#hydraulic universal testing machine manufacturer

Explore tagged Tumblr posts

Text

To perform tension, compression, bending, and shearing tests on metal and non-metal materials, a hydraulic universal testing machine with an underside-type oil cylinder and four columns is employed. Applications include metallurgy, building, light industry, aircraft, aviation, materials, universities, and scientific research facilities.

#hydraulic universal testing machine#hydraulic universal testing machine price#hydraulic universal testing machine suppliers#hydraulic universal testing machine manufacturer#hydraulic universal testing machine in India#hydraulic testing machine#hydraulic testing machine price#hydraulic testing machine suppliers#hydraulic testing machine in India

0 notes

Text

From Humidity Chambers to Testing Machines - India’s Expert Equipment Manufacturer

Kant Plastology has established itself as a leader in the field of manufacturing high-quality testing and processing equipment. With a strong focus on innovation and precision, we are dedicated to delivering solutions that meet the diverse needs of industrial, research, and development sectors across India and beyond. Our products are engineered with cutting-edge technology to ensure superior performance and reliability, making us a trusted partner for businesses and institutions.

We take pride in offering a comprehensive range of machinery that caters to different industries, including materials testing, manufacturing, and quality control. Our commitment to customer satisfaction drives us to continuously innovate and create products that help our clients achieve accurate and repeatable results. With strict quality control and advanced manufacturing practices, Kant Plastology ensures that every machine leaving our facility meets the highest industry standards.

Reliable Manufacturing Equipment for Industrial, Research, and Quality Control Needs

One of our standout products is the universal tensile testing machine, designed to deliver precision in evaluating material strength, elasticity, and tensile properties. This machine is vital for industries requiring consistent quality assurance in their production processes. Additionally, as a leading hydraulic press machine manufacturer in India, we offer robust solutions tailored for applications requiring high-pressure operations, ensuring efficiency and durability in every project.

Kant Plastology is also renowned as a humidity chamber manufacturerin India, providing equipment that offers controlled environments for testing materials under various temperature and humidity conditions. Furthermore, as a trusted tensile testing machine manufacturer, we focus on creating customizable solutions that cater to the specific testing needs of our clients.

At Kant Plastology, we believe in building relationships based on trust, quality, and exceptional service. Our goal is to empower businesses with reliable machinery that enhances their operational efficiency and supports their growth. Partner with us today and experience the expertise and dedication that set Kant Plastology apart in the industry.

#tensile testing machine manufacturer#humidity chamber manufacturerin India#hydraulic press machine manufacturer#universal tensile testing machine

0 notes

Text

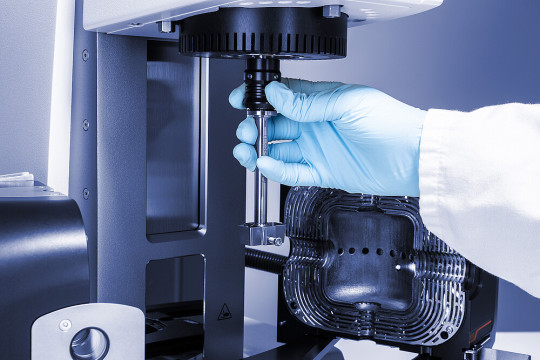

Computerized Universal Testing Machine Front Open with Hydraulic Grip

Computerized universal testing machine with a front-open design and hydraulic grip is a versatile testing instrument used for evaluating the mechanical properties of various materials. This type of machine offers a front-opening configuration, allowing easy sample loading and positioning, while hydraulic grips provide secure and reliable clamping of the test specimens. Consider the maximum load capacity of the testing machine, which determines the range of materials and specimen sizes it can handle. Machines typically have load capacities ranging from a few kilonewtons to several hundred kilonewtons or more, depending on the application requirements.

Universal Testing Machines supplied completed with UTM Software. It has a wide range of applications. A number of materials and metals in different forms and shapes can be tested for a variety of tests like tension, Compression, Transverse, Bend, Shear, Brinell Hardness, etc. Special attachments are also available for testing of flat belts, chain links, wire ropes etc.

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire Ropes etc.

Hydraulic grips provide a reliable clamping mechanism for securing the test specimen during testing. The hydraulic system allows for controlled and consistent gripping force application, ensuring accurate and repeatable results.

testing machine, universal testing machine, computerized universal testing machine, universal testing machine with hydraulic, computerized universal testing machine with hydraulic, universal testing machine with front open, universal testing machine with hydraulic front open

#manufacture#industrial equipment#metallurgical#manufacturer#testing#metallographicequipments#testing machine#universal testing machine#front open universal testing machine#hydraulic universal testing machine#computerized universal testing machine#universal testing machine with hydraulic#universal testing machine with front open

1 note

·

View note

Text

What Makes ICCL Male Connector Fittings the Trusted Choice for International Projects?

In the realm of global infrastructure and industrial development, every connection truly matters — and I mean that quite literally. Whether you're diving into oil and gas pipelines, chemical processing units, HVAC systems, or water distribution projects, even the tiniest component can have a huge impact. That’s why engineers, project managers, and industrial buyers all over the globe consistently rely on ICCL Male Connector Fittings for their strength, precision, and long-lasting reliability.

So, what makes ICCL stand out from the crowd of fitting manufacturers? Why do so many international projects across various environments and industries opt for ICCL Male Connector Fittings? Let’s take a closer look.

1. Unmatched Global Standards and Certifications

One major reason why ICCL fittings are favored worldwide is their adherence to international standards. ICCL Male Connector Fittings are crafted with care to meet:

ISO and DIN standards

ASME and ASTM specifications

RoHS and REACH compliance

This means that whether a project is taking place in Europe, the Middle East, Asia, or the Americas, ICCL connectors are guaranteed to meet or even surpass the necessary technical expectations.

2. Precision Engineering for a Perfect Fit

At the core of every ICCL male connector is precision machining. Each fitting is produced with tight tolerances, ensuring a flawless, leak-free fit every single time. This level of precision is especially crucial in applications that involve:

High-pressure fluid transfer

Hydraulic or pneumatic systems

Industrial automation lines

Chemical or corrosive environments

Thanks to ICCL’s advanced CNC processes and strict quality control, every fitting performs exactly as promised — with no room for error.

