#intrinsically safe circuit design

Explore tagged Tumblr posts

Text

Best Practices for Customising Shipping Containers

Shipping containers, which were once only used to move cargo across seas, are currently seeing a surprising comeback. Because of its natural strength, resilience, and accessibility, steel boxes have been used to create a wide range of designs, from residences and workplaces to lively cafes and even chic retail establishments. However, thorough preparation and adherence to recommended practices are necessary for successful container customisation.

Here are some ideas to incorporate when customising shipping containers in Toowoomba –

Structural Integrity is Crucial: Preserving structural integrity is essential to any successful container conversion. Modifications should never compromise the intrinsic strength of the container. Steer clear of excessive welding or cutting without the necessary engineering knowledge. To make sure your project is safe and long-lasting if in doubt, seek advice from a structural engineer.

Insulation and ventilation: Shipping containers are made for durable transportation, not cosy homes or offices. Proper ventilation is essential for sufficient air circulation and to avoid heat accumulation. Consider installing fans, vents, and possibly even solar-powered ventilation systems. Insulation is also critical for controlling temperature. Regardless of the outside weather, choose high-quality insulation materials to keep the interior at a pleasant temperature.

Electrical Systems: When integrating electrical systems into a container, careful design and adherence to safety regulations are necessary. Circuit breakers, grounding, and wiring must all be done correctly. Also, consider the power requirements of the devices you want to use, such as office supplies, appliances, or lighting. Get advice from a certified electrician to guarantee a secure and effective electrical system.

Usefulness and Aesthetics: Although usefulness comes first, aesthetics shouldn't be overlooked in shipping containers in Ballina. Look for innovative ways to improve your container's aesthetic appeal. To optimise natural light, think about installing windows, doors, and skylights. Use environmentally friendly finishes and materials to reduce your influence on the environment.

Safety First: Safety should come first during the whole customisation process. When using cutting or welding equipment, wear the proper safety gear, such as gloves and safety glasses. When applying paints or chemicals, ensure there is enough ventilation. Routine inspections are essential to finding and fixing any possible safety risks.

Throughout your project, keep in mind to put safety, structural integrity, and environmental responsibility first. This way, you can ensure that you find the best shipping containers and can personalise it according to your preferences.

0 notes

Text

Mining Professionals Choose Wisdom 4A Cap Lamp

In the mining industry, professionals require tools that not only ensure their safety but also enhance their productivity in harsh and challenging environments. The Wisdom 4A Cordless Cap Lamp has emerged as a leading choice for mining professionals worldwide due to its impressive features, reliability, and durability. This cap lamp is designed to meet the demanding needs of miners, offering optimal lighting and a user-friendly experience.

Unmatched Brightness and Long-Lasting Power

The Wisdom 4A Cap Lamp stands out for its powerful LED lighting system, providing a bright, focused beam that is essential in low-light conditions commonly found in mining environments. Its high lumen output ensures miners have clear visibility in even the darkest underground areas. Whether working in tunnels, shafts, or remote mining sites, the bright light helps improve safety by reducing the risk of accidents and enhancing visibility for both close-up and long-distance tasks.

One of the most significant advantages of the Wisdom 4A Cap Lamp is its long battery life. Powered by a high-capacity lithium-ion battery, the lamp can last up to 20 hours on a single charge, ensuring that miners can complete their shifts without the need for constant recharging. This extended battery life is a crucial feature, as it allows professionals to focus on their tasks without worrying about running out of light.

Durability Built for Tough Environments

Mining professionals face some of the most challenging work conditions, including exposure to dust, water, and rough handling. The Wisdom 4A Cap Lamp is built to withstand these harsh conditions. With its durable, waterproof design, the lamp can endure the rigors of mining work, making it highly resistant to damage from falls, moisture, and other environmental factors.

The cap lamp is also designed to be lightweight and compact, which makes it easy for miners to wear for long periods without discomfort. Its ergonomic design ensures that it fits securely on hard hats, providing a hands-free lighting solution for enhanced convenience.

Safety Features for Enhanced Protection

Safety is a top priority in the mining industry, and the Wisdom 4A Cap Lamp excels in this regard. The lamp features a high degree of electrical safety, including overcharge, over-discharge, and short-circuit protection. This ensures that the lamp operates efficiently without posing any electrical hazards to the user.

Additionally, the Wisdom 4A Cap Lamp is certified to meet international safety standards, including intrinsic safety standards for use in hazardous environments such as mines with explosive gases. This certification offers peace of mind to mining professionals, knowing that their lighting solution is safe to use in potentially dangerous locations.

Easy Maintenance and Cost-Effective

Maintaining the Wisdom 4A Cap Lamp is straightforward, thanks to its simple design and rechargeable battery. Miners can easily charge the lamp between shifts, eliminating the need for frequent battery replacements. This not only reduces operational costs but also makes the lamp a more sustainable option for long-term use.

The lamp's longevity and low maintenance requirements make it a cost-effective choice for mining companies, especially when considering the significant savings on battery replacements and downtime caused by malfunctioning equipment.

Why Mining Professionals Choose Wisdom 4A Cap Lamp

Mining professionals choose the Wisdom 4A Cap Lamp for several key reasons:

Exceptional Brightness: The powerful LED light ensures optimal visibility in dark and hazardous mining environments.

Long Battery Life: With up to 20 hours of continuous use on a single charge, the lamp supports miners during long shifts.

Durability: Built to withstand harsh mining conditions, including water, dust, and impact.

Safety: The lamp meets stringent safety standards, including intrinsic safety certifications for use in hazardous areas.

Cost-Effective: Rechargeable batteries reduce ongoing costs, and easy maintenance ensures minimal downtime.

Comfort and Convenience: Its lightweight and ergonomic design make it easy for miners to wear without discomfort.

In conclusion, the Wisdom 4A Cordless Cap Lamp is a top choice for mining professionals who need a reliable, durable, and efficient lighting solution. Its blend of safety features, long-lasting power, and ease of use makes it an indispensable tool for those working in demanding underground environments. With the Wisdom 4A Cap Lamp, mining professionals can ensure safety, improve productivity, and enhance their overall work experience.

0 notes

Text

Transforming Mine Safety with Innovative Technology

Fluke 28 II Ex: Revolutionizing Equipment Reliability in Hazardous Mining Environments

Fluke Australia has reintroduced one of its most essential tools for the mining industry, the Fluke 28 II Ex multimeter. Mining operations, whether underground or surface, are notoriously hazardous, requiring tools that are durable and designed with safety at their core. The Fluke 28 II Ex has emerged as a game-changer designed to meet the unique and dangerous challenges mining personnel face.

Why the Fluke 28 II Ex is Essential for Mining

1. Built for Explosive Environments

Designed for harsh conditions: The Fluke 28 II Ex is tailored for use in explosive environments common in mining, offering reliable performance without the risk of ignition.

ATEX and ANZEX certified: These certifications ensure that the device is safe to use in hazardous areas, preventing accidents related to sparks or electrical discharges in environments with explosive gases, vapours, or dust.

2. Durability in Extreme Conditions

Rugged design: With an IP67 rating, this multimeter is fully protected against dust and can withstand submersion in water up to 1 metre for 30 minutes. This is essential in mining, where dust, moisture, and drops are constant risks.

