#multi warehouse

Explore tagged Tumblr posts

Text

What to look for in a 3PL warehouse management system

When you're managing a 3PL (third-party logistics) operation, choosing the right warehouse management system (WMS) can make all the difference. The complexities of 3PL services demand a WMS that is not just functional but also adaptable, scalable, and user-friendly. This article will guide you through the crucial features to consider in a 3PL warehouse management system, ensuring it enhances your operations and drives your business forward.

1. Scalability and Flexibility

First and foremost, scalability is crucial. As your business grows, so too will your warehouse operations. Your WMS should be able to handle an increasing number of clients, orders, and inventory without a hitch. Look for a system that offers modular features, allowing you to add functionalities as your needs evolve. Flexibility is equally important; you need a system that can be tailored to different clients' requirements and can adapt to various industries, whether you're dealing with retail, manufacturing, or e-commerce.

2. Integration Capabilities

A top-notch 3PL WMS must seamlessly integrate with other systems. This includes your existing ERP (Enterprise Resource Planning), TMS (Transportation Management System), and other critical software. Integration ensures smooth data flow across your operations, reducing manual entry errors and enhancing overall efficiency. An integrated system can also provide real-time updates, which is vital for keeping your clients informed and satisfied.

3. Real-Time Visibility and Analytics

In the fast-paced world of logistics, real-time visibility is non-negotiable. Your WMS should offer comprehensive tracking of inventory, orders, and shipments in real-time. This capability not only helps in better decision-making but also enhances transparency with your clients. Moreover, advanced analytics tools are indispensable. They allow you to monitor key performance indicators (KPIs), identify trends, and make data-driven decisions. With robust analytics, you can optimize warehouse operations, reduce costs, and improve service levels.

4. User-Friendly Interface

A user-friendly interface can significantly impact the efficiency of your warehouse operations. Your staff, from warehouse workers to managers, should be able to navigate the system easily without extensive training. A well-designed WMS will have intuitive dashboards, easy-to-understand reports, and straightforward workflows. The easier the system is to use, the quicker your team can adapt, reducing downtime and increasing productivity.

5. Customization and Personalization

Every 3PL operation is unique, and a one-size-fits-all solution rarely works. The WMS you choose should offer customization options to meet your specific needs. This includes customizable reporting, workflow automation tailored to your processes, and personalized user roles and permissions. Personalization ensures that the system works in harmony with your existing operations and can adjust as your business processes change.

6.Inventory Management

Effective inventory management is at the heart of any successful warehouse operation. Your WMS should provide accurate and real-time inventory tracking, support multiple picking methods (such as FIFO, LIFO, batch picking), and handle various inventory types and statuses. Advanced features like automated replenishment alerts, cycle counting, and cross-docking can further enhance inventory management, ensuring you always have the right products in the right place at the right time.

7. Robust Reporting and Compliance Features

In the logistics industry, compliance with regulations and standards is crucial. A good WMS will offer robust reporting features that help you stay compliant with industry standards and client requirements. Look for a system that provides detailed audit trails, customizable compliance reports, and support for industry-specific regulations. This not only helps you avoid penalties but also builds trust with your clients by ensuring transparency and accountability.

8. Customer Support and Training

Even the best systems can encounter issues or require adjustments. Excellent customer support and comprehensive training resources are essential for maximizing your WMS's potential. Ensure that the provider offers reliable support options, including phone, email, and live chat. Additionally, look for a WMS that provides extensive training materials, such as online tutorials, webinars, and user manuals, to help your team get up to speed quickly and efficiently.

9. Mobile Accessibility

In today's fast-moving world, mobile accessibility is no longer a luxury but a necessity. A WMS with mobile capabilities allows your staff to access critical information and perform essential tasks on-the-go. Whether it's scanning barcodes, updating inventory, or tracking shipments, mobile accessibility can greatly enhance the flexibility and responsiveness of your warehouse operations.

10. Cost-Effectiveness

Finally, while the initial investment is important, you must also consider the long-term value. Assess the total cost of ownership, including implementation, training, and ongoing support. A cost-effective WMS should deliver a high return on investment through improved efficiency, reduced errors, and enhanced client satisfaction.

Choosing the right 3PL warehouse management system is a critical decision that can significantly impact your business's success. By focusing on scalability, integration capabilities, real-time visibility, user-friendliness, customization, inventory management, robust reporting, customer support, mobile accessibility, and cost-effectiveness, you can find a system that not only meets your current needs but also supports your growth and adaptation in the ever-evolving logistics landscape.

