#management PDM software

Explore tagged Tumblr posts

Text

Streamline Projects with PDM Product Data Management

At Symetri, we empower your business with PDM product data management to boost efficiency and streamline workflows. From integrating Digital Twin Technology to leveraging Twinmotion for Revit, our expert team ensures seamless collaboration and data accuracy. Whether you need BIM project support or advanced PDM software, we deliver tailored solutions that enhance productivity and decision-making.

Discover how PDM product data management can transform your processes. Visit our PDM solutions page and take the first step towards innovation today!

#Digital Twin Technology#Twinmotion for Revit#BIM Project Support#PDM product data#management PDM software

0 notes

Text

What Sets PDMS Apart in Piping Design? A Practical Guide for Engineers

PDMS (Plant Design Management System) is a powerful 3D piping software widely used in engineering and construction for designing piping systems, particularly in industries like oil, gas, and power generation. PDMS is well-known for its capacity to simplify and improve complicated plant layouts, allowing engineers to accurately design, visualize, and evaluate facility components. This guide highlights the core features that make PDMS a standout tool in piping design & engineering. Read more: https://casamaruka.com/what-sets-pdms-apart-in-piping-design-a-practical-guide-for-engineers/

2 notes

·

View notes

Text

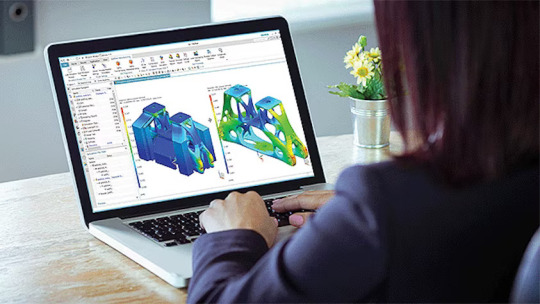

Optimizing Group Projects with SolidWorks PDM: The Ultimate Collaboration Tool

Group assignments can be challenging, especially in engineering, where collaboration and accuracy are crucial. SolidWorks Product Data Management (PDM) is a powerful tool that streamlines collaborative efforts, making group assignments more efficient and manageable. In this blog, we'll explore how SolidWorks PDM facilitates collaboration, enhances productivity, and ensures project success. We'll also highlight the benefits of seeking the Best Solidworks Assignment Help Online and solidworks Assignment Help to maximize your academic performance.

What is SolidWorks PDM?

SolidWorks PDM is a data management solution that centralizes the storage, organization, and control of project data. It allows multiple users to work on the same project simultaneously while ensuring that everyone has access to the latest information. This system is particularly beneficial for group assignments, where collaboration and version control are essential.

Key Features of SolidWorks PDM

Centralized Data Storage

SolidWorks PDM provides a secure, centralized repository for all project files. This ensures that team members can easily access and share data, reducing the risk of lost or misplaced files.

Version Control

With SolidWorks PDM, every modification is tracked, and previous versions are saved. This feature allows team members to revert to earlier versions if needed and ensures that everyone is working with the most up-to-date information.

Workflow Automation

The workflow automation feature streamlines the approval process. Tasks are automatically assigned, and notifications are sent to the relevant team members, ensuring that projects move forward without unnecessary delays.

Access Control

SolidWorks PDM allows administrators to set permissions for different users, ensuring that only authorized personnel can access sensitive information. This feature helps maintain data security and integrity.

Integration with CAD Software

SolidWorks PDM seamlessly integrates with SolidWorks CAD software, providing a cohesive environment for design and data management. This integration enhances productivity and reduces the likelihood of errors.

Benefits of Using SolidWorks PDM for Group Assignments

1. Enhanced Collaboration

SolidWorks PDM facilitates real-time collaboration among team members. By centralizing data storage and providing version control, it ensures that everyone is working on the same page. Team members can easily share updates and feedback, leading to more efficient project completion.

2. Improved Productivity

The workflow automation feature of SolidWorks PDM streamlines the approval process, reducing bottlenecks and ensuring that projects stay on track. By automating routine tasks, team members can focus on more critical aspects of the project, enhancing overall productivity.

3. Reduced Errors

Version control and access control features of SolidWorks PDM significantly reduce the likelihood of errors. Team members can always access the latest version of a file, and unauthorized changes are prevented. This ensures that the final output is accurate and meets the required standards.

4. Time Savings

With SolidWorks PDM, team members can quickly locate and access the necessary files, reducing the time spent searching for information. Workflow automation further saves time by eliminating manual approval processes. These time savings translate into more efficient project completion and better use of resources.

5. Better Project Management

SolidWorks PDM provides tools for tracking project progress and managing tasks. Team leaders can monitor the status of assignments, identify potential issues, and allocate resources effectively. This leads to better project management and successful completion of group assignments.

Seeking the Best Solidworks Assignment Help Online

While SolidWorks PDM offers numerous benefits for collaborative engineering projects, seeking professional assistance can further enhance your academic performance. The Best Solidworks Assignment Help Online provides expert guidance and support for your group assignments. Here are some reasons to consider seeking solidworks Assignment Help:

Expert Guidance

Professional assignment help services employ experts with extensive knowledge and experience in SolidWorks and PDM. They can provide valuable insights and guidance, helping you understand complex concepts and complete your assignments effectively.

