#lithium ion cell testing machines

Explore tagged Tumblr posts

Text

Ensuring Battery Safety and Performance: A Comprehensive Guide to Lithium-Ion Cell Testing Machines

In today’s rapidly advancing world of electric vehicles (EVs), consumer electronics, and renewable energy systems, lithium-ion batteries have become the cornerstone of modern technology. Their high energy density, lightweight design, and longevity make them a preferred choice across industries. However, ensuring the safety, reliability, and performance of these batteries is crucial. This is where lithium-ion cell testing machines play a vital role.

Why is Lithium-Ion Battery Testing Essential?

Lithium-ion batteries are known for their efficiency, but they can pose safety risks if not tested properly. Issues like thermal runaway, capacity degradation, and inconsistent performance can result in catastrophic failures. Comprehensive testing ensures that:

Battery cells meet safety standards.

Performance metrics are consistent and reliable.

The risk of hazards like short circuits or overheating is minimized.

By investing in state-of-the-art cell testing equipment, manufacturers can enhance product quality and build customer trust.

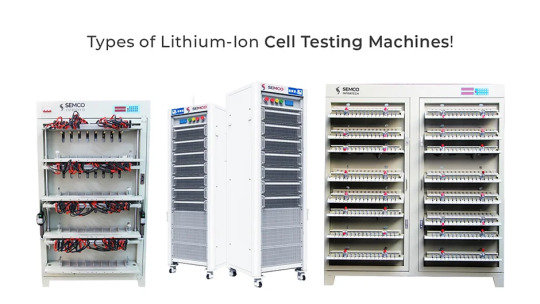

Types of Lithium-Ion Cell Testing Machines

A wide array of testing machines is available to cater to different testing needs. Here are some of the most commonly used ones:

1. Battery Cycle Testers

These machines test the charge and discharge cycles of a battery to assess its longevity and efficiency. Cycle testing is essential for understanding how a battery will perform over time.

2. Cell Sorting Machines

Lithium-ion cell sorting machines are used to categorize cells based on their voltage, capacity, and internal resistance. Accurate sorting ensures that only high-quality cells are used in battery packs.

3. Battery Pack Testers

These devices evaluate the performance of a complete battery pack. They simulate real-world conditions to ensure the pack’s durability and reliability.

4. Environmental Test Chambers

These chambers simulate extreme conditions, such as high temperatures, humidity, or vibrations, to assess a battery’s resilience and safety under various scenarios.

5. Impedance Testers

Impedance testers measure the internal resistance of a cell, which is a key indicator of its health and performance.

Key Features to Look for in Lithium-Ion Cell Testing Machines

When selecting a lithium-ion cell testing machine, it’s important to consider the following features:

Accuracy and Precision: High-quality testing equipment provides accurate and consistent results.

Automation: Automated machines improve efficiency and reduce the chance of human error.

Data Logging: Advanced machines offer robust data analysis and reporting capabilities.

Safety Standards: Ensure the equipment complies with global safety certifications like UL, CE, or ISO.

Benefits of Using Lithium-Ion Cell Testing Machines

Investing in reliable cell testing equipment offers multiple benefits:

Enhanced Product Safety: Comprehensive testing minimizes the risk of battery failures and accidents.

Improved Performance: Testing ensures that batteries deliver optimal performance in real-world applications.

Regulatory Compliance: Proper testing helps manufacturers meet industry standards and regulations.

Cost Efficiency: Identifying and eliminating defective cells reduces long-term operational costs.

Future Trends in Lithium-Ion Cell Testing

With advancements in technology, battery testing machines are becoming smarter and more efficient. Key trends include:

AI Integration: Artificial intelligence is enabling predictive analytics and more precise defect detection.

Faster Testing: New methods are reducing testing times without compromising accuracy.

Sustainability Focus: Eco-friendly testing solutions are gaining popularity to align with green manufacturing practices.

Conclusion

As the demand for lithium-ion batteries continues to soar, ensuring their safety and performance is more critical than ever. High-quality lithium-ion cell testing machines are indispensable tools for achieving this goal. By integrating these advanced systems into the production process, manufacturers can deliver safer, more reliable, and high-performing batteries that meet the needs of a rapidly evolving market.

Invest in the right battery testing equipment today and take a step towards a safer, greener future.

#electric vehicles#energy storage system#lithium ion batteries#lithium ion cell testing machines#cell testing equipment#testing machines#cycle testing#lithium ion cell sorting machines#battery testing machines

0 notes

Text

Semco Infratech’s lithium-ion battery assembly line delivers a fully automated solution for manufacturing high-performance battery packs. From cell sorting and laser welding to BMS integration and end-of-line testing, each stage is optimized for precision, scalability, and production speed—ideal for EV, ESS, and industrial battery applications. ☎️ Phone: +91-8920681227 📧 Email: [email protected] 🌐 Website: www.semcoinfratech.com

https://www.semcoinfratech.com/lithium-ion-battery-assembly-line/

#lithium-ion battery assembly line#battery pack manufacturing#Semco Infratech#EV battery production#battery assembly automation#lithium battery machines#cell sorting machine#BMS integration#battery welding machine#end of line testing#battery production equipment#lithium battery assembly process#battery pack testing#automated battery line#battery manufacturing in India

0 notes

Text

The Importance of Lithium Ion Battery Safety Testing

Present Situation

Since the mass production of lithium batteries, it has quickly led the trend in the battery field with its high energy ratio, long cycle life, and high electrode voltage. It has an absolute advantage in mobile phones, computers and other industries. And become one of the important research topics of the current new energy vehicles.

In order to meet the market demand for high storage energy, enterprises have increased the specific energy research and development of individual batteries. Although it is possible to increase the waiting time of the mobile phone, it also makes the volumetric energy density of a single battery higher and higher. The safety of lithium batteries is becoming more and more prominent. The main constraint to the commercialization of high-capacity and lithium-ion batteries is safety.

Constrained Problem

However, in recent years, with the large-scale utilization of the market and the increase in the capacity of the battery itself, under the abuse conditions (such as heating, overcharging, over-discharge, short circuit, vibration, extrusion, etc.), lithium batteries have serious problems such as fire and explosion. This can cause fatal effects on companies caused by explosions or recalls of products due to safety hazards. Various companies are investing in the development of new lithium battery safety prevention technologies. In addition, it also simulates possible problems and develops a more compatible detection method.

Launch standard

In order to analyze and solve such problems, the international proposed multiple security standards, such as IEC 62133, UL1642, IEEE 1625 and so on. China has also introduced the recommended standard GB/T 18287-2000. At the same time, some standards such as: UN 38.3, GB 4943 provide a guarantee for the safety of lithium batteries in aviation and long-distance transportation and equipment use. This article makes some simple discussions on the current IEC 62133 partial detection methods.

Battery Test Equipment

Mechanical Shock (crush hazard)

The Reason

Mechanical shock is primarily used to simulate an environment in which the product is subjected to impact during use, handling, or transportation. In order to determine the adaptability of the product to various impact forces, and to assess the integrity of its structure. The commonly used battery testing equipment is battery crush test chamber.

Test Standard Requirements

The IEC 62133 standard requires that a fully charged single cell or battery pack be fixed to the test machine by a rigid method. The method should be capable of supporting all solid surfaces of the battery or battery pack. A single cell or battery pack has to withstand the equivalent of three shocks. The impact should be applied in three directions perpendicular to each other. At least one direction should be perpendicular to the horizontal plane.

The impact acceleration of a single cell or battery pack should be such that the minimum average acceleration is 75 g and the peak acceleration should be between 125 g and 175 g in the first 3 ms. The cells or battery pack should be tested at an ambient temperature of 20 ± 5 °C. After the test, the sample was left for one hour before the visual inspection. During the test, the battery or battery pack does not ignite, does not explode, and does not leak.

