#lab testing instruments manufacturer in India

Explore tagged Tumblr posts

Text

Discover Effective Lab India, a top lab testing instruments supplier and manufacturer in India, offering high-quality solutions for all your testing needs.

1 note

·

View note

Text

Use of Melt Flow Index Tester in Plastic Research Labs

Source of Info: https://www.perfectgroupindia.co.in/blog/use-of-melt-flow-index-tester-in-plastic-research-labs

Introduction

An important instrument in plastic research labs for analyzing how plastic flows when melted under specific conditions is the Melt Flow Index Tester. This tool makes it simpler for researchers to identify whether different plastic materials behave well for extrusion or molding. Labs can compare various polymers and select the most suitable one for their needs by measuring the flow rate. Additionally it supports innovation in the development of plastics and helps guarantee product quality. Perfect Group India provides high-performance instruments designed to meet the demands of modern laboratories for accurate and reliable testing solutions.

What Is a Melt Flow Index Tester? The Melt Flow Index Tester is used to measure the melt flow rate of thermoplastic polymers. The amount shows how many grams of polymer at a given temperature and pressure, flow through an opening of a particular size in ten minutes. An important feature that finds how a plastic will behave during extrusion or injection molding is its MFR.

The tester applies pressure to a sample using a piston and a heated barrel. The plastic passes through the die as it melts and softens and the quantity acquired is weighed and noted. The outcome helps manufacturers and researchers in comparing various materials or confirming that a batch satisfies the required standards.

Why Plastic Research Labs Rely on Melt Flow Index Tester

Accurate Material Characterization Plastic research labs use the Melt Flow Index Tester to analyze and classify thermoplastics. The flow rate provides information about the molecular weight of the polymer. High flow rates show lower molecular weight, whereas low flow rates indicate higher molecular weight. Researchers can better understand material properties and industry quality with the use of this data.

Essential for New Product Development In plastic innovation and development, engineers need reliable data to create new blends or modify existing polymers. Equipment allows them to measure how different formulations perform during processing. This information guarantees materials will behave properly when shaped into final products.

Consistency in Quality Testing Verifying the quality of materials from multiple sources is the responsibility of plastic labs. Regularity is important whether working with recycled materials or raw polymers. Every sample tested is guaranteed to meet the standard melt flow rate by a Melt Flow Index Tester. This keeps performance and manufacturing processes.

Supports Recycling Research Plastic research laboratories focus on recycling and reusing thermoplastics as industries move toward the environment. After multiple uses the properties of these materials can change. Labs can measure how the melt flow changes after processing and make sure the recycled materials are still beneficial by using this device.

Standard Compliance Many industries require compliance with international testing standards such as ASTM D1238 or ISO 1133. Melt flow testing is a recognized method under these standards. Having a tester in the lab guarantees that all products or samples are tested and documented in accordance with accepted standards..

Advantages of Melt Flow Index Tester Use in Labs

Speed and Simplicity: The tester is quick to set up and record data. Best for busy lab environments.

Cost-Effective Analysis: It provides a reasonably priced means of acquiring important material data.

Non-Destructive Evaluation:The balance of the batch is left unaffected because just a small amount is used.

Reliable Comparisons:makes it simple to compare recycled, blended materials.

Flexible Testing Conditions: Adjustable temperature and load settings allow a wide variety of thermoplastics to be tested.

How Melt Flow Index Tester Helps in Industrial Decision-Making Research labs are not the only places where the equipment provides data. Businesses depend on this data to make wise choices throughout:

Purchasing raw materials: Make sure suppliers live up to quality standards.

Setting process parameters: Use mold speed, temperature or injection pressure to flow rates.

Quality control checks: Before starting manufacturing this device identifies any flaws or defects.

Design improvements: To increase strength or moldability, change the additives or polymer combinations.

As a result, the tester supports both innovation and superior manufacturing by acting as a link between research labs and industrial uses.

Key Applications of Melt Flow Testing in Plastics

Injection Molding: Analyze the ease of flow into molds and reduce waste.

Extrusion: Check how polymers behave under pressure and high heat.

Film Production: Guarantee plastic films maintain thickness and clarity.

Pipe Manufacturing: Verify that materials used for pipes can maintain forming without deforming.

Packaging Solutions: Confirm plastic containers hold their shape under process conditions.

Promoting Quality Testing with Perfect Group India High-performance testing equipment from Perfect Group India satisfies the requirements for modern plastic research labs. Our Melt Flow Index Tester is a trusted partner in quality testing because it is made to provide accurate and reliable results. Our testers are designed for ease of use and performance, with strong construction, user-friendly interfaces and following international standards.

Our tools help you move toward better products and more accurate processes, whether you work in a quality assurance company, plastic processing facility or research lab.

Conclusion To measure how materials behave during the melting and molding processes, plastic research labs use the Melt Flow Index Tester. The equipment helps researchers to identify the proper flow rate, which is required for creating high-quality plastic products. Labs can create better materials, increase the strength of their products and guarantee right processing methods by testing the flow properties. It also allows the comparison of various plastic levels for a range of uses. It is a useful tool for manufacturers and researchers with trustworthy outcomes and ease of use. Perfect Group India provides tools for allowing accurate plastic material research for reliable testing solutions.

#industrial#equipments#perfectgroupindia#perfectinstruments#technology#droptester#business#boxcampressiontester#toploadertester#prefectgroupindia

0 notes

Text

Use of Melt Flow Index Tester in Plastic Research Labs

Source of Info: https://www.perfectgroupindia.co.in/blog/use-of-melt-flow-index-tester-in-plastic-research-labs

Introduction

An important instrument in plastic research labs for analyzing how plastic flows when melted under specific conditions is the Melt Flow Index Tester. This tool makes it simpler for researchers to identify whether different plastic materials behave well for extrusion or molding. Labs can compare various polymers and select the most suitable one for their needs by measuring the flow rate. Additionally it supports innovation in the development of plastics and helps guarantee product quality. Perfect Group India provides high-performance instruments designed to meet the demands of modern laboratories for accurate and reliable testing solutions.

What Is a Melt Flow Index Tester?

The Melt Flow Index Tester is used to measure the melt flow rate of thermoplastic polymers. The amount shows how many grams of polymer at a given temperature and pressure, flow through an opening of a particular size in ten minutes. An important feature that finds how a plastic will behave during extrusion or injection molding is its MFR.

The tester applies pressure to a sample using a piston and a heated barrel. The plastic passes through the die as it melts and softens and the quantity acquired is weighed and noted. The outcome helps manufacturers and researchers in comparing various materials or confirming that a batch satisfies the required standards.

Why Plastic Research Labs Rely on Melt Flow Index Tester

1. Accurate Material Characterization

Plastic research labs use the Melt Flow Index Tester to analyze and classify thermoplastics. The flow rate provides information about the molecular weight of the polymer. High flow rates show lower molecular weight, whereas low flow rates indicate higher molecular weight. Researchers can better understand material properties and industry quality with the use of this data.

2. Essential for New Product Development

In plastic innovation and development, engineers need reliable data to create new blends or modify existing polymers. Equipment allows them to measure how different formulations perform during processing. This information guarantees materials will behave properly when shaped into final products.

3. Consistency in Quality Testing

Verifying the quality of materials from multiple sources is the responsibility of plastic labs. Regularity is important whether working with recycled materials or raw polymers. Every sample tested is guaranteed to meet the standard melt flow rate by a Melt Flow Index Tester. This keeps performance and manufacturing processes.

4. Supports Recycling Research

Plastic research laboratories focus on recycling and reusing thermoplastics as industries move toward the environment. After multiple uses the properties of these materials can change. Labs can measure how the melt flow changes after processing and make sure the recycled materials are still beneficial by using this device.

5. Standard Compliance

Many industries require compliance with international testing standards such as ASTM D1238 or ISO 1133. Melt flow testing is a recognized method under these standards. Having a tester in the lab guarantees that all products or samples are tested and documented in accordance with accepted standards..

Advantages of Melt Flow Index Tester Use in Labs

• Speed and Simplicity: The tester is quick to set up and record data. Best for busy lab environments.

• Cost-Effective Analysis: It provides a reasonably priced means of acquiring important material data.

• Non-Destructive Evaluation:The balance of the batch is left unaffected because just a small amount is used.