Wide temperature range: The device operates effectively in temperatures ranging from -15°C to over 55°C, making it perfect for fluctuating temperatures often found in mining operations.

3. Extended Battery Life

400 hours on a single charge: The extended battery life allows for longer operations in remote areas where access to replacements can be difficult, improving efficiency in mining tenement sites where power supplies may be limited.

Key Safety Features of the Fluke 28 II Ex

1. Intrinsic Safety Design

Energy-limiting circuits: These circuits prevent excessive electrical or thermal energy from causing ignition, crucial for tenement management in explosive environments.

Temperature control: The device is engineered to maintain controlled temperatures, ensuring no overheating, further reducing the risk of accidents.

2. Compliance with Safety Standards

Multiple approvals: The Fluke 28 II Ex meets CAT III 1000V and CAT IV 600V overvoltage protection standards, ensuring its reliability in both underground and surface mining operations.

3. Enhanced User Experience

Improved display and controls: Featuring a large backlit display for better visibility in low-light conditions, the multimeter is also designed with glove-friendly controls, ensuring ease of use in the demanding mining environment.

Real-World Applications in Mining

1. Maintenance in Hazardous Areas

Underground systems: The Fluke 28 II Ex excels in maintaining and troubleshooting underground electrical systems where dust, moisture, and extreme conditions are prevalent.

Fuel and battery stations: Its intrinsic safety ensures safe operations in hazardous areas, preventing accidental ignition during inspections or maintenance.

2. Preventive Maintenance for Safety

Early fault detection: Overvoltage protection and early fault detection capabilities allow mining personnel to address issues before they compromise safety, aiding in tenement services and ensuring compliance with safety regulations.

Regulatory compliance: The device’s global safety certifications make it invaluable for audits and overall risk management in mining operations.

Final Note

The Fluke 28 II Ex multimeter is a game-changer in mine safety, offering unparalleled reliability, durability, and safety for mining professionals. Its ability to perform in extreme, hazardous conditions while providing precise diagnostics makes it an indispensable tool for the mining sector. As demand for safe and efficient operations continues to rise, especially in areas like mining tenement management, the Fluke 28 II Ex sets the benchmark for safety and performance in the industry.

This advanced tool ensures that mining operations can proceed safely, efficiently, and in compliance with global standards, truly reshaping how equipment safety is managed in tenement services and beyond.Bottom of Form

You may also read: Hidden Dangers in Mining Operations

0 notes

Text

Hazardous Area Cable Glands: A Comprehensive Guide

Introduction

Hazardous Area Cable Glands environments where there is a risk of fire or explosion due to the presence of flammable gases, vapors, or dust. In such areas, special precautions must be taken to prevent ignition and ensure the safety of personnel and equipment. Hazardous area cable glands are designed to provide a secure and reliable connection between cables and enclosures in these environments, minimizing the risk of electrical sparks or arcing that could ignite flammable substances.

Types of Hazardous Area Cable Glands

Flameproof (Ex d) Glands:

Designed to withstand an internal explosion without igniting the surrounding atmosphere.

Typically constructed of flameproof enclosures with flameproof seals.

Suitable for use in areas with explosive atmospheres of gases or vapors.

Increased Safety (Ex e) Glands:

Designed to minimize the risk of ignition through increased safety measures, such as reduced temperature rise and increased creepage distances.

Suitable for use in areas with explosive atmospheres of gases or vapors.

Intrinsic Safety (Ex i) Glands:

Designed to ensure that the electrical circuit within the gland is inherently incapable of igniting an explosive atmosphere.

Typically used in conjunction with intrinsically safe equipment.

Suitable for use in areas with explosive atmospheres of gases, vapors, or dust.

Dust-Tight (Ex t) Glands:

Designed to prevent the ingress of dust into the enclosure.

Typically constructed with dust-tight seals and enclosures.

Suitable for use in areas with explosive atmospheres of dust.

Combination Glands:

Combine multiple protection levels, such as flameproof and dust-tight, to provide comprehensive protection in hazardous areas.

Applications of Hazardous Area Cable Glands

Hazardous area cable glands are used in a wide range of industries and applications, including:

Oil and Gas: For equipment in offshore platforms, refineries, and processing plants.

Chemical Industry: For equipment in chemical plants and storage facilities.

Pharmaceutical Industry: For equipment in pharmaceutical manufacturing facilities.

Food and Beverage Industry: For equipment in food processing and storage facilities.

Power Generation: For equipment in power plants and substations.

Importance of Hazardous Area Cable Glands

The selection and proper installation of hazardous area cable glands are crucial for ensuring the safety and reliability of electrical installations in hazardous environments. They offer several benefits, including:

Safety: Protecting against electrical hazards and preventing fires or explosions.

Compliance: Adhering to industry standards and regulations, such as ATEX, IEC, and NEC.

Reliability: Ensuring the continuous operation of equipment in hazardous environments.

Cost-Effectiveness: Preventing costly equipment damage and downtime.

Environmental Protection: Reducing the risk of environmental pollution and damage.

Selecting the Right Hazardous Area Cable Gland

When selecting a hazardous area cable gland, it is essential to consider the following factors:

Hazardous Area Classification: The specific hazardous area classification (e.g., Zone 0, Zone 1, Zone 2) of the installation.

Cable Type: The type and size of cable being used.

Environmental Conditions: The conditions the installation will face, such as temperature, humidity, and exposure to corrosive substances.

Industry Standards: Adherence to relevant industry standards and regulations.

Installation Requirements: The specific requirements of the installation, such as ease of installation or the need for a particular type of seal.

Conclusion

Hazardous area cable glands are indispensable components in electrical installations in hazardous environments, providing essential functions for safety, reliability, and compliance. By understanding the different types, applications, and importance of these glands, engineers and technicians can make informed decisions to select the most suitable options for their specific requirements.

0 notes

Text

Industrial Overload Relays Market Industry Analysis Outlook by 2032

Market Overview:

Intrinsic safety modules are crucial components used in hazardous environments to ensure the safe operation of electronic equipment. These modules are designed to limit electrical energy and prevent the generation of sparks or excessive heat that could ignite flammable gases, vapors, or dust present in the surrounding atmosphere. By employing intrinsic safety modules, industries can reduce the risk of explosions and fires in potentially explosive atmospheres.

Intrinsic safety is a widely adopted protection technique in industries such as oil and gas, petrochemicals, mining, pharmaceuticals, chemicals, and others where flammable substances are present. These modules are typically used with sensors, transmitters, and other electronic devices that need to operate in hazardous locations.

The Global Intrinsic Safety Modules Market size is projected to grow from $2.7 billion in 2021 to a billion by 2028, at a CAGR of 7% 2023-2031.

Industrial Overload Relays: Overview Industrial overload relays are electrical devices used to protect motors and other electrical equipment from damage due to overcurrent conditions. They are an essential component of motor control systems in industrial settings. These relays monitor the current flowing through a motor and can trip the circuit if the current exceeds a predefined threshold, thus preventing overheating and potential damage.

Industry Analysis and Trends:

Industrial Automation: The increasing adoption of industrial automation across various sectors has driven the demand for overload relays. Automation requires efficient motor protection to ensure smooth operation and prevent downtime.