Free Fall

The Reason

The drop test is primarily used to simulate the free fall that a product may experience during handling. Mainly to examine the ability of the product to resist accidental impact. 80% of electronics damage is due to drop and collision. R&D personnel often spend a lot of time and cost and do related quality tests for products. The most common structural tests are dropped and impact tests. In fact, the company most commonly used battery testing equipment include battery drop tester and heavy impact tester

Test standard requirements

The IEC 62133 standard requires free fall at an ambient temperature of 20 °C ± 5 °C, and each battery is fully charged. Each fully charged battery or cell needs to fall 10M down to the concrete floor. And repeat 3 times. The battery or cell should have an impact force in a random direction when it falls. After the test, the battery or cell should be placed for 1 hour. Then visually check. The battery has no fire or explosion. The drop test examines the possible drop in the transportation environment or customer use. From a safety point of view, it is to test the solder sealing performance of the battery.

Thermal abuse

The Reason

The safety problem of lithium-ion batteries is mainly caused by fire, explosion and other phenomena caused by thermal runaway. The reasons for thermal runaway are as follows:

External conditions

Intrinsic conditions

While the external temperature is rising, the internal temperature of the battery is also rising. While the external temperature is rising, the internal temperature of the battery is also rising. After rising to a certain temperature, the diaphragm will thermally close. Therefore, the function of protecting the positive and negative poles is safe. However, if the separator fails to close effectively, or the diaphragm melts and ruptures, or another exothermic reaction occurs inside the battery to cause the battery temperature to continue to rise, it may cause safety problems. In general, The battery testing equipment commonly used by the company is thermal abuse test chamber.

Test Standard Requirements

IEC 62133 requires that each cell be fully charged and placed in a chamber with gravity or circulating air convection. The temperature of the chamber was raised to 130 °C ± 2 °C at a rate of 5 ° C / min ± 2 ° C / min. The battery needs to be placed in this environment for 10 minutes (30 minutes for large cells). During the test, the battery does not ignite and does not explode.

When the battery system is abnormal, the temperature rises. IIn order to prevent danger, thermoplastic insulation melts (120℃ ~ 140℃). In addition, the membrane pores close and become insulators. This prevents the electrolyte from passing through. So as to achieve the purpose of cutting off the current. Thereby achieving the purpose of interrupting the current.

Because of the high temperature condition, the internal separator of the battery will thermally be shrunk too much. And This will cause a short circuit between the inner positive and negative electrode sheets. The battery continues to act under the external heat source hot box, while the internal battery generates short-circuit current heat Q.

The two types of heat cause the battery separator to continue to shrink, causing more internal short circuits, and the internal heat of the battery rises exponentially during a vicious cycle. Because of the chamber constant temperature for 10 minutes of 30 minutes, the battery cannot dissipate heat. As a result, heat builds up quickly. Eventually, the battery is out of control.

Conclusion

As the user’s requirements for the energy density of lithium-ion batteries continue to increase, the safety performance of lithium batteries is facing increasing challenges. Many companies have studied many security measures to improve the safety of batteries. Conducting extreme testing helps companies find deficiencies in their products and produce safer products.

Last but not least, excellent battery testing equipment will play a good catalytic role for enterprises. We are a manufacturer of battery test equipment and environmental test equipment with 13 years of production and design experience. We believe that our products can help companies prevent battery fires, explosions and other extreme conditions, and produce safer products. It can also promote the stable development of lithium batteries and their derivatives.

0 notes

Text

Buy Cylindrical Cell Grading Machine in India

Why precision matters in cell grading

As India rapidly scales up its lithium battery production, the demand for high-speed and accurate Cell Grading Machines has become mission-critical. For any lithium battery manufacturer, grading cylindrical cells based on voltage, internal resistance, and capacity is the foundation of building a safe, high-performance battery pack.

If you’re looking to buy a Cylindrical Cell Grading Machine in India, there’s one name that consistently outperforms the competition—Semco Infratech.

What is a Cylindrical Cell Grading Machine?

A Cylindrical Cell Grading Machine is a specialized system used to automatically sort cylindrical lithium-ion cells into different bins based on specific parameters. These parameters typically include:

Open Circuit Voltage (OCV)

Internal Resistance (IR)

Capacity (in advanced models)

Cell Barcode

By accurately classifying cells, manufacturers ensure optimal pack balancing, longer battery life, and enhanced product safety.

Semco Infratech: India’s market leader

Unlike imported machines that often struggle with service, scalability, or integration, Semco Infratech builds machines specifically designed for the Indian manufacturing ecosystem. Our graders are built for speed, precision, and flexibility—backed by localized support and engineering customization.

Semco’s Cell Grading Machines are ideal for:

EV battery pack manufacturers

Energy storage system assemblers

Battery cell resellers and repurposers

Pilot and R&D labs for lithium batteries

Key features of Semco Cell Grading Machines

Semco Infratech offers a range of high-performance graders that cater to different production scales and technical needs. Here’s what sets our machines apart:

Fast throughput: Sort ≥10 PPM across multiple channels (10CH, 32CH, 64CH, etc.)

Accurate IR and voltage readings: Consistency that matches global testing standards

Real-time barcode integration: Full traceability and automated data logging

Minimal human error: Full automation ensures reduced dependency on skilled labor

MES-compatible: Ready for Industry 4.0 integration with your manufacturing execution systems

Benefits of buying from Semco Infratech

When you buy from Semco, you're not just buying a machine—you're investing in a long-term production advantage.

Pan-India support network

Quick lead times and local spares availability

Custom software integration

On-site training and AMC plans

Designed for Indian conditions—power, temperature, and floor layout

Compared to imported systems

Many Indian manufacturers opt for Chinese or Korean machines, only to discover limitations such as:

Delayed after-sales service

Language barriers in software/UI

Difficulty in integrating with Indian data systems

High logistics and maintenance cost

Semco Infratech eliminates all of these issues with its Made-in-India advantage, real-time support, and custom engineering capabilities.

Industries we serve

Our Cylindrical Cell Grading Machines are already deployed in:

EV manufacturing units

Solar and inverter battery plants

Government research labs

Lithium battery assembly lines across India

From startups to top-tier OEMs, Semco machines are trusted across the spectrum for their reliability, service, and ROI.

Ready to upgrade your cell grading line?

If your current setup is still semi-automated or relies on imported equipment with service delays, it’s time to switch. Semco Infratech offers the fastest delivery, localized training, and machines engineered for India’s lithium revolution.

Visit our website: www.semcoinfratech.com Or use our direct product link: Explore Cell Grading Machines

For business inquiries, demos, or a site visit, contact us via the form on our product page.

Conclusion

Buying a Cylindrical Cell Grading Machine in India is no longer a logistical challenge—it’s a strategic decision. And with Semco Infratech, you're choosing performance, speed, and service excellence. Join the top lithium battery manufacturers who trust Semco to keep their production lines running fast and fault-free.

#Cell Grading#Cylindrical Cell#Cell Grading Machines#Lithium Battery Manufacturers#bussiness#lithium-ion cell grading#cell grading machine

0 notes

Text

Curved Batteries: The Future of Sleek Wearables 🌀🔋

Wearable electronics are quickly evolving, and so are the energy storage solutions that power them. As devices become thinner, more flexible, and designed for the human body, traditional battery shapes no longer fit the bill. That’s why curved batteries are becoming a key part of innovation. As a lithium battery manufacturer, we at Ufine Battery have spent years developing custom curved battery solutions tailored to wearable tech.

In this article, we’ll explore how curved batteries are made, why they matter, and where they’re headed.

