#install Gas Turbine Control Systems

Explore tagged Tumblr posts

Text

How Gas Turbine Produces Electricity and Its Components

Today, most of the power plants essentially install Gas Turbine Control Systems. To produce electricity, the gas turbine works by heating the mixture of air and fuel at very high temperatures that in turn spin the turbine blades. The spinning turbine generates initiatives that randomly convert the energy into electricity. The gas turbine is used along with the steam turbine in the combined power plant to develop power efficiently.

The Gas and Steam Turbine Control System produces electricity in the following steps- 1.Ignites Air and Fuel Mixture- The gas turbine system compresses the air and then mixes it with the fuel which is burned at extremely high temperatures that result in the production of a hot gas.

2.Hot Gas Spins Turbine Blades- The hot air and fuel mixture then passes through blades in the turbine that spins both of them very quickly.

3.Fast-Spinning Blades Turns to Drive Shaft-The fast-spinning turbine blades then rotate the turbine drive shaft.

4.The Turbine Rotation Controls The Generator-The spinning turbine is linked with the rod within the generator that in shots the large magnet which is surrounded by coils of copper wire.

5.The Magnet of the Generator Interchanges the Electrons and Produces Electricity-The generator that is revolving very fast produces a powerful magnetic field that in turn lines up the electrons available around the copper coils and then in turn allows them to move. The movement that happens through the wire of electrons is called electricity.

Components of Gas Turbine System The majority of fuel power plants install combustion gas turbines. The combustion turbines are installed in various power plants of today's era. These are basic complex machines that are made of three main components-

The Compressor- This is one of the main components of gas turbine systems that induce air into the engines, create pressure and then feed the same into the combustion chamber at speeds of hundreds of miles per hour.

The Combustion System- This component of the gas chamber is made up of a ring of fuel injectors that inoculate a sturdy stream of fuel into the combustion chambers, in which the fuel gets mixed with the air. The resultant mixture is then burned at extremely high temperatures exceeding 200 degrees F. The combustion then creates a high-temperature, high-pressure gas stream which then enters the turbine section and expands it.

The Turbine- It is an intricate collection of alternate stationery and spinning aero foil-section blades. As hot combustion gas tends to expand through the turbine, it then spins the rotating blades. The rotating blades then perform dual functions- first, they drive a compressor to induce more pressurized air into the combustion section. As a result, it spins a generator to produce electricity.

0 notes

Text

Why Knock Out Drums Are Essential in Gas Processing Systems

What Is a Knock Out Drum?

The Role of Knock Out Drums in Gas Processing

In any gas processing facility, it is vital to maintain clean and dry gas streams. This is critical to both operational efficiency and equipment protection. This is where the knock out drum plays a key role. Installed at strategic points within the system, typically upstream of compressors or other sensitive machinery, the drum effectively separates liquid droplets from the gas flow. By capturing these contaminants early in the process, the knock out drum helps prevent corrosion, erosion, and fouling in downstream components. Its importance is further amplified when integrated with a well-designed filtration system, ensuring that only high-quality gas continues through the plant. Modern knockout drum design focuses not only on maximizing separation efficiency but also on reducing pressure drop and handling variable flow rates, making it an indispensable part of safe and reliable gas processing operations.

Key Functions: Separating Liquids from Gas Streams

We have listed the key functions of knock out drum as follows:

Removes Entrained Liquids: Captures liquid droplets (such as water, hydrocarbons, and condensates) carried within the gas stream through gravity-based separation.

Prevents Liquid Carryover: Ensures that only dry gas proceeds downstream, reducing the risk of liquid contamination in compressors, turbines, and other critical equipment.

Enhances Filtration Efficiency: Acts as a pre-separation stage to reduce the load on finer downstream filters in the overall filtration system.

Protects System Integrity: Minimizes corrosion, erosion, and fouling caused by liquid within gas processing systems.

Handles Surge Conditions: Provides temporary storage for liquid surges, helping to stabilize system performance and protect downstream units.

Supports Consistent Gas Quality: Helps maintain the required gas quality specifications by removing unwanted liquids through optimized knockout drum design.

How Knock Out Drums Improve Equipment Protection

In gas processing operations, one of the constant challenges is protecting downstream equipment from the damaging effects of liquid. A well-designed knock out drum serves as a crucial safeguard in this regard. By efficiently separating entrained liquids from the gas stream, it prevents these contaminants from reaching sensitive components such as compressors, turbines, heat exchangers, and control valves. Without this protective barrier, liquids can cause corrosion and erosion leading to blockages and premature wear. An integrated filtration system that includes an optimized knockout drum design ensures that the bulk of harmful materials are removed early. This can significantly extend the life of the equipment and reduce maintenance costs. In this way, knock out drums contribute directly to the reliability, efficiency, and safety of gas processing facilities.

Supporting Regulatory Compliance and Safety Standards

Gas processing industry is highly regulated and meeting environmental and safety standards is not an option but a fundamental requirement. In this regard, the knock out drums play an essential role. They help in achieving and maintaining compliance with these standards. They help in removing liquids from gas streams and ensure that the processed gas meets stringent quality and emission limits before it reaches pipelines or end-users. In addition to this, an effective knockout drum design can help reduce the risk of liquid carryover, which can lead to dangerous conditions like compressor surge, fires, or even explosions. By incorporating knock out drums within a broader filtration system, you can help support cleaner operations, minimize the release of pollutants and protect both the workforce and the environment. Knock out drums contribute not only to equipment performance but also to the overall safety and regulatory compliance of gas processing facilities.

Design Considerations for Optimal Performance

Achieving optimal performance from a knock out drum requires careful attention to its design. Several factors influence the efficiency of liquid in gas processing applications. First, sizing is critical — an undersized drum may lead to poor separation, while an oversized unit can increase costs unnecessarily. Proper knockout drum design takes into account factors such as gas flow rate, pressure, temperature, and the expected level of liquid contaminants. Internals like vane packs, mesh pads, or demister elements can be incorporated to enhance separation efficiency without causing excessive pressure drop. The orientation of the drum (horizontal or vertical) should also align with space constraints and process needs. Integrating the drum seamlessly with the plant’s filtration system ensures a layered approach to gas cleaning, allowing finer filtration downstream to operate more effectively. By considering these elements, operators can maximize the performance and reliability of their knock out drums in demanding gas processing environments.

Maintenance Best Practices to Maximize Drum Lifespan

Regular maintenance is key to ensuring that a knock out drum continues to deliver reliable performance throughout its service life. In any gas processing facility, adopting the right maintenance practices helps prevent efficiency losses and costly unplanned shutdowns. There must be routine inspections that focus on checking the condition of internal components such as vane packs, mesh pads, and other elements of the knockout drum design for signs of wear or fouling.

At the same time, it is also important to monitor liquid levels and verify the proper functioning of drain systems to avoid liquid carryover. Periodic cleaning of the drum and associated piping ensures that the filtration system remains effective and free of buildup. In addition to all this, tracking pressure drop across the drum can serve as an early indicator of potential blockages or internal damage. By following these best practices, operators can significantly extend the lifespan of the knock out drum and maintain optimal performance in their gas processing systems.

