#it ensures stable and efficient operation in electrical protection and automation systems.

Explore tagged Tumblr posts

Text

Numerical Relays - Adlite Electricals

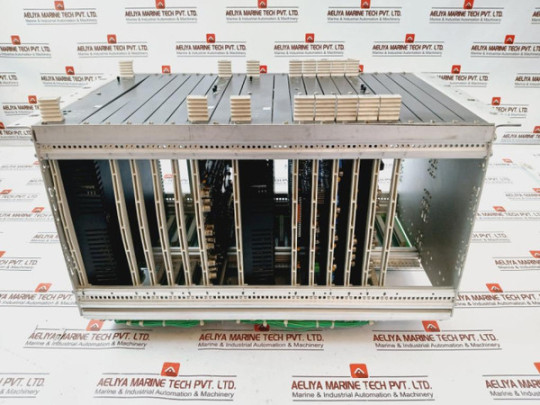

Enhance Power System Efficiency with CGI 14N 75-250VDC Relay

For reliable electrical system performance, a high-quality auxiliary relay is essential. The CGI 14N 75-250VDC Relay, available at Adlite Electricals, is designed for superior performance in industrial, commercial, and power utility applications. With its voltage range of 75-250VDC, it ensures stable and efficient operation in electrical protection and automation systems.

What is the CGI 14N 75-250VDC Relay?

The CGI 14N 75-250VDC Relay is an advanced auxiliary relay used in control and protection circuits. It processes electrical signals efficiently and enables precise switching for power management.

Key Features of CGI 14N 75-250VDC Relay

This relay offers exceptional advantages, making it an ideal choice for power system applications:

Wide Voltage Compatibility: Operates efficiently between 75-250VDC, making it suitable for diverse electrical systems.

High-Speed Response: Ensures rapid activation to prevent faults and enhance system safety.

Rugged and Durable Design: Built for long-term use in demanding industrial environments.

Compact and Easy Installation: Allows seamless integration into various electrical setups.

Reliable Contact Multiplication: Enhances control circuit performance and dependability.

Applications of CGI 14N 75-250VDC Relay

The CGI 14N 75-250VDC Relay is widely used in multiple industries due to its high reliability and efficiency, including:

Power Plants: Assists in relay protection and circuit breaker operations.

Industrial Automation: Enables precise switching in manufacturing processes.

Substations: Supports stable grid management and fault isolation.

Renewable Energy Systems: Facilitates integration in solar and wind energy projects for efficient power control.

Why Choose CGI 14N 75-250VDC Relay from Adlite Electricals?

When it comes to sourcing top-quality electrical protection devices, Adlite Electricals is your trusted provider. Here’s why:

Genuine and Certified Products: Ensuring superior quality and reliability.

Affordable Prices: Get the best value for high-performance electrical components.

Hassle-Free Online Shopping: A seamless purchasing experience with expert support.

Fast and Secure Delivery: Ensuring timely arrival of your relay in perfect condition.

Conclusion

The CGI 14N 75-250VDC Relay is a must-have for industries that require a dependable, high-speed, and durable relay solution. Its wide voltage range and compact design make it ideal for numerous electrical applications.

Order your CGI 14N 75-250VDC Relay today from Adlite Electricals and enhance your system’s efficiency and safety!

Related Products

#CGI 110VDC Master Trip Relay

#CGI 14C 18-52VDC Relay

#CGI 14C 75-250VDC Relay

#CGI 14N 18-52VDC Relay

#CGI 14S 230VAC Relay

#CGI 24C 18-52VDC Relay

#CGI 24C 75-250VDC Relay

#CGXH1 3 Element Aux 110 VDC Relay

#Crompton TCSR Unit 110 VDC Relay

#Megawin M140c Relay

#Megawin MB 140c (Breaker Manager Relay)

#Enhance Power System Efficiency with CGI 14N 75-250VDC Relay#For reliable electrical system performance#a high-quality auxiliary relay is essential. The CGI 14N 75-250VDC Relay#available at Adlite Electricals#is designed for superior performance in industrial#commercial#and power utility applications. With its voltage range of 75-250VDC#it ensures stable and efficient operation in electrical protection and automation systems.#What is the CGI 14N 75-250VDC Relay?#The CGI 14N 75-250VDC Relay is an advanced auxiliary relay used in control and protection circuits. It processes electrical signals efficie#Key Features of CGI 14N 75-250VDC Relay#This relay offers exceptional advantages#making it an ideal choice for power system applications:#•#Wide Voltage Compatibility: Operates efficiently between 75-250VDC#making it suitable for diverse electrical systems.#High-Speed Response: Ensures rapid activation to prevent faults and enhance system safety.#Rugged and Durable Design: Built for long-term use in demanding industrial environments.#Compact and Easy Installation: Allows seamless integration into various electrical setups.#Reliable Contact Multiplication: Enhances control circuit performance and dependability.#Applications of CGI 14N 75-250VDC Relay#The CGI 14N 75-250VDC Relay is widely used in multiple industries due to its high reliability and efficiency#including:#Power Plants: Assists in relay protection and circuit breaker operations.#Industrial Automation: Enables precise switching in manufacturing processes.#Substations: Supports stable grid management and fault isolation.#Renewable Energy Systems: Facilitates integration in solar and wind energy projects for efficient power control.#Why Choose CGI 14N 75-250VDC Relay from Adlite Electricals?#When it comes to sourcing top-quality electrical protection devices#Adlite Electricals is your trusted provider. Here’s why:

0 notes

Text

Top 5 Industrial Automation Low-Voltage Switchgear Accessories You Need to Utilize

Stable and proper electrical systems are most important in industrial automation, and low-voltage switchgear is one of the most important elements that connects these systems. However, to reach the best performance, safety, and lifespan, the correct accessories for low-voltage switchgear need to be selected.

In this article, we will discuss the 5 must-have low-voltage switchgear accessories that industrial automation requires to run at its optimum and be less down.

1. Circuit Breakers – Protection and Safety from Overloading

Circuit breakers are the most important devices of low-voltage switchgear equipment. Circuit breakers safeguard electric circuits from problems like short circuits, overloads, and faults by breaking power supply to the circuit when they detect abnormal conditions.

Why They Are Important?

- Protect equipment from electrical fire and damage.

- Comply with industry safety standards.

- Recover quickly from a fault.

Recommendation: Use high-level circuit breakers with remote monitoring and diagnostic capabilities to improve automation efficiency.

2. Surge Protection Devices (SPDs) – Voltage Spike Protection

Voltage spikes and transients destroy electrical equipment in automation systems. SPDs function by absorbing excess voltage, thereby safeguarding sensitive hardware.

Why They Are Important?

- Reduce electrical surge downtime.

- Protect the automatic equipment and control panel from damage.

- Extend the life of electrical equipment.

Pro Tip: Install SPDs with real-time sensing sensors. That way, you can detect and fix voltage problems as they occur.

3. Busbar Systems – More Efficient Power Distribution

A busbar system is important since it allows the transmission of electrical energy more efficiently in switchgear setups. Busbars conduct better, lose less energy, and work better with systems than regular wiring.

Why They Matter?

- Simplified and less costly wiring installation.

- Minimization of energy losses by reducing the power loss.

- Simple extension to and integration with automated systems.

It is suggested that insulated busbar systems shall be employed for safety and to prevent accidental short circuits.

4. Motor Protection Relays – Intelligent Monitoring for Motors

Electric motors are a fundamental component of industrial automation. Motor protection relays safeguard motors against overloading, phase imbalance, and overheating to enable motors to run faultlessly and continuously.

Why Are They Important?

- Prevent costly motor failure and operational downtime.

- Allow remote monitoring for easy predictive maintenance. - Improve operational efficiency with auto-reset.

Tip: Incorporate programmable motor protection relays with automation systems for real-time monitoring and control.