Our Software Services:

Order Management Software | Dsd Route Accounting Software | Inventory Management Software | Fleet Management Software

#warehouse management software#multi warehouse#warehouse#bmobile route software#multi warehouse management software#bmobile

0 notes

Text

Warehouse Services | Garage Perfect

Unlock Efficiency and Savings with Warehouse Services from Garage Perfect

Introduction to Warehouse Services: What We Offer at Garage Perfect

warehouse services, storage solutions, logistics support, warehouse management, inventory control

The Advantages of Utilizing Professional Warehouse Services for Your Business

benefits of warehouse services, cost-effective storage, improved supply chain management, scalability in logistics, enhanced efficiency

How Garage Perfect's Warehouse Services Stand Out from the Competition

unique selling points, tailored solutions, state-of-the-art facilities, dedicated customer support, technology integration in warehousing

Real-World Success Stories: Clients Who Transformed Their Operations with Our Warehouse Services

case studies warehouse services, client testimonials garage perfect, success stories in logistics management

Your Step-by-Step Guide to Getting Started with Garage Perfect's Warehouse Services

how to use warehouse services, onboarding process garage perfect, consultation for storage needs.

Conclusion: Elevate Your Business Efficiency with Garage Perfect's Unmatched Warehouse Services Today!

#Office Space Services in Ottawa#Commercial Garage Flooring#Retail Store Services in Ontario#Distilleries Services#Ottawa Garage Storage Solutions#Restaurants Services#Multi-Unit Condo Services in Ontario#Warehouse Services#Residential Garage Quartz#Kitchen Cabinets Services in Ottawa#Garage Storage Services#Contur Cabinets Services#Concrete Floors in Ottawa#Overhead Storage Services in Ottawa#Wall Systems Services in Ontario#Overhead Garage Storage & Platforms#acid stain concrete floor kanata#acid stain concrete floor nepean#acid stain concrete floor orleans#acid stain concrete floor ottawa#acid stained concrete#acid stained concrete kanata#acid stained concrete nepean#acid stained concrete ottawa#acid wash concrete floor kanata#acid wash concrete floor nepean#acid wash concrete floor orleans#acid wash concrete floor ottawa#acid wash concrete kanata#acid wash concrete nepean

0 notes

Text

watched “it started with swap shop”, and if i get motivated i might gif a lot of mike’s moments. but i honestly don’t know yet

#also generally its peak as fuck. like everything from the first minute until they went to ‘going live!’ was amazing#like. cheggers having an explosive entrance? the warehouse is back?? all of them having a good time??? sign me up!!#multi-colored swap shop#clocky’s rambles

0 notes

Text

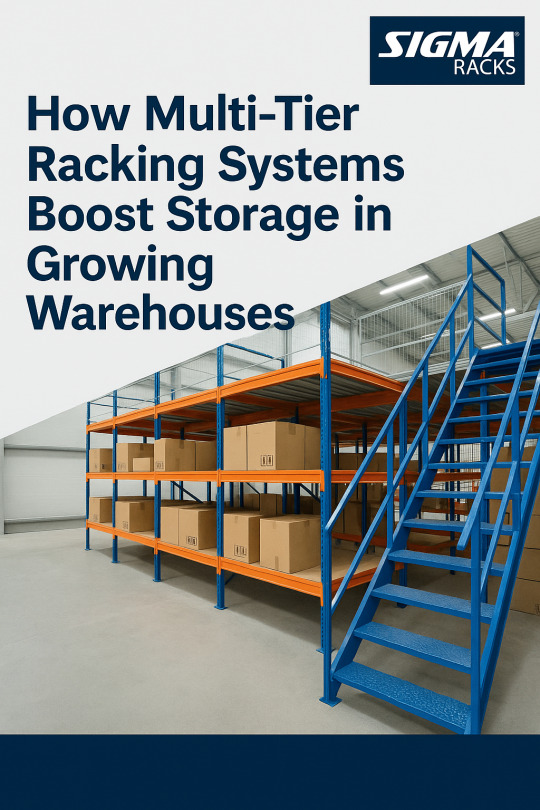

How Multi-Tier Racking Systems Boost Storage in Growing Warehouses?

As warehouse operations grow, so does the pressure on available space. Instead of investing in costly expansions or relocating, many businesses are now turning to a smarter solution — multi-tier racking systems.

These systems are built to utilize vertical height by adding multiple rack-supported levels within the same floor space. That means you can literally double or triple your storage capacity without changing the warehouse footprint.

Multi-tier racking systems are ideal for operations that deal with high SKU volumes, seasonal inventory fluctuations, or growing product lines. Each level can be configured for different storage types — from shelving and bins to pallets — making them perfect for order picking, spare part storage, or inventory segregation.

Beyond just space, these systems support faster access, better organization, and safer workflows. With built-in staircases, handrails, and walkways, movement across tiers remains efficient and compliant with safety norms.

Engineered for strength and flexibility, multi-tier systems are modular — which means they can be expanded or reconfigured as the warehouse grows. Whether it's retail, automotive, pharma, or e-commerce, they offer scalable storage without the cost of physical expansion.