Customized Solutions

Assignment help services offer customized solutions tailored to your specific requirements. Whether you need assistance with a particular aspect of the project or comprehensive support, they can provide the help you need.

Time Management

Balancing multiple assignments and responsibilities can be challenging. Seeking solidworks Assignment Help allows you to manage your time more effectively, ensuring that you can focus on other important tasks without compromising the quality of your work.

Quality Assurance

Professional assignment help services ensure that your assignments are of the highest quality. They provide thorough reviews and edits, ensuring that your final output meets academic standards and is free of errors.

Plagiarism-Free Work

Reputable assignment help services guarantee original, plagiarism-free work. This ensures that your assignments are unique and adhere to academic integrity guidelines.

Conclusion

Collaborative engineering projects can be complex and challenging, but SolidWorks PDM provides the tools necessary to streamline group assignments and enhance productivity. By centralizing data storage, providing version control, automating workflows, and ensuring data security, SolidWorks PDM facilitates efficient collaboration and successful project completion.

In addition to utilizing SolidWorks PDM, seeking the Best Solidworks Assignment Help Online can further enhance your academic performance. Expert guidance, customized solutions, and quality assurance ensure that your assignments meet the highest standards. By combining the benefits of SolidWorks PDM with professional assignment help, you can achieve success in your engineering studies and group projects.

For those looking to maximize their efficiency and productivity in group assignments, integrating SolidWorks PDM and leveraging solidworks Assignment Help is the way to go. This combination provides a comprehensive approach to collaborative engineering, ensuring that you and your team can achieve your academic and project goals with ease.

reference:

#solidworks#assignmenthelp#solidworks assignment help#solidworksassignmenthelp#studentassistance#education#school#academicsuccess

3 notes

·

View notes

Text

Diploma in Haryana - Your Gateway to a Bright Future | Educational Powerhouse

Introduction to Diploma in Haryana

Choosing the right diploma can feel overwhelming. But if you're eyeing opportunities in Haryana, you're already on the right track. Known for its robust education system and skill-based learning institutions, pursuing a diploma in Haryana is a strategic move for a bright future.

Whether you're a recent 10th pass student or someone looking to upskill, diploma programs in Haryana offer flexibility, industry relevance, and career-ready qualifications. Let's explore the various aspects of diploma education in this progressive state.

Why Choose a Diploma in Haryana?

Affordable Yet Quality Education

Government and private institutes offer low-cost but high-quality diploma courses.

Scholarships and fee concessions available for meritorious and SC/ST students.

Skill-Based Curriculum

Most diploma programs are designed to equip students with practical skills.

Programs in polytechnic, paramedical, and engineering fields are in high demand.

Recognized Institutions

Haryana has several AICTE, DTE, and UGC-approved institutes.

Institutions like Bhiwani Polytechnic, Government Polytechnic Sonipat, and Ambala Institute of Technology are renowned.

Career-Oriented Programs

High employability across manufacturing, healthcare, construction, and IT sectors.

Many companies in NCR recruit diploma holders directly from campus.

Popular Diploma Courses in Haryana

Engineering Diplomas

Mechanical Engineering

Electrical Engineering

Civil Engineering

Computer Engineering

Non-Engineering Diplomas

Fashion Designing

Hotel Management

Early Childhood Care & Education

Mass Communication

Medical & Paramedical Diplomas

Pharmacy (D.Pharm)

Medical Lab Technician

Radiology Technician

Operation Theatre Technician

IT and Computer-Based Diplomas

Software Development

Data Entry & Office Automation

Web Designing

Cyber Security

Eligibility Criteria

For Engineering Diplomas:

Minimum qualification: 10th pass with Science and Math.

Some lateral entry programs available after 12th or ITI.

For Paramedical Diplomas:

10+2 with PCB or PCM streams.

For Other Streams:

Varies based on course, often 10th or 12th pass.

Admission Process in Haryana

Centralized Online Admissions

Conducted by Haryana State Technical Education Society (HSTES).

Includes online application, document verification, and seat allotment.

Entrance Exams

Some courses like D.Pharm or Diploma in Education may require entrance tests.

Direct Admission

Many private institutions offer direct admissions based on merit.

Top Government Diploma Colleges in Haryana

1. Government Polytechnic, Hisar

Offers over 10 diploma programs.

Strong industry collaborations.

2. Government Polytechnic, Ambala

Focus on engineering and applied sciences.

3. Bhiwani Polytechnic Institute

Known for Mechanical and Civil Engineering.

4. Government Polytechnic for Women, Faridabad

Empowering women through vocational education.

Best Private Diploma Colleges in Haryana

1. Lingaya’s Institute of Management and Technology, Faridabad

2. PDM Polytechnic, Bahadurgarh

3. JMIT Radaur

4. Somany Polytechnic, Rewari

These institutions offer high-end labs, experienced faculty, and placement assistance.

Career Scope After Diploma in Haryana

Employment Opportunities

Government jobs in state services, Indian Railways, and defense sector.

Private sector jobs in industries like Maruti Suzuki, Hero MotoCorp, and Infosys.

Entrepreneurship

Start your own business in repair, consultancy, or training.

Higher Education

Lateral entry into 2nd year of B.Tech/B.E.

Advanced diplomas or certifications to specialize further.

