#geotechnical considerations

Explore tagged Tumblr posts

Text

Little P.Eng.'s Comprehensive Seismic Structural Services Aligned with ASCE 7-22 and NBCC Standards

In an era where architectural ambition pushes the limits of engineering, safeguarding structural integrity against natural calamities, particularly seismic activities, becomes paramount. This detailed exposé delves into the sophisticated seismic structural engineering services provided by Little P.Eng., a firm renowned for its compliance with the latest American Society of Civil Engineers (ASCE) 7-22 standards and the Canadian National Building Code (NBCC). Their work spans across Canada and the United States, encompassing a diverse range of buildings and non-structural elements, reflecting the pinnacle of safety, reliability, and innovation in modern construction.

1. Introduction

The unpredictable nature of seismic activities has long posed a significant challenge to the realms of construction and civil engineering. Within this volatile environment, Little P.Eng. has emerged as a beacon of reliability, offering cutting-edge seismic structural engineering services across Canada and the United States. Their adherence to the ASCE 7-22 and NBCC codes ensures not only the structural integrity of vast construction undertakings but also the safety and longevity of non-structural elements, affirming their position at the forefront of seismic resilience in contemporary infrastructure.

2. Understanding Seismic Structural Engineering

2.1. The Science of Earthquake Engineering

Before delving into Little P.Eng.'s specialized services, one must understand the core principles of seismic structural engineering. This discipline focuses on making buildings and non-structural components resistant to earthquake shocks through specialized planning, design, detailing, and, subsequently, construction. It encompasses geological science, material engineering, and structural analysis to develop structures capable of withstanding seismic disturbances.

2.2. Evolution of Seismic Codes: From ASCE 7-10 to ASCE 7-22

Seismic building codes are dynamic, evolving in response to the continuous advancements in engineering research and catastrophic lessons learned from each seismic event. The transition from ASCE 7-10 to ASCE 7-22 is a reflection of this evolution, marking significant strides in risk reduction and structural robustness, emphasizing not just human safety but also post-earthquake functionality and rapid recovery for communities.

3. Little P.Eng.’s Integration of ASCE 7-22 in Seismic Structural Engineering

3.1. Innovations in Seismic Design Philosophies

Little P.Eng. employs a forward-thinking approach to integrate the innovations outlined in ASCE 7-22. These include state-of-the-art seismic design philosophies involving base isolation, energy dissipation devices, and performance-based seismic design (PBSD), allowing for structures that are more flexible, absorb and dissipate seismic energy, and maintain structural integrity during earthquakes.

3.2. Site-Specific Hazard Analysis and Geotechnical Considerations

One of the critical aspects of ASCE 7-22 is the emphasis on site-specific hazard analyses. Little P.Eng.'s engineers led by Meena Rezkallah carry out comprehensive geotechnical evaluations, considering soil-structure interaction, liquefaction potential, and site-specific seismic hazard assessments. By understanding the geological variances across different regions in North America, they ensure that each design is intrinsically aligned with its environmental context.

4. Adherence to NBCC Standards: Expanding Safety Parameters Across Canada

4.1. Bridging Policies between Countries

While their services in the United States predominantly adhere to ASCE standards, Little P.Eng. seamlessly bridges engineering policies between the U.S. and Canada by aligning their practices with the NBCC. This code compliance not only underscores their versatility in handling cross-border projects but also reflects their commitment to upholding the highest safety and professional standards in every geographical locale.

4.2. Understanding NBCC’s Seismic Provisions

The NBCC has distinct seismic provisions, necessitating specialized knowledge and an adaptive engineering approach. Little P.Eng.'s expertise in Canadian seismic codes ensures that structural and non-structural components comply with regional regulations, catering to Canada's unique seismic challenges, especially in high-risk provinces.

5. Comprehensive Services for Buildings and Non-Structural Elements

5.1. Diverse Building Typologies

Little P.Eng.'s portfolio encompasses a variety of buildings, from residential high-rises and expansive commercial complexes to critical facilities like hospitals and emergency response centers. Each building type presents unique challenges, and the firm’s nuanced, context-oriented approach to seismic retrofitting and sustainable design practices sets industry standards.

5.2. Protecting Non-Structural Components

Beyond the buildings themselves, Little P.Eng. extends its engineering prowess to safeguard non-structural elements. These components, often overlooked, can pose significant hazards during seismic events. From architectural elements to mechanical and electrical systems, the firm implements exhaustive strategies to enhance the safety of these components, thereby protecting human life and minimizing economic loss.

6. Future Directions and Continuous Advancements

6.1. Embracing Technological Innovations

As the field of seismic structural engineering advances, Little P.Eng. remains committed to incorporating new technologies, including artificial intelligence and machine learning, for predictive analysis, design optimization, and risk management. Their continual investment in technology positions them as a leader in future-proofing structures against earthquakes.

6.2. Contribution to Global Seismic Safety Standards

Harnessing Advanced Engineering: Little P.Eng.'s Comprehensive Seismic Structural Services Aligned with ASCE 7-22 and CNBCC Standards in North America

7. Conclusion

Little P.Eng.’s comprehensive seismic structural engineering services, grounded in the latest ASCE and NBCC standards, represent a confluence of scientific mastery, innovative engineering, and a deep commitment to safeguarding human lives and investments. Their work across diverse building typologies and non-structural components in Canada and the United States cements their stance as a pivotal player in shaping resilient, sustainable, and safe urban landscapes. As seismic activity remains an unpredictable threat, the foresight and innovation of firms like Little P.Eng. are society's best bet for a safer tomorrow.

References

[1] American Society of Civil Engineers. (2022). Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE/SEI 7-22). ASCE.

[2] National Research Council Canada. (2020). National Building Code of Canada.

Tags:

Little P.Eng.

ASCE 7-22

design optimization

earthquake resilience

energy dissipation

building codes

seismic design

advanced materials

non-structural components

CNBCC

technological innovations

cross-border projects

geotechnical considerations

mechanical systems safety

base isolation

sustainable construction

electrical systems safety

Seismic structural engineering

critical infrastructure

artificial intelligence

urban resilience

construction techniques

seismic retrofitting

site-specific analysis

predictive analysis

professional standards

safety regulations

risk management

performance-based design

global seismic standards

Engineering Services

Structural Engineering Consultancy

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng.#ASCE 7-22#design optimization#earthquake resilience#energy dissipation#building codes#seismic design#advanced materials#non-structural components#CNBCC#technological innovations#cross-border projects#geotechnical considerations#mechanical systems safety#base isolation#sustainable construction#electrical systems safety#Seismic structural engineering#critical infrastructure#artificial intelligence#urban resilience#construction techniques#seismic retrofitting#site-specific analysis#predictive analysis#professional standards#safety regulations#risk management#performance-based design#global seismic standards

0 notes

Text

Corrugated Metal Tanks Selection Guide

Corrugated Metal Tanks Selection Guide Optimizing Storage Solutions for Durability, Capacity & Cost-Effectiveness

1. Material & Corrosion Protection

Select based on stored medium and environment:

Galvanized Steel (G235):

Applications: Potable water, stormwater retention, agricultural slurry.

Protection: Standard zinc coating (Z275+). Suitable for pH-neutral environments.

Aluminized Steel Type 2 (AZ150):

Applications: Wastewater, industrial process water, high-humidity/saline atmospheres.

Protection: Aluminum-silicon alloy coating resists oxidation & sulfides.

Polymer-Coated Steel (e.g., CSPE/PVC):

Applications: Aggressive chemicals (pH 2–12), mining leachate, corrosive soils.

Protection: Dual-layer fusion-bonded coating (≥0.40 mm thick).

Key Consideration: Match coating to fluid corrosivity (ASTM A929) and atmospheric corrosivity (ISO 12944 C2–C5).

Balance capacity needs with site constraints:

Diameter Range: 1.5m (5ft) to 30m+ (100ft+)

Height Range: Standard 3m–12m (10ft–40ft); engineered designs up to 20m (65ft).

Profile:

Deep-Corrugated (150×50 mm / 6×2 in): High ring stiffness for tall tanks.

Shallow-Corrugated (68×13 mm / 2.67×0.5 in): Cost-effective for mid-height tanks.