The location of installation of these Knockout drums are in India.

0 notes

Text

Digital Flow Meters vs Mechanical: Which Is Best for Your Business in Abu Dhabi?

In sectors where efficiency and accuracy are most important—such as oil & gas, manufacturing, or water treatment—flow meters are used in the measurement and monitoring of liquid and gas flow. Abu Dhabi businesses typically must make an important choice when they need to pick these devices: digital flow meters or mechanical flow meters?

Being a reliable name in flow meter suppliers in Abu Dhabi, Advanced Flow Controls Trading – LLC knows how crucial it is to make the right decision. Through this blog, we will study the major distinctions between digital and mechanical flow meters and guide you in choosing which one best suits your operations.

Understanding Flow Meters

Prior to comparing, it's fundamental to comprehend what a flow meter is. A flow meter calculates the velocity at which a fluid (liquid or gas) passes through a pipe or system. The information it gives industries allows them to control processes, maintain product consistency, minimize waste, and meet the standards of regulatory authorities.

Two primary types of flow meters widely used are:

Mechanical Flow Meters

Digital (or Electronic) Flow Meters

Each has its advantages and best applications, particularly in the commercial and industrial spheres of Abu Dhabi.

What Are Mechanical Flow Meters?

Mechanical flow meters function by having moving components—typically a paddlewheel, turbine, or gear—that turn as fluid flows through. The turn is then transformed into a measurable value that displays the flow rate.

Advantages:

Affordable: Suitable for small to medium operations with limited funds.

Simple design: Easy to install and maintain.

Durable for constant flows: Has good performance when applied in uniform, non-corrosive fluid conditions.

Drawbacks:

Wear and tear: Parts that move can deteriorate over time, particularly with dirty or abrasive fluids.

Less accurate: In contrast to digital meters, mechanical types lack accuracy.

Not suited to complicated data logging: Mechanical types do not provide smart features.

What Are Digital Flow Meters?

Digital flow meters or electronic or smart flow meters employ sophisticated sensors and software to capture flow rates with no mechanical movement. Technologies employed are electromagnetic, ultrasonic, and Coriolis principles.

Benefits:

Superior accuracy and reliability: Ideal for critical applications involving precise monitoring of flow.

No moving parts: Minimizes maintenance and maximizes lifespan.

Data logging and remote monitoring: Most models have connectivity options for real-time monitoring.

Flexible to different fluids: Capable of handling corrosive, viscous, or multi-phase flows.

Disadvantages:

Higher initial cost: Pricier than mechanical meters.

Needs technical installation: Setting up and installation might need professional help.

Which One Is Best for Your Abu Dhabi Business?

It depends on your business, the scale of operations, and budget.

Opt for Mechanical Flow Meters if:

You are dealing with clean, non-corrosive fluids.

Your operations are low to medium sized.

Budget is a primary limitation, and fundamental flow measurement is sufficient.

Select Digital Flow Meters if:

Your process needs high accuracy and real-time monitoring.

You need to automate data tracking or tie it in with your systems.

You operate in harsh environments such as oil & gas, chemical processing, or water treatment.

Why Select Advanced Flow Controls Trading – LLC

Being a top flow meter supplier company in Abu Dhabi, Advanced Flow Controls Trading – LLC provides both digital and mechanical solutions for the UAE market. Not only do we assist you in choosing the correct flow meter, but we also provide installation, calibration, and after-sales services.

Our engineers make sure that your equipment is technically correct as well as operationally effective whether you're replacing your system or building a new one.

Final Thoughts

In the highly competitive industry scene today, selecting the appropriate flow meter is not merely a technical choice—it's a strategic one. Although mechanical flow meters continue to address many conventional requirements, digital flow meters are rapidly emerging as the top choice for Abu Dhabi businesses with a focus on accuracy, automation, and efficiency.

Partner with a trusted expert like Advanced Flow Controls Trading – LLC to find the right solution for your business. From product selection to after-sales support, we’re committed to delivering the highest standards in flow measurement technology.

0 notes

Text

Maximize Energy Efficiency with CHP (Combined Heat and Power) Systems

What is CHP (Combined Heat and Power) and Why It’s the Future of Energy Efficiency

Introduction Combined Heat and Power (CHP), also known as cogeneration, is a highly efficient process that generates electricity and captures useful thermal energy in a single, integrated system. CHP systems are a proven solution for enhancing energy security, reducing greenhouse gas emissions, and lowering energy costs.

How Does CHP Work?

CHP systems simultaneously produce electricity and thermal energy from a single fuel source such as natural gas, biogas, biomass, or even hydrogen. Instead of wasting the heat generated during electricity production, CHP captures and utilizes it for heating, cooling, or industrial processes.

Key components of a CHP system include:

Prime mover (e.g., gas turbine, steam turbine, or reciprocating engine)

Generator

Heat recovery unit

Control systems

Benefits of CHP Systems

1. Improved Energy Efficiency CHP systems can achieve efficiency levels of 60–80%, compared to just 45–50% for conventional power generation.

2. Lower Energy Costs By producing power on-site and reducing grid dependency, CHP significantly cuts electricity and heating bills.

3. Reduced Carbon Emissions Efficient fuel use means fewer greenhouse gases and pollutants, supporting sustainability goals.

4. Reliable Power Supply CHP offers enhanced energy resilience by continuing to provide power during grid outages.

5. Fuel Flexibility Modern CHP systems can run on multiple fuel sources including natural gas, biogas, or renewable fuels.

Ideal Applications of CHP

CHP is versatile and adaptable, making it suitable for various sectors:

Commercial Buildings: Hotels, hospitals, universities, and data centers

Industrial Facilities: Food processing, chemical manufacturing, pharmaceuticals

District Energy: Urban heating and cooling networks

Municipal Infrastructure: Wastewater treatment plants and government buildings

CHP and Sustainability Goals

Governments and businesses worldwide are prioritizing sustainable energy strategies. CHP aligns perfectly with carbon reduction targets and green building certifications (such as LEED). It also supports compliance with clean energy regulations and incentives.

How to Implement a CHP System

Step 1: Feasibility Study Analyze site energy use, fuel availability, and economic viability.

Step 2: System Design and Sizing Customize the CHP system based on thermal and electrical load profiles.

Step 3: Installation and Integration Seamlessly integrate CHP with existing infrastructure.

Step 4: Monitoring and Maintenance Use real-time analytics and routine servicing to maximize uptime and efficiency.

CHP vs Traditional Power Generation

Feature

CHP System

Traditional Grid Power

Efficiency

60–80%

45–50%

Heat Recovery

Yes

No

Emissions

Lower

Higher

Reliability

High (on-site generation)

Dependent on external supply

Government Incentives for CHP

Many countries offer incentives for adopting CHP technologies, including:

Investment tax credits

Feed-in tariffs

Grants and low-interest loans

Carbon offset programs

Check with local energy authorities to explore financial support opportunities.