3. Material Excellence and Customization

Not all materials are created equal. ICCL utilizes high-grade stainless steel (SS 304, SS 316), brass, carbon steel, and special alloys based on the specific needs of each project. This diverse selection of materials allows ICCL to serve industries such as:

Marine and offshore

Oil and gas

Aerospace

Water treatment

When it comes to renewable energy, ICCL stands out by offering tailored configurations, threads, and finishes. This means international clients can find exactly what they need without sacrificing compatibility or performance.

4. Proven Corrosion and Temperature Resistance

For projects that span various climate zones, consistent performance is crucial. ICCL Male Connector Fittings are designed to withstand:

- High salinity environments, like coastal and offshore areas

- Extreme temperatures, whether scorching hot or freezing cold

- Harsh chemicals and fluids

These fittings are rigorously tested through salt spray tests, thermal cycling, and pressure burst evaluations, making them perfect for demanding environmental conditions.

5. Ease of Installation and Interchangeability

Global contractors often face tight deadlines and diverse teams. That’s why ICCL Male Connectors are crafted to be:

- Quick to install using standard tools

- Universally compatible with tubing and piping systems worldwide

- Safe and efficient, minimizing downtime and risks during installation

Their user-friendly design helps reduce operational hiccups, making them ideal for multinational teams working under pressure.

6. Trusted by Engineers Across 30+ Countries

Reputation is everything. ICCL has earned the trust of clients in over 30 countries by delivering:

- Consistent product quality

- Timely global delivery

- Exceptional technical support

You’ll find ICCL fittings in everything from massive infrastructure projects in the Middle East to renewable energy facilities in Europe and manufacturing plants across Asia.

7. Sustainable and Future-Ready Manufacturing

With a growing emphasis on sustainability and ESG compliance, ICCL ensures its fittings are:

- Eco-friendly, produced in energy-efficient facilities

- Free from lead and toxins

- Designed for long-lasting use, reducing waste

This dedication to sustainability makes ICCL the go-to choice for forward-thinking engineering firms around the world.

8. Cost-Effective Without Compromise

In international projects, striking the right balance between cost and quality is essential. ICCL’s fittings provide:

When it comes to competitive global pricing, bulk order efficiencies, and lower maintenance and replacement costs, ICCL Male Connectors truly stand out as a wise long-term investment, particularly for projects that need to stick to tight budgets and keep operational costs in check.

Final Thoughts: ICCL – Connecting the World, One Fit at a Time

In our increasingly interconnected industrial world, selecting the right components goes beyond just functionality — it’s about ensuring global compatibility, durability, and reliability. ICCL Male Connector Fittings deliver on all these fronts.

Whether you’re an engineer working on challenging offshore rigs, a procurement officer for a multinational construction company, or a project manager focused on building smart cities, ICCL guarantees that every connection you make is designed to endure.

0 notes

Text

Common Tests Conducted in Geo Textiles Testing Labs Explained

In modern civil engineering and construction projects, geo textiles are indispensable materials used for soil stabilization, erosion control, filtration, drainage, and reinforcement. Given their critical role in ensuring structural integrity and environmental protection, geo textiles must meet strict quality and performance standards before deployment. This is where geo textiles testing becomes essential.

Testing labs worldwide conduct a variety of tests on geo textiles to verify their mechanical, hydraulic, and environmental properties. These tests help engineers, manufacturers, and contractors ensure the geo textile materials they use will perform reliably under the demanding conditions of construction sites.

In this blog, we explain the most common tests conducted in geo textiles testing labs, what each test measures, and why it’s important for overall material performance.

What Are Geo Textiles?

Geo textiles are permeable fabrics made from synthetic or natural fibers designed to interact with soil and rock. They serve multiple functions such as separation, filtration, drainage, reinforcement, and protection in civil engineering applications including roads, embankments, retaining walls, landfills, and erosion control.

Why Testing Geo Textiles Matters

Geo textiles must withstand mechanical stresses, harsh environmental exposure, and chemical interaction with soils or water. Improperly tested or substandard geo textiles can lead to project failures such as soil erosion, structural collapse, or waterlogging. Therefore, testing labs evaluate geo textiles through standardized methods to certify their quality and performance.

Common Tests Conducted in Geo Textiles Testing Labs

1. Tensile Strength Test

Purpose: Measures the maximum force a geo textile can endure when stretched before breaking.

Why It Matters: Tensile strength indicates the material’s ability to withstand soil pressure and mechanical loads during installation and service.

How It’s Done: Using a universal testing machine, a specimen of the geo textile is pulled until it breaks, recording the force and elongation.

2. Elongation Test

Purpose: Measures how much a geo textile stretches under tensile load before failure.

Why It Matters: Elongation affects the fabric’s ability to deform without breaking, important for applications requiring flexibility.

Method: Often conducted alongside tensile tests, elongation is expressed as a percentage increase from the original length.

3. Tear Resistance Test

Purpose: Assesses the material’s ability to resist propagation of tears once initiated.

Why It Matters: Geo textiles can be exposed to sharp objects or rough handling; tear resistance ensures durability during installation and use.

Procedure: A pre-cut specimen is subjected to controlled tearing force, usually via trapezoid or tongue tear methods.

4. Puncture Resistance Test

Purpose: Evaluates resistance to penetration by sharp or pointed objects.

Why It Matters: Geo textiles often lie beneath rocks or debris; puncture resistance ensures they remain intact under such conditions.

How It Works: A standardized probe is pushed through the fabric, and the force required is measured.

5. Water Permeability Test

Purpose: Measures the flow rate of water through the geo textile.

Why It Matters: Important for filtration and drainage functions — the fabric must allow water to pass while retaining soil particles.

Method: Water is passed through the fabric under a set hydraulic head or pressure, and flow rate is recorded.

6. Apparent Opening Size (AOS) Test

Purpose: Determines the effective pore size of the geo textile.

Why It Matters: AOS dictates which size soil particles the fabric will retain, crucial for preventing soil migration and erosion.

Procedure: Testing involves passing a range of sieve sizes through the fabric and measuring retention.

7. UV Resistance Test

Purpose: Assesses how well the geo textile withstands degradation from ultraviolet radiation.

Why It Matters: Exposure to sunlight during storage and installation can weaken synthetic fibers; UV resistance ensures longevity.

Test Method: Samples are exposed to artificial UV light for a set duration, then tested for changes in tensile strength and elongation.

8. Chemical Resistance Test

Purpose: Evaluates the geo textile’s ability to resist deterioration from chemicals commonly found in soils and water (e.g., acids, alkalis, oils).