5. Remote Monitoring and Control Devices – Increasing Automation Scope

New businesses must monitor switchgear remotely to be efficient and have low maintenance costs.

Remote monitoring devices allow operators to monitor voltage levels, power consumption, and system status from a distance.

Why Are They Important?

- Perform routine maintenance to avoid unexpected breakdowns.

- Require fewer resources and time to reduce manual inspections.

- Increase system reliability with real-time fault notifications.

Pro Tip: Implement IoT-enabled remote monitoring systems for easy integration with industrial automation systems.

Final Thoughts:

Buy good quality low-voltage switchgear accessories when you purchase them for safety, performance, and efficiency in industrial automation.

Circuit breakers, surge protective devices, busbar systems, motor protection relays, and remote monitoring systems will help you to ensure a healthy and strong electrical system.

10 notes

·

View notes

Text

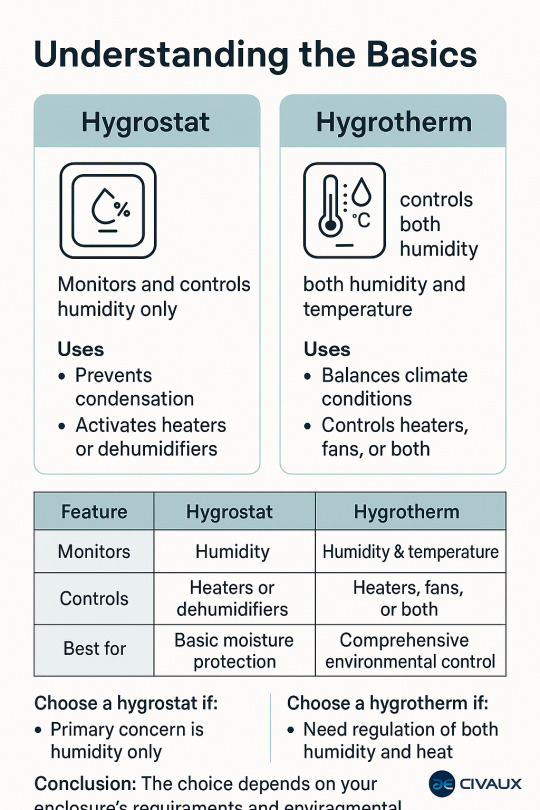

Hygrostat vs. Hygrotherm: Which Offers Better Moisture Management?

Moisture is one of the most damaging yet often overlooked threats to electrical enclosures and control panels. In high-humidity regions like the GCC, effective moisture management is critical to ensuring equipment longevity, operational safety, and uninterrupted performance. Two of the most widely used solutions in this space are hygrostats and hygrotherms. But which one is better for your application?

In this article, we compare hygrostats vs. hygrotherms in terms of functionality, performance, and suitability for different environments — helping you make the right choice for your electrical enclosure needs.

What is a Hygrostat?

A hygrostat is a humidity-regulating device that monitors the relative humidity inside an enclosure and activates connected equipment (like a heater or fan) when a preset humidity threshold is exceeded. It’s a single-function device focused purely on moisture control.

Key Functions:

· Monitors internal humidity

· Activates heaters or dehumidifiers to prevent condensation

· Simple and cost-effective solution for moisture problems

What is a Hygrotherm?

A hygrotherm is a dual-function device that combines the capabilities of a thermostat (for temperature) and a hygrostat (for humidity). It can monitor and control both parameters, ensuring balanced temperature and humidity regulation within the enclosure.

Key Functions:

· Simultaneous monitoring of temperature and humidity

· Activates heaters, fans, or filters based on combined conditions

Why Moisture Control Matters

In regions with high temperature fluctuations — like warehouses, factories, and outdoor panels in the Middle East — condensation can form inside enclosures. This can lead to:

· Corrosion of components

· Electrical short circuits

· Reduced equipment lifespan

· Safety risks for operators

Choosing the right controller ensures stable environmental conditions, reduces downtime, and cuts maintenance costs.

When to Use a Hygrostat

Choose a hygrostat if:

· Your enclosure operates in a relatively stable temperature range

· Your primary concern is humidity only

· You need a low-cost, targeted solution

· You’re upgrading older enclosures with basic needs

When to Use a Hygrotherm

Choose a hygrotherm if:

· Your environment experiences extreme heat and humidity (e.g., GCC summer months)

· You’re running sensitive electronics or automation panels

· You need proactive climate control for both heat and moisture

· You want to consolidate devices into a single, efficient unit

Conclusion: Which is Better?

Both hygrostats and hygrotherms are effective tools for enclosure climate control — but the better choice depends on your environmental conditions and system complexity.

· For basic, budget-friendly moisture protection: ✅ Go with a hygrostat.

· For comprehensive, long-term protection in critical systems: ✅ Invest in a hygrotherm.

Civaux Electric, we offer both hygrostats and hygrotherms with wide voltage range, compact design, and reliable performance — built to handle the GCC’s demanding climates.

#Hygrostat#Hygrotherm#Moisture management#Humidity control devices#Temperature and humidity regulator#Industrial climate control#electrical equipment#switchgears#electrical#panel#lowvoltage#dubai#united arab emirates

2 notes

·

View notes

Text

How High Voltage Switchgear Powers Smart Cities and Green Energy

As the world shifts toward sustainability and smart technology, the demand for efficient, safe, and intelligent power infrastructure is greater than ever. At the heart of this transformation lies high voltage switchgear—a critical component enabling the stable flow of electricity across urban centers and renewable energy systems.

Whether it’s a solar farm, wind power installation, or a smart city grid, high voltage switchgear ensures that electricity is distributed reliably, equipment is protected, and faults are isolated instantly. But what exactly does it do, and why is it so essential for the future?

Let’s explore how high voltage switchgear powers smart cities and green energy systems.

High Voltage Switchgear in Smart Cities

1. Ensures Grid Reliability in Urban Networks

Smart cities rely on interconnected, data-driven infrastructure—and electricity is the lifeline. High voltage switchgear acts as the backbone of urban grids by:

Managing complex power flows between multiple sources (solar, wind, grid, battery)

Isolating faults to prevent blackouts

Supporting rapid load switching during demand spikes

This helps maintain uninterrupted power supply to critical systems like traffic lights, hospitals, IoT devices, public transportation, and EV charging stations.

2. Enables Intelligent Control and Automation

Modern switchgear is equipped with smart sensors, communication interfaces, and remote operation capabilities. This allows city engineers and utilities to:

Monitor real-time power status

Predict and prevent faults

Optimize energy flow using automation

Such intelligent switchgear systems reduce response times, improve energy efficiency, and lower maintenance costs—making them perfect for dynamic, data-rich city environments.

3. Supports Renewable Integration

Cities are increasingly integrating solar panels, wind turbines, and microgrids. High voltage switchgear plays a vital role in:

Synchronizing variable energy inputs with the main grid

Controlling energy flow from renewable sources

Protecting the grid from surges or fluctuations

Without switchgear, managing decentralized and renewable inputs would be chaotic and risky.

High Voltage Switchgear in Green Energy Systems

1. Facilitates Clean Power Distribution

Green energy systems generate electricity from sustainable sources like sunlight, wind, and hydropower. High voltage switchgear is used at various stages:

In solar and wind farms to connect turbines/panels to transformers

In substations to step up/down voltages for safe transmission

In battery storage systems for controlled charging/discharging

It ensures clean power reaches homes and industries safely and efficiently.

2. Protects Expensive Renewable Infrastructure

Equipment in green energy plants—like inverters, batteries, and transformers—can cost millions. High voltage switchgear safeguards these systems by:

Cutting off power during faults

Preventing overloads and short circuits

Ensuring smooth switching between power sources

This reduces downtime and prolongs the lifespan of renewable assets.