Government Support & Scholarships

State-Level Schemes

Post Matric Scholarship Scheme

Haryana SC/BC Post-Matric Scholarship

Central Government Schemes

Pragati Scholarship (for girls)

Saksham Scholarship (for differently-abled students)

Industry Tie-Ups and Internships

Many diploma colleges have tie-ups with industry leaders for internships and placements:

Hero MotoCorp

JCB India Ltd.

HCL Technologies

Fortis Healthcare

FAQs About Diploma in Haryana

1. What is the duration of a diploma in Haryana?

Ans: Most diploma courses range from 2 to 3 years.

2. Is diploma in Haryana valid for government jobs?

Ans: Yes, if completed from AICTE/DTE-recognized institutions.

3. Can I do B.Tech after a diploma?

Ans: Yes, via lateral entry into the 2nd year of an engineering program.

4. Are online diploma courses available in Haryana?

Ans: Some institutions offer hybrid or online diploma programs.

5. How can I apply for scholarships?

Ans: Visit the official Haryana scholarship portal or your college’s admin office.

Conclusion

Pursuing a diploma in Haryana is more than just earning a qualification, it’s a step toward a successful and fulfilling career. With recognized institutions, practical learning, affordable education, and wide-ranging course options, Haryana sets the perfect stage for students aiming to shine in the real world.

So, if you’ve been wondering whether a diploma in Haryana is worth it, the answer is a resounding yes. Take that step. Invest in yourself. Haryana is ready to welcome your ambition.

0 notes

Text

Why Should You Invest in PDM Software for Your Business?

In today’s fast-paced digital era, managing product data effectively is crucial for business success. Product Data Management (PDM) software offers a robust solution to streamline your operations, enhance collaboration, and secure your valuable intellectual property. If you’re wondering whether PDM software is a worthwhile investment, read on to discover its transformative benefits.

Better Data Management

Imagine a single, centralized hub for all your product-related information from initial plans and CAD models to technical specifications and detailed reports. PDM software makes this a reality, eliminating scattered data across various locations, reducing errors, and preventing costly duplication. By providing a unified source of truth, PDM ensures that all teams are working with the most current and accurate information, fostering clearer communication and better decision-making.

Encourage Collaboration

Modern product development often involves diverse teams spanning different departments and even geographical locations. PDM software breaks down silos by enabling seamless, simultaneous access to process information for design, engineering, manufacturing, and marketing teams. It provides a shared environment where teams can review plans, track changes, and discuss updates in real-time, significantly accelerating development cycles and fostering a more cohesive work environment.

Output Control and Data Integrity

Maintaining data integrity is paramount in a constantly evolving product landscape. PDM software offers robust output control by meticulously monitoring changes to historical records and automatically saving new versions of files. This proactive approach prevents data loss and ensures that every modification is tracked, providing a complete audit trail. Should the need arise, the ability to revert to previous versions ensures flexibility and minimizes the risk of costly mistakes.

Improved Security and Access Control

In a competitive business world, protecting your intellectual property and sensitive information is more critical than ever. PDM software empowers you with enhanced security by limiting data access strictly to authorized personnel. Administrators can set granular permissions for each user within the organization, safeguarding confidential information from unauthorized viewing or modification. Furthermore, PDM systems meticulously track audit trails, allowing you to monitor who accessed or changed data and when, thereby strengthening your overall data security posture.

Why DDSPLM?

DDSPLM Private Limited is a leading engineering solution vendor and a Siemens Expert Partner. Their expertise in the field positions them to provide comprehensive PDM solutions that can help businesses optimize their product development processes and achieve their digitalization objectives.

Conclusion

Investing in PDM software is a strategic move that can significantly enhance your business’s efficiency, collaboration, and data security. By centralizing data, facilitating teamwork, ensuring data integrity, and providing robust access controls, PDM software empowers businesses to navigate the complexities of product development with confidence, reduce errors, and accelerate time-to-market. It’s an invaluable tool for any organization looking to gain a competitive edge and achieve long-term success.

0 notes

Text

Why SOLIDWORKS 3D CAD Software is the Go-To Choice for Modern Product Design in India

In today’s fast-paced industrial landscape, precision, efficiency, and innovation are no longer optional—they are essential. From automotive to aerospace, and from industrial design to consumer products, every sector demands high-performance tools that can bring ideas to life faster and more accurately. SOLIDWORKS 3D CAD Software stands as a benchmark in this domain, empowering professionals with an intuitive platform for 3D modeling, simulation, design validation, and manufacturing readiness.

At Tech Savvy Engineers Pvt. Ltd., a premier SOLIDWORKS Authorized Reseller in India since 2002, we understand the design challenges faced by Indian industries. That’s why we offer genuine SOLIDWORKS solutions tailored to the needs of engineers, product designers, and manufacturers in Delhi, Haryana, and the Delhi NCR region.

💡 What is SOLIDWORKS 3D CAD Software?

SOLIDWORKS 3D CAD Software is an industry-leading computer-aided design (CAD) solution developed by Dassault Systèmes. It allows users to design products in a 3D environment, helping them visualize, simulate, and refine designs before they ever reach the production floor. Whether you're creating a simple mechanical part or a complex assembly, SOLIDWORKS offers a unified platform that enhances creativity, ensures design accuracy, and shortens development cycles.

🚀 Key Features That Make SOLIDWORKS 3D CAD Stand Out

Parametric and Direct Modeling Quickly create and edit models using intuitive parametric controls and direct geometry manipulation.

