#microcontroller company

Explore tagged Tumblr posts

Text

Why Choosing the Right Microcontroller Distributor Matters More Than You Think

Talk to any engineer working on embedded systems, and they'll tell you — the microcontroller is everything. It’s the little chip doing the heavy lifting, quietly powering devices we use daily. Whether it’s a home automation product, a factory sensor, or a portable medical device, there’s a microcontroller ticking away inside. But while product teams obsess over which MCU to use, many forget to ask a simple but important question: Where are we getting it from?

It’s not a minor detail. In fact, your choice of microcontroller distributor could make or break your project.

The Real Cost of the Wrong Supplier

Let’s be honest. Delays hurt. Missing components, inconsistent supply, or vague technical support aren’t just annoyances — they cost teams time and money. That’s why working with a trusted MCU supplier matters just as much as selecting the right MCU itself.

Here’s the thing: There are plenty of microcontroller companies out there. But not all of them understand the pressure product teams face. That’s where companies like OM Electronic come in. They don’t just ship chips — they understand how the Indian electronics industry works. They know what’s at stake.

What Makes a Good MCU Partner?

You can Google a part number and find hundreds of sellers. So what separates a top microprocessor company from a fly-by-night seller?

First, there's reliability. Are they delivering the exact part, in the promised time frame, and with proper documentation? Next, there's expertise. Can they help you find an alternative if your preferred part is unavailable? Can they give you insights into life-cycle availability or share datasheets quickly when needed?

Then there’s authenticity. A good microcontroller supplier ensures your parts are original, factory-sealed, and traceable. That matters more than people think — especially when dealing with tight tolerances and safety standards.

Why OM Electronic Gets It Right

When you’re sourcing MCUs, especially for industrial or commercial applications, you can’t afford surprises. OM Electronic has built a reputation in India as a microcontroller distributor that delivers not only on time but also with real-world product knowledge.

They carry microcontrollers from global leaders, suited for everything from basic embedded systems to complex IoT applications. And unlike many generic vendors, they work with you — offering support during the selection process and even helping solve problems when you're stuck.

That kind of service is rare. And it’s exactly why they're considered one of the best microprocessor distributors in India today.

The Bigger Picture

Think beyond your current project. If your company plans to scale, enter new markets, or simply reduce downtime, you need a component partner who can scale with you. That’s why many hardware companies today are reevaluating who they source from.

Choosing the right MCU company isn’t about one-time pricing. It’s about long-term reliability, supply chain strength, and honest communication.

Final Thoughts

The world of embedded systems is exciting — and demanding. Products are getting smarter, faster, and more connected. But with that comes pressure: tighter deadlines, shrinking margins, and growing complexity.

In such a space, small decisions — like who supplies your microcontrollers — become big ones. If you’re serious about building better products, it’s time to be serious about your sourcing too.

Companies like OM Electronic don’t just sell components. They help product teams across India build smarter and deliver on time. And in today’s environment, that’s exactly what you need from a microcontroller distributor.

#top microprocessor company#best microprocessor distributor in india#mcu supplier#mcu distributor#microcontroller supplier#microcontroller distributor#microcontroller company#mcu company

0 notes

Text

At my last job, we sold lots of hobbyist electronics stuff, including microcontrollers.

This turned out to be a little more complicated than selling, like, light bulbs. Oh how I yearned for the simplicity of a product you could plug in and have work.

Background: A microcontroller is the smallest useful computer. An ATtiny10 has a kilobyte of program memory. If you buy a thousand at a time, they cost 44 cents each.

As you'd imagine, the smallest computer has not great specs. The RAM is 32 bytes. Not gigabytes, not megabytes, not kilobytes. Individual bytes. Microcontrollers have the absolute minimum amount of hardware needed to accomplish their task, and nothing more.

This includes programming the thing. Any given MCU is programmed once, at the start of its life, and then spends the next 30 years blinking an LED on a refrigerator. Since they aren’t meant to be reflashed in the field, and modern PCs no longer expose the fast, bit-bangable ports hobbyists once used, MCUs usually need a third-party programming tool.

But you could just use that tool to install a bootloader, which then listens for a magic number on the serial bus. Then you can reprogram the chip as many times as you want without the expensive programming hardware.

There is an immediate bifurcation here. Only hobbyists will use the bootloader version. With 1024 bytes of program memory, there is, even more than usual, nothing to spare.

Consumer electronics development is a funny gig. It, more than many other businesses, requires you to be good at everything. A startup making the next Furby requires a rare omniexpertise. Your company has to write software, design hardware, create a production plan, craft a marketing scheme, and still do the boring logistics tasks of putting products in boxes and mailing them out. If you want to turn a profit, you do this the absolute minimum number of people. Ideally, one.

Proving out a brand new product requires cutting corners. You make the prototype using off the shelf hobbyist electronics. You make the next ten units with the same stuff, because there's no point in rewriting the entire codebase just for low rate initial production. You use the legacy code for the next thousand units because you're desperately busy putting out a hundred fires and hiring dozens of people to handle the tsunami of new customers. For the next ten thousand customers...

Rather by accident, my former employer found itself fulfilling the needs of the missing middle. We were an official distributor of PICAXE chips for North America. Our target market was schools, but as a sideline, we sold individual PICAXE chips, which were literally PIC chips flashed with a bootloader and a BASIC interpreter at a 200% markup. As a gag, we offered volume discounts on the chips up to a thousand units. Shortly after, we found ourselves filling multi-thousand unit orders.

We had blundered into a market niche too stupid for anyone else to fill. Our customers were tiny companies who sold prototypes hacked together from dev boards. And every time I cashed a ten thousand dollar check from these guys, I was consumed with guilt. We were selling to willing buyers at the current fair market price, but they shouldn't have been buying these products at all! Since they were using bootloaders, they had to hand program each chip individually, all while PIC would sell you programmed chips at the volume we were selling them for just ten cents extra per unit! We shouldn't have been involved at all!

But they were stuck. Translating a program from the soft and cuddly memory-managed education-oriented languages to the hardcore embedded byte counting low level languages was a rather esoteric skill. If everyone in-house is just barely keeping their heads above water responding to customer emails, and there's no budget to spend $50,000 on a consultant to rewrite your program, what do you do? Well, you keep buying hobbyist chips, that's what you do.