Why It Matters: Ensures fabric integrity in chemically aggressive environments like landfills or industrial sites.

How It’s Performed: Samples are immersed in chemical solutions for specified periods, then retested for mechanical properties.

9. Water Absorption Test

Purpose: Measures how much water the geo textile absorbs when submerged.

Why It Matters: High absorption may affect the fabric’s weight, flexibility, and hydraulic performance.

Procedure: The dry weight is compared to the weight after soaking in water for a specific time.

10. Thickness and Mass per Unit Area Test

Purpose: Measures the fabric thickness and weight per square meter.

Why It Matters: These physical properties influence performance characteristics like strength, permeability, and durability.

Method: Thickness is measured using mechanical or digital gauges; mass is calculated from weighed fabric samples.

How These Tests Support Construction Projects

Quality Assurance: Confirm geo textiles meet design specifications and international standards (ASTM, ISO, AASHTO).

Safety: Prevent material failure that could jeopardize structural integrity or cause environmental damage.

Regulatory Compliance: Many construction projects require certified test reports to meet local and international regulations.

Material Selection: Helps engineers choose the right geo textile for specific soil, load, and environmental conditions.

Cost Efficiency: Ensures durability and reduces maintenance or replacement costs.

International Standards Guiding Geo Textile Testing

Common test methods used in labs generally follow established standards such as:

ASTM (American Society for Testing and Materials) – widely used for tensile strength, permeability, UV resistance, etc.

ISO (International Organization for Standardization) – harmonizes test methods globally for consistent results.

AASHTO (American Association of State Highway and Transportation Officials) – essential for highway and transportation projects.

Choosing a Reliable Geo Textiles Testing Lab

When selecting a testing lab for geo textiles, consider:

Accreditation: ISO/IEC 17025 accreditation ensures lab competence and quality management.

Comprehensive Testing: Ability to perform all relevant mechanical, hydraulic, chemical, and environmental tests.

Experienced Staff: Skilled technicians and engineers for accurate testing and interpretation.

Clear Reporting: Detailed test reports with interpretations for easy decision-making.

Fast Turnaround: Timely results to keep projects on schedule.

Conclusion

Geo textiles are vital components in infrastructure projects, offering solutions to complex geotechnical challenges. However, their effectiveness depends heavily on rigorous testing that ensures durability, strength, permeability, and environmental resistance.

Geo textiles testing labs conduct a suite of standardized tests—ranging from tensile strength and tear resistance to UV and chemical resistance—that collectively guarantee material quality and suitability. Understanding these common tests helps manufacturers improve products, engineers select the right materials, and contractors ensure project success.

0 notes

Text

Why Smart Parts Exports is Your Trusted Source for Mahindra Genuine Parts

In today’s fast-paced and highly aggressive automotive production, maintaining the staging, well-being, and longevity of your vehicle is more important than ever. The footing of that reliability goes about using the right spare parts. For Mahindra vehicle owners, this measure fix on Mahindra Genuine Parts—components specifically designed and manufactured to meet the original engineering degree of your vehicle. These parts guarantee seamless rapport, superior durability, and optimal performance under all driving conditions.

At Smart Parts Exports, we understand how testing genuine parts are to safeguard your Mahendra running smoothly. That’s why we are committed to provide only 100% authentic Mahindra spare parts to purchasers in all directions the world. With our global reach, substantial statement, and deep manufacturing expertise, we have one of the most trusted handles in the business. Whether you're carrying a personal vehicle or managing an entire fleet, count on us for quality, reliability, and complete customer satisfaction.

The Importance of Using Mahindra Genuine Parts

Mahindra is a brand known for constructing bumpy, strongly made, and high-performance vehicles suitable for both urban and off-road use. From SUVs and private enterprise vehicles to tractors, Mahindra's portfolio is multiple and widely used across continents. Anyway, keeping up the showing of these vehicles depends significantly on the use of Mahindra genuine spare parts.

Genuine parts are developed alongside Mahindra vehicles to ensure perfect agreement and seamless meshing. These parts undergo studious quality checks, ensuring they meet the high standards set by the manufacturer. In contrast, feigned or non-genuine parts may compromise machine recital, fuel efficiency, and even safety.

Why Choose Smart Parts Exports?

Smart Parts Exports has positioned itself as a global leader in automotive spare parts distribution. With a solid reputation for delivering Mahindra spare parts across continents, we stand out for several reasons:

Authenticity Guaranteed Every part you order from Smart Parts Exports is 100% genuine. We source all our Mahindra genuine parts directly from authorized distributors or the manufacturer, eliminating the risk of forged or substandard elements.

Wide Range of Parts Whether you're looking for engine components, suspension parts, brake systems, electricals, or body parts, our catalog covers an extensive range of Mahindra parts for both old and new vehicle models.

Global Reach From India to Africa, the Middle East to Latin America, Smart Parts Exports hand over high-quality Mahindra spare parts to purchasers across the universe. Our logical logistics and shipping network ensure timely deliveries no matter where you are located.

Competitive Pricing While genuine parts can often be big-budget, we work hard to offer the best practicable charge to our purchaser without compromising on quality. Our direct partnerships and large volumes allow us to keep costs low and pass on the decrease.

Exceptional Customer Support Our team is a collection of automotive experts who can help you identify the perfect Mahindra genuine spare parts for your vehicle. Whether you're a garage owner, fleet operative, or an individual Mahindra owner, we offer personalized support every step of the way.

Applications of Mahindra Parts

Mahindra vehicles are used in a variety of supplication, counting transportation, agriculture, and logistics. Each application puts unique stress on disparate vehicle arrangement. For example, tractors may have experience on their hydraulic and engine components, while commercial vehicles might stand in need of frequent replacements of brake pads or clutch kits.

Using Mahindra genuine parts ensures that the replacing integrant can hold out against the pressure of the job. Whether it's a Bolero, Scorpio, XUV500, or a Mahindra tractor, Smart Parts Exports has the right parts to keep your vehicle running like new.

A Long-Term Investment in Performance and Safety

Choosing Mahindra genuine spare parts is not just about protecting your vehicle on the road today—it’s about safeguarding your financing for years to come. Genuine parts extend the life of your vehicle, improve fuel efficiency, and make compact the probability of future breakdowns.In addition, using verified parts helps keep up the resale value of your Mahindra vehicle, which can be significantly impacted by the use of substitute or unsuited parts.

