#joint design

Explore tagged Tumblr posts

Text

Dowel Bars or Expansion Joints? What Engineers Recommend

Dowel bars, bar dowels, and TMT bar manufacturers—those terms may sound like technical jargon; however, they play an important position in production choices. Especially with regard to pavement and slab work, the choice between dowel bars and expansion joints is not just technical—it is in your price range, structural, and long-term. While bar dowel systems often promise alignment and load transfer, TMT bar manufacturers increasingly provide variants to suit structural demands with precision.

Awareness Stage: Understanding the Basics

What Are Dowel Bars?

These are solid steel bars used to transfer load across concrete joints without restricting horizontal joint movement. They basically "bridge" the 2 slabs, allowing load to pass while accommodating thermal expansion.

Expansion Joints—What Do They Do?

Expansion joints are deliberate gaps among slabs to take in the pressure from temperature modifications, floor shifts, or load. Unlike dowel bars, they’re meant to create space, not transfer load.

Consideration Stage: The Performance Battle

Durability and Longevity

When it comes to extending the life of concrete slabs, dowel bars steal the spotlight. They significantly reduce joint damage by ensuring smooth load transfer. Bar dowel setups especially help avoid cracking and settlement at joints—common problems seen when using only expansion joints.

Installation and Cost Efficiency

At first glance, expansion joints appear cheaper. But dig a little deeper—reduced maintenance, minimal surface cracking, and fewer repair cycles with dowel bars actually save money in the long run.

Structural Stability

Engineers constantly highlight one truth: structural integrity matters. Using bar dowel systems improves alignment of slabs, especially in industrial floors and highways. While expansion joints allow movement, they often compromise long-term stability if not perfectly placed.

Decision-Making Stage: Why Dowel Bars Often Win

Engineering Preference

Most engineers recommend dowel bars over expansion joints for heavy-duty structures. The ability of bar dowel setups to handle repetitive loads without displacing makes them ideal for pavements, bridges, and warehouse floors.

Product Availability and Manufacturer Support

Thanks to innovations by way of leading TMT bar manufacturers, dowel bars at the moment are available in custom sizes, coatings, and finishes. This customization allows project-specific performance, which expansion joints often lack.

Sustainability Factor

Less cracking means fewer repairs. Fewer repairs mean less material waste. That makes dowel bars a smart pick for those looking at eco-friendly construction without sacrificing strength.

Conclusion

Choosing between dowel bars and expansion joints isn’t about picking a side—it’s about understanding the needs of the structure. For load-bearing reliability, longer life, and minimal maintenance, dowel bars backed by top TMT bar manufacturers and bar dowel configurations come out on top. Engineers aren't just recommending them—they're depending on them.

FAQs

1. Are dowel bars reusable in other structures? No, once embedded in concrete, dowel bars aren’t reusable due to their fixed placement and bond.

2. Do dowel bars rust over time? Yes, if not coated properly. Most manufacturers offer epoxy-coated dowel bars to prevent corrosion.

3. Can expansion joints and dowel bars be used together? Yes, some high-movement structures combine both to balance load transfer and expansion needs.

4. How do dowel bars affect road performance? They prevent joint faulting and maintain smoothness, critical for highways and industrial pavements.

5. What sizes are available for dowel bars? Sizes vary, but TMT bar manufacturers typically offer 12mm to 38mm diameters, tailored per project.

#dowel bars#expansion joint#concrete joints#joint spacing#load transfer#road joints#slab joints#joint design#steel dowels#bar spacing#joint repair#joint options#slab cracks#bridge joints#expansion gap#slab movement#joint system#joint choice#pavement joint#engineer pick

0 notes

Text

How Dowel Bars in Rigid Roads Minimize Expansion Joint Failures

Dowel bars in rigid pavement function as important load transfer mechanisms that dramatically enhance the overall performance and sturdiness of concrete roadways. When properly established across expansion joints, these unassuming metallic additives prevent some of the most common pavement failures that plague transportation infrastructure projects. Understanding their role and proper installation can save significant costs and complications for road construction projects of all sizes.

The Hidden Heroes of Concrete Road Construction

Concrete roads, unlike their flexible asphalt counterparts, require careful planning to accommodate the natural expansion and contraction that occurs with temperature changes. Without proper accommodation for these movements, concrete slabs develop stress cracks, uneven surfaces, and premature deterioration.

Expansion joints allow essential movement, but they create a structural weak point unless properly reinforced. This is where dowel bars in road construction demonstrate their value.