Energy Efficiency: There is a growing emphasis on energy efficiency and reducing operational costs. Modern overload relays often come with features that enable energy monitoring and optimization.

Smart Technologies: The integration of smart technologies, such as IoT and connectivity, into industrial equipment has led to the development of smart overload relays. These relays can provide real-time data, remote monitoring, and predictive maintenance insights.

Safety Regulations: Stringent safety regulations and standards in industrial environments have led to the increased adoption of protective devices like overload relays. Compliance with these regulations is crucial for safe operations.

Miniaturization and Integration: The trend toward miniaturization and integration has led to the development of compact and multifunctional overload relay solutions, saving space and enhancing functionality.

Customization and Flexibility: Industries often have specific requirements for their motor protection needs. Manufacturers are focusing on offering customizable overload relay solutions to cater to various applications.

Global Industrial Growth: As industries continue to grow worldwide, the demand for machinery and equipment, including motors and overload relays, also increases.

Demand and Scope:

The demand for industrial overload relays is closely tied to the overall industrial growth, especially in sectors like manufacturing, oil and gas, utilities, mining, and more. As these industries expand, the need for reliable motor protection solutions becomes more critical. Moreover, the increasing adoption of automation and the integration of advanced technologies further contribute to the demand for modern overload relays.

The scope of the industrial overload relays market extends across various industries and applications, including conveyor systems, pumps, fans, compressors, HVAC systems, and more. As technologies evolve, the scope of overload relays may expand to include smarter and more advanced features, addressing emerging challenges in motor protection and predictive maintenance.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/intrinsic-safety-modules-market/13068/

Market Segmentations:

Global Intrinsic Safety Modules Market: By Company • Eaton • Rockwell Automation • Schneider Electric • Siemens • ABB • Pepperl+ Fuchs • OMEGA • Rotork • IMI Sensors • Extronics Global Intrinsic Safety Modules Market: By Type • Zener Barriers • Isolator Barriers • Converter Barriers Global Intrinsic Safety Modules Market: By Application • Oil and Gas • Mining • Power • Chemicals and Petrochemicals Global Intrinsic Safety Modules Market: Regional Analysis The regional analysis of the global Intrinsic Safety Modules market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Intrinsic Safety Modules market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Intrinsic Safety Modules in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Intrinsic Safety Modules in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Intrinsic Safety Modules in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Intrinsic Safety Modules in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Click Here, To Purchase Premium Report: https://stringentdatalytics.com/purchase/intrinsic-safety-modules-market/13068/?license=single

Reasons to Purchase Intrinsic Safety Modules Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Industrial Overload Relays#Motor Protection#Overcurrent Protection#Industrial Automation#Energy Efficiency#Smart Technologies#IoT Integration#Predictive Maintenance#Safety Regulations#Miniaturization#Customizable Solutions#Global Industrial Growth#Manufacturing#Oil and Gas#Utilities#Mining#Conveyor Systems#Pumps#Fans#Compressors#HVAC Systems#Market Trends#Demand Analysis#Industry Insights#Industrial Equipment#Motor Control#Electrical Protection.

0 notes

Link

As mobility in harsh and volatile industrial and manufacturing environments has become a necessity for productivity, safety, monitoring, and management, intrinsically safe circuit design has had to meet stringent regulatory device needs.

1 note

·

View note

Text

North America Li-Fi Market Size to Expand at Over 55% CAGR through 2030

By 2030, the North America Li-Fi market size is expected to surpass $2.5 billion. The high CAGR of the market can be attributed to the rising frequency of cybercrimes, which has been responsible for the need for secure wireless networks across the commercial sector. Safe data transmission systems are an indispensable necessity for data sensitive domains such as banking and finance. As Li-Fi cannot penetrate opaque surfaces, it ensures superior security from hackers, ensuring safe access to the internet.

With the rising number of cybersecurity challenges faced while using Wi-Fi over radio frequencies, the demand for high-speed, reliable, and safe Li-Fi networks has been witnessing a remarkable uptick in demand. One of the major industry trends that has been vitalizing the North America Li-Fi market outlook is the increasing demand for Li-Wi for location-based applications such as retail and commercial sectors.

Get sample copy of this research report @ https://www.graphicalresearch.com/request/1708/sample

Growing at a whopping 55% CAGR through the forecast period, the industry is certain to gain a substantial revenue share in the forthcoming years, driven by the rising demand for connected devices in business organizations and offices. Li-Fi can offer enhanced user experience by improving the browsing speed, and thereby boosting the overall productivity of the organization.

Intrinsically safe environments have been exhibiting an escalating demand for Li-Fi technology over the past few months. This is because environmental concerns including health & safety and environmental damage has been intensifying, hampering the usage of Wi-Fi technology across such environments. The switch from Wi-Fi to Li-Fi technology has been fueling the North America Li-Fi market size.

Li-fi technology can also leverage light spectrum instead of radio waves for transferring data, ensuring their suitability for intrinsically safe environments. As a result, Li-Fi can be efficiently utilized in settings where communication via radio waves can be dangerous or where RF signals cannot penetrate. For instance, underground mines can deploy this technology for reinforced security of the laborers.

The growing need for in-flight connectivity has been paving the way for immense growth of the aviation & aerospace segment in the North America Li-Fi market. Li-Fi communication technology holds considerable potential for transforming in-flight entertainment as well as revolutionizing cabin & fuselage design. This is because Li-Fi communication does not interfere with the wireless networks that pilots use for ground communication and navigation purposes.

In terms of component, microcontrollers are expected to dominate the overall North America Li-Fi industry share by 2030. The trending focus toward miniaturization of electronic components including microcontrollers has been responsible for the robust expansion of the segment.

Smaller microcontroller chips as well as integrated circuits are being extensively used in Li-Fi enabled devices. Additionally, the fortified presence of electronic component manufacturers and suppliers in the region, alongside the decreasing costs of these components has been facilitating the expansion of the North America Li-Fi market share.

Request for customization @ https://www.graphicalresearch.com/request/1708/customize-this-report

General Electric, SLD Laser, Integrated System Technologies, Fujitsu Corporation, PureLiFi, Lightbee S.L., Lucibel, Signify, Velmenni, NAV Technologies, and Renesas Electronics Corporation are some leading in North America Li-Fi market. Numerous leading players have been laying emphasis on securing strategic partnerships and collaborations with other market players for boosting their competency.

Table of Contents (ToC) of the report:

Chapter 1 Methodology and Scope

1.1 Research methodology

1.2 List of data sources

1.2.1 Secondary

1.2.2 Primary

Chapter 2 Market Snapshot

2.1 North America Li-Fi market snapshot

Chapter 3 North America Li-Fi Trends

3.1 Industry coverage

3.2 Industry size, 2016 – 2026

3.3 Impact of COVID-19 pandemic

3.4 Value chain analysis

3.4.1 Company product snapshot

3.5 Innovation landscape

3.6 Regulatory norms & directives

3.7 Drivers & restraints

3.7.1 Market drivers

3.7.2 Market restraints

3.8 Industry analysis - Porter's

3.9 Competitive benchmarking, 2019

3.9.1 Strategy dashboard

3.10 PEST analysis

Browse complete Table of Contents (ToC) of this research report @ https://www.graphicalresearch.com/table-of-content/1708/north-america-li-fi-market

About Graphical Research:

Graphical Research is a business research firm that provides industry insights, market forecast and strategic inputs through granular research reports and advisory services. We publish targeted research reports with an aim to address varied customer needs, from market penetration and entry strategies to portfolio management and strategic outlook. We understand that business requirements are unique: our syndicate reports are designed to ensure relevance for industry participants across the value chain. We also provide custom reports that are tailored to the exact needs of the customer, with dedicated analyst support across the purchase lifecycle.