Advanced Assembly Capabilities Manage large assemblies with powerful tools that ensure smooth performance and easy navigation.

Integrated Simulation Tools Validate your designs with integrated simulation to test stress, strain, motion, and thermal impacts early in the process.

Sheet Metal, Weldments, and Mold Tools Specialized features for manufacturing processes like sheet metal design, welding, and mold tooling.

Automated Drawing Creation Generate 2D drawings directly from 3D models with accurate dimensions, tolerances, and annotations.

Data Management Integration Seamless collaboration with SOLIDWORKS PDM for version control, access control, and data integrity.

🏭 Industries Benefiting from SOLIDWORKS 3D CAD Software in India

Automotive & Transportation

Aerospace & Defense

Heavy Engineering & Machinery

Consumer Electronics

Medical Devices

Tool & Die Manufacturing

With the rise of Industry 4.0 and digital manufacturing in India, SOLIDWORKS helps engineers transition from 2D legacy systems to a modern, connected product development platform.

📈 Benefits of Choosing SOLIDWORKS from Tech Savvy Engineers Pvt. Ltd.

Authorized Reseller Since 2002 We’ve been delivering genuine SOLIDWORKS solutions for over two decades. When you buy from us, you're not just purchasing software—you’re investing in proven reliability.

Certified Training & Support Our SOLIDWORKS-certified experts provide hands-on training, onboarding, and support to ensure your teams are always productive.

Engineering Consultancy Services Our engineers work closely with clients across sectors, offering simulation, modeling, and manufacturing guidance.

Flexible Licensing Options Choose from perpetual or term licenses tailored to your company’s size and growth trajectory.

PAN India Service with a Focus on NCR Based in Delhi NCR, we serve clients across Delhi, Haryana, Gurugram, Faridabad, and surrounding regions with unmatched customer care.

🎯 Why SOLIDWORKS 3D CAD Software Is the Future of Design

Innovation Speed: Drastically reduce time from concept to product.

Accuracy & Error Reduction: Simulate real-world conditions to catch design flaws early.

Collaboration: Share models, drawings, and revisions effortlessly across departments.

Sustainability: Optimize material usage and reduce prototyping waste.

Whether you're a startup designing your first prototype or an established enterprise scaling up your product portfolio, SOLIDWORKS gives you the edge to compete locally and globally.

🛠 SOLIDWORKS Packages Available

At Tech Savvy, we offer all editions of SOLIDWORKS 3D CAD Software:

SOLIDWORKS Standard: Perfect for core 3D modeling needs.

SOLIDWORKS Professional: Includes tools for design validation, data management, and photorealistic rendering.

SOLIDWORKS Premium: Adds advanced simulation and motion analysis tools.

We help you choose the right package based on your business goals and technical requirements.

💬 What Our Customers Say

“Switching to SOLIDWORKS from a 2D platform was a game-changer. With Tech Savvy's support, we were up and running in no time.” – Rahul V., Mechanical Design Engineer, Gurugram

“Their post-sales service is excellent. Any issue is resolved with priority. Highly recommended!” – Anita S., Product Manager, Faridabad

🔚 Final Thoughts

In an era where design innovation drives business success, having the right tools is crucial. SOLIDWORKS 3D CAD Software is not just a design platform��it’s a complete ecosystem that enhances every phase of product development.

As a trusted name in engineering solutions, Tech Savvy Engineers Pvt. Ltd. is your ideal partner to unlock the full potential of SOLIDWORKS in India. Our commitment to genuine software, expert guidance, and long-term support makes us the preferred choice for businesses serious about design excellence.

📞 Let’s Get Started Today!

For consultation, demo, licensing, or training, reach out to us:

📞 Call: +91-9650032300 📧 Email: [email protected] 🌐 Website: https://techsavvy.co.in/

#solidworks cad software#solidworks 3d cad software#solidworks cad#solidworks training#training solidworks

0 notes

Text

Streamline Your Fashion Workflow with A2000’s Apparel PDM Software

In the fashion and apparel industry, managing product data across multiple teams and timelines can quickly become overwhelming. Enter A2000’s Apparel PDM Software, a powerful, centralised solution designed to simplify your product development process and elevate your brand’s operational efficiency.

Read More :- Streamline Your Fashion Workflow with A2000’s Apparel PDM Software

#Apparel#PDMSoftware#ApparelSoftware#FashionTech#FashionSoftware#ProductDevelopment#TechInFashion#USA#FashionIndustry#ApparelDesign#InnovationInFashion#FashionManagement#PDM#FashionTechnology#USAApparel#FashionSolutions#ClothingSoftware#FashionProduction#ApparelManufacturing#TechForFashion

0 notes

Text

0 notes

Text

How Piping Modeling and Drafting Courses in Chennai Can Boost Your Career

Introduction:

In today’s fast-evolving industrial landscape, piping design plays a crucial role across sectors like oil & gas, petrochemicals, power plants, and infrastructure. With the growing demand for skilled piping professionals, many engineering students and working professionals are turning their attention toward specialized training. One of the most sought-after locations for this training is Chennai—a city known for its strong engineering foundation and presence of reputed training institutes.

The Rise of Piping Modeling Courses in Chennai

The demand for piping modeling courses in Chennai has grown significantly in recent years. These courses focus on both the theoretical and practical aspects of designing complex piping systems. Students gain exposure to real-world applications through industry-grade projects, case studies, and software tools.