Conclusion

When it comes to sourcing Mahindra spare parts, there’s no free space for settlement. At Smart Parts Exports, we combine reliability, authenticity, and affordability to deliver the distinctly best in Mahindra parts to buyers around the world. Whether you’re managing a fleet, running a workshop, or revenue care of your personal Mahindra vehicle, trust us to provide the right solutions with the right parts—every time.

Choose Smart Parts Exports for all your Mahindra genuine parts needs and experience the difference that quality makes.

0 notes

Text

#frontopenwithhydraulicgripscomputerizeduniversaltesting machine#manufacturer#supplier#fmi#finemanufacturing

0 notes

Text

How to Maintain and Calibrate a Universal Testing Machine for Accurate Results

A Universal Testing Machine (UTM) is a crucial piece of equipment used in various industries, including manufacturing, construction, and research, to test the mechanical properties of materials. Whether performing tensile, compression, flexural, or shear tests, the accuracy of a UTM is essential for ensuring reliable data and compliance with industry standards.

To maintain consistent and accurate results, regular maintenance and calibration are necessary. This article explores the best practices for maintaining and calibrating a Universal Testing Machine, ensuring optimal performance and longevity.

Why Maintenance and Calibration Are Essential

Over time, UTMs can experience wear and tear, affecting their precision, load accuracy, and test repeatability. Factors such as environmental conditions, improper handling, and mechanical stress can lead to inaccurate measurements.

Regular maintenance and calibration ensure:

Accurate test results for quality control and research.

Compliance with industry standards such as ASTM, ISO, and EN.

Prolonged lifespan of the UTM, reducing long-term operational costs.

Safety for operators, preventing sudden failures during testing.

Routine Maintenance of a Universal Testing Machine

Proper maintenance of a UTM involves regular inspections, cleaning, lubrication, and software updates. Below are key steps to keep your machine in excellent working condition.

1. Regular Visual Inspection

Perform a visual check before and after each testing session. Look for:

Loose bolts, screws, and connections that may affect stability.

Cracks or deformations in grips, load cells, and fixtures.

Unusual noises during operation, which may indicate mechanical wear.

Hydraulic leaks in systems using hydraulic power.

2. Cleaning and Lubrication

Wipe down machine surfaces after each use to prevent dust buildup.

Clean lead screws and ball screws using lint-free cloths and manufacturer-approved solvents.

Apply lubricants to moving parts (as recommended by the manufacturer) to prevent friction-related wear.

3. Checking Load Cells and Sensors

The load cell is the heart of a UTM, converting force into measurable data. To ensure accuracy:

Avoid exceeding load limits, which can damage the load cell.

Store load cells in a stable, temperature-controlled environment.

Check for sensor drift or deviations in readings over time.

4. Software Updates and Functionality Checks

Keep testing software up to date to benefit from improvements and bug fixes.

Verify that data acquisition systems are properly connected and recording values accurately.

Perform sample test runs to check for inconsistencies.

5. Environmental Control

Maintain stable room temperature and humidity levels to prevent expansion/contraction of machine components.

Keep the UTM free from vibrations and excessive air currents, which may influence readings.

How to Calibrate a Universal Testing Machine

Calibration is the process of verifying and adjusting the machine’s accuracy by comparing its output to a known standard. Calibration should be performed:

At least once a year (or more frequently for critical applications).

Whenever the machine is relocated to a new environment.

After major repairs or part replacements.

Step-by-Step Calibration Process

1. Verify Calibration Standards

Before beginning, ensure that calibration is performed using certified reference standards that comply with:

ASTM E4 for force calibration.

ISO 7500-1 for verification of static uniaxial testing.

ISO 9513 for extensometer calibration.

2. Prepare the Machine for Calibration

Ensure the machine is clean and free from obstructions.

Warm up the system for 30-60 minutes to stabilize sensors.

Position the load cell and crosshead in a neutral state.

3. Conduct Load Verification

Apply a known reference weight or force to the load cell.

Compare displayed results with the certified reference values.

Adjust calibration settings if deviations exceed allowable tolerance limits.

4. Verify Crosshead Movement and Displacement Sensors

Use a certified displacement gauge to check crosshead travel.

Compare measured displacement vs. actual displacement.

Adjust settings if any significant error is detected.

5. Test Repeatability and Linearity

Perform multiple load tests at different force levels.

Ensure that readings are consistent across different trials.

Check for linearity by plotting results and verifying deviations.

6. Document Calibration Data

Record all measurements before and after adjustments.

Generate a calibration certificate detailing:

Load cell accuracy.

Displacement sensor accuracy.

Testing conditions.

Many companies opt for third-party calibration services accredited by ISO/IEC 17025, ensuring traceability to national metrology institutes.

Common Calibration and Maintenance Mistakes to Avoid

Skipping Routine Checks – Minor issues, if ignored, can lead to major failures.

Using Incorrect Load Standards – Always use certified weights and reference materials.

Failing to Recalibrate After Relocation – Moving a UTM can impact its alignment and accuracy.

Overloading the Load Cell – This can cause permanent deformation and inaccurate readings.

Ignoring Software Updates – Outdated software may cause data errors and test inconsistencies.

Conclusion

Maintaining and calibrating a Universal Testing Machine is critical for ensuring accurate, reliable, and repeatable test results. Proper care involves routine inspections, cleaning, lubrication, and software checks, while regular calibration ensures compliance with industry standards.

By following these best practices, businesses can maximize the lifespan of their UTM, improve testing accuracy, and maintain compliance with regulatory requirements. Investing in proper maintenance and calibration ultimately leads to better quality control, improved research data, and safer products across various industries.

0 notes

Text

Where Can You Find The Best Engineering Laboratory Equipment Manufacturer In Africa

The engineering laboratory equipment manufacturers in Africa are indispensable for the advancement of technical education, research, and industry in the continent. These manufacturers provide different types of equipment depending on the branches of engineering, including civil, mechanical, electrical, and chemical engineering. Such equipment can include wind tunnels, material testing machines, heat exchangers, hydraulic benches, fluid mechanics apparatus, etc. This Blog will outline the major companies where you can find a reliable and trustworthy engineering laboratory equipment manufacturer in Africa and we will also talk about the role they have played in areas of engineering education and research.

The Role of Engineering Laboratory Equipment in Learning and Training in African Countries.

In an African context, engineering education and practice is better achieved with the support of appropriate engineering laboratory equipment. By this means students expectations, skills, and attitudes are transformed through experiential learning. This range of motion not only improves comprehension and retention, but also helps student development of hands-on skills which are invaluable in the field of engineering.