And I talked to these guys. All the time! They were real, functional, profitable businesses, who were giving thousands of dollars to us for no real reason. And the worst thing. The worst thing was... they didn't really care? Once every few months they would talk to their chip guy, who would make vague noises about "bootloaders" and "programming services", while they were busy solving actual problems. (How to more accurately detect deer using a trail camera with 44 cents of onboard compute) What I considered the scandal of the century was barely even perceived by my customers.

In the end my employer was killed by the pandemic, and my customers seamlessly switched to buying overpriced chips straight from the source. The end! No moral.

546 notes

·

View notes

Text

Birdwatching got really popular in the early days of the Unpleasantness. However, now that the bosses are forcing us all back to the office, the birds don't have anyone to watch them. That's why I built an autonomous bird-observation robot. Its name is SparrowScope 9000, and I recommend not becoming too emotionally attached to it, because it is your competition.

There's a lot of obvious benefits to having a robotic birdwatcher. It can start up early in the morning and go to its charging dock late at night. It never makes a mistake identifying a bird. It won't get tired, cold, hungry, or develop pointless drama with "Uncle" Hudson Carl online over his fucking misdocumentation of Northern Cardinals. You can pop over to its little webpage and see what it spotted that day, and feel pretty good. It's like you're really there, even though you're stuck in an office building wondering if you have enough staples loaded in your stapler to get through the month, or if you should maybe talk to Jan in Requisitioning to get a fresh refill.

However, there are flaws. One of the big things is that the US military doesn't let regular people – civilians – have super-accurate GPS. They fuck with the data a little bit, so that you can't somehow threaten national security by knowing where you are. I didn't know this before I started on the project, and the bird sanctuary has a lot of elevated walkways ever since the flood. SparrowScope 9000 became more of a SoggyScope Wet-Thousand.

If a real technology company had assembled it, that would probably have been the end of the story. They'd have put in some total garbage like a modern microcontroller, maybe some parts made in this century. Not me. This thing is half old pinball machine parts and the other half Aibos. It kept trucking right down the river, and I never saw it again. I do get updates from it periodically as it spots a new bird, but my work schedule forbids me from taking a few days off to drive to the next county over and see if I can figure out which swamp it's floated into this time.

Even with this small disaster, I'm pretty proud of what I accomplished. Our avian friends get looked at by a creepy robot covered in seaweed, and we can all experience what it was like for one brief, shining moment in which we still had hobbies.

420 notes

·

View notes

Note

Tell me about printer protocols o3o

off the top of my head....lesgoooooo

Bonjour isn't a printing protocol but it is a service protocol...idk if it does all device discovery or just printers. apple thing. anyway, uh pretty sure apple also use CUPS, or parts of it. which again, service protocol. that's that good Common UNIX Printing System. okay.

so we got a CUPS an we got a printer. an they gotta talk. idk how it used to work, but since at least the mid 00s printers typically use something called PostScript. or maybe GhostScript. which could jus be PS but a funnye FOSS version ???? special language that the microcontroller in a printer can convert into what colours it gotta mix and put where. i gotta start looking all this up bc it's been a hot min.

assuming the printer is physically plugged to the computer this is all done as a serial connection. since USB is serial. we don't talk about the parallel port. idk how network stuff affects this but presumably it's just wrapped in IP packets ?

printers are brats. and this is fine. this was fine. until companies started making them dystopian as fuck. i can handle a printer being a bit of a dick sometimes, selectively working. i can't handle ink-subscription-based DRM. or cloud print only. or any of that shit.

tbh i would be happy saving to a usb drive, walking to the printer room and plugging that drive in. no fuckery required. if you want stuff to print out remotely that's what fax is for. we should bring back fax.

you might be able to tell i've watched a lotta CRD

this got a bit off topic lmao but if u want me to re-inform myself on how printer talk then i can do

11 notes

·

View notes

Text

How to know if a USB cable is hiding malicious hacker hardware

Are your USB cables sending your data to hackers?

We expect USB-C cables to perform a specific task: transferring either data or files between devices. We give little more thought to the matter, but malicious USB-C cables can do much more than what we expect.

These cables hide malicious hardware that can intercept data, eavesdrop on phone calls and messages, or, in the worst cases, take complete control of your PC or cellphone. The first of these appeared in 2008, but back then they were very rare and expensive — which meant the average user was largely safeguarded.

Since then, their availability has increased 100-fold and now with both specialist spy retailers selling them as “spy cables” as well as unscrupulous sellers passing them off as legitimate products, it’s all too easy to buy one by accident and get hacked. So, how do you know if your USB-C cable is malicious?

Further reading: We tested 43 old USB-C to USB-A cables. 1 was great. 10 were dangerous

Identifying malicious USB-C cables

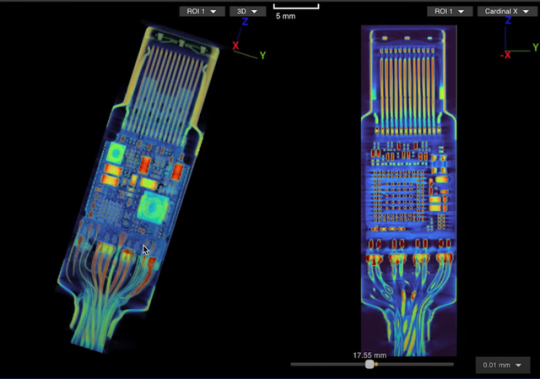

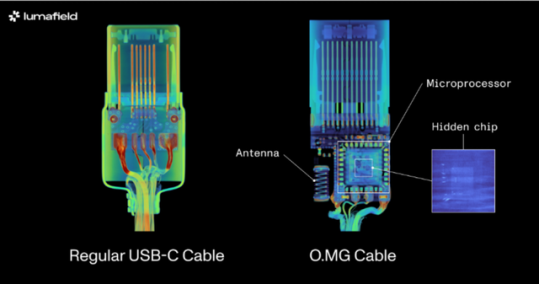

Identifying malicious USB-C cables is no easy task since they are designed to look just like regular cables. Scanning techniques have been largely thought of as the best way to sort the wheat from the chaff, which is what industrial scanning company, Lumafield of the Lumafield Neptune industrial scanner fame, recently set out to show.