If your current setup is running out of space, it might be time to look upward — literally.

#multi tier racks#multi-tier racking system#warehouse storage systems#vertical warehouse storage#warehouse expansion solutions#modular racking system#warehouse pallet racks

1 note

·

View note

Text

Collision Sentry Corner Pro: Smart Safety Solution for Warehouse Blind Spots

In fast-paced industrial environments, especially warehouses and logistics hubs, blind corner collisions are a constant safety risk. Heavy equipment, like forklifts, pallet jacks, and even foot traffic, can create a hazardous mix when visibility is poor. This is where the Collision Sentry Corner Pro steps in — a smart, compact, and highly effective device designed to prevent accidents before they happen.

Why Blind Spots Are Dangerous in Warehouses

Warehouses are typically filled with racking systems, narrow aisles, and high shelves — all of which create blind spots. Forklifts navigating tight corners or intersections often face the risk of crashing into another vehicle or even a pedestrian. These collisions not only cause injuries but also lead to equipment damage, product loss, and costly downtime.

Traditional convex mirrors offer limited visibility and rely on the operator’s awareness. In contrast, a proactive safety alert system like Collision Sentry Corner Pro takes the guesswork out of blind corner navigation.

What is Collision Sentry Corner Pro?

The Collision Sentry Corner Pro is a plug-and-play safety device that mounts easily at corners, intersections, and aisle ends within warehouses. Using infrared motion sensors and LED warning lights, it detects motion on both sides of the blind corner. When motion is detected from two or more directions, the system activates a bright visual alert — flashing LED lights — to warn both parties of potential collision.

It’s a non-intrusive, battery-operated device that requires no wiring or network connectivity, making it incredibly easy to install and relocate as needed.

Key Features:

Infrared Motion Detection: Accurate sensing of movement in both directions.

Flashing LED Warning Lights: High-visibility alert that captures attention immediately.

Plug-and-Play Design: No electrical installation required.

Magnetic & Strap Mounting Options: Quick setup on racking systems.

Battery-Powered (with AC option): Long-lasting battery life ensures uninterrupted operation.

Adjustable Sensitivity: Customize detection range based on environment.

Real-World Use Case: How It Prevents Collisions

Imagine a warehouse aisle where two forklifts are approaching a T-intersection from opposite sides. Without visibility, both operators may proceed — risking a head-on collision. If the Collision Sentry Corner Pro is installed at that corner, it detects movement from both directions and flashes bright warning lights to stop operators in their tracks. This momentary alert allows both parties to slow down and avoid impact — saving lives, equipment, and inventory.

Benefits for Warehouse Safety and Productivity

Reduces Accidents: Acts as a reliable warning system where mirrors or human awareness might fail.

Increases Operator Confidence: Operators feel more secure when approaching blind spots.

Improves Workflow Efficiency: Prevents downtime due to accident investigations and repairs.

Protects High-Value Inventory: Avoids losses from collision-induced product damage.

Compliance with Safety Protocols: Adds a layer of protection that aligns with OSHA and HSE guidelines.

Easy to Deploy, Easier to Trust

One of the standout aspects of the Collision Sentry Corner Pro is how adaptable it is. Whether you're setting up in a new facility or looking to upgrade safety protocols in an existing one, this device integrates seamlessly. You can even move it around depending on traffic flow changes, seasonal warehouse layouts, or special event configurations.

Conclusion

Workplace safety isn’t optional — it’s essential. As warehouse operations scale and automation becomes more prevalent, so must smart safety tools. The Collision Sentry Corner Pro is more than just a gadget; it’s a proactive investment in the well-being of your staff and the protection of your operations.

If you're looking to enhance safety in your facility’s high-traffic corners, this device is the intelligent solution you've been waiting for. Contact SharpEagle for more details.

#collision sentry corner guard#collision sentry forklift system#collision sentry for blind spot#Collision Sentry for Blind Warehouse Corners#Infrared Corner Collision Sentry#Collision Sentry Safe zone Guard#collision sentry warning system#Collision Sentry Multi-Zone#collision sentry blind-corner warning system#Collision sentry corner#Collision Warning Sentry Protection#Collision Sentry Corner Pro#corner pro

0 notes

Text

PEB contractors | PEB Companies in Chennai - Mekark

Mekark is a trusted PEB contractor, delivering high-quality Pre-Engineered Buildings, Multi-Storey Steel Buildings, Industrial Sheds, Factory Sheds, and Warehouses. Our expert team ensures precision engineering, durable materials, and cost-effective solutions tailored to industrial and commercial needs. With a commitment to excellence, we provide customized, energy-efficient, and structurally sound solutions that meet industry standards and client expectations.