3. Promotes Scalability and Future Expansion

As green energy demand grows, switchgear enables the modular expansion of renewable facilities. New solar panels or wind turbines can be integrated into the existing system without overhauling the entire setup. This is crucial for:

Scaling solar farms

Expanding wind energy projects

Connecting new EV charging hubs

Modern high voltage switchgear supports flexible and future-ready grid designs.

Benefits of High Voltage Switchgear in Smart & Green Systems

✅ Reduced Energy Waste Efficient switching and fault isolation minimize power loss.

✅ Sustainability Compliance Supports eco-friendly operations by replacing SF6 gas with greener alternatives.

✅ Remote Monitoring & Predictive Maintenance IoT and AI-driven diagnostics reduce outages and extend asset life.

✅ Lower Operational Costs Less downtime, fewer manual checks, and smarter controls mean more savings.

Real-World Applications

EV Charging Stations High voltage switchgear balances load and ensures safety as cities expand EV infrastructure.

Smart Substations Equipped with remote diagnostics and digital relays for next-gen power delivery.

Green Industrial Parks Powering clean-tech factories and data centers using wind and solar energy with reliable switchgear support.

The Future: Digital + Sustainable Switchgear

The next generation of high voltage switchgear will be:

Eco-Friendly: Using SF6-free insulation alternatives

Digitally Integrated: With real-time cloud monitoring

AI-Enabled: For predictive maintenance and fault analytics

Compact & Modular: For easy deployment in urban areas

As we build smarter, greener cities, high voltage switchgear is no longer optional—it’s mission-critical.

Conclusion

Smart cities and green energy systems can’t function without safe, reliable, and intelligent electrical infrastructure. High voltage switchgear plays a foundational role in this transition by enabling grid flexibility, protecting vital equipment, and integrating renewable sources into modern power networks.

As energy needs grow, so does the importance of upgrading to smart, sustainable high voltage switchgear—the unsung hero behind the future of power.

0 notes

Text

Best Quality Computer Power Cord Manufacturer – Concord Industries

In today’s digital world, the computer has become an essential part of both professional and personal life. From offices to educational institutions and homes, computers are relied upon for work, communication, entertainment, and more. However, one critical component that ensures the seamless functioning of a computer is often overlooked—the computer power cord. Without a high-quality power cord, even the most advanced computer can become vulnerable to power failures, short circuits, or hardware damage.

This is where Concord Industries plays a significant role as a leading manufacturer of the best quality computer power cords in India. With a reputation built on trust, reliability, and excellence, Concord Industries has become a preferred supplier for OEMs, electronics brands, and distributors looking for superior computer power connectivity solutions.

Why Is the Quality of a Computer Power Cord Important?

A computer power cord is responsible for connecting your device to the main power source. Any compromise in its quality can lead to:

Power interruptions

Overheating issues

Electrical shocks

Damage to internal components

Data loss due to sudden shutdowns

Therefore, choosing a best quality computer power cord is essential to ensure not only the longevity of the computer but also user safety and operational efficiency.

Concord Industries – Pioneers in Computer Power Cord Manufacturing

Concord Industries stands as a trusted name in the power cord manufacturing sector, offering high-performance computer power cords that meet global standards. The company combines innovation, advanced technology, and rigorous quality control to manufacture cords that guarantee safety, durability, and smooth power delivery.

Key Features of Concord’s Computer Power Cords:

Superior Insulation and Protection: Concord uses premium materials for insulation, providing protection against electric shocks, overheating, and voltage fluctuations.

Robust Build Quality: The cords are made with high-grade copper conductors, ensuring reliable conductivity and minimal power loss during transmission.

Compatibility: Concord’s computer power cords are compatible with a wide range of desktops, CPUs, monitors, printers, and other IT peripherals.

Safe and Durable Connectors: The connectors are engineered for a snug fit, ensuring stable connections without the risk of loose contacts or sparks.

Compliance with International Standards: Each power cord is manufactured following BIS, ISI, and other global electrical safety certifications, making them suitable for both domestic and export markets.

Customizable Solutions: Concord Industries offers customized lengths, plug types, and configurations to meet specific client and market needs.

Applications of Concord’s Computer Power Cords

Concord’s computer power cords are used in a variety of IT and electronic equipment, such as:

Desktops and CPUs

Monitors and displays

Printers and scanners

Servers and data systems

Routers, switches, and modems

Whether for home offices, corporate workstations, or industrial IT setups, Concord provides reliable power solutions tailored to diverse environments.

Why Choose Concord Industries?

Concord Industries has earned its reputation through decades of expertise, customer-focused services, and strict adherence to quality. Here’s why businesses and brands prefer Concord:

Experience and Trust: Decades of specialized experience in power cord manufacturing.

Advanced Technology: Modern manufacturing units with automated processes for precision and efficiency.

Rigorous Quality Testing: Every product undergoes multiple stages of inspection to ensure maximum safety.

Timely Deliveries: Efficient production and logistics for on-time bulk order fulfillment.

Competitive Pricing: High-quality products at industry-competitive prices.

Conclusion

In the world of computing, dependable power is essential. Concord Industries ensures that your computers and IT systems stay powered safely and efficiently with its best quality computer power cords. By focusing on durability, safety, and performance, Concord Industries has become a trusted partner for brands and businesses across India.

Choose Concord Industries for your computer power cord needs—where quality meets reliability.

Visit:- https://concordindustries.in/computer-power-cord-manufacturer/

0 notes

Text

Maintenance measures for NPK fertilizer production line equipment

In the fertilizer production industry, scientific maintenance of NPK fertilizer production line equipment not only extends equipment lifespan but also reduces downtime and lowers production costs.

1.Daily Checks and Cleaning

Before starting up each day, check that key components like mixers and granulators run smoothly, with no unusual noise or vibration. After shutdown, promptly clean out leftover fertilizer to prevent caking and corrosion. Regularly lubricate parts like conveyor belts and bearings to reduce wear.

2.Regular Maintenance of Key Equipment

Mixer: Inspect mixer blades for wear to avoid uneven mixing.

Fertilizer Granulator: Clean molds regularly to prevent clogging and ensure proper granule formation.

Dryer: Clean heat exchangers to maintain stable thermal efficiency.

Screener Machine: Check screen mesh integrity to avoid broken granules.

3.Electrical and Control System Maintenance

NPK lines rely on automated control systems. Regularly check sensors, PLC modules, and wiring connections to prevent electrical failures. Keep systems dust-proof and moisture-proof.

4.Seasonal Maintenance

During hot or humid seasons, strengthen cooling and anti-corrosion measures. In winter, protect against freezing to prevent pipes or equipment from cracking.

Scientific maintenance is core to efficient NPK fertilizer production line operation. Through standardized daily checks, scheduled upkeep, and professional servicing, companies can boost equipment reliability, ensure continuous production, and cut operating costs.

0 notes

Text

What Are Optocouplers, and How Can They Elevate Your Electronics Design?

Introduction to Optocouplers: The Essential Isolation Component

Optocouplers, commonly known as opto-isolators, are ingenious electronic devices designed to safely transfer signals between isolated circuits using light. These components protect sensitive electronic systems from high voltage, noise interference, and potential circuit failures, significantly improving reliability and performance.

Optocouplers primarily consist of:

Infrared LED (Emitter): Converts electrical signals into light.

Photodetector (Receiver): Converts received light back into electrical signals.

By providing electrical isolation, optocouplers safeguard delicate circuits, ensuring stable and safe operation.

How Do Optocouplers Function in Electronic Systems?

Understanding the working principle of optocouplers is crucial for their effective implementation. Their operation follows these simple steps:

An electrical input signal activates the internal LED.

The LED emits infrared light proportional to the input current.

The photodetector receives this infrared signal.