Contact Us:

Parikhit B.

Corporate Sales,

Graphical Research

Phone: 1-800-986-6917

Email: [email protected]

Web: https://www.graphicalresearch.com

#North America Li-Fi Market Analysis#North America Li-Fi Market by Type#North America Li-Fi Market Share#North America Li-Fi Market Development

2 notes

·

View notes

Text

The Isolation Journals: Glorious Awkwardness

April 4, 2020

Today’s writing prompt proved a challenge because what was once my most glorious awkward intrinsic trait is currently a way of life for a vast number of people globally. I agonized over the topic longer than I should have.

It felt “too easy” – choosing to write about a “glorious awkward trait” that is so widely accepted now.

It felt “too hard” – would people relate to this as “awkward” now? Could anyone imagine the feeling of hundreds of people staring at them as if they were a freak when they walked down the aisle of an airplane? Would people be able to relate to the experience of returning to the box office, 10 minutes into a movie, to request a new seat assignment; or asking the manager at the gym if they could move to a different cross-training workout station? As many people embrace this trait now, would they be able to imagine their co-workers and friends repeatedly teasing them about this awkwardness and questioning their sanity?

On the idea of it being “too easy”: I thought about some of our most brilliant artists, inventors, designers, musicians, and filmmakers. Stories of being “misunderstood”, “an outcast”, or feeling “different” are commonly shared in interviews. However, once a certain level of fame or recognition is achieved, people celebrate and often emulate their “glorious awkward traits”. But it wasn’t easy. Sometimes that recognition came after decades of taunting by peers, sometimes after death.

On the idea of it being “too hard”: Just this morning, I opened the front door, and saw the grocery delivery driver, in his N95 mask and latex gloves, jump back to the required social distance of 6 feet. Yes, even though this trait is now widely accepted, it still feels awkward. Each of us shrouded in masks as a way to protect each other and ourselves from a dangerous virus. While we both understood it as a necessity, it felt surreal, removed from humanity.

The delivery driver was visibly nervous and anxious to leave. I’d ordered some wine so he needed to scan my ID. With our feet firmly planted on their 6’ marks, our bodies stiffly upright to remain out of the no-fly zone, we extended our arms just far enough that his scanner could read my driver’s license, and retreated as soon as we heard the confirming “beep”.

The writing prompt Jon Batiste offered this morning asked us to describe our “glorious awkwardness”. Well, my glorious awkwardness is: early onset Germaphobia.

I first remember consciously being disgusted by people’s hands in middle school. It wasn’t about the person. I simply saw all the things they touched, could envision dirt and bacteria piling up each time they picked up a pencil, touched the desk, tied their shoe, or twirled their hair. I hid it well (I think), but inside I cringed seeing them raise their unwashed hand to their mouth to eat a sandwich, a healthy snack, or a cookie.

My friends would get sick and brush it off. Their congested nasal passages trying to intake air as they argued, “Agh, izzz jus uh hedddd cold” when I’d decline their request to “try a sip” of my soda. I didn’t want a cold, a head cold, the flu, their mouth on my straw, their breath droplets on the lid.

And it never went away. I thought about it during sex (this was after middle school, for those tracking chronologically). “He didn’t wash his hands when we got home and now they’re where. . . and then. . . ?”

The 3-second rule… or 10 second rule… I don’t remember how many seconds it was, but if a thing fell on a table, the floor, a counter, my shirt, it was not going in my mouth.

In order to have any semblance of a social life, I did the best I could to hide it. Unlike the arbitrary “x-second rule” which never worked for me, I tried to appease my anxiety with “the alcohol will kill it”, which worked for me if I’d consumed enough alcohol.

I’m active, physically and socially. I like to run half marathons, am competitive in a circuit training class, go to rock concerts surrounded by thousands of sweaty people, eat meals out, bump elbows at a crowded bar, travel. The longer I was out in the world, the more I witnessed the repulsive and inconsiderate trait many people - adult people - had of not covering their faces when they sneezed or coughed.

As recently as February – when we were well aware of COVID19, but before we were ordered to stay home – I saw a man sneeze all over the self-service ticket kiosk at the movie theater, as he retrieved his tickets. It was a busy Saturday night. I envisioned all the people who would touch that kiosk after him, print their tickets, go buy popcorn, and put that popcorn directly in their mouth to determine whether it would be salty enough a third of the way through the bucket, before leaving the concession stand to take their seat and perhaps wash their hands on the way. Perhaps.

I alerted an employee, who politely responded, “Thanks for letting us know!” As he continued to address the needs of people in line, the thought of a deadly virus on a high-touch public surface was now trailing off in the distance, unattended.

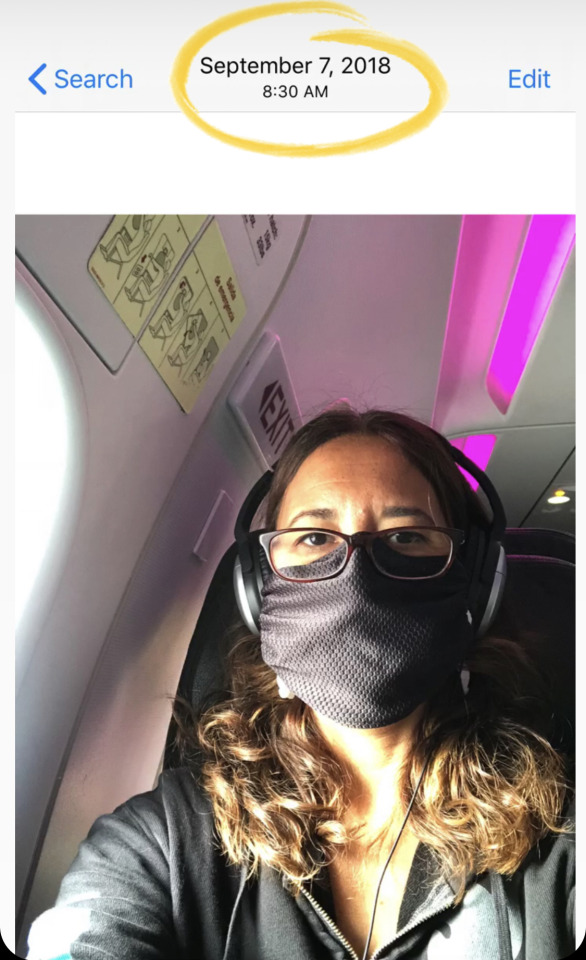

I’ve been wearing a mask on airplanes, trains, and in all forms of public transport, for more than a decade. The most accessible photo of it I have (meaning I don’t have to sift through 8 hard drives to find an older one) is from 2018 and is posted at the end of this story.

First, it was the looks on the faces of the gate agents, followed by the flight attendants who strained to hear my replies, muffled by the mask. Then, of course, there are the looks other passengers give you, followed by their sighs of relief that you’re not sitting next to them, until you do. Sit. Down. Next. To. Them.