🎯 Why Curved Batteries Are a Game-Changer

Traditional lithium-ion batteries are rigid and rectangular. That works well for phones and laptops, but not for wristbands, rings, or smart glasses. Curved batteries change the game by adapting to the product's shape, not the other way around.

✅ More Design Freedom

With curved battery packs, engineers can place energy cells into rounded surfaces, wrap them around corners, or fit them into non-linear spaces. This opens up 30% more design freedom, especially important for:

Smartwatches

Fitness trackers

Smart jewelry

Medical sensors

Hearing aids

Design no longer needs to compromise comfort for power.

✅ Better Ergonomics

Curved batteries enable low-profile, lightweight wearables that sit close to the skin and move with the user. Comfort is no longer optional—it's expected by consumers. Flexible cells make it possible.

✅ High Performance in Small Spaces

Our curved lithium batteries pack just as much energy density as traditional cells. In many cases, they outperform flat packs because of improved surface integration and thermal management.

🔬 How Curved Batteries Are Designed

At Ufine Battery, we’ve developed a step-by-step process for curved cell design. Every project begins with understanding the mechanical, electrical, and thermal needs of the end product.

1. Defining the Curve Radius

The first decision is the bend radius—how tightly the battery needs to curve. This affects material selection, cell architecture, and separator flexibility.

2. Material Selection

Unlike flat batteries, curved cells require flexible substrates. We use:

Ultra-thin aluminum and copper foils

Flexible polymer separators

Soft PTC (positive temperature coefficient) materials

Our team balances conductivity, safety, and form factor in every choice.

3. Stress Simulation

We run mechanical stress simulations to predict how the battery will behave after thousands of flex cycles. This helps prevent delamination, separator puncture, or capacity loss.

4. Prototyping and Testing

Before production, each curved battery design goes through physical testing:

Bend cycle stress tests

Drop tests

Charge-discharge analysis

Internal resistance tracking

Heat and humidity stress tests

We want to be sure it works not just in the lab but in real-world use.

🏭 From Lab to Factory: Scaling Production

Scaling up curved battery production is a challenge most manufacturers aren’t ready for. But at Ufine, we’ve invested in tooling, training, and QC systems to make it work.

💡 Custom Tooling

Our factory uses precision rolling and laminating machines customized for flexible substrates. We also developed jig systems that allow each pack to be molded into specific curvatures without damaging electrodes.

🧪 Inline Testing

Every unit is tested for capacity, leakage, resistance, and dimensional tolerance—before and after curvature is applied. This prevents failures in the field.

🚀 Fast Turnaround

Even with all this testing, we’re known for fast production cycles. Unlike large brands with long lead times, we offer short turnaround—even for small runs.

💬 Why Work with Ufine Battery?

We’re not the largest battery manufacturer—but we’re proud to be the most adaptable. Our strength lies in our custom curved cell capabilities and customer-first approach.

What Makes Ufine Different?

📐 Custom Curved Cell Design: We tailor batteries to your product—not the other way around.

🛠️ OEM & ODM Services: From idea to prototype to scale, we’ve got you covered.

🔋 Full Range of Chemistries: Li-ion, 18650, LiFePO4, ultra-thin, high-temp, cold-temp, high-rate

📦 Small MOQs: Even one piece is enough to start your project.

⚡ Fast Response & Support: We answer quickly and clearly.

🕐 Quick Shipping: Don’t wait months. Get your parts on time.

🛡️ 1-Year Warranty: We stand by our quality and back it up.

Our clients include startups, medical device companies, smart wear brands, and even R&D labs.

👀 Where Curved Batteries Are Being Used

1. Smartwatches and Fitness Bands

Curved batteries are the heart of nearly every modern wrist-wearable. The slight arc allows them to sit flush against the wrist while maintaining enough power for Bluetooth, display, and sensors.

2. Medical Devices

Skin-mounted patches, hearing aids, and diagnostic bands all benefit from curved, low-profile batteries. Safety and long cycle life are especially critical here.

3. Fashion-Tech

Designers are creating earrings, bracelets, and rings that include smart functionality. Curved batteries make this possible without bulking up the piece.

4. AR Glasses

As augmented reality wearables go mainstream, flexible batteries help fit power cells into the temple arms without adding weight or discomfort.

📈 What’s Next for Curved Battery Innovation?

At Ufine Battery, we’re constantly experimenting with:

Ultra-thin flexible cells that are thinner than a credit card

Bendable LiFePO₄ chemistry for higher safety in flexible formats

Hybrid curve-pouch cells with asymmetric shapes

Battery+antenna integrated modules for wearable IoT

We're also testing smart coatings that improve water resistance and self-healing polymers that extend battery life.

📩 Ready to Talk Curved Battery Projects?

If you’re a designer, engineer, or startup founder working on wearables, we’d love to help. Our team can review your specs, suggest battery formats, and ship samples fast.

💬 Drop us a line at Ufine Battery 📦 Get a quote—even for just one piece 🎨 Need custom shapes? We do that daily ⏱️ Tight schedule? We deliver fast

The future of wearables is curved—and we’re powering it.

0 notes

Text

LQMs for High-Performance Discovery of Next-Gen Materials

Accelerating Next-Gen Material Discovery with Large Quantitative Models

Automotive, consumer electronics, and aerospace companies compete to develop stronger, lighter, more efficient, and eco-friendly materials. Innovative material discovery has been laborious, trial-and-error, expensive, and error-prone. This often requires years of research, many prototypes, and thorough physical testing.

Large Language Models (LLMs) and other AI improvements have improved data processing and drawn conclusions from current literature, but they lack the deep scientific understanding needed for materials science advances. LLMs are good at knowledge management and workflow optimisation because they process and develop conclusions from existent material. LLMs lack the molecular interactions and physical laws understanding needed for drug and material discovery.

Presenting Large Quantitative Models

Large Quantitative Models (LQMs) are novel. Enterprise AI and AI-powered materials science are moving towards LQMs. Since they incorporate the fundamental quantum equations driving physics, chemistry, and biology, LQMs are aware of how molecules behave and interact, unlike LLMs.

For scientific discovery, LQMs use quantum-accurate simulations to predict chemical characteristics orders of magnitude more accurately than LLMs, which use textual input. They learn math, physics, chemistry, biology, and molecular interactions. LQMs model real-world systems.

When used with generative chemistry, LQMs can explore the entire chemical space for desired molecules. They can enable quantitative AI simulations that digitally examine how molecules or compounds respond billions of times before the most promising options are tested in labs or physical prototypes. Highly accurate synthetic data from these simulations is utilised to train LQMs, improving their speed, intelligence, and efficacy.

R&D Changes in Different Industries

Researchers and manufacturers benefit greatly from AI and quantum equations. Cutting R&D cycles from years to months or weeks speeds up time to market. LQMs improve projected accuracy and help researchers uncover novel materials, compounds, and alloys faster than standard models. Reduce lab experimentation to save money. They optimise production and produce eco-friendly products to enhance sustainability. These incentives boost innovation and help companies dominate.

Manufacturing executives may remain ahead of foreign competitors, reduce supply chain issues, and create new product and design possibilities by integrating LQMs into processes.

Real-World Applications Encourage

SandboxAQ, a leading LQM company, is influencing multiple sectors.

Discovering Alloys

With the U.S. Army Futures Command Ground Vehicle Systems Centre, SandboxAQ is changing alloy development. They detected five high-performing alloys utilising machine learning and high-throughput virtual screening from over 7,000 compositions. These alloys used less conflict minerals and reduced weight by 15% while maintaining strength and elongation.