• Reliable Comparisons:makes it simple to compare recycled, blended materials.

• Flexible Testing Conditions: Adjustable temperature and load settings allow a wide variety of thermoplastics to be tested.

How Melt Flow Index Tester Helps in Industrial Decision-Making

Research labs are not the only places where the equipment provides data. Businesses depend on this data to make wise choices throughout:

• Purchasing raw materials: Make sure suppliers live up to quality standards.

• Setting process parameters: Use mold speed, temperature or injection pressure to flow rates.

• Quality control checks: Before starting manufacturing this device identifies any flaws or defects.

• Design improvements: To increase strength or moldability, change the additives or polymer combinations.

As a result, the tester supports both innovation and superior manufacturing by acting as a link between research labs and industrial uses.

Key Applications of Melt Flow Testing in Plastics

• Injection Molding: Analyze the ease of flow into molds and reduce waste.

• Extrusion: Check how polymers behave under pressure and high heat.

• Film Production: Guarantee plastic films maintain thickness and clarity.

• Pipe Manufacturing: Verify that materials used for pipes can maintain forming without deforming.

• Packaging Solutions: Confirm plastic containers hold their shape under process conditions.

Promoting Quality Testing with Perfect Group India

High-performance testing equipment from Perfect Group India satisfies the requirements for modern plastic research labs. Our Melt Flow Index Tester is a trusted partner in quality testing because it is made to provide accurate and reliable results. Our testers are designed for ease of use and performance, with strong construction, user-friendly interfaces and following international standards.

Our tools help you move toward better products and more accurate processes, whether you work in a quality assurance company, plastic processing facility or research lab.

Conclusion

To measure how materials behave during the melting and molding processes, plastic research labs use the Melt Flow Index Tester. The equipment helps researchers to identify the proper flow rate, which is required for creating high-quality plastic products. Labs can create better materials, increase the strength of their products and guarantee right processing methods by testing the flow properties. It also allows the comparison of various plastic levels for a range of uses. It is a useful tool for manufacturers and researchers with trustworthy outcomes and ease of use. Perfect Group India provides tools for allowing accurate plastic material research for reliable testing solutions.

0 notes

Text

Hyphen Cables – Premier Manufacturer of Single and Multi-Core Cable Wires in India

In the ever-evolving world of electrical and electronic systems, the need for dependable and high-performance wiring solutions is paramount. Whether for residential, commercial, or industrial applications, single and multi-core cables wires manufacturers are vital for ensuring smooth power distribution and signal transmission. Among the top manufacturers in India, Hyphen Cables has established itself as a trusted and innovative brand, offering a comprehensive range of single and multi-core cable wires that meet stringent quality and safety standards.

Understanding Single and Multi-Core Cables

Single-core cables consist of one conductor, typically used where minimal power or signal transmission is required. These are ideal for domestic wiring, small machinery, or compact electrical devices.

Multi-core cables, on the other hand, contain two or more conductors, each insulated individually and enclosed in a common sheath. These cables are widely used in control panels, industrial equipment, communication systems, and complex installations requiring multiple connections within a single cable system.

The type of cable used often depends on the specific needs of the application, and choosing the right manufacturer plays a critical role in ensuring performance, durability, and safety.

Why Choose Hyphen Cables?

Hyphen Cables, one of India’s most reputed cable manufacturers, specializes in the design and production of both single and multi-core cable wires. With a focus on quality, innovation, and customer satisfaction, Hyphen offers products that cater to diverse sectors, including residential, infrastructure, manufacturing, power, and automation.

Some of the key features of Hyphen’s cable offerings include:

High-Grade Conductors: Manufactured using high-purity electrolytic copper or aluminum for superior conductivity.

Advanced Insulation: Use of FR, FRLS, PVC, and XLPE insulation materials to ensure thermal stability and flame resistance.

Durable Sheathing: Designed to withstand mechanical wear, moisture, chemicals, and environmental stress.

Flexible Construction: Especially in multi-core cables, flexibility is critical for easy installation in tight or complex spaces.

Custom Solutions: Available in various core configurations, sizes, and voltage ratings to suit project-specific needs.

Quality Assurance and Certifications

Hyphen Cables is ISO-certified and strictly adheres to national and international manufacturing standards such as IS 694, IS 1554, and IEC norms. All cables undergo rigorous quality control tests in state-of-the-art in-house labs, including tests for insulation resistance, tensile strength, voltage endurance, and fire resistance.

This unwavering commitment to quality has made Hyphen a preferred supplier for clients in sectors ranging from residential real estate to large-scale industrial plants.

Applications Across Industries

Hyphen’s single and multi-core cables are widely used in:

Building and domestic wiring

Control panels and switchgear

Power distribution networks

Automation and instrumentation

Renewable energy systems

Conclusion

For organizations and contractors seeking reliable, high-performance cabling solutions, Hyphen Cables stands out as one of India’s most dependable manufacturers of single and multi-core wires manufacturers. Combining technical expertise with a customer-focused approach, Hyphen delivers cables that not only meet today’s requirements but are also built to last well into the future.

Choose Hyphen Cables — where quality, performance, and trust go hand in hand.

Visit:- https://www.hyphencables.com/single-multi-core-flexible-wires-cables.html

0 notes

Text

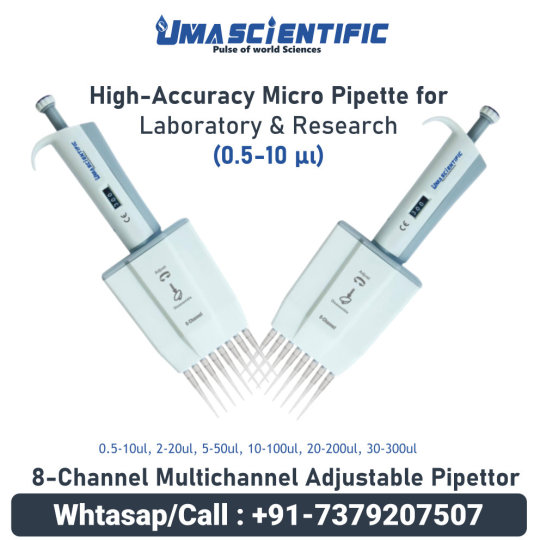

Multichannel Micropipette: Why UMA Scientific is India’s Smartest Lab Choice

Introduction: The Hidden Power of Choosing the Right Pipette

Laboratories today are under pressure — more tests, faster results, and no room for error. From biotech and diagnostics to academia and pharma, precision and throughput are key.

Among the most critical lab tools is the micropipette, and when you're dealing with multi-well plates and high-volume workflows, nothing beats the efficiency of a multichannel micropipette.

But how do you choose the right one?

In this in-depth guide, we’ll walk you through:

What to consider when choosing a multichannel pipette

Benefits of 8 vs. 12-channel pipettes

Volume range selection

Key features to look for

And why UMA Scientific is one of India’s most trusted micropipette manufacturers — especially for labs across South India

What is a Multichannel Micropipette?

A multichannel micropipette is a specialized lab instrument designed to aspirate and dispense liquid through multiple channels simultaneously—typically in 8 or 12 rows.

This allows you to:

Transfer liquids to/from 96- or 384-well plates quickly

Perform ELISA, PCR, or serial dilution faster

Reduce manual error and wrist fatigue

Multichannel micropipettes are game-changers for labs dealing with repetitive tasks.

Key Factors When Choosing a Multichannel Micropipette

1. Number of Channels: 8 vs. 12

🔹 8-Channel Micropipette

Ideal for 96-well plates

Easier to handle

Great for diagnostics and basic research labs

🔹 12-Channel Micropipette

Covers a full row of a 96-well plate

Speeds up processes

Best for high-throughput screening, pharma, and ELISA workflows

📌 UMA Scientific offers both models—so you can choose based on your lab’s volume and workflow.

2. Volume Range

Choosing the right volume range depends on your application. UMA Scientific offers:

0.5–10 µl – Ideal for DNA/RNA work

2–20 µl – Good for ELISA and qPCR

5–50 µl – Used in basic liquid transfers

10–100 µl – Suitable for protein work, buffers

20–200 µl – Great for biochemical reactions

30–300 µl – Useful in sample dilutions and diagnostics

3. Accuracy and Reproducibility

High precision is non-negotiable. UMA Scientific’s pipettes are:

ISO 8655 calibrated

Designed for consistent performance

Pre-tested for leakage and volume consistency

4. Ease of Use and Comfort

Long hours of pipetting can cause strain. Choose a pipette with:

Soft plunger movement

Lightweight body

Low-force tip ejection

Thumb-friendly design

UMA Scientific designs each pipette keeping Indian lab conditions and user comfort in mind.