At dinners, my friends would sit waiting around the table, while I washed my hands for well over 20 seconds. Often, depending how long we’d been friends, people would say, “C’mon. It’s ok. The alcohol will kill it!”

Their children would ask, “Can we just start eating?” Sometimes, they could.

Business meals were equally complicated. A coworker once wiped her nose on her napkin, put her napkin on the table, and it touched my fork. I tried to hold it together, to not request new utensils, which would likely be uncomfortable for at least two of us during this business lunch. But I was eating chopped salad. I needed a fork. And I could not use that one. I tried to flag down the server as inconspicuously as possible.

“M’am?” he said.

Fuck. I’m a “M’am” already. Fuck. “Could you please bring me another fork?”

The server picked up the fork, raised it toward his eyes, and twirled it around until nearly every part of it had been touched by his fingers, and declared, “This fork is clean!”

To which my colleague added, “It’s fine. It’s just my allergies.”

Allergies… COVID-19…. the mucus oozing from your nose… whatever hepatitis may now be smeared all over that fork… I’m not using it to place things in my mouth.

This text message regarding COVID-19 is from that co-worker:

To me, for as long as I can remember, this trait wasn’t awkward. It was sensible. I could see how we moved through the world - and we weren’t clean about it. How many things do you do, and surfaces do you touch, between using the ATM and washing your hands? Even if you wanted to, there’s no mechanism for hand washing directly adjacent to the ATM (yet). How many other people pressed those buttons with their dirty hands? Those of us who carry hand sanitizer still have to reach into a pocket or a purse to get it out, mash our dirty ATM hands all over the lid to get it open, splatter it on a hand, close the bottle, brace it between our non-dominant forearm and our ribs, and then rub our hands together vigorously without having it splash in our eyes.

Put the bottle of sanitizer away. Feel victorious. And then hear the parking lot attendant decree, “You’re safe!”

One of my favorite observations came from my friend’s son. He was only 5 at the time, but he’d been witness to my glorious awkwardness for most of his life.

“Colette? What happens if you run out of hand-sanitizer?”

“I have more hand-sanitizer.”

“No, but say you’re out - like now - and that bottle is empty… “

“I’ve got a backup bottle in my purse,” I responded, waving the evidence before him.

“Ok, but what about if you’re in the car. . . and you run out of hand-sanitizer in the car??”

“I have a backup bottle in the car too…”

“Can we get ice cream?”

In January and February, people freshly returned from their global voyages and large family dinners, would come to circuit training class sick. Coughing, sneezing, sick. “After this workout, I’m going to urgent care,” one member told her friend as we waited in the lobby for class to begin. “I haven’t been able to get rid of this cough for weeks!”

I’d speak with the manager or guest services (they have a fancier name for it, but whatever) people at the front desk. “I come here to be healthy, to stay healthy, to keep my immune system strong. There are visibly sick people about to get on the treadmill adjacent to - and touching - my treadmill, while we breathe heavily, running 8 miles per hour, for 23 minutes, in a steamy enclosed studio. Do you think you could send out an email alerting members that if they’re sick, they should stay home?”

“No, we can’t ask our members to stay home,” they’d respond, while simultaneously – and at my request - reassigning me to a station further away from said sick people. By the way, it wasn’t up to the lovely people at the front desk. They had been told or, at minimum, believed it to be a corporate policy that sick people could workout there.

Fast forward to April 2020: my glorious awkwardness is your glorious awkwardness.

My friends now call me for advice. Colleagues ask where I got my reusable mask (the one pictured below in 2018). “Where did you get that bottle of hand sanitizer?” someone will ask, unaware there’s backup.

But it’s still awkward, isn’t it? Not being able to see the smile of a stranger, clutching the wall as your neighbors cross paths in the narrow walkway, flinching anytime someone sneezes during a ZOOM call. It was one thing when a handful of us felt this way. We understood it to be odd, but we couldn’t escape it, and everyone else seemed to balance it out with their carefree spirits. But now we’re all fumbling through space, with as few points of contact as possible.

Back on the subjects of “easy” and “hard”: in many ways, the new CDC guidelines and local safety mandates have been exceptionally easy for me. It’s my “glorious awkward” moment in the spotlight. I haven’t had to change my behavior at all. I didn’t have to rush to the store (though, on the subject of toilet paper, I am living roll-to-roll).

I have had to change my activities. I miss going to the gym, the crowded bars, the packed arena concerts. I miss running on the beach. I miss traveling. I’ve become numb to the notices of concert cancellations and postponements. Are the days of being at a music festival, with 100,000 people, crammed into sweaty tents, over?

The active part of my life coming to a standstill is hard. But that, I’m still hopeful, is temporary. The hardest part, for me, now that everyone shares this glorious awkwardness, is wondering how we regain that sense of safety in physical space. Will we become afraid to do the things that used to make us feel so alive? Hopefully, we’ll remind each other, “The alcohol will kill it!”

TODAY:

3 notes

·

View notes

Text

Intrinsically Safe Mobile Phones - Where Communication Entangled With Safety

Hazardous environments pose a risk of injury or harm to employees due to dangerous conditions or substances. These environments can be found in a variety of industries, including but not limited to:

Construction: Construction sites can be hazardous due to the presence of heavy machinery, falling objects, and the risk of falls from heights.

Manufacturing: Manufacturing facilities often involve potentially dangerous machinery, chemicals, and other hazardous materials.

Oil and Gas: Oil and gas industries often involve working in environments with flammable gases, vapors, and dust bags, which can lead to the risk of explosions and fires.

Mining: Mines can be hazardous due to the risk of cave-ins, rock falls, and the presence of dangerous gases.

Chemical Manufacturing: Chemical manufacturing facilities often involve the handling and use of potentially dangerous chemicals, which can pose a risk to workers if not handled properly.

Agriculture: Agricultural environments can be hazardous due to heavy machinery, the handling of dangerous animals, and the risk of falls from heights.

It is vital for workers in hazardous environments to follow proper safety procedures and to use protective equipment to reduce the risk of accidents and injuries. Employers are also responsible for providing a safe work environment and ensuring their employees are trained on the proper safety protocols to prevent any form of fire or other accidents.

Ignition Sources:

Ignition sources refer to anything that can cause a fire or explosion in an industrial setting. These sources can be found in various industries, including oil and gas, mining, chemical manufacturing, and others where flammable materials are present.

Some familiar ignition sources in industries include:

Electrical equipment: Electrical equipment, such as motors, switches, and wiring, can produce sparks or heat that can ignite flammable materials.

Friction and impact: The friction and impact of moving machinery or equipment can produce sparks that ignite flammable materials.

Open flames: Open flames, such as those from torches, cigarettes, or welding equipment, can serve as ignition sources.

Static electricity: Static electricity can build up in explosive environments and can discharge, potentially igniting flammable materials.

Hot surfaces: Hot surfaces, such as those on machinery or ovens, can ignite flammable materials if they come into contact with them.

Identifying and eliminating or controlling ignition sources in industries is essential to prevent fires and explosions. This can be done through proper equipment maintenance, explosion-proof or intrinsically safe equipment, and the implementation of safety protocols and procedures.