Battery lifespan forecast:

By decreasing the end-of-life (EOL) projection time by 95%, SandboxAQ advanced lithium-ion battery research. Their low mean absolute error predicted EOL 35 times more accurately with 50 times fewer data. After training on almost a million hours of data, predictions can be made in six cycles. This might cut cell testing time from months to days and battery development time by four years.

Catalyst Design:

Together with DIC and AWS, SandboxAQ is revolutionising catalyst design. They found superior nickel-based catalysts by leveraging its QEMIST Cloud and high-performance computers to better predict catalytic activity. This discovery speeds up the search for effective, non-toxic, and affordable industrial catalysts by reducing computation time from six months to five hours.

Cleaner Energy:

The energy industry is transforming materials and chemical process optimisation with Aramco. SandboxAQ is using LQMs to construct a multi-GPU-enabled computational fluid dynamics solver to improve material design and process efficiency in oil and gas facilities to help Aramco lower its carbon footprint.

Discovery of drugs

AQBioSim from SandboxAQ correctly and scientifically models molecular behaviour using LQMs. It helps biopharma teams explore enormous chemical landscapes and speed up discovery by four times by simulating interactions, anticipating findings, and refining drug ideas in silico. This improves candidate quality, predicts toxicity and efficacy earlier, and cuts discovery time from years to weeks.

Materials and chemicals:

Teams can mimic the actual world with AQChemSim before entering the lab. Since it uses basic principles, it accurately predicts the behaviour of molecules, materials, and industrial systems in real life. Teams can forecast performance under duress, expedite formulation, and enhance sustainable practices to shorten development cycles.

Cybersecurity:

SandboxAQ's AQtive Guard platform uses LQMs to revolutionise identity and cryptography management at scale. Risk analysis, unprecedented visibility, automated remediation, deep, AI-powered insight, post-quantum cryptography readiness, and compliance speed are its priorities.

Different Domains:

Medical diagnostics, treatment planning, and navigation are improved by LQMs, increasing autonomy and accuracy.

Solving Expertise, Scalability, and Cost Issues

Manufacturing executives often complain about AI technology affordability, scalability, and competence. SandboxAQ addresses these challenges. Although integrating AI requires an initial investment, SandboxAQ's platforms save R&D costs by expediting discoveries and minimising lab costs. Businesses are seeing product development and efficiency advances.

Scalable platforms like the cloud-native AQChemSim allow manufacturers of all sizes to use high-performance computing resources to do quantum-accurate simulations, democratising material discovery. The AQtive Guard platform is intelligent, fast, and scalable.

SandboxAQ's platforms enable enterprises to get quantum-powered insights without quantum computing teams by using AI-driven solutions that need minimum expertise.

Future and Beyond Manufacturing

LQMs facilitate previously impossible innovations and transform how industries develop next-generation materials and solutions. By replacing trial-and-error testing with fast, multi-dimensional search, LQMs accelerate design and discovery. They can solve strategic material-related business difficulties because of their particular qualifications.

SandboxAQ said it will work with industry experts and set new benchmarks to maximise LQMs' potential in battery, catalytic, and semiconductor applications. LQMs are being used by the company and NVIDIA to accelerate industry advances.

#LargeQuantitativeModels#LQMs#SandboxAQ#LargeQuantitativeModelsLQMs#NextGenMaterialsdiscovery#LQMsLargeQuantitativeModels#technology#technews#technologynews#news#govindhtech

0 notes

Text

Why Your Business Needs Battery Warranty Management Software

There’s a point where sticky notes, spreadsheets, and endless WhatsApp chats just don’t cut it anymore. If you’re in the business of batteries—selling, servicing, or scaling—you know that warranty claims can turn into a maze faster than a lithium-ion cell can overheat.

From different usage conditions to unpredictable failure patterns, managing battery warranties is not for the faint-hearted. And in an industry where downtime means lost trust and lost revenue, speed and accuracy aren’t optional—they are everything.

That is where a powerful battery warranty management software steps in. It does not just store claims; it streamlines your entire post-sales ecosystem. Think faster claims, cleaner data, happier customers, and teams that stop playing email ping-pong.

Welcome to the future of warranty management. It’s faster, sharper, and built to handle the charge.

Bad Warranty Processes Bleed Money and Trust Fast

The impact of mismanaged warranties isn’t just a back-office problem. It's a full-blown business bottleneck. When your team spends hours manually locating paperwork or validating serial numbers, efficiency tanks.

Misfiled or fraudulent claims can chip away at profit margins. Customers stuck in limbo grow frustrated, and service teams scramble to keep up with disconnected systems. Worse still, regulatory audits can go sideways without proper documentation.

Warranty chaos doesn’t just slow down operations—it hits where it hurts most: your reputation and your bottom line.

Battery Warranties Come With Built-In Complexity

Batteries don’t live easy lives. Usage varies wildly—what works in a solar setup may not in an e-scooter. That alone makes warranty terms a game of precision. Add to that discharge cycles, temperature exposure, charging behavior, and real-time diagnostics, and you’ve got yourself a data-driven puzzle.

Some claims require field testing. Others need photo evidence. And don’t even start on the logistics of returns, replacements, or dealer-level coordination.

A basic ticketing tool or Excel sheet won’t survive this level of complexity—it needs intelligence built for batteries.

Claim Smarter, Not Harder With the Right Software

A robust battery warranty management software eliminates the manual mess. It automates verification using QR codes or serial numbers and checks claims against real-time data in seconds.

No guesswork. No fake claims. No endless back-and-forths. Just fast, smart validations that your team and your customers can trust.

It’s not just automation—it’s peace of mind on autopilot.

One Source of Truth for Everyone Involved

When sales teams, dealers, and service centers all operate on different systems, things slip through the cracks. Warranty details get buried in inboxes. Customers get different answers from different people. That’s how trust erodes—silently, and quickly.

With centralized, cloud-based battery warranty management software, everyone sees the same data in real time. Claim statuses. Service notes. Warranty periods. All updated and accessible from anywhere.

You’re not just fixing batteries—you’re fixing communication, too.

Faster Resolutions Mean Stronger Customer Loyalty

Nobody enjoys waiting for updates—especially customers who rely on your battery to power their ride, home, or business. When claims move slowly, so does your brand’s credibility.

Automated workflows inside the software move things along—notifications get sent, technicians get assigned, and approvals happen faster. The result? Customers who feel valued. Teams that feel empowered. And a business that runs like a well-oiled machine.

Service isn’t just a cost—it’s your most powerful retention tool.

Insights That Turn Service Data Into Strategic Action

Data without insight is noise. But with intelligent analytics built into your battery warranty management software, patterns start to emerge. You’ll see which models are failing more often, what regions face higher returns, and where service bottlenecks slow things down.

These insights help engineering teams build better batteries. They guide procurement decisions. They even help you negotiate smarter warranties with suppliers.

When your service desk starts informing your product roadmap, you know you’re doing it right.

Modern Tools That Keep You Future-Ready

A great battery warranty management software doesn’t just solve today’s problems—it prepares you for what’s next. Think API integrations with your CRM and ERP systems, mobile accessibility for field agents, role-based access for security, and compatibility with IoT-backed smart batteries.

As your business grows, so does the software—scaling effortlessly to handle more products, more customers, and more complexity without the chaos.

The future doesn’t wait. Neither should your tech.

The Final Word: Warranty Can Be a Winning Strategy

Battery businesses that thrive aren’t just building better products—they’re delivering better experiences. And that experience doesn’t stop at the sale—it extends into how quickly and professionally you handle a claim.

Investing in reliable, cloud-based battery warranty management software is one of the smartest moves you can make. It cuts costs, strengthens your brand, builds trust, and turns service into a strategic advantage.

Because when your warranty system works like a charm, your whole business shines.