Whether you're new to the field or upgrading your skills, choosing a well-structured piping design courses in chennai can be a game-changer. These programs offer detailed modules on pipeline layouts, isometric drawings, 3D modeling, and stress analysis—making you job-ready in just a few months.

What Will You Learn?

One of the key highlights of a piping modeling certification course in Chennai is the hands-on training in popular design software such as:

AutoCAD Plant 3D

PDMS (Plant Design Management System)

CAESAR II for stress analysis

SmartPlant 3D

In addition, learners also gain a strong grasp of international codes and standards like ASME, ANSI, and API. These technical competencies are essential for any piping design professional planning to work in global projects.

Who Should Take These Courses?

Mechanical, civil, or chemical engineering graduates

Working professionals in construction or plant engineering

Freshers seeking a career in industrial design

Engineers looking to switch into oil & gas or infrastructure projects

A piping modeling course in Chennai offers both beginner and advanced levels, so anyone can get started regardless of prior experience.

Career Opportunities After Certification

After finishing a certification program in piping modelling in Chennai, students might consider jobs like:

Piping Design Engineer

Piping Draftsman

3D Modeler – Piping Systems

Plant Layout Engineer

CAD Engineer – Piping

Thanks to Chennai’s active industrial network, many institutes also offer placement support with top MNCs and EPC companies.

Why Chennai?

Chennai is not just an IT hub—it’s also a major center for engineering education and industrial development. The city is home to top mechanical and civil engineering colleges, numerous fabrication companies, and oil & gas consultancy firms. This ecosystem makes it the ideal place to pursue piping modeling courses in Chennai.

Final Thoughts

If you're an aspiring engineer looking to break into high-demand industries, enrolling in a piping modeling and drafting course in Chennai is a smart investment. With the right certification, industry tools, and expert guidance, you can build a successful career in piping design.

#pipingcourseinchennai#pipingdesignanddraftingcourseinchennai#pipingdesigncertificationcourseinchennai#pipingdesigncoursesChennai#pipingdesigncourses#pipingdesigncertificationcourse#pipingdesignanddraftingcourse#pipingcourse#pipingdesigncertification#pipingdesignanddrafting

0 notes

Text

Understanding Maintenance Management: A Key Component in Operational Excellence

In the modern industrial and commercial world, the importance of maintenance management cannot be overstated. It plays a pivotal role in ensuring the longevity, efficiency, and productivity of assets and infrastructure. Whether it’s a manufacturing plant, a hospital, a commercial building, or even a fleet of vehicles, maintenance is necessary to keep systems running smoothly and to avoid costly breakdowns. But more than just routine repairs, maintenance management is a structured approach to preserving and enhancing the value of an organization’s physical assets.

What is Maintenance Management?

Maintenance management is the process of planning, controlling, and executing maintenance activities in a way that optimizes the use of resources while minimizing downtime and maintenance costs. It involves everything from regular inspections and preventative maintenance to emergency repairs and long-term infrastructure planning.

The goal of maintenance management is to ensure that assets continue to perform their intended functions with minimal interruption, maximum safety, and at the lowest possible cost. It combines technical knowledge with strategic planning and data analysis to improve reliability and extend the life of equipment.

Types of Maintenance Strategies

There are several maintenance strategies that organizations may adopt depending on their specific needs, budget, and risk tolerance:

Reactive Maintenance: Often referred to as "run-to-failure," this involves fixing equipment only after it breaks down. While this may be acceptable for non-critical assets, it can lead to expensive repairs and unexpected downtime.

Preventive Maintenance (PM): This strategy is based on regular inspections and servicing to prevent equipment failure. It is time-based and follows a set schedule regardless of the actual condition of the asset.

Predictive Maintenance (PdM): This approach uses data from sensors and analytics tools to predict when an asset is likely to fail, allowing maintenance to be performed just in time. It reduces unnecessary maintenance and prevents unplanned failures.

Condition-Based Maintenance (CBM): Similar to predictive maintenance, CBM relies on real-time monitoring of an asset’s condition to determine when maintenance is necessary.

Reliability-Centered Maintenance (RCM): A comprehensive approach that considers the function of an asset, the ways it can fail, and the consequences of failure, aiming to develop a customized maintenance strategy that optimally balances cost, risk, and performance.

Benefits of Effective Maintenance Management

An effective maintenance management system can deliver numerous benefits to an organization:

Reduced Downtime: By proactively identifying and addressing potential issues, equipment is less likely to fail unexpectedly.

Extended Asset Life: Regular maintenance reduces wear and tear, thus prolonging the life span of critical assets.

Lower Costs: Planned maintenance is generally less expensive than emergency repairs, and it helps avoid production losses.

Improved Safety: Well-maintained equipment is less likely to pose safety hazards to workers and the environment.

Increased Efficiency: Properly functioning machinery and systems ensure that operations run smoothly and without disruption.

The Role of Technology in Maintenance Management

Modern technology has revolutionized maintenance management, making it more data-driven and predictive than ever before. Computerized Maintenance Management Systems (CMMS) are software tools that help organizations track maintenance tasks, schedule inspections, manage spare parts inventory, and generate reports.

The integration of the Internet of Things (IoT), artificial intelligence (AI), and machine learning has further advanced the capabilities of maintenance management systems. These technologies allow real-time monitoring, fault detection, and automatic alerts, enabling organizations to make smarter maintenance decisions.