Practical laboratories also increase the effectiveness of occupational education, thus allowing the students to face the industrial reality. Further, provision of proper engineering tools aids in creativity as well as technology, which plays a crucial role in promoting the economy of Africa. Therefore, the expenditures in such laboratories place such students in the right direction towards the psychics who are responsible for the self sustained development and industrialization of the continent.

Engineering Laboratory Equipment manufacturers play an important role, as they provide the reliable and accurate equipment to school, colleges and in the research centers. Engineering Laboratory Equipment manufacturers are instrumental in filling this gap by designing Cost effective and durable materials for the African colleges and research centers. Such affirmative action equips the young generation with practical skills and thinking which will propel them into the scientific and technological careers that are imperative for the development of the continent.

Leading Engineering Laboratory Equipment Manufacturer In Africa

LSS Africa

LSS Africa is one of the leading engineering laboratory equipment manufacturers in Africa. They provide high quality engineering equipment in the areas of education and industrial fields. Among the products manufactured by this company are material testing machines, fluid mechanics benches, thermodynamic apparatuses, etc. LSS Africa has made a mark in supporting African universities and technical institutes by providing reliable and cutting-edge equipment.

SciLab Export

SciLab Export is a well-known manufacturer of all kinds of laboratory and engineering equipment for educational and industrial purposes. It includes precise calibrators, advanced robotics trainers, PLC programming stations, structural engineering testing equipment etc. The same factors and the focus on innovation and quality policy secured SciLab Export as a supplier for institutions willing to improve their educational facility in the field of engineering.

Didactic Africa

Didactic Africa is concerned with manufacturing and supplying educational laboratory equipment for technical and engineering practical work. The company provides a broad spectrum of equipment, including fluid power trainers, heat transfer units and mechatronics addressing the ideas repeatedly practiced in theory. Their products are in great demand in training facilities, polytechnics and university institutions in Africa.

Engineering Laboratory Equipment

Engineering Laboratory Equipment offers a wide range of teaching aids in different fields of engineering including electrical, civil and mechanical engineering. They deal in wind tunnels, vibration analysis kits, and electrical circuit trainers among others. Their equipment helps to promote the careful study and comprehension of engineering concepts through hands-on experimentation.

LSS Algeria

LSS Algeria is one of the leading African manufacturers of scientific and engineering equipment, which targets the delivery of dependable solutions to universities, research centers, and industrial laboratories. They offer a wide range of engineering equipment such as soil testers, fluid mechanics apparatus and electronic trainer kits, thus making them a significant player in the education and industrial markets of Africa.

Overview of Engineering Laboratory Equipment

Engineering laboratory equipment is critical in conducting experiments, carrying out research and providing training within various disciplines of engineering. Such tools make it possible for students, researchers and professionals to grasp difficult concepts, test hypotheses, and devise strategies to respond to given challenges. The following is some of the engineering laboratory equipment that is often used.

Wind Tunnels

This Wind Tunnel equipment is more commonly used for conducting fluid dynamics studies on airframes and combustion engine-powered automobiles. It enables engineers to study the behavior of airflow over geometrical shapes and enhance their designs to achieve better performance and safety.

Material Testing Machines

The devices are used for evaluating a range of engineering materials regarding their mechanics relative to tension, compression, and twisting. They are the most important machines in the testing of materials which focus on construction structures, metals, and plastics which have to withstand mechanical wear and tear.

Heat Exchangers

Heat exchanger is also referred to as a thermal transfer unit which is made for some kind of heat conduction from one fluid to another. Such systems are widely used in Mechanical and Electrical Engineering, particularly in HVAC systems, generating power poles, as well as chemical processes.

As stated in Wikipedia, heat transfer as a section of thermal engineering describes the heat creation, useful work, heat exchange and heat modification in physical systems. In this perspective, there are various processes which are aimed at affecting the transmission of heat. This would include, but is not limited to thermal conduction, thermal convection, thermal radiation and phase change.

Hydraulic Benches

A hydraulic bench is equipment that is made up of a movable base used for the investigation of fluid parameters like the velocity of flow, drop in pressure, and the formation of hydraulic jumps. Such equipment is very common in studies within civil and environmental engineering fields.

Electrical Circuit Trainers

Such trainers are applicable and useful in demonstrating lessons on electrical circuit controlling, Ohm law, Kirchhoff laws, and countless other basic electric and electronic circuit structures. They are very important for students learning electrical and electronics engineering.

Conclusion

In the laboratory, opting for the appropriate engineering laboratory equipment manufacturer in Africa is necessary to guarantee the precision and safety of experiments. Providers like Didactic Africa, LSS Africa, or others have a wide array of engineering equipment that are perfect for meeting the specific requirements of African laboratories. In their emphasis on quality, innovation, and customer support, these providers enhance science teaching and research in the continent. No matter if its an educational laboratory or a research center, these top manufacturers serve reliable engineering laboratory equipment that will help to achieve the desired result.

#engineering laboratory equipment manufacturers in Africa#engineering laboratory equipment#engineering laboratory equipment manufacturer

0 notes

Text

The Importance of Calibration and Maintenance for Universal Testing Machines

A Universal Testing Machine (UTM) is a critical piece of equipment used to test the mechanical properties of materials, including tensile, compression, flexural, and shear strength. UTMs are widely used in industries such as construction, aerospace, automotive, and manufacturing to ensure product quality, safety, and compliance with industry standards.

However, to maintain accuracy and reliability, regular calibration and maintenance of a UTM are essential. Without proper upkeep, a UTM may provide incorrect results, leading to faulty material assessments, product failures, and potential safety risks. In this article, we will explore the importance of calibration and maintenance for Universal Testing Machines, along with best practices to ensure long-term performance and accuracy.

1. Why Calibration is Essential for UTMs

Ensuring Accuracy and Reliability

Calibration is the process of comparing the UTM’s measurements to a known standard to verify its accuracy. Over time, mechanical wear, environmental factors, and frequent usage can cause slight deviations in measurement readings. Without calibration, these deviations can lead to inaccurate test results, which may compromise product quality.

Compliance with Industry Standards

Various industries have strict guidelines regarding material testing, and compliance with standards such as ASTM, ISO, and DIN is mandatory. Regular calibration ensures that your UTM meets these standards and provides legally valid test results.

