#inventoryoptimization

Explore tagged Tumblr posts

Text

28 notes

·

View notes

Text

This is now an additional inventory slots post

79K notes

·

View notes

Text

How Smart Inventory Tools Boost Retail Profits

Running a retail business isn’t just about selling products—it’s about managing them smartly too. One of the biggest challenges retailers face is inventory management.

Stock too much, and your cash gets stuck. Stock too little, and you lose sales.

That’s where smart inventory tools come in. These digital solutions are designed to help retailers stay on top of their stock levels, reduce losses, and improve overall profits.

In this blog, we’ll explore how using the right inventory software can boost your retail business.

What Are Smart Inventory Tools?

Smart inventory tools are advanced software systems that automate and streamline your inventory management process. They help you:

Track stock in real time

Manage multiple locations

Forecast demand

Reduce wastage and pilferage

Get low-stock alerts

Generate reports

Whether you run a grocery store, apparel shop, or electronics store, these tools help you manage stock more efficiently and make better business decisions.

How They Help You Boost Profits

Let’s dive into the actual ways these tools increase your retail earnings:

Avoid Over-Stocking & Under-Stocking

Overstocking leads to dead stock and higher holding costs. Under-stocking means lost sales and disappointed customers.

✅ Smart inventory software tracks what’s selling and what’s not. It gives you alerts so you only restock what’s needed—no more guesswork.

Reduce Manual Errors

Manual inventory tracking is time-consuming and error-prone. Wrong entries can lead to poor purchasing decisions and inventory mismatches.

✅ With barcode scanning and automated entries, smart tools reduce human errors and keep your stock levels accurate.

Faster Billing & Checkout

Inventory tools integrated with your POS system (like Shopaver POS) speed up billing. The system automatically updates stock as soon as a product is sold.

✅ Faster checkout means happier customers and more sales per hour.

Real-Time Stock Visibility

If you manage multiple stores or sell online, you need to know stock levels in real time across all locations.

✅ Smart tools show you exactly what’s available and where—helping you transfer or reorder stock without delays.

Smarter Purchasing Decisions

With sales trends and stock reports at your fingertips, you know which products to buy more of and which ones to phase out.

✅ This data-driven approach improves your cash flow and profit margins.

Lowers Theft & Pilferage

When inventory is tracked digitally, it’s easier to detect mismatches, shrinkage, or missing items.

✅ This discourages theft and gives you more control over your assets.

📈 Real Results Retailers See

Retailers using smart inventory tools often report:

30–50% reduction in stockouts

20–40% improvement in stock turnover ratio

Up to 25% increase in profitability

With cloud-based systems like Shopaver, even small businesses can afford powerful inventory management features without heavy setup or maintenance costs.

Choosing the Right Tool

When picking a smart inventory tool, look for:

POS integration

Real-time syncing

Simple dashboard

Low-stock alerts

Reporting & analytics

Multi-location support

WhatsApp or app-based access

💡 Bonus if it comes with features like e-invoicing, GST reports, and mobile access!

🚀 Final Thoughts Smart inventory tools are no longer just for big brands—they're essential for every modern retailer. With the right software, you can reduce waste, speed up operations, and improve customer satisfaction—all while increasing your bottom line.

So if you’re still using spreadsheets or guessing your stock, it’s time to upgrade. Try a smart POS and inventory system like Shopaver and watch your retail profits grow!

#RetailBusiness#InventoryOptimization#RetailSolutions#RetailAutomation#BusinessEfficiency#RetailInsights#RetailPOS#DigitalInventory#RetailGrowth

0 notes

Text

How Does Cloud-Based POS Software Enhance Inventory Management for Fashion Retailers?

Listen to this blog now! - Cloud-Based POS Software Enhance Inventory Management

Fashion retail is fast-paced. New trends come and go like a flash, and managing inventory effectively can be the difference between being a trendsetter or left behind. Traditional systems often lag, leading to stockouts, overstocking, or inaccurate inventory counts. Enter cloud-based POS software, your fashion store's secret weapon.