Challenges in Maintenance Management

Despite its importance, maintenance management is not without challenges. Organizations often struggle with:

Lack of Skilled Personnel: Maintenance requires technical expertise, and a shortage of skilled technicians can affect efficiency.

Budget Constraints: Limited financial resources may lead to deferred maintenance, which can cause long-term damage.

Resistance to Change: Implementing new systems or changing existing processes can meet resistance from staff accustomed to traditional methods.

Data Overload: With the abundance of data generated by modern systems, it can be difficult to focus on the most critical information without the right tools.

Best Practices for Maintenance Management

To overcome these challenges and achieve the full benefits of maintenance management, organizations should adopt the following best practices:

Develop a Comprehensive Maintenance Plan: Identify critical assets and define clear maintenance schedules and procedures.

Invest in Training: Ensure that maintenance staff are trained in the latest techniques and technologies.

Utilize CMMS Tools: Use digital tools to automate and streamline maintenance activities.

Monitor Performance: Track key performance indicators (KPIs) such as Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) to measure effectiveness.

Foster a Culture of Continuous Improvement: Encourage regular feedback and updates to maintenance practices based on performance data.

Conclusion

Maintenance management is more than just fixing what's broken; it’s a strategic function that supports the overall success of an organization. By implementing structured maintenance strategies and embracing modern technologies, businesses can increase operational reliability, reduce costs, and improve safety. As industries continue to evolve, so too must our approach to maintaining the equipment and infrastructure that support them. Investing in strong maintenance management is not just a smart decision—it's a critical component of long-term organizational resilience and growth.

0 notes

Text

Streamline Projects with PDM Product Data Management

At Symetri, we empower your business with PDM product data management to boost efficiency and streamline workflows. From integrating Digital Twin Technology to leveraging Twinmotion for Revit, our expert team ensures seamless collaboration and data accuracy. Whether you need BIM project support or advanced PDM software, we deliver tailored solutions that enhance productivity and decision-making.

Discover how PDM product data management can transform your processes. Visit our PDM solutions page and take the first step towards innovation today!

#Digital Twin Technology#Twinmotion for Revit#BIM Project Support#PDM product data management#PDM software

0 notes

Text

A2000 Software: Propelling Fashion Management with Apparel PDM Software

Effective management of product data plays a crucial role in fashion businesses that seek improved productivity and the preservation of quality standards. Apparel PDM Software by A2000 Software presents a robust, integrated solution to manage product data for different product categories such as apparel, footwear, and accessories. With elements from Footwear ERP Software and Apparel ERP Software, A2000 Software achieves a seamless flow of work right from design until distribution.

Visit Us - https://justpaste.it/f1egn

0 notes

Text

Elevate Your Career with the ICAgile Product Management Certification (ICP-PDM)

Introduction :-

In today’s competitive market, the role of a product manager has evolved into a strategic function that drives business growth and customer satisfaction. The ICAgile Certified Professional in Product Management (ICP-PDM) certification is designed to equip aspiring and experienced product managers with the tools, techniques, and frameworks needed to excel in Agile environments. This blog explores the ICAgile Product Management certification, its benefits, and how it can transform your career.

What is the ICP-PDM Certification?

The ICP-PDM certification, offered by the International Consortium for Agile (ICAgile), validates your expertise in Agile product management. It focuses on building customer-centric products, aligning product strategy with business goals, and managing the entire product lifecycle effectively.

This certification emphasizes practical learning through real-world case studies, hands-on activities, and group discussions. It’s ideal for professionals like product managers, product owners, business analysts, and anyone involved in creating and delivering products.

Key Learning Objectives

By completing the ICP-PDM certification training, participants will gain:

Product Lifecycle Mastery: Learn how to manage products from ideation to retirement while aligning them with customer needs and organizational goals.

Market Research Skills: Understand how to conduct market research to identify opportunities and deliver competitive products.

Agile Integration: Integrate Agile principles into product strategy and execution for faster delivery and continuous improvement.

Outcome-Oriented Roadmaps: Create strategic roadmaps that focus on delivering measurable outcomes rather than just outputs.

Cross-Functional Collaboration: Develop skills to work effectively with development teams, marketing professionals, and other stakeholders.

Benefits of ICP-PDM Certification

Career Advancement The ICP-PDM certification is globally recognized, making it a valuable credential for professionals looking to advance their careers in Agile product management. Certified professionals are often preferred for senior roles in organizations undergoing Agile transformations.

Enhanced Skills The training equips you with modern tools and techniques to create innovative products that meet market demands while delivering business value.

Lifetime Validity Unlike many certifications that require renewal, the ICP-PDM certification comes with lifetime validity, ensuring long-term credibility without recurring fees.

Global Recognition This certification is recognized worldwide, opening doors to opportunities across industries and geographies.

Practical Learning Through interactive sessions and real-world case studies, participants gain hands-on experience that can be applied immediately in their roles.

Course Structure

The ICP-PDM training typically spans two days (14-16 hours) of live instructor-led sessions. Here’s what you can expect:

Interactive Learning Environment: Activities, group discussions, and simulations ensure an engaging experience.

Comprehensive Curriculum: Covers topics like market research, product strategy, customer experience design, and Agile integration.

Certification Exam: No formal exam; certification is awarded upon successful completion of training and participation in activities.