The company employed both 2D and 3D scanning techniques on the O.MG USB-C cable — a well-known hacked cable built for covert field-use and research. It hides an embedded Wi-Fi server and a keylogger in its USB connector. PCWorld Executive Editor Gordon Ung covered it back in 2021, and it sounds scary as hell.

What Lumafield discovered is interesting to say the least. A 2D X-ray image could identify the cable’s antenna and microcontroller, but only the 3D CT scan could reveal another band of wires connected to a die stacked on top of the cable’s microcontroller. You can explore a 3D model of the scan yourself on Lumafield’s website.

It confirms the worst — that you can only unequivocally confirm that a USB-C cable harbors malicious hardware with a 3D CT scanner, which unless you’re a medical radiographer or 3D industrial scientist is going to be impossible for you to do. That being so, here are some tips to avoid and identify suspicious USB-C cables without high-tech gear:

Buy from a reputable seller: If you don’t know and trust the brand, simply don’t buy. Manufacturers like Anker, Apple, Belkin, and Ugreen have rigorous quality-control processes that prevent malicious hardware parts from making it into cables. Of course, the other reason is simply that you’ll get a better product — 3D scans have similarly revealed how less reputable brands can lack normal USB-C componentry, which can result in substandard performance. If you’re in the market for a new cable right now, see our top picks for USB-C cables.

Look for the warning signs: Look for brand names or logos that don’t look right. Strange markings, cords that are inconsistent lengths or widths, and USB-C connectors with heat emanating from them when not plugged in can all be giveaways that a USB-C cable is malicious.

Use the O.MG malicious cable detector: This detector by O.MG claims to detect all malicious USB cables.

Use data blockers: If you’re just charging and not transferring data, a blocker will ensure no data is extracted. Apart from detecting malicious USB-C cables, the O.MG malicious cable detector functions as such a data blocker.

Use a detection service: If you’re dealing with extremely sensitive data for a business or governmental organization, you might want to employ the services of a company like Lumafield to detect malicious cables with 100 percent accuracy. Any such service will come with a fee, but it could be a small price to pay for security and peace of mind.

11 notes

·

View notes

Text

Where did the Furbishes come from?

I've recently decided to dig deeper into the origins of Furbishes, since they're one of the fakes fascinating me the most.

Until recently, the only facts listed on the Furby wikia have been that someone named Nien-chu Tang registered the trademark for this and Baby Brainy (both having "B/O ELECTRONIC" as the vendor name written on their packaging and tags) and that the probable vendor was Teamforce.

Having seen that, I went in deeper. Looking over some images on the wiki and eBay listings, it can be seen that while the Furbish boxes - both English and Japanese - are very generic with no manufacturer info whatsoever, the Baby Brainy one (also from "B/O ELECTRONIC") features a UPC barcode.

The first digits of a UPC barcode identify the company that it's registered to. This can be looked up, e.g. here.

Voila, we find a company named "Pro-TV Development Inc."

More searching reveals that it's registered both in the US and Taiwan.

Moreover, many entries for this company show the contact person's name, which is specified as "NIANZU TANG", which can be another romanization of "Nien-chu Tang" that we've seen before.

With more searching, we can find an archived page showing that they produced interactive toys.

There's still a working website of the company itself (protv.com.tw), however there is no mention of interactive toys.

The company was also at some point called "Serendipity" (this snapshot also shows Nien-chu Tang's name written in Chinese).

The above and some more info is now listed in a wiki page.

Conclusion and questions

Ultimately, I still aim to find out who the people responsible for the actual development were. Who programmed the microcontroller? Who voiced the Furbish?

It's also now known that Furby fakes with "Furdish" programming came from several different vendors - at least Pro-TV and Teamforce.

That might mean that someone (another company?) came up with a ready design for a Furby fake which was then licensed or cloned further.

I really hope that more interesting info would show up over time.

Update Jun 6: I've missed a blog post on the wiki showing a TF-9901 label on what's claimed to be the board of a Furbish. This was written earlier than anything was known about Pro-TV, but shows that Teamforce also had some involvement.

1 note

·

View note

Text

Why Python Will Thrive: Future Trends and Applications

Python has already made a significant impact in the tech world, and its trajectory for the future is even more promising. From its simplicity and versatility to its widespread use in cutting-edge technologies, Python is expected to continue thriving in the coming years. Considering the kind support of Python Course in Chennai Whatever your level of experience or reason for switching from another programming language, learning Python gets much more fun.

Let's explore why Python will remain at the forefront of software development and what trends and applications will contribute to its ongoing dominance.

1. Artificial Intelligence and Machine Learning

Python is already the go-to language for AI and machine learning, and its role in these fields is set to expand further. With powerful libraries such as TensorFlow, PyTorch, and Scikit-learn, Python simplifies the development of machine learning models and artificial intelligence applications. As more industries integrate AI for automation, personalization, and predictive analytics, Python will remain a core language for developing intelligent systems.

2. Data Science and Big Data

Data science is one of the most significant areas where Python has excelled. Libraries like Pandas, NumPy, and Matplotlib make data manipulation and visualization simple and efficient. As companies and organizations continue to generate and analyze vast amounts of data, Python’s ability to process, clean, and visualize big data will only become more critical. Additionally, Python’s compatibility with big data platforms like Hadoop and Apache Spark ensures that it will remain a major player in data-driven decision-making.

3. Web Development

Python’s role in web development is growing thanks to frameworks like Django and Flask, which provide robust, scalable, and secure solutions for building web applications. With the increasing demand for interactive websites and APIs, Python is well-positioned to continue serving as a top language for backend development. Its integration with cloud computing platforms will also fuel its growth in building modern web applications that scale efficiently.

4. Automation and Scripting

Automation is another area where Python excels. Developers use Python to automate tasks ranging from system administration to testing and deployment. With the rise of DevOps practices and the growing demand for workflow automation, Python’s role in streamlining repetitive processes will continue to grow. Businesses across industries will rely on Python to boost productivity, reduce errors, and optimize performance. With the aid of Best Online Training & Placement Programs, which offer comprehensive training and job placement support to anyone looking to develop their talents, it’s easier to learn this tool and advance your career.