Pre-Engineered Building Manufacturer

Mekark designs and manufactures Pre-Engineered Buildings (PEB) that provide a faster, more efficient, and cost-effective alternative to conventional construction. These structures are factory-fabricated, reducing on-site labor and ensuring precision. Our PEB solutions are widely used for industrial, commercial, and institutional buildings, offering durability, flexibility, and energy efficiency.

Multi-Storey Steel Building Manufacturer

For industries requiring multi-level infrastructure, Mekark specializes in Multi-Storey Steel Buildings that optimize vertical space while maintaining strength and stability. These buildings are ideal for offices, warehouses, and manufacturing units, designed to withstand seismic forces and heavy loads. With modular construction techniques, we ensure quick assembly and long-lasting performance.

Industrial Shed Manufacturer

Mekark constructs Industrial Sheds that cater to manufacturing units, storage facilities, and production plants. Our sheds are designed with proper ventilation, insulation, and high load-bearing capacities to support heavy-duty machinery and seamless industrial operations. We customize layouts based on client requirements to enhance efficiency and safety.

Factory Shed Building Manufacturer

A well-planned Factory Shed is crucial for smooth production flow. Mekark designs factory sheds with ample working space, proper column spacing, and durable roofing solutions. Our factory sheds are built to accommodate industrial equipment, storage needs, and worker movement while ensuring optimal airflow and energy efficiency.

Warehouse Construction

Efficient storage and logistics require a well-designed warehouse. Mekark specializes in Warehouse Construction with high ceilings, reinforced flooring, and optimized layouts for seamless material handling. Our warehouses are built to maximize storage capacity, facilitate easy access, and enhance supply chain efficiency for businesses of all scales.

For more details:

Website - https://www.mekark.com/

Contact: +91 9790924754

Email: [email protected]

Follow Us:

Facebook: https://www.facebook.com/profile.php?id=100089566346921

Instagram: https://www.instagram.com/mekarkindustrial/

Twitter: https://x.com/MekarkPEB

YouTube: https://www.youtube.com/channel/UCsCdBcilS4Ib5l1C7l2u3bg

Pinterest: https://in.pinterest.com/mekarkindustrialmanufacturer/_profile/

#pre-engineered building manufacturer company#Multi storey steel building#industrial shed manufacturer#warehouse shed construction

0 notes

Text

Heavy duty racks are useful when the business management needs tough equipment that can accommodate large amounts of goods and burdensome weight. To cater for maximum load utilization of the racks these are designed to be very strong and durable and are made from materials such as steel meant for bearing maximum load in warehouses factories and other retail outlets.

Consequently, these racks can be arranged in several different ways due to flexibility, ideal for warehousing palletized products, industrial tools, or miscellaneous products in bulk. This enabled them to make the best use of vertical space thus businesses saw a significant improvement in efficiency through improvement in the storage area.

For More blog Visit Us : penposh.com/

#Heavy Duty Racks#Mild Steel Heavy Duty Racks#Heavy Duty Industrial Pallet Rack#Multi Tier Rack#Warehouse Storage Racks#Material Handling Racks#Cold Storage Racks#Mobile Storage Rack

0 notes

Text

Safe Zone Collision Sentry Corner Guard - All you need to know

In industrial environments, safety is not just a priority; it is a necessity. Ensuring the well-being of employees and the protection of valuable equipment are crucial aspects of efficient and productive operations.

Blind spots and corners, however, pose significant challenges, often leading to unexpected collisions and accidents. Traditional safety measures like mirrors and signage have a limited scope as they fail to provide real-time warnings for threats, obstacles, and pedestrians that the operator might oversee, highlighting the need for more advanced solutions.

The Safe Zone Corner Guard System by SharpEagle is a groundbreaking innovation designed to enhance workplace safety. This state-of-the-art device not only prevents accidents but also minimises equipment damage, reduces downtime, and fosters a culture of safety within the workplace.

By investing in zone-safe solutions like the Safe Zone Collision Sentry Corner Guard, businesses can take proactive steps towards creating safer, more productive industrial environments.

What is a Safe Zone Corner Guard?

The Safe Zone Corner Guard is an innovative safety device designed to prevent accidents and collisions in industrial environments, particularly around blind spots and corners. This system employs advanced sensor technology to detect motion on both sides of a corner, providing real-time alerts to employees and forklift operators.

Key Features and Design Elements

At the core of the Safe Zone Corner Guard are its sophisticated sensors that detect any approaching movement. Once motion is detected, the system activates a dual alert mechanism consisting of bright LED lights and alarms — a combination that ensures engagement of the operator’s visual and auditory senses, even in noisy environments.

One of the standout features of the Safe Zone Corner Guard System is its customizable audio settings. Users can adjust the volume and pitch of the alarms to suit the specific noise levels of their workplace, making it adaptable to various environments, from bustling warehouses to quieter office spaces.

The system’s snap-on design allows for quick and hassle-free installation, ensuring that it can be deployed with minimal disruption to ongoing operations.