Who Should Enroll?

The ICP-PDM certification is ideal for:

Product Managers

Product Owners

Business Analysts

UX/UI Designers

Marketing Professionals

Entrepreneurs

Software Engineers looking to transition into product roles

How to Get Certified?

Enroll in an ICAgile-Accredited Course: Choose a trusted training provider offering ICP-PDM certification courses.

Complete the Training: Attend the two-day interactive sessions led by expert trainers.

Participate Actively: Engage in group discussions, activities, and assessments during the course.

Receive Your Certification: Upon successful completion of the course requirements, you’ll earn your ICP-PDM certificate.

Why Choose ICP-PDM?

Unlike framework-specific certifications, the ICP-PDM takes a framework-neutral approach, allowing you to apply its principles across various Agile methodologies like Scrum or SAFe. This flexibility makes it highly valuable for professionals working in diverse environments.

Conclusion

The ICP-PDM certification is more than just a credential—it’s a pathway to mastering modern product management practices that drive innovation and business success. Whether you’re an experienced product manager or someone looking to transition into this field, this certification equips you with the skills needed to excel in today’s dynamic market.

By earning this globally recognized credential, you not only enhance your career prospects but also gain the confidence to lead successful product initiatives in any organization. Take the first step toward becoming an expert in Agile product management by enrolling in an ICP-PDM course today!

0 notes

Text

Elevating Product Lifecycle Management for Manufacturing with Siemens Teamcenter PLM

In today’s fast-paced manufacturing landscape, efficient product lifecycle management (PLM) is paramount for innovation and competitive advantage. Siemens Teamcenter PLM emerges as a modern, adaptable solution, seamlessly connecting people and processes through a unified digital thread. This blog explores how Teamcenter PLM empowers manufacturing industries, its core features, operational mechanisms, and the distinct advantages of partnering with DDSPLM.

What is Siemens Teamcenter?

Siemens Teamcenter is a comprehensive product lifecycle management software designed to tackle complex product development challenges. It provides a robust framework for organizations to gain control over their product data and processes, from initial concepts to manufacturing and beyond. Teamcenter’s intuitive user interface fosters broad participation, ensuring that all stakeholders can contribute effectively to the product development journey.

Key Components and Features

Teamcenter boasts a robust set of features designed to manage every aspect of the product lifecycle:

Product Data Management (PDM): Offers a single, reliable source for all product data, supporting multi-CAD and ECAD data management, intelligent part numbering, and efficient data exchange. This eliminates data silos and ensures everyone is working with the most current information.

Bill of Materials (BOM) Management: Provides a single, accurate product definition for the BOM, allowing for flexible configurations and tailored views that cater to different roles within the organization. This ensures precision in manufacturing and assembly.

Change Management and Workflow Process: Optimizes product change management, enabling users to understand the impact of changes comprehensively. It also automates PLM processes through defined workflow templates, ensuring that changes are implemented efficiently and effectively.

Document Management: Extends PDM beyond engineering with seamless integrations with Microsoft Office and Adobe, facilitating the creation and updating of various documents across the product lifecycle.

Preconfigured Capabilities: Teamcenter Rapid Start offers preconfigured capabilities for quick deployment of basic Product Data Management (PDM), providing a clear and scalable growth path to full PLM functionality as your needs evolve.

How Teamcenter Works

Teamcenter operates by taking complete control of product data and processes, encompassing 3D designs, electronics, embedded software, documentation, and the Bill of Materials. It champions design re-use and integrates disconnected design flows, allowing teams to create, manage, and re-use native design data from multiple CAD systems within a secure, centralized environment. Furthermore, it intelligently ties virtual and physical product definitions together, enabling comprehensive digital validation before physical prototypes are even created.

Benefits to Manufacturing Industries

Implementing Siemens Teamcenter PLM can bring transformative benefits to manufacturing industries:

Accelerated Product Development: By promoting design re-use and seamlessly integrating various design flows, Teamcenter significantly speeds up the product development cycle.

Improved Data Accuracy and Consistency: With a single source of product data and precise BOM definition, organizations can ensure high levels of data accuracy and consistency across all departments.

Optimized Change Management: Teamcenter enables effective planning and quick, accurate implementation of product changes, minimizing disruptions and errors.

Enhanced Collaboration: By connecting people and processes across functional silos, Teamcenter fosters better communication and collaboration, leading to more cohesive product development.

Reduced Costs: Eliminating the need for standalone spreadsheets and disparate systems, and reducing reliance on costly physical prototypes, directly contributes to significant cost savings.

Why DDSPLM?

As a Siemens Expert Partner, DDSPLM stands as a trusted advisor with over 25 years of experience in engineering solutions. Having served more than 700 customers across diverse industry verticals, DDSPLM possesses the deep expertise and proven track record to help businesses effectively implement and maximize the value of Siemens Teamcenter PLM software. Their experience ensures tailored solutions and robust support for your PLM journey.

Conclusion

Siemens Teamcenter PLM is an indispensable tool for modern manufacturing, offering a comprehensive and integrated approach to product lifecycle management. From streamlined data management to accelerated product development and enhanced collaboration, its benefits are far-reaching. Partnering with experienced advisors like DDSPLM further ensures a successful implementation, empowering manufacturing industries to achieve greater innovation, efficiency, and competitiveness.

