative solutions by visiting this blog.

Conclusion

Effective aeration is the cornerstone of successful shrimp farming. Whether you’re managing a nursery, hatchery, or grow-out pond, having the right aeration setup tailored to each stage’s unique requirements is essential for maximizing productivity and profitability. With AirOxi, you can ensure optimal water quality, reduce shrimp stress, and achieve consistent growth rates.

Upgrade your aeration system today with AirOxi and experience the difference it makes in your shrimp farming operation!

Contact AirOxi for your aquaculture aeration requirements

+917041004098

www.buy.airoxi.com

To know more call us at:

+91 – 9652122060

Email: [email protected]

www.buy.airoxi.com

#envirment #everyone #airoxitube #airoxi #airoxidiffuser #airoxiproducts #aquarium #aquaculture #fishing #fishingfarm #shrimp #shrimptank #fishtank #tank #RAS #aeration #aerationsystem #bubble #post #postoftheday #oxygenation #hatcheries #shrimpfarm #aqualife #blower #microbubblegenerator #transportationaeration #turbineblower #submersibleaerator #biofloc #growoutponds #nurseries #oxygenconcentrator #diffuser

#fish farming#aeration solution#shrimp farming#airoxi tube#aquaculture#aeration tubes#airoxitube#airoxi#aeration#fish

0 notes

Text

Jual fine bubble diffuser specifications | 0813-3535-3290

Jual fine bubble diffuser specifications Diameter: 10 Dalam dunia pengolahan air, terutama dalam pengolahan air limbah dan proses aerasi, teknologi pengenalan udara sangat penting. Salah satu alat yang paling efektif dalam proses aerasi adalah fine bubble diffuser. Alat ini berfungsi untuk mendispersikan udara ke dalam air dalam bentuk gelembung-gelembung halus yang meningkatkan proses pertukaran gas, seperti oksigen, di dalam air. PT Hefram Asasta Indonesia, sebagai perusahaan yang bergerak di bidang solusi pengolahan air, menawarkan produk fine bubble diffuser yang dirancang untuk memberikan efisiensi terbaik dalam berbagai aplikasi.

Artikel ini akan membahas tentang spesifikasi fine bubble diffuser yang ditawarkan oleh PT Hefram Asasta Indonesia, termasuk cara kerjanya, keunggulannya, dan mengapa teknologi ini menjadi pilihan utama dalam pengolahan air.

Apa Itu Fine Bubble Diffuser?

Fine bubble diffuser adalah perangkat yang digunakan untuk menghasilkan gelembung udara kecil (fine bubbles) yang dimasukkan ke dalam air. Gelembung-gelembung kecil ini memiliki luas permukaan yang besar, yang memfasilitasi pertukaran gas (seperti oksigen) antara udara dan air dengan efisiensi yang tinggi. Proses ini sangat penting dalam sistem aerasi untuk memperbaiki kualitas air, baik di industri pengolahan air limbah, akuakultur, atau sistem penjernihan air.

PT Hefram Asasta Indonesia memproduksi fine bubble diffuser dengan teknologi terbaru, memastikan bahwa perangkat ini memberikan hasil yang optimal dalam meningkatkan kualitas air. Beberapa jenis diffuser yang umum digunakan antara lain adalah disk diffuser, tubular diffuser, dan plate diffuser, yang semuanya memiliki kemampuan untuk menghasilkan gelembung halus dalam jumlah besar.

Spesifikasi Fine Bubble Diffuser dari PT Hefram Asasta Indonesia

Ukuran GelembungFine bubble diffuser dari PT Hefram Asasta Indonesia menghasilkan gelembung dengan ukuran antara 0,1 mm hingga 3 mm. Gelembung halus ini memastikan bahwa proses pertukaran gas lebih efisien karena memiliki luas permukaan yang lebih besar dibandingkan dengan gelembung besar.

Efisiensi Transfer Oksigen (OTE)Salah satu parameter utama yang menentukan kualitas fine bubble diffuser adalah Oxygen Transfer Efficiency (OTE), yang mengukur seberapa efektif diffuser dalam mentransfer oksigen ke dalam air. Produk dari PT Hefram Asasta Indonesia memiliki tingkat OTE antara 20% hingga 35%, tergantung pada kondisi air dan desain diffuser.

Bahan dan MaterialMaterial yang digunakan dalam pembuatan diffuser sangat penting untuk menjamin daya tahan dan kinerja alat. PT Hefram Asasta Indonesia menggunakan bahan berkualitas tinggi seperti EPDM (Ethylene Propylene Diene Monomer), silikon, dan PVC untuk komponen diffuser, yang memastikan bahwa alat ini tahan terhadap korosi.

Tingkat Tekanan OperasiFine bubble diffuser dari PT Hefram Asasta Indonesia dirancang untuk beroperasi pada tekanan antara 0,5 bar hingga 4 bar, tergantung pada kedalaman dan kebutuhan sistem aerasi. Hal ini memungkinkan diffuser bekerja dengan efisiensi maksimal dalam berbagai kondisi.

Air Flow RateAliran udara pada fine bubble diffuser dapat disesuaikan, dengan rentang aliran udara antara 0,5 hingga 20 m³/h per diffuser. Hal ini memungkinkan diffuser untuk digunakan dalam berbagai skala aplikasi, mulai dari sistem pengolahan air kecil hingga besar.

Durabilitas dan Umur LayananProduk diffuser dari PT Hefram Asasta Indonesia memiliki daya tahan yang lama, dengan umur layanan membran dapat mencapai hingga 10 tahun, tergantung pada kondisi operasi dan perawatan. Material yang digunakan untuk membran, seperti EPDM atau silikon, dirancang untuk tahan terhadap berbagai kondisi kimiawi dan suhu ekstrem.