It’s not just a checkout tool anymore. It’s your real-time, central command centre for inventory, sales, and strategy.

Streamline your inventory—switch to cloud POS today!

Real-Time Inventory Visibility

Instant Stock Updates Across Channels

Cloud POS gives you live tracking of your stock—no more guessing or manual syncing between the store and your online site. Sell a denim jacket in-store? It’s instantly updated online.

Elimination of Manual Errors

No more spreadsheets or delays. Automated tracking means fewer human mistakes and a more accurate picture of your stock levels.

Example: Imagine This…

You’re running a festive sale. A customer checks your website, sees a trendy top is in stock, visits the store, and finds it waiting. That’s real-time accuracy saving a sale!

Centralized Inventory Control

Managing Multiple Stores from One Dashboard

If you’re a brand with multiple locations, you know the pain of disconnected systems. Cloud POS brings everything into one platform, all store inventory in one place.

Remote Access and Operational Flexibility

Whether you're home, travelling, or on the floor, you can log in and see what's happening in real-time. Manage transfers, check stock, or update SKUs with a few clicks.

Use Case: Boutique to Chain

A boutique in Delhi scales to 5 locations across India. The owner still manages stock from her home office thanks to cloud POS.

Automated Stock Alerts and Replenishment

Low-Stock Notifications

Get notified when stock levels dip below a set threshold. No more running out of bestselling items.

Automatic Purchase Orders

Set rules to auto-generate purchase orders. It saves time and ensures timely restocking.

Peak Season Prep

During Diwali or Christmas sales, demand skyrockets. Cloud POS helps ensure you don’t lose sales due to stockouts.

Seamless Integration with E-commerce Platforms

Unified Inventory

Your online and in-store stock are part of the same system. Sell anywhere, fulfill from anywhere.

Omnichannel Customer Experience

Customers today browse online, buy offline, and expect consistency. Cloud POS supports that by syncing all touchpoints.

Real World Example

A customer buys a kurta online, picks it up in-store the same day. That's seamless omnichannel retail powered by integrated POS.

Smart Analytics and Demand Forecasting

Leverage Past Sales Data

See what’s trending, what's stale, and what needs reordering, all from one dashboard.

Optimise Reordering

Why guess order quantities when your POS can forecast it based on data?

Fashion is Fast, Data Helps

Fashion changes fast, but your POS can analyse patterns to keep your inventory stylish and relevant.

Enhanced Workflow Automation

Barcode and RFID Scanning

Scan to add, remove, or relocate stock, simple and error-free.

Fast and Accurate Stocktaking

Do cycle counts in hours, not days. Keep your team focused on selling, not counting.

Save Time, Cut Errors

Automation reduces staffing needs and improves stock accuracy.

Scalability for Growing Retailers

No Heavy Infrastructure

No servers. No complex installations. Just internet and a browser.

Easy to Add Outlets or Products

Open a new store or launch a new collection? Add it to the POS and go live instantly.

Future-Proofing

Scale your fashion empire without scaling your headaches.

Cloud POS vs Traditional POS

Inventory Control Differences

Traditional POS updates locally. Cloud POS updates everywhere instantly.

Cloud is the New Standard

From flexibility to accuracy, cloud wins hands down.

Improved Audit Trails and Compliance

Full Traceability

Every item movement is logged. Perfect for audits, shrinkage analysis, or performance reviews.

Better Control

Inventory accountability becomes clearer and easier to enforce

Customer Satisfaction Through Better Inventory

Fewer Out-of-Stock Frustrations

Customers find what they want when they want it. Happy customers = repeat business.

Speedy Service

Faster checkout and instant inventory checks make a better experience at the counter.

Vendor and Supplier Management

Track Supplier Performance

See which vendors are consistently late or sending damaged goods.

Simplified Ordering

Reorder from reliable vendors directly from your POS.

Access Anywhere, Anytime

Mobile or Desktop Access

Use tablets, phones, or laptops. Your inventory travels with you.

Decisions On-the-Go

Approve a purchase order or check stock levels while sipping your coffee.

