#patch panel din rail

Explore tagged Tumblr posts

Text

6 PORT NANO DIN RAIL FIBER OPTIC PATCH PANELS

Exploring the 6-Port Nano DIN-Rail Fiber Patch Panel: A Compact Solution for Network Connectivity

In today’s world of high-speed connectivity and data transfer, managing network infrastructure efficiently is more important than ever. One such solution that has gained traction is the 6-Port Nano DIN-Rail Fiber Patch Panel. This innovative device provides a compact, organized, and effective way to manage fiber optic connections, ensuring that your network runs smoothly and reliably.

Let’s take a deeper dive into what the 6-Port Nano DIN-Rail Fiber Patch Panel is and why it might be the perfect fit for your network needs.

What is a 6-Port Nano DIN-Rail Fiber Patch Panel?

A DIN-rail fiber patch panel is a versatile and space-saving device designed to organize fiber optic cables, making them easier to manage, troubleshoot, and maintain. The "6-port" indicates that the panel can accommodate up to six fiber optic connections, ideal for smaller network environments or distributed systems that require a more compact solution.

The Nano designation typically refers to its small size, making it perfect for environments where space is at a premium. This feature is especially valuable in industrial settings, data centers, or smaller server rooms, where every inch of space counts.

The panel mounts to a DIN rail (a metal rail standardized for mounting electrical components), allowing for easy installation and ensuring that your networking equipment is secure and well-organized.

Key Features and Benefits

1. Space Efficiency

One of the most significant advantages of the 6-Port Nano DIN-Rail Fiber Patch Panel is its compact size. It offers a sleek, low-profile design that can easily fit into tight spaces. This makes it ideal for environments like telecom cabinets, small data centers, or industrial applications where space is limited.

2. Easy Installation

The DIN-rail mounting system makes the patch panel incredibly easy to install. It can be securely fastened to any standard 35mm DIN rail, which is a common feature in network and industrial equipment. This makes installation quick, reducing the time and effort needed compared to traditional rack-mounted panels.

3. Improved Cable Management

With its six ports, the patch panel allows you to keep your fiber optic cables neatly organized. Proper cable management is essential in maintaining a tidy and efficient network. The fiber connections can be easily traced and identified, making troubleshooting much simpler.

4. Enhanced Performance

Fiber optics are known for their high bandwidth capabilities, which ensures fast and reliable data transfer. The fiber patch panel allows for optimal performance by minimizing signal loss and ensuring that your network runs smoothly without degradation in speed or connectivity.

5. Versatility

Despite its compact size, the 6-Port Nano DIN-Rail Fiber Patch Panel is highly versatile. It can support various types of fiber optic connectors, including SC, LC, and MTP/MPO, making it adaptable to a wide range of network configurations. It is compatible with both single-mode and multi-mode fibers, further enhancing its flexibility.

6. Durable Construction

These patch panels are built to withstand the harsh conditions often found in industrial or outdoor environments. They are usually made from high-quality materials, such as metal or robust plastic, that provide excellent durability. Many also feature dustproof and weather-resistant designs, making them suitable for use in areas with high levels of dust or moisture.

7. Cost-Effective Solution

Given its compact size and efficient design, the 6-Port Nano DIN-Rail Fiber Patch Panel can be a cost-effective solution compared to larger, more complex alternatives. It allows businesses and organizations to scale their network infrastructure without the need for bulky equipment, saving both money and space.

Who Benefits from Using the 6-Port Nano DIN-Rail Fiber Patch Panel?

Small to Medium-Sized Businesses (SMBs) For businesses with smaller network setups, the 6-Port Nano DIN-Rail Fiber Patch Panel offers the perfect balance of functionality and space-saving design. It’s ideal for SMBs that need reliable fiber connectivity but have limited space for equipment.

Telecommunications Providers Telecom providers can benefit from the modular and scalable nature of these panels, which allow for easy installation and maintenance of fiber networks in various environments.