Untuk informasi lebih lengkap, Anda dapat menghubungi dan mendapatkan penawaran harga yang terjangkau:

Kontak kami: https://wa.me/6281335353290

Lokasi: https://maps.app.goo.gl/XHtDvZAHB7ZxjkVDA

Marketplace: https://tokopedia.link/9UDx90fNvOb

Keunggulan Fine Bubble Diffuser dari PT Hefram Asasta Indonesia

Efisiensi Tinggi dalam Pertukaran GasDengan menghasilkan gelembung yang sangat kecil, fine bubble diffuser dapat mencapai tingkat efisiensi oksigen yang lebih tinggi dibandingkan dengan jenis diffuser lainnya. Hal ini meningkatkan kinerja sistem aerasi dan mengurangi konsumsi energi.

Pemasangan yang Mudah dan FleksibelProduk dari PT Hefram Asasta Indonesia dirancang untuk kemudahan pemasangan, baik pada sistem aerasi bawah permukaan (sub-surface) maupun di permukaan. Fleksibilitas ini membuat fine bubble diffuser cocok untuk berbagai jenis instalasi.

Meningkatkan Kualitas Air dengan CepatKarena gelembung yang dihasilkan lebih halus dan luas permukaan yang lebih besar, proses transfer oksigen ke dalam air menjadi lebih cepat. Hal ini membantu dalam pengolahan air limbah dan meningkatkan kualitas air secara efisien.

Tahan Lama dan Hemat Biaya OperasionalDengan penggunaan material berkualitas tinggi dan teknologi terbaru, diffuser ini memiliki masa pakai yang panjang dan memerlukan sedikit perawatan.

Cocok untuk Berbagai AplikasiFine bubble diffuser dari PT Hefram Asasta Indonesia dapat digunakan dalam berbagai aplikasi, mulai dari pengolahan air limbah domestik, industri, hingga akuakultur. Kemampuan untuk menyesuaikan dengan kebutuhan spesifik membuatnya sangat versatil.

Aplikasi Fine Bubble Diffuser

Fine bubble diffuser sangat populer dalam berbagai bidang pengolahan air, antara lain:

Pengolahan Air LimbahDigunakan untuk meningkatkan oksigen terlarut dalam air limbah, yang sangat penting dalam proses biologis pengolahan air.

AquacultureDalam budidaya ikan dan udang, oksigen terlarut sangat vital untuk pertumbuhan dan kesehatan organisme akuatik. Fine bubble diffuser menyediakan oksigen yang diperlukan dengan efisien.

Penjernihan AirSistem aerasi dengan fine bubble diffuser juga digunakan untuk meningkatkan kualitas air di reservoir dan danau, membantu proses pengendapan dan pemisahan partikel.

Fine bubble, diameter: 10 Bubble size 1-2 mm

Fine bubble diffuser adalah teknologi yang sangat efisien dalam meningkatkan kualitas air melalui proses aerasi. Dengan spesifikasi yang dirancang untuk memberikan performa optimal, produk dari PT Hefram Asasta Indonesia menawarkan berbagai keunggulan, seperti efisiensi tinggi dalam transfer oksigen, daya tahan yang lama, dan fleksibilitas dalam pemasangan. Teknologi ini sangat cocok untuk aplikasi pengolahan air limbah, akuakultur, dan penjernihan air, menjadikannya pilihan utama bagi banyak industri.

Dengan produk yang mengutamakan kualitas dan kinerja, PT Hefram Asasta Indonesia memastikan bahwa fine bubble diffuser yang mereka tawarkan dapat memenuhi kebutuhan pengolahan air yang semakin kompleks. Investasi dalam teknologi ini akan memberikan manfaat jangka panjang bagi peningkatan kualitas air dan efisiensi operasional.

Sebagai solusi untuk pengolahan air yang lebih efisien, fine bubble diffuser dari PT Hefram Asasta Indonesia merupakan pilihan terbaik untuk menciptakan sistem aerasi yang optimal. Dengan inovasi dan kualitas tinggi, PT Hefram Asasta Indonesia siap membantu Anda dalam mencapai pengolahan air yang lebih efektif dan berkelanjutan.

Baca Juga:

Untuk informasi lebih lengkap Anda dapat menghubungi dan mendapatkan penawaran harga yang terjangkau :

Kontak kami : https://wa.me/6281335353290

Lokasi :https://maps.app.goo.gl/XHtDvZAHB7ZxjkVDA

Marketplace : https://tokopedia.link/9UDx90fNvOb

youtube

diffuser fine bubble, diffuser fine bubble 10 inch, air diffuser fine bubble ,diffuser fine bubble adalah, fine bubble air diffuser, fine bubble diffuser air flow rate, aquarium fine bubble diffuser

aerostrip fine bubble diffuser, fine bubble tubular air diffuser, fine bubble diffuser adalah, difference between fine bubble diffuser and coarse bubble diffuser

#diffuserfinebubble #diffuserfinebubble10inch #airdiffuserfinebubble #diffuserfinebubbleadalah, #finebubbleairdiffuser #finebubblediffuserairflowrate #aquariumfinebubblediffuser

#aerostripfinebubblediffuser #finebubbletubularair #diffuserfinebubblediffuseradalah #difference #betweenfinebubblediffuserandcoarsebubblediffuser

0 notes

Text

A fine bubble diffuser is a device used in wastewater treatment systems to diffuse air or oxygen into water, creating small bubbles. These fine bubbles increase the surface area for oxygen transfer, which enhances the efficiency of biological treatment processes, particularly in aeration tanks. The global fine bubble diffuser market, valued at USD 3,200.1 million in 2023, is expected to grow at a 5.2% CAGR from 2024 to 2034, reaching USD 5,604.2 million by 2034, driven by increasing demand for efficient wastewater treatment solutions.