Capacity Calc:textCopy CodeVolume (m³) = π × (Diameter/2)² × Height

Design Standards: ASTM A760 (material), AWWA D103 (fabrication), EN 10245 (EU).

3. End Configurations & Roof Systems

Adapt to functional requirements:

Base Options:

Flat Bolted Floor: For granular/stable foundations.

Concrete Slab Foundation: Required for fluid-tight integrity.

Roof Types:

Open-Top: For non-volatile liquids (e.g., irrigation).

Cone Roof (Self-Supporting): Standard for rainwater/firewater storage.

Flat Roof (Supported): Requires internal columns; allows roof access.

Fixtures:

Access hatches (OSHA-compliant), vents, overflow pipes, level gauges.

4. Geotechnical & Foundation Requirements

Ensure long-term stability:

Soil Bearing Capacity: ≥ 100 kPa (2,000 psf) for tanks <10m diameter.

Foundation Types:

Compacted Granular Pad: 300mm min. thickness (for small tanks).

Reinforced Concrete Ringwall: Essential for tanks >8m diameter.

Settlement Tolerance: Max differential settlement ≤ 1:500 (per AWWA D103).

Anchorage: Anchor bolts (ASTM F1554) required in seismic/windy zones.

5. Applications & Industry-Specific Considerations

ApplicationCritical Design FactorsPotable WaterNSF/ANSI 61 certification, full-weld seam inspection.Firewater StorageUL/FM approval, seismic design (IBC/ASTM E2026).Agricultural SlurryAbrasion-resistant coating, conical floor for drainage.Industrial ProcessLining compatibility (e.g., epoxy for chemicals).Stormwater HarvestingDebris exclusion screens, overflow bypass.

6. Fabrication & Installation Methods

Spiral-Rib Technology:

On-site continuous helical winding for large diameters (>6m).

Advantages: No horizontal seams, faster installation.

Bolted Panel Systems:

Shop-fabricated curved panels (1.2m–2.4m wide).

Advantages: Transportable, flexible height adjustments.

QA/QC:

Seam testing (vacuum/air pressure), coating thickness verification.

7. Corrosion Management & Lifespan

Design Life: 30–50 years (depending on coating/environment).

Cathodic Protection (ICCP):

Recommended for tanks in corrosive soils (resistivity <5,000 Ω·cm).

Lining Systems:

Spray-applied polyurea/coal tar epoxy for internal corrosion control.

Inspection: Ultrasonic thickness testing every 5–10 years.

8. Cost-Benefit Analysis

FactorCorrugated Metal TankConcrete TankPolyethylene TankInstallation Time40% fasterSlow (curing required)Fast (but size-limited)Material Cost$$$$$$$$$Lifespan30–50 years50+ years15–25 yearsExpansion FlexibilityEasily modifiableDifficultNot feasible

Selection Checklist

Fluid Type: pH, temperature, abrasiveness.

Capacity Needed: Total volume, peak drawdown rate.

Site Conditions: Soil report, seismic zone, wind loads.

Regulatory: NSF, UL/FM, local codes.

Accessories: Roof type, manways, mixers, level sensors.

Supplier Qualifications: AWWA D103 certified fabricator.

0 notes

Text

What Does a Building Survey Include for Land Development Projects?

When it comes to building surveys for land development projects, a comprehensive understanding of the components involved is vital for ensuring compliance, efficiency, and investment security. Building surveys are essential for identifying potential obstacles, structural concerns, and legal considerations, providing developers with an informed foundation to proceed confidently. Here’s an in-depth look at what a building survey includes for land development projects, with each component tailored for maximum utility and value.

Understanding Building Surveys in Land Development

A building survey is a detailed inspection of a property's physical condition, focusing on elements that influence development potential. These surveys provide a roadmap for decision-making, budgeting, risk assessment, and compliance with planning and zoning regulations. For land development, the scope is broader and more intricate than standard property transactions.

1. Detailed Site Analysis and Topographical Survey

A fundamental element of any building survey is the site analysis. This begins with a topographical survey that maps out the exact features of the land:

Contour levels and gradients

Natural and artificial structures

Vegetation and existing trees

Boundary lines and encroachments

Access points and surrounding infrastructure

This analysis helps determine the buildable area, necessary earthworks, and design feasibility. Accurate topographical data also enables civil engineers and architects to design with precision.

2. Structural Integrity Assessment of Existing Buildings

If there are existing buildings or structures on the land, a thorough structural survey is carried out. This includes:

Foundations and footings inspection

Load-bearing walls and columns

Roofing structure

Internal and external wall condition

Floors and ceilings

Basements and underground structures

Structural assessments help determine whether existing elements can be reused, modified, or must be demolished, impacting the development timeline and budget.

3. Environmental Impact Studies and Soil Investigations

Environmental and geotechnical data form the backbone of responsible development. Surveys include:

Soil composition testing for bearing capacity

Contamination checks (hydrocarbons, heavy metals)

Water table levels and flood risk assessment

Drainage and permeability studies

Tree preservation assessments

Habitat and ecological reports

These factors influence planning permissions, construction methods, and foundation designs. Failure to address environmental risks can halt a project midway or result in regulatory penalties.

4. Building Services and Utilities Mapping

Understanding the availability and condition of infrastructure and utilities is crucial. This includes:

Electricity, gas, and water supply

Sewage and drainage systems

Telecommunications and broadband access

Existing service routes and capacity

Surveys identify the need for service upgrades, relocations, or new installations, significantly affecting the cost and scheduling of the development.

5. Planning Constraints and Zoning Compliance

Building surveys delve into the planning history and zoning regulations relevant to the land:

Zoning classifications and permissible land use

Height restrictions and floor area ratios (FAR)

Setback requirements

Heritage overlays or conservation areas

Protected views and easements

Reviewing planning constraints early helps streamline the planning application process and ensures that proposed developments align with local authority policies.

6. Legal and Boundary Surveys

Legal clarity is critical in land development. A cadastral or boundary survey ensures:

Exact land ownership delineation

Identification of easements or rights of way

Encroachments or boundary disputes

Access and road frontage legality

Boundary surveys are typically conducted by licensed surveyors and are used to prepare title plans and land registry submissions.

7. Measured Building Surveys (For Existing Structures)

If development involves existing buildings—whether for renovation or integration—a measured survey is carried out to capture accurate floor plans and elevations. These include:

Room dimensions and ceiling heights

Window and door placements

Staircases and circulation spaces

Roof layouts and parapets

Measured surveys allow architects to create as-built drawings, essential for extensions, refurbishments, or conversions.

8. Flood Risk and Drainage Strategy

With increasing regulatory pressure on sustainable development, a Flood Risk Assessment (FRA) is often a prerequisite:

Proximity to rivers or coastal areas

Historic flood events

Surface water management

Drainage strategy integration with SuDS (Sustainable Drainage Systems)

A well-developed FRA mitigates long-term risks and aids in achieving planning approval from local authorities and the Environment Agency.

9. Archaeological and Heritage Assessments

In historically sensitive areas, building surveys include archaeological assessments to ensure compliance with preservation laws. This includes:

Historic land usage analysis

Scheduled monument proximity

Listed buildings and structural implications

Necessary permissions from heritage bodies

Failing to conduct these assessments can result in costly legal disputes or development bans.

10. Accessibility and Traffic Impact Surveys

For larger developments, particularly mixed-use or commercial, transport and accessibility assessments are vital. These include:

Traffic generation analysis

Impact on local roads and junctions

Pedestrian and cyclist accessibility

Public transport proximity

Parking feasibility studies

These surveys form part of the transport statement or transport assessment required during planning.

11. Health and Safety Assessments

Surveys often assess asbestos, lead-based paints, or hazardous materials in existing buildings. Additional Health and Safety Executive (HSE) compliance inspections may cover:

Fire safety evaluations

Access and egress audits

Construction phase health and safety planning

This ensures the site meets all obligations under CDM Regulations (Construction Design and Management).