Cloud Security and Data Backup

Secure Hosting

Most cloud POS providers use encrypted, secure servers.

Automatic Backups

Even if your hardware crashes, your data is safe and recoverable.

Sustainability and Waste Reduction

Avoid Overstocking

Only order what’s needed. Reduce unsold stock waste.

Environmentally Friendly

Less waste = greener business practices.

Conclusion

For fashion retailers, managing inventory is no longer a backend task—it’s a front-line business strategy. Cloud-based POS software transforms inventory from a headache into a competitive advantage. Whether you're a boutique or a multi-store brand, the real-time visibility, automation, and smart insights of a cloud POS help you stay lean, fast, and profitable.

Upgrade your inventory game, and watch your fashion business thrive.

Source: https://www.wondersoft.com/blogs/how-does-cloud-based-pos-software-enhance-inventory-management-for-fashion-retailers

#CloudPOS#FashionRetail#InventoryManagement#POSSoftware#RetailTechnology#CloudBasedPOS#RetailInventory#FashionPOS#RetailSolutions#SmartRetail#POSSystem#RetailInnovation#InventoryOptimization#RetailManagement#CloudTechnology

0 notes

Text

Objectives of Inventory Management for Efficient Stock Handling

Introduction to Inventory Management Objectives

Inventory management is a key function for every business dealing with products, stock, or supply chains. Whether you're in retail, manufacturing, logistics, or healthcare, handling inventory efficiently helps keep operations smooth and costs under control. The Objectives of Inventory Management focus on maintaining the right balance of stock—avoiding both overstocking and stockouts. In 2025, as technology and customer expectations grow, businesses must align their inventory processes with precise goals to stay competitive.

Why Inventory Management Is Crucial in 2025

In today’s fast-paced market, customer demands are immediate, and delivery expectations are tighter. If businesses don’t have proper inventory control, it can lead to lost sales, high storage costs, and poor customer satisfaction. The Objectives of Inventory Management ensure that companies have the right goods at the right time, without unnecessary waste or delays. With rising inflation, supply chain disruptions, and digital transformation trends, efficient inventory management is more critical than ever.

Key Objectives of Inventory Management

The core Objectives of Inventory Management revolve around maintaining accurate stock levels, ensuring availability, minimizing costs, and improving service quality. These objectives help organizations operate efficiently by reducing losses and increasing profits. Good inventory practices also improve overall planning, purchasing, and warehousing decisions.

Ensuring Product Availability Without Over-Stocking

One of the main objectives is to ensure that the right quantity of products is available when needed. Overstocking can lead to higher holding costs and wastage, especially with perishable or seasonal items. On the other hand, understocking results in lost sales and dissatisfied customers. A well-managed inventory system aims to strike a balance between demand and supply.

Minimizing Inventory Holding Costs Effectively

Another crucial goal is to reduce the cost of holding stock in warehouses. This includes storage, insurance, taxes, depreciation, and obsolescence. The Objectives of Inventory Management aim to minimize these costs by optimizing how much stock is kept and for how long. This not only saves money but also frees up warehouse space for more important items.

Improving Order Accuracy and Fulfillment

Inventory management directly affects order accuracy. Delays in delivery or shipping the wrong products can harm customer relationships. One of the key Objectives of Inventory Management is to ensure that every order is picked, packed, and shipped correctly. Accurate inventory systems help track available stock and reduce the chances of errors.

Optimizing Stock Turnover Rates for Better Efficiency

High turnover rates indicate that goods are being sold and replenished quickly, which is healthy for business. Low turnover can signal excess stock or low demand. Inventory systems should help track turnover and improve efficiency. Meeting this objective ensures that capital isn’t tied up in slow-moving items and helps businesses respond quickly to market changes.

Maintaining Accurate Inventory Records and Data

Having up-to-date and correct inventory data is essential. Inventory inaccuracies can lead to poor decisions in purchasing, sales, and production. Maintaining accurate records is a fundamental Objective of Inventory Management, as it provides real-time insights into what is in stock, what needs restocking, and what should be phased out.