0 notes

Text

Beyond the Horizon: The Future of Solar Energy

The world is undergoing a profound energy transformation, and solar energy stands at the heart of it. Once a costly and niche power source, solar energy has become one of the fastest-growing renewable energy options globally. As technology advances and climate change concerns intensify, the future of solar energy looks brighter than ever. From urban rooftops to deserts, oceans, and even space, the sun’s rays are being harnessed increasingly innovatively to power the future.

As nations pledge to reduce carbon emissions and shift toward sustainable energy, solar technology is expanding in scale and evolving in form, function, and efficiency. The coming decades promise groundbreaking developments redefining how we generate, store, and consume solar power.

Breakthroughs in Solar Technology

At the core of the solar energy revolution is continuous innovation. Traditional silicon-based photovoltaic (PV) panels are being improved yearly, offering higher energy conversion rates, better durability, and lower production costs. But the future lies beyond silicon.

Emerging technologies like perovskite solar cells capture global attention due to their high efficiency, low production cost, and flexibility. These materials can be printed onto surfaces, offering the possibility of ultra-thin, lightweight, and semi-transparent solar panels. Such advancements could lead to widespread solar integration into windows, facades, cars, and clothing.

Another exciting area is multi-junction solar cells, which combine layers of different materials to capture more solar spectrum. These cells are already used in space technology and could soon find commercial applications on Earth. Flexible, rollable, and organic solar panels are also on the horizon, opening new doors for creative and practical solar deployment across diverse environments.

Energy Storage and Grid Independence

One of the significant challenges with solar energy has always been intermittency—it only works when the sun is shining. However, the future of solar is tightly linked with advances in energy storage. Integrating efficient, affordable batteries will make it possible to store excess energy during the day and use it at night or during cloudy periods.

Lithium-ion batteries, currently the most common storage technology, are joining solid-state batteries, flow batteries, and other emerging options that promise longer life cycles, faster charging, and better safety. As battery technology matures, the potential for off-grid solar systems will increase, especially in rural or remote areas.

In addition, energy storage will help stabilize national grids by reducing peak demand and preventing blackouts. Solar energy, storage, and innovative grid systems will empower individuals, businesses, and communities to generate, store, and manage their power independently.

Smart Integration and Digital Innovation

The digital revolution is reshaping how we interact with energy. In the future, solar energy systems will be deeply integrated with smart home and smart grid technologies. Homeowners will use AI-powered platforms to monitor real-time solar panel performance, battery levels, and energy usage. These systems will automatically adjust energy flows to maximize efficiency and minimize costs.

Machine learning algorithms can forecast solar production based on weather data, optimizing when and how stored energy is used. On a larger scale, digital platforms will help grid operators balance supply and demand, integrate multiple energy sources, and facilitate peer-to-peer energy trading.

Blockchain technology is already being tested for decentralized energy markets. In such systems, individuals can sell surplus solar power directly to others in their community, bypassing traditional utilities and creating a democratized energy economy.

Urban and Architectural Integration

Integrating solar energy into infrastructure will be essential as cities grow and urban density increases. Future urban landscapes will feature solar panels embedded into windows, sidewalks, walls, and rooftops. Building-integrated photovoltaics (BIPV) are expected to become mainstream, transforming entire buildings into energy-generating structures.

Solar roads and solar glass are also gaining attention. While still in early stages, these innovations can turn everyday surfaces into clean power sources. Public spaces, parking lots, and transit stations could all contribute to energy generation, reducing a city’s carbon footprint and promoting environmental awareness.

Vertical solar farms on skyscrapers and solar-covered bike paths are already being piloted in some countries, offering a glimpse into how future cities will blend function, sustainability, and beauty.

Space-Based Solar Power

One of the most ambitious and visionary ideas in the solar world is space-based solar power (SBSP). This futuristic approach involves placing solar power satellites in orbit, where they can collect solar energy 24/7 without atmospheric interference. The energy would then be transmitted to Earth using microwave or laser technology.

Though still under development, major agencies like NASA, ESA, and China’s space program are investing in SBSP research. If realized, it could provide an almost limitless supply of clean energy to Earth and play a crucial role in global decarbonization.

Solar energy may also support long-term space missions and extraterrestrial colonies in the future. Solar-powered habitats on the Moon or Mars could make human settlement in space more viable by ensuring a sustainable power source.

Global Access and Energy Equity

The future of solar energy also includes expanding access to underserved populations. Around 770 million people still live without access to electricity, mostly in sub-Saharan Africa and South Asia. Solar energy offers a decentralized, scalable, and affordable solution to electrify remote areas where grid infrastructure is too expensive or impractical.

Portable solar kits, solar-powered water pumps, and community microgrids are already making a difference. The future will bring more robust and cost-effective solutions tailored to local needs. Educational institutions, healthcare centers, and small businesses will thrive with access to reliable solar power, helping break the cycle of poverty and inequality.

As prices drop and governments introduce favorable policies, solar energy will play a key role in achieving United Nations Sustainable Development Goal 7: affordable and clean energy for all.

Environmental and Economic Impact

Wider adoption of solar energy will dramatically reduce global reliance on fossil fuels, leading to lower greenhouse gas emissions, cleaner air, and less water consumption. Solar farms require significantly less water than traditional power plants, critical in drought-prone areas.

Economically, solar energy will continue to be a significant job creator. The renewable energy sector employs millions worldwide, and the solar industry represents a large and growing share. From manufacturing and installation to R&D and maintenance, the solar workforce will expand rapidly, supporting green jobs and sustainable growth.

Solar energy offers attractive returns for investors. As technologies become more efficient and markets mature, investing in solar projects—whether residential, commercial, or utility-scale—has become both profitable and impactful.

A Brighter, Cleaner Tomorrow

The future of solar energy is bold, boundless, and brimming with possibility. From technological breakthroughs and more intelligent infrastructure to equitable access and interplanetary applications, solar power redefines how humanity views energy.

As we face urgent environmental and social challenges, the shift to solar isn’t just a wise choice, but also represents a cleaner planet, stronger economies, and a fairer world. Every ray of sunlight that hits our Earth holds potential. The question is no longer if we should harness it, but how far we’re willing to go to build a future fueled by the sun.

0 notes

Text

Key Considerations When Choosing a Lithium-Ion Battery Pack Supplier

In today’s tech-driven world, lithium-ion batteries are powering everything from consumer gadgets to electric vehicles (EVs) and renewable energy storage systems. As demand continues to grow, selecting the right lithium-ion battery pack supplier is essential to ensure your project’s success. From safety standards to performance, the right supplier can make a world of difference in both the short and long term.

In this blog post, we’ll explore the key factors you should consider when choosing a lithium-ion battery pack supplier, helping you make the right decision for your needs.

1. Performance Specifications

One of the most important considerations when selecting a lithium-ion battery pack supplier is the performance characteristics of their batteries. Every project has unique power needs, and understanding these will help you find the best supplier for your application. Here are the most critical performance factors to consider:

Energy Density: Energy density refers to how much energy the battery can store in relation to its weight and volume. If your project has space or weight limitations, choosing a supplier that offers high energy density batteries is crucial. High-density batteries can store more energy in a compact package, making them ideal for applications like electric vehicles, drones, and portable power banks.

Capacity: The battery capacity, often measured in amp-hours (Ah) or watt-hours (Wh), is another important factor. The right capacity depends on how long you need the battery to power your device or system before requiring a recharge. A higher capacity will deliver longer runtimes, but it may come with trade-offs in size and weight.

Voltage and Configuration: Lithium-ion battery packs come in a variety of voltage options. Ensure that the supplier offers packs that meet the voltage requirements for your application, whether it's a 3.7V cell for small electronics or higher-voltage configurations for more demanding applications like electric vehicles.