12. Sustainability and Energy Performance Reports

Modern developments prioritize sustainability. Building surveys might include:

Energy Performance Certificates (EPCs)

BREEAM or LEED feasibility studies

Solar exposure and wind analysis

Thermal imaging surveys

Retrofitting opportunities for existing buildings

Sustainable features not only enhance building performance but improve eligibility for green funding incentives.

Conclusion

A comprehensive building survey for land development is not just a technical formality—it is a critical phase that dictates the project’s scope, timeline, cost-efficiency, and compliance. Investing in detailed, professional building surveys upfront minimizes risks and maximizes development potential.

From topographical insights to planning constraints, utility mapping to sustainability assessments, building surveys provide the essential intelligence to proceed with clarity and confidence.

0 notes

Text

Digging Deep Types of Excavation and When to Use Each

Excavation is more than just digging a hole in the ground. It forms the foundation for countless construction and engineering projects, from home-building to highways to massive infrastructure developments. The art and science of excavation involve using the right techniques and understanding soil composition, project requirements, and environmental factors.

If you're in the construction business or planning a project requiring excavation, knowing the different types of excavation and their specific uses can make or break your efforts. This blog covers the various types of excavation, when to employ each, and how these techniques can impact your project.

What Is Excavation and Why Is It Important?

Excavation refers to the process of removing earth, soil, or rock from a site to create space for a specific purpose. It serves as the first step in many construction projects. Whether it’s for laying a foundation, creating drainage systems, or installing pipes, understanding excavation is critical to the long-term success of these projects.

The importance of excavation lies in its precision and planning. Using the wrong type of excavation can lead to safety hazards, project delays, or excessive costs. This is why understanding the types of excavation and matching them to your project is vital.

The Different Types of Excavation

Understanding the various types of excavation requires an examination of the material being removed, the purpose of the excavation, and the specific techniques used for each type. Below, we explore the most common types and detail when and why you might use them.

Earth Excavation

What Is It?

Earth excavation involves the removal of the layer of soil located on top of the ground, sometimes referred to as the "topsoil." This includes soil that hasn’t been compacted and forms the top level of the earth’s surface.

When to Use It:

Preparing a project site for foundation work.

Removing unsuitable material to make way for stable, compacted fill.

Creating space for temporary or permanent structures.

Pro Tip: Always analyze the soil composition before beginning earth excavation. A thorough geotechnical survey ensures the ground can sustain the structure being built.

Rock Excavation

What Is It?

Rock excavation involves removing large quantities of rock that hinder construction. Because of its complexity, this type of excavation often requires specialized machinery, explosives, or cutting-edge techniques.

When to Use It:

Creating tunnels or highways in mountainous terrain.

Removing large rock formations to ensure stable construction.

Installing deep foundations for large-scale buildings.

Equipment Needed:

Rock excavation typically requires a rock breaker, explosives, or heavy-duty machines such as hydraulic excavators and jackhammers.

Key Consideration: Rock excavation is one of the most time-consuming and expensive types of excavation. Factor this into your project's budget and timeline.

Muck Excavation

What Is It?

Muck refers to a combination of water and soil. Muck excavation involves removing this mixture, which is known to be unstable for construction.

When to Use It:

Clearing land for road construction.

Stabilizing wetlands and swampy areas.

Preparing the groundwork for bridges or pipelines.

Expert Tip:

Instead of outright removing muck, some contractors may opt to spread it across larger areas for better drainage and evaporation.

Cut and Fill Excavation

What Is It?

This technique combines two excavation processes. The "cut" involves removing soil or rock, while the "fill" uses that same material to level out a construction site. It’s also referred to as "stripping."

When to Use It:

Grading land for roads or railways.

Balancing uneven terrain for commercial developments.

Preparing flat agricultural fields.

Benefit:

It minimizes material transportation costs since cut material is repurposed for fills.

Channel Excavation

What Is It?

Channel excavation refers to altering or improving existing waterways or creating new channels to control water flow.

When to Use It:

Constructing canals or drainage systems.

Flood control and irrigation.

Redirecting water for hydroelectric power projects.

Environmental Consideration:

Channel excavation must be carefully planned to avoid disrupting local ecosystems or agitating sediment in water bodies.

Basement Excavation

What Is It?

This type of excavation focuses on carving out space below ground level, typically for basements or underground structures.

When to Use It:

Building residential or commercial properties with basements.

Creating underground parking lots.

Installing storage systems below ground.

Key Challenges:

Basement excavation often involves managing groundwater, preventing soil collapse, and reinforcing sides to avoid cave-ins.

Topsoil Excavation

What Is It?

Topsoil excavation involves removing the topmost layer of soil, which is rich in organic matter but may not be stable for construction.

When to Use It:

Landscaping projects.

Removing vegetation and debris for building preparations.

Creating space for agricultural or gardening purposes.

Quick Note: Topsoil can often be repurposed elsewhere for landscaping, making it a sustainable option.

Trench Excavation

What Is It?

Trench excavation is used for creating narrow, long trenches for utilities such as pipelines, cables, or drainage systems.

When to Use It:

Installing underground utilities like gas pipelines and sewer lines.

Laying down foundation footings or anchors.

Structuring irrigation channels.

Safety First: Trenches are prone to collapsing. Always implement protective measures such as trench boxes or shoring.

Factors to Consider When Choosing an Excavation Method

Choosing the right excavation method requires a deep understanding of your project goals and environmental conditions. Here are a few key factors to consider:

Soil and Rock Composition: A geotechnical survey will help determine the right equipment and techniques based on soil types.

Project Requirements: Foundations, underground structures, or landscape changes will dictate the type of excavation required.

Environmental Impact: Ensure compliance with local environmental regulations and consider how excavation may impact local ecosystems.

Costs and Timeline: Some methods like rock excavation are more labor-intensive and costly than others. Always factor these into your planning.

Elevate Your Next Project

Excavation is a complex yet critical part of any successful construction project. From selecting the right equipment to matching the excavation type to your project's specific needs, understanding this foundational process can help ensure your project stays on track and within budget. Whether it’s carving out space for a foundation or improving water flow, the correct approach will make all the difference.

Are you ready to dig deeper into your next project? Use this guide to decide the best excavation techniques and consult with experienced professionals to streamline your efforts.

We serve Acworth, Atlanta, Austell, Bowdon, Bremen, Buchanan, Carrollton, Chattahoochee Hills, College Park, Dallas, Douglasville, East Cobb, East Point, Fayetteville, Hiram, Kennesaw, Lithia Springs, Marietta, Mableton, Mt. Zion, Newnan, Palmetto, Powder Springs, Rockmart, Smyrna, South Fulton, Tallapoosa, Temple, Union City, Villa Rica, Vinings, and Whitesburg Ga

interior demolition contractors, demolition company atlanta, demolition companies near me, demo contractor, demolition near me, demo contractors, demolition contractor near me, demolition company near me, demolition contractors near me, demolition contractors atlanta ga

West Georgia Demolition Contractors

Douglasville, GA 30135

678-616-8346

Original Post : https://www.wgdemolitioncontractors.com/digging-deep-types-of-excavation-and-when-to-use-each

#Interior Demolition Douglasville GA#Total Demolition Services#Selective Demolition Experts#Professional Deconstruction#Residential Demolition Contractors#Commercial Demolition Services#Structural Demolition Specialists#Demolition and Deconstruction#Safe Demolition Practices#Sustainable Demolition Solutions

0 notes

Text

CFA Piling Method: A Complete Guide for Builders and Engineers

CFA Piling, or Continuous Flight Auger piling, has become a cornerstone of modern foundation engineering. Known for its efficiency, reduced environmental impact, and adaptability to a range of soil types, CFA piling offers a solution to complex geotechnical challenges.

In this comprehensive guide, we’ll break down everything you need to know about CFA piling — from its process and advantages to its real-world applications and limitations.

What is CFA Piling?

CFA piling is a type of bored piling method used for creating deep concrete foundations without the need for open excavation. The technique uses a continuous flight auger that bores into the ground and simultaneously pumps concrete through its hollow stem as the auger is withdrawn.

Unlike traditional bored piles, the CFA method eliminates the need for casing or bentonite slurry, making it quicker and cleaner — ideal for urban or environmentally sensitive areas.

How CFA Piling Works

CFA piling involves a systematic and well-controlled process to ensure structural integrity and ground stability.