5. Cybersecurity and Ethical Hacking

With cyber threats becoming increasingly sophisticated, cybersecurity is a critical concern for businesses worldwide. Python is widely used for penetration testing, vulnerability scanning, and threat detection due to its simplicity and effectiveness. Libraries like Scapy and PyCrypto make Python an excellent choice for ethical hacking and security professionals. As the need for robust cybersecurity measures increases, Python’s role in safeguarding digital assets will continue to thrive.

6. Internet of Things (IoT)

Python’s compatibility with microcontrollers and embedded systems makes it a strong contender in the growing field of IoT. Frameworks like MicroPython and CircuitPython enable developers to build IoT applications efficiently, whether for home automation, smart cities, or industrial systems. As the number of connected devices continues to rise, Python will remain a dominant language for creating scalable and reliable IoT solutions.

7. Cloud Computing and Serverless Architectures

The rise of cloud computing and serverless architectures has created new opportunities for Python. Cloud platforms like AWS, Google Cloud, and Microsoft Azure all support Python, allowing developers to build scalable and cost-efficient applications. With its flexibility and integration capabilities, Python is perfectly suited for developing cloud-based applications, serverless functions, and microservices.

8. Gaming and Virtual Reality

Python has long been used in game development, with libraries such as Pygame offering simple tools to create 2D games. However, as gaming and virtual reality (VR) technologies evolve, Python’s role in developing immersive experiences will grow. The language’s ease of use and integration with game engines will make it a popular choice for building gaming platforms, VR applications, and simulations.

9. Expanding Job Market

As Python’s applications continue to grow, so does the demand for Python developers. From startups to tech giants like Google, Facebook, and Amazon, companies across industries are seeking professionals who are proficient in Python. The increasing adoption of Python in various fields, including data science, AI, cybersecurity, and cloud computing, ensures a thriving job market for Python developers in the future.

10. Constant Evolution and Community Support

Python’s open-source nature means that it’s constantly evolving with new libraries, frameworks, and features. Its vibrant community of developers contributes to its growth and ensures that Python stays relevant to emerging trends and technologies. Whether it’s a new tool for AI or a breakthrough in web development, Python’s community is always working to improve the language and make it more efficient for developers.

Conclusion

Python’s future is bright, with its presence continuing to grow in AI, data science, automation, web development, and beyond. As industries become increasingly data-driven, automated, and connected, Python’s simplicity, versatility, and strong community support make it an ideal choice for developers. Whether you are a beginner looking to start your coding journey or a seasoned professional exploring new career opportunities, learning Python offers long-term benefits in a rapidly evolving tech landscape.

#python course#python training#python#technology#tech#python programming#python online training#python online course#python online classes#python certification

2 notes

·

View notes

Text

So I often see novel computer keyboard designs, but I hadn't really felt inspired to make my own until now.

See, Hackaday recently ran a piece on Stephen Holdaway's "Unicode Binary Input Terminal", which lets you flip switches to input any Unicode character — by flipping switches to indicate its binary value in UTF-8 encoding.

It displays the character on the little display, and you can then flip another switch to send the character like a keyboard would over USB.

Among the usual comments about how Holdaway should have built the device by using only 555 timers came the suggestion that UTF-8 is unwieldy, and that he should have added even more toggle switches to enter longer bitstreams directly. Now, I don't want to take that tack on it; toggle switches get expensive. But there are other ways to input long sets of binary data!

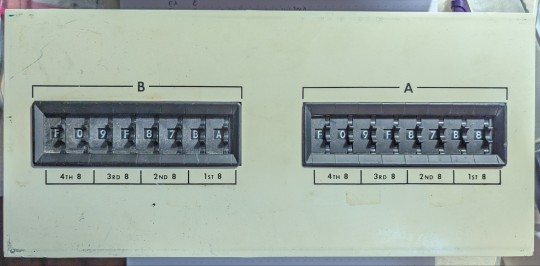

Years ago, I found this panel in some surplus or thrift shop; I honestly don't remember any more. It's got two sets of eight hexadecimal thumbwheel switches; each one can be set to a hexadecimal "digit" between 0 and F, and the binary pattern of that hexit read off the leads in the back.

(If anyone out there recognizes where this panel originally came from, let me know; it has no other markings besides the visible ones, and the switch banks just each bear a sticker saying they came from the Digitran Company of Pasadena, California, and were probably made in 1972. (Remarkably, Digitran still makes very similar switches — I think there's a military spec for them — though they're presently owned by Electro Switch Corp, and are of the sort that don't list prices on the webpage. For similar devices, Surplus Sales of Nebraska has 6-hexit banks, albeit with shorter numbers, available for $225 each, or slightly taller ones for $15 per hexit and you have to fabricate your own frame.)

At any rate, the switch banks are easily removed from the panel. My plan is to set them in a new panel with a display between them and have a toggle or slider switch to change modes, so you can enter UTF-8 streams (anywhere between eight ASCII characters and a single dual-character-point emoji; the wheels are currently set to display the US flag) or sets of UTF-16 or UTF-32 characters; a final button would again send the character(s) over USB.

I'm currently dithering over how best to implement this. Obviously Unicode isn't going to fit in any of my usual microcontrollers, and the 64 data lines required to read the switches will need some GPIO expanders or shift registers. I do have a couple of unused Raspberry Pi ZeroWs lying around, which would let me leverage Linux font and Unicode handling, and then I could hook it to an Arduino or Teensy to handle the USB part, unless there's an obvious way for a Pi to be a USB client. The display is a similar dither; I've got some small graphical LCDs and a tiny OLED display, and even some e-ink displays that might work for this. Heck, I should see if I can find those dot-matrix VFDs I have somewhere. It's more likely to be a color LCD if I want emoji support, but requirements are flexible right now.

25 notes

·

View notes

Text

Automotive Power Electronics Market Growing Business Factors, Industry Trends, Share, Size, Growth, Opportunity And Forecast 2033

According to a new industry report by Fact.MR, a market research and competitive intelligence provider, the global automotive power electronics market is projected to reach $6 billion by 2033, growing at a CAGR of 4.1% from 2023 to 2033.

Power electronics encompass a wide range of solid-state devices used for power regulation and conversion, including silicon-controlled rectifiers (SCRs), diodes, thyristors, power MOSFETs, gate turn-off thyristors, and more. These devices are crucial in controlling vehicle electronics. The term "automotive electronics" covers the application of power electronic devices in modern systems such as electric power steering, seat control, braking systems, central body management, and HEV main inverters.