Discharge Rate: The discharge rate indicates how quickly the battery can release its stored energy. This is especially important for power-intensive applications, such as electric vehicles, power tools, and industrial machines. Be sure to choose a supplier that can lithium ion battery pack suppliers provide a battery with the appropriate discharge rate for your specific use case.

2. Safety Standards and Compliance

Safety is paramount when dealing with lithium-ion batteries. Poorly designed or faulty batteries can result in overheating, fire, or other catastrophic failures. When evaluating potential suppliers, you must prioritize safety. Here’s what to look for:

Battery Management System (BMS): A high-quality Battery Management System (BMS) is essential for maintaining safe battery operation. The BMS monitors critical factors like voltage, temperature, and charge/discharge cycles to prevent overcharging, over-discharging, or overheating. Choose a supplier that includes a reliable BMS in their battery packs.

Safety Certifications: Reputable suppliers should provide batteries that meet international safety standards and regulations. Look for certifications like UL 2054, CE, RoHS, and UN 38.3 for safe transport. These certifications ensure that the battery pack has undergone rigorous safety testing and complies with industry regulations.

Thermal Management: Lithium-ion batteries are sensitive to temperature fluctuations. Without proper thermal management, a battery could overheat, resulting in potential hazards. Choose a supplier that uses quality thermal management solutions, such as integrated heat sinks or cooling mechanisms, to ensure stable battery performance.

Short Circuit and Overcharge Protection: Suppliers who integrate overcharge protection, over-discharge protection, and short circuit protection into their battery packs provide an added layer of security to prevent dangerous situations.

3. Customization Options

No two projects are the same, and finding a supplier that offers customization can be a significant advantage. Depending on your application, you may need batteries with specific dimensions, voltage, or configurations. Here’s what to consider:

Custom Pack Design: Some projects require unique battery pack designs, whether for size constraints, power needs, or specific device requirements. Suppliers that offer custom design services can help tailor the pack to meet these unique needs.

Flexible Voltage and Capacity Options: If your application requires a specific voltage or a non-standard battery size, seek a supplier who can provide tailored voltage and capacity configurations.

Modular Battery Systems: For larger-scale applications, consider a supplier who offers modular battery packs. These allow you to scale the system to meet evolving power demands by adding or removing individual modules as needed.

4. Quality Control and Reliability

When it comes to batteries, reliability is key. A supplier that offers consistent, high-quality products is a supplier you can trust. Check the following factors to gauge the supplier’s quality control measures:

Production and Testing Standards: Ask the supplier about their production and testing processes. A reputable supplier will have a clear process in place for quality assurance, including rigorous testing to ensure each battery meets the required specifications. Look for suppliers with established quality management systems such as ISO 9001.

Cycle Life and Durability: A battery’s cycle life is the number of charge and discharge cycles it can undergo before its capacity starts to degrade. Choose a supplier that offers batteries with long cycle life for better longevity and fewer replacements, especially for high-use applications like EVs or large-scale energy storage systems.

Track Record and Reputation: Take the time to research potential suppliers’ reputations. Look for customer reviews, case studies, and industry accolades to gauge the reliability and performance of their products.

5. Customer Service and Support

Even after purchasing a lithium-ion battery pack, you may encounter issues or have questions regarding integration, performance, or maintenance. Exceptional customer service and ongoing support are invaluable in ensuring the continued success of your project.

Technical Support: Ensure that the supplier offers robust technical support to help you with integration, troubleshooting, and system optimization. A supplier with a knowledgeable team can assist you in getting the best performance from your battery packs.

Warranty and After-Sales Service: A strong warranty policy can provide peace of mind, especially for long-term projects. Look for suppliers who offer clear warranty terms and after-sales services in case the battery experiences issues during its lifespan.

Training and Documentation: Some suppliers offer training or documentation to help you understand how to use and maintain the battery packs. These resources can be particularly useful if you’re working with complex battery management systems or large battery arrays.

6. Cost-Effectiveness and Value

While cost should not be the only factor in your decision-making process, it is important to balance price with value. A low-cost battery may save money upfront but could lead to higher long-term costs if it’s less durable or has poor performance. Here are some things to consider:

Total Cost of Ownership (TCO): The TCO includes more than just the initial purchase price. Consider factors like longevity, maintenance, and energy efficiency when calculating the overall cost. A higher-quality battery may cost more initially, but it can save you money over time by requiring fewer replacements and offering better performance.

Bulk Discounts and Volume Pricing: If you need to order large quantities of batteries, inquire about bulk discounts or volume pricing. Many suppliers offer lower prices per unit for large orders, helping you cut costs in large-scale projects.

Hidden Costs: Ensure that you are fully aware of any additional fees, such as shipping, handling, or installation costs. A supplier who provides a transparent pricing structure will help you avoid surprises down the road.

7. Supply Chain and Delivery Times

Supply chain reliability and timely delivery are essential for project deadlines and smooth execution. The last thing you want is a supplier who causes delays or has trouble meeting delivery schedules.

Lead Times: Check with the supplier regarding production lead times and delivery times. Ensure their timelines align with your project’s schedule and click here allow for buffer time in case of unexpected delays.

Stock Availability: If you require ongoing battery replacements or additional units, make sure that the supplier has a sufficient inventory and can fulfill future orders promptly.

Shipping and Logistics: Lithium-ion batteries are classified as hazardous materials for shipping purposes, so it’s important that the supplier is experienced in handling shipping regulations and can provide reliable logistics for safe and timely delivery.

Selecting the right lithium-ion battery pack supplier is a crucial step in ensuring the success of your project. By considering performance specifications, safety features, customization options, quality control, and supplier reputation, you can make an informed choice that aligns with your project’s needs and goals. Additionally, strong customer support and cost-effectiveness will ensure a long-lasting and reliable partnership. Take your time to evaluate your options and choose a supplier that not only meets your technical requirements but also provides exceptional service and value for your investment.

0 notes

Text

Safety and Efficiency in Lithium-Ion Battery Manufacturing in India: Best Practices

As India accelerates its transition to electric vehicles (EVs) and renewable energy storage solutions, lithium-ion (Li-ion) batteries have become the foundation of this transformation. These batteries are critical not only for EVs, but also for solar storage, grid stabilization, and consumer electronic devices. With rising demand, India's battery manufacturing business is fast increasing. However, increased manufacturing presents substantial hurdles in terms of safety, efficiency, and environmental sustainability. This blog will explore the best practices for maintaining safety and efficiency in lithium-ion battery manufacturing in India.

1. Understanding the Lithium-Ion Battery Manufacturing Process

To appreciate the importance of safety and efficiency in lithium-ion battery manufacturing, it is necessary to understand the many processes involved in production:

Cell Manufacturing: This is the first and most important phase. It entails producing individual cells from raw materials such as lithium, cobalt, nickel, and graphite. These materials are mixed to form electrodes (anode and cathode), which are then applied to thin foils.

Cell Assembly: The coated electrodes are stacked or coiled to form cylindrical, prismatic, or pouch cells. The cells are subsequently filled with electrolyte solution and sealed.

Module and Pack Assembly: After the cells are manufactured, they are organized into battery modules and integrated into packs that power electric automobiles and other large-scale applications.

Testing & Quality Control: The cells and packs are extensively tested for voltage, capacity, internal resistance, and temperature stability to assure their safety and functionality.

Each step needs a high level of precision, and errors might have an impact on the battery's performance and safety.

2. Safety. Best Practices for Lithium-Ion Battery Manufacturing

Because of the volatile nature of the ingredients used in lithium-ion battery manufacture, safety is of the utmost importance, especially when handling them. The following are best practices to maintain safety during the production process:

a) Material Safe Handling The basic elements used in Li-ion batteries, including lithium, cobalt, nickel, and solvents, are dangerous. It is vital to develop stringent handling protocols.