1. Site Setup

The piling rig is positioned over the pile location. The auger is aligned vertically and drilling begins.

2. Drilling

The continuous flight auger is drilled into the ground to the designed depth. Spoil (soil) is carried up through the auger flights and deposited around the borehole or removed mechanically.

3. Concrete Pumping

Concrete is pumped through the hollow stem of the auger from the base upward. This bottom-up method helps maintain bore stability and ensures the pile is properly formed.

4. Reinforcement Placement

Once the auger is completely withdrawn and the pile is filled with concrete, a steel reinforcement cage is inserted into the fresh concrete to provide strength and support.

Benefits of CFA Piling

CFA piling offers several advantages that make it a preferred option for many engineers and developers.

Minimal Noise and Vibration

As a non-percussive technique, CFA piling causes less disruption compared to driven piles. This makes it ideal for work near sensitive structures, hospitals, or residential areas.

Fast Installation

Because concrete is pumped as the auger is withdrawn, CFA piles can be installed quickly — reducing project timelines.

Versatile Soil Compatibility

CFA piles work well in a wide range of ground conditions, including soft clays, silts, sands, and gravels.

Environmentally Friendly

The technique produces less noise, vibration, and spoil, and eliminates the need for temporary casing, making it a cleaner and more sustainable method.

Cost-Effective

Speed, simplicity, and reduced site disruption contribute to overall cost savings — especially for large-scale foundation projects.

Applications of CFA Piling

CFA piling is used in a broad range of construction sectors:

Residential buildings and apartment blocks

Commercial and industrial facilities

Infrastructure projects like bridges, underpasses, and retaining walls

Basement and underground car park foundations

Marine and dockside works

Temporary works such as shoring or slope stabilization

Challenges and Considerations

While CFA piling has many advantages, it also requires careful planning and execution.

Ground Conditions

Extremely hard soils or rocky layers may be unsuitable, as these can cause excessive wear on the auger or prevent proper drilling.

Concrete Quality and Pressure

Maintaining consistent flow and pressure of concrete is vital. Poor control can lead to defects like voids or shaft collapse.

Reinforcement Cage Insertion

Timing is crucial — inserting the cage before the concrete sets is essential to ensure correct placement and integrity.

Best Practices for CFA Piling

Use experienced operators and modern equipment to reduce risk of errors

Conduct thorough soil investigations before design and planning

Monitor concrete pressure and volume during installation

Keep reinforcement cages rigid and ready for fast placement

Perform integrity testing (e.g. sonic logging) on completed piles when necessar.

Conclusion

CFA piling is a powerful foundation solution that balances speed, precision, and environmental responsibility. Whether you're constructing a high-rise, a warehouse, or a bridge, CFA piles can provide the support your structure needs with minimal disruption to the surrounding area.

By understanding the method, benefits, and limitations, stakeholders can make informed decisions and ensure successful implementation.

Looking for CFA piling experts or need help with your next foundation project? Reach out to our team for consultation and design support.

Contact Us

Address: 21-21a Highmeres Rd, Leicester, Leicestershire, LE4 9LZ Phone: 0845 880 3627 Website: https://www.midlandpiling.co.uk/

1 note

·

View note

Text

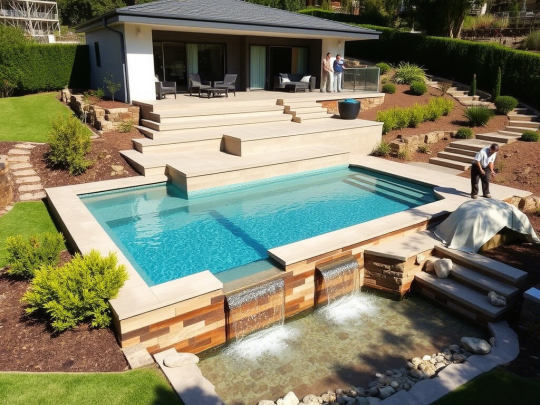

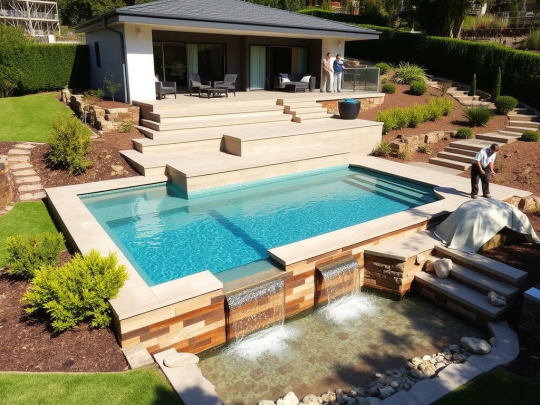

Smart Solutions on Building Pool on a Sloping Block

Dreaming of a backyard oasis but worried about your sloping property? At Aqua Living Pools, we've mastered the art of transforming challenging slopes into stunning aquatic retreats, having built over 300 pools on sloping blocks across the Gold Coast, Brisbane and Northern NSW.

This guide reveals how modern engineering and creative design can turn your sloping block from a challenge into your pool's best feature.

Why Sloping Blocks Make Exceptional Pool Sites

Contrary to popular belief, sloping properties offer unique advantages:

Natural infinity edge potential with panoramic views

Built-in privacy��from elevation changes

Dramatic water features using the slope's gradient

Creative multi-level entertaining spaces

Recent data from the Australian Bureau of Statistics shows:

38% of residential blocks in coastal NSW/QLD have significant slopes

Sloping block pools have increased 72% in popularity since 2018

Homes with engineered slope pools see 15-25% higher property values

"Sloping blocks let us create pools you couldn't achieve on flat land," says Mark Wilson, Aqua Living Pools' Senior Designer. "They become true architectural features."

Aqua Living's Proven Approach to Sloping Block Pools

1. Site Assessment & Engineering

Detailed land surveys

Soil testing and geotechnical reports

Hydraulic calculations

Retaining wall requirements

2. Design Solutions

Slope Angle

Recommended Solution

Key Benefit

0-15°

Cut-and-fill

Cost-effective

15-25°

Retaining walls

Maximizes space

25°+

Cantilevered design

Stunning views

3. Construction Process

Laser-leveled foundations

Reinforced concrete structures

Integrated drainage systems

Customized coping solutions

See our sloping block pool portfolio for inspiring examples.

5 Brilliant Design Ideas for Sloping Blocks

1. Infinity Edge Illusions

Vanishing overflow edges

Glass panel boundaries

Reflective water surfaces

2. Multi-Level Entertaining

Pool on one level, spa on another

Integrated sunken fire pits

Staircase beach entries

3. Natural Rock Features

Waterfalls using elevation

Boulder-lined plunge pools

Stone retaining as design features

4. Under-Deck Pools

Utilizing space under elevated homes

Creative lighting solutions

Weather-protected swimming

5. Lap Pools Along Contours

Following the land's natural fall

Glass fence panoramas

Exercise-focused designs

Blue Haven Pools confirms these designs add 30% more visual impact than flat-block pools.

Cost Considerations for Sloping Block Pools

Budget Factors

Degree of slope (5-25% price variation)

Retaining requirements

Access challenges

Soil conditions

Typical Price Ranges

Solution

Average Cost

Timeline

Basic Retaining

$45,000-$65,000

8-10 weeks

Tiered Design

$65,000-$95,000

10-14 weeks

Cantilevered

$95,000-$150,000+

14-20 weeks

"Investing in proper engineering saves money long-term," notes Wilson. "We've fixed many budget pools that failed on slopes."

Engineering Essentials for Slope Stability

Must-Have Structural Elements

Helical piers for unstable soils

Grade beams around perimeter

Contoured footings

Surface water diversion

Drainage Systems

French drains behind walls

Slot drains in decking

Subsoil aggregation layers

Overflow management

Plungie Pools recommends spending 15-20% of budget on proper drainage.