0 notes

Text

BIG SALE DIFFUSER FINE BUBBLE HUB:(081335353290)

Diffuser fine bubble adalah perangkat aerasi yang menghasilkan gelembung udara kecil dengan diameter kurang dari 1 mm. Berbeda dengan model standar, diffuser ini menggunakan teknologi canggih untuk menciptakan gelembung yang lebih halus dan seragam, memaksimalkan transfer oksigen ke dalam air. Desainnya yang inovatif memungkinkan distribusi gelembung secara merata, menciptakan luas permukaan yang besar untuk kontak optimal antara udara dan air. Hasilnya, sistem aerasi lebih efisien dalam meningkatkan oksigenasi dan perbaikan kualitas air, mendukung pertumbuhan mikroorganisme, serta mengoptimalkan proses pengolahan limbah.Dalam aplikasi industri dan lingkungan, diffuser fine bubble merupakan solusi terkini untuk meningkatkan kinerja sistem aerasi secara signifikan.

Untuk pembelian bisa anda kunjungi link dibawah ini:

Shopee:https://shopee.co.id/Air-Diffuser-Fine-Bubble-Disc-10-Inch-i.749609936.15280185273?sp_atk=219b75b4-27d6-4b0c-9fad-ac6c0fa4f896&xptdk=219b75b4-27d6-4b0c-9fad-ac6c0fa4f896 Tokopedia:https://www.tokopedia.com/heframid/air-diffuser-fine-bubble-air-disc-10-inch?extParam=src%3Dshop%26whid%3D13549232

Atau bisa hubungi toko kami lewat no:081335353290

diffuser fine bubble,fine bubble tube diffuser,fine bubble air diffuser,fine bubble diffuser design,fine bubble diffuser price

#fine bubble diffuser brands#ceramic disc fine bubble diffuser#cost of fine bubble diffuser#fine bubble diffuser design#fine bubble disc diffuser for wastewater treatment#10 inch fine bubble disc diffuser#disc type fine bubble diffuser#fine bubble diffuser oxygen transfer efficiency#fine bubble diffusers#bubble diffuser

0 notes

Text

Aerator Parts & Accessories for Lawn & Pond

Maintaining a lush lawn and a healthy pond requires proper aeration. Aerators introduce air into the soil or water, promoting the growth of beneficial organisms and ensuring optimal health for your lawn and pond. Understanding the parts and accessories available can help you choose the right equipment and keep your aerator in top condition.

Lawn Aerator Parts

Tines: Tines are the core components of lawn aerators. They penetrate the soil, creating small holes that allow air, water, and nutrients to reach the grass roots. There are two main types of tines:--Hollow Tines: Remove soil plugs, reducing compaction and promoting better soil structure.: --Solid Tines: Puncture the soil without removing plugs, useful for less compacted soils.

Drive Mechanism: The drive mechanism powers the aerator's movement and tine action. It can be manual, motorized, or tractor-mounted, each suited for different lawn sizes and conditions.

Rollers and Spikes: Some aerators use rollers with attached spikes to aerate the soil. These are generally less effective than tines but can be useful for lightly compacted areas.

Weight Tray: A weight tray allows you to add additional weight to the aerator, increasing the penetration depth of the tines or spikes, especially in harder soils.

Handle and Frame: The handle and frame provide stability and ease of use. They should be sturdy and comfortable to ensure effective operation.

Pond Aerator Parts

Diffusers: Diffusers are essential for pond aerators. They break air into small bubbles, increasing the oxygen transfer rate to the water. Common types include:

Membrane Diffusers: Flexible membranes with fine pores, producing fine bubbles and requiring minimal maintenance.

Stone Diffusers: Made from porous stones, producing coarser bubbles and requiring more frequent cleaning.

Air Pumps: The air pump is the heart of a pond aerator, pushing air through the diffusers. It should be powerful enough to circulate the entire pond volume and energy-efficient for continuous operation.

Tubing: Tubing connects the air pump to the diffusers. It should be durable, flexible, and resistant to UV light and other environmental factors.

Check Valves: Check valves prevent water from flowing back into the air pump when it’s turned off. This is crucial to protect the pump and ensure consistent aeration.

Weighted Bases: Weighted bases keep the diffusers anchored at the bottom of the pond, ensuring even air distribution throughout the water column.

Accessories for Aerators

Replacement Parts: Keeping spare tines, diffusers, and tubing on hand ensures you can quickly replace worn or damaged components, minimizing downtime.

Cleaning Kits: Regular maintenance is essential for both lawn and pond aerators. Cleaning kits help keep tines, diffusers, and other parts free from debris and buildup, ensuring optimal performance.

Lubricants: Lubricating moving parts reduces wear and tear, extending the lifespan of your aerator. Use lubricants recommended by the manufacturer for best results.

Timers and Controllers: Automating your aeration system with timers and controllers ensures consistent operation, saving time and improving efficiency.

Protective Covers: Protective covers shield your aerator from the elements when not in use, prolonging its lifespan and maintaining its performance.