Personal Protective Equipment (PPE): Workers should wear suitable PPE, such as gloves, goggles, and flame-retardant gear, to avoid direct contact with hazardous chemicals and prevent injury.

Proper Ventilation: Certain compounds, such as solvents used in cell manufacture, might create harmful vapors. Manufacturing facilities should be well-ventilated to avoid harmful fumes from accumulating.

b) Fire and Explosion Prevention. Lithium-ion batteries can overheat, short-circuit, and even catch fire if they are damaged or made incorrectly. Some of the recommended practices are:

Automated and Controlled Environments: Use automated systems to reduce human error. Machines that handle volatile materials should be kept in sealed, temperature-controlled areas to avoid fire hazards.

Explosion-Proof Systems: To reduce the risk of fires or explosions in locations where combustible materials are handled or stored, employ explosion-proof equipment and structures.

c) Battery Testing and Monitoring. Ensuring that every cell and pack is extensively tested before it reaches the manufacturing floor is critical for both safety and longevity.

Cycle Testing: Every cell should be thoroughly cycle tested to ensure that it can endure repeated charging and discharging without overheating, short-circuiting, or losing capacity.

Temperature Control: Check battery cells for temperature rise during charging and discharging cycles. If a battery exceeds its safe temperature range, it must be deactivated or modified.

d) Employee Training and Awareness. Safety in the industrial process is dependent on the workforce's skill and awareness. Regular training on current safety standards and emergency response methods should be provided. Employees should be knowledgeable with:

Hazardous Material Handling: Proper ways for handling dangerous chemicals and materials should be emphasized during training.

Emergency Protocols: Employees must understand what procedures to take in the event of a fire, spill, or equipment malfunction to ensure minimal damage and safe escape.

3. Efficiency Best Practices for Lithium-Ion Battery Manufacturing

To meet rising demand for lithium-ion batteries, producers must assure efficient production methods. High efficiency not only lowers operational expenses, but also reduces waste, energy consumption, and the environmental impact.

a) Automation and robotics The use of automation in battery manufacture is a significant efficiency enhancer. Automated methods improve homogeneity, decrease human error, and accelerate production. Several applications include:

Automated Cell Assembly: Robotics can speed up the electrode coating process, reduce human intervention, and maintain consistency in the layers of coating on electrodes.

Material handling: Automated systems can efficiently convey raw materials and completed products throughout the factory, eliminating delays and increasing output.

b) Energy efficiency Battery manufacture is an energy-intensive process, although there are numerous strategies to reduce energy use.

Energy-Efficient Equipment: Manufacturers should invest in energy-saving machinery and process technology, such as low-temperature furnaces and coolers.

Solar Power Integration: Integrating solar panels into a manufacturing plant can assist satisfy energy needs in a sustainable manner, reducing the facility's carbon footprint.

c) Lean Manufacturing Techniques. Implementing lean manufacturing concepts can assist to eliminate waste, increase efficiency, and streamline operations. Some key practices are:

Just-in-Time (JIT) Production: By optimizing the supply chain and inventory systems, producers may reduce excess material waste and lower storage costs.

Six Sigma approaches help discover and reduce inefficiencies in the production process by emphasizing continuous improvement and variation reduction.

d) Waste Management & Recycling The disposal of waste items, particularly dangerous ones, can create substantial environmental issues. Implementing a comprehensive waste management system, which includes:

Material Recycling: Manufacturers should use a closed-loop recycling method to recover valuable materials like lithium, cobalt, and nickel from spent batteries. This decreases the requirement for raw material extraction and minimizes environmental impact.

Disposal Protocols: Batteries that are found to be damaged or no longer serviceable must be disposed of in accordance with strict environmental requirements to avoid contamination or leaking of harmful substances.

e) Supply Chain Optimization. Another important part of total production efficiency is to maintain an efficient supplier network. Streamlining the whole supply chain, from raw material sourcing to completed product distribution, can improve production timelines and lower costs.

Supplier partnerships: Establishing good partnerships with key suppliers of vital raw materials (such as lithium and cobalt) can assist to avoid shortages, stabilize pricing, and ensure consistent quality.

Inventory Management: Using advanced inventory management systems, such as RFID or IoT-enabled tracking, allows you to check stock levels in real time, reducing the danger of overproduction or material shortages.

Conclusion

As India strives to become a global powerhouse for lithium-ion battery manufacturing, prioritizing safety and efficiency in production is not only a regulatory need, but also a moral and economic imperative. By using best practices in material handling, fire safety, automation, and waste management, manufacturers can reduce the risks associated with battery production while increasing operating efficiency. With the correct emphasis on safety standards, workforce training, and sustainable practices, India can take the lead in producing high-quality, dependable, and environmentally responsible lithium-ion batteries to fulfill the growing demands of the EV and renewable energy sectors.

By adopting these best practices, the lithium-ion battery manufacturing industry in India will not only contribute to the nation's economic prosperity but also assure a safer, cleaner and more sustainable future for all.

0 notes

Text

Semco SLB 5V 3A 8CH is an 8-channel pouch cell tester designed for precise lithium-ion battery analysis. Widely used in battery R&D and production for its reliability, speed, and smart control.

#Semco SLB 5V 3A 8CH#8CH pouch cell tester#lithium-ion battery tester#battery testing equipment#pouch cell testing machine#lithium battery testing system#multi-channel battery tester#5V 3A battery tester#battery R&D equipment#precision battery tester

0 notes

Text

Battery Manufacturing Equipment Market, Drivers, Future Outlook | BIS Research

Battery Manufacturing Equipment refers to the machinery, tools, and systems used in the production of batteries, typically for industrial, automotive, or consumer applications. This equipment encompasses the full range of processes involved in battery production, including material handling, electrode preparation, cell assembly, electrolyte filling, formation, aging, testing, and packaging.

According to BIS Research,the global battery manufacturing equipment market is projected to reach $88,093.50 million by 2031 from $9,439.22 million in 2021, growing at a CAGR of 27.12% during the forecast period 2022-2031.

Battery Manufacturing Equipment Overview

Battery manufacturing equipment plays a critical role in the production of various types of batteries, including lithium-ion, lead-acid, and solid-state batteries, among others. As demand for batteries rises due to the growth of electric vehicles (EVs), renewable energy storage, and portable electronics, the need for advanced, reliable, and efficient manufacturing equipment becomes increasingly important.

Key Stages of Battery Manufacturing

Material Handling and Preparation

Electrode Manufacturing

Cell Assembly

Electrolyte Filling and Sealing

Formation and Aging

Advancements in Battery Equipement

Automated Assembly Lines

AI and Machine Learning Integration

Environmentally Friendly Manufacturing

Download the Report Click Here !

Market Segmentation

1 By Application

2 Equipment By Process

3 By Battery Type

4 By Region

Demand – Drivers and Limitations

The following are the demand drivers for the global battery manufacturing equipment market:

• Rising Demand for Electric Vehicles (EVs) • Government Initiatives to Reduce Carbon Footprints and e-Waste

The market is expected to face some limitations too due to the following challenge:

• Rising Cost and Competitive Pressure for Battery Equipment Manufacturers • Logistics and Supply Chain Risks

Request a sample of this report on the Battery Manufacturing Equipment Market

Recent Developments in the Global Battery Manufacturing Equipment Market

• In May 2022, by aiding customers in the U.S. with battery manufacture, Xiamen Tmax Equipments maintained a favorable connection with them. It offered them the pouch cell pilot line, which comprises 52 machines ranging from mixing to testing. In accordance with the real requirements of the customer, Xiamen Tmax Equipments supplied complete solutions for the production of coin cells, cylinder cells, pouch cells, prismatic cells, and battery packs on a lab, pilot, and large-scale.