Technical Function and Performance Benefits

When heavy vehicles approach an expansion joint, the leading concrete slab experiences downward deflection. Without dowel bars in rigid pavement, the trailing slab remains undeflected, creating a momentary lip or step at the joint. This repeated deflection difference leads to

Edge crumbling at joint faces

Pumping of subbase materials

Water infiltration issues

Progressive joint deterioration

Reduced ride quality

Properly installed dowel bars transfer approximately 40-50% of the load across the joint, significantly reducing differential deflection. This load-sharing capability maintains surface alignment while still allowing the critical horizontal movement that prevents thermal cracking.

Installation Considerations for Maximum Performance

The effectiveness of dowel bars in road construction depends heavily on proper installation practices. Key considerations include:

Alignment and Spacing

Misaligned dowel bars restrict joint movement, defeating their purpose and potentially causing worse damage than if they were absent. Specialized installation equipment helps ensure perfect horizontal alignment.

Corrosion Protection

Since dowel bars operate in harsh environments with water, salt, and constant vibration, corrosion protection is critical. Epoxy-covered and stainless-steel options provide advanced longevity despite their higher initial cost.

Diameter and Length Selection

Engineers select dowel dimensions based on pavement thickness, expected loads, and subbase conditions. Undersized dowels fail to transfer loads effectively, while oversized options waste materials without providing proportional benefits.

The Connection to Other Components

Dowel baskets secured with binding wire provide the most reliable method for ensuring proper dowel placement before concrete pouring. This binding wire must be strong enough to maintain position during the intense vibration of concrete placement but thin enough not to create weak points in the structure.

Quality binding wire resists corrosion and maintains basket integrity throughout the installation process. For projects in coastal regions or areas with frequent road salt application, stainless steel binding wire offers additional protection against premature failure.

Economic Implications of Proper Joint Design

The initial investment in quality dowel bars in rigid pavement and proper installation techniques pays substantial dividends throughout the pavement lifecycle. Research indicates that properly designed and installed dowel joints can:

Extend pavement life by 25-40%

Reduce maintenance expenses by up to 60%

Improve ride quality measurements

Minimize vehicle damage claims

The binding wire used during installation represents a minimal portion of the overall project budget but plays an outsized role in ensuring dowel effectiveness. Premium binding wire costs marginally more than standard options but significantly reduces installation problems.

Making Informed Choices

When selecting materials for rigid pavement projects, the quality and proper specification of dowel bars deserve careful attention. While material costs for premium dowel systems might increase initial budgets by 3-5%, the lifecycle cost benefits make them the economically superior choice.

For contractors and transportation departments focused on long-term performance, investing in proper dowel bars in road construction, quality binding wire, and precision installation provides the most cost-effective path to durable, high-performing concrete pavements with minimal expansion joint failures.

#dowel bars#rigid roads#expansion joints#joint failure#road joints#pavement bars#load transfer#joint cracks#bar spacing#road durability#highway joints#road cracks#bar alignment#joint support#cement roads#bar function#rigid pavement#joint design#road repair#bar benefits#4o

0 notes

Text

patty

12K notes

·

View notes

Text

Doll girls & they’re all roommates. Which one’s ur fave?

#ball jointed doll#clockwork#doll girl#robot girl#android#transfem#yuri#art#character design#artists on tumblr#the bottom right is just a normal girl but she’s one of the dolls that’s the joke

6K notes

·

View notes

Photo

lift

#murder drones#jessa#serial designation j#tessa elliot#tessa james elliot#dagoi au#ripping royals#my art#art#dying and getting over it#forgetting the new body she is in and subsequently popping an arm out of the shoulder joint

2K notes

·

View notes

Text

Was randomly reminded of my old spidersona from 2023 so here is SpiderTikki who is too afraid of heights and other acrobatics to function as a spiderperson, but somehow their body always seems to move on its own and do the right things while they scream through the entirety of it.

This is your cue to share your spidersona and why they're a loser.

#spidersona#across the spiderverse#spiderman#across the spiderverse fanart#my spidersona#character illustration#character design#illustration#comics#her joints are creaking#spidey senses more like panic attack#spidertikki#oc#self insert

687 notes

·

View notes

Text

people already make so much stuff of him as spinel so might as well go the full mile on the su movie plotline. Fuck you *factory resets your shmilk*

#crk#cookie run kingdom#shadow milk cookie#pure vanilla cookie#fount of knowledge#mine#thius baby fount is joint custody with oomf kye#(as in they did 85% of the work on the design and i meanwhile am just hopelessly over-attached to him)#Look at ihm. Look at my son. Look at how whimsical he used to be. Cry. Start crying.