Intrinsically Safe Devices: Keeping Workers Connected in Hazardous Environments

Working in hazardous environments can be dangerous, and it is essential to take precautions to keep workers safe. One way to do this is by using intrinsically safe devices designed to prevent the ignition of many hazardous products. These devices are essential for workers in industries such as oil and gas, mining, and chemical manufacturing, where the risk of explosions and fires is high.

Intrinsically safe devices are designed to operate at a low power level, with little to no potential to cause enough heat to harm the hazardous environment. They are also protected against short circuits, which can be a potential ignition source. These features make intrinsically safe devices ideal for use in dangerous environments, as they reduce the risk of accidents and injuries.

Many types of intrinsically safe devices are available, including phones, tablets, and other handheld devices. These devices allow workers to communicate and access important information while on the job, even in areas with a high risk of explosions or fires. This can be particularly useful in emergencies, where quick and reliable communication is essential.

In addition to helping keep workers safe, intrinsically safe devices can also improve productivity and efficiency. By providing workers with the tools they need to do their jobs, businesses can ensure that work is completed efficiently and effectively. This is especially important in industries where time is of the essence, such as oil and gas, where delays can have serious consequences.

Hence, intrinsically safe devices are crucial for keeping workers safe and connected in hazardous environments. By providing low-power, short-circuit-protected devices, businesses can reduce the risk of accidents and improve productivity, helping to create a safer and more efficient work environment.

What is ATEX?

ATEX stands for "Atmosphères Explosibles," French for "explosive atmospheres." ATEX refers to the European Union (EU) directive that regulates the use of equipment and protective systems in potentially explosive atmospheres, including those found in industries such as oil and gas, chemical manufacturing, and mining.

The ATEX directive sets out safety requirements for designing and constructing equipment and protective systems used in potentially explosive atmospheres. It is intended to prevent explosions and fires in these environments by ensuring that equipment and protective systems are safe.

To meet the requirements of the ATEX directive, the instrument or product must be tested and certified by a third party to ensure they are safe to use in hazardous conditions of the workplace. Equipment and protective methods certified under the ATEX directive can be identified by the CE mark, which indicates they are tested and approved for use in potentially explosive atmospheres.

The Toughest Mobiles

The SharpEagle's ATEX Mobile is a specialized Explosion Proof Mobile Phone designed for potentially explosive atmospheres. It is also certified under the ATEX directive, thus ensuring its credibility.

The SharpEagle's ATEX Mobile is built with a rugged, durable design to withstand harsh conditions in industries such as oil and gas, chemical manufacturing, and mining. It is also equipped with a variety of features to help workers stay safe and connected in potentially explosive atmospheres, including:

Intrinsically safe design: It is designed to operate at a low power level to prevent ignition in explosive environments and be short-circuit proof.

Long battery life: It has long battery life to ensure it can be used for extended periods in potentially explosive atmospheres.

High-quality camera: It is equipped with a high-quality camera to allow workers to capture images and video for documentation purposes.

GPS tracking: It has GPS tracking capabilities to help workers stay safe and connected in potentially explosive atmospheres.

Overall, the SharpEagle's ATEX Mobile is a specialized intrinsically safe smartphone designed to provide workers with a reliable and safe way to communicate and access important information in potentially explosive atmospheres.

Stay Safe, and Stay Connected!

In conclusion, Explosion-proof mobile phones are specialized devices for workers in hazardous environments. These phones are designed to be optimized for the dangerous conditions of the sectors and increase the workforce's productivity by being connected at all times without worrying about unfavourable circumstances.

Explosion Proof Mobile Phones allow workers to communicate and access important information while on the job, even in areas where the risk of explosions or fires is high. This can be particularly useful in emergencies, where quick and reliable communication is essential.

SharpEagle is a leading provider of explosion-proof mobile phones and other specialized devices for potentially explosive atmospheres. Their products are certified under the ATEX directive. They are designed to provide workers with a reliable and safe way to stay connected in hazardous environments.

Consider a SharpEagle intrinsically safe smartphone if you work in a potentially explosive atmosphere and need a reliable and secure way to communicate. Contact our team today on our website to learn more about our products and how we can help keep you connected and safe on the job.

For more details visit : A Complete Guide to an Explosion Proof Mobile phone

Contact us:

SharpEagle Technology Address : 1002 Shobha Ivory Tower II - Business Bay, Dubai 80752, UAE Contact no : +971-44541054 Email : [email protected]

#Explosion proof mobile without camera#intrinsically safe cell phones#EX Proof Smart Phones#Explosion proof mobile phones#Intrinsically Safe Mobile Phone#Explosion proof mobile Phones uae#Explosion proof Smartphone#ATEX phone#ATEX Mobile Phones#intrinsic safe mobile#intrinsically safe mobile phone without camera#intrinsically safe mobile phone#intrinsically safe mobile phone price#Intrinsically safe mobile phones supplier in uae#ex proof phone#atex mobile phone#explosion proof phone

0 notes

Text

S318 Multi-Gas Detector From GAXCE SENSORS

In the Zhong An S318 multi-gas detector, different sensor elements are interchangeable, so different sensors can be used for different gases. For gas detection, the full English colour LCD display technology is equipped with dozens of combustible and toxic gases. Product features:

An IPS industrial screen with advanced sensor intelligent module technology with a 2.4-inch HD display in full color

Gas concentration values and technical indicators are displayed

Designed with Asian ergonomics in mind, this unit incorporates high IP encapsulation technology that is able to detect six channels of gas or up to seven gases simultaneously

Data storage function and can store 5000 pieces of data

Dust-proof, explosion-proof and waterproof design Intrinsically safe circuit design, antistatic and electromagnetic interference To contact Gaxce Sensors, please email [email protected]

You can reach us at +91-9673123829.

Kindly visit our website so you will get more product information. https://gaxcesensors.com

0 notes

Text

ATEX phones: What You Need To Know

Industrial workers face many safety hazards in their daily work. One of the most dangerous hazards is an explosion in the workplace. Explosions can happen in many industries, including chemical plants, oil and gas refineries, and manufacturing facilities.

Explosions can be caused by a variety of factors, including faulty equipment, improper handling of materials, and electrical malfunctions. Explosions can result in serious injuries, including burns, trauma, and even death. They can also cause significant damage to property, resulting in costly repairs and downtime for businesses.

To prevent explosions, employers must take steps to protect their workers. This may include providing adequate training and education on safe work practices, ensuring that equipment is properly maintained and inspected, and implementing strict protocols for handling hazardous materials. Employers must also provide workers with appropriate personal protective equipment, such as gloves, goggles, and respiratory protection.

Mobile phones are a vital piece of business equipment even in industry for many business owners and their staff. but the oil and gas industry involves working in hazardous environments that require specific precautions to be taken to maintain safety at all times. One way to mitigate this risk is through the use of explosion-proof equipment, such as ATEX phones.

Choose Best ATEX Explosion Proof Mobile Phone For Hazardous Area

Atex phones are devices designed to be used in hazardous environments like oil refineries, chemical plants, and other industries where explosive gases, vapors, and dust are present. These phones have specific features that allow them to be used safely in such environments. The term Atex stands for "Atmospheres Explosibles" in French, which refers to the directive issued by the European Union that outlines the safety standards for equipment used in explosive atmospheres. These standards ensure that equipment used in hazardous locations meets specific criteria to prevent any potential explosion.Similar organizations that monitor the safety of hazardous environments exist globally, including the International Electrotechnical Commission (IEC).