Conclusion

CHP (Combined Heat and Power) is a smart, sustainable solution for businesses and facilities seeking energy efficiency, cost savings, and environmental responsibility. Whether you're looking to reduce your carbon footprint or gain energy independence, CHP is the future of smart energy systems.

0 notes

Text

How Smart Energy Management is Powering the Future of Industries

Smart Energy Management solutions are not just changing the game, they're putting the power back in your hands. By harnessing advanced data analytics, automation, and predictive algorithms, these cutting-edge systems give you the control to monitor, analyze, and optimize your energy use in real-time. Whether you're a small-scale operation or a large corporation, these solutions can be tailored to your needs. By integrating renewable energy sources and dynamically managing energy demands, industries gain significant cost savings, enhanced operational efficiency, and a reduced carbon footprint, putting you in control of your energy future.

These solutions are not just about your industry. They're about shaping a greener, more efficient future for our planet. By participating in demand response programs and adjusting energy usage based on grid conditions, industries can unlock further economic and environmental advantages. Smart Energy Management is a cornerstone of sustainable industrial growth on a global scale, making you feel part of a more significant, sustainable movement that is shaping the future of our planet.

Business Case for Smart Energy Management in Industries

1. Manufacturing

Intelligent energy management optimizes motor control, reduces idle HVAC usage through occupancy-based adjustments, and implements energy-efficient lighting solutions. These measures significantly cut energy costs while improving operational productivity and sustainability.

2. Data Centers

Dynamic power management adjusts server activity to match real-time workloads, while advanced cooling strategies reduce energy consumption in high-demand environments. These solutions ensure efficient operations and minimize the environmental impact of data centers.

3. Oil and Gas

Intelligent energy systems monitor drilling energy use, optimize pipeline flow, and integrate renewables like solar and wind. These innovations enhance efficiency, lower operational costs, and support sustainability in the energy sector.

Advantages of Smart Energy Management Solutions in Industries

1. Integrate Green Energy

As part of our Smart Energy Management solutions, intelligent energy management facilitates the seamless integration of renewable energy sources such as solar and wind into industrial operations. This process involves [specific steps or technologies, such as the installation of solar panels on rooftops and the setup of wind turbines in suitable locations], which reduces reliance on fossil fuels, lowers carbon emissions, and supports sustainability goals, making industries more resilient to energy market fluctuations.

2. Lower Operational Expense

Our innovative energy solutions are not just about sustainability. They're about improving your bottom line. By optimizing energy consumption through real-time monitoring and intelligent automation, industries can significantly reduce operational costs. You can streamline energy use during peak hours and minimize waste, improving financial performance and providing security and confidence in your investment.

3. Optimize Asset Maintenance

Advanced analytics in intelligent energy systems enable predictive maintenance of critical assets. This process involves [specific steps or technologies], which reduces unexpected downtime and repair costs. It ensures equipment operates efficiently, prolonging its lifespan while maintaining smooth production workflows.

4. Regulatory Compliance

Innovative energy solutions help industries comply with stringent energy and environmental regulations by tracking usage and emissions data. Automated reporting, which [explains how it works and its benefits], ensures accurate compliance documentation, reduces penalties, and enhances corporate reputation.

5. Enhanced Energy Monitoring

Real-time energy monitoring provides actionable insights into usage patterns, enabling industries to identify inefficiencies and implement corrective measures. This level of visibility drives informed decision-making and fosters a culture of energy efficiency.

Why Partner with Web Synergies?

At Web Synergies, we combine cutting-edge technology with industry expertise to deliver tailored solutions that drive transformation and success. Here's why partnering with us is the right choice for your business:

Comprehensive Solutions:

From Smart Energy Management to Digital Twins and Integrated Suite, we offer a full spectrum of IT services designed to optimize operations, reduce costs, and enhance sustainability.

Proven Expertise:

With decades of experience across diverse industries, we understand businesses' unique challenges and provide customized strategies to meet their goals.

Sustainability Focus:

Our solutions are designed to support your journey towards net-zero emissions, enabling more imaginative resource utilization and reduced environmental impact.

Global Reach, Local Touch:

Operating across Singapore, India, Japan, UAE, Vietnam, Malaysia, and the USA, we combine global best practices with regional insights to deliver exceptional value.

Customer-Centric Approach:

We are committed to building long-term partnerships through consistent innovation, seamless implementation, and unmatched support tailored to your business needs.

Partner with Web Synergies to empower your business with solutions that drive innovation, efficiency, and sustainable growth.

#SmartEnergyManagement#IndustrialEfficiency#GreenTechnology#EnergyInnovation#SustainableIndustries#EnergyOptimisation#SmartManufacturing#IndustrialAutomation#RenewableIntegration#FutureOfEnergy#SmartGridTechnology#CarbonFootprintReduction#DigitalTransformation#Industry40

0 notes

Text

Floating Wind Turbines Market Propelled by Global Shift Toward Decarbonization and Net-Zero Emissions

Market Overview

The floating wind turbines market is emerging as a pivotal solution in the transition to clean and renewable energy sources. Unlike conventional fixed-bottom offshore turbines, floating wind turbines are designed to operate in deeper waters where wind resources are stronger and more consistent. This opens up vast oceanic areas for wind energy production, offering immense potential to meet the growing global electricity demand sustainably. With governments and energy companies pushing for carbon neutrality, floating wind technology is becoming a strategic choice to unlock offshore wind resources in locations previously deemed inaccessible.

Market Dynamics

Several driving forces are propelling the floating wind turbines market forward. Firstly, the urgent need to decarbonize energy systems is encouraging nations to explore innovative renewable technologies. Floating turbines present a viable alternative to land-based and shallow-water installations, allowing energy harvesting from ultra-deep waters. Moreover, advancements in turbine technology—such as the use of lightweight composite materials and enhanced control systems—have significantly improved the reliability and efficiency of floating platforms.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS10965

Economic incentives and policy frameworks, such as renewable energy targets and green subsidies, are also spurring investment in floating wind projects. At the same time, the high initial capital costs and complex installation processes pose significant challenges. However, ongoing R&D is driving cost reductions, especially in mooring systems, floating platforms (like semi-submersibles and tension-leg platforms), and gearbox vs. direct-drive technology. Furthermore, demand from offshore oil and gas platforms for renewable power solutions is creating new application opportunities.

Key Players Analysis

The floating wind turbines market features a blend of traditional wind energy giants and innovative marine engineering firms. Leading players include Siemens Gamesa Renewable Energy, GE Renewable Energy, Vestas Wind Systems, and Ørsted, all of whom are investing heavily in floating technologies. Equinor, a key pioneer in floating wind farms, continues to develop projects using semi-submersible platforms. Meanwhile, Principle Power and Aker Solutions are gaining traction by offering turnkey solutions and advanced floating platforms.

These players are adopting strategic partnerships, joint ventures, and acquisitions to strengthen their foothold. Many are also focusing on vertical integration—from component manufacturing (rotor blades, nacelles, generators) to maintenance services—to reduce costs and increase operational efficiency.