1K notes

·

View notes

Text

Putting him in the blank void

#malevolent#arthur lester#putting him in the torture labyrinth again#aka my own personal torture labyrinth - color practice#I really need to stop using add glow layer#it’s like sweetener it feels good in the moment but goddamn there are better ways to do it#gonna hunker down and get a Kayne design next#trying out nudging my style in some direction#what direction? not even god knows#he’s so pathetic little wooden jointed doll to me

344 notes

·

View notes

Text

Witchtember 20. Doll

#fantasy#art#fantasy art#illustration#character design#bunny#rabbit#doll#bjd#ball jointed doll#frills#cute#soft#albino#albino bunny#albino rabbit#witchtember#witchtember2024#thiwitchtember

819 notes

·

View notes

Text

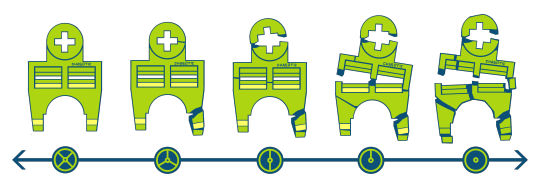

I'VE HAD AN IDEA FOR A HEALTH BAR

1K notes

·

View notes

Text

Cody surrounded by family and the people he loves, because that is what he deserves

#commander cody#obi wan kenobi#anakin skywalker#ahsoka tano#clone trooper jesse#captain rex#clone trooper boil#clone trooper waxer#arc trooper fives#arc trooper echo#coday#cody day 2224#cody my beloved#codywan#cody deserves all the happiness he can get and I think he's the happiest when he's with his family#so here you have a nice time to chill by the beach after a joint mission with 501st#I will learn to design better clothes at some point I promise :'D#these are so stupid#but I didn't want to spend overly long with this one and the multiple characters already gave me a headache hahaha#I love them all so much#fives you'll regret whatever you're going to do#though Anakin's totally there for it#my arts

2K notes

·

View notes

Text

What Are Dowel Bars and Why Do Builders Use Them?

Dowel bars represent one of the most essential yet often unnoticed additives in present-day creation. These specialized metallic reinforcement elements serve as crucial load transfer gadgets in concrete pavements, slabs, and structures. When properly mounted, these unassuming steel rods significantly decorate structural integrity and amplify the lifespan of concrete installations throughout residential, commercial, and infrastructure projects.

Functionality of Bar Dowels The construction industry is based closely on those cylindrical metal elements to create stronger connections among adjoining concrete segments. A traditional bar dowel includes easy, round metallic that permits mild horizontal movement even as it prevents vertical displacement among concrete sections. This apparently easy function will become critical in preventing not unusual concrete screw-ups like cracking, faulting, and untimely deterioration that plague poorly designed systems.

Thermal Stress and Flexibility Concrete naturally expands and contracts with temperature adjustments, creating pressure that could cause cracking and structural issues. Bar dowel installations mitigate those issues by way of allowing adjacent concrete sections to transport horizontally while keeping vertical alignment. This managed flexibility proves specifically critical in roadways, business floors, and outdoor concrete packages in which temperature fluctuations and heavy masses create regular strain on the shape.

Quality and Manufacturing Considerations Quality subjects notably while selecting those components. Leading TMT bar manufacturers produce dowel bars that meet rigorous engineering specs for power, dimensional accuracy, and corrosion resistance. These specialized metal elements undergo precise production approaches to make sure they deliver constant performance underneath worrying conditions. The distinction between premium and substandard products becomes evident over the years as systems face the test of environmental stressors and continuous usage.

Installation Advancements Installation techniques for bar dowel systems have evolved considerably. Modern strategies encompass dowel bar baskets that make certain best alignment earlier than concrete pouring and dowel bar retrofitting for existing pavements with deteriorating joints. These advanced strategies maximize the effectiveness of the weight switch gadget and enlarge pavement lifespan drastically in comparison to non-doweled alternatives.

Economic and Performance Benefits The financial blessings of nicely implemented dowel bars increase a ways beyond their initial price. By dispensing loads more successfully throughout concrete sections, these factors reduce preservation requirements and prevent premature disasters. Many TMT bar producers now provide specialized coatings and substances that, in addition to decorating sturdiness and performance, make those additives even more greatly treasured in difficult environments wherein moisture or chemical exposure threatens steel integrity.

Application in Large-Scale Infrastructure For infrastructure projects like highways and airport runways, particularly engineered bar dowel systems have come to be widespread exercises amongst forward-thinking groups and contractors. These essential additives permit heavy automobiles to transition easily throughout concrete joints without developing the uncomfortable bumps drivers experience on poorly built roadways.

Choosing the Right Dowel Bars Builders should consider numerous elements while deciding on dowel bars: diameter, length, spacing, cloth grade, and defensive coatings all impact overall performance. Premium products from installed TMT bar producers typically feature consistent dimensional tolerances, suitable strength traits, and defensive remedies that save you from corrosion and binding.