Case Study: Gold Coast Cliffside Transformation

Challenge:

35° oceanfront slope

Limited machinery access

Salt spray exposure

Our Solution:

Cantilevered concrete shell

Corrosion-resistant rebar

Infinity edge with glass balustrade

Result:

Award-winning design

Zero erosion in 5 years

120° ocean views from pool

Council Regulations for Sloping Blocks

Key Considerations

Cut/fill limits (typically 1m)

Retaining wall heights

Boundary setbacks

Stormwater management

Approval Tips

Engage surveyors early

Consider "exempt development" options

Prepare engineering certifications

Allow 8-12 weeks for approvals

Maintenance Advantages of Slope Pools

Natural debris runoff - Less manual cleaning

Better circulation - Gravity assists flow

Easier equipment access - Often at top level

Simpler drainage - Water naturally moves away

Common Mistakes to Avoid

1. Underestimating Retaining Needs

Walls require proper footings

2. Poor Drainage Planning

Leads to erosion and wall failure

3. Choosing Wrong Materials

Some tiles crack with ground movement

4. DIY Attempts

Slope pools require professional engineering

Why Choose Aqua Living Pools for Your Slope?

300+ Slope Pool Projects

In-House Engineering Team

Custom Design Solutions

5-Year Structural Warranty

Take the First Step Toward Your Slope Pool

Ready to transform your challenging block? Explore Aqua Living's sloping block pool solutions or book a complimentary site assessment.

0 notes

Text

Smart Solutions on Building Pool on a Sloping Block

Dreaming of a backyard oasis but worried about your sloping property? At Aqua Living Pools, we've mastered the art of transforming challenging slopes into stunning aquatic retreats, having built over 300 pools on sloping blocks across the Gold Coast, Brisbane and Northern NSW.

This guide reveals how modern engineering and creative design can turn your sloping block from a challenge into your pool's best feature.

Why Sloping Blocks Make Exceptional Pool Sites

Contrary to popular belief, sloping properties offer unique advantages:

Natural infinity edge potential with panoramic views

Built-in privacy from elevation changes

Dramatic water features using the slope's gradient

Creative multi-level entertaining spaces

Recent data from the Australian Bureau of Statistics shows:

38% of residential blocks in coastal NSW/QLD have significant slopes

Sloping block pools have increased 72% in popularity since 2018

Homes with engineered slope pools see 15-25% higher property values

"Sloping blocks let us create pools you couldn't achieve on flat land," says Mark Wilson, Aqua Living Pools' Senior Designer. "They become true architectural features."

Aqua Living's Proven Approach to Sloping Block Pools

1. Site Assessment & Engineering

Detailed land surveys

Soil testing and geotechnical reports

Hydraulic calculations

Retaining wall requirements

2. Design Solutions

Slope Angle

Recommended Solution

Key Benefit

0-15°

Cut-and-fill

Cost-effective

15-25°

Retaining walls

Maximizes space

25°+

Cantilevered design

Stunning views

3. Construction Process

Laser-leveled foundations

Reinforced concrete structures

Integrated drainage systems

Customized coping solutions

See our sloping block pool portfolio for inspiring examples.

5 Brilliant Design Ideas for Sloping Blocks

1. Infinity Edge Illusions

Vanishing overflow edges

Glass panel boundaries

Reflective water surfaces

2. Multi-Level Entertaining

Pool on one level, spa on another

Integrated sunken fire pits

Staircase beach entries

3. Natural Rock Features

Waterfalls using elevation

Boulder-lined plunge pools

Stone retaining as design features

4. Under-Deck Pools

Utilizing space under elevated homes

Creative lighting solutions

Weather-protected swimming

5. Lap Pools Along Contours

Following the land's natural fall

Glass fence panoramas

Exercise-focused designs

Blue Haven Pools confirms these designs add 30% more visual impact than flat-block pools.

Cost Considerations for Sloping Block Pools

Budget Factors

Degree of slope (5-25% price variation)

Retaining requirements

Access challenges

Soil conditions

Typical Price Ranges

Solution

Average Cost

Timeline

Basic Retaining

$45,000-$65,000

8-10 weeks

Tiered Design

$65,000-$95,000

10-14 weeks

Cantilevered

$95,000-$150,000+

14-20 weeks

"Investing in proper engineering saves money long-term," notes Wilson. "We've fixed many budget pools that failed on slopes."

Engineering Essentials for Slope Stability

Must-Have Structural Elements

Helical piers for unstable soils

Grade beams around perimeter

Contoured footings

Surface water diversion

Drainage Systems

French drains behind walls

Slot drains in decking

Subsoil aggregation layers

Overflow management

Plungie Pools recommends spending 15-20% of budget on proper drainage.

Case Study: Gold Coast Cliffside Transformation

Challenge:

35° oceanfront slope

Limited machinery access

Salt spray exposure

Our Solution:

Cantilevered concrete shell

Corrosion-resistant rebar

Infinity edge with glass balustrade

Result:

Award-winning design

Zero erosion in 5 years

120° ocean views from pool

Council Regulations for Sloping Blocks

Key Considerations

Cut/fill limits (typically 1m)

Retaining wall heights

Boundary setbacks

Stormwater management

Approval Tips

Engage surveyors early

Consider "exempt development" options

Prepare engineering certifications

Allow 8-12 weeks for approvals

Maintenance Advantages of Slope Pools

Natural debris runoff - Less manual cleaning

Better circulation - Gravity assists flow

Easier equipment access - Often at top level

Simpler drainage - Water naturally moves away

Common Mistakes to Avoid

1. Underestimating Retaining Needs

Walls require proper footings

2. Poor Drainage Planning

Leads to erosion and wall failure

3. Choosing Wrong Materials

Some tiles crack with ground movement

4. DIY Attempts

Slope pools require professional engineering

Why Choose Aqua Living Pools for Your Slope?

300+ Slope Pool Projects

In-House Engineering Team

Custom Design Solutions

5-Year Structural Warranty

Take the First Step Toward Your Slope Pool

Ready to transform your challenging block? Explore Aqua Living's sloping block pool solutions or book a complimentary site assessment.

0 notes

Text

Smart Solutions on Building Pool on a Sloping Block

Dreaming of a backyard oasis but worried about your sloping property? At Aqua Living Pools, we've mastered the art of transforming challenging slopes into stunning aquatic retreats, having built over 300 pools on sloping blocks across the Gold Coast, Brisbane and Northern NSW.

This guide reveals how modern engineering and creative design can turn your sloping block from a challenge into your pool's best feature.

Why Sloping Blocks Make Exceptional Pool Sites

Contrary to popular belief, sloping properties offer unique advantages:

Natural infinity edge potential with panoramic views

Built-in privacy from elevation changes

Dramatic water features using the slope's gradient

Creative multi-level entertaining spaces

Recent data from the Australian Bureau of Statistics shows:

38% of residential blocks in coastal NSW/QLD have significant slopes

Sloping block pools have increased 72% in popularity since 2018

Homes with engineered slope pools see 15-25% higher property values

"Sloping blocks let us create pools you couldn't achieve on flat land," says Mark Wilson, Aqua Living Pools' Senior Designer. "They become true architectural features."

Aqua Living's Proven Approach to Sloping Block Pools

1. Site Assessment & Engineering

Detailed land surveys

Soil testing and geotechnical reports

Hydraulic calculations

Retaining wall requirements

2. Design Solutions

Slope Angle

Recommended Solution

Key Benefit

0-15°

Cut-and-fill

Cost-effective

15-25°

Retaining walls

Maximizes space

25°+

Cantilevered design

Stunning views

3. Construction Process

Laser-leveled foundations

Reinforced concrete structures

Integrated drainage systems

Customized coping solutions

See our sloping block pool portfolio for inspiring examples.

5 Brilliant Design Ideas for Sloping Blocks

1. Infinity Edge Illusions

Vanishing overflow edges

Glass panel boundaries

Reflective water surfaces

2. Multi-Level Entertaining

Pool on one level, spa on another

Integrated sunken fire pits

Staircase beach entries

3. Natural Rock Features

Waterfalls using elevation

Boulder-lined plunge pools

Stone retaining as design features

4. Under-Deck Pools

Utilizing space under elevated homes

Creative lighting solutions

Weather-protected swimming

5. Lap Pools Along Contours

Following the land's natural fall

Glass fence panoramas

Exercise-focused designs

Blue Haven Pools confirms these designs add 30% more visual impact than flat-block pools.