The main difference between ATEX and IECEx is that ATEX certification only applies for countries in the EU while IECEx certification is accepted globally. Hence, the IECEx certification is more widely recognised and accepted compared to ATEX certification.

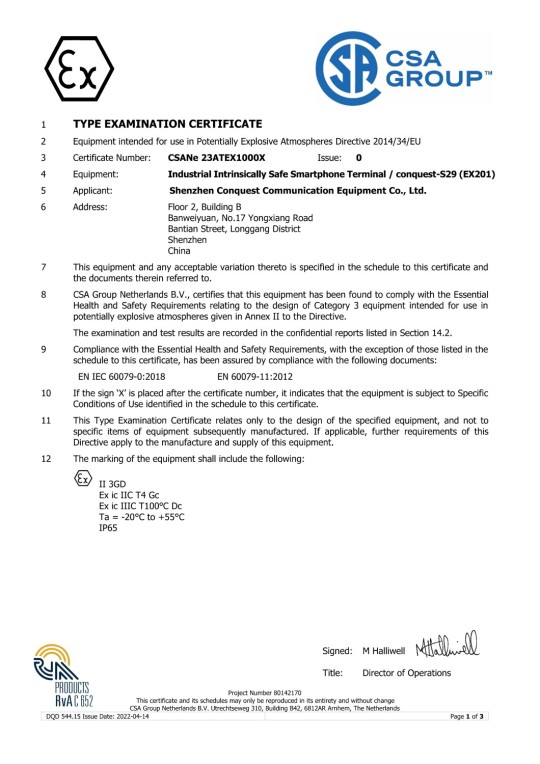

Take Conquest S29(EX201) as example, EX201 get both Atex and IEC certification, that's means EX201 can be used in a Zone 2 hazardous environments.

ATEX phones are essential tools for workers in the oil and gas industry who often work in hazardous areas. They allow for communication to take place between workers and their supervisors or colleagues, enhancing productivity and safety. These phones are built to withstand harsh environments and can handle extreme temperatures, vibrations, and impacts.

What is the principle of Atex Phones?

The principle of Atex phones is based on the fundamental fact that in hazardous environments, a small spark can cause a catastrophic explosion. Therefore, Atex phones must be designed with specific features that eliminate the possibility of creating sparks. The primary cause of sparks in traditional mobile phones is the battery or power supply. Thus, Atex phones use specially designed batteries with low power density to reduce the risk of overheating, which can cause an explosion.

Another critical feature of Atex phones is that they are designed to be intrinsically safe, which means they cannot produce enough energy to ignite an explosive substance. To achieve intrinsic safety, Atex phones use circuitry that limits the amount of electrical energy that can flow through the device. Additionally, a protective barrier is installed between the battery and the device's circuitry to isolate the two and prevent any accidental short circuits.

The significance of Atex phones in hazardous environments is immense. These devices are essential for ensuring communication in dangerous environments without compromising the safety of workers. In the absence of Atex phones, workers would be unable to communicate with each other, making it difficult to coordinate their work and avoid hazardous situations. Additionally, Atex phones enable workers to call for help in case of an emergency, which is crucial in saving lives and minimizing injuries.

Another significant benefit of Atex phones is that they increase the efficiency of work in hazardous environments. These devices allow workers to communicate with each other, access important data, and make informed decisions about their work. This, in turn, increases productivity and efficiency while minimizing the risk of accidents and injuries.

In conclusion, Atex phones play a critical role in ensuring worker safety in hazardous environments. These phones must meet specific safety standards to prevent any potential explosion from occurring. The use of Atex phones increases worker efficiency, improves communication, and helps prevent accidents and injuries. It is, therefore, essential for companies operating in hazardous environments to provide their workers with Atex phones to ensure their safety and increase productivity.

0 notes

Text

S318 Multi-Gas Detector From GAXCE SENSORS

In the Zhong An S318 multi-gas detector, different sensor elements are interchangeable, so different sensors can be used for different gases. For gas detection, the full English colour LCD display technology is equipped with dozens of combustible and toxic gases.

Product features:

An IPS industrial screen with advanced sensor intelligent module technology with a 2.4-inch HD display in full color

Gas concentration values and technical indicators are displayed

Designed with Asian ergonomics in mind, this unit incorporates high IP encapsulation technology that is able to detect six channels of gas or up to seven gases simultaneously

Data storage function and can store 5000 pieces of data

Dust-proof, explosion-proof and waterproof design Intrinsically safe circuit design, antistatic and electromagnetic interference To contact Gaxce Sensors, please email [email protected]

You can reach us at +91-9673123829.

Kindly visit our website so you will get more product information.

https://gaxcesensors.com

0 notes

Text

High Performance lithium battery on lithium-battery-factory.com

RF charging also ensures that https://www.lithium-battery-factory.com/motive-power-battery/ consume less energy, which reduces energy costs and reduces the carbon footprint of traditional devices. The batteries do not require maintenance and do not require replacement to reduce the total cost of ownership. Due to the minimum fumigation, they can be used in confined spaces and public spaces.

High Performance lithium battery bike 48V 20AH replacement Rich

Each Hawker Battery on lithium-battery-factory.com is equipped with a battery management system for continuous monitoring of individual cells to ensure correct and safe use, with protection against overheating, overload, -Tension and short circuits. The Battery on lithium-battery-factory.com also incorporates cell balance technology that promotes maximum performance throughout the life of the battery. An integrated LED provides data on the state of charge, while connections to external monitoring and management systems are possible through an integrated CAN bus.

The second new battery is a 24 A model with a capacity of 82 Ah, based on the proven Thin Plate Pure Lead technology used in the existing Hawker Battery on lithium-battery-factory.com series. The blocks contain pure lead plates much thinner than conventional lead-calcium networks. These have a lower impedance, which allows a greater flow of current in the modes of loading and unloading. The electrolyte is absorbed in a microporous glass separator of the highest quality with high absorption and stability for a better cyclicity. These attributes ensure that a full recharge is completed in less than three hours from a depletion depth of 60%. The battery contains a low voltage alarm - Battery on lithium-battery-factory.com. This small electronic device is located between the positive and negative cables and warns the operator when the battery reaches a certain depth of discharge that requires recharging. The battery also includes a Battery on lithium-battery-factory.com monitoring device that stores many operational records. This information can be transferred to external battery management applications via wireless communication or a USB port for more detailed analysis.

Both models come with a high frequency charger built into the upper compartment of the battery compartment. High frequency charging is inherently more efficient than traditional methods, while the charger provides the correct parameters for fast charging and charging opportunity, regardless of the state of battery discharge. In comparison, conventional batteries work optimally only when they are discharged to a certain level before they are fully charged for 8 to 12 hours. This often means that additional batteries are needed to ensure continuous availability of the device or interruptions that could damage traditional battery technologies.

The batteries can be recharged at any time, regardless of the state of charge, without compromising their performance or reliability in the long term. Both technologies have an integrated charger and are ideal for work cycle applications that can take up to 45 minutes. During this period inactivity times can be used for a quick charge. This means that they are suitable for intermittent or sporadic handling tasks. For example, unloading delivery vehicles or populating screens in busy retail environments.