Industrial Applications In industrial settings, the need for reliable fiber optic connectivity is crucial, and these panels’ durable construction ensures long-lasting performance. The ability to mount them on a DIN rail adds a layer of convenience for industrial network systems.

Data Centers Though it’s a smaller solution, the 6-Port Nano DIN-Rail Fiber Patch Panel can be used effectively in data center environments that require a high-density network with limited space. Its efficient cable management and compact design help reduce clutter and improve airflow within server racks.

How to Choose the Right Fiber Patch Panel

When selecting a 6-Port Nano DIN-Rail Fiber Patch Panel, it's important to consider several factors:

Fiber Type: Ensure that the patch panel is compatible with the type of fiber you are using—whether single-mode or multi-mode.

Connector Compatibility: Verify that the panel supports the type of connectors you plan to use, such as LC, SC, or MTP/MPO.

Installation Space: Measure the available space in your equipment rack or cabinet to ensure that the panel will fit comfortably.

Durability Requirements: If the panel will be used in harsh environments, opt for one with enhanced protection against dust, moisture, and physical damage.

Conclusion

The 6-Port Nano DIN-Rail Fiber Patch Panel is a powerful yet compact solution for organizing and managing fiber optic connections in various network environments. Its space-saving design, easy installation, and versatility make it a perfect choice for small to medium-sized networks, industrial applications, and telecommunications systems. By improving cable management and ensuring better performance, it helps create a more efficient and reliable network infrastructure.

If you’re looking for an effective way to streamline your network setup, the 6-Port Nano DIN-Rail Fiber Patch Panel is definitely worth considering.

1 note

·

View note

Video

nano-din-rail by Ananthasasikala P Via Flickr: We designed 6 port patch panels for industrial use with a Din rail. This Din rail patch panel is used to terminate the fiber up to six cores.

#din rail fiber patch panel#din rail patch panel#fiber optic patch panel din rail mounted#din rail enclosure#din rail fiber optic patch panel#din rail mount fiber patch panel#din rail mounted patch panel#patch panel din rail#din rail connectors#din rail mount#din rail box#din rail adapter#din rail enclosure box#rack-mount din rail#din rail mount enclosure#din rail mounting adapter#Panduit din rail patch panel#din rail housing#mini din rail#din rail outlet#din rail box enclosure#what is a din rail#enclosure with din rail#what is din rail#din rail panel#din rail mounted connectors#enclosure din rail#din rail mount box

1 note

·

View note

Text

#I'm Chinese business man Chinese manufacturer If you need anything#please tell us#we have the right price and high quality products#as well as excellent service#Contact Information:#whatsapp: https://wa.me/+8613123606387 https://zjbcfiberftth.com#✅Skype: 8613123606387 Port: Ningbo#China Production Capacity:10000 Piece/Pieces Per Week Payment Terms: T/T#Paypal#Money Gramfiber optic patch panel sc#black box fiber optic patch panel#panduit fiber optic patch panel#fiber optic patch panel 48 port#ortronics fiber optic patch panel#wall mounted fiber optic patch panel#rack mount fiber optic patch panel#fiber optic patch panel termination#48 port fiber optic patch panel price#din rail mount fiber optic patch panel#fiber optic patch panel enclosure#din rail fiber optic patch panel#fiber optic patch panel visio stencil download#fiber optic patch panel visio stencils#fiber optic patch panel wiki#fiber optic cable patch panel#fiber optic patch panel installation#19 fiber optic patch panel#24 port fiber optic patch panel price#tyco fiber optic patch panel#fiber optic patch panel din rail mounted

1 note

·

View note

Text

2 _ 22 _ A Flawless Order

First

The factory was alive. Parts and sections once cold and silent, now howled with the intent of struggling through a monotonous existence in a world that would forsaken it. After however many years it lulled since the contraption ground into inactivity, it is remarkable that the place still mostly worked. From within the bowls of the construction arose indignant grinding and screeching, the whole of the operation not entirely seamless. It might yet come undone at the seams and rip itself apart.