Materials Used in the Construction of Corner Guards

The Safe Zone Corner Guard System is constructed using high-quality, durable materials designed to withstand the rigours of industrial environments. The housing is made from robust, impact-resistant plastic that can endure collisions and harsh conditions without compromising its functionality. The LED lights are encased in shatter-proof glass to protect them from damage, while the sensors are designed to be both sensitive and resilient, ensuring reliable performance over time.

Importance of Safe Zone Corner Guards

Preventing Accidents and Injuries

In industrial settings, corners and blind spots are notorious for causing accidents. Unprotected corners can lead to unexpected collisions between employees, machinery, and equipment, resulting in injuries and damage.

Safe Zone Collision Sentry Corner Guards play a crucial role in mitigating these risks by providing real-time warnings to those approaching a corner. The advanced sensor technology detects motion from both directions, triggering visual and audio alerts to ensure everyone is aware of the potential hazard.

This proactive approach significantly reduces the likelihood of accidents, creating a safer work environment.

SharpEagle provides a range of forklift lighting solutions to enhance your workplace safety - Read about the complete range and functions of forklift safety lights.

Statistics on Workplace Accidents Related to Unprotected Corners

Workplace accidents are a significant concern in industrial environments, with many incidents occurring due to unprotected corners.

According to the National Safety Council (NSC), workplace accidents involving collisions between people and moving equipment are the third leading cause of workplace deaths. Furthermore, a study by the same organisation highlights that unprotected corners and low visibility account for 93% of systemic risks connected to these accidents.

Implementing Safe Zone Corner Guards can drastically reduce these statistics. By providing clear and immediate warnings, these devices help prevent collisions and ensure that employees can navigate corners safely. This reduction in accidents not only protects workers but also minimises downtime and lowers costs associated with equipment damage and injury-related absences.

Benefits of Safe Zone Corner Guard

The Safe Zone Corner Guard System offers a multitude of benefits for industrial and warehouse settings.

Accident Prevention

The primary benefit of Safe Zone Corner Guards is the prevention of accidents. By detecting motion and providing real-time visual and audio alerts, the system ensures that employees are aware of potential hazards around corners, reducing the risk of collisions and injuries.

Protection of Equipment

In addition to safeguarding employees, the Safe Zone Corner Guard System protects valuable equipment and machinery from damage caused by collisions. This not only prolongs the lifespan of the equipment but also minimises repair and replacement costs.

Increased Productivity

A safer work environment leads to increased productivity. When employees feel secure and confident navigating their workspace, it inevitably leads to higher efficiency and output.

Customisable Alerts

The customisable audio settings of the Safe Zone Corner Guard System allow businesses to tailor the alerts to their specific environment, ensuring that warnings are effective without being disruptive. This adaptability makes it suitable for a variety of settings, from noisy warehouses to quieter offices.

Enhanced Safety Culture

Implementing Safe Zone Corner Guards promotes a culture of safety within the workplace. Employees become more aware of safety protocols and practices, fostering a proactive approach to accident prevention and overall workplace well-being.

Our experts at SharpEagle recommend the top three products to increase workplace safety!

Installation and Maintenance Guide

Step-by-Step Guide to Install Safe Zone Corner Guards

Unpack the System: Carefully remove the Safe Zone Corner Guard components from the packaging. Ensure all parts, including sensors, LED lights, and mounting hardware, are present.

Choose the Installation Location: Identify the corners where the Safe Zone Corner Guard will be most effective. Ideal locations are high-traffic areas with frequent blind spot collisions.

Clean the Surface: Clean the surface of the corner where the device will be mounted to ensure a secure attachment. Remove any dust, grease, or debris.

Mount the Bracket: Attach the mounting bracket to the chosen location using the provided screws or adhesive pads. Ensure the bracket is securely fixed and level.

Attach the Sensor Unit: Snap the sensor unit onto the mounted bracket. Ensure it is firmly in place and correctly oriented to cover both sides of the corner.

Connect the Power Supply: If the unit is battery-operated, insert the batteries. For wired units, connect the power supply to a nearby outlet.

Test the System: Activate the Safe Zone Corner Guard to test its functionality. Walk towards the corner from both directions to ensure the sensors trigger the visual and audio alerts.

Tips for Proper Installation

Optimal Height: Install the sensors and lights at a height that ensures visibility and detection of both personnel and equipment.

Secure Mounting: Ensure all components are securely mounted to prevent them from being dislodged by vibrations or impacts.

Visibility: Position the LED lights so they are clearly visible from all angles to maximise the warning effect.

Maintenance Guidelines

Regular Cleaning

Clean the sensors and lights regularly to prevent dust and debris from obstructing their functionality.

Perform Battery Checks

For battery-operated units, check and replace batteries periodically to ensure continuous operation.