Reducing Wastage, Obsolescence, and Shrinkage

Inventory shrinkage can result from theft, damage, or administrative errors. Obsolete stock refers to items that are no longer sellable. Wastage affects profit margins directly. One of the major Objectives of Inventory Management is to reduce these losses through better planning, tracking, and security measures. Implementing proper systems and employee training can help prevent such issues.

Enhancing Supplier and Vendor Coordination

Good inventory management involves coordination with suppliers to ensure timely deliveries and accurate restocking. Reliable supplier relationships help avoid delays and reduce the risk of running out of stock. Meeting the Objectives of Inventory Management means working closely with vendors to align supply schedules with demand forecasts.

Forecasting Demand with Inventory Control

Demand forecasting plays a major role in inventory success. It helps businesses predict what products are needed, in what quantity, and at what time. This allows for smarter purchasing decisions. The Objectives of Inventory Management include using historical data, market trends, and seasonal patterns to anticipate future demand and avoid last-minute surprises.

Using Technology for Smarter Inventory Decisions

Modern inventory management uses technologies like RFID, barcodes, and real-time tracking systems. These tools improve accuracy, speed, and visibility in inventory operations. Businesses that invest in these systems can meet their inventory goals more efficiently. Automation and cloud-based platforms also help small businesses manage inventory without huge IT investments.

Benefits of Achieving Inventory Management Objectives

When businesses meet their inventory management goals, they enjoy better cash flow, improved customer satisfaction, reduced operational costs, and more reliable planning. It also increases accountability within the organization and allows for more accurate financial reporting. Meeting the Objectives of Inventory Management leads to better control, greater flexibility, and long-term profitability.

AIDC Technologies India: Your Inventory Management Partner

AIDC Technologies India is a trusted provider of advanced inventory and automation solutions. With years of experience in barcode, RFID, RTLS, and warehouse automation, AIDC helps businesses streamline their inventory processes and meet their objectives efficiently. From hardware to software, AIDC offers end-to-end systems designed to improve accuracy, reduce errors, and simplify stock handling.

Whether you are a retailer, manufacturer, or logistics company, AIDC provides customized solutions to help you achieve your specific Objectives of Inventory Management. Their services are scalable, cost-effective, and built to meet industry demands in 2025 and beyond.

Call to Action: Book Now AIDC Technologies

If you're looking to upgrade your inventory system and improve your stock management performance, it's time to act. Book Now AIDC Technologies and experience smarter, faster, and more reliable inventory solutions designed for your business needs.

Conclusion: Smarter Inventory, Smarter Business in 2025

The Objectives of Inventory Management are not just operational tasks—they are the backbone of a successful business. From reducing costs to improving customer satisfaction, efficient inventory management touches every aspect of an organisation. With technology playing a bigger role than ever, businesses must adapt and invest in smarter systems. Partnering with AIDC Technologies India ensures that your inventory goals are met with precision, scalability, and innovation.

#InventoryManagement2025#EfficientStockHandling#SmartInventorySolutions#InventoryOptimization#StockControlStrategies#WarehouseEfficiency#InventoryGoals2025#AIDCInventorySystems#RealTimeInventory

0 notes

Text

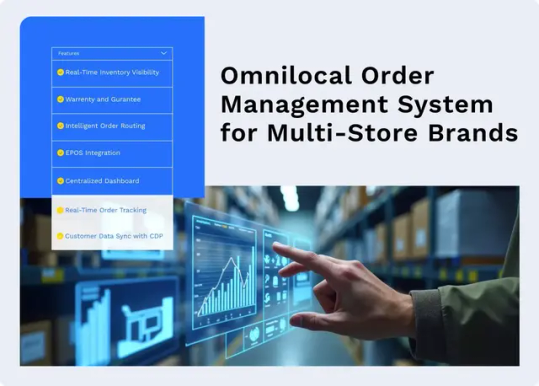

Omnilocal Order Management System for Multi-Store Brands

In today’s rapidly evolving retail landscape, multi-store brands face increasing pressure to deliver seamless customer experiences across both online and offline channels. This is where an Omnilocal Order Management System (OMS) becomes essential.