Regional Analysis

Europe remains the undisputed leader in the floating wind turbine market, with the UK, Norway, and France spearheading development through well-funded demonstration and pilot projects. The North Sea and the Atlantic Coast offer ideal wind conditions, coupled with strong government support. Asia-Pacific is rapidly catching up, led by Japan and South Korea, both of which are investing heavily in floating wind to meet energy security and emission targets. China is also ramping up investments, particularly in the deep-water zones of the South China Sea.

In North America, the U.S. is making notable strides, with California and the Gulf of Maine identified as hotspots for floating wind installations. The region’s vast coastline and recent legislative incentives are expected to propel future growth. Other regions such as South America and the Middle East are still in the exploratory phases but show promise due to their extensive coastlines and renewable goals.

Recent News & Developments

The floating wind sector has witnessed several exciting developments in recent months. Equinor recently announced the expansion of its Hywind Tampen project in the North Sea, now hailed as the world’s largest floating wind farm. Similarly, a consortium led by TotalEnergies and Green Investment Group was awarded contracts for floating wind farms off the coast of South Korea.

On the technology front, GE Renewable Energy has begun testing a hybrid turbine system designed specifically for floating platforms, promising increased energy capture and reduced weight. Moreover, regulatory frameworks in Europe and Asia have been streamlined to accelerate floating wind farm approvals, significantly shortening project timelines.

Browse Full Report @ https://www.globalinsightservices.com/reports/floating-wind-turbines-market/

Scope of the Report

The floating wind turbines market report spans a detailed evaluation of various segments, including turbine types such as spar-buoy, semi-submersible, and tension-leg platforms. It further categorizes the market by key products like turbines, towers, floating platforms, and mooring systems. Technologies such as direct drive, gearbox, and hybrid systems are closely analyzed alongside critical components including nacelles, rotor blades, generators, and control systems.

Applications covered include commercial power generation and offshore oil & gas integration. Materials like steel, concrete, and composites are evaluated for their performance in floating structures. The market is also segmented by water depth (shallow, deep, ultra-deep), end users (utility and non-utility), and installation types (fixed vs. floating). Additionally, solution-based segmentation encompasses turnkey services, component manufacturing, and maintenance services, offering a comprehensive insight into industry growth trajectories.

In summary, the floating wind turbines market is well-positioned for robust growth, backed by technological innovation, expanding offshore opportunities, and global sustainability efforts. As the industry matures and costs continue to fall, floating wind stands to become a cornerstone of the future global energy mix.

Discover Additional Market Insights from Global Insight Services:

Textile Flooring Market: https://www.globalinsightservices.com/reports/textile-flooring-market/

Wood Charcoal Market: https://www.globalinsightservices.com/reports/wood-charcoal-market/

Carbon Capture Concrete Market: https://www.globalinsightservices.com/reports/carbon-capture-concrete-market/

Dimer Acid-Based (DAB) Polyamide Resins Market: https://www.globalinsightservices.com/reports/dimer-acid-based-dab-polyamide-resins-market/

Laminated Glass Market: https://www.globalinsightservices.com/reports/laminated-glass-market/

0 notes

Text

Industrial Oil Filtration Solutions Gallery – Explore Our Projects & Systems

Welcome to the project showcase of OilFilterMachineIndia.com – your trusted partner for advanced industrial oil filtration solutions across India. Our gallery highlights a wide range of systems and technologies we've delivered for clients in the power, manufacturing, and oil processing sectors.

From transformer oil purification systems to high-precision online oil particle counters, explore how we solve real-world industrial challenges with innovative oil purification and filtration technology.

🔧 Featured Systems in Our Gallery

✅ Transformer Oil Purification Systems

View real installations of our transformer oil purification systems, built to restore dielectric strength, remove moisture and gas, and ensure transformer reliability. These are used by power utilities, transformer OEMs, and EPC contractors across India.

✅ Transformer Oil Reclamation Units

Check out our high-efficiency transformer oil reclamation units, engineered to extend the life of insulating oils through vacuum dehydration, degassing, and sludge removal processes.

✅ Hydraulic Oil Filtration Machines

Our gallery features hydraulic oil filtration machines designed for offline and online purification of hydraulic fluids, preventing equipment wear and extending service life.

🛢️ Advanced Oil Purification & Cleaning Systems

We provide fully integrated oil purification systems for transformer, turbine, and gear oils. Each unit is custom-built with multiple filtration stages, vacuum technology, and PLC control for performance and precision.

✅ Turbine Oil Cleaning Systems

Explore our turbine oil cleaning systems that remove varnish, water, and oxidation from turbine oils in power plants and heavy industries.

✅ Gear Oil Filtration Systems

Get a closer look at gear oil filtration systems designed to protect gearboxes and transmission systems from abrasive contaminants.

✅ Oil Filtration & Cleaning Systems

Our oil filtration & cleaning systems offer full-spectrum contamination control for multiple industries including steel, cement, paper, and power.

🔬 High-Precision Monitoring & Impregnation Technology

✅ Online Oil Particle Counters

Discover our advanced online oil particle counters, ideal for real-time contamination monitoring and ISO cleanliness compliance.

✅ Trickle Impregnation Technique

We also showcase the trickle impregnation technique, ideal for motor winding insulation and enhanced coil performance in manufacturing units.

✅ Vacuum Impregnation Plant

See our vacuum impregnation plants in action – used for electrical insulation in transformers, stators, and rotors with complete vacuum drying and resin impregnation capabilities.

🌐 Evacuation System for Transformers

Our gallery also includes installations of evacuation systems for transformers, essential for vacuum drying and degassing before oil filling in transformer manufacturing and servicing.

📞 Need a Custom Oil Filtration System?

Whether you need a turnkey oil purification system, a vacuum impregnation plant, or online oil particle counters, OilFilterMachineIndia.com has the technology and expertise to deliver.

#Industrial Oil Filtration Solutions#Transformer Oil Purification Systems#Hydraulic Oil Filtration Machines#Vacuum Impregnation Plant#Transformer Oil Reclamation Units#Online Oil Particle Counters#Trickle Impregnation Technique#Oil purification system#Turbine Oil Cleaning Systems#Gear Oil Filtration Systems#Oil Filtration & Cleaning Systems#Evacuation System for Transformers

0 notes

Text

Medium Voltage Motor Market Growth Driven by Industrial Modernization Trends

The global medium voltage motor market is poised for significant growth, driven by rising demand across industrial sectors such as oil & gas, power generation, mining, and manufacturing. These motors, typically operating in the voltage range of 1 kV to 6.6 kV, play a critical role in large-scale industrial operations where high power output and efficiency are essential. The market is witnessing a surge in adoption due to factors such as infrastructure expansion, the rise of energy-efficient technologies, and growing industrial automation.

Market Overview

Medium voltage motors are essential in applications requiring high torque, reliable performance, and durability. Industries like petrochemicals, water treatment, pulp & paper, and cement manufacturing extensively use these motors to power pumps, compressors, conveyors, and fans. Unlike low-voltage alternatives, medium voltage motors provide the necessary output to handle heavy-duty operations while reducing energy losses.