•In June 2022, Wuxi Lead Intelligent Equipment Co., Ltd. signed a contract with Volkswagen to deliver 20GWh lithium battery manufacturing equipment. The company would strengthen its presence in the European market and mark a new era of its global operation.

Battery Manufacturing Equipment Future Outlook

Several key trends and advancements are expected to shape the future of this industry

Increased Automation and Digitalization

Scalability and Flexibility

Sustainability and Energy Efficiency

Regionalization and Decentralization of Manufacturing

Access more detailed Insights on Advanced Materials,Chemicals and Fuels Research Reports

Conclusion

Battery manufacturing equipment is at the forefront of the global energy transformation, playing a crucial role in producing the batteries that power electric vehicles, renewable energy storage, and portable devices.

The evolution of battery technology, such as the shift towards solid-state batteries and the use of innovative materials, is reshaping the design and function of manufacturing equipment. Automation, digitalization, AI integration, and sustainable practices are expected to dominate the future of battery production, improving efficiency, reducing costs, and enhancing quality.

#Battery Manufacturing Equipment Market#Battery Manufacturing Equipment Report#Battery Manufacturing Equipment Industry

0 notes

Text

Battery Grade Propanesulfolactone, Global Market Size Forecast, Top 10 Companies Rank and Market Share

Battery Grade Propanesulfolactone Market Summary

Battery grade propanesulfolactone, also known as propanesultone, is a chemical compound that is sometimes used as an electrolyte additive in lithium-ion batteries. It is a cyclic sulfonic ester with the molecular formula C3H6O3S. Propanesulfolactone is a colorless liquid with a slightly sweet odor.

According to the new market research report “Global Battery Grade Propanesulfolactone Market Report 2024-2030”, published by QYResearch, the global Battery Grade Propanesulfolactone market size is projected to reach USD 0.04 billion by 2030, at a CAGR of 6.9% during the forecast period.

Figure. Global Battery Grade Propanesulfolactone Market Size (US$ Million), 2019-2030

Figure. Global Battery Grade Propanesulfolactone Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Battery Grade Propanesulfolactone include Jiangsu Hicomer New Material, Changshu Juhe Chemical, etc. In 2023, the global top three players had a share approximately 45.0% in terms of revenue.

About The Authors

Yunmei Sun---Lead Author

Email: [email protected]

Sun Yunmei has 2 years of industry research experience, focusing on research in the chemical industry chain related fields, including medical grade reagents, high-purity reagents for semiconductors, and chemical laboratory equipment.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

All Functions in One Semco 10CH Sorting Unit

In today’s high-speed battery manufacturing landscape, operational efficiency is driven by smart integration. Instead of relying on multiple disconnected devices for cell testing, barcode scanning, and sorting, manufacturers now need a compact, centralized solution that can handle everything seamlessly. That’s exactly what Semco Infratech’s 10CH Multifunction Sorting Machine with Barcode delivers—all critical functions in one automated unit, purpose-built for lithium-ion cell grading at scale.

Integrated testing, grading, and barcode tracking

The Semco 10CH Sorting Unit combines three core functions into one industrial-grade system:

Electrical performance testing of cylindrical lithium-ion cells

Multi-level sorting based on programmable voltage and internal resistance ranges

Real-time barcode scanning for digital traceability

This consolidation eliminates the need for separate devices, manual data entry, or batch re-handling. Each cell is scanned, tested, graded, and sorted within seconds—accurately and without operator dependency.

High-speed 10-channel architecture

At the heart of this multifunction system is Semco’s high-performance 10-channel parallel testing platform. It allows:

Simultaneous testing of 10 lithium-ion cells

Speed of 1.5–2 seconds per cell

Accurate measurement of Open Circuit Voltage (OCV) and Internal Resistance (IR) with ±0.5% precision

Fast, automatic sorting into up to 10 programmable grading bins

With one machine, you achieve what used to require multiple operators, tools, and processes.

Barcode integration for full traceability

The integrated barcode module ensures that every tested cell is digitally tagged with its performance data. This enables:

Cell-level tracking throughout the production cycle

Automated quality reporting and digital batch logs

Seamless MES/ERP integration

Fast recall or warranty validation, when needed

This feature is essential for EV battery manufacturers and exporters who need traceable data for compliance and product validation.

Built for production and R&D environments

Whether you're running a large-scale EV pack line or a lithium-ion R&D lab, this all-in-one sorting unit is engineered to deliver:

Consistent results for thousands of cells per day

Adaptability to cell formats like 18650, 21700, and 32700

User-friendly operation with minimal training

Reliable operation in 24/7 production setups

It is already deployed in leading battery facilities across India—proving its scalability and performance under real-world conditions.

Cost-effective automation with local support

Many manufacturers still rely on Chinese systems that require additional hardware or lack local support. Semco’s solution offers:

Fully integrated functions in a single compact footprint

Zero import delays and India-wide service network

Easy upgrades, spare part availability, and on-site training

Faster ROI and lower total cost of ownership compared to modular or imported setups

This makes it the most cost-efficient and scalable investment for companies moving toward high-precision automation.

Conclusion

All Functions in One Semco 10CH Sorting Unit isn’t just a promise—it’s a proven operational advantage. From barcode-enabled traceability and high-accuracy testing to intelligent binning and real-time reporting, Semco Infratech’s 10CH Multifunction Sorting Machine with Barcode delivers everything a modern battery manufacturer needs in one powerful, integrated system.

Explore the product here: 👉 https://bit.ly/3IgAtBG

For manufacturers serious about scaling lithium-ion production without compromising on speed, traceability, or quality, Semco’s all-in-one sorting unit is the clear industry benchmark.

#Sorting Machine#Multifunction Sorting Machine#10CH Multifunction Sorting Machine#10CH Multifunction Sorting Machine with Barcode

0 notes

Text

Which Companies Specialize in Manufacturing of Battery Production Machines?

The global battery production machine market size is expected to grow from USD 7.3 billion in 2022 to USD 19.4 billion by 2027, at a CAGR of 21.5% from 2022 to 2027.

Battery production machines are used to manufacture lithium-ion batteries. Lithium-ion batteries are made of three major components: cathode, anode, and electrolyte, and they are available in multiple variants, depending on the materials combined with lithium, such as cobalt, nickel, manganese, titanium, and iron. Various machine types, such as mixing machines, coating and drying machines, calendaring machines, slitting machines, electrode stacking machines, assembling and handling machines, and formation and testing machines, have been covered in the report’s scope.

Battery Production Machine companies include:

Hitachi, Ltd. (Japan),

Durr Group (Germany),

Wuxi Lead Intelligent Equipment Co., Ltd. (China),

Shenzhen Yinghe Technology Co., Ltd. (China), and

Schuler Group (Germany).

Download PDF Brochure:

Hitachi, Ltd. is a multinational conglomerate headquartered in Tokyo, Japan. The company operates through the Digital Systems & Services, Green Energy & Mobility, Connective Industries, Automotive Systems Business, Hitachi Construction Machinery Co., Ltd., Hitachi Metals, and Others segments. It offers lithium-ion battery production machines through its subsidiary Hitachi High-Tech Corporation. Hitachi High-Tech Corporation was established in 1947 and is listed on Tokyo Stock Exchange, operating independently in the Hitachi Group. In May 2020, the High-Tech Corporation was delisted and became a wholly owned subsidiary of Hitachi, Ltd. The subsidiary operates in four business categories: Nano-Technology Solutions, Analytical & Medical Solutions, Core Technology Solutions, and Value Chain Solutions.