Conclusion

Investing in the right aerator parts and accessories for your lawn and pond is crucial for maintaining their health and beauty. Regular maintenance, timely replacement of worn components, and using appropriate accessories will keep your aeration system running efficiently. By understanding the different parts and their functions, you can make informed decisions and ensure your lawn and pond thrive year-round.

0 notes

Text

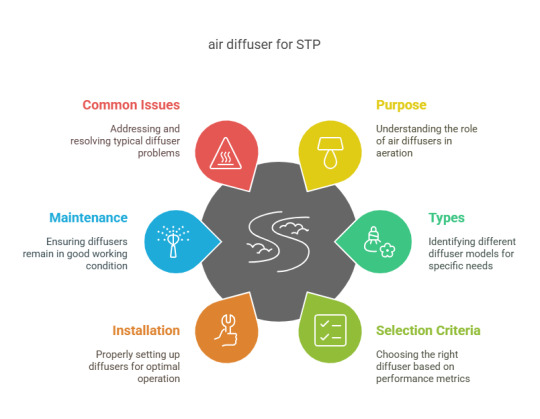

Unlocking Efficient Sewage Treatment: The Role of Air Diffuser for STP by Titan Aeration

In today’s world, efficient wastewater treatment is a necessity — not just for compliance with environmental regulations but for protecting public health and preserving water resources. One of the most vital components of any Sewage Treatment Plant (STP) is the air diffuser. An air diffuser for STP plays a critical role in ensuring that the biological treatment processes are effective and energy-efficient.

At Titan Aeration, we specialize in providing high-performance air diffusers for STP, tailored to meet the demands of modern wastewater treatment plants. In this blog, we will explore what an air diffuser is, how it works, its types, its benefits, and why it’s indispensable in sewage treatment plants.

What is an Air Diffuser for STP?

An air diffuser for STP is a mechanical device used in sewage treatment plants to distribute air uniformly into the wastewater. The main purpose of this process, known as aeration, is to supply oxygen to aerobic microorganisms, which break down organic matter in the sewage.

How Does an Air Diffuser Work in STPs?

1. Oxygen Transfer

The diffuser releases compressed air into the sewage in the form of bubbles. These bubbles help increase the dissolved oxygen (DO) levels in the water, which is crucial for microbial activity.

2. Mixing of Wastewater

Apart from oxygenation, the air bubbles also ensure uniform mixing of wastewater. This prevents the settling of solids and enhances the overall treatment efficiency.

3. Support for Biological Treatment

Bacteria and other microorganisms require oxygen to digest the organic matter present in sewage. The air diffuser for STP supports this biological activity, ensuring complete and efficient decomposition.

Types of Air Diffusers Used in STP

1. Fine Bubble Diffuser

These diffusers release small bubbles that offer a higher surface area, resulting in better oxygen transfer. They are energy-efficient and are widely used in municipal and industrial STPs.

2. Coarse Bubble Diffuser

Coarse bubble diffusers emit larger bubbles and are used where clogging is a concern. They offer better mixing but less oxygen transfer efficiency than fine bubble types.

3. Tube Diffuser

Tube diffusers are cylindrical and used for their high performance and resistance to fouling. They are a great option for continuous operation systems.

4. Disc Diffuser

Disc diffusers are flat and circular, commonly made from EPDM or silicone. They are known for high oxygen transfer efficiency and easy maintenance.

Why Choose Titan Aeration’s Air Diffuser for STP?

At Titan Aeration, we understand the importance of robust and efficient aeration systems in sewage treatment. Our air diffusers for STP are:

· Made with High-Quality Materials: We use durable and non-corrosive materials like EPDM and silicone.

· Energy-Efficient: Designed to minimize power consumption while maximizing oxygen transfer.

· Low Maintenance: Our diffusers are easy to install, operate, and maintain.

· Customizable: We provide tailored solutions depending on tank size, air flow rate, and treatment load.

Key Benefits of Using an Air Diffuser for STP

1. Enhanced Oxygen Transfer

Fine and uniformly dispersed bubbles ensure a higher oxygen transfer rate, improving biological treatment efficiency.

2. Cost-Effective Operation

Efficient oxygen distribution reduces energy usage, which is one of the highest operational costs in STPs.

3. Improved Water Quality

Better aeration ensures the removal of BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), and other pollutants.

4. Reduced Odors

Efficient treatment reduces the formation of anaerobic zones that cause foul odors.

5. Long Lifespan

High-quality air diffusers from Titan Aeration are built to last, even under challenging operating conditions.

Applications of Air Diffuser for STP

· Municipal Wastewater Treatment Plants

· Industrial Sewage Treatment

· Housing Societies and Residential Complexes

· Hospitals and Educational Institutions

· Hotels and Commercial Buildings

Factors to Consider While Choosing an Air Diffuser for STP

1. Oxygen Requirement

Evaluate the oxygen demand of your plant to determine the type and number of diffusers required.

2. Tank Design

The shape and size of the aeration tank influence the choice of diffuser (disc or tube).

3. Air Flow Rate

Choose diffusers that can handle your plant’s air supply without clogging or over-pressuring.

4. Maintenance and Durability

Opt for low-maintenance diffusers with resistance to fouling, tearing, and chemical damage.

Maintenance Tips for Air Diffuser for STP

· Regular Cleaning: Prevent clogging and biofilm buildup by cleaning periodically.

· Air Filter Maintenance: Ensure that the air supply is clean to prevent dust or oil damage to the diffuser.

· Backflushing: Occasionally reverse air flow to clear out obstructions in fine bubble diffusers.

· Periodic Inspection: Check for cracks, hardening, or fouling of membranes to replace on time.