The detector converts the optical signal back into electrical output.

This method ensures that circuits on either side remain electrically isolated, reducing the risk of damage from voltage spikes and interference.

Why Use Optocouplers in Electronic Designs?

Optocouplers offer substantial benefits that enhance the performance, safety, and efficiency of electronic systems. Key reasons to choose optocouplers include:

High Voltage Protection: Optocouplers prevent voltage surges from reaching sensitive circuit components.

Noise Reduction: They effectively minimize electromagnetic interference, preserving signal integrity.

Safety Assurance: Provide critical isolation to protect equipment and operators from electrical hazards.

Increased Reliability: Ensure stable and consistent signal transmission under varying operating conditions.

Different Types of Optocouplers Available Today

Multiple varieties of optocouplers exist to cater to specific electronic applications. Familiarizing yourself with these categories can simplify the selection process:

Transistor Optocouplers:

Commonly used in general-purpose isolation applications.

Ideal for moderate-speed signal transmissions.

Darlington Optocouplers:

Utilize a Darlington transistor configuration for higher sensitivity.

Suitable for applications needing higher current gain and lower input current.

Triac Optocouplers:

Primarily used for switching and controlling AC loads.

Common in motor control, lighting dimmers, and AC-powered circuits.

High-Speed Optocouplers:

Engineered for rapid communication and digital interfacing.

Critical for high-frequency data transmissions and real-time control systems.

Practical Applications: Where Optocouplers Shine

Optocouplers are versatile devices extensively employed across diverse industries. Some prominent applications include:

Industrial Automation:

Programmable Logic Controllers (PLCs)

Robotic arms and automated machinery

Motor drives and motion controllers

Power Electronics:

Power supplies and battery chargers

High-voltage DC/AC converters

Solar inverters and renewable energy systems

Telecommunications and Networking:

Modems and routers

Telephone line isolation

Ethernet communication equipment

Medical Equipment:

Patient monitoring devices

Diagnostic imaging equipment

Laboratory instrumentation

Selecting the Best Optocoupler for Your Electronics Project

Picking the appropriate optocoupler can significantly impact your circuit’s reliability and efficiency. Essential considerations include:

Isolation Voltage: Choose devices with isolation ratings higher than the expected peak voltage.

Current Transfer Ratio (CTR): Opt for higher CTR values for better sensitivity and signal reliability.

Propagation Delay: Critical in digital communication; select fast optocouplers for high-speed data transmission.

Temperature Ratings: Ensure devices can withstand your application's thermal environment.

Best Practices for Effective Optocoupler Implementation

Proper use and installation of optocouplers can maximize their effectiveness. Here’s how you can optimize their performance:

Precisely regulate LED currents to ensure optimal light emission without excessive power dissipation.

Avoid excessive loads on photodetectors, ensuring consistent and stable operation.

Maintain short and isolated signal paths to minimize signal loss and interference.

Conduct periodic performance assessments, especially isolation resistance checks, to maintain reliability.

Current Innovations Shaping Optocoupler Technology

Continuous technological advancements enhance the performance and application potential of optocouplers. Notable trends include:

Ultra-Compact Designs: Optocouplers are increasingly miniaturized, fitting smaller, modern electronic devices.

Enhanced Speed and Bandwidth: Innovations focus on high-speed optocouplers for rapid data transmission and communication.

Energy Efficiency: New-generation optocouplers emphasize reduced power consumption, essential for battery-operated devices.

Integration in IoT and Smart Technologies: Optocouplers are integral to smart home devices, connected appliances, and IoT-based systems for reliable communication.

Overcoming Common Optocoupler Challenges

While optocouplers offer extensive benefits, users can occasionally face challenges. Here’s how to address common issues:

Signal Attenuation: Select devices with higher CTR and carefully design circuits to maintain signal integrity.

Temperature Variations: Opt for optocouplers with broad operating temperature ranges and use thermal management techniques.

Cost and Performance Balance: Analyze device specifications and choose options providing optimal balance between performance and budget.

Tips for Enhancing the Lifespan of Optocouplers

Maintaining optocouplers ensures their longevity and reliability in your electronic projects. Follow these maintenance guidelines:

Regularly inspect circuits for signs of overheating, wear, or abnormal signal behaviors.

Replace worn or damaged optocouplers promptly to avoid system downtime or circuit failures.

Adhere strictly to manufacturer recommendations regarding voltage and current limits to avoid premature degradation.

Conclusion: Why Optocouplers are Indispensable in Electronics

Optocouplers play a critical role in ensuring safe, efficient, and reliable electronic circuit operation. Their exceptional ability to isolate signals, reduce interference, and enhance circuit safety makes them indispensable across industrial, commercial, and consumer electronic applications. By carefully selecting appropriate optocouplers, adhering to implementation best practices, and keeping pace with technological advancements, you can significantly elevate your electronics designs, guaranteeing optimal performance, safety, and efficiency in your projects.

0 notes

Text

Signal & Stability: Capturing Data with Recorders and Shaping Power with Rectifiers

Where Real-Time Monitoring Meets Reliable Power Conversion

In today's automated industrial environments, real-time performance tracking and consistent power delivery are non-negotiable. Whether it's measuring key process variables or converting AC to DC for precision systems, Recorders and Rectifiers stand as foundational components in modern control and automation systems. At Dropship Automation Solutions, we provide high-precision devices that help industries collect, analyze, and regulate — with accuracy and resilience.

1. Recorders: The Eyes of Your System

📈 What is a Recorder? A recorder is an industrial device used to log, display, and monitor data such as temperature, pressure, voltage, or flow rate. Recorders are essential for maintaining traceability, quality control, and performance diagnostics across manufacturing and processing operations.

🔧 Types & Use Cases • Types: Paper Recorders, Digital Chart Recorders, Data Loggers, Multi-Channel Recorders • Applications: Pharmaceutical manufacturing, power plant monitoring, food processing compliance, HVAC analytics • Benefits: Accurate trend analysis, easy integration with SCADA/PLC systems, data backup, compliance-ready

🧠 Why Recorders Are Vital Modern automation demands visibility. Recorders provide it. By logging critical parameters in real time, they ensure regulatory compliance, process optimization, and early fault detection—enabling engineers to make smarter decisions without guesswork.

2. Rectifiers: The Backbone of DC Power Systems

⚡ What is a Rectifier? A rectifier is an electronic device that converts alternating current (AC) into direct current (DC). This is essential for machines and control systems that require stable, low-noise DC voltage to operate efficiently.

🔧 Types & Functions • Types: Single-phase, Three-phase, Half-wave, Full-wave, Bridge Rectifiers • Applications: Battery charging units, DC motor drives, power supplies for control panels, electroplating systems • Benefits: Stable DC output, compact design, thermal protection, high conversion efficiency

⚙️ Why Rectifiers Are Indispensable Most industrial controllers, sensors, and communication modules rely on DC power. Rectifiers ensure that this power is clean, uninterrupted, and appropriately rated for sensitive equipment. Their reliability is critical for minimizing system downtime.

🔄 Combining Recorders & Rectifiers in Industrial Systems

Example Application:

A rectifier supplies clean DC power to a control panel.

A recorder tracks panel voltage and load conditions over time.

When anomalies appear, alerts are triggered, allowing preventive maintenance before failure.

This synergy helps in maintaining both electrical health and historical traceability, a cornerstone of modern Industry 4.0 strategies.

✅ Empowering Your Automation with Precision Technology

At Dropship Automation Solutions, our recorders and rectifiers are selected for their industrial-grade durability, accuracy, and intelligent integration capabilities. Whether you're logging mission-critical data or ensuring consistent power flow, we supply tools engineered for performance under pressure.