Download Free Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=8423

The rising popularity of electric vehicles (EVs) is the primary driver of the global automotive power electronics market. EVs are seen as a crucial step toward modern mobility solutions, offering cleaner and more efficient transportation compared to traditional automobiles. The depletion of fuel resources and public concern over increasing pollution levels have fueled global demand for electric vehicles.

Compliance with safety and vehicle emission standards, along with the growing demand for vehicle connectivity, infotainment, and powertrain electrification, is expected to propel the global automotive power electronics market during the forecast period. The use of electronics in powertrain systems is projected to increase at a faster rate due to intensified efforts by regional governments and environmental agencies to reduce emissions by promoting environmentally friendly vehicles, such as hybrids and EVs.

Key Takeaways from Market Study

In 2023, the global automotive power electronics market was valued at $4 billion.

The market is projected to grow at a CAGR of 4.1% from 2023 to 2033, reaching $6 billion by 2033.

In 2022, the Asia Pacific region held 38.7% of the global market share.

The passenger car segment is anticipated to grow at a CAGR of 3.7% during the forecast period.

“Global automotive power electronics market projected to witness considerable growth due to increasing modernization of vehicles, expanding demand for vehicle electrification, and rising need for connected car devices,” says a Fact.MR analyst.

Key Companies Profiled in Automotive Power Electronics Market Report

Infineon Technologies AG

Texas Instruments, Inc

Mitsubishi Electric Corporation

NXP Semiconductors NV

Toshiba Corporation

Robert Bosch GmbH

Get Customization on this Report for Specific Research Solutions: https://www.factmr.com/connectus/sample?flag=RC&rep_id=8423

Competitive Landscape

Big manufacturers control the market, which is only moderately concentrated. The leading companies in the automotive power electronics sector are focusing on broadening their product lines and investing in research and development to generate high-end products. In addition, several entrepreneurs are focused on new technologies to boost their market share.

In September 2021, Panasonic Corporation and Infineon Technologies AG signed a collaboration agreement to research and manufacture the second generation (Gen2) of their renowned gallium nitride (GaN) technology. This will enhance efficiency and power density levels.

In June 2021, STMicroelectronics announced STi2GaN solutions for automotive applications. The STi2GaN series includes GaN-based drivers and safeguards, a monolithic power stage, and System-in-Package (SiP) solutions for application-specific integrated circuits with additional processing and control circuitry.

Infineon Technologies AG purchased Cypress Semiconductor Company in April 2020. Cypress provides a diverse set of software ecosystems, microcontrollers, connection components, and high-performance storage.

Infineon Technologies launched the CoolMOS CFD7A family in April 2020. These high-performance silicon-based components can be used in both the PFC and DC-DC stages of onboard charger systems, as well as HV-LV DC-DC converters designed specifically for EV use.

Key Segments of Automotive Power Electronics Industry Research

By Device Type :

Power ICs

Power Modules/Discretes

By Drive Type :

IC Engine Vehicles

Electric Vehicles

By Vehicle Type :

Passenger Cars

Commercial Vehicles

By Electric Vehicle Type :

Battery Electric Vehicles

Hybrid Electric Vehicles

Plug-in Hybrid Electric Vehicles

By Application :

Body Electronics

Chassis & Powertrain

Infotainment & Telematics

Safety & Security Systems

𝐑𝐞𝐚𝐝 𝐌𝐨𝐫𝐞: https://www.factmr.com/report/automotive-power-electronics-market

Regional Analysis

Asia Pacific dominates the worldwide automobile power electronics industry. Japan and South Korea are helping to drive market development in Asia Pacific as automotive production increases.

The North American market is increasing rapidly. The United States dominates the North American market thanks to the existence of major electric vehicle manufacturers such as Tesla. Furthermore, Germany is making a significant contribution to European market growth as electric vehicle usage increases.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

one of the things that sucks hugely about the dismantling of right to repair and the fast-paced bullshit late capitalist world we have to inhabit is that there is hardly such thing as being a repair person anymore for most electric devices. It’s just not feasible and companies keep making shit harder to fix and I hate it so much.

I remember still when I was a kid and we could take the television out to this shop and there was a guy there who would fix them. That shop has been closed for at least a decade now.

People don’t or can’t even fix phones or computers now, computers used to be devices synonymous with some place you could take it and have it serviced, but now there’s just a flood of unfixable landfill machines. I understand that can get them into more hands but they’re just not even worth it they’re so short-lived and useless.

No more special screws and adhesives, no more cheap plastic tabs and un-diagnosable un-fixable pcbs, stop putting fucking wifi radios and microcontrollers in things that don’t need them.