Why Air Diffuser Efficiency Matters in STP

A poorly functioning air diffuser for STP can lead to insufficient oxygen levels, poor microbial activity, and incomplete treatment. This can result in untreated or partially treated wastewater being discharged, violating environmental norms and causing harm to aquatic ecosystems.

With increasing urbanization and tighter pollution control regulations, optimizing your STP’s aeration system is more crucial than ever. At Titan Aeration, we help you achieve this with our reliable and efficient range of air diffusers.

Conclusion

The air diffuser for STP is not just a component — it’s the heart of the aeration process in sewage treatment. By ensuring proper oxygen supply, it enables effective microbial digestion, energy efficiency, and regulatory compliance. Whether you’re upgrading an existing system or setting up a new one, choosing the right air diffuser is critical.

Titan Aeration is committed to offering top-quality air diffusers that enhance the performance of your STP, reduce operational costs, and support sustainable wastewater management. Get in touch with us today for a customized solution that fits your treatment plant’s needs.

Frequently Asked Questions (FAQs)

Q1. What is the purpose of an air diffuser in an STP?

An air diffuser introduces air into the sewage to increase dissolved oxygen levels, supporting the biological breakdown of organic matter by microorganisms.

Q2. How often should air diffusers in STPs be maintained?

It depends on the type of diffuser and wastewater characteristics. However, regular inspection and cleaning every 6 to 12 months are generally recommended.

Q3. Which is better for STPs — fine bubble or coarse bubble diffuser?

Fine bubble diffusers offer better oxygen transfer efficiency, making them ideal for most STPs. Coarse bubble diffusers are used where clogging is a concern.

Q4. Can Titan Aeration provide custom solutions for different STP sizes?

Yes, Titan Aeration offers customized air diffuser for STP solutions based on plant size, treatment capacity, and client requirements.

Q5. What is the lifespan of an air diffuser for STP?

With proper maintenance, Titan Aeration’s diffusers can last anywhere between 5 to 8 years or more, depending on operational conditions.

Visit here for more details: https://titanaeration.com/magnum-membrane-air-tube-diffusers.html Website: www.titanaeration.com Contact us: +91 20 6640 1400 Email id: [email protected]

0 notes

Text

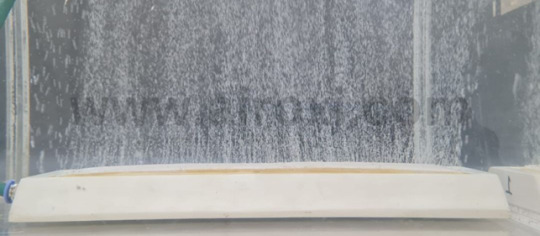

The Essential Guide to Fine Bubble Disc Diffusers: Working and Benefits of Use

In the realm of wastewater treatment, the fine bubble disc diffuser is a critical component. It plays a significant role in aeration processes, ensuring efficient oxygen transfer and improving the overall treatment process. This blog will delve into the workings of the fine bubble disc diffuser and its numerous benefits. Whether you are a facility manager, engineer, or environmentalist, understanding this technology can help you make informed decisions for your projects.

What is a Fine Bubble Disc Diffuser?

A fine bubble disc diffuser is a device used in wastewater treatment plants to introduce air into the water. It creates fine bubbles, which increase the surface area for oxygen transfer, thereby enhancing the biological treatment process. These diffusers are known for their efficiency and reliability, making them a preferred choice in modern wastewater treatment systems. How Does a Fine Bubble Disc Diffuser Work? To grasp the importance of a fine bubble disc diffuser, it's essential to understand its operation. Here’s a step-by-step explanation of how this device works:

Air Supply: Compressed air is supplied to the diffuser system through a network of pipes.

Distribution: The air is evenly distributed through the diffuser membrane, which is designed with numerous tiny pores. Bubble Formation: As the air passes through these pores, it forms fine bubbles. The size of the bubbles is crucial; smaller bubbles provide a larger surface area for oxygen transfer. Oxygen Transfer: The fine bubbles rise through the water, transferring oxygen from the air to the water. This oxygen is then used by microorganisms to break down organic matter in the wastewater. Efficient Mixing: The rising bubbles create a mixing action, ensuring that oxygen is evenly distributed throughout the water column, enhancing the overall treatment efficiency.

Benefits of Using a Fine Bubble Disc Diffuser The fine bubble disc diffuser offers several advantages, making it an essential component in wastewater treatment systems: High Oxygen Transfer Efficiency: The small size of the bubbles produced by these diffusers ensures a large surface area for oxygen transfer, resulting in higher efficiency compared to coarse bubble diffusers. Energy Efficiency: Fine bubble disc diffusers require less energy to operate, leading to significant cost savings over time. Their design minimizes air resistance, reducing the power needed for air compression.

Improved Treatment Performance: By ensuring efficient oxygen distribution and mixing, these diffusers enhance the biological treatment process, leading to better water quality and higher treatment performance. Durability and Low Maintenance: Fine bubble disc diffusers are made from high-quality materials, ensuring durability and long service life. They require minimal maintenance, reducing downtime and operational costs. Versatility: These diffusers can be used in various types of aeration tanks and are suitable for different stages of the wastewater treatment process, making them a versatile choice for facility managers. Fine Bubble Diffuser Specifications When selecting a fine bubble disc diffuser, it's important to consider its specifications to ensure it meets your specific needs. Here are some key specifications to look for: Membrane Material: The membrane should be made from durable materials such as EPDM or silicone, which resist fouling and chemical degradation. Bubble Size: The diffuser should produce bubbles in the range of 1-3 mm for optimal oxygen transfer efficiency. Air Flow Rate: The diffuser should be capable of handling the required airflow rate for your system. Operating Temperature: Ensure the diffuser can operate within the temperature range of your wastewater treatment process. Mounting Options: Look for diffusers with flexible mounting options to suit different tank configurations. Fine Bubble Disc Diffuser Price The price of fine bubble disc diffusers can vary based on several factors, including size, material, and manufacturer. Investing in high-quality diffusers may have a higher upfront cost but will offer long-term benefits in terms of efficiency, durability, and reduced maintenance costs. To get the best value for your investment, consider the total cost of ownership rather than just the initial purchase price.