System Testing

Conduct regular tests to ensure the sensors and alarms are functioning correctly. Schedule these tests as part of routine safety checks.

Troubleshooting Common Issues

No Power

If the unit is not powering on, check the power supply connection or replace the batteries.

False Alarms

Ensure the sensors are free from obstructions and not exposed to excessive vibrations or reflective surfaces that might trigger false alarms.

No Alerts

If the sensors are not detecting motion, clean the sensor lenses and check for proper alignment. Verify that the system is turned on and fully operational.

Future Scope

The future scope for Safe Zone Corner Guards is promising, as ongoing advancements in technology and growing awareness of workplace safety continue to drive innovation in this field.

Integration with Smart Technologies

As industrial environments become increasingly automated and connected, the Safe Zone Corner Guard System could integrate with broader smart technology frameworks. This includes enabling real-time data collection and analysis.

Enhanced Sensor Technology

Future iterations of Safe Zone Corner Guards may incorporate advanced sensor technologies, such as infrared, ultrasonic, or LiDAR sensors. These enhancements would improve detection accuracy and range, allowing the system to identify potential hazards more effectively, even in complex environments with multiple obstacles and varying levels of activity.

Customisable and Modular Designs

Future designs could offer greater customisation and modularity, allowing businesses to tailor the system to their specific needs. Modular units that can be easily expanded or reconfigured would provide flexibility for different industrial setups and evolving safety requirements.

Regulatory Compliance and Standardisation

As workplace safety regulations evolve, Safe Zone Corner Guards will likely adapt to meet new standards and compliance requirements. Enhanced features that align with global safety standards can help businesses maintain compliance and improve their safety ratings.

Expanding Applications

While currently focused on industrial and warehouse settings, the application of Collision Sentry Safe Zone Corner Guards could extend to other environments, such as construction sites, hospitals, schools, and commercial buildings. Each of these settings presents unique safety challenges that the system could help mitigate.

Case Studies and Success Stories

1. Global Logistics Warehouse

A leading global logistics company implemented the Safe Zone Corner Guard System across its major distribution centres. With a high volume of foot traffic and machinery operating in close quarters, the company faced frequent accidents at blind corners. After installing the Safe Zone Corner Guards, the facility saw a 40% reduction in corner-related collisions within the first six months. The system’s visual and audio alerts significantly enhanced awareness, allowing workers to navigate safely and efficiently.

2. Automotive Manufacturing Plant

An automotive manufacturing plant integrated Safe Zone Corner Guards into its assembly line operations. The plant, which had previously experienced several costly incidents involving forklifts and heavy machinery, reported a notable decrease in accidents. The customisable audio settings were particularly beneficial in the noisy environment, ensuring that alerts were heard over the ambient noise. This implementation not only improved safety but also led to a 20% increase in overall productivity, as employees could focus on their tasks without constant fear of accidents.

3. Retail Distribution Center

A large retail distribution centre adopted Safe Zone Corner Guards to enhance safety in its high-traffic areas. The centre had numerous narrow aisles and blind spots, posing significant risks to workers and equipment. After deploying the Safe Zone Corner Guard System, the centre observed a dramatic decline in near-miss incidents and collisions. The management noted that the easy installation and minimal maintenance of the system allowed for a seamless integration into their existing safety protocols.

Choosing the Right Safe Zone Corner Guard for Your Needs

Factors to Consider

Environment

Assess the environment where the corner guard will be installed. Different settings, such as warehouses, manufacturing plants, and retail spaces, have varying requirements. Consider factors like noise levels, lighting conditions, and potential environmental hazards.

Type of Traffic

Understand the type and volume of traffic in the area. High-traffic zones with frequent movement of forklifts and heavy machinery will need more robust solutions compared to areas with only pedestrian traffic.

Potential Hazards

Identify specific hazards present in your workplace. This could include sharp corners, blind spots, and high-speed machinery. Choose a corner guard that can effectively mitigate these risks.

Importance of SharpEagle Safe Zone Corner Guard

The SharpEagle Safe Zone Corner Guard stands out due to its advanced sensor technology, customisable alerts, and durable construction. It provides real-time visual and audio warnings, significantly reducing the risk of accidents and enhancing overall workplace safety. Easy installation and minimal maintenance requirements make it a reliable and cost-effective solution for a variety of industries.

Recommendations Based on Industry Requirements

Warehousing and Logistics

For environments with high forklift traffic and narrow aisles, choose a corner guard with robust sensors and loud, customisable audio alerts to ensure clear visibility and audibility in noisy conditions.

Manufacturing

In manufacturing plants with heavy machinery, select a corner guard that can withstand harsh conditions and provide precise motion detection to prevent collisions.

Retail Distribution

For retail distribution centres with mixed traffic (pedestrians and machinery), opt for a versatile corner guard that offers adjustable alert settings to cater to different noise levels and visibility requirements.