4 notes

·

View notes

Text

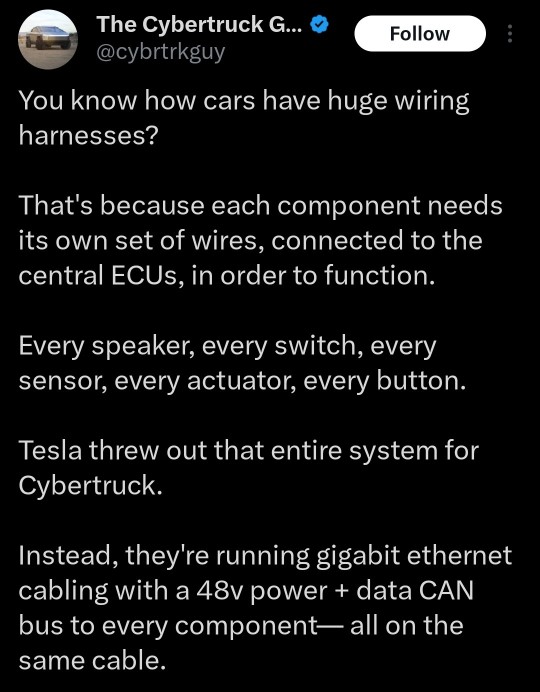

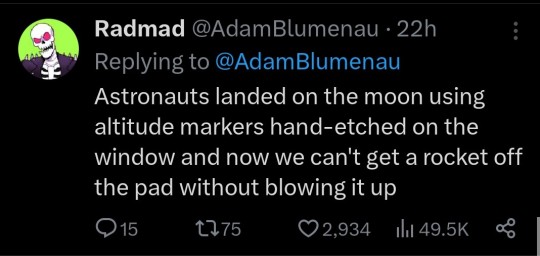

This is an insane design, who would make a system like this for a CAR, am I misunderstanding what this is saying? I find it hard to believe that a company like Tesla is actually going to design something like this that functions as intended, imagine trying to modify a harness like this by installing something simple like heated seats and the entire fucking truck breaks, I don't give a shit about functionality when the entire vehicle is designed to fail after doing something like a car wash! What about in the case of a crash? You're talking about sending possibly up to 92 volts through these systems in a collision, that'll get those computers, microcontrollers and switches real nice and toasty, I can easily believe that these things are going to be gigantic liability risk billboards in even the tiniest of collisions, oh hooray a car that insurance won't cover when it's involved in any collision regardless of the size. I can't wait for the shit storms of trashed cyber trucks sitting in dealer lots, eventually they won't be able to get the new ones off the lots and they'll have to release a "new and improved version" every few years, ah capitalism the literal definition of "turn a product into a lifestyle, and then watch the money start-a flowing". I love the modern age, its almost like all those sci-fi movies and shows from the 70's somehow predicted these things would happen, oh wait they were judging the current events of their time and predicting how the future would look, and let me tell you, this shit is getting too fucking real for me. Sure the car only lasts two years "but it can dance" its literally the Apple company sickness seeping into other markets, it is truly terrifying to watch several billionaires take over vast coverages of markets so quickly, steamrolling the smaller businesses in the process all the while self-employment is all but wiped out and all the sub-billionare companies are taken over and everything becomes a corporate controlled corrupt government puppet state where free will is annihilated in favor "of maximizing profits" . This is what the world is turning into, and I'm in the generation that is going to have to live through it, I hate baby boomers

#cybertruck#automotive#this is insane#design#capitalist hell#capitalism#fuck capitalism#i hate corporations#repent for your sins against the corporate gods!#death trap#i need antidepressants now

42K notes

·

View notes

Text

Torque Sensors: Precision Force Measurement with Star EMBSYS Engineering

In today's technology-driven industries, precise force and motion measurement is essential for performance analysis, quality control, and predictive maintenance. Among the most critical tools used for this purpose is the torque sensor. A torque sensor, also known as a torque transducer, measures the twisting force applied to an object such as a rotating shaft or system. This measurement is crucial across multiple domains including automotive testing, robotics, aerospace, manufacturing, and power tools. Companies like Star EMBSYS have emerged as leaders in designing innovative torque sensor systems that offer accuracy, reliability, and seamless integration into modern control environments.

What is a Torque Sensor?

A torque sensor detects and quantifies rotational force. It converts the mechanical input—torque—into an electrical signal that can be read, recorded, and analyzed. Depending on the application, torque sensors can be either rotary or static (reaction) types. Rotary torque sensors are used in systems where the shaft rotates continuously, while reaction torque sensors measure torque in stationary systems.

Most torque sensors work using strain gauge technology, where strain gauges are bonded to a shaft or component that deforms slightly when torque is applied. The change in resistance of the strain gauge is proportional to the amount of torque and is converted into an output signal. This output can be analog, digital, or processed through a microcontroller.

Applications Across Industries

Torque sensors are used wherever rotational motion and force need to be measured accurately. In automotive testing, torque sensors help analyze engine performance, transmission efficiency, and steering systems. In robotics, they ensure that joints and actuators apply the correct force, enhancing both safety and control. In aerospace, torque sensors are used to verify the performance of control systems and components under dynamic load conditions.

Manufacturing industries use torque sensors for monitoring tightening processes (e.g., bolt fastening), ensuring machines apply the correct force consistently to maintain product quality. Even in the medical field, torque sensors are used in rehabilitation devices and robotic surgical systems to ensure delicate and precise force control.

Star EMBSYS: Advanced Torque Sensing Solutions

Star EMBSYS stands out in the torque sensing domain through its dedication to precision engineering and smart embedded integration. Leveraging years of experience in embedded systems and sensor technologies, Star EMBSYS develops torque sensors that are tailored to meet the exact demands of modern industry.

Their sensor systems combine mechanical design with intelligent electronics, including signal conditioning, filtering, and digital output capabilities. Star EMBSYS offers both rotary and reaction torque sensors with customized features such as shaft compatibility, torque range, environmental sealing, and mounting configurations. This flexibility allows seamless integration into a variety of applications, whether for field testing, laboratory research, or embedded in production lines.

Key Features of Star EMBSYS Torque Sensors

High Accuracy: Star EMBSYS sensors are designed for precision, capable of detecting even minute changes in torque for sensitive applications.

Rugged Construction: Built to withstand harsh environments including vibration, temperature variations, and dust, these sensors are ideal for industrial use.

Versatile Outputs: Sensors are available with analog (voltage/current) and digital (SPI, UART, CAN) outputs, making them easy to interface with microcontrollers and PLCs.

Custom Design Options: Star EMBSYS offers customizable solutions tailored to unique mechanical or electrical requirements.

Real-Time Monitoring: Their solutions support fast response times and continuous monitoring, which is crucial for real-time control systems.

The Future of Torque Measurement

With the ongoing shift toward smart automation and digital monitoring, torque sensors are evolving beyond simple measurement tools. Star EMBSYS is advancing in this direction by developing IoT-ready sensors that can transmit data wirelessly, support remote diagnostics, and feed into centralized control systems. These capabilities allow businesses to track machinery performance, prevent failures, and optimize operations in real time.

In conclusion, torque sensors are essential for modern engineering and process control. With companies like Star EMBSYS offering state-of-the-art solutions, industries can rely on accurate torque measurement to enhance safety, efficiency, and innovation. Their commitment to customization, integration, and precision makes them a trusted partner in the world of torque sensing technology.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

Best APFC Panel Manufacturer in India: A Guide to Smarter Energy Efficiency

Every industrial setup depends on power. But when electricity isn't used efficiently, it leads to higher bills, system overloads, and premature equipment failure. An APFC Panel offers a solution that balances your electrical load and improves the power factor automatically.

In this guide, you’ll learn how an APFC Panel works, why it’s essential for energy control, and why DJ Electro Controls is a trusted choice for industries searching for dependable APFC Panel manufacturers.

What Is an APFC Panel?