🛒 Monitor Smarter, Power Safer

Ready to upgrade your automation systems? Get in touch with our technical experts for the best-fit solution:

📞 Call: +1 (234) 288-1755 📧 Email: [email protected] 📍 Visit: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

Entering the Solar Stop Sign Factory: Green Smart Manufacturing Protects Road Safety

In the global wave of advocating low-carbon environmental protection and smart transportation, solar stop signs have become an important part of the modern road safety system with their advantages of zero carbon emissions, autonomous power supply, and high visibility. And behind every reliable and durable solar stop sign, it is inseparable from the precision manufacturing of professional factories. Today, let us walk into a leading solar stop sign factory to explore how it injects a steady stream of power into global road safety with the concept of green smart manufacturing.

Green production base: harmonious coexistence with nature

From site selection to construction, this solar stop sign factory has always been based on the concept of "environmental protection first". The factory is located in the suburban industrial park and is surrounded by green belts. It not only effectively reduces the impact of production on surrounding residents, but also purifies the air and regulates the microclimate through vegetation. The factory adopts a fully enclosed production workshop equipped with advanced waste gas and wastewater treatment systems. The small amount of waste gas generated during the production process is discharged in compliance with the standards after multiple treatments such as activated carbon adsorption and ultraviolet disinfection; the wastewater is purified by the sewage treatment station to achieve the reuse of reclaimed water for greening irrigation and equipment cleaning in the factory area, truly achieving "zero wastewater discharge". In terms of energy use, the factory sets an example and adopts a large amount of clean energy. A large area of solar photovoltaic panels are laid on the top of the workshop, and the annual power generation can meet 30% of the factory's electricity demand. The remaining power is connected to the power grid to achieve "self-generation and self-use, and surplus power is connected to the grid". The lighting system in the workshop is all LED energy-saving lamps, and through intelligent sensing control, the lights are turned off when people leave, minimizing energy waste. Even the production equipment has been transformed for energy efficiency, reducing energy consumption by more than 20% compared with traditional equipment. This model of "using solar energy to make solar products" perfectly interprets the closed loop of green production, and also makes every solar stop sign that leaves the factory carry environmental protection genes.

Intelligent production line: a double breakthrough in precision and efficiency Stepping into the production workshop, the breath of automation and intelligence hits you. The factory has introduced a full-process intelligent production line, which has achieved highly automated operations from raw material processing to finished product assembly, which has not only greatly improved production efficiency, but also ensured the consistency of product precision. In the core component production area, the manufacturing of solar panels can be called "millimeter-level" precision engineering. Through fully automatic laser cutting equipment, silicon wafers are accurately cut into specified sizes with an error control of less than 0.1 mm; automatic welding robots complete the string welding of solar cells at a frequency of 3 times per second to ensure stable and efficient circuit connection. Each solar panel must undergo EL testing (electroluminescence testing), and high-definition imaging technology is used to check internal hidden cracks, cold welding and other problems. Unqualified products are directly eliminated to ensure the quality of core components from the source. The production of logo shells also demonstrates the advantages of intelligence. Using 3D modeling and CNC stamping technology, shells of different sizes and shapes can be quickly customized according to the traffic standards of different countries and regions. After the special engineering plastics are formed at high temperature by the injection molding machine, they immediately enter the automated spraying line, and the anti-ultraviolet coating is evenly covered by electrostatic spraying technology to ensure that the shell will not fade or crack during long-term outdoor use. In the assembly process, the robotic arm accurately grabs the solar panels, energy storage batteries, LED modules and other components, and completes the assembly according to the preset program. The whole process takes only 90 seconds, which is more than 5 times more efficient than manual assembly. The intelligent control system is the "brain" of the production line. It monitors the production data of each link in real time through the Internet of Things technology, such as equipment operating parameters and product test results. When the system finds that the parameters of a certain device are abnormal, it will immediately issue an alarm and automatically adjust to prevent unqualified products from flowing into the next process. At the same time, the system can also dynamically adjust the production plan according to the order volume to achieve flexible production. Small batch customized orders can be completed in as short as 48 hours to meet the urgent needs of customers.

Strict testing system: Make every sign stand the test "Our products must work normally in an environment of minus 40 degrees to plus 70 degrees, and must withstand heavy rain, typhoons, and sandstorms, so they must pass the most stringent tests." The words of the factory quality inspection person in charge reveal the special mission of the solar stop sign. To this end, the factory has established an industry-leading testing center equipped with more than ten types of professional testing equipment to conduct a comprehensive "physical examination" of each batch of products. Environmental simulation testing is one of the most challenging links. In the walk-in high and low temperature test chamber, the product must undergo an extreme temperature cycle test from -40℃ to 70℃. After 1000 hours of continuous operation, the performance attenuation rate must be controlled within 5%; the rain test simulates a heavy rain environment, with a rainfall of 100 mm per hour continuously washing the product for 24 hours to ensure that the shell sealing performance meets the standard and the internal circuit is not damp; in the dust test, the product is placed in a test chamber filled with quartz sand. After 8 hours of strong wind and dust impact, the light brightness and signal stability must still be maintained. In addition to extreme environmental testing, functional testing is also meticulous. The optical testing laboratory uses a spectrometer to measure the brightness, chromaticity and flickering frequency of LED lights to ensure that they meet the optical standards of international traffic signs. In the daytime, the visible distance of the sign is not less than 300 meters; at night, the light can penetrate fog for more than 150 meters. The battery performance test simulates different lighting conditions, records the charging efficiency and discharge time of the battery, and ensures that the sign can still work normally for more than 72 hours in continuous rainy weather. Each sign must also undergo vibration testing and impact resistance testing to cope with bumps and collisions during transportation and installation. Only products that pass all test items can obtain a factory certificate with a detailed test report. This "hard-working" testing system has enabled the factory's solar stop signs to pass certification in many countries and regions around the world, including the EU CE certification, the US FCC certification, and the China CCC certification, clearing the way for the product to enter the international market.

Humanized management: condensing the creative power of the team The core competitiveness of the factory lies not only in advanced equipment, but also in a professional and dedicated team. The factory implements the "people-oriented" management concept to create a comfortable working and growth environment for employees. The workshop is equipped with an intelligent ventilation system and a constant temperature device. The temperature is controlled at around 26℃ in summer and above 18℃ in winter, which effectively improves the stuffy or cold working environment of traditional factories. For positions with strong physical labor, the factory has introduced power-assisted robotic arms to reduce the labor intensity of employees and reduce the risk of work-related injuries. In terms of skill training, the factory has established a complete training system. New employees are required to participate in a three-month paid training after joining the company, covering equipment operation, quality standards, safety regulations, etc.; old employees regularly participate in technical upgrade training to learn how to operate new equipment and new processes. The factory also established a "Skill Innovation Award" to encourage employees to put forward production improvement suggestions. An old technician once proposed an optimization plan for the installation process of solar panels, which increased the assembly efficiency by 15% and saved nearly one million yuan in costs. The suggestion not only won a bonus, but was also included in the factory's standard operating procedures. Employee care is also meticulous. The factory is equipped with facilities such as employee restaurants, gyms, and reading rooms to provide convenient living services for employees; birthday parties, skill competitions and other activities are held every month to enhance team cohesion; shuttle buses are provided for employees who live far away to solve commuting problems. This humane management atmosphere has given employees a strong sense of belonging to the company and also provided personnel guarantees for the stability of product quality.

Conclusion: From factories to roads, guarding every trip When solar stop signs are installed at city intersections, rural roads, and around schools from this factory, they are not only the enforcers of traffic rules, but also the disseminators of green concepts. This factory takes green production as the cornerstone, intelligent technology as the engine, strict testing as the guarantee, and humanistic management as the link, integrating every bit of ingenuity into the product, allowing solar stop signs to shine all over the world, contributing real strength to reducing traffic accidents and reducing carbon emissions. If you are looking for a reliable partner for upgrading transportation facilities, you might as well take a look at such a factory - here, you can see not only an efficient production line, but also a persistence in quality, adherence to environmental protection, and deep concern for the safety of every road user. I believe that such a factory will provide the most solid support for your project, allowing green and safety to go hand in hand and illuminate every road ahead.