An Omnilocal Order Management System is a centralized solution that manages orders, inventory, and fulfillment across all locations — whether it’s a physical store, an e-commerce platform, a mobile app, or a marketplace. It ensures that your customers can shop anywhere and still receive a consistent, efficient experience.

More than just a software tool, this system supports the shift from siloed online or offline operations to unified omnichannel commerce. For brands managing multiple stores, it offers real-time inventory visibility, optimized fulfillment routing, integrated logistics, and smarter decision-making — all from one place.

An Omnilocal Order Management System helps you centralize operations while localizing customer experiences — the perfect balance for multi-store brands aiming to scale smartly and stay competitive.

It’s more than just technology; it’s the future of customer-centric retail that delivers faster fulfillment, smarter inventory management, and seamless omnichannel shopping.

Ready to take your brand to the next level?

Get started with Sekel Tech’s Omnilocal Order Management System today and transform how you manage orders, inventory, and customer experience across all your stores and channels.

#omnilocalordermanagement#multistoreinventory#retailtech#brand management#smartretail#digitaltransformation#inventoryoptimization

0 notes

Text

Distribution Management Software

mSELL Distribution Management Software offers a smart, real-time solution to streamline and automate your entire distribution network. From order booking and inventory tracking to distributor performance monitoring, mSELL ensures efficient supply chain operations, better stock visibility, and improved coordination between manufacturers, distributors, and retailers — all in one powerful platform.

0 notes

Text

This Simple Automation Hack Could Save You Millions in Inventory Loss

Is your business still juggling spreadsheets, emails, and manual approvals to manage procurement and inventory? That’s not just outdated—it’s costing you time, money, and control.

When procurement is slow, inventory piles up—or worse, runs out when you need it most. That’s where automation becomes your silent growth partner. It cuts the chaos, predicts your needs, and helps you manage inventory like a pro.

Whether you run a manufacturing unit, a retail store, or a large supply chain business, the right automation strategy can turn your inventory headaches into smooth, efficient processes.

Let’s break it down simply so you understand why this matters—and what you can do to start improving today.

What Does Procurement Automation Actually Mean?

Imagine if your system could:

Reorder stock automatically before it runs out

Flag slow-moving items so you stop overbuying

Match purchase orders with invoices—without manual effort

Alert you when vendor prices spike

That’s the power of automation in procurement. It’s not just about doing things faster—it’s about doing them smarter.

And when automation is customized to your unique business process through Custom ERP Software Development Services, it becomes a complete solution—not just a feature.

Step One: Know Your Real Inventory Challenges

Before fixing anything, you need to know what’s broken. Here are a few real-life problems most businesses face:

▶ No real-time stock visibility – You don’t know what’s in your warehouse right now

▶ Manual data entry – Too many spreadsheets and human errors

▶ Slow decision-making – Approvals take days, not hours

▶ Disconnected systems – Procurement, sales, and inventory don’t talk to each other

Sound familiar? If yes, automation can help fix these pain points fast—and without hiring extra hands.

How Automation Can Boost Inventory & Procurement Performance

Here’s how you can start getting results with automation—fast:

1. Evaluate Current Procurement & Inventory SystemsStart by reviewing your existing procurement and inventory workflows, identifying inefficiencies and system gaps. Use tools like ERP, barcode scanning, or RFID to track real-time data, minimize errors, and improve stock visibility. Understanding movement trends, stockouts, and overstock issues helps streamline your entire process.

2. Set Procurement Goals & KPIsSet clear goals such as reducing stockouts, lowering holding costs, and improving turnover rates. Track essential KPIs like order cycle time, forecast accuracy, and supplier performance. These insights help optimize inventory levels, improve supplier relationships, and drive smarter procurement decisions.

3. Choose Automation Technologies for ProcurementAdopt cloud-based ERP and AI tools to automate procurement tasks like purchase orders and demand forecasting. IoT devices can provide real-time warehouse data, automate stock alerts, and reduce manual errors. Integrating systems ensures all teams work with accurate, up-to-date inventory data.