APFC stands for Automatic Power Factor Control. These panels are designed to correct the lag between active power (used to run equipment) and reactive power (wasted energy). When the power factor is low, more current is drawn from the source, increasing your energy cost.

An APFC Panel improves this by activating or deactivating capacitor banks in real time based on the electrical load. It requires no manual switching and functions automatically using sensors and intelligent controllers.

Why Power Factor Matters in Industrial Systems

A low power factor reduces the overall efficiency of your electrical setup. It leads to:

Excess electricity usage

Overloaded transformers and cables

Higher monthly power charges

Equipment wear due to voltage drops

By using an APFC Panel, you reduce this reactive power demand and keep your energy bills under control while protecting machinery.

What Makes DJ Electro Controls a Reliable APFC Panel Manufacturer?

Among many names in the field, DJ Electro Controls is a well-recognised APFC Panel Manufacturer in India known for consistent quality, tested products, and service-oriented engineering.

Key Benefits:

Microcontroller logic that tracks real-time load

Capacitor banks that switch automatically

Digital control panels with LCD/LED status displays

Protection features against voltage spikes and short circuits

Modular structure for ease of maintenance and expansion

Their panels are tailored for commercial, industrial, and utility environments where load fluctuations are frequent.

Where Are APFC Panels Used?

Industries across various sectors rely on APFC Panels for uninterrupted performance. These include:

Cement plants

Textile mills

Cold storage facilities

Plastic manufacturing

Shopping complexes

Hospitals and labs

Steel and casting units

Wherever large motors or heavy-duty equipment is used, APFC Panels can maintain stable performance.

Key Features to Look for in a Reliable APFC Panel

To get long-term value from your panel, you should look for:

Accurate sensing and switching logic

Durable capacitors with a high discharge cycle

User-friendly display and alarms

Flexible design for future expansion

Post-installation service and spares support

DJ Electro Controls provides all these features with tested systems that are easy to install and built to handle tough conditions.

Top Advantages of Installing an APFC Panel

1. Cuts Down Monthly Bills

Power factor penalties can add up fast. Installing an APFC system corrects this and saves money.

2. Reduces Electrical Losses

Better power balance means less wastage and fewer electrical faults.

3. Extends Equipment Lifespan

Voltage stability improves motor and transformer life.

4. Meets Utility Norms

Maintains your facility’s compliance with electricity board standards.

5. Operates Automatically

Once installed, the system works without human interference.

FAQ Section

Q1. What is the ideal power factor to maintain in an industrial setup?

Answer: Most utility companies recommend a power factor close to 1.0. Anything below 0.9 may attract penalties.

Q2. How often should APFC Panels be serviced?

Answer: Basic checks every 6–12 months help maintain capacitor health and controller accuracy.

Q3. Can APFC Panels be used in residential complexes?

Answer: Yes, in high-rise residential buildings with elevators, pumps, and HVAC systems, APFC Panels offer consistent performance.

Q4. Do APFC Panels work with diesel generators?

Answer: They do, but compatibility depends on the generator’s alternator rating. Always check with the panel manufacturer.

Q5. Are custom-built panels better than standard ones?

Answer: Custom panels are better for industries with irregular load patterns. DJ Electro Controls provides both standard and customised solutions.

Conclusion

Energy efficiency is not just about reducing usage it’s about managing it wisely. APFC Panels are a one-time investment that deliver long-term savings and stability. Whether you manage a manufacturing facility, commercial space, or utility unit, improving your power factor is a smart decision.

DJ Electro Controls continues to be a trusted name among businesses that value reliable performance and excellent post-installation service.

#djelectrocontrol#apfc manufacturer#apfc panels#apfc supplier in india#apfc panel supplier#apfc panels near me

0 notes

Text

Comprehensive Guide to Logic ICs, Decoders, and Transceivers – Sourcing Quality Components in India

Logic integrated circuits (ICs) are fundamental building blocks of modern electronic devices. They perform critical logical functions that enable devices to process, transmit, and receive digital signals efficiently. Among the vast range of logic ICs, decoders and transceivers are key components that enable signal translation and communication.

This guide explores the role of these components and why sourcing them from a leading decoder company and a top transceiver supplier in india is crucial for project success. It also highlights the advantages of choosing top semiconductor companies in india and the convenience of buying parts online.

What Are Logic ICs and Why Are They Important?

Logic ICs are chips designed to carry out logic functions in electronic circuits. These include simple gates such as AND, OR, and NOT, as well as complex components like decoders and multiplexers. Logic ICs interpret digital inputs and produce the corresponding outputs, which control various operations within electronic devices.

These ICs are the foundation for everything from microcontrollers to consumer electronics and industrial machinery. Without reliable logic ICs, devices cannot function accurately or consistently.

Understanding the Role of a Decoder

A decoder company manufactures decoders, which are specialized logic ICs that convert coded inputs into a set of outputs. Decoders play a crucial role in enabling electronic systems to interpret binary or coded data.

For example, in digital display systems, decoders convert binary signals into visual outputs, such as numbers on a seven-segment display. In memory management, decoders help select specific memory locations based on input addresses.

Choosing a leading decoder company ensures that the decoders you get meet industry standards for accuracy, speed, and reliability. This is vital in applications where precision decoding is critical, including computing, telecommunications, and embedded systems.

The Importance of Transceivers in Communication

Communication between electronic devices depends heavily on the ability to send and receive data effectively. This is where transceivers come in. A transceiver supplier provides integrated circuits that function as both transmitters and receivers.

Transceivers are used extensively in industrial automation, automotive electronics, and network communication protocols like RS-485, CAN, and Ethernet. By partnering with a top transceiver supplier in india, companies can secure high-quality transceivers that ensure robust data transmission and reduce communication errors.

Quality Assurance with Top Semiconductor Companies

The semiconductor industry demands stringent quality control to maintain the performance and durability of components. Sourcing parts from top semiconductor companies in india is essential to guarantee authenticity and compliance with international standards.

Such companies provide components that undergo rigorous testing and certification. This reduces the risk of failures, extends the life of electronic systems, and supports the development of reliable products.

Benefits of Buying Electronic Components Online

In the current digital age, the option to buy electronic components online has revolutionized procurement processes. Online platforms offer several advantages:

Wide Selection: Easy access to a broad inventory, including the latest parts.

Detailed Information: Datasheets, specifications, and technical documents are readily available.