Cost Considerations for Sloping Block Pools

Budget Factors

Degree of slope (5-25% price variation)

Retaining requirements

Access challenges

Soil conditions

Typical Price Ranges

Solution

Average Cost

Timeline

Basic Retaining

$45,000-$65,000

8-10 weeks

Tiered Design

$65,000-$95,000

10-14 weeks

Cantilevered

$95,000-$150,000+

14-20 weeks

"Investing in proper engineering saves money long-term," notes Wilson. "We've fixed many budget pools that failed on slopes."

Engineering Essentials for Slope Stability

Must-Have Structural Elements

Helical piers for unstable soils

Grade beams around perimeter

Contoured footings

Surface water diversion

Drainage Systems

French drains behind walls

Slot drains in decking

Subsoil aggregation layers

Overflow management

Plungie Pools recommends spending 15-20% of budget on proper drainage.

Case Study: Gold Coast Cliffside Transformation

Challenge:

35° oceanfront slope

Limited machinery access

Salt spray exposure

Our Solution:

Cantilevered concrete shell

Corrosion-resistant rebar

Infinity edge with glass balustrade

Result:

Award-winning design

Zero erosion in 5 years

120° ocean views from pool

Council Regulations for Sloping Blocks

Key Considerations

Cut/fill limits (typically 1m)

Retaining wall heights

Boundary setbacks

Stormwater management

Approval Tips

Engage surveyors early

Consider "exempt development" options

Prepare engineering certifications

Allow 8-12 weeks for approvals

Maintenance Advantages of Slope Pools

Natural debris runoff - Less manual cleaning

Better circulation - Gravity assists flow

Easier equipment access - Often at top level

Simpler drainage - Water naturally moves away

Common Mistakes to Avoid

1. Underestimating Retaining Needs

Walls require proper footings

2. Poor Drainage Planning

Leads to erosion and wall failure

3. Choosing Wrong Materials

Some tiles crack with ground movement

4. DIY Attempts

Slope pools require professional engineering

Why Choose Aqua Living Pools for Your Slope?

300+ Slope Pool Projects

In-House Engineering Team

Custom Design Solutions

5-Year Structural Warranty

Take the First Step Toward Your Slope Pool

Ready to transform your challenging block? Explore Aqua Living's sloping block pool solutions or book a complimentary site assessment.

0 notes

Text

Smart Solutions on Building Pool on a Sloping Block

Dreaming of a backyard oasis but worried about your sloping property? At Aqua Living Pools, we've mastered the art of transforming challenging slopes into stunning aquatic retreats, having built over 300 pools on sloping blocks across the Gold Coast, Brisbane and Northern NSW.

This guide reveals how modern engineering and creative design can turn your sloping block from a challenge into your pool's best feature.

Why Sloping Blocks Make Exceptional Pool Sites

Contrary to popular belief, sloping properties offer unique advantages:

Natural infinity edge potential with panoramic views

Built-in privacy from elevation changes

Dramatic water features using the slope's gradient

Creative multi-level entertaining spaces

Recent data from the Australian Bureau of Statistics shows:

38% of residential blocks in coastal NSW/QLD have significant slopes

Sloping block pools have increased 72% in popularity since 2018

Homes with engineered slope pools see 15-25% higher property values

"Sloping blocks let us create pools you couldn't achieve on flat land," says Mark Wilson, Aqua Living Pools' Senior Designer. "They become true architectural features."

Aqua Living's Proven Approach to Sloping Block Pools

1. Site Assessment & Engineering

Detailed land surveys

Soil testing and geotechnical reports

Hydraulic calculations

Retaining wall requirements

2. Design Solutions

Slope Angle

Recommended Solution

Key Benefit

0-15°

Cut-and-fill

Cost-effective

15-25°

Retaining walls

Maximizes space

25°+

Cantilevered design

Stunning views

3. Construction Process

Laser-leveled foundations

Reinforced concrete structures

Integrated drainage systems

Customized coping solutions

See our sloping block pool portfolio for inspiring examples.

5 Brilliant Design Ideas for Sloping Blocks

1. Infinity Edge Illusions

Vanishing overflow edges

Glass panel boundaries

Reflective water surfaces

2. Multi-Level Entertaining

Pool on one level, spa on another

Integrated sunken fire pits

Staircase beach entries

3. Natural Rock Features

Waterfalls using elevation

Boulder-lined plunge pools

Stone retaining as design features

4. Under-Deck Pools

Utilizing space under elevated homes

Creative lighting solutions

Weather-protected swimming

5. Lap Pools Along Contours

Following the land's natural fall

Glass fence panoramas

Exercise-focused designs

Blue Haven Pools confirms these designs add 30% more visual impact than flat-block pools.

Cost Considerations for Sloping Block Pools

Budget Factors

Degree of slope (5-25% price variation)

Retaining requirements

Access challenges

Soil conditions

Typical Price Ranges

Solution

Average Cost

Timeline

Basic Retaining

$45,000-$65,000

8-10 weeks

Tiered Design

$65,000-$95,000

10-14 weeks

Cantilevered

$95,000-$150,000+

14-20 weeks

"Investing in proper engineering saves money long-term," notes Wilson. "We've fixed many budget pools that failed on slopes."

Engineering Essentials for Slope Stability

Must-Have Structural Elements

Helical piers for unstable soils

Grade beams around perimeter

Contoured footings

Surface water diversion

Drainage Systems

French drains behind walls

Slot drains in decking

Subsoil aggregation layers

Overflow management

Plungie Pools recommends spending 15-20% of budget on proper drainage.

Case Study: Gold Coast Cliffside Transformation

Challenge:

35° oceanfront slope

Limited machinery access

Salt spray exposure

Our Solution:

Cantilevered concrete shell

Corrosion-resistant rebar

Infinity edge with glass balustrade

Result:

Award-winning design

Zero erosion in 5 years

120° ocean views from pool

Council Regulations for Sloping Blocks

Key Considerations

Cut/fill limits (typically 1m)

Retaining wall heights

Boundary setbacks

Stormwater management

Approval Tips

Engage surveyors early

Consider "exempt development" options

Prepare engineering certifications

Allow 8-12 weeks for approvals

Maintenance Advantages of Slope Pools

Natural debris runoff - Less manual cleaning

Better circulation - Gravity assists flow

Easier equipment access - Often at top level

Simpler drainage - Water naturally moves away

Common Mistakes to Avoid

1. Underestimating Retaining Needs

Walls require proper footings

2. Poor Drainage Planning

Leads to erosion and wall failure

3. Choosing Wrong Materials

Some tiles crack with ground movement

4. DIY Attempts

Slope pools require professional engineering

Why Choose Aqua Living Pools for Your Slope?

300+ Slope Pool Projects

In-House Engineering Team

Custom Design Solutions

5-Year Structural Warranty

Take the First Step Toward Your Slope Pool

Ready to transform your challenging block? Explore Aqua Living's sloping block pool solutions or book a complimentary site assessment.

0 notes

Text

Smart Solutions on Building Pool on a Sloping Block

Dreaming of a backyard oasis but worried about your sloping property? At Aqua Living Pools, we've mastered the art of transforming challenging slopes into stunning aquatic retreats, having built over 300 pools on sloping blocks across the Gold Coast, Brisbane and Northern NSW.

This guide reveals how modern engineering and creative design can turn your sloping block from a challenge into your pool's best feature.

Why Sloping Blocks Make Exceptional Pool Sites

Contrary to popular belief, sloping properties offer unique advantages:

Natural infinity edge potential with panoramic views

Built-in privacy from elevation changes

Dramatic water features using the slope's gradient

Creative multi-level entertaining spaces

Recent data from the Australian Bureau of Statistics shows:

38% of residential blocks in coastal NSW/QLD have significant slopes

Sloping block pools have increased 72% in popularity since 2018

Homes with engineered slope pools see 15-25% higher property values

"Sloping blocks let us create pools you couldn't achieve on flat land," says Mark Wilson, Aqua Living Pools' Senior Designer. "They become true architectural features."