0 notes

Text

Driving Innovation: The Role of a Modern Power Supply Manufacturer in Today's Technology

In an increasingly connected and electrified world, power supply manufacturers play a vital role in ensuring that modern devices, machinery, and systems operate efficiently and reliably. From industrial automation to consumer electronics and renewable energy systems, every component that requires electricity depends on a stable and secure power source. As demand for smart technologies and sustainable energy solutions grows, power supply manufacturers are evolving rapidly to meet the dynamic needs of various industries.

A power supply manufacturer is responsible for designing, developing, and producing devices that convert electrical energy into usable forms for a wide range of applications. These products include AC-DC converters, DC-DC converters, uninterruptible power supplies (UPS), battery chargers, and custom-designed solutions. Their goal is to ensure consistent voltage and current flow to protect sensitive electronics and maintain system performance. The reliability and efficiency of these power supplies are crucial for everything from smartphones and medical devices to data centers and electric vehicles.

One of the key trends driving innovation in the power supply industry is energy efficiency and miniaturization. As space becomes more limited in compact electronics and mobile devices, manufacturers are focusing on smaller yet more powerful units. At the same time, there's a strong push toward achieving higher energy efficiency to reduce heat, save power, and meet stringent environmental regulations. Advanced power supply units today incorporate technologies like GaN (Gallium Nitride) or SiC (Silicon Carbide) to achieve greater power density and faster switching speeds.

Quality and safety are non-negotiable in the world of power supplies. Reputable manufacturers adhere to international standards and certifications such as ISO 9001, CE, UL, and RoHS to ensure their products meet global safety and environmental requirements. Rigorous testing procedures are conducted to evaluate performance under various conditions including load changes, voltage fluctuations, and temperature extremes. These standards help industries like healthcare, defense, and aerospace — where reliability can be a matter of life or death — trust in the performance of the power solutions they adopt.

Customization is another key area where modern power supply manufacturers add value. Many industries require tailored power solutions that match specific voltage requirements, environmental conditions, or form factors. Manufacturers work closely with engineers and designers to develop bespoke power supplies that integrate seamlessly with the end product. Whether it's a waterproof unit for outdoor telecom equipment or a high-voltage supply for industrial lasers, customization ensures optimal compatibility and performance.

In conclusion, a power supply supplier is more than just a supplier of electrical components — it is a critical enabler of modern technology. By focusing on innovation, energy efficiency, quality control, and customer-specific solutions, these manufacturers help power everything from our everyday gadgets to complex industrial systems. As the demand for smarter, greener, and more connected technologies continues to rise, power supply manufacturers will remain at the forefront of technological progress, quietly driving the systems that keep our world running.

0 notes

Text

Buy Lithium-Ion Batteries in Bahrain – AAGE International’s Smart Power Solutions

In today’s world of rapid technological advancements and growing energy demands, the need for reliable, high-performance energy storage has never been greater. Across industries and critical infrastructure in Bahrain, Lithium-Ion Batteries have emerged as the smart, efficient, and long-lasting solution for power storage and backup needs.

However, not all battery suppliers are created equal, and when it comes to sourcing premium Lithium-Ion batteries for non-automotive applications, businesses in Bahrain look beyond standard offerings. This is where AAGE International stands out - a trusted partner in delivering advanced energy storage solutions tailored for industrial, commercial, and critical infrastructure requirements.

Unlike typical car battery dealers, AAGE International specializes in providing Lithium-Ion batteries designed for sectors that demand uncompromised performance, reliability, and safety.

Why Lithium-Ion Batteries Are the Smart Choice for Bahrain’s Industries

Lithium-Ion batteries have revolutionized energy storage thanks to their superior energy density, long service life, and high efficiency. Their benefits extend far beyond portable electronics and electric vehicles; in fact, Bahrain’s industrial and infrastructure sectors rely heavily on Lithium-Ion batteries for critical operations.

Key Advantages of Lithium-Ion Batteries:

High Energy Density: Store more energy in a smaller footprint—essential for space-constrained facilities.

Longer Life Cycle: Designed for thousands of charge and discharge cycles, reducing replacement costs.

Fast Charging: Shorter recharge times minimize downtime and ensure operational continuity.

Low Self-Discharge Rate: Retains charge over extended periods, ideal for backup applications.

Minimal Maintenance: Requires little to no upkeep compared to older battery technologies.

Environmental Benefits: More energy-efficient and lower environmental impact than traditional battery systems.

Common Applications of Lithium-Ion Batteries in Bahrain

Lithium-Ion battery technology is transforming multiple industries in Bahrain, including:

1. Data Centers and IT Infrastructure

Reliable power is critical for servers, networking equipment, and backup systems. Lithium-Ion batteries provide consistent performance, ensuring uptime for data-intensive operations.

2. Telecommunications

With the need for uninterrupted connectivity, telecom towers and communication hubs use Lithium-Ion batteries for backup and energy stabilization.

3. Healthcare Facilities

Hospitals and laboratories depend on stable power for life-saving equipment. Lithium-Ion batteries ensure backup energy during outages, protecting critical care environments.

4. Renewable Energy Storage

Solar and wind energy projects require efficient storage solutions to manage energy fluctuations. Lithium-Ion batteries support grid stability and renewable energy integration.

5. Industrial Automation

Manufacturing operations depend on automation systems that require uninterrupted power. Lithium-Ion batteries help maintain productivity even during grid disruptions.

AAGE International – Bahrain’s Trusted Lithium-Ion Battery Partner

As the demand for high-quality Lithium-Ion Batteries grows, businesses must partner with suppliers who bring more than just products to the table. AAGE International has built a reputation for delivering intelligent, application-focused battery solutions tailored for Bahrain's unique industrial and infrastructure requirements.

What Sets AAGE International Apart:

1. Industry-Specific Expertise

AAGE International does not supply car batteries. Instead, their focus is on critical sectors like telecommunications, energy, healthcare, and industrial operations, providing customized solutions for specialized needs.

2. Comprehensive Product Portfolio

From small-scale installations to large energy storage systems, AAGE International offers a wide range of Lithium-Ion battery configurations to suit diverse operational requirements.

3. Quality and Safety First

All products meet international standards for performance, safety, and environmental responsibility, ensuring long-term reliability even in demanding conditions.

4. Tailored Energy Solutions

AAGE International provides end-to-end services, including:

Technical consultations

System design and engineering

Installation support

Preventive maintenance

Ongoing performance monitoring

Why Businesses in Bahrain Choose AAGE International for Lithium-Ion Batteries

Proven Reliability

AAGE International’s solutions have been implemented across Bahrain's most critical sectors, earning trust through consistent performance and expert support.

Customized Solutions

No two businesses are alike. AAGE International assesses each client's specific power requirements, designing tailored Lithium-Ion battery systems that optimize efficiency and reliability.

Future-Ready Energy Storage

As Bahrain’s economy grows and renewable energy adoption accelerates, AAGE International provides scalable energy storage systems that adapt to evolving needs.

Cost-Effective Investment

While Lithium-Ion batteries offer long-term performance, their upfront investment is significant. AAGE International’s expert guidance ensures maximum return on investment through optimized system design and longevity.

Supporting Bahrain’s Vision 2030 with Smart Energy Solutions

Bahrain’s Vision 2030 emphasizes economic diversification, technological advancement, and environmental sustainability. Reliable, efficient energy storage is essential to achieving these goals. AAGE International contributes to this vision by:

Supporting renewable energy projects with efficient battery storage

Providing backup power for digital infrastructure

Enabling healthcare and critical public services

Offering environmentally responsible, energy-efficient solutions

By aligning with Bahrain’s national development objectives, AAGE International plays a vital role in building a more resilient and sustainable future.