Applications of Fine Bubble Disc Diffusers Fine bubble disc diffusers are widely used in various applications due to their efficiency and versatility: Municipal Wastewater Treatment: They are commonly used in municipal wastewater treatment plants to enhance the biological treatment process. Industrial Wastewater Treatment: Industries such as food processing, pharmaceuticals, and chemicals use these diffusers to treat their wastewater before discharge. Aquaculture: In aquaculture, fine bubble disc diffusers help maintain optimal oxygen levels in fish ponds and tanks, promoting healthy fish growth. Agriculture: These diffusers are also used in agricultural settings for treating wastewater from livestock operations. Conclusion Fine bubble disc diffusers are a vital component in modern wastewater treatment systems. Their ability to efficiently transfer oxygen, reduce energy consumption, and improve treatment performance makes them an excellent choice for various applications. By understanding how these diffusers work and recognizing their benefits, you can make informed decisions for your wastewater treatment projects.

0 notes

Text

Maximizing Efficiency: Understanding the Wastewater Nitrification System

Introduction to Wastewater Treatment

Wastewater treatment plants play a vital role in ensuring environmental sustainability and public health. Among the many processes involved, plant treatment nitrification process is a cornerstone for removing nitrogen compounds from wastewater, preventing their release into natural water bodies where they can cause harm.

The Significance of Nitrification

Nitrogen compounds, if discharged into water bodies untreated, can lead to eutrophication, harmful algal blooms, and depletion of oxygen levels, posing serious threats to aquatic life and water quality.

Understanding the Wastewater Nitrification System

Overview of the Process

Ammonia Oxidation: Ammonia is first converted into nitrite by ammonia-oxidizing bacteria (AOB).

Nitrite Oxidation: Nitrite is then oxidized into nitrate by nitrite-oxidizing bacteria (NOB).

Factors Influencing Nitrification Efficiency

Temperature: Nitrification rates are optimal in the temperature range of 20-30°C.

pH Level: Nitrification is favored in slightly alkaline conditions (pH 7.5-8.5).

DO Levels: Dissolved oxygen (DO) is crucial for the activity of nitrifying bacteria; adequate aeration is essential.

Presence of Inhibitors: Compounds like heavy metals or certain chemicals can inhibit nitrification and need to be controlled.

Strategies for Enhancing Nitrification Efficiency

Advanced Aeration Techniques

Utilizing fine bubble diffusers and surface aerators can enhance oxygen transfer efficiency, ensuring optimal conditions for nitrification.

Bioaugmentation

Introducing specialized nitrifying bacteria cultures can supplement the existing microbial community, boosting nitrification rates and resilience.

Process Optimization

Regular monitoring of key parameters such as ammonia, nitrite, and nitrate levels allows for timely adjustments in operating conditions to maximize nitrification efficiency.

Challenges and Innovations in Nitrification

Addressing Seasonal Variations

Seasonal changes in temperature and organic loading can impact nitrification rates, necessitating adaptive strategies such as adjusting aeration rates or implementing seasonal process modifications.

Dealing with Shock Loads

Unexpected spikes in ammonia concentration or hydraulic loads can stress the nitrification system. Implementing buffer tanks or emergency bypass systems can mitigate the effects of shock loads.

Harnessing Technology for Monitoring and Control

Advancements in sensor technology and automation allow for real-time monitoring of key process parameters, enabling proactive management and optimization of the nitrification process.

Conclusion

The wastewater nitrification system is a critical component of wastewater treatment plants, playing a pivotal role in nitrogen removal and safeguarding water quality. By understanding the intricacies of nitrification and implementing innovative strategies, wastewater treatment facilities can maximize efficiency, minimize environmental impact, and contribute to sustainable water management practices.

0 notes

Text

Revitalizing Water Treatment: The Significance of Aeration and Its Process

Introduction

Water treatment plays a crucial role in ensuring clean and safe water for various purposes. Among the many processes involved in water treatment, aeration stands out as a significant step. This article will explore the importance of aeration in water treatment and delve into the process behind it. There are many water treatment companies in Chennai and across India. Let's dive into the world of water treatment and discover how aeration contributes to revitalizing our water sources.

Understanding Water Treatment

Water treatment is the process of purifying water to make it suitable for various applications. It includes drinking, industrial processes, and agricultural use. It involves several stages such as coagulation, sedimentation, filtration, disinfection, and aeration. Aeration plays a crucial role in enhancing water quality by improving its taste, odor, and purity.