4. Manage Vendors & SuppliersUse software to monitor supplier performance in real-time—quality, delivery, and cost metrics. Automate vendor selection based on data and create a supplier portal for easy communication and reordering. Predictive analytics helps assess risk and keep your procurement plans agile and reliable.

These small upgrades lead to a massive impact over time—fewer delays, less waste, and more control over your spending.

But That’s Just the Start…

Want to go deeper into:

How AI fits into your procurement strategy?

Real examples of companies saving 30% on inventory costs?

The tech tools that make automation easy to implement?

👉 Curious to see how automation can completely change your procurement game?There’s a lot more we’ve uncovered in our main blog—especially around the tech stack, real-world use cases, and long-term ROI.

👉 Read the full breakdown here: 🔗 How Automation in Procurement Drives Efficient Inventory Optimization

#ProcurementAutomation#InventoryOptimization#SupplyChainSolutions#ERPSoftwareDevelopment#DigitalProcurement#SmartInventoryManagement#AutomationInBusiness#CustomERP#ProcurementStrategy#AIInSupplyChain

0 notes

Text

📊 Unlocking Retail Potential with CPG Data Analytics

In today’s fast-paced retail environment, data isn’t just power; it’s profit. 🔍💼

This powerful visual represents how CPG data analytics is transforming product decisions, from inventory optimization to real-time consumer behavior tracking. The future of shelf strategy and category performance is here — and it’s driven by insights.

#CPGDataAnalytics#RetailTech#DataDrivenDecisions#InventoryOptimization#ConsumerInsights#Quation#FMCGInnovation#retail industry

0 notes

Text

13 notes

·

View notes

Text

Having pockets is like being on lite mode

Idk if that makes sense

11K notes

·

View notes

Text

Why Invest in a Warehouse Management System Today

Managing a warehouse in today’s fast-moving market isn’t easy. With increasing customer expectations and supply chain complexities, using manual processes or outdated systems is risky.

To stay competitive and profitable, businesses must adopt a robust Warehouse Management System (WMS).

What is a Warehouse Management System?

A Warehouse Management System is a software solution that helps manage and optimize warehouse operations like inventory control, stock tracking, picking, packing, and shipping. It's a powerful tool designed to enhance visibility, accuracy, and productivity in your supply chain.

A good Warehouse System works alongside tools such as shop stock management software, sales inventory software, and software for inventory and sales to offer end-to-end control.

Top Reasons to Invest in an Inventory Management System Today

1. Accurate Inventory Tracking

Manual inventory tracking lead to human errors and mismatches. A Warehouse Management System offers:

Real-time stock visibility

Barcode and RFID integration

Reduced shrinkage and stockouts

Smooth syncing with shop inventory management tools

2. Faster and Reliable Order Fulfillment

Fulfilling customer orders quickly and accurately improves brand loyalty. Stock Management System allows:

Intelligent pick-pack-ship automation

Instant stock updates

Integration with store stock software

Seamless returns management

3. Cost Savings Across the Supply Chain

With automation and analytics, a Warehouse Management System reduces operational overheads:

Fewer manual errors and returns

Optimized labor and space usage

Works with billing and inventory management software for financial accuracy

4. Scalability for Future Growth

As your operations expand, a flexible Inventory Management System supports:

Multi-location warehouses

Cloud access and remote monitoring

Compatibility with shop management software and POS tools

5. Smarter Decisions with Data Insights

An Inventory Management System tracks all warehouse activities and provides key performance indicators:

Real-time dashboards

Inventory turnover reports

Trends to integrate with software for shop inventory systems

Core Features of a Stock Management Software You Should Look For

When choosing a Warehouse Management System, ensure it supports integration with your business software ecosystem:

Shop inventory management software

Software for inventory and sales

Store management software

Billing and inventory management software

Sales inventory software

These features not only enhance functionality but ensure the system grows with your business needs.