Selecting the Right Lithium-Ion Battery Supplier in Bahrain

Choosing a supplier for Lithium-Ion batteries is a strategic decision with long-term implications. Businesses should evaluate:

Technical Expertise: Does the supplier understand complex industrial power needs?

Product Quality: Are the batteries certified, safe, and durable?

Customization: Can solutions be tailored to specific operational requirements?

After-Sales Support: Is ongoing maintenance and performance monitoring provided?

AAGE International excels in all these areas, positioning them as one of Bahrain’s most trusted providers of advanced Lithium-Ion battery solutions.

Explore AAGE International’s Smart Power Solutions

Whether your organization needs energy storage for telecom networks, renewable energy projects, data centers, or healthcare facilities, AAGE International provides:

High-performance Lithium-Ion battery technologies

Expert system design and consultation

Professional installation and technical support

Reliable maintenance and monitoring services

To explore how AAGE International can power your business with advanced energy storage, visit AAGE International's website.

Conclusion

In Bahrain’s rapidly advancing industrial and infrastructure sectors, smart, efficient energy storage is not optional—it's a necessity. Lithium-Ion Batteries have proven to be the ideal solution for businesses that demand performance, safety, and long-term reliability.

For companies seeking more than just off-the-shelf battery products, AAGE International provides intelligent, customized energy solutions designed to meet the unique power demands of Bahrain's industries.

⚡ Power your business with advanced Lithium-Ion battery solutions. Learn more at AAGE International.

#batteries#battery#battery manufacturer#battery supplier#bahrain#branding#commercial#entrepreneur#lithium ion batteries#industrial

0 notes

Text

What are the applications of intelligent glue potting production line in the home appliance industry?

The intelligent glue potting production line is widely used in the home appliance industry. It mainly improves the sealing, shock resistance, thermal conductivity and structural strength of home appliances through automated, high-precision glue (such as sealant, thermal conductive glue, structural glue, etc.) dispensing and filling processes. The following are specific application scenarios and advantages:

1.Waterproof sealing treatment

Applied products: washing machines, dishwashers, water heaters, air conditioner outdoor units, etc.

Function: Filling glue in the joints of electrical housings, circuit boards, wiring terminals, etc. to prevent water vapor and dust from invading and improve the IP protection level.

Intelligent advantages: The visual positioning system automatically identifies the glue filling position, and the 3D path planning adapts to complex structures to avoid manual leakage or overflow of glue.

Vacuum potting technology

Inline vacuum potting machine: For example, the SEC-S400-ZL/ZHL ensures no air bubbles remain in the adhesive during potting through rapid vacuum extraction and high sealing performance, reducing leakage caused by bubbles.

Smart production line integration:

Vacuum potting production line: By integrating MES systems for data collection and uploading, it covers key data such as production quantities and equipment exceptions, enabling real-time monitoring of the potting process and timely resolution of stringing and leakage issues.

2.Fixation and protection of electronic components

Applied products: refrigerator control panels, microwave oven circuits, smart home appliance main control modules, etc.

Function: Bond and fix components on PCB boards, or perform overall potting protection to avoid short circuits or desoldering caused by vibration and moisture.

Intelligent advantages: High-precision piezoelectric valve controls micro-dispensing to avoid glue contamination of sensitive components; real-time monitoring of glue volume to ensure consistency.

3.Heat conduction and heat dissipation management

Applied products: LED TV backlight module, power adapter, induction cooker heat dissipation components.

Function: Fill with thermal conductive silicone to transfer the heat of heating components (such as power chips) to the heat sink to extend life.

Intelligent advantages: Temperature sensor feedback adjusts the glue thickness to ensure thermal efficiency; two-component glue is automatically mixed and proportioned.

4.Structural bonding and shock absorption

Applied products: refrigerator compressor fixing, vacuum cleaner motor assembly, fan blade bonding.

Function: Replace screws or welding, reduce noise and vibration, and reduce weight.

Intelligent advantages: The robot arm operates at multiple angles to adapt to complex assembly lines; the force control system ensures the uniformity of the glue layer.

5.Aesthetics and surface treatment

Applied products: smart speaker edge sealing, oven panel bonding.

Function: Hide the seams and improve the appearance texture; some transparent glue is used for decorative packaging (such as LED indication area).

Intelligent advantages: Laser ranging accurately controls the width of the glue line to avoid burr problems caused by manual operation.

The core advantages of intelligent glue pottling:

1.Efficiency improvement: 24-hour continuous operation, the speed can reach 3-5 times that of manual operation.

2.Stable quality: reduce defects such as bubbles and glue breakage, and the glue utilization rate reaches more than 95%.

3.Flexible production: quickly switch the glue filling scheme of different home appliance models through software.

4.Data traceability:record process parameters (such as glue quantity, temperature, time), and support quality traceability.

Typical case

Air conditioning motor potting: fully automatic line completes coil thermal conductive glue filling, and the temperature resistance is increased to more than 150℃.

Smart toilet circuit board: automatic spraying of three-proof glue (moisture-proof, mildew-proof, and salt spray-proof), the failure rate is reduced by 60%.

Washing machine door seal: multi-axis robot cooperates with visual system to realize precise glue coating on three-dimensional curved surfaces.

Future trends

1.AI optimization:analyze the glue curing effect through machine learning and dynamically adjust parameters.

2.Green process: cooperate with low-VOC environmentally friendly glue to meet RoHS standards.

3.Modular design: seamlessly integrated with home appliance assembly lines, supporting small batch customized production.

Intelligent glue filling technology is becoming a key link in the intelligent manufacturing of home appliances, especially in high-end, waterproof and high-reliability products.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

0 notes

Text

DEIF Controller: Precision Control for Power Management Systems

Introduction: The Need for Intelligent Power Control

In today’s energy landscape, efficient and reliable power management is essential for industries, data centers, ships, and renewable energy systems. One of the most trusted solutions in this field is the DEIF controller. Known for its precision, flexibility, and robust engineering, the DEIF controller is widely used to manage and automate power generation, distribution, and synchronization across multiple sectors.

What Is a DEIF Controller?

A DEIF controller is an advanced control unit used in electrical systems to monitor, protect, and control power equipment such as generators, engines, and switchgear. Developed by DEIF, a global leader in control and instrumentation solutions, these controllers are engineered to meet the demands of complex power systems.

Whether you need to manage a single generator or a multi-generator setup with utility backup, DEIF controllers offer scalable solutions that ensure stability, safety, and efficiency.

Key Features of DEIF Controller

The DEIF controller is equipped with a host of features that make it one of the most reliable tools in power management:

Auto-Synchronization: Ensures seamless power transfer between generators or from generator to grid, minimizing downtime.

Multi-Generator Control: Ideal for parallel operation of multiple generators, enhancing load sharing and fuel efficiency.

User-Friendly Interface: DEIF controllers come with intuitive displays and remote monitoring options for real-time control and data logging.

Comprehensive Protection: Includes built-in alarms, circuit protection, voltage/frequency regulation, and fault diagnostics.

Customizable Programming: Users can configure control logic to suit site-specific applications using DEIF’s flexible software platforms.

These features allow the DEIF controller to deliver unmatched control in diverse environments—from offshore oil rigs to solar farms and utility substations.

Applications of DEIF Controller

The DEIF controller is widely used in various sectors due to its adaptability and reliability:

Marine and Offshore: Controls shipboard generators, thrusters, and emergency systems with high safety standards.

Industrial Power Plants: Ensures balanced and stable operation of diesel or gas-powered generators in manufacturing and processing plants.

Renewable Energy: Integrates with wind, hydro, and solar power systems for smart grid synchronization.