The market is characterized by advancements in motor designs, including improved insulation, enhanced energy efficiency, and smart monitoring capabilities. Technological innovations and regulatory support for energy conservation are further accelerating market growth.

Key Market Drivers

1. Growing Industrial Automation: The push towards Industry 4.0 and smart factories is increasing demand for reliable motor solutions. Medium voltage motors, known for their high-performance capabilities, are vital for automated manufacturing lines and process control systems. Companies are investing in automation to enhance productivity, minimize downtime, and lower operational costs, all of which boost motor demand.

2. Energy Efficiency Regulations: Governments and regulatory bodies across regions are introducing stringent energy efficiency standards for industrial equipment. Medium voltage motors, designed with energy-saving technologies, help industries comply with these standards while reducing energy consumption. The trend toward energy-efficient solutions is expected to significantly contribute to market expansion.

3. Infrastructure Development and Urbanization: Developing economies are investing heavily in infrastructure projects, including power plants, water treatment facilities, and transportation networks. These projects require robust, efficient motors for operational reliability. As urbanization accelerates, the demand for medium voltage motors in sectors like construction, utilities, and transport is rising.

4. Renewable Energy Integration: The global shift towards renewable energy sources such as wind and solar power has increased the need for reliable motor systems. Medium voltage motors are widely used in renewable energy installations, particularly for wind turbine operations and auxiliary functions in solar plants. This integration supports market growth as countries transition to sustainable energy models.

Regional Insights

Asia-Pacific dominates the medium voltage motor market due to rapid industrialization, infrastructure development, and manufacturing growth in countries like China, India, and Southeast Asia. The region's expanding power sector, particularly in renewable energy, is creating substantial demand for these motors.

North America and Europe are also significant markets, driven by modernization of aging industrial infrastructure, emphasis on energy efficiency, and technological advancements in motor designs. Stringent regulations in these regions further encourage the adoption of efficient medium voltage motors.

Latin America and the Middle East & Africa are emerging markets witnessing gradual growth, supported by investments in mining, oil & gas, and infrastructure projects.

Challenges in the Market

Despite the positive outlook, the medium voltage motor market faces several challenges. High initial costs of advanced motor systems, complex installation requirements, and maintenance needs can deter small to mid-sized enterprises. Additionally, global supply chain disruptions and raw material price volatility can impact production and availability.

However, ongoing research and development, coupled with industry efforts to enhance motor efficiency and reduce costs, are expected to overcome these challenges over time.

Future Outlook

The future of the medium voltage motor market looks promising, with sustained demand from industries prioritizing efficiency, reliability, and operational excellence. As the global focus on energy conservation and sustainable development intensifies, manufacturers are expected to introduce smarter, more efficient motor technologies.

In conclusion, the medium voltage motor market is set to experience steady growth, supported by industrial modernization, regulatory initiatives, and technological advancements. Industries worldwide are recognizing the importance of reliable motor solutions in achieving energy efficiency and operational effectiveness, positioning medium voltage motors as a key component in future industrial growth.

0 notes

Text

From Steam to Savings: The Science Behind Condenser Expansion Machines

In the evolving landscape of energy optimization and industrial efficiency, Condenser Expansion Machines (CEMs) are playing a transformative role. These specialized mechanical devices, often integrated into large-scale power generation systems or industrial cooling units, harness principles of thermodynamics to improve energy recovery and reduce waste.Get more news about Condenser Expansion Machine,you can vist our website!

At their core, Condenser Expansion Machines operate on a simple yet powerful idea: converting low-pressure steam or vapor into mechanical work. This is done by utilizing the residual pressure in the exhaust steam—usually considered waste after turbines have extracted the bulk of its energy. CEMs recapture this overlooked energy by allowing the steam to expand within a secondary chamber, driving pistons or rotors in the process. The result? Added power output without additional fuel consumption.

The implementation of CEMs is particularly significant in thermal power plants, such as those relying on coal, natural gas, or biomass. In traditional cycles, after steam passes through the turbine, it enters the condenser where it is cooled and returned to water form. However, much of its potential energy is lost in this transition. With a CEM installed between the turbine exhaust and the condenser, that intermediate energy is harnessed and converted into supplemental power—either to boost the plant’s electricity output or to drive auxiliary systems like pumps or compressors.

Beyond energy recapture, CEMs offer environmental and economic benefits. By maximizing the energy yield from a given volume of steam, they contribute to lower greenhouse gas emissions per unit of power produced. For energy-intensive industries, this translates into reduced operational costs and better sustainability metrics. CEMs also reduce the thermal load on condensers, which can improve the overall longevity and efficiency of the cooling system.

Technologically, the design of Condenser Expansion Machines varies depending on application and scale. They may employ reciprocating piston designs in smaller systems or more complex radial inflow turbines for high-capacity installations. Materials used in construction must withstand constant exposure to moisture, fluctuating pressures, and thermal stress, requiring robust engineering and corrosion-resistant alloys.

Recent advancements in control systems and digital monitoring have pushed CEMs into the realm of smart industrial solutions. Integrated sensors and data analytics platforms allow real-time performance assessment, predictive maintenance, and remote optimization. This evolution has made CEMs increasingly attractive not just for traditional utilities but also for industries like chemical manufacturing, pulp and paper, and food processing where process steam is abundant.

Looking ahead, Condenser Expansion Machines are poised to become key tools in global efforts to decarbonize energy systems and transition toward more sustainable industrial practices. As industries strive to meet tightening environmental regulations and consumer expectations for greener production, the efficient use of every available energy resource will become more critical than ever.

In conclusion, the Condenser Expansion Machine exemplifies how innovative engineering can breathe new life into existing infrastructure. By turning steam that would otherwise be wasted into valuable work, it bridges the gap between traditional energy systems and the efficiency standards of the future—one expansion cycle at a time.

0 notes

Text

How Knock-Out Drums and Demister Pads Help Reduce Emissions in Fuel Gas Processing

As industries strive to meet environmental regulations and reduce operational risks, gas-liquid separation systems like knock-out drums are gaining increasing importance. These crucial components play a major role in refining, petrochemical, and power industries where clean fuel gas is essential. One of the leading innovations in this area is the integration of demister pads, which enhance the separation process and contribute to emission control.

In this article, we’ll explore how knock-out drum manufacturers are designing efficient systems, the role of demister pads in enhancing performance, and why these technologies are essential for modern fuel gas processing.

What is a Knock-Out Drum?

A knock-out drum (also known as a vapor-liquid separator) is a pressure vessel used to remove liquid droplets, condensates, and solids from gas streams before they proceed to downstream equipment like turbines, burners, or compressors. This prevents damage, corrosion, and unsafe combustion conditions.

Knock-out drums typically rely on gravity and internal elements like baffles or demister pads to separate liquid from gas. When properly installed and maintained, they improve the quality of fuel gas and reduce environmental impact.

Why Are Knock-Out Drums Crucial?

Emission Control: Uncontrolled release of hydrocarbons and moisture into burners can create smoke, soot, and harmful emissions. Knock-out drums trap these before they enter combustion systems.