5. Autoclavability and Maintenance

In biomedical labs, contamination is the enemy.

UMA Scientific pipettes are:

Fully autoclavable at 121°C

Easy to clean

Made with chemical-resistant, durable material

This means long life, clean work, and peace of mind.

UMA Scientific: Built for Indian Labs

As an Indian manufacturer, UMA Scientific understands the unique needs of local labs:

Budget-sensitive pricing

Robust design to suit diverse lab conditions

Local service and faster delivery

Regional distribution across South India – Tamil Nadu, Karnataka, Kerala, Telangana, Andhra Pradesh

Product Line Overview: UMA’s 8 & 12 Channel Micropipettes

ModelChannelsVolume Ranges AvailableAutoclavableErgonomicAccuracy (%)UMP-8C80.5–10, 2–20, 5–50 µl etc.✅ Yes✅ Yes±0.5 to ±1.5%UMP-12C1210–100, 20–200, 30–300 µl✅ Yes✅ Yes±0.5 to ±1.2%

📦 All models come with calibration certificate & ready-to-use packaging.

South India Focus: UMA's Strong Regional Network

South India is a major hub for research, medical, and academic excellence. UMA Scientific is proud to serve top cities and institutions including:

Tamil Nadu

Chennai – Biotech & diagnostics labs

Coimbatore – Engineering & pharma colleges

Madurai – Government hospitals & pathology labs

Karnataka

Bengaluru – Research labs, startups, pharma

Mysuru – University teaching labs

Kerala

Kochi, Trivandrum – Medical colleges, biotech zones

Telangana

Hyderabad – Genome Valley, diagnostics labs, pharma majors

Andhra Pradesh

Vizag & Vijayawada – Research centers, diagnostics labs

Our fast dispatch system ensures delivery within days, not weeks.

Real Use Case: 12-Channel in Diagnostic Testing

A diagnostic lab in Hyderabad needed to run ELISA for hundreds of COVID samples. Switching from single-channel to UMA’s 12-channel pipette reduced sample loading time by over 60%.

Result:

Less operator fatigue

Fewer pipetting errors

3x faster processing

Real Use Case: 8-Channel in Education

A teaching lab in Madurai uses 5 UMA Scientific 8-channel pipettes for hands-on student training in pipetting technique and microplate handling.

Benefits:

Affordable lab setup

No compromise on quality

Easy to sterilize and maintain

Why UMA Scientific is a Better Choice

✅ Indian Brand with Global Quality

✅ Best Price-to-Performance Ratio

✅ Service Support Across India

✅ Custom Volume Requests Possible

✅ Bulk Pricing for Colleges & Labs

✅ ISO Calibrated, Leak Tested

Available Accessories

UMA Scientific also offers:

Replacement pipette tips

Calibration service kits

Volume check kits

Pipette holders and stands

Ask for combo pricing or academic lab starter kits.

Testimonials

🗣️ "We replaced international brands with UMA pipettes. Saved money and got great results." – Biotech Firm, Bengaluru

🗣️ "Best pipettes for our ELISA kits. UMA’s 12-channel is smooth and accurate." – Diagnostic Lab, Kochi

🗣️ "Affordable and autoclavable—perfect for our college lab." – Assistant Professor, Chennai

Conclusion: Choose Smart, Choose UMA

If you're ready to upgrade your lab’s liquid handling workflow, UMA Scientific’s 8 & 12-channel micropipettes are the smart choice.

With a blend of engineering precision, ergonomic design, local support, and affordability, UMA Scientific helps Indian labs compete with the best in the world.

So whether you're pipetting 8 samples or 800, do it faster, cleaner, and smarter with UMA.

SEO Tags and Keywords

Primary Keywords: multichannel micropipette India, 8 channel pipette, 12 channel micropipette, UMA Scientific pipette, lab pipette India, adjustable pipette manufacturer India, micropipette South India

Secondary Keywords: pipette for ELISA, lab pipette Hyderabad, Chennai lab supplier, autoclavable micropipette, biotech pipette India, affordable pipette manufacturer

Hashtags: #MultichannelMicropipette #UmaScientific #LabToolsIndia #8ChannelPipette #12ChannelMicropipette #ResearchLabsIndia #SouthIndiaLabs #LabEfficiency #MadeInIndiaLabEquipment

1 note

·

View note

Text

Flow Cytometry Market: Innovation, Growth & Opportunity

The global flow cytometry market is projected to be valued at USD 6.75 billion in 2025 and is anticipated to reach USD 9.78 billion by 2030, registering a CAGR of 7.69% over the forecast period (2025–2030).

The flow cytometry market plays a vital role in modern biomedical research and clinical diagnostics, offering a powerful tool for analyzing and sorting cells based on their physical and chemical characteristics. Widely used in immunology, oncology, and infectious disease monitoring, flow cytometry enables rapid, high-throughput analysis of individual cells, supporting advances in precision medicine and targeted therapies. As healthcare systems increasingly adopt technologies for early disease detection and personalized treatment approaches, demand for flow cytometry instruments, reagents, and software continues to rise. The market is also being shaped by improvements in automation, integration with AI-driven analytics, and growing applications in areas such as stem cell research and drug discovery.

Key Market Segments

Products & Services

Instruments represent roughly one-third of market revenue (~35%)

Reagents and consumables are growing faster, predicted at CAGR ~8–8.2% over the coming decade

Software, particularly for automated gating and analytics, is the fastest-growing sub-segment (~10% CAGR)

Technology

Traditional cell-based platforms hold over 70% share

Bead-based assays grow at ~7–9% CAGR

Cutting-edge technologies include spectral cytometry, image-enabled sorters, and real-time AI gating like GateNet, which matches human experts in accuracy.

Applications

Clinical diagnostics constitute ~45% of the market

Fastest-growing is stem‑cell/regenerative medicine (~9.8% CAGR)

Significant roles in oncology and immunology, with these niches expected to expand from USD 3.4Bn (2024) to USD 5.5Bn by 2030 (~8.2% CAGR)

Also used in drug discovery, translational research, infectious disease testing, and precision medicine.

End Users

Hospitals and clinics lead (~41% share)

Pharma & biotech companies seeing ~8–9% CAGR.

Diagnostic labs, academic institutions, and CROs are notable growth segments.

Regional Breakdown

North America dominates (approx. 39–40% share); U.S. alone was ~USD 1.43Bn in 2024, forecast to reach USD 2.96Bn by 2033 (~8.4% CAGR) .

Asia‑Pacific is the fastest-growing region (~8.3–9%), driven by China and India’s expanding R&D and healthcare infrastructure

Europe shows solid growth; emerging markets in South America, the Middle East, and Africa are gaining traction.

Market Drivers & Challenges

Drivers

Increasing incidence of cancer, immunodeficiency, and infectious diseases

Migration toward automated, high-parameter systems, coupled with AI-driven workflows enhancing speed and reducing operator dependency

Rising demand from regenerative medicine, cell therapies, and CAR‑T manufacturing pipelines.

Ongoing R&D investments from governments & private sector, including NIH’s $42Bn+ annual biomedical budget.

Challenges

High cost of instruments, reagents, and licensing software

Technical expertise shortage, especially in advanced gating techniques

Regulatory hurdles in clinical deployment and ensuring quality compliance.

Conclusion

The flow cytometry market is entering a golden era, driven by escalating clinical demand, technological leaps, and smart automation. With robust growth rates (~7–9% CAGR) and a projected market approaching USD 10–12Bn by 2030, it offers fertile ground for both established industry leaders and nimble innovators. As AI becomes embedded and global access broadens, flow cytometry is poised to play an even more pivotal role in precision medicine, cell therapies, and global health.

For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence: https://www.mordorintelligence.com/industry-reports/global-flow-cytometry-market-industry?utm_source=tumblr

About Mordor Intelligence:

Mordor Intelligence is a trusted partner for businesses seeking comprehensive and actionable market intelligence. Our global reach, expert team, and tailored solutions empower organizations and individuals to make informed decisions, navigate complex markets, and achieve their strategic goals.