Data Centers and Hospitals: Provides uninterrupted power management for critical infrastructure.

No matter the complexity of the installation, the DEIF controller simplifies power automation while ensuring system security and performance.

Why Choose a DEIF Controller?

Choosing a DEIF controller means investing in reliability, performance, and future-ready technology. With a global presence and proven track record, DEIF products are trusted by power engineers, OEMs, and energy managers across the world. Their technical support, regular firmware updates, and long-term product life cycle make them a valuable addition to any power system.

Conclusion

The DEIF controller stands as a symbol of innovation and dependability in the world of power control and automation. With its robust features, broad application range, and intuitive design, it helps businesses and facilities manage their energy systems with confidence and precision. As the world continues to move toward smarter, more connected energy solutions, DEIF remains a trusted partner in powering progress.

0 notes

Text

The BHEL 69203PY1A Power Supply Module UN0661 A-P is a high-performance industrial power module designed for reliable and efficient energy distribution. Engineered by Bharat Heavy Electricals Limited (BHEL), this unit ensures stable voltage output and protection for sensitive automation equipment. Ideal for heavy-duty applications, it offers long operational life and easy integration into control systems. With its compact design and robust build, it supports uninterrupted operations in demanding environments. Perfect for power plants, process industries, and automation panels. Trust Auto2mation for genuine BHEL modules that deliver safety, stability, and superior performance in industrial automation systems.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Bhel#Power Supply

0 notes

Text

Power Quality Equipment Market Drivers Shaping Global Demand and Innovation

The global demand for reliable and uninterrupted electricity has never been higher, driving significant investments in the power quality equipment market. As industries, commercial facilities, and utilities aim to mitigate power disturbances and equipment malfunctions, the market for solutions like voltage regulators, surge protectors, UPS systems, and harmonic filters continues to grow. Several drivers are fueling the widespread adoption of power quality equipment across sectors.

Key Drivers Fueling the Power Quality Equipment Market

1. Rapid Industrialization and Urbanization

One of the primary factors propelling the demand for power quality equipment is the surge in industrial activities and urban expansion, especially in emerging economies. Modern industries rely heavily on automation, precision machinery, and digital technologies that are highly sensitive to voltage fluctuations, power surges, or outages. To protect critical assets and maintain operational continuity, industries are increasingly investing in advanced power quality solutions.

Additionally, urban infrastructure projects such as smart cities, metro rail systems, and high-tech buildings require stable and high-quality power supply, further stimulating market growth.

2. Rising Integration of Renewable Energy Sources

The global transition toward renewable energy sources like solar, wind, and hydropower introduces variability and unpredictability to the power grid. Fluctuations in generation can cause voltage instability, frequency deviations, and harmonic distortions. Power quality equipment plays a crucial role in mitigating these effects and ensuring seamless integration of renewables into the grid.

As countries push to meet sustainability targets and reduce carbon emissions, investments in renewable infrastructure—and consequently, power quality management—are increasing substantially.

3. Growing Emphasis on Energy Efficiency and Cost Reduction

Industries and commercial establishments are under constant pressure to improve energy efficiency, reduce operating costs, and enhance productivity. Poor power quality can lead to increased energy losses, premature equipment failures, and production downtime. Power quality equipment helps optimize electrical performance, lower energy consumption, and extend the lifespan of machinery.

As organizations strive for operational excellence and competitive advantage, the adoption of power quality solutions is becoming a strategic priority across sectors such as manufacturing, data centers, healthcare, and transportation.

4. Complex and Aging Electrical Infrastructure

In many developed regions, the electrical infrastructure is aging, leading to higher incidences of power quality issues like voltage sags, spikes, and transient disturbances. Modernizing legacy grids with advanced power quality equipment is essential to maintaining reliability and meeting the demands of digitized economies.

Simultaneously, emerging markets are investing in new grid infrastructure with built-in power quality management capabilities, ensuring resilience from the outset. Both scenarios create ample growth opportunities for power quality equipment manufacturers and solution providers.

5. Regulatory Standards and Compliance Requirements

Governments and regulatory bodies worldwide have implemented strict standards for power quality to protect critical infrastructure, ensure consumer safety, and support economic productivity. Compliance with these standards often necessitates the deployment of power quality monitoring and correction equipment.

For instance, standards such as IEEE 519 for harmonic control or IEC standards for voltage quality push utilities, industries, and commercial entities to invest in high-performance power quality solutions.

Technological Advancements and Innovation

The market is also witnessing rapid technological evolution, with manufacturers introducing smarter, more efficient, and IoT-enabled power quality devices. Integration with real-time monitoring systems, data analytics, and automation allows for predictive maintenance, fault detection, and optimized power management.

Advanced power quality solutions are increasingly leveraging AI and machine learning algorithms to forecast disturbances and implement corrective actions autonomously, minimizing downtime and improving energy reliability.

Conclusion

The power quality equipment market is poised for sustained growth as industries, utilities, and governments recognize the critical role of power stability in supporting economic development, renewable energy integration, and technological progress. Driven by factors such as industrialization, energy efficiency goals, grid modernization, and regulatory frameworks, the demand for reliable power quality solutions will continue to expand across global markets. Manufacturers focusing on innovation, digital integration, and sustainable solutions are well-positioned to capitalize on emerging opportunities in this evolving landscape.

0 notes

Text

Transforming Spaces with Innovation: Smart Home & Office Automation in Kochi

In today’s tech-driven world, comfort, security, and efficiency are no longer luxuries — they’re expectations. Whether it’s your home or workplace, automation is revolutionizing how we interact with our environment. From intelligent lighting to smart security systems and energy-efficient controls, the shift toward smarter living and working is undeniable. If you’re looking to upgrade, finding the best smart home automation company in Kochi is your first step toward a seamless and connected lifestyle.

Elevate Everyday Living with Home Automation Solutions

Smart homes are becoming increasingly popular in Kochi and across Kerala. With tailored home automation solutions, homeowners can control lighting, temperature, appliances, entertainment systems, and security — all from a smartphone or voice assistant. These systems are designed for convenience and can be customized for every lifestyle and budget.

Imagine walking into your home as lights adjust automatically, the air conditioner sets to your preferred temperature, and music begins to play — all without lifting a finger. That’s the power of smart automation.

Why Kochi Chooses the Best in Smart Home Technology

The demand for smart homes is growing, and so is the need for reliable, innovative service providers. The best smart home automation company in Kochi stands out by offering end-to-end solutions — from consultation and design to installation and support. They bring together top-tier products and expert technicians to ensure seamless integration of technology into your home.

Whether you’re upgrading an existing space or building a new one, a trusted provider ensures your home is not only smarter but also future-ready.

Electrical Voltage Services in Kochi: A Foundation for Safety

Automation relies heavily on stable and safe electrical infrastructure. That’s where electrical voltage services in Kochi come in. Proper voltage regulation and surge protection are essential to protect sensitive smart devices and appliances. Skilled technicians ensure your home or office meets all safety standards while optimizing energy efficiency.

Voltage management also prevents equipment damage, reduces electricity bills, and contributes to the longevity of your automation systems.

Boost Productivity with Office Automation

It’s not just homes that benefit from automation — office automation is changing the way businesses operate. From automated lighting and climate control to smart conference rooms and access control, offices in Kochi are embracing intelligent systems to enhance productivity and reduce operational costs.

Smart offices foster a more collaborative and efficient environment, saving time and resources while providing better control over building management.

Conclusion

Whether you want a more comfortable home, a secure office, or safer electrical infrastructure, the future lies in automation. Partner with the best smart home automation company in Kochi to experience advanced home automation solutions, ensure safety through electrical voltage services in Kochi, and elevate your workspace with office automation. The smart choice today builds a smarter tomorrow.

0 notes