Equipment Protection: Removing liquids from gas reduces erosion and corrosion in downstream components.

Operational Efficiency: Clean gas burns more efficiently, improving energy output and reducing fuel consumption.

Regulatory Compliance: Facilities using knock-out drums are better equipped to meet stringent emission standards.

Demister Pads: The Hidden Heroes

While knock-out drums do much of the heavy lifting, demister pads significantly enhance their performance. These are mesh-type internal components installed inside the separator. As gas flows through the pad, it traps fine droplets by coalescing them into larger ones, which then fall into the collection chamber below.

Benefits of demister pads include:

Improved liquid removal efficiency (up to 99% of fine mist)

Reduced risk of carryover

Better fuel gas quality for combustion systems

For industries where even a trace of liquid can impact performance, demister pads are essential.

Choosing the Right Knock-Out Drum Manufacturer

With rising demand for reliable gas-liquid separation, selecting an experienced knock-out drum manufacturer is critical. Key criteria include:

Design Expertise: A custom-engineered solution based on pressure, flow, and gas composition.

Material Quality: Use of corrosion-resistant materials and high-quality welds.

Integration of Demister Pads: Optimized placement and material selection for maximum efficiency.

Compliance: Adherence to global standards like ASME, API, and local environmental norms.

Companies like Sungov offer tailor-made knock-out drums and are recognized for their engineering precision and adherence to safety and compliance requirements.

Applications Across Industries

Knock-out drums and demister pads are used across various sectors including:

Oil & Gas

Chemical Plants

Power Generation

Pharmaceutical Manufacturing

Petrochemical Facilities

Their ability to improve gas quality and protect sensitive equipment makes them indispensable across operations where gas purity matters.

Final Thoughts

With growing global focus on sustainability and clean energy, industries must invest in effective gas-liquid separation systems. A well-designed knock-out drum paired with high-efficiency demister pads ensures not only cleaner emissions but also safer and more cost-effective operations.

If your facility is seeking to optimize fuel gas systems or improve emission control, consult a reputed knock-out drum manufacturer who can offer customized solutions aligned with your process needs.

0 notes

Text

How Do Contact Output Modules Improve Flexibility in Turbine Control Systems?

In modern industrial automation and turbine control environments, scalability and signal expansion are essential. As systems grow in complexity, they often require additional I/O capabilities—especially for sending command signals to auxiliary devices, alarms, and field relays. This is where Contact Output Expansion Modules, like the IS200DTBDG1A, come into play. These modules allow you to extend the number of dry contact outputs available within GE Mark VI or VIe control systems, providing greater control flexibility without the need for complete system overhauls. Let’s explore what contact output modules do, where they are used, and why they are essential for scalable and reliable turbine control architectures. What Is a Contact Output Expansion Terminal Module? A contact output module is a terminal board that provides additional relay outputs or dry contact points used to control field devices. The IS200DTBDG1A is a GE-designed board that interfaces with the main control processor to output discrete signals when triggered by automation logic. Each contact acts like an electrical switch, opening or closing based on the controller’s command—ideal for controlling: Relays Circuit breakers Solenoids Warning indicators Shutdown signals Key Functions of the IS200DTBDG1A Board 1. Signal Expansion for Complex Systems As control systems grow—whether through added sensors, alarms, or safety functions—the need for more outputs increases. This board adds dedicated dry contact outputs without needing to replace or upgrade the main controller. 2. Discrete Command Signal Control Each contact output can represent a binary state (on/off) to trigger critical field equipment. This makes it ideal for alarm systems, motor starters, and interlock systems. 3. Integration with GE Mark VI Systems The module is fully compatible with GE’s Mark VI/VIe platforms, ensuring seamless integration without signal mismatch or configuration issues. 4. Rugged, Industrial Design Designed for harsh conditions found in turbine enclosures and control panels, the IS200DTBDG1A can operate reliably in environments with high vibration, temperature fluctuations, and electrical noise. Where Is It Used? The IS200DTBDG1A contact output module is commonly used in: Gas and steam turbine control panels Power plant automation systems Industrial DCS/PLC cabinets Oil & gas skids and compressor control units Its key role is to transmit safe, isolated command signals to field devices from the central control logic. Operational Benefits ✔ Scalability Instead of replacing a controller when output points are maxed out, you can simply add modules like the IS200DTBDG1A for quick expansion. ✔ Isolation and Protection Contact outputs are electrically isolated, which protects the main controller from voltage spikes or grounding issues in field wiring. ✔ Simplified Maintenance With clearly labeled terminals and test points, these boards make it easy for technicians to troubleshoot and verify control signals during shutdowns or commissioning. Installation and Maintenance Considerations To ensure long-term reliability: Use shielded cables to avoid interference Regularly check terminals for secure connections Verify logic mapping in the controller to confirm that outputs are assigned correctly Also, replacing these modules with OEM-certified hardware—such as the IS200DTBDG1A—ensures continued compatibility and system reliability. Conclusion In critical control systems like those found in gas and steam turbines, every signal matters. The IS200DTBDG1A Contact Output Expansion Terminal Module ensures that your control system has the flexibility, reliability, and capacity to scale with operational needs. Whether you're automating alarms, controlling breakers, or sending trip signals, this module provides a trusted, field-proven interface for executing your most essential commands. For operators and engineers alike, it's an indispensable component for robust and responsive turbine automation.

0 notes

Text

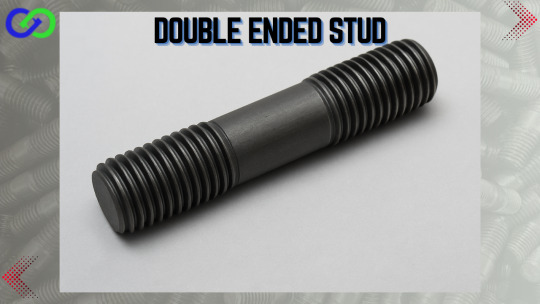

Double Ended Stud: Complete Guide

Ananka Fasteners offers premium-quality Double Ended Studs, engineered for maximum performance and durability. Designed to meet the highest industrial standards, our double ended studs deliver superior fastening solutions across industries that demand strength, precision, and corrosion resistance.

With advanced manufacturing facilities and a deep understanding of industrial fastening solutions, we deliver top-quality double ended studs tailored to meet diverse engineering applications.

What is a Double Ended Stud?

A Double Ended Stud is a type of fastener that features threads on both ends, separated by an unthreaded shank or a body in the middle. These studs are designed to be screwed into a tapped hole at one end while the other end accommodates a nut to fasten components together securely. Unlike standard bolts, double ended studs offer higher strength, precise alignment, and improved load distribution.