With a team of over 550 domain experts and on-ground specialists spanning 150+ countries, Mordor Intelligence possesses a unique understanding of the global business landscape. This expertise translates into comprehensive syndicated and custom research reports covering a wide spectrum of industries, including aerospace & defense, agriculture, animal nutrition and wellness, automation, automotive, chemicals & materials, consumer goods & services, electronics, energy & power, financial services, food & beverages, healthcare, hospitality & tourism, information & communications technology, investment opportunities, and logistics.

For any inquiries or to access the full report, please contact:

[email protected] https://www.mordorintelligence.com/

#flow cytometry market#flow cytometry market size#flow cytometry market share#flow cytometry market trends

0 notes

Text

Clove Bud Oil Manufacturing Plant Project Report

Procurement Resource, a trusted leader in procurement intelligence and market research, proudly introduces its latest Clove Bud Oil Manufacturing Report. Designed for entrepreneurs, investors, and established businesses, this report serves as an essential guide to setting up and managing a successful clove bud oil manufacturing facility. It offers a detailed roadmap encompassing key industry trends, cost structures, operational insights, and long-term investment potential.

Clove Bud Oil: A Valuable Essential Oil with Diverse Applications

Clove bud oil, derived from the dried flower buds of the clove tree (Syzygium aromaticum), is an essential oil rich in eugenol—a compound known for its antiseptic, analgesic, and anti-inflammatory properties. With its powerful aroma and therapeutic characteristics, clove bud oil finds widespread use in pharmaceuticals, cosmetics, personal care products, food and beverages, and aromatherapy.

Growing consumer awareness around natural and herbal remedies has significantly driven the global demand for clove bud oil. The essential oil market is also being propelled by shifting preferences toward clean-label, plant-based ingredients and holistic health solutions, making clove bud oil a highly sought-after commodity.

Request a Free Sample Now: https://www.procurementresource.com/reports/clove-bud-oil-manufacturing-plant-project-report/request-sample

Comprehensive Report Highlights for a Profitable Clove Bud Oil Plant Setup

Procurement Resource’s Clove Bud Oil Manufacturing Plant Report is a meticulously curated resource that outlines all the technical, financial, and operational aspects necessary for business success. Whether you're an investor looking for new opportunities or an existing manufacturer seeking to scale operations, this report equips you with actionable intelligence.

Market Analysis

The report starts with a deep-dive market analysis that maps the global dynamics of the clove bud oil sector.

Market Trends and Growth Drivers: Explores the rising popularity of essential oils, the impact of natural wellness trends, and consumer demand in pharmaceuticals and cosmetics.

Segmentation and Regional Performance: Assesses market performance across North America, Europe, Asia-Pacific, and emerging markets.

Raw Material and End Product Pricing: Tracks fluctuations in clove bud prices, regional supply challenges, and final product margins.

Competitive Landscape: Evaluates key players, market share, distribution strategies, and innovation trends.

Technical and Operational Insights

One of the most valuable features of the report is its operational blueprint for setting up a manufacturing plant. From raw material sourcing to end-product packaging, every stage of production is thoroughly explained.

Manufacturing Process Overview:

Step 1: Raw Material Collection – Sourcing high-quality clove buds, preferably from regions like India, Sri Lanka, or Indonesia.

Step 2: Cleaning and Drying – Removing impurities and ensuring uniform moisture content.

Step 3: Steam Distillation – Utilizing stainless steel stills to extract oil via low-pressure steam.

Step 4: Oil Separation and Collection – Condensing steam and separating pure essential oil from water.

Step 5: Filtration and Storage – Filtering oil to remove particulate matter and storing it in dark, airtight containers.

Machinery and Equipment Needs:

Steam distillation unit

Condensers and separators

Stainless steel tanks

Bottling and labeling equipment

Quality testing lab instruments

Production Options: The report outlines the feasibility of operating an automatic, semi-automatic, or manual setup, along with recommendations for scalability.

Infrastructure & Utilities: Includes guidance on location planning, water and power requirements, storage, and waste management systems.

Manpower Requirements: Offers staffing models for production, quality control, logistics, and administration.

Quality Standards and Compliance: Advises on meeting ISO, GMP, FSSAI, and FDA requirements where applicable.

Financial and Economic Assessment

Establishing a clove bud oil plant requires a careful evaluation of capital expenditures, running costs, and profitability metrics. The report provides an extensive financial model to help investors assess business viability.

Capital Investment Estimates:

Land and infrastructure development

Equipment and machinery procurement

Licenses, certifications, and working capital

Operating Costs:

Raw materials and packaging

Utility consumption

Labor and maintenance

Transportation and logistics

Profit Projections and ROI:

Revenue forecasts based on output capacity and market demand

ROI calculation based on different scales of production

Sensitivity analysis considering price volatility and raw material availability

Break-even Analysis: Helps determine the minimum output required to cover operational expenses and achieve financial sustainability.

Sustainability, Innovation, and Market Opportunities

With sustainability becoming a cornerstone of modern manufacturing, clove bud oil production offers several advantages. The use of eco-friendly extraction techniques, minimal chemical processing, and biodegradable waste contributes to a low environmental footprint.

Eco-conscious Manufacturing: Promotes steam distillation as a greener alternative to solvent extraction, reducing chemical use.

Byproduct Utilization: Highlights opportunities to use clove hydrosol (distillation water) in cosmetics and aromatherapy.

Organic and Fair-Trade Certifications: Discusses the benefits of obtaining certifications that appeal to ethical consumers and global buyers.

Market Outlook: The global essential oils market is poised for robust growth, with clove bud oil benefiting from strong demand in both developed and developing markets. The Asia-Pacific region, particularly India, Indonesia, and Sri Lanka, holds significant promise due to favorable climatic conditions, agricultural expertise, and low labor costs.

Why Choose Procurement Resource?

Procurement Resource stands at the forefront of market intelligence and cost analysis, offering unmatched expertise across multiple sectors. Clients benefit from:

Customized Cost Modeling – Get tailored estimates for capital and operating expenses across various production capacities.

Price Tracking Tools – Stay ahead of raw material price fluctuations with real-time analytics.

Supply Chain Optimization – Identify the most reliable sourcing partners and efficient logistics strategies.

Actionable Data – Turn market insights into strategic decisions that enhance profitability.

Backed by a team of industry analysts and seasoned researchers, Procurement Resource ensures that every report is accurate, timely, and actionable.

Get a Free Sample Report

For businesses and stakeholders seeking to explore opportunities in the essential oil industry or establish a Clove Bud Oil Manufacturing Plant, Procurement Resource’s comprehensive report is an indispensable resource. It delivers the clarity and confidence needed to launch and scale a successful venture.

Request a Free Sample Now: https://www.procurementresource.com/reports/clove-bud-oil-manufacturing-plant-project-report/request-sample

About Procurement Resource

Procurement Resource empowers businesses with best-in-class procurement intelligence and market research services. The company supports clients in optimizing costs, improving supply chain resilience, and making informed strategic decisions. Services include:

In-depth market research

Cost and price trend analysis

Feasibility studies and project reports

Benchmarking and supply chain insights

With offices across North America, Europe, and Asia-Pacific, Procurement Resource is committed to delivering global insights with local relevance.

Contact Information:

Company Name: Procurement Resource Contact Person: Ashish Sharma (Sales Representative) Email: [email protected] Address: 30 North Gould Street, Sheridan, WY 82801, USA Phone Numbers: UK: +44 7537171117 USA: +1 307 363 1045 Asia-Pacific (APAC): +91 1203185500

#business#Clove Bud Oil#Clove Bud Oil Manufacturing#Clove Bud Oil Manufacturing Plant Project Report#Clove Bud Oil Manufacturing Report

0 notes

Text

The Cost of Non-Compliance: Why Investing in Compliance Certification Services Pays Off

In an era of increasing complexity and stringency of regulatory frameworks, compliance is more than just a checkbox; it is now a strategic imperative for global businesses. Equally daunting is the task of navigating within the certification regimes of BIS, FMCS, WPC, and EPR for manufacturers, importers, and brand owners with ambitions to enter the Indian market. Although often underrated, one of the biggest business risks is a non-compliance penalty, which translates into delayed product launches, financial penalties, product seizures, and loss of market reputation. This is why investing in compliance certification services is not a cost but a wise business decision.