Aqua Living's Proven Approach to Sloping Block Pools

1. Site Assessment & Engineering

Detailed land surveys

Soil testing and geotechnical reports

Hydraulic calculations

Retaining wall requirements

2. Design Solutions

Slope Angle

Recommended Solution

Key Benefit

0-15°

Cut-and-fill

Cost-effective

15-25°

Retaining walls

Maximizes space

25°+

Cantilevered design

Stunning views

3. Construction Process

Laser-leveled foundations

Reinforced concrete structures

Integrated drainage systems

Customized coping solutions

See our sloping block pool portfolio for inspiring examples.

5 Brilliant Design Ideas for Sloping Blocks

1. Infinity Edge Illusions

Vanishing overflow edges

Glass panel boundaries

Reflective water surfaces

2. Multi-Level Entertaining

Pool on one level, spa on another

Integrated sunken fire pits

Staircase beach entries

3. Natural Rock Features

Waterfalls using elevation

Boulder-lined plunge pools

Stone retaining as design features

4. Under-Deck Pools

Utilizing space under elevated homes

Creative lighting solutions

Weather-protected swimming

5. Lap Pools Along Contours

Following the land's natural fall

Glass fence panoramas

Exercise-focused designs

Blue Haven Pools confirms these designs add 30% more visual impact than flat-block pools.

Cost Considerations for Sloping Block Pools

Budget Factors

Degree of slope (5-25% price variation)

Retaining requirements

Access challenges

Soil conditions

Typical Price Ranges

Solution

Average Cost

Timeline

Basic Retaining

$45,000-$65,000

8-10 weeks

Tiered Design

$65,000-$95,000

10-14 weeks

Cantilevered

$95,000-$150,000+

14-20 weeks

"Investing in proper engineering saves money long-term," notes Wilson. "We've fixed many budget pools that failed on slopes."

Engineering Essentials for Slope Stability

Must-Have Structural Elements

Helical piers for unstable soils

Grade beams around perimeter

Contoured footings

Surface water diversion

Drainage Systems

French drains behind walls

Slot drains in decking

Subsoil aggregation layers

Overflow management

Plungie Pools recommends spending 15-20% of budget on proper drainage.

Case Study: Gold Coast Cliffside Transformation

Challenge:

35° oceanfront slope

Limited machinery access

Salt spray exposure

Our Solution:

Cantilevered concrete shell

Corrosion-resistant rebar

Infinity edge with glass balustrade

Result:

Award-winning design

Zero erosion in 5 years

120° ocean views from pool

Council Regulations for Sloping Blocks

Key Considerations

Cut/fill limits (typically 1m)

Retaining wall heights

Boundary setbacks

Stormwater management

Approval Tips

Engage surveyors early

Consider "exempt development" options

Prepare engineering certifications

Allow 8-12 weeks for approvals

Maintenance Advantages of Slope Pools

Natural debris runoff - Less manual cleaning

Better circulation - Gravity assists flow

Easier equipment access - Often at top level

Simpler drainage - Water naturally moves away

Common Mistakes to Avoid

1. Underestimating Retaining Needs

Walls require proper footings

2. Poor Drainage Planning

Leads to erosion and wall failure

3. Choosing Wrong Materials

Some tiles crack with ground movement

4. DIY Attempts

Slope pools require professional engineering

Why Choose Aqua Living Pools for Your Slope?

300+ Slope Pool Projects

In-House Engineering Team

Custom Design Solutions

5-Year Structural Warranty

Take the First Step Toward Your Slope Pool

Ready to transform your challenging block? Explore Aqua Living's sloping block pool solutions or book a complimentary site assessment.

0 notes

Text

Smart Solutions on Building Pool on a Sloping Block

Dreaming of a backyard oasis but worried about your sloping property? At Aqua Living Pools, we've mastered the art of transforming challenging slopes into stunning aquatic retreats, having built over 300 pools on sloping blocks across the Gold Coast, Brisbane and Northern NSW.

This guide reveals how modern engineering and creative design can turn your sloping block from a challenge into your pool's best feature.

Why Sloping Blocks Make Exceptional Pool Sites

Contrary to popular belief, sloping properties offer unique advantages:

Natural infinity edge potential with panoramic views

Built-in privacy from elevation changes

Dramatic water features using the slope's gradient

Creative multi-level entertaining spaces

Recent data from the Australian Bureau of Statistics shows:

38% of residential blocks in coastal NSW/QLD have significant slopes

Sloping block pools have increased 72% in popularity since 2018

Homes with engineered slope pools see 15-25% higher property values

"Sloping blocks let us create pools you couldn't achieve on flat land," says Mark Wilson, Aqua Living Pools' Senior Designer. "They become true architectural features."

Aqua Living's Proven Approach to Sloping Block Pools

1. Site Assessment & Engineering

Detailed land surveys

Soil testing and geotechnical reports

Hydraulic calculations

Retaining wall requirements

2. Design Solutions

Slope Angle

Recommended Solution

Key Benefit

0-15°

Cut-and-fill

Cost-effective

15-25°

Retaining walls

Maximizes space

25°+

Cantilevered design

Stunning views

3. Construction Process

Laser-leveled foundations

Reinforced concrete structures

Integrated drainage systems

Customized coping solutions

See our sloping block pool portfolio for inspiring examples.

5 Brilliant Design Ideas for Sloping Blocks

1. Infinity Edge Illusions

Vanishing overflow edges

Glass panel boundaries

Reflective water surfaces

2. Multi-Level Entertaining

Pool on one level, spa on another

Integrated sunken fire pits

Staircase beach entries

3. Natural Rock Features

Waterfalls using elevation

Boulder-lined plunge pools

Stone retaining as design features

4. Under-Deck Pools

Utilizing space under elevated homes

Creative lighting solutions

Weather-protected swimming

5. Lap Pools Along Contours

Following the land's natural fall

Glass fence panoramas

Exercise-focused designs

Blue Haven Pools confirms these designs add 30% more visual impact than flat-block pools.

Cost Considerations for Sloping Block Pools

Budget Factors

Degree of slope (5-25% price variation)

Retaining requirements

Access challenges

Soil conditions

Typical Price Ranges

Solution

Average Cost

Timeline

Basic Retaining

$45,000-$65,000

8-10 weeks

Tiered Design

$65,000-$95,000

10-14 weeks

Cantilevered

$95,000-$150,000+

14-20 weeks

"Investing in proper engineering saves money long-term," notes Wilson. "We've fixed many budget pools that failed on slopes."

Engineering Essentials for Slope Stability

Must-Have Structural Elements

Helical piers for unstable soils

Grade beams around perimeter

Contoured footings

Surface water diversion

Drainage Systems

French drains behind walls

Slot drains in decking

Subsoil aggregation layers

Overflow management

Plungie Pools recommends spending 15-20% of budget on proper drainage.

Case Study: Gold Coast Cliffside Transformation

Challenge:

35° oceanfront slope

Limited machinery access

Salt spray exposure

Our Solution:

Cantilevered concrete shell

Corrosion-resistant rebar

Infinity edge with glass balustrade

Result:

Award-winning design

Zero erosion in 5 years

120° ocean views from pool

Council Regulations for Sloping Blocks

Key Considerations

Cut/fill limits (typically 1m)

Retaining wall heights

Boundary setbacks

Stormwater management

Approval Tips

Engage surveyors early

Consider "exempt development" options

Prepare engineering certifications

Allow 8-12 weeks for approvals

Maintenance Advantages of Slope Pools

Natural debris runoff - Less manual cleaning

Better circulation - Gravity assists flow

Easier equipment access - Often at top level

Simpler drainage - Water naturally moves away

Common Mistakes to Avoid

1. Underestimating Retaining Needs

Walls require proper footings

2. Poor Drainage Planning

Leads to erosion and wall failure

3. Choosing Wrong Materials

Some tiles crack with ground movement

4. DIY Attempts

Slope pools require professional engineering

Why Choose Aqua Living Pools for Your Slope?

300+ Slope Pool Projects

In-House Engineering Team

Custom Design Solutions

5-Year Structural Warranty

Take the First Step Toward Your Slope Pool

Ready to transform your challenging block? Explore Aqua Living's sloping block pool solutions or book a complimentary site assessment.