0 notes

Text

SolidWorks CAD Software: A Complete Guide to 3D Design, Modeling, and Engineering Innovation

In today’s fast-paced world of engineering and product development, the ability to visualize and simulate designs before production is critical. This is where SolidWorks CAD Software plays a transformative role.

As one of the leading computer-aided design (CAD) tools in the industry, SolidWorks empowers engineers, designers, and manufacturers to create high-quality 3D models, run simulations, and produce detailed drawings for all types of products. From simple mechanical components to complex machinery and assemblies, SolidWorks provides a user-friendly yet powerful platform for innovation.

What is SolidWorks CAD?

SolidWorks CAD (Computer-Aided Design) is a 3D modeling software developed by Dassault Systèmes. It is widely used across industries like automotive, aerospace, electronics, consumer goods, and manufacturing for creating precise 3D models and 2D drawings. SolidWorks offers a suite of tools that include part modeling, assembly design, sheet metal work, mold design, and more.

The software is parametric, which means users can create models based on mathematical relationships. This allows easy modifications and design iterations without starting from scratch. Whether you’re designing a single part or a full mechanical system, SolidWorks helps maintain consistency and accuracy throughout the development cycle.

Key Features of SolidWorks

3D Modeling: The core of SolidWorks is its powerful 3D modeling capabilities. You can create complex parts and assemblies with ease, using intuitive sketching tools and feature-based modeling.

Simulation and Analysis: With SolidWorks Simulation, engineers can test their designs under real-world conditions. This includes stress analysis, thermal testing, motion studies, and fluid dynamics.

Drawing and Documentation: SolidWorks automatically generates detailed 2D drawings from 3D models. These drawings include dimensions, tolerances, material specs, and annotations that meet industry standards.

Sheet Metal Design: Specialized tools for creating sheet metal parts, including bend allowances, flat patterns, and unfolding operations.

Weldments and Structures: Design and analyze frames, trusses, and structural components using weldment features and standard profiles.

Assemblies and Interference Checking: Assemble multiple components into a single system and use tools to detect clashes and interference before manufacturing.

Integration and Collaboration: SolidWorks integrates seamlessly with other tools like PDM (Product Data Management) and PLM (Product Lifecycle Management) systems. It also supports collaborative design through cloud-based platforms.

Benefits of Using SolidWorks CAD

Increased Productivity: With parametric design and automation tools, repetitive tasks are minimized, enabling designers to work faster.

Cost-Effective Development: Simulating designs before production helps in identifying errors early, reducing the cost of rework and physical prototyping.

Better Visualization: 3D modeling provides a realistic view of the final product, aiding in presentations, marketing, and customer approvals.

Industry Compliance: SolidWorks supports global drafting standards (ISO, ANSI, DIN), making it suitable for multinational projects.

Scalability: Whether you are a freelancer, a startup, or a large corporation, SolidWorks offers scalable licensing and feature sets to fit your needs.

Who Uses SolidWorks?

SolidWorks is used by:

Mechanical engineers for product design and simulation.

Industrial designers for aesthetic and ergonomic modeling.

Manufacturing teams for CNC machining and tooling design.

Students and educators for academic learning and projects.

Startups and inventors for prototyping and patenting new ideas.

Future of SolidWorks CAD Software

The future of SolidWorks is evolving with trends like cloud computing, artificial intelligence, and real-time collaboration. Dassault Systèmes continues to enhance SolidWorks with cloud-based design tools under the 3DEXPERIENCE platform, allowing teams to work from anywhere and manage projects more efficiently.

With increasing integration of AR/VR and AI-powered design suggestions, SolidWorks aims to further reduce development time and enhance innovation. Staying updated with its latest versions ensures users have access to the newest tools and features.

Conclusion

SolidWorks CAD Software is not just a design tool—it is a complete solution that bridges creativity, engineering, and production. Its user-friendly interface, powerful simulation features, and robust support community make it the go-to choice for professionals across the globe. Whether you're building the next big invention or streamlining manufacturing operations, SolidWorks can bring your ideas to life with precision and efficiency.

Stay ahead in design and innovation with Tech Savvy – your trusted partner in digital engineering solutions.

#Solidworks CAD Software#Solidworks Cad#autodesk autocad software In Haryana#SOLIDWORKS 3D CAD Software

1 note

·

View note

Text

Streamlining Success with Apparel Accounting Software: Why A2000 Stands Out

Accurate, Real-Time Financial Management

Our business intelligence tools reduce errors and enhance accuracy, while the integrated financial software ensures that every number aligns seamlessly across your operations. Combined, these features make A2000 a leading choice for businesses that need dependable, intelligent Apparel Accounting Software.

Creative Freedom with Smart Tools

Creativity thrives, too. With our PDM/Design Module, you can bring your designs from sketch to production without losing artistic intent or operational control. It’s your digital atelier, helping you balance art with efficiency.

Read More:- Streamlining Success with Apparel Accounting Software: Why A2000 Stands Out

#ApparelAccounting#AccountingSoftware#USA#FashionFinance#ApparelIndustry#FinancialManagement#SmallBusinessUSA#RetailAccounting#FashionAccounting#EntrepreneurTips#SoftwareSolutions#BusinessFinance#AccountingForApparel#MadeInUSA#ApparelBusiness#TechForFashion#FinanceInFashion#ApparelTech#SoftwareForRetail#USAStartups

0 notes