Non-Compliance Costs – The Real Ones

For example, foreign manufacturers must obtain FMCS approval from the Bureau of Indian Standards (BIS) before selling certain products in India. Missing this requirement means the product cannot be imported, cannot be launched in the market, and may attract penalty charges. The direct and indirect losses include:

Degraded earnings resulting from product launch delays

Fines and penalties for regulatory violations

Adverse effects on reputation with business partners and customers

Storage and logistics overheads for unsellable products

Costs of resubmission due to application rejection

In industries like electronics, telecom, automotive, and consumer goods, where product life cycles are short and competition is intense, speed to market is a critical differentiator. Non-compliance can derail even the best-planned strategies.

The Value of Compliance Certification Services

Professional compliance certification services prove their worth by offering end-to-end support—from determining applicable standards to handling technical documentation and communication with authorities. These services allow businesses to remain focused on core operations while meeting mandatory legal standards.

Key benefits include:

Document Accuracy: Ensuring complete and correct submissions that comply with BIS or WPC guidelines.

Efficient Time-saving: Streamlining processes to reduce delays and avoid rework.

Regulatory Expertise: Staying updated with evolving Indian norms for accurate guidance.

End-to-End Coordination: From lab testing to audits, everything is managed efficiently.

Foreign Manufacturer Support: Meeting AIR (Authorized Indian Representative) requirements under FMCS.

Role of FMCS Certification Consultants

FMCS Certification consultants are instrumental for foreign manufacturers aiming to sell products under BIS-mandated categories in India. Their services typically include:

Product applicability analysis under FMCS

Preparation of technical documents and legal paperwork

Coordination with BIS-approved testing laboratories

Application filing and regulatory follow-ups

Factory inspections and post-certification compliance

By involving specialists, businesses minimize errors, avoid rejections, and accelerate their certification process.

Why It Pays to Invest

While some companies may hesitate at the upfront cost of hiring professional services, the long-term benefits far outweigh the investment. Quick approvals, legal compliance, reduced risk of fines, and smoother market entry lead to substantial financial and strategic gains.

Moreover, comprehensive compliance certification services offer flexibility—helping companies manage multiple certifications such as WPC, EPR, or ISI under a single point of contact, simplifying compliance management significantly.

Fusion Compliance Services: Your Trustworthy Compliance Partner

Fusion Compliance Services is one of the most reputed names in regulatory consulting, known for its reliable FMCS Certification consultants and complete compliance certification services. With a streamlined and transparent certification process, the company supports both domestic and international manufacturers entering the Indian market with confidence and speed.

Contact Us

Fusion Compliance Services 📞 Phone: +91 9696966665 📧 Email: [email protected] | [email protected] 🌐 Website: www.fusioncomplianceservices.com 🏢 Address: S1 520, Cloud-9, Vaishali Sector 1, Near Mahagun Metro Mall, Ghaziabad, Uttar Pradesh - 201012

#ComplianceCertificationServices#FMCSCertificationConsultants#BISCompliance#RegulatoryComplianceIndia#ProductCertificationIndia#FMCSApproval#IndianMarketEntry#FusionComplianceServices

0 notes

Text

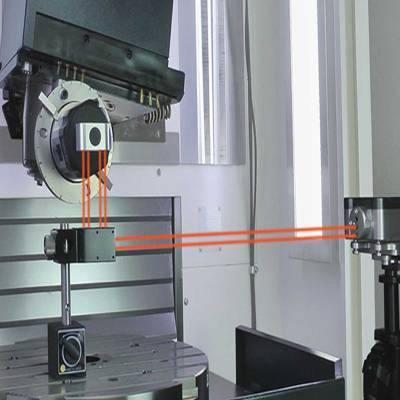

RF Test Equipment Market Size Ensuring Reliability in High-Frequency Communications

The RF Test Equipment Market Size is critical for validating the performance of wireless communication systems—including 5G, IoT networks, aerospace, defense, and automotive radar. With spectrum complexity increasing and RF devices integrating with digital processors, precise testing across frequencies, modulation schemes, and transmission standards is essential to ensure reliability, compliance, and security.

Market Size Research Future projects that global RF test equipment demand will reach USD 15.8 billion by 2030, growing at a CAGR of 6.7% between 2023 and 2030. Factors driving this growth include rapid global deployment of 5G infrastructure, expanding wireless device usage, and stringent regulatory standards.

Market Size Overview

RF test equipment encompasses a range of tools—signal generators, spectrum analyzers, vector signal analyzers, network analyzers, power meters, and communication testers—that verify signal integrity, receiver sensitivity, transmitter power, and RF chain performance. These instruments are essential during R&D, manufacturing validation, and routine field maintenance.

As devices like smartphones, IoT sensors, vehicle-to-everything (V2X) units, and network nodes become more complex, RF testing is moving toward automated, cloud-enabled, and AI-assisted solutions to support high-volume production and sustainable operation.

Key Drivers

1. 5G Rollout and Beyond

With the rollout of 5G and exploration of 6G, test instruments must support wide frequency bands, millimeter-wave testing, ultra-low latency metrics, and multi-antenna (MIMO) evaluation.

2. Growth of IoT and Connected Devices

The proliferation of IoT devices from home automation to industrial sensors is increasing the load on RF testing for Bluetooth, Wi-Fi, LoRa, NB-IoT, and cellular modules.

3. Automotive Radar & V2X Testing

Advanced driver-assistance systems (ADAS) and autonomous vehicles rely on radar and communication subsystems, increasing demand for precise RF field-testing equipment.

4. Regulatory and Compliance Testing

Equipment manufacturers must meet global standards for electromagnetic interference (EMI), wireless certification, and spectral compliance—driving the demand for EMI testing chambers, signal analyzers, and filters.

Market Size Segmentation

By Product Type:

Signal Generators

Spectrum Analyzers

Vector Signal Testers

Network Analyzers

Power Meters

Others (EMI Pre-compliance Tools)

By Frequency Range:

Below 3 GHz

3–6 GHz

Above 6 GHz (including mmWave)

By End User:

Telecommunication Infrastructure

Consumer Electronics

Aerospace & Defense

Automotive & Transportation

Industrial & Manufacturing

Research & Academic Institutions

Regional Overview

North America

Leading in test instrumentation adoption due to advanced 5G deployments, strong presence of OEMs, and robust R&D investment.

Europe

Market Size growth driven by 5G expansion, automotive radar development, and stringent certification processes in Germany, the UK, and France.

Asia-Pacific

The fastest-growing region, with China, Japan, South Korea, and India rapidly deploying 5G networks and scaling consumer electronics production.

Key Players

Major RF test equipment manufacturers are advancing into integrated software and AI-driven testing platforms:

Keysight Technologies

Rohde & Schwarz

National Instruments (NI)

Anritus Corporation

Tektronix (Fortive Corporation)

EXFO Inc.

Oscilent

VIAVI Solutions

LitePoint (Novanta)

Yokogawa Electric

These providers offer solutions ranging from lab-grade instrumentation to portable handheld testers and cloud-enabled automated test suites.

Trends to Watch

Cloud-Connected Test Labs: Remote calibration, automated reporting, and shared test infrastructure via cloud platforms.

AI-Enhanced Testing: Predictive fault detection and self-tuning instruments reduce cycle time and improve yield.

Portable RF Analyzers: Compact tools for field engineers testing base stations, towers, and broadcasting equipment.

Integrated IoT Testbeds: Platforms that combine RF testing with protocol analysis for IoT connectivity validation.

EMC/EMI Convergence: Multi-function analyzers covering both RF performance and EMC compliance testing.

Challenges

High Cost of Advanced Testers: Especially for mmWave and multi-antenna systems.

Complexity in Test Integration: Integrating RF test workflows with software and digital validation ecosystems.

Short Technology Lifecycles: Rapid need to update test equipment with new standards like 5G-Advanced and 6G.

Skilled Workforce Shortage: RF instrumentation prescribing domain knowledge is still rare.

Future Forecast

RF test platforms will evolve toward modular, scalable, and software-defined instruments compatible with automated production lines and remote management frameworks. The integration of edge-AI and digital twin-based test management will further accelerate deployment and reduce downtime.