Expert Tips on Making an Informed Decision

Evaluate Your Needs: Conduct a thorough assessment of your workplace to identify the areas with the highest risk of collisions and accidents.

Seek Professional Advice: Consult safety experts like SharpEagle to get product recommendations tailored to your specific requirements.

Test the System: Test the Safe Zone Corner Guard in a small industrial zone before full-scale implementation to ensure it meets your safety needs.

Consider Future Scalability: Choose a system that can be easily expanded or upgraded as your safety needs evolve.

Compliance and Regulations

Ensure that the Safe Zone Corner Guard you choose complies with relevant safety regulations and standards. This not only enhances workplace safety but also ensures that your business meets legal and industry-specific compliance requirements. SharpEagle’s products are designed to adhere to these standards, providing an added layer of security.

Conclusion

From their advanced sensor technology and customisable alerts to their durable construction and easy installation, Safe Zone Corner Guards by SharpEagle offer a comprehensive solution to prevent accidents and protect both employees and equipment.

Investing in Safe Zone Collision Sentry Corner Guards is not just about complying with safety regulations — it's about creating a safer, more productive work environment. By mitigating risks associated with blind corners and unprotected areas, you can significantly reduce accidents, minimise downtime, and foster a culture of safety.

We encourage you to explore Safe Zone Corner Guards for your safety needs. Take proactive steps to enhance workplace safety and protect your most valuable assets—your employees. Contact us today to learn more about how Safe Zone Corner Guards can revolutionise safety in your workplace.

#top rated safety corner guards#what is a blind corner protection system#improving warehouse safety with safe zones#safe zone creation for warehouses#warehouse corner guard with motion sensor and alarm#best audible warning corner guards for industrial use#SharpEagle Safe Zone Corner Guard reviews#Safe Zone Corner Guard for construction sites#Safe Zone Corner Guard System#collision sentry warning system#blind corner warning system#collision sentry multi-zone#Collision warning system

0 notes

Text

youtube

Indo Storage Technologies, Shelving Racks Manufacturers: Streamline your operations and enhance productivity with our tailored storage systems.Call or WhatsApp us today at +91 97395 49891 to discuss your unique requirements and unlock the perfect solution for your business..

#manufacturer#storage solutions#ideas#storage#industrial#warehouse#racks#shelf#book shelves#shelvingunit#shelvingsystem#shelvingstorage#multi tierracks#Youtube

0 notes

Text

Revolutionize your supply chain with our comprehensive solutions tailored to optimize efficiency across multiple warehouses and elevate inventory management to new heights.

0 notes

Text

In the fast-paced and highly regulated world of the food industry, maintaining precise temperature control is paramount to ensure product safety and quality. One indispensable tool in achieving this is the temperature probe.

#temperature and humidity data logger#warehouse monitoring system uae#temperature loggers#disposable loggers#single-use loggers#multi-use datalogger#temperature monitoring system#Food industry temperature probe

0 notes

Text

Why is an effective labeling system crucial for warehouse racking

In the dynamic and fast-paced world of metal storage solutions, warehouse efficiency is paramount for businesses striving to stay competitive. One often overlooked yet crucial aspect that significantly impacts the overall efficiency of a warehouse is the labelling system used for its racking. In this blog post, we will delve into the reasons why an effective warehouse racking labelling system is indispensable for maximizing storage space, streamlining operations, and ultimately enhancing the overall productivity of a metal storage facility.

A well-designed and properly implemented warehouse racking labelling system is the backbone of a storage facility's organization. By assigning unique labels to specific storage locations, it becomes easier for warehouse personnel to locate and access items swiftly. This level of organization reduces the time spent searching for products and minimizes the risk of errors in order fulfilment, leading to improved customer satisfaction.

Metal storage solutions are designed to make the most of available space, and an effective labelling system complements this objective seamlessly. Through strategic labelling, warehouses can optimize their racking systems by assigning precise locations to different products based on size, weight, and retrieval frequency. This meticulous organization ensures that every inch of storage space is utilized efficiently, allowing for increased inventory capacity without the need to expand the warehouse's physical footprint.

A warehouse racking labelling system goes beyond mere organization; it is a powerful tool for streamlining inventory management processes. By incorporating barcode or RFID technology into the labelling system, businesses can automate tracking and monitoring of inventory movements. This not only reduces the likelihood of human errors but also provides:

Real-time visibility into stock levels.

Facilitating better decision-making regarding restocking.

Reordering.

Inventory rotation.

Time is money in the logistics industry, and an effective labelling system contributes significantly to time savings. Warehouse personnel can quickly locate and pick items for orders, resulting in faster order processing and fulfilment. This increased efficiency boosts productivity and allows businesses to meet customer demands more promptly, ultimately strengthening their market competitiveness.