Key Features of Double Ended Studs

Threaded on both ends with consistent or varied thread types/sizes

Chamfered ends for easy assembly

Available in metric and imperial sizes

Custom lengths and threads as per client specifications

High tensile strength and excellent mechanical stability

Corrosion-resistant materials available for harsh environments

Applications of Double Ended Studs

Double ended studs are widely used in:

Automotive (engine assemblies, exhaust systems)

Oil & Gas (flanges, high-pressure fittings)

Petrochemical and Chemical Industries

Power Plants (turbines, boilers)

Construction and Heavy Machinery

Marine and Offshore Installations

Types of Double Ended Studs We Manufacture

We offer a wide variety of double ended studs to meet industrial requirements:

Fully Threaded Studs

Tap-End Studs (one short thread for screwing into a tapped hole, one long for a nut)

Reduced Shank Studs

Continuous Threaded Studs

Studs with Chamfered Ends

Material Grades

We manufacture double ended studs in various grades and alloys:

Stainless Steel:

SS 304, 304L, 316, 316L, 310, 321, 347

Alloy Steel:

ASTM A193 Grade B7, B7M, B8, B8M, B16

High-Temperature Alloys:

Inconel 600, 625, 718

Hastelloy C22, C276

Monel 400, K500

Nickel 200/201

Titanium Grade 2 / Grade 5

Duplex & Super Duplex:

UNS S31803, S32205, S32750, S32760

Others:

Brass, Copper, Silicon Bronze, Carbon Steel, Aluminium Bronze

Standard Specifications

Our double ended studs conform to the following standards:

ASTM / ASME: A193, A320, A307

DIN / ISO / BS / JIS Standards

Custom specifications as per client drawings

Surface Coating & Finishes

To improve performance and corrosion resistance, we offer various coatings:

Zinc Plated (Clear/Yellow/Black)

Hot Dip Galvanized (HDG)

PTFE Coated (Blue, Green, Red)

Xylan, Teflon, and Fluoropolymer Coating

Black Oxide, Dacromet, Geomet

Why Choose Ananka Fasteners?

Precision Engineering with CNC machining and threading Wide Range of Materials and grades available Custom Manufacturing to meet specific application needs Strict Quality Control in accordance with ISO standards Timely Delivery with export-ready packaging Global Supply Network across the USA, Europe, Middle East, Africa & Asia

Industries We Serve

Oil & Gas

Aerospace

Automotive

Marine

Petrochemical

Power Generation

Construction & Infrastructure

Double Ended Studs Exporter – Global Reach

Ananka Fasteners exports premium quality double ended studs to several countries including:

USA, UK, Germany, France, and Italy

UAE, Saudi Arabia, Oman, Qatar

South Africa, Nigeria, Kenya

Australia, Singapore, Malaysia

Brazil, Mexico, and Canada

Contact Us

Looking for a reliable Double Ended Stud supplier?Contact Ananka Fasteners today for competitive pricing, technical consultation, and bulk orders.

Frequently Asked Questions (FAQs)

Q1. What is the difference between a double ended stud and a threaded rod?A double ended stud has threads on both ends with an unthreaded middle portion, while a threaded rod is fully threaded along its entire length.

Q2. Can double ended studs be customized?Yes, we offer custom sizes, thread types, and coatings based on your requirements.

Q3. Which coating is best for marine applications?PTFE or Xylan-coated stainless steel studs are ideal for corrosion resistance in marine environments.

Q4. Do you provide test certificates?Yes, we provide MTC, NABL-approved lab reports, and third-party inspection reports on request.

#DoubleEndedStuds#StudBolts#IndustrialFasteners#FastenerSolutions#EngineeringFasteners#PrecisionFasteners#MechanicalFasteners#ThreadedStuds#BoltingSolutions#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#Tumblr#tumblr blog#bolt#stud bolt#articles

0 notes

Text

Cogeneration: The Smart Solution for Energy Efficiency and Cost Savings

Cogeneration, also known as combined heat and power (CHP), is a proven technology that generates electricity and useful thermal energy in a single, integrated system. Unlike traditional power generation, which wastes a significant amount of energy as heat, cogeneration captures and utilizes that heat for productive purposes, resulting in higher efficiency and lower energy costs.

What is Cogeneration?

Cogeneration is the simultaneous production of electricity and thermal energy from a single fuel source such as natural gas, biogas, biomass, or waste heat. The system typically consists of an engine, turbine, or fuel cell that drives a generator to produce electricity. The waste heat from this process is then recovered to produce hot water, steam, or heating for buildings, industrial processes, or district energy systems.

Key Components of a Cogeneration System:

Prime Mover (Engine or Turbine)

Electric Generator

Heat Recovery System

Control Systems

Benefits of Cogeneration

Cogeneration offers multiple advantages for industrial, commercial, and residential applications:

1. Energy Efficiency

CHP systems can reach efficiency levels of 70% to 90%, compared to around 50% for conventional methods.

2. Cost Savings

By producing both electricity and heat onsite, cogeneration reduces utility bills and minimizes energy losses.

3. Reduced Carbon Emissions

CHP systems lower greenhouse gas emissions by using energy more efficiently and relying on cleaner fuel sources.

4. Energy Security

Cogeneration improves energy resilience by providing decentralized power during grid outages or energy price spikes.

5. Scalability

From small-scale micro-CHP units for homes to large-scale industrial systems, cogeneration is adaptable to various energy demands.

Common Applications of Cogeneration

Cogeneration is widely used across several industries and sectors:

Hospitals and Healthcare Facilities

Universities and Schools

Data Centers

Manufacturing Plants

Wastewater Treatment Facilities

Hotels and Resorts

Cogeneration and Renewable Energy

When integrated with renewable sources like biogas, landfill gas, or wood chips, cogeneration further enhances sustainability. Biogas cogeneration, for example, turns organic waste into clean energy, supporting circular economy goals.

Government Incentives and Policy Support

Many countries offer financial incentives and regulatory support to encourage the adoption of cogeneration. These may include:

Tax credits and rebates

Feed-in tariffs

Net metering

Grants for feasibility studies and installations

Is Cogeneration Right for Your Business?

If your facility has a consistent demand for both electricity and thermal energy, cogeneration could significantly lower your operating costs while improving sustainability. Conducting an energy audit and a feasibility assessment can help determine the best configuration and payback period for your site.

Final Thoughts

Cogeneration represents a smart, efficient, and environmentally friendly approach to power generation. Whether you're looking to reduce energy expenses, cut emissions, or enhance energy reliability, cogeneration systems offer a practical solution that benefits both your bottom line and the environment.

0 notes

Text

How Flow Meters Facilitate Middle East Biofuel And Renewable Energy Production

The UAE is witnessing growth in the industrial sector. To achieve efficiency, safety and compliance, accurate measurement and control of fluid flow is a must. With oil & gas, water treatment, chemical processing, and manufacturing industries picking up, demand for quality flow meters has never been more so. Ali Yaqoob has emerged as a leading supplier, having a comprehensive line of flow meters for business in the UAE to cater to the different requirements.

The Importance of Flow Meters in the UAE

Flow meters are crucial devices that measure the flow of liquid or gas whether it be a volume or a mass. The flow measurement is significant and fundamental in the UAE, which has some quality industries that use high quality standards as well as safety measures, accurate flow measurement gives:

Billed accurately and inventory reported

Environmental and safety rules are met

Better control of process and related operating costs

Early detection of leaks or inefficiencies in the system

Full Range of Flow Meters

Ali Yaqoob is also known as one of the best Flow Meter Suppliers in the region, offering solutions for a vast range of applications. They have the following product offerings:

Positive Displacement Flow Meters

Turbine Flow Meters

Electromagnetic Flow Meters

Ultrasonic Flow Meters

Coriolis Mass Flow Meters

Every category is tailored for special applications, from the measurement of water and fuel to chemicals and industrial gases, so customers can receive the most appropriate technology for their purpose.