Trending Report Highlights

Explore related sectors driving enhanced testing, connectivity, and automation:

USB Flash Drives Market Size

Bakery Release Agents Market Size

Circular Waterproof Connector Market Size

Capacitor Bank Controllers Substation Automation Market Size

Robotic Waste Sorting Market Size

Electromagnetic Compatibility (EMC) Filtration Market Size

Flash Charger Adapter Market Size

PM2.5 Sensor Market Size

Switched Capacitor Filter Market Size

Ultrasound Pulser IC Market Size

Pressfit Connectors Market Size

Sensor Signal Conditioner ICs Market Size

Waterproof LED Module Market Size

0 notes

Text

Reliable Herbal Medicine Testing Services – India

India, being the global hub of Ayurveda and traditional herbal medicine, ayurvedic medicines testing labs has witnessed an increasing demand for reliable herbal medicine testing services to ensure the safety, quality, and efficacy of products reaching both domestic and international markets.

As the herbal industry grows rapidly with consumers turning toward natural and plant-based remedies, it has become essential for manufacturers, exporters, and healthcare providers to verify their products through scientific testing. Reliable herbal medicine testing

services in India provide comprehensive laboratory support to assess the purity, identity, potency, and safety of raw herbs, extracts, and finished formulations like tablets, capsules, syrups, oils, and powders. These services are critical not only for compliance with national regulations such as AYUSH, FSSAI, and the Drugs and Cosmetics Act but also for meeting global standards laid out by authorities in the USA, Europe, the Middle East, and Southeast Asia. The testing process typically begins with raw material authentication to prevent adulteration and misidentification, a common challenge in herbal sourcing.

This includes microscopic analysis and modern chromatographic techniques like HPTLC and HPLC for identifying active botanical constituents. Reliable labs also carry out detailed physicochemical testing, including pH, ash values, moisture content, extractive values, and solubility, which help establish baseline quality parameters. Ensuring safety is a core aspect of herbal testing.

Accredited labs in India conduct thorough contamination testing for heavy metals (lead, mercury, arsenic, cadmium), pesticide residues, microbial load (such as E. coli, Salmonella, and mold), and aflatoxins. These contaminants, if undetected, can pose serious health risks to consumers and may result in product recalls or export rejections. Therefore, testing ensures that herbal products are not only effective but also safe for human use.

Moreover, stability and shelf-life studies are conducted to determine product longevity and validate label claims regarding expiry dates and storage conditions. India's top herbal testing laboratories are often NABL-accredited and ISO/IEC 17025-compliant, assuring that testing methods, equipment, and technicians meet global

benchmarks for quality and consistency. These labs are equipped with advanced analytical instruments such as Gas Chromatography (GC), Mass Spectrometry (MS), FTIR, UV-Vis spectrophotometers, and Atomic Absorption Spectroscopy (AAS), enabling accurate detection and quantification of ingredients and contaminants.

Many offer end-to-end services, including preparation of Certificates of Analysis (CoA), regulatory documentation, product dossier support, and even guidance on international compliance for herbal exports.

Their services are crucial for Ayurvedic and nutraceutical companies aiming to build trust, expand globally, and differentiate their brand in a competitive marketplace. Reliable herbal medicine testing also helps foster innovation, as R&D teams can scientifically evaluate the effects and composition of new plant-based formulations. In conclusion, India’s reliable herbal medicine testing services provide the essential scientific backbone that supports the ancient wisdom of Ayurveda in the modern world.

These services ensure that consumers receive safe, high-quality, and effective products while enabling herbal businesses to grow with credibility, compliance, and confidence in the global market.

follow more information:

https://isspllab.com/services-ayush-herbal-products/

1 note

·

View note

Text

Vashishat Scientific: Leading Lab Equipment Manufacturer

Vashishat Scientific Corporation stands as India's premier Chemistry lab equipment manufacturer and Physics lab equipment supplier. With 25+ years of expertise, we deliver precision instruments for educational and research institutions worldwide. Our ISO-certified production facility combines innovation with reliability. We serve universities, schools, and industrial laboratories across 35+ countries. Every product undergoes rigorous quality testing before dispatch.

Why Choose Our Laboratory Equipment?

1. Premium Quality Chemistry Lab Equipment

We manufacture:

• Glassware & Apparatus

Borosilicate glass products with perfect calibration.

• Analytical Instruments

Precision tools for accurate measurements.

• Safety Equipment

Fume hoods, cabinets, and protective gear.

2. Innovative Physics Lab Equipment

Our physics range includes:

• Measurement Devices

Advanced tools for electrical and thermal studies.

• Demonstration Kits

Interactive learning modules for students.

• Research-grade Instruments

For cutting-edge scientific investigations.

Global Lab Equipment Exporter Network

As a trusted Physics lab equipment exporter, we ship to:

• European Union

CE-certified products meeting EU standards.

• Middle East

Durable equipment for harsh climates.

• Southeast Asia

Cost-effective solutions for growing markets.

• African Nations

Robust designs for challenging environments.Vashishat Scientific Corporation remains committed to excellence as both a Chemistry lab equipment supplier and Physics lab equipment manufacturer. Our customer-centric approach ensures timely deliveries and after-sales support. We continuously innovate to meet evolving scientific needs. Partner with us for reliable laboratory solutions. Contact our team today for customized quotations.

0 notes

Text

Use of Melt Flow Index Tester and Why it is Important

Source of Info: https://www.perfectgroupindia.co.in/blog/use-of-melt-flow-index-tester-and-why-it-is-important

Introduction For measuring the flow rate of molten thermoplastic polymers under specific pressure and temperature settings a Melt Flow Index Tester is a required instrument. By measuring the thickness as well as processing properties of plastic materials this test helps businesses in maintaining stability and quality in performance. It is important in industries which include manufacturing, automotive and packaging. Reducing manufacturing errors and also improving material selection and maintaining loyalty to global standards are all made possible by accurate melt flow data. A reliable equipment from trusted businesses like Perfect Group India is necessary to get the best possible product performance.

Understanding About MFI Testing Instrument A Melt Flow Index Tester is a piece of equipment used in laboratories to measure the rate at which molten plastic flows through a die with a given size under controlled settings. It offers a numerical value that represents the thickness of thermoplastic materials when they melt. In facilities that manufacture parts made of plastic, polymer production facilities and quality control labs this instrument is important. Manufacturers are more likely to select the right material for its right use by using the melt flow index to calculate how a polymer will behave during processing.

Why Melt Flow Index Matters in Manufacturing One important measure for understanding the processing potential of plastic materials is the melt flow index. It affects the strength of the structure, wall thickness, mold filling and even recyclability. The equipment helps in finding irregularities in polymer grains that could result in defects or failures during production. Purchasing an excellent tester from Perfect Group India guarantees accurate data and accurate outcomes both which are important in maintaining product quality and reducing down on material waste.

Uses of Melt Flow Index Tester Across Industries

Plastic Packaging Industry Materials that need specific flow rates are needed for thin wall molding in plastic packaging. Every batch of raw materials must have the right flow features for smooth packaging production which is confirmed by the Melt Flow Index Tester.

Automotive Sector Thermoplastics are used for both functional and decorative parts in the automotive sector. In order to reduce failures during using the tool can help in selecting materials that provide a perfect balance of strength to flexibility.

Medical Equipment Manufacturing Strict quality controls are a requirement for medical devices. Manufacturers can guarantee safety and conformance to medical requirements by reducing the use of poor or unsafe materials through the use of a Melt Flow Index Tester.

Construction Material Production Melt flow index testing is very beneficial for pipes, insulation and composite materials used in construction. It confirms that the materials will withstand changes in pressure and temperature over time.

Benefits of Using a High Quality Melt Flow Index Tester Purchasing a premium Melt Flow Index Tester has the following benefits:

Improved Product Quality: Better product quality can result from producers guaranteeing material similarity through regular monitoring of melt flow rates.

Reduced Material Waste: The use of incorrect or damaged materials is stopped through accurate testing.

Cost Effective: Costs can be reduced by avoiding manufacturing line breakdowns and reducing scrap.

Regulatory Compliance: It helps in meeting ASTM D1238 and ISO 1133 standards which are mandatory for many industrial uses.

Perfect Group India aims to provide accurate tools that offer all of these advantages with unmatched durability and usefulness.