Convenience: Ability to order components anytime from anywhere.

Faster Delivery: Reliable logistics ensure prompt delivery to keep projects on schedule.

Buying components online from reputable suppliers enhances efficiency and helps engineers and manufacturers avoid delays caused by limited local availability.

Conclusion

Logic ICs, decoders, and transceivers are indispensable in modern electronics. Securing these components from a leading decoder company and a top transceiver supplier in india ensures that your projects benefit from quality and reliability.

By choosing parts from top semiconductor companies in india and leveraging the convenience to buy electronic components online, engineers and companies can streamline their supply chain and focus on innovation.

For anyone involved in electronics design or manufacturing, sourcing trusted components is key — and the companies that specialize in these components play a vital role in the industry’s success.

#Leading decoder company#top transceiver supplier in india#decoder company#transceiver supplier#top semiconductor companies in india#buy electronic components online#electronic components online

0 notes

Link

#AnalogDevices#ASILx#automotiveEthernet#automotivefunctionalsafety#automotivemicrocontrollers#automotivesemiconductors#Bosch#Futurride#InfineonTechnologies#ISOISO26262#MarvellTechnology#Micron#NXPSemiconductors#Onsemi#Qualcomm#RenesasElectronics#software-definedvehicles#STMicroelectronics#sustainablemobility#TechInsights#TexasInstruments#ULSolutions

0 notes

Text

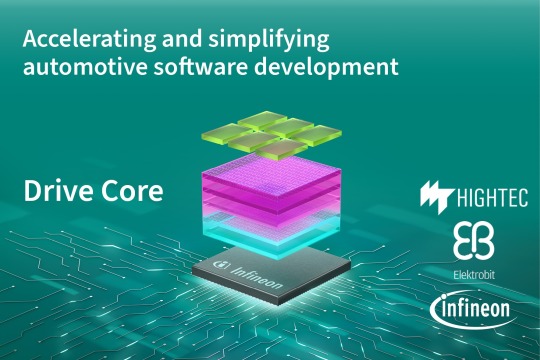

Saarbruecken, Erlangen, and Munich, Germany, July 21, 2025 – HighTec EDV-Systeme, Elektrobit and Infineon are partnering to accelerate software innovation in the automotive industry by enabling the integration of Rust applications with AUTOSAR Classic basic software. As ecosystem partners to Infineon Technologies’ Drive Core for AURIX™ microcontrollers, HighTec and Elektrobit are delivering a comprehensive development bundle. This joint offering includes Elektrobit’s EB tresos AutoCore and HighTec’s automotive-grade LLVM-based Rust and C/C++ compiler. Specific to the AURIX TC4x families, HighTec and Elektrobit will offer a Drive Core software bundle that contains all tools and software in a single package to get started with Rust and AUTOSAR Classic. Through this close cooperation, embedded software developers gain seamless access to all they need in one package to take advantage of Rust’s memory safety and performance for functional safety applications, even in the most complex automotive ECUs. Rust's performance, reliability and above all its memory safety make it indispensable for modern automotive software. It directly addresses the growing demand for cybersecurity and functional safety driven by software-defined vehicles and regulations like UN R155 and the EU Cyber Resilience Act. By combining Elektrobit’s AUTOSAR Classic Basic Software with HighTec’s ISO 26262 ASIL D-certified Rust compiler, developers can now seamlessly integrate Rust-based software components into AUTOSAR environments. This enables a hybrid development approach, where new software written in Rust can operate alongside legacy C/C++ code basis, reducing risks while ensuring compliance with stringent safety standards. The Drive Core software bundle for Infineon’s AURIX TC4x includes microcontrollers and everything developers need to get started: EB tresos configuration tool, the Infineon AURIX TC4x MCALs and comprehensive examples and tutorials to develop AUTOSAR software components in Rust. Elektrobit’s EB tresos now supports clean, efficient Rust development – minimizing or eliminating the need for “unsafe” code. This integration provides developers with a robust tool chain that not only generates system-access code but also enables advanced static analysis through tools like Rust’s Clippy and automatic code formatting. This solution enhances productivity while minimizing the cost and complexity of developing safety-critical automotive software. HighTec’s Rust and C/C++ compiler is built on proven LLVM open-source technology. As the industry’s first Rust compiler for Infineon’s AURIX TC3x and TC4x microcontroller series, it is specifically optimized to leverage the architecture-specific functions of the AURIX microcontrollers. HighTec’s compiler is known for its rapid build system and advanced code optimizations, which accelerate the development and certification of safety-critical applications. Infineon has the largest Microcontroller Abstraction Layer portfolio in the industry and embraces an ecosystem approach to drive innovation and growth. This is why Infineon introduced Drive Core, a comprehensive software bundle portfolio that provides a foundation for automotive software development. "We believe that Drive Core is a game-changer for the automotive industry, and we are excited to see companies such as HighTec and Elektrobit leveraging it to drive innovation," said Patrick Will, Senior Director of Automotive Software at Infineon. “By taking Rust to the AUTOSAR Classic environment, Elektrobit continues to drive innovation in the automotive software industry,” said Florian Bartels, Senior Expert and System Architect at Elektrobit. “Rust’s inherent safety features and its seamless integration into existing AUTOSAR Classic environments make it a perfect fit for modern ECU development, enabling developers to create reliable, secure and high-performance automotive software.” “Our partnership with Elektrobit empowers automotive customers to build safer and more efficient software solutions,” said Mario Cupelli, CTO at HighTec. “By offering our proven Rust compiler along with Elektrobit’s tools in a comprehensive bundle, we give automotive suppliers and OEMs a competitive edge.” In addition to their tools and software bundle for Rust and AUTOSAR Classic, HighTec and Elektrobit are offering workshops and hands-on sessions for practical insights and guidance on integrating Rust within AUTOSAR Classic projects. For more information on Drive Core, please visit https://www.infineon.com/drivecore. For more information on EB tresos and how Elektrobit is incorporating Rust into automotive software, please visit https://www.elektrobit.com/rust/. To learn more about HighTec’s Rust compiler for Infineon AURIX TC3x and TC4x, please visit www.hightec-rt.com/rust. These websites also include information on how to register and obtain the AUTOSAR Rust Bundle. FOR MORE BLOGS - beyondthepunchlines.com Read the full article

0 notes