Special Offers on Best Brands

Ali Yaqoob is an official distributor of the global top-branded products, such as the most sought-after Liquid Controls M7 & M15 flow meter. Such systems are reputed for precision, reliability, and little or no maintenance required, and thus fit well in harsh environments. Ali Yaqoob also provides special promotions and offers periodically, thus providing extra value to enterprises requiring addition or upgrade in flow measurement capacity.

Value-Added Services

Besides providing top-notch flow meters, Ali Yaqoob provides:

Expert technical assistance to assist clients to choose the appropriate flow meter for their application

Installation services and after-sales services

Calibration and maintenance services to ensure long-term accuracy and reliability

Conclusion

For companies looking for dependable flow meter UAE solutions, Ali Yaqoob is an excellent partner. With a wide line of products, alliances with top global brands, and a focus on customer satisfaction, they have emerged as one of the best Flow Meter Suppliers in the region. Whether you need a stocked flow meter or an engineered-to-order solution, Ali Yaqoob is well placed to deliver as per your needs with skill and speed

0 notes

Text

Warm-up vent silencer

We specialize in offering advanced noise manipulate solutions tailor-made to satisfy the demands of cutting-edge business systems. Our Warm-Up Vent Silencer is engineered to reduce high-decibel noise generated all through the nice and warm-up and venting process of boilers, turbines, and different steam or gas structures.

During warm-up cycles, pressurized steam or gasoline is released through vent lines, creating a surprising and excessive noise that could pose extreme safety hazards and environmental worries. The Anpam Warm-Up Vent Silencer is engineered to effectively reduce noise while maintaining optimal device performance.Our silencers combine reactive and absorptive silencing strategies to deal with a huge range of frequencies, delivering superior noise attenuation whilst preserving high waft performance.

Constructed from excessive-grade materials inclusive of chrome steel or carbon metal, our vent silencers are constructed for sturdiness and high-temperature operation. Each unit is custom-designed to in shape uniquely go with the flow costs, stress drops, and acoustic requirements, ensuring an excellent health to your device. The silencers are smooth to put in and hold, with strong inner components that ensure lengthy provider existence even in the maximum demanding conditions.

Why choose anpam engineering?

Proven noise control technology

Tailored engineering and fabrication

Reliable performance in harsh environments

End-to-quit assist and consultation

If you're trying to lessen noise, boom safety, and enhance operational efficiency, the solution begins with silence. Trust Anpam Engineering for splendid warm-up vent silencers that deliver overall performance you may hear—by using how little you do.

Anpam Engineering’s dedication to pleasant and overall performance has made us a relied on companion throughout power generation, oil & gas, and process industries. We collaborate carefully with customers to understand their operational demanding situations and supply tailored solutions that observe enterprise standards and environmental rules.

Whether you are upgrading an current system or designing a brand new installation, our Warm-Up Vent Silencer provides reliable and efficient noise control. Choose Anpam Engineering for engineered excellence, established overall performance, and support.

0 notes

Text

Enhancing Industrial Filtration Efficiency with Liquid Coalescers

In today’s competitive industrial landscape, maintaining operational efficiency and equipment longevity is crucial. One often-overlooked yet vital component in achieving this goal is the use of liquid coalescers. These advanced filtration devices are key to separating immiscible liquids, removing contaminants, and ensuring the purity of fuels, chemicals, and compressed gases across multiple industries.

Whether it's in oil and gas, petrochemicals, or power generation, leading coalescer manufacturers are engineering high-efficiency filtration systems tailored for modern industrial needs. In this blog, we explore how liquid coalescers work, their benefits, and why companies across the USA are investing in them for optimal performance.

What Are Liquid Coalescers?

Liquid coalescers are filtration devices designed to separate water and particulate contaminants from liquid hydrocarbons and other fluid streams. They operate by coalescing small water droplets into larger ones, which can then be removed more easily through gravity separation or mechanical means.

These filters are critical in industries where the presence of water or solids in fuels and process fluids can lead to corrosion, equipment failure, or process inefficiency. Coalescers are commonly used in compressor stations, refineries, chemical plants, and power facilities.

How Do Liquid Coalescers Work?

Liquid coalescers function in two primary stages:

Coalescing Stage: The fluid passes through a coalescing media that attracts small droplets of water or other immiscible liquids. These droplets merge into larger drops as they pass through the media.

Separation Stage: Once coalesced, the larger droplets become heavy enough to separate by gravity or are captured by a secondary separation element, depending on the coalescer design.

This two-stage filtration approach ensures high efficiency and minimal fluid contamination downstream.

Why Are Coalescers Essential in Industrial Applications?

Protect Equipment: Water and particulates in fluids can damage turbines, compressors, and pumps. Coalescers prevent this by ensuring only clean fluid reaches critical systems.

Increase Efficiency: Cleaner fluids improve the thermal and chemical stability of processes, leading to higher throughput and fewer disruptions.

Extend Filter Life: Using liquid coalescers upstream reduces the load on final stage filters, extending their life and reducing maintenance costs.

Regulatory Compliance: Many industries in the USA must meet strict environmental and quality regulations. Coalescers help ensure compliance by removing unwanted substances from discharge streams.

Choosing the Right Coalescer Manufacturers

The efficiency of a coalescing system depends greatly on the expertise and quality control of the coalescer manufacturer. Reputed companies like SG Industries have emerged as trusted coalescer manufacturers in the USA, offering customized solutions backed by international certifications, robust engineering, and extensive field experience.

When selecting a coalescer manufacturer, consider:

Proven industry experience

ASME and ISO certifications

Scalable design capabilities

Strong post-sales support

In-house testing and R&D facilities

Investing in high-quality coalescers from trusted manufacturers ensures not just effective filtration but also long-term operational benefits.

Growing Demand for Coalescers USA

With stricter regulations, rising fuel quality demands, and a shift toward sustainable industrial practices, the demand for coalescers in the USA is increasing rapidly. Industries are actively upgrading outdated filtration systems with modern coalescers that offer higher performance, reduced energy consumption, and better reliability.

Moreover, coalescers are evolving with smart monitoring features, corrosion-resistant materials, and modular configurations, making them adaptable to a variety of installations.

Conclusion

Liquid coalescers are no longer optional in modern industrial operations—they are a necessity. From protecting equipment to improving process efficiency, these advanced filters offer measurable advantages. Choosing the right coalescer manufacturers, especially from experienced providers in the USA, ensures your facility is equipped to handle today’s fluid filtration challenges with confidence.

If you’re looking to enhance your filtration systems, reduce maintenance costs, and maintain fluid purity, investing in quality coalescers is the smart step forward.

0 notes