Features to Look for in a MFI Tester Some factors can greatly affect performance when choosing a Melt Flow Index Tester:

Digital Display for real time flow rate readings

High temperature accuracy and stability

User friendly interface for smooth operation

Multiple test weight options for different materials

Built in safety features for operator protection

Because of their success and stability our models at Perfect Group India include all of those features and are trusted by customers in many different kinds of industries.

How to Maintain and Calibrate a MFI Instrument To guarantee unchanged performance the Melt Flow Index Tester needs to be adjusted and maintained on a regular basis just like any other quality instrument. This includes:

Cleaning the barrel and die after each use

Continuous testing with standards and certified scales

Routine inspections for wear and tear

In order to maintain the value of your investment over time Perfect Group India provides complete support services such as certification and training.

Why Choose Perfect Group India? Perfect Group India shines out as one of the largest manufacturers in India of testing instruments or equipment thanks to years of experience and a continuous commitment to quality. With outstanding reliability, accuracy and durability, our instruments are made to satisfy the changing demands of the polymer and plastic industries.

Final Thoughts In the highly competitive manufacturing world of today having the correct equipment can result in huge improvements. More than just a lab tool a Melt Flow Index Tester maintains quality, accuracy and effectiveness. Whether you work in packaging, automotive or medical manufacturing, choosing a trustworthy tester from Perfect Group India can help businesses stay on top of material optimization and quality control.

#industrial#equipments#perfectgroupindia#perfectinstruments#technology#business#droptester#boxcampressiontester#prefectgroupindia

0 notes

Text

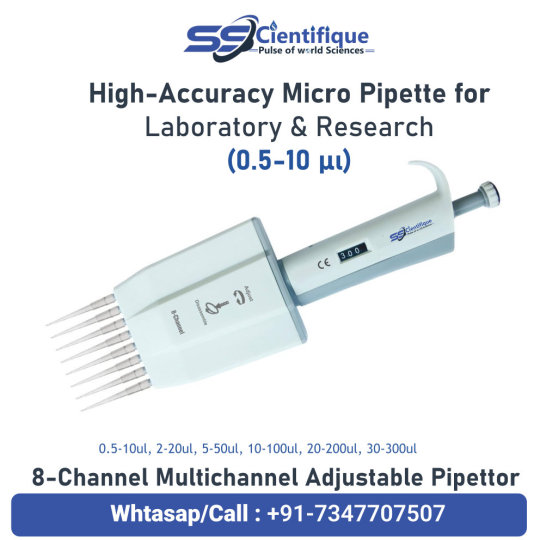

Buy 8-Channel & 12-Channel Multichannel Micropipettes in India – Sscientifique’s Premium Lab Solution for South India

Multichannel Micropipette, 8-Channel Micropipette, 12-Channel Pipette, Sscientifique, Micropipette Manufacturers in India, Best Pipette in Tamil Nadu, Kerala Lab Instruments, Adjustable Micropipette in South India

🧪 Introduction: Revolutionizing Liquid Handling in Modern Labs

Liquid handling is a cornerstone of any life science, diagnostics, pharmaceutical, or educational laboratory. When your lab processes multiple samples at once, time, accuracy, and consistency are everything. This is where multichannel micropipettes—specifically 8-channel and 12-channel models—become essential.

At the forefront of this revolution is Sscientifique, one of the most trusted micropipette manufacturers in India. Known for innovation, durability, and affordability, Sscientifique proudly offers high-performance 8-channel and 12-channel adjustable micropipettes, designed for Indian labs and global standards.

🔍 What is a Multichannel Micropipette?

A multichannel micropipette is a precision instrument that allows the user to dispense or aspirate liquid from multiple wells simultaneously. Common configurations include:

8-Channel Pipette – For 8-well strips or 96-well plates

12-Channel Pipette – For full-row access in 96-well microplates

Unlike single-channel pipettes, multichannel variants boost throughput while minimizing repetitive stress injuries.

✅ Why Sscientifique Multichannel Micropipettes Are the Best in India

Here’s what sets Sscientifique apart:

1. High Accuracy and Precision

Each pipette undergoes rigorous calibration and testing, ensuring reproducibility across all channels, with minimal error.

2. Adjustable Volume Options

Available in various volume ranges:

0.5–10 µl

2–20 µl

5–50 µl

10–100 µl

20–200 µl

30–300 µl

This allows customization based on sample type and experiment.

3. Ergonomic and Lightweight

Engineered for comfort, especially during long lab hours. The slim, light body minimizes fatigue.

4. Autoclavable Parts

Ensures sterility—ideal for microbiology, molecular biology, and clinical settings.

5. ISO & CE Certified

Complies with global standards for scientific instruments.

🌐 Coverage in South India – State-wise Focus

Sscientifique proudly serves major scientific hubs across South India, including Tamil Nadu, Kerala, Andhra Pradesh, Telangana, Karnataka, and Puducherry.

📍 Tamil Nadu (Chennai, Coimbatore, Madurai)

With a growing biotech sector and educational institutions, our micropipettes are a perfect fit for academic research labs and pharma R&D labs in Tamil Nadu.

📍 Kerala (Thiruvananthapuram, Kochi)

The healthcare and diagnostics industry in Kerala demands precise instruments. Our 8-channel and 12-channel micropipettes meet international standards for pathology labs.

📍 Andhra Pradesh (Amaravati, Visakhapatnam)

With increasing demand for diagnostic and clinical labs, Sscientifique supports state health labs, medical colleges, and pharma companies with reliable liquid handling tools.

📍 Telangana (Hyderabad, Warangal)

Hyderabad is India’s genome valley—home to major biotech players. Our multichannel micropipettes are trusted by research firms and BSL labs across Telangana.

📍 Karnataka (Bangalore, Hubli)

From academic labs to large pharmaceutical companies in Bangalore, the demand for quality pipettes is rising. Sscientifique caters with rapid supply and consistent performance.

📍 Puducherry

As a growing center for higher education and life science research, Puducherry benefits from Sscientifique’s affordable and reliable multichannel pipettes.

0 notes

Text

Melt Flow Index Tester Top Model

Source of Info: https://www.perfectgroupindia.co.in/blog/melt-flow-index-tester-top-model

Introduction

A professionally built instrument for measuring the flow features of thermoplastic polymers is Melt Flow Index Tester top model. Its digital PID temperature controller, automatic sample cutting and conformance to ASTM D1238 and ISO 1133 requirements make it perfect for research and development and quality control labs. This premium model's simple to use design and solid build guarantee accurate results. It is excellent for modern labs needing dependable high performance testing solutions because of its modular layout which makes maintenance simple. For advanced melt flow testing instruments depend on Perfect Group India.

Why Melt Flow Index Tester Matters in Polymer Testing

The flow properties of thermoplastics need to be confirmed using a Melt Flow Index Tester. Manufacturers can use this information to project how materials will react during extrusion or molding operations. In material comparison, product development and quality control it is an important factor. Without a trustworthy testing equipment your manufacturing process can be at risk of flaws that may affect the performance of the finished product and result in costly rejects or recalls. This is when Perfect Group India provides superior instruments that are helpful.

The Top Model from Perfect Group India

We at Perfect Group India have perfected our skills to manufacture excellent testing equipment throughout the years. Our best models are unique in the industry because of its smart features, excellent design and easy to use construction.

This model includes:

Digital PID temperature controller for pinpoint accuracy.

Touchscreen interface for ease of use.

Auto cutting mechanism for improved repeatability.

Solid build quality suited for long term industrial usage.

Smart Features for Smart Testing

With its many abilities our advanced Melt Flow Index Tester offers the greatest laboratory work productivity:

High temperature range support for testing a wide variety of thermoplastics.

Modular design that allows easy maintenance and calibration.

Multiple test weights to suit various testing scenarios.

Each component of this tester has been designed to produce test data that is dependable and repeatable. You are investing in a tool that will provide genuine value in the long run when you select Perfect Group India.

Designed for Modern Labs

Whether your business produces plastic products on a small scale or produces polymers on a large scale then your lab needs a Melt Flow Index Tester that can provide fast and accurate results. With features that allow for quick setup and easy control our top model is made to fit in perfectly with modern lab processes. Also its small design saves room without compromising functionality. Data maintaining, analysis and legal documentation are made simple by the tester's easy interaction with data management systems.