The Significance of Aeration in Water Treatment

Aeration is a process that involves introducing air or oxygen into the water. It is to drop undesirable components and enhance their quality. It serves many purposes in water treatment.

a) Oxygenation:

Aeration increases the oxygen content in water. It is vital for sustaining aquatic life in natural bodies of water and promoting the growth of beneficial bacteria in water treatment facilities.

b) Removal of Dissolved Gases:

Aeration helps drop undesirable dissolved gases like hydrogen sulfide and carbon dioxide. It contributes to unpleasant odors and can be harmful to humans and aquatic organisms.

c) Volatile Organic Compound (VOC) Removal:

Aeration also reduces the amount of volatile organic compounds (VOCs). It can cause water to have an unpleasant odor and taste. VOCs are often found in water sources near industrial areas and can be harmful to human health. Aeration helps in removing these compounds and making water safe for consumption. Aeration assists in removing volatile organic compounds. For example, solvents and industrial chemicals, from water sources. These compounds can be toxic and pose a risk to human health.

d) Removal of Iron and Manganese:

Aeration aids in oxidizing iron and manganese, facilitating their subsequent removal through filtration processes. This helps prevent staining, unpleasant tastes, and odors caused by these minerals.

The Aeration Process

The process of aeration involves two primary methods: surface aeration and diffused aeration.

a) Surface Aeration:

Surface aeration involves the mechanical introduction of air into the water through methods like spraying, cascading, or stirring. These methods create turbulence and increase the water's exposure to air, facilitating oxygen transfer and gas exchange. Surface aeration is employed in wastewater treatment plants, ponds, and lagoons.

b) Diffused Aeration:

Diffused aeration, also known as fine-bubble aeration, involves the release of air in small bubbles. It is through diffusers placed at the bottom of a water body or treatment tank. The fine bubbles rise to the surface, allowing for efficient oxygen transfer and circulation. Diffused aeration is used in activated sludge systems, aerobic digesters, and other applications. It requires precise control of dissolved oxygen levels.

Conclusion

In conclusion, aeration plays a vital role in revitalizing water treatment processes. Water treatment companies in India recognize its significance. The selection of the aeration method depends on various factors, including the size of the water body, and the amount of impurities. H2O Bazaar becomes the bridge for water treatment businesses. The best platform for listing products ranges from water treatment chemicals, filters, and coagulants to cooling towers.

0 notes

Text

The Power of Ceramic Diffusers in Fish Hatcheries and Nurseries

For fish farmers, creating the ideal environment for healthy growth and optimal yields is paramount. One of the most critical factors in aquaculture is dissolved oxygen (DO) levels in the water. Insufficient oxygen can lead to stress, disease, poor growth, and even mass mortality. This is where efficient aeration systems come into play, and among them, AirOxi ceramic plate diffusers stand out as a game-changer. This blog explores the significant advantages of using AirOxi diffusers in fish hatcheries and nurseries, highlighting how they contribute to a thriving aquatic ecosystem.

The Oxygen Imperative in Aquaculture

Fish, like all aerobic organisms, require oxygen to survive and thrive. In aquaculture systems, oxygen is consumed by the fish themselves, as well as by the decomposition of organic matter and the respiration of bacteria. In intensive farming setups, where fish are stocked at high densities, the demand for oxygen is particularly high. Maintaining adequate DO levels is crucial for:

Growth and Development: Oxygen is essential for metabolic processes, enabling fish to convert feed into energy and biomass efficiently.

Disease Resistance: Well-oxygenated water helps strengthen the immune system of fish, making them less susceptible to diseases.

Feed Conversion Ratio (FCR): Optimal oxygen levels improve the efficiency with which fish convert feed into growth, reducing waste and maximizing profitability.

Stress Reduction: Low oxygen levels can cause stress in fish, leading to reduced growth, impaired reproduction, and increased susceptibility to disease.

Traditional Aeration Methods and Their Limitations

Traditional aeration methods, such as air stones, surface agitators, and venturi injectors, have been used in aquaculture for many years. However, these methods often suffer from several limitations:

Low Oxygen Transfer Efficiency: They may not effectively dissolve oxygen into the water, resulting in significant energy waste.

Large Bubble Size: These methods typically produce large bubbles that rise quickly to the surface, limiting the time for oxygen to dissolve.

Uneven Oxygen Distribution: They may create areas of high and low oxygen concentration within the tank or pond.

Maintenance Issues: Some methods require frequent maintenance or replacement due to clogging or wear and tear.

AirOxi Ceramic Diffusers: A Superior Aeration Solution

AirOxi ceramic plate diffusers offer a superior alternative to traditional aeration methods, addressing many of their limitations and providing significant benefits for fish hatcheries and nurseries. These diffusers are constructed from high-quality ceramic materials with precisely engineered pores. This unique design creates extremely fine bubbles, maximizing the surface area for oxygen transfer and improving the efficiency of aeration.

Key Advantages of AirOxi Diffusers:

Micro-Bubble Technology: AirOxi diffusers produce a vast number of micro-bubbles, which significantly increase the contact time between air and water, leading to much higher oxygen transfer rates compared to traditional methods. This translates to more efficient oxygen dissolution and reduced energy consumption.

Uniform Oxygen Distribution: The fine bubbles generated by AirOxi diffusers create a more uniform oxygen distribution throughout the water column, eliminating dead zones and ensuring that all fish have access to adequate oxygen. This is particularly important in densely stocked tanks and raceways.

Durability and Longevity: AirOxi diffusers are made from durable ceramic materials that are resistant to clogging and degradation. This ensures a long lifespan and reduces the need for frequent replacement, resulting in long-term cost savings.

Low Maintenance: Unlike some other aeration systems, AirOxi diffusers require minimal maintenance. Periodic cleaning is usually sufficient to maintain their performance.

Quiet Operation: AirOxi diffusers operate quietly, creating a less stressful environment for fish and workers.

Versatile Applications: AirOxi diffusers can be used in a wide range of aquaculture systems, including tanks, ponds, raceways, and recirculating aquaculture systems (RAS).