Errors in warehouse operations can have far-reaching consequences, ranging from shipping the wrong products to delays in order fulfilment. A well-implemented warehouse racking labelling system minimizes the risk of errors by providing clear and accurate information about the location and identity of stored items. This, in turn, reduces the likelihood of incorrect shipments, returns, and associated costs, fostering a more reliable and trustworthy reputation for the metal storage facility.

In the ever-evolving business landscape, scaling and adapting operations is essential for sustainability. An effective labelling system for warehouse racking is designed to be scalable and adaptable, accommodating changes in inventory size, product types, and storage configurations. Whether a business expands its product range or reconfigures its storage layout, a well-thought-out labelling system ensures a smooth transition without disrupting day-to-day operations.

Maintaining compliance is non-negotiable in industries with stringent regulatory requirements, such as pharmaceuticals or food storage. A warehouse racking labelling system incorporating industry-standard practices ensures adherence to regulatory guidelines regarding inventory tracking, traceability, and product rotation. This safeguards the business from potential legal issues and fosters a culture of responsibility and reliability.

Conclusion:

In conclusion, the importance of an effective warehouse racking labelling system must be balanced in metal storage solutions. A well-designed labelling system is the linchpin of a successful warehouse operation, from optimizing space utilization and streamlining inventory management to enhancing productivity and reducing errors. Businesses that invest in a robust labelling system for their racking position themselves for immediate efficiency gains and set the stage for long-term scalability and adaptability in the ever-evolving world of metal storage. As we navigate the future of logistics, one thing remains clear – a meticulous and well-implemented labelling system is the key to unlocking the full potential of warehouse racking systems.

0 notes

Text

Office Space Services in Ottawa | Garage Perfect

Use Garage Perfect's skilled office space services in Ottawa to revamp your workspace. Get a free consultation with us today to maximize effectiveness and style! 📞 Contact us: +1 (613) 288-9315 🔗 Learn more: https://www.garageperfect.ca/office-space-flooring/

#Home Gyms Services#Bathroom Services#Hallways Services#Ottawa Garage Floor Coating#Basements Services in Ottawa#Condo Floors Services#Ottawa Garage Flooring#Balconies & Porches Services#Office Space Services in Ottawa#Commercial Garage Flooring#Retail Store Services in Ontario#Distilleries Services#Ottawa Garage Storage Solutions#Restaurants Services#Multi-Unit Condo Services in Ontario#Warehouse Services#Residential Garage Quartz#Kitchen Cabinets Services in Ottawa#Garage Storage Services#Contur Cabinets Services#Concrete Floors in Ottawa#Overhead Storage Services in Ottawa#Wall Systems Services in Ontario#Overhead Garage Storage & Platforms#acid stain concrete floor kanata#acid stain concrete floor nepean#acid stain concrete floor orleans#acid stain concrete floor ottawa

0 notes

Text

Temperature Sensitive Ingredients

Find the ambient, refrigerated, and frozen storage services. Our experienced staff and superior customer service have established Refrig-It as a leader in the handling and storage of temperature-sensitive ingredients and food products.

0 notes

Text

Who is the Largest cold storage Building Manufacturers company in India?

Cold Storage Building Manufacturers Steel Structures, Industrial Roofing Sheds, and MS Portable Cabins are some of the things that VEDANSHI INDUSTRIES manufactures. Cold Storage Building Manufacturers Additionally, VEDANSHI INDUSTRIES offers steel fabrication services of the highest caliber.

Secondary Members/Cold Formed Members Cold Storage Building Manufacturers Roof and wall panel Manufacturers C Purlin Suppliers Z Purlin Suppliers Warehouse Manufacturers Multi Storey Steel Building Manufacturers Z Purlin Manufacturers Roofing Sheet Manufacturers

Website – https://www.cpurlin.in/

#c purlin suppliers#primary framing solution#c purlin manufacturers#multi storey steel building manufacturers#secondary members/cold formed members#z purlin manufacturers#roofing sheet manufacturers#cold storage building manufacturers#warehouse manufacturers#roof and wall panel manufacturers

0 notes

Text

the cat king being desire's son is a great headcanon but also given that the other child of desire in sandman is part of a multi-decade scheme to topple dream of the endless i think it would be funny if desire considers him kind of a family disappointment because he just seems to hang out in this one town in the pacific northwest being dramatic. yeah this is my son he hasn't gotten close to destroying reality even once. he lives in an abandoned warehouse. he's hung up on an uptight edwardian ghost who won't even give him the time of day. cringe.

#i am not sure what portion of the dead boy detectives fandom has also seen sandman#but the cat king being rose's great-great uncle would also be fun for me personally#dead boy detectives#the cat king#desire of the endless#sandman#lulu speaks#lulu watches things#lulu watches dead boy detectives#lulu watches sandman

3K notes

·

View notes