Avoiding Costly Errors and Rework

If a UTM is not calibrated correctly, manufacturers may produce materials based on incorrect data. This can lead to:

Product failures due to incorrect material strength analysis.

Wastage of raw materials caused by inaccurate specifications.

Expensive recalls and liability issues if faulty products reach the market.

By calibrating the UTM at regular intervals, businesses can avoid such costly mistakes and maintain product integrity.

2. The Importance of Regular Maintenance

Prolonging the Lifespan of the Machine

A well-maintained UTM lasts significantly longer than one that is neglected. Regular maintenance prevents mechanical wear, lubrication issues, and electrical malfunctions, reducing the likelihood of unexpected breakdowns.

Ensuring Smooth Operation

A poorly maintained UTM may develop issues such as sticking grips, misalignment of the crosshead, or fluctuations in load cell readings. These issues can disrupt testing procedures, leading to inconsistent results. Routine maintenance helps keep the machine running smoothly and efficiently.

Enhancing Safety

Universal Testing Machines operate under high forces, and a malfunctioning unit can pose a safety risk to operators. Routine maintenance checks help identify potential hazards such as loose fixtures, worn-out components, or hydraulic system failures, ensuring a safer working environment.

3. Best Practices for Calibration and Maintenance of UTMs

A. Regular Calibration Schedule

Annual Calibration: Most UTMs should be calibrated at least once a year by a certified technician.

After Heavy Use: If the machine is used frequently or for high-force tests, more frequent calibrations may be necessary.

Post-Maintenance Calibration: If any major component is repaired or replaced, recalibration is required to verify accuracy.

B. Key Maintenance Steps

Visual Inspection: Check for any visible damage, loose parts, or misaligned components before each test.

Lubrication of Moving Parts: Keep lead screws, bearings, and grips well-lubricated to prevent wear and tear.

Cleaning and Dust Removal: Regularly clean the machine to remove dust, debris, and test residues that can affect performance.

Load Cell and Sensor Checks: Inspect load cells, displacement sensors, and extensometers for signs of malfunction.

Software Updates: Ensure that the testing software is up to date to maintain compatibility and accuracy in data collection.

Hydraulic System Maintenance (for Hydraulic UTMs): Regularly check hydraulic fluid levels, hoses, and seals to prevent leaks and pressure loss.

4. Common Calibration and Maintenance Mistakes to Avoid

Ignoring Small Measurement Deviations

Minor errors in readings may not seem significant initially, but over time, they can accumulate and lead to substantial inaccuracies. Any irregularities in test results should be investigated immediately.

Skipping Maintenance Due to Downtime Concerns

Some companies avoid maintenance checks to prevent production delays. However, neglecting maintenance can result in machine failures, leading to longer downtimes and expensive repairs.

Using Unqualified Calibration Services

Calibration should be performed by certified professionals using traceable standards to ensure compliance with industry regulations. In-house or uncertified calibrations may lead to inaccurate results.

5. The Long-Term Benefits of Proper UTM Calibration and Maintenance

Improved Testing Accuracy: Ensures reliable and precise material strength assessments.

Increased Machine Lifespan: Prevents premature wear and costly breakdowns.

Reduced Operational Costs: Minimizes repair expenses and unexpected downtime.

Better Compliance: Meets industry regulations and avoids legal issues.

Enhanced Workplace Safety: Reduces risks associated with malfunctioning equipment.

Conclusion

Regular calibration and maintenance of a Universal Testing Machine (UTM) are essential for ensuring accurate test results, machine longevity, and workplace safety. Without proper calibration, test data can be unreliable, leading to product failures and compliance issues. Likewise, routine maintenance prevents mechanical failures, enhances efficiency, and extends the machine’s lifespan.

To keep your UTM performing at its best, always follow a structured calibration and maintenance schedule, use certified calibration services, and address any performance issues immediately. Investing in proper care today ensures long-term reliability and cost savings, making calibration and maintenance a vital aspect of any material testing process.

0 notes

Text

The Impact Of Engineering Laboratory Equipment Manufacturers In India

The engineering laboratory equipment manufacturers of India have become very active players in the education and industrial market throughout the world. Indian manufacturers supply a wide range of equipment including universal testing machines, hydraulic benchtops, fluid mechanics kits, vibration test systems, heat exchangers, and CNC machines for training purposes. These manufacturers are becoming more and more important in nurturing future engineers and research scientists by helping education and research institutions as well as industries with affordable and dependable solutions. In this Blog, we mentioned 6 impacts of engineering laboratory equipment manufacturers in India.

Impact Of Engineering Laboratory Equipment Manufacturers In India

Support for Research and Development

The Indian manufacturers provide advanced machinery like material testing machines, fluid mechanics setups, and thermal engineering equipment, which comfortably encourages leading-edge research and innovation. Their products allow researchers to perform experiments with a high degree of accuracy, facilitating development and technology progress in diverse engineering areas.

Contribution to Skill Development

The use of engineering lab equipment from Indian manufacturers plays a significant role in the development of skills, especially for technical institutions and training centers. Industry-related skill acquisition like CNC training and operation of automated systems is made possible by this equipment to boost the professionals’ and students’ employability in the shifting job market.

Enhancement of Engineering Education

Engineering laboratory equipment manufacturers in India produce high-quality engineering laboratory equipment that enables students to gain practical, hands-on experience. This exposure to real-world applications and experimental techniques enhances their understanding of complex engineering concepts, bridging the gap between theoretical knowledge and practical skills.

Encouragement of Collaboration between Industries and Institutes

The presence of good engineering lab instruments made the collaboration of industry and academia to be enhanced. The Indian manufacturers are able to varnish customized forms that tend to suit specific industrial needs hence helping the academic bodies to do some research work that seeks to solve the problems in a given industry. This helps in exchanging knowledge and speed of innovation.

Boost to Economic Growth

The activity of manufacturing equipment for the engineering laboratories also makes the right contribution towards the economic development of India. Even supplying goods into several countries leads Indian producers to obtain good revenues, create employment opportunities, and promote the advancement of manufacturing.

Encouragement of Innovation and Quality Standards

Manufacturers in India provide new and better ways of using the equipment through innovative means. They comply with certain international standards such as ISO, and CE which helps their products to be safe, reliable and relevant to the world market. This focus on quality and new ideas not only raises the stature of the Indian manufacturers but also uplifts the quality of engineering education and research in the country.