Which Businesses Should Use Warehouse Management Software

From small retail shops to large warehouses, anyone handling inventory benefits from Warehouse Management System the Warehouses include:

Retailers using shop stock management software

Grocery stores using shop inventory management tools

E-commerce brands needing software for inventory and sales

Wholesalers tracking bulk stock with store stock software

Why You Shouldn’t Delay

Every day without a proper Warehouse Management System is a missed opportunity to optimize operations. Failing to modernize leads to:

Inventory mismanagement

Higher costs

Delayed orders

Disconnected software systems (like POS and shop inventory management software)

By investing in WMS today, you position your business for:

Faster delivery

Greater accuracy

Long-term growth

Conclusion

In today’s digital-first world, a Warehouse Management System is no longer optional. Whether you run a retail store, eCommerce business, or wholesale unit.

Integrating your warehouse with systems like shop management software, store management software, and billing and inventory management software will drive better results.

#WarehouseManagementSystem#InventoryManagement#ShopInventorySoftware#StoreManagementSoftware#RetailTech#InventorySolutions#BillingAndInventorySoftware#WarehouseAutomation#SalesInventorySoftware#RetailSoftware#SupplyChainSolutions#InventoryTracking#BusinessSoftware#InventoryOptimization#StockManagement

0 notes

Text

#inventory#inventorymangement#sap#oracle#propelapps#scm#inventoryoptimization#supplychain#mobilescm#mobilesupplychain

0 notes

Text

Top 10 Important Objectives of Inventory Management System

AIDC India Explains the Key Objectives of Inventory Management System in 2025

In today’s fast-paced business world, inventory is the heart of every operation. Whether it’s a retail store, manufacturing unit, hospital, or warehouse—keeping stock levels accurate is crucial. That’s where the Objectives of Inventory Management System come into play.

AIDC Technologies India, a leader in smart automation and tracking solutions, explains how modern inventory management systems in 2025 are helping businesses stay efficient, responsive, and profitable. Let’s dive into the top 10 objectives that make these systems essential.

1. Maintain Optimal Stock Levels with AIDC’s Inventory Solutions

One of the main Objectives of Inventory Management System is to maintain the right amount of stock—no more, no less. AIDC India’s systems are designed to alert you when to reorder and when you’re overstocking.

This helps avoid stockouts (running out of goods) and excess stock (tying up capital), ensuring a healthy balance. With real-time tracking, you always know how much inventory you have on hand.

2. Streamline Inventory Operations Through AIDC’s Automation

Manual inventory processes are slow and error-prone. In 2025, automation is a must. Another important goal in the Objectives of Inventory Management System is to make inventory tracking, updating, and reporting automated.

AIDC’s system uses RFID, barcode scanning, and cloud-based tools to streamline operations. This helps reduce manual work, improves speed, and minimizes human errors—making your operations more efficient and less stressful.

3. Reduce Holding Costs with AIDC’s Smart Inventory Management

Every business wants to cut costs, and the Objectives of Inventory Management System directly support this. AIDC Technologies India helps companies reduce holding costs—expenses related to storing unsold goods.

By optimizing inventory turnover and space utilization, businesses save on warehousing, insurance, and potential product obsolescence. Smart inventory practices mean better use of every rupee.

4. Improve Supply Chain Visibility with AIDC’s Inventory System

When you have multiple warehouses or supply chain points, visibility becomes a challenge. One of the critical Objectives of Inventory Management System is to give you full control and transparency across all locations.

AIDC’s system displays inventory movement and status in real-time across branches, stores, or warehouses. This enables better decision-making and faster response times in case of disruptions.

5. Enhance Order Fulfillment Accuracy with AIDC Technologies

Order accuracy is key to customer satisfaction. Another of the top Objectives of Inventory Management System is to ensure that the right product reaches the right place at the right time.

AIDC India’s software reduces errors in picking, packing, and shipping. It automatically checks stock availability before processing orders, reducing returns and increasing customer trust.