0 notes

Text

Bored Piling for Urban Environments: Key Considerations for a Solid Start

Navigating the Complexities of Urban Construction with the Right Foundation Strategy

Urban construction is a balancing act—space is tight, timelines are strict, and safety is paramount. That’s why choosing the right foundation method is crucial. Among the most reliable and efficient methods, bored piling stands out, especially in metropolitan areas like Sydney. But while it’s a proven solution, it’s not without its challenges. Here's what piling contractors, developers, and builders need to know when considering bored piling in an urban setting.

What Is Bored Piling?

Bored piling is a deep foundation technique where cylindrical holes are drilled into the ground and then filled with reinforced concrete. Unlike driven piles, bored piles are quieter and cause less ground vibration—making them ideal for city projects.

Why Bored Piling Works in Urban Environments

1. Minimal Disruption

Urban environments are dense and active. Bored piling is less noisy and disruptive compared to driven piles, making it a better option for areas with strict noise and vibration regulations.

2. Precision Engineering

Bored piles allow for more control over depth and alignment, a crucial advantage when working around existing infrastructure like water mains, cables, and nearby buildings.

3. Heavy Load-Bearing Capacity

In cities, structures like apartment towers, office blocks, and transport hubs demand foundations that can handle significant weight. Bored piles offer high load-bearing capacity and are well-suited for such demands.

Key Considerations for Urban Bored Piling

1. Site Accessibility

Urban sites often have limited access. Choosing experienced piling contractors who can bring in compact equipment and navigate tight sites is essential.

2. Soil Conditions

Inner-city soil profiles can vary drastically. Soil testing and geotechnical reports are vital before selecting between screw piling, bored piling, or other methods.

3. Safety and Compliance

With people, traffic, and neighboring properties nearby, safety is non-negotiable. Work with piling experts who follow industry standards and have a proven track record in urban environments.

Alternatives to Consider: Is Screw Piling Right for You?

In some urban situations—like residential builds or sites with less load-bearing demand—screw piling might be a faster and more cost-effective alternative. Especially in cities like Sydney, screw piling Sydney contractors often recommend this method for its quick installation and minimal mess.

However, for large-scale or high-rise projects, bored piling still remains the gold standard.

Choosing the Right Piling Partner

Your piling partner can make or break your project. Look for contractors who:

Have a proven track record in urban projects

Offer both screw piling and bored piling solutions

Can guide you through council approvals and compliance

Are known as reliable piling experts with a strong portfolio

End Note

Urban construction demands smart planning, reliable partners, and techniques that balance efficiency with safety. Whether you opt for screw piling in Sydney or a tailored bored piling solution, working with experienced piling contractors ensures your project begins on solid ground.

#screw piling#screw piling newcastle#screw pile suppliers#specialist piling contractors#screw piling sydney#piling contractors#piling companies#piling experts#screw piling central coast#bored piling

0 notes

Text

What Goes into Building a Modern Road?

Building a modern road is not just about laying down asphalt. It includes a careful planning process, environmental considerations, and regulatory and community approvals. This is where modern roadway construction experts lay the first blueprint and complete the final pavement layer. Head to https://www.facebook.com/ersnell/videos/28390557650558111/ for additional information.

Planning and feasibility studies Contractors start the construction process even before visiting the site. Road planners, civil engineers, and the government evaluate the necessity of roads based on traffic, economic development, and connectivity issues. Moreover, the contractors analyze the terrain, various environmental impacts, and other existing costs. This phase also includes collecting community and stakeholders' input to meet the local needs. Design and engineering Once the project is approved, engineers create a detailed road design, including mapping the road’s alignment and determining drainage systems, utilities, sidewalks, and intersections. Moreover, they conduct soil testing and geotechnical analysis of the terrain to decide the road structure. Furthermore, contractors pick materials for highway construction based on expected traffic volume and environmental conditions. Engineers also utilize advanced design software and simulation tools to analyze the road’s performance in scenarios involving heavy loads, weather extremes, and future growth. Furthermore, they ensure that the design complies with transportation codes, safety standards, and accessibility guidelines. Permitting and environmental approvals Modern road construction projects pass through a rigorous permit process. Environmental agencies review plans for a minimal impact on local ecosystems, wildlife, and water sources. Moreover, these projects often require mitigation plans when wetlands and protected areas are affected. The team also tests the noise and air quality in the urban zones. To learn more, visit https://www.ersnell.com/division/roadway/. Site preparation and earthwork After processing the approval, construction works on clearing the debris, old infrastructure, and vegetation from the terrain. Followed by which they begin excavation, compaction, and grading processes. This is a step where the surface is shaped and leveled to match the road structure. Before road construction, drainage systems, utility conduits, and culverts are installed to prevent erosion and manage water flow.

About E.R. Snell: E.R. Snell is the company you can trust with heavy civil construction. This company has an expert team of contractors working extensively to lay the groundwork for a reliable and smooth roadway. If you want to join their team or hire them for road construction, contact them now. To get more details, visit https://www.ersnell.com/ Contact: 7709850600 Original Source: https://bit.ly/407krjr

0 notes

Text

Essential Considerations for Developing Land in Mountain Regions

Developing land in mountain regions requires careful planning, foresight, and respect for the unique challenges presented by the terrain, climate, and ecosystem. These areas are often characterized by dramatic landscapes, pristine nature, and various ecological complexities, making it crucial to consider multiple factors before developing. Whether for residential, commercial, or recreational purposes, land development in mountain regions demands a delicate balance between progress and preservation. This article explores the key considerations developers must consider when developing in mountainous areas.

Understanding the Topography and Terrain Challenges

Topography is the first and foremost consideration when developing land in mountain regions. Mountainous areas are typically characterized by steep slopes, uneven ground, and rocky or unstable soil, all of which can present significant challenges to construction. Builders must thoroughly assess the terrain to determine how best to use the land, considering the natural features and elevation differences.

The steepness of slopes is particularly important. Steep areas require specialized construction techniques, such as terracing or anchoring structures to prevent landslides or erosion. Building foundations in mountain regions also need to be reinforced to handle shifting ground and the weight of structures. Geotechnical surveys are often required to ensure the land is stable enough to support construction.

Another aspect of the terrain to consider is access to the site. Roads and infrastructure may be limited or difficult to build in mountainous regions due to the challenging geography. Developers must carefully plan transportation routes, ensuring that they can be safely accessed by vehicles and emergency services. This may involve building roads that wind through the mountains, creating tunnels, or employing innovative engineering solutions.

Environmental Impact and Preservation

One of the most important factors to consider when developing land in mountain regions is the environmental impact. Mountain ecosystems often have delicate flora and fauna, which may be endangered or unique. The development process must prioritize sustainability and minimize harm to the surrounding environment.

Before any construction begins, an environmental impact assessment (EIA) is essential to evaluate the potential effects of development on local ecosystems, water resources, and wildlife. This assessment helps identify the areas most at risk of degradation and guides the mitigation of negative impacts. Measures could include limiting construction to certain areas, protecting natural habitats, or incorporating wildlife corridors into the design.

Preserving water resources is also a key consideration in mountain regions. Mountains often serve as vital watersheds, and development can affect the natural flow of water, leading to flooding, erosion, or contamination of water supplies. Developers must ensure that any construction is planned with proper drainage systems, water conservation measures, and techniques to protect the integrity of nearby rivers, lakes, or aquifers.

Incorporating green infrastructure into the development design is another effective way to minimize environmental impacts. This could include rain gardens, green roofs, and permeable pavement, which help manage stormwater runoff and reduce the strain on local water systems.

Climate and Weather Conditions

Mountain regions are known for their variable and often harsh climate. Understanding the area's weather patterns is essential for successful development, as it impacts everything from construction timelines to the long-term durability of buildings. In many mountain areas, temperatures vary significantly between seasons, with harsh winters, heavy snowfall, and high winds, followed by short, warm summers.

Construction schedules need to account for seasonal changes. In regions where snow and ice are common, work may need to be scheduled for warmer months, and buildings must be designed to withstand extreme winter conditions. Insulation, heating systems, and weatherproofing techniques must be factored into the design to ensure structures remain comfortable and functional year-round.