Key Engineering Laboratory Equipment

Universal Testing Machine

Universal testing machines (UTMs) are highly applicable in testing the tensile and compressive strength of various materials. Indian manufacturers have UTM’S which are provided with digital controls as well as internal and external additions like load and deformation measurement, thus making them crucial for testing materials in construction and materials engineering, and related fields.

Hydraulic Bench

Hydraulic benches find application in fluid mechanics laboratories for geophysical designs in flow measurement, energy loss measurements, and studies on hydraulic jumps. Hydraulic benches manufactured in India are strong and reversibly handled with the use of modular systems that allow versatile procedures and precise chips to conduct various fluid experiments.

Heat Transfer Unit

Heat transfer units offer experimental provisions to examine the different ways in which heat can be transferred which in this scholarship include conduction, convection, and radiation. Heat transfer units constructed in India are designed with additional devices that make it possible to capture accurate and relevant data required in thermal engineering skills.

CNC training machine

CNC training machines play a significant role in equipping students with knowledge on the use of computer numerical control. Indian manufacturers of durable CNC training machines with advanced controls and devices enhance occupational practice amongst students of safe precision machinery.

Fluid Mechanics Equipment

Flow channels and wind tubes belong to fluid mechanics Equipment and are used to investigate the flow of fluid in the transportation of heat or any other processes. There are a lot of fluid mechanics apparatuses available in India that have excellent measurement techniques and are also suitable for both teaching and research skills in civil and mechanical engineering.

Why Opt For Jlab India?

Jlab India is one of the leading Engineering laboratory equipment manufacturers in India. Our devotion to quality, innovation, and customer satisfaction is simply unmatched. Jlab Export has a variety of products that meet the highest international standards and thus guarantees every laboratory is fully fitted with dependable, precise, and long-lasting instruments. Owing to the strong presence of Jlab Export in the global market and the ability to understand the specific needs of clients and offer tailor-made services, our company has turned out to be an integral partner for educational, research, and industrial entities.

#engineering laboratory equipment manufacturers in India#engineering laboratory equipment manufacturer#engineering laboratory equipment

0 notes

Text

Strong R&D Focus in Water Pump Manufacturing

A leading water pump supplier prioritizes research and development (R&D) to drive innovation, improve efficiency, and develop cutting-edge solutions for various industries. A strong R&D focus ensures the continuous evolution of pump technology, making systems more energy-efficient, reliable, and sustainable.

Here’s how R&D shapes the water pump industry:

1. Innovation in Pump Design and Performance

Computational Fluid Dynamics (CFD) Modeling: Optimizes impeller and casing designs to improve hydraulic efficiency.

Advanced Materials: Development of corrosion-resistant alloys, composites, and coatings to enhance durability.

Compact and Lightweight Designs: Reducing pump size while maintaining high performance for easy installation and operation.

2. Energy Efficiency and Sustainability

High-Efficiency Motors: Incorporation of IE3 and IE4 energy-efficient motors to reduce power consumption.

Variable Frequency Drives (VFDs): Allows real-time speed adjustments based on demand, optimizing energy use.

Renewable Energy Integration: Development of solar-powered and hybrid water pumps to promote sustainability.

Smart Water Management: Research into IoT-enabled pumps that optimize water usage and reduce waste.

3. Digitalization and Smart Pump Technologies

IoT-Enabled Pumps: Remote monitoring, predictive maintenance, and automated operation for smart infrastructure.

AI-Driven Performance Analytics: Use of artificial intelligence to analyze pump efficiency and detect early signs of failure.

Cloud-Based Monitoring Systems: Integration of real-time performance tracking and alerts via mobile applications.

4. Enhanced Durability and Reliability

Wear-Resistant Coatings: Nanocoatings and ceramic linings to extend pump lifespan.

Self-Diagnostic Systems: Pumps that monitor their own condition and alert users to potential failures.

Anti-Clogging and Self-Cleaning Mechanisms: Essential for sewage and wastewater pumps to prevent blockages.

5. Customization for Industry-Specific Needs

Industrial Applications: High-pressure multistage pumps for oil & gas, mining, and manufacturing sectors.

Agriculture and Irrigation: Solar and energy-efficient pumps designed for large-scale farming operations.

Municipal and Infrastructure Projects: High-capacity pumps for flood control, wastewater treatment, and urban water supply.

6. Sustainability and Eco-Friendly Pump Solutions

Circular Economy Initiatives: Development of recyclable and modular pump components to reduce environmental impact.

Low-Carbon Manufacturing Processes: Adoption of green production techniques to minimize energy consumption and emissions.

Water Conservation Technologies: Pumps designed for precise water distribution, reducing waste in irrigation and industrial applications.

7. Advanced Testing and Quality Assurance

Automated Performance Testing: AI-powered test benches ensure pumps meet high standards before deployment.

Real-World Simulation Labs: Testing pumps in various environmental conditions to validate performance.

Compliance with Global Standards: Continuous R&D efforts to meet ISO, ANSI, and NSF certifications for quality assurance.

8. Collaboration with Research Institutions and Industry Leaders

University Partnerships: Working with academic institutions to develop next-generation pump technologies.

Joint Ventures with Tech Firms: Collaborating with IoT and AI companies to enhance smart pump functionalities.

Government and Sustainability Grants: Funding R&D initiatives for energy-efficient and climate-resilient pump solutions.

9. Future Trends in Water Pump R&D

Hydrogen-Powered Pumps: Exploring hydrogen fuel cells as an alternative energy source for pumps.

Bio-Inspired Designs: Using nature-inspired engineering to improve efficiency and minimize friction losses.

AI-Optimized Pumping Networks: Fully automated water distribution systems using machine learning for smart cities.

A strong R&D focus is essential for a Water Pump Supplier to stay ahead in an evolving industry. By investing in technological advancements, sustainability, and energy efficiency, suppliers can offer innovative solutions that meet the demands of modern industries while ensuring environmental responsibility. For more info contact Water Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

What Makes ICCL Male Connector Fittings the Trusted Choice for International Projects?

In the realm of global infrastructure and industrial development, every connection truly matters — and I mean that quite literally. Whether you're diving into oil and gas pipelines, chemical processing units, HVAC systems, or water distribution projects, even the tiniest component can have a huge impact. That’s why engineers, project managers, and industrial buyers all over the globe consistently rely on ICCL Male Connector Fittings for their strength, precision, and long-lasting reliability.