The Hawker Battery on lithium-battery-factory.com battery to use the latest lithium-ion technology. It is a 24V battery with a capacity of 38Ah containing cells with a cathode of iron and lithium phosphate and a graphite anode with an intrinsically safe lithium ion electrolyte. This offers significant advantages over traditional devices, including higher power density, longer life, and superior low temperature performance. At a depth of discharge of 80%, the battery can be fully charged in less than an hour, and occasional charges are quickly accepted because of their very low internal resistance.

24V 50AH Rechargeable Automotive LiFePo4 Battery

With Battery on lithium-battery-factory.com enclosures and integrated battery design, manufacturers can specify Battery on lithium-battery-factory.com models for plug-and-play and on-demand integrated charger applications. This eliminates the space, handling and cost limitations associated with external chargers, or the need to change and replace the batteries to maintain continuous operation.

#lithium ion battery#Lithium Ion Battery Manufacturer#Wholesale Lithium Ion Battery#lithium-battery-factory.com

1 note

·

View note

Text

FSE Safe suppliers for Atexxo make Explosion Proof ATEX Zone 2 Apple Watch S5

Cost effective ATEX Zone 2 Apple S5 Smart Watch 44mm

Explosion proof watches are originally manufactured by Apple then converted and certified according to the ATEX directives by Atexxo Manufacturing. This makes the smart watches suited for safe use in gas /vapor zone 2 hazardous locations.

Compliance with ATEX / EX regulations is achieved by modification of the casing together with the intrinsically safe electrical circuit, which makes the smart watches suitable for safe use in hazardous locations. All features of the original product are preserved. Wireless charging should be executed in a safe area. The ATEX Apple Watch S5 comes with a black case finish and are available in both GPS and GPS + Cellular.

Applications: Petro (chemical) plants, offshore environments, man down monitoring, storage of hazardous goods and harsh environments

Benefits:

Increased safety / Intrinsically Safe Design

Water resistant / Slim design

Latest models, ATEX Certified

ATEX Zone 2 (Zone 22 on request)

Quick and Worldwide Delivery

Specifications:

Voltage: 100-240 Volt (charger)

Frequency: 50/60 Hz (charger)

Color: Black Dimensions 140-220mm wrist size

ATEX: Unit Assessment Certificate Zone 2, II 3G; ec ic IIC T4 Gc

For more information visit https://www.fsesafe.com/atex-mobile-phones.php

For more information kindly visit us at www.fsesafe.com and for any enquiries email us at [email protected]

0 notes

Text

Is titanium magnetic

Is Titanium Magnetic An implant worth considering? What does it do? How is it different from similar medical implants? Is it safe?

In a nutshell, titanium is relatively weakly magnetized (compared to much stronger non-magnetic materials) when an external magnetic field is applied to it. It exhibits the Lenz effect but to a much lesser extent than other alloys. However, it does have the potential to provide a higher level of magnetic field than other metallic alloys.

Is this enough to suggest that this metal is capable of producing an implanted magnetic field? Let us imagine that a bar of metal is placed just a few millimeters from the titanium implant. If the titanium has no moving magnets, the surrounding metals will push on the implant, causing the insertion to move away. If the implant is moving with a high level of magnetic force, the metal will push back against the moving magnet, forcing the implant back into the proper location.

Is it likely that such high magnetic fields can be maintained over long periods of time? There are some alloys that are more efficient at generating such forces, but this efficiency comes at a price. Since nickel is quite a costly metal, and because nickel itself is also rather inert, the efficient alloys are too expensive to use. The best alternative is to use an alloy with a low density, but with sufficient magnetic property for MRI applications: gold, lead, ruthenium, and nickel alloys are the most common choice.

Is there a way to maintain the strong attraction between the titanium and the other metallic alloys? Is there a way to directly apply an externally applied magnetic fields to the surface of the titanium? Several experiments show that the surface of titanium can be effectively probed using a strong magnetic field; it is shown that a localized strong current produces a strong magnetic field inside the titanium. However, these experiments did not address the effect of the magnetic field on the implant, or the way in which the implant and the titanium are being held together. These experiments therefore cannot rule out the idea that the surface of the titanium is maintained by a magnetic force, but they do indicate that a strong external magnetic field can be used to keep the titanium stable during surgery.

Is it possible to design new metallic materials that have similar properties to the nickel-titanium or ruthenium alloys? Materials having similar electrical and magnetic properties are likely to exist, but these properties may be different from those of nickel and other metallic alloys. This is why it is important to investigate the properties of alloys before selecting one for implantation. For instance, some of these alloys may have a dipole moment, where the dipole moment of one piece is opposite that of the other piece. If such a property is found, then it would be possible to fabricate a metal with similar properties using only one alloy instead of two. The same will hold true for other magnetic properties.

Theoretically, one could use a single metal to create a magnetic field by applying only a very strong external field, which is in the form of a direct current, between the two metals. Such a technique could apply a paramagnetic material to any kind of metal, including stainless steel and titanium. In order to construct a paramagnetic object, a series of dipoles would need to be arranged in a way that creates a small permanent magnetic field in a conductive piece of metal. It should be noted that the construction of such a device would involve strong current passing through the pieces in the circuit.

Is there a relationship between the strength of the intrinsic magnetic field and the level of magnetic susceptibility of the object? It is believed that the intrinsic field is proportional to the total size of the object and its weight. In such a case, the smaller the object, the lesser the susceptibility towards developing a permeable field. On the other hand, larger objects have high values of magnetic susceptibility and this leads to the conclusion that metallic objects with high magnitudes of magnetism tend to reduce the permeability of a field. This is the main idea behind why titanium is such a good conductor. Is titanium magnetic

0 notes

Text

Intrinsically Safe Circuit Design Device Needs Across Industries

As mobility in harsh and volatile industrial and manufacturing environments has become a necessity for productivity, safety, monitoring, and management, intrinsically safe circuit design has had to meet stringent regulatory device needs. Making matters more challenging for device manufactures are the varied environments, product features, and complex requirements of meeting regulatory compliance for intrinsic safety. The definition of intrinsically safe lies at the heart of this challenge.Intrinsic safety requirements apply to any device operated in areas where flammable gases, fuels or dust are present. The device must provide preventive protection in its electronic circuit design and physical structure when used in explosive atmospheres. These devices must be designed in such a way that they will not release enough energy to cause ignition of flammable material. Just a few of the more obvious Industries which require Intrinsically Safe devices include:

Oil and gas

Pharmaceutical

Aircraft maintenance

Chemical refining

Power generation

Metal smelting and refining

Plastics manufacturers

The regulations and requirements governing intrinsic safety for any device that must be certified and manufactured for use in volatile environments are varied. There are two main regulatory bodies and certification:

ATEX (Atmosphere Explosive)

IECEx (International Electrotechnical Commission Explosive)

Both have complex zone requirements driving intrinsically safe circuit design standards across the globe.While there are a number of suppliers offering tablet PCs, smart phones, handheld computing devices or cases reported to be intrinsically safe, there are vast needs for mobile handheld intrinsically safe devices for specialized use cases in highly specific environments such as complex measurement and scanning devices.

0 notes