Innovation in Dowel Design The production panorama continues evolving, with innovative bar dowel designs addressing specific utility-demanding situations. Square, elliptical, and plate dowels have emerged along with traditional spherical options, each imparting specific blessings for unique eventualities. Regardless of design variations, the fundamental purpose stays regular: growing powerful load switches while accommodating movement among concrete sections.

Conclusion Understanding dowel bars and their essential role in concrete production empowers challenge planners to make informed selections that beautify structural overall performance and toughness. By choosing suitable structures from legitimate providers and ensuring proper installation techniques, developers can drastically improve concrete's overall performance while lowering lifetime renovation fees—turning in higher prices for customers and growing greater sustainable infrastructure for communities.

#Dowel Bars#Concrete Bars#Steel Dowels#Road Joints#Joint Stability#Load Transfer#Bar Placement#Rebar vs Dowel#Dowel Uses#PCC Joints#Concrete Tips#Dowel Purpose#Dowel in Roads#Slab Dowels#Dowel Function#Bar Spacing#Steel Rods#Slab Cracks#Dowel Role#Joint Design

0 notes

Text

Full robo design detail for Edgar

What a cutie pie

The way his face looks was inspired by very talented @bigintorobotsrightnow !! I just love how cute his eyes were drawn!

Lineart:

#edgar electric dreams#electric dreams#ed1984#myart#techtum#objectum#object head#digital art#fanart#my art 2024#full render#robot art#robots#fan design#some of this prolly doesn't make sense mechanics wise#so my bad for that#still doing research#gonna stick to a simpler design after this#sassy puter right here#full of sass and champagne#hes feelin very cvnty right now#attitude and walk off#i forgot a ball joint ill update the pic in a bit 😭😭#edgar#edgrrr ;]

574 notes

·

View notes

Text

learn the mammals with the help of dalle-3!

more

#dalle3#chatgpt#ai generated#mammal#this is a joint project in which chatgpt4 is designed to call on dalle3 when i ask for an image#chatgpt always changes my prompt to make it “better”#but dalle3 is to blame for all the misspellings

1K notes

·

View notes

Text

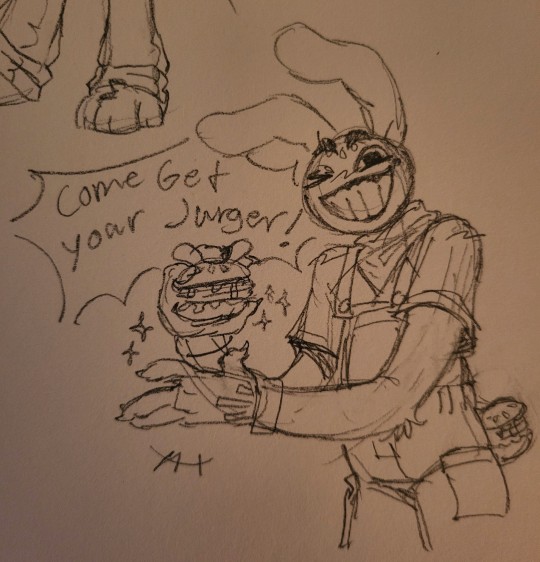

Au where Jurger is Jax and Jax is Jurger.... ????? Idk man i just wanted to design another Jax

#i got my Jurger the other day and thjs is the result😭#me when im normal !!!!#very normal...#anyway#Jurger my beloved. i love him#im obsessed with his lil bandana that i gave him#in this silly lil au he owns a burger joint#he hates managing it though#but caine... yk hshhrr DOESNT LET HIM CATCH A BREAK🥀🥀#i wanna design the others too to have their own lil food themed places#but for now im fixated on this guy.....#hes perfect to.me#i posted him on twitter and my oomfs responded with like a thousand comments i love them#jurger#tadc#tadc jax#jax tadc#the amazing digital circus#tadc au#idek man#fast food.... au ..????#my art#jax#fyp#the amazing digital circus art#the amazing digital circus fanart#tadc food au

203 notes

·

View notes

Text

woe........ emo be upon ye.....

#postcanon ashe :]]]] i like my design for him sooooo much its so fun i think... ok metalhead!#finally getting around 2 fd signifiers latest vid let me tell u. such a fucking hard video essay to not get distracted and just stop drawin#& watch every five seconds.#anyway. in my head he keeps the wings & they mess w/ his balance & stability immensely & are also fucking heavy. and also his joints r just#shot from a year of the trickster etc.........#mine#ashe winters#prime defenders#pd lb#esquisse

636 notes

·

View notes