So, what makes ICCL stand out from the crowd of fitting manufacturers? Why do so many international projects across various environments and industries opt for ICCL Male Connector Fittings? Let’s take a closer look.

1. Unmatched Global Standards and Certifications

One major reason why ICCL fittings are favored worldwide is their adherence to international standards. ICCL Male Connector Fittings are crafted with care to meet:

ISO and DIN standards

ASME and ASTM specifications

RoHS and REACH compliance

This means that whether a project is taking place in Europe, the Middle East, Asia, or the Americas, ICCL connectors are guaranteed to meet or even surpass the necessary technical expectations.

2. Precision Engineering for a Perfect Fit

At the core of every ICCL male connector is precision machining. Each fitting is produced with tight tolerances, ensuring a flawless, leak-free fit every single time. This level of precision is especially crucial in applications that involve:

High-pressure fluid transfer

Hydraulic or pneumatic systems

Industrial automation lines

Chemical or corrosive environments

Thanks to ICCL’s advanced CNC processes and strict quality control, every fitting performs exactly as promised — with no room for error.

3. Material Excellence and Customization

Not all materials are created equal. ICCL utilizes high-grade stainless steel (SS 304, SS 316), brass, carbon steel, and special alloys based on the specific needs of each project. This diverse selection of materials allows ICCL to serve industries such as:

Marine and offshore

Oil and gas

Aerospace

Water treatment

When it comes to renewable energy, ICCL stands out by offering tailored configurations, threads, and finishes. This means international clients can find exactly what they need without sacrificing compatibility or performance.

4. Proven Corrosion and Temperature Resistance

For projects that span various climate zones, consistent performance is crucial. ICCL Male Connector Fittings are designed to withstand:

- High salinity environments, like coastal and offshore areas

- Extreme temperatures, whether scorching hot or freezing cold

- Harsh chemicals and fluids

These fittings are rigorously tested through salt spray tests, thermal cycling, and pressure burst evaluations, making them perfect for demanding environmental conditions.

5. Ease of Installation and Interchangeability

Global contractors often face tight deadlines and diverse teams. That’s why ICCL Male Connectors are crafted to be:

- Quick to install using standard tools

- Universally compatible with tubing and piping systems worldwide

- Safe and efficient, minimizing downtime and risks during installation

Their user-friendly design helps reduce operational hiccups, making them ideal for multinational teams working under pressure.

6. Trusted by Engineers Across 30+ Countries

Reputation is everything. ICCL has earned the trust of clients in over 30 countries by delivering:

- Consistent product quality

- Timely global delivery

- Exceptional technical support

You’ll find ICCL fittings in everything from massive infrastructure projects in the Middle East to renewable energy facilities in Europe and manufacturing plants across Asia.

7. Sustainable and Future-Ready Manufacturing

With a growing emphasis on sustainability and ESG compliance, ICCL ensures its fittings are:

- Eco-friendly, produced in energy-efficient facilities

- Free from lead and toxins

- Designed for long-lasting use, reducing waste

This dedication to sustainability makes ICCL the go-to choice for forward-thinking engineering firms around the world.

8. Cost-Effective Without Compromise

In international projects, striking the right balance between cost and quality is essential. ICCL’s fittings provide:

When it comes to competitive global pricing, bulk order efficiencies, and lower maintenance and replacement costs, ICCL Male Connectors truly stand out as a wise long-term investment, particularly for projects that need to stick to tight budgets and keep operational costs in check.

Final Thoughts: ICCL – Connecting the World, One Fit at a Time

In our increasingly interconnected industrial world, selecting the right components goes beyond just functionality — it’s about ensuring global compatibility, durability, and reliability. ICCL Male Connector Fittings deliver on all these fronts.

Whether you’re an engineer working on challenging offshore rigs, a procurement officer for a multinational construction company, or a project manager focused on building smart cities, ICCL guarantees that every connection you make is designed to endure.

0 notes

Text

Kant Plastology – Innovating Industrial Machines for Superior Performance

Precision, durability, and innovation are the cornerstones of industrial success, and Kant Plastology stands as a leader in manufacturing high-quality testing and industrial machines. With a commitment to excellence, they provide reliable and advanced solutions tailored to meet the specific needs of diverse industries such as plastics, automotive, and aerospace. From cutting-edge designs to meticulous craftsmanship, Kant Plastology ensures their machines deliver optimal performance and long-term reliability.

The team at Kant Plastology is dedicated to understanding the unique challenges of their clients, crafting equipment that not only meets expectations but exceeds them. Their wide range of products reflects their expertise in delivering personalized solutions, whether clients require testing instruments for material analysis, production machinery, or laboratory equipment. This commitment to quality and innovation has made Kant Plastology a trusted partner for businesses seeking precision-engineered machines.

Efficiency Meets Expertise in Precision-Engineered Hydraulic Press Machines

For businesses in search of a reputed hydraulic press machine manufacturer, Kant Plastology offers durable and efficient solutions crafted with industry-leading expertise. Additionally, they excel in producing the universal tensile testing machine, a vital tool for evaluating material properties with exceptional accuracy and ease of use.

Their product line also includes advanced solutions for plastics testing, earning recognition as a trusted melt flow index tester manufacturer. Furthermore, for climate-controlled testing applications, they stand out as a notable humidity chamber manufacturer in India, delivering reliable performance and precision.

Kant Plastology’s focus on innovation, customer-centric support, and precision engineering ensures that every client receives unparalleled value. With their expertise, you can trust them to provide the right solutions to elevate your processes and achieve excellence in your operations.

#humidity chamber manufacturer in India#melt flow index tester manufacturer#tensile testing machine#hydraulic press machine manufacturer

1 note

·

View note

Text

China LPG cylinder manufacturing machinery supplier

Jiangsu Far East Universal Equipment Co., Ltd has focused on top quality LPG cylinder manufacturing machines for over 20 years in China. We started as a small operation, but now have become one of the leading suppliers in the LPG cylinder manufacturing machines industry in China. Today, Jiangsu Far East has been one of the top producers of quality LPG cylinder manufacturing machines, such as: Hydraulic press, decoiler and blanking production line, Deep drawing machine, LPG cylinder trimming machine, Welding machine, Water pressure test machine, Heat treatment furnace and printing machine etc. Contact us at: Address:Industrial Estate in The North Of Shengao Town, Jiangyan District, Taizhou, Jiangsu, China Email:[email protected] Phone:+86-523-88662888 Website: https://www.yd-jd.com/

1 note

·

View note