6. Prevent Stockouts and Surpluses with AIDC’s Forecasting Tools

Forecasting is all about planning ahead. A major objective within the Objectives of Inventory Management System is to predict demand accurately. AIDC’s smart software analyzes past trends, seasonal changes, and current data to help businesses stock up correctly.

This prevents lost sales due to empty shelves and avoids surplus inventory that may go unsold. Predictive tools make inventory smarter and reduce guesswork.

7. Increase Warehouse Productivity Using AIDC’s Inventory Software

Efficient warehouses mean faster deliveries and lower costs. That’s why improving warehouse productivity is one of the Objectives of Inventory Management System.

AIDC provides features like automated item location, smart shelving suggestions, and quick scanning tools. These reduce time spent looking for items and increase the speed of operations from inbound to outbound.

8. Ensure Data Accuracy with RFID & Barcode Integration by AIDC

Data errors can be expensive. An essential part of the Objectives of Inventory Management System is to ensure real-time, error-free data. AIDC Technologies India uses RFID and barcode systems to eliminate manual entry mistakes.

Each item can be tagged and scanned instantly. Whether it’s during receiving, transferring, or dispatching, the system ensures the right data is captured every time.

9. Improve Vendor Coordination with AIDC’s Inventory Tracking System

Smooth coordination with vendors leads to better supply chain performance. One of the newer Objectives of Inventory Management System in 2025 is enhancing communication with suppliers.

AIDC’s platform allows real-time updates, delivery schedules, and order tracking—keeping suppliers and buyers on the same page. This reduces delays and ensures timely replenishment of stock.

10. Boost Customer Satisfaction Through AIDC’s Efficient Inventory Control

Ultimately, all the Objectives of Inventory Management System serve one major goal: customer satisfaction. When customers receive the right products on time and without errors, they’re more likely to return.

AIDC India’s system improves delivery accuracy, speeds up service, and reduces product unavailability—helping businesses build trust and retain loyal customers.

Why AIDC India Leads in Inventory Management Systems in 2025

AIDC Technologies India is not just a software provider—they are a strategic partner in your growth. Their inventory management solutions are tailored to meet the unique needs of retail, manufacturing, healthcare, logistics, and more.

Whether it’s automation, real-time tracking, or predictive analytics, AIDC’s tools help businesses meet all 10 key Objectives of Inventory Management System in 2025. Their systems are:

Scalable and easy to use

Cloud and mobile compatible

Customizable to industry-specific needs

Backed by excellent support and training

With AIDC, companies of all sizes—from startups to large enterprises—gain the competitive edge they need to thrive in today’s dynamic market.

Book a Free Demo with AIDC Technologies India Today

AIDC Technologies India to schedule your free consultation or live demo.

#InventoryOptimization#InventoryManagement2025#SmartStockControl#InventoryEfficiencyGoals#AIDCInventorySolutions#DigitalInventorySystems

0 notes

Text

Reorder Point Formula: The Key to Smarter Warehouse Management!Prevent stockouts, avoid overstocking, and streamline your inventory processes with the power of the reorder point formula. Optimize warehouse operations and ensure smooth supply chain efficiency!

#ReorderPointFormula#WarehouseManagement#InventoryManagement#StockReplenishment#SupplyChainEfficiency#InventoryOptimization#WarehouseOperations#omneelabwms#wms#ai#supplychain#cloud#software#warehouse#omneelab#automation

0 notes

Text

mSELL's Inventory Management Software is a powerful solution designed to streamline stock and dispatch operations for businesses. It offers real-time inventory visibility, ensuring accurate stock level monitoring and reducing the risks of overstocking or stockouts. The software automates order fulfillment, minimizing manual errors and enhancing customer satisfaction with timely deliveries. With features that optimize delivery routes and support business scalability, mSELL helps companies boost operational efficiency, cut costs, and respond effectively to changing market demands.

#InventoryManagement#InventorySoftware#StockManagement#InventorySolutions#WarehouseManagement#InventoryControl#InventorySystem#SmartInventory#SupplyChainSolutions#InventoryOptimization#InventoryTracking#RealTimeInventory#BusinessEfficiency#InventoryTech#mSELL

0 notes