Improved Water Quality: The efficient aeration provided by AirOxi diffusers helps maintain optimal water quality by promoting the breakdown of organic waste and reducing the build-up of harmful substances like ammonia and nitrites.

AirOxi in Fish Hatcheries and Nurseries:

In fish hatcheries and nurseries, where delicate larvae and fry are raised, maintaining optimal water quality and oxygen levels is absolutely critical. AirOxi diffusers are particularly well-suited for these applications because:

Gentle Aeration: The fine bubbles produced by AirOxi diffusers provide gentle aeration that does not harm delicate larvae and fry.

Enhanced Larval Survival: The high oxygen levels provided by AirOxi diffusers promote better larval survival rates and faster growth.

Reduced Stress: The quiet operation and uniform oxygen distribution of AirOxi diffusers create a less stressful environment for young fish.

The AirOxi Difference:

The AirOxi brand is synonymous with quality and innovation in aquaculture aeration. AirOxi diffusers are engineered to deliver superior performance, durability, and value. The AirOxi commitment to research and development ensures that their products remain at the forefront of aeration technology. Choosing AirOxi means investing in a reliable and efficient aeration solution that will contribute to the success of your aquaculture operation. AirOxi offers a range of diffuser sizes and configurations to suit different needs and applications.

Conclusion:

Maintaining adequate dissolved oxygen levels is essential for successful aquaculture. AirOxi ceramic plate diffusers offer a superior aeration solution compared to traditional methods, providing numerous benefits for fish hatcheries and nurseries. From micro-bubble technology and uniform oxygen distribution to durability and low maintenance, AirOxi diffusers contribute to a healthier and more productive aquatic environment. Investing in AirOxi is an investment in the future of your fish farm.

For more information, please visit:

Website: https://www.airoxi.com

Product Page: https://www.airoxi.com/products

YouTube Channel: https://youtu.be/zJ1XHJItX0o or https://www.youtube.com/channel/UCXt9ms_jsteAVhvJXPfY88Q

By implementing AirOxi diffusers, fish farmers can create an optimal environment for their fish, leading to improved growth rates, reduced disease incidence, and increased profitability. The AirOxi brand stands for excellence in aquaculture aeration, making it a trusted choice for professionals in the industry.

Contact AirOxi for your aquaculture aeration requirements

+917041004098

www.buy.airoxi.com

#fish farming#aeration solution#shrimp farming#aquaculture#airoxi tube#aeration tubes#airoxitube#aeration#airoxi#fish

0 notes

Text

Aeration Grids and Decanters for Superior Wastewater Treatment

Introduction:

In the world of wastewater treatment, the quest for superior efficiency and performance is ever-present. The need to effectively treat wastewater and ensure clean water resources for our communities has led to the development of advanced technologies. Among these, aeration grids and decanters have emerged as key players in achieving superior wastewater treatment results. In this blog, we will explore the role of aeration grids and decanters, their benefits, and how they contribute to the overall efficiency of wastewater treatment processes.

Understanding Aeration Grids:

Aeration grids play a crucial role in wastewater treatment by providing oxygen to the treatment process. They are typically placed at the bottom of a treatment tank or basin and consist of a network of fine bubble diffusers. These diffusers release oxygen into the wastewater, promoting the growth of beneficial bacteria and facilitating the breakdown of organic matter. The controlled aeration provided by the grids helps optimize the treatment process and enhance overall efficiency.

Advantages of Aeration Grids:

Increased Oxygen Transfer: Aeration grids efficiently transfer oxygen to the wastewater, maximizing the biological treatment process. This results in improved removal of pollutants and organic matter, leading to superior water quality.

Energy Efficiency: Aeration grids are designed to minimize energy consumption while maximizing oxygen transfer efficiency. Their advanced diffuser systems ensure optimal oxygen dispersion, reducing energy costs associated with aeration.

Flexibility and Scalability: Aeration grids can be customized to suit specific wastewater treatment needs. They can be designed for various tank sizes and configurations, allowing flexibility in plant design and enabling scalability as treatment demands grow.

The Role of Decanters:

Decanters are vital components in the final stage of the wastewater treatment process. They help separate the clarified effluent from the settled solids or sludge. By employing gravity or mechanical methods, decanters ensure the efficient removal of treated water while minimizing the carryover of solids. This step is crucial in achieving superior water quality and meeting stringent regulatory standards.

Benefits of Decanters:

Enhanced Clarification: Decanters effectively separate the clarified effluent from the settled solids, resulting in high-quality water suitable for reuse or safe discharge. This helps meet regulatory requirements and environmental standards.

Minimized Sludge Buildup: By efficiently removing treated water, decanters help minimize the accumulation of solids and sludge in the treatment tank or basin. This reduces the frequency and costs associated with sludge handling and disposal.

Automated Operation: Modern decanter systems are equipped with advanced control mechanisms, allowing for automated operation and precise control of the decanting process. This ensures consistent performance and reduces the need for manual intervention.

Conclusion:

Aeration grids and decanters play critical roles in achieving superior wastewater treatment results. By providing efficient oxygen transfer and effective separation of clarified effluent, they contribute to the overall efficiency and effectiveness of the treatment process. Incorporating these advanced technologies into wastewater treatment plants can lead to improved water quality, reduced operating costs, and enhanced compliance with regulatory standards. Embracing aeration grids and decanters paves the way for a sustainable and environmentally responsible approach to wastewater treatment.

Contact us today to learn more about how aeration grids and decanters can elevate the performance of your wastewater treatment processes.

0 notes