Perfect Group India Your Reliable Partner in Quality Testing

Perfect Group India offers full solutions along with testing equipment sales. Trust, creativity and excellent customer service are the basis of our brand. Years of research and development as well as feedback from engineers, lab technicians and quality experts, were used in creating the Melt Flow Index Tester top model.

When you partner with us you also benefit from:

Nationwide delivery and setup.

Responsive technical support.

Custom calibration and maintenance services.

Competitive pricing without compromising on quality.

Perfect Group India is a top choice for companies wishing to improve their material testing abilities because of this.

Compatibility with Global Standards

The following important international testing requirements are met by our Melt Flow Index Tester:

ASTM D1238

ISO 1133

This guarantees that your test results have been acknowledged worldwide, which improves product exporting, international client collaboration and conformity to laws in many countries.

Maintenance Made Easy

Compared to many other testers available on the market our Melt Flow Index Tester is made to be easily maintained. Because of their modular design, the parts are easy to clean and quickly accessible. Also, we offer on call assistance and a detailed instruction manual to help you troubleshoot typical problems without wasting important testing time.

Environmentally Conscious Engineering

Our best model was designed with environmentally friendly operations in mind. Through excellent thermal insulation and the best energy use, the tester reduces power consumption while maintaining performance. Innovative thinking that helps the environment and our clients is what we at Perfect Group India believe in.

Why Now is the Time to Upgrade

Having the latest equipment in your lab is important for staying ahead in the competitive world of today. Test quality can be affected and your operations slowed down by an antique Melt Flow Index Tester. Our modern model gives you speed, accuracy and dependability, all of which are necessary for both legal conformity and scalable expansion.

Final Thoughts

In the plastics and polymer sector the importance of a high quality Melt Flow Index Tester cannot be shown enough. Accuracy and stability are necessary when you are performing detailed research and development or regular quality inspections. The best model offered by Perfect Group India is a long term investment in the facilities of quality control for your business and not just a product. It delivers the best value in its price range because of its innovative functions, strong build and full assistance from industry professionals.

0 notes

Text

How Calibration Services Manufacturers in Ahmedabad Ensure Accuracy

In today’s fast-paced and highly competitive industrial environment, accuracy is not a luxury—it’s a necessity. Whether in pharmaceuticals, automotive, aerospace, or electronics, even the slightest deviation in measurements can result in product failure, regulatory non-compliance, or financial loss. This is where calibration services play a vital role, ensuring that instruments and devices function as intended. Ahmedabad, a key industrial hub in India, is home to several highly capable calibration service providers. But how exactly do Calibration Services Manufacturers in Ahmedabad ensure such precise levels of accuracy?

Let’s explore how they deliver excellence across industries.

Understanding the Importance of Calibration in Industry

Calibration is the process of comparing the readings of an instrument or equipment to a known standard and adjusting it to eliminate measurement errors. Over time, equipment can drift from its original settings due to environmental conditions, wear and tear, or frequent usage. Regular calibration ensures instruments provide accurate, consistent, and repeatable results.

In industries like pharmaceuticals, where a small deviation can compromise product quality and patient safety, calibration is not just recommended—it’s mandatory. Similarly, in sectors like aerospace or automotive, where tight tolerances are crucial, uncalibrated tools can lead to costly rework or even accidents.

Beyond safety and quality, proper calibration also ensures compliance with industry standards and regulations. Government bodies and international organizations require regular calibration of tools and equipment to maintain certifications, legal standards, and audit readiness.

Advanced Tools and Technology Used in Calibration

To achieve high levels of accuracy, calibration service manufacturers in Ahmedabad utilize state-of-the-art tools and technologies. These include master gauges, high-resolution digital instruments, laser measurement systems, and environmental testing chambers. Many facilities are equipped with climate-controlled labs to maintain ideal temperature and humidity levels—both of which can influence the accuracy of measurements.

Moreover, advanced calibration management software helps track instrument history, automate scheduling, and generate compliant certificates with traceability to national and international standards. Real-time data logging and automated reporting make the process more efficient and transparent.

Ahmedabad-based manufacturers often invest in constant upgrades to their equipment and software, ensuring they meet global expectations in both precision and performance.

Quality Standards Followed by Calibration Experts

One of the key reasons why clients trust calibration services from Ahmedabad is the strict adherence to quality standards. Reputed calibration labs follow international guidelines such as ISO/IEC 17025, which specifies the general requirements for the competence of testing and calibration laboratories. This standard ensures that the lab has both the technical competence and a robust quality management system.

In addition to ISO/IEC 17025, many providers also comply with NABL (National Accreditation Board for Testing and Calibration Laboratories) accreditation. These certifications validate that the lab can produce technically valid results and operates with full transparency and consistency.

Maintaining these certifications involves regular internal audits, proficiency testing, training of personnel, and documentation of processes. These practices form the foundation of trustworthy calibration services that clients can rely on.

Industries Served by Calibration Services in Ahmedabad

The versatility of Ahmedabad’s industrial base means calibration service providers here are well-versed in serving a wide range of industries:

Pharmaceuticals & Healthcare: Calibration of weighing scales, pressure gauges, temperature sensors, and lab instruments to ensure product safety and regulatory compliance.

Automotive: Measurement of torque tools, dimensional inspection of parts, and performance testing of sensors and controls.

Aerospace & Defense: Precision calibration of altitude sensors, gyroscopes, pressure instruments, and more—where even micro-errors can have critical consequences.

Food & Beverage: Monitoring temperature, pressure, and humidity in processing and storage equipment to ensure hygiene and safety standards.

Manufacturing & Engineering: Routine calibration of measurement and test instruments (MTI), CNC machines, and dimensional tools for production accuracy.

Thanks to their broad domain experience, calibration providers in Ahmedabad can offer both in-house and on-site calibration services tailored to each sector’s unique requirements.

Why Choose Ahmedabad for Calibration Services

Ahmedabad has rapidly evolved into one of India’s top cities for industrial manufacturing and engineering excellence. It offers a strong ecosystem of skilled professionals, modern infrastructure, and cost-effective services that make it an ideal location for calibration services.

Calibration Services Manufacturers in India are widely respected not only for their technical expertise but also for their customer-centric approach. Many providers offer flexible service schedules, fast turnaround times, and fully traceable digital documentation. Whether you're a small business or a large industrial operation, manufacturers in Ahmedabad are well-equipped to deliver accurate, efficient, and cost-effective calibration solutions tailored to your specific needs.

One notable name in this space is Machinery Clinic, which has built a solid reputation for providing accurate and dependable calibration services tailored to diverse industrial sectors. With a focus on quality, integrity, and continuous improvement, they stand out as a trusted partner for businesses seeking reliable calibration solutions.

Conclusion

Accuracy is the foundation of quality in today’s manufacturing industry. Selecting a reliable calibration service provider is crucial to ensure your equipment performs with precision and consistency. By leveraging advanced technology, adhering to international standards, and serving diverse industrial sectors with expertise and care, Ahmedabad-based companies play a key role in supporting operational efficiency and long-term success.

With companies like Machinery Clinic leading the way, Ahmedabad continues to strengthen its position as a go-to destination for professional, certified calibration services that keep your business running safely and smoothly.

0 notes

Text

The Cost of Non-Compliance: Why Investing in Compliance Certification Services Pays Off

In an era of increasing complexity and stringency of regulatory frameworks, compliance is more than just a checkbox; it is now a strategic imperative for global businesses. Equally daunting is the task of navigating within the certification regimes of BIS, FMCS, WPC, and EPR for manufacturers, importers, and brand owners with ambitions to enter the Indian market. Although often underrated, one of the biggest business risks is a non-compliance penalty, which translates into delayed product launches, financial penalties, product seizures, and loss of market reputation. This is why investing in compliance certification services is not a cost but a wise business decision.

Non-Compliance Costs – The Real Ones

For example, foreign manufacturers must obtain FMCS approval from the Bureau of Indian Standards (BIS) before selling certain products in India. Missing this requirement means the product cannot be imported, cannot be launched in the market, and may attract penalty charges. The direct and indirect losses include:

Degraded earnings resulting from product launch delays

Fines and penalties for regulatory violations

Adverse effects on reputation with business partners and customers

Storage and logistics overheads for unsellable products

Costs of resubmission due to application rejection