For the time, he supposed, the child was on some sort of mission. Or something. It was too much to hope that the boy was not in the heart of a prelude to a disaster.

Hunched awkwardly in the doorway to the office, the Thin Man scrutinized the reverberating clashing and mincing with a raised brow. He wondered what the factory produced… or what it once created. Certainly not televisions. The Signal Tower provided those. He did feel an inkling of sympathy for the lost children.

The pummeling din dampened a great deal when he shut the door. It was far too much activity, energy, such a… racket. He would wait for now, let the child fulfill his compulsion for exploration. When the kid was ready, he would resurface. That’s how this usually worked.

Beside the little package of food tossed onto the desk, an intercom receiver and control pad lay embedded in the dusty surface. It didn’t matter if the device forgot its purpose, could no longer carry the current and fulfill its role. For so long the device has been inert, lonely and neglected.

He swept his hand over the tarnished panel, the lights beside the scribbled slots blinked. The static thrummed, physically manifesting in vibrating particles.

“M͘҉͟o̡͡no͞,” he projected, through the receiver. From beyond the thick cinderblock wall, his projected call reverberated with a metallic echo. The Thin Man sat at the desk and bent forward, as if he needed to speek directly into the contraption. “P̧a̶gi̢͢n̷̡͞g̡̕͠ ̛M̴o͘͡n̸͝o͢.̵ ̵̨̕W͏̢͝o͢u͠l͟d҉͡ ͜Yo̢͜u̡ Has͠t̸̵̸e̶̸n̢ ̶̕Y͞o͝u͞͏r̴̶͟ ̶C͏u̷̶r̸r͟e̡nt͟ Ą͡cti̢v̴͝i̴̕͝t̴͞ies̴͏,̴͢ A̧n҉d̸ R͟e͟p͢o̴͡r̢̧t͘͜ To҉ ̸̷T̸҉h̢e͏̨ ͠Ma̸͢͞n͜a͏̢ger̶̨’̵s͜ ͠O̢̡ff͠i̸c҉҉ę.̷”

Perhaps the child would get a kick out of that. Or not. It might remind the boy that he was still waiting. Alas, some things never changed.

__

On the other side of the factory, or more to the middle, or off center of the near center.

The strange flower growing from the cement pillar garbled some speek. Mono paused on the catwalk and gave it his attention, but hesitantly. Only because the flower was unusual and sounded like the Thin Man, but he wasn’t certain what it was saying. It was distorted. Also, why was the flower speek? Trick? Did flower catch the Thin Man?

For a while he stared down from his perch with his hands on his knees, tilting his head. It couldn’t get him from up here, he thinks. The flower didn’t say anything else, but maybe he wasn’t moving. Some nasties only reacted to movement. It didn’t know where he was.

He pushed up into standing and hurried away, checking along the metal grate for something he could lift. Some pieces of metal, a little bit of pipe (too small), this ratty old glove. He spied a canister a little ahead, and rushed to snag that. Racing back over to the flower, he chucked the canister off the platform and managed to knock the whole funnel off the wall. Direct hit!

On a path below choked by vapor, emerged the mechanic, glaring down at the shattered flower spread across the ground.

Yeek!

Mono ducked back a step, but it was meaningless. The Mechanic turned its glare upward, and if he could easily see the creature below through the grate, then there was a good chance it saw him as well. This suspicion was confirmed when the heavy clatter of boots began pounding below, a snort trumpeted out. A ladder was somewhere down there, but he didn’t remember specifics. He took off on the walkway in the direction he had initially been going, gaze sifting for a way down or cover. The catwalk was tol, and ahead the rail bent aside.

An earthquake shook the surface beneath his feet and he nearly lost his balance; walking on the uneven and porous surface was challenging, now he was at a full dash with a boulder rebounding across the floor. If that wasn’t enough, a bleating crack tore out and a large metal tool smashed against the rail. Right above his head!

Mono stumbled and grabbed for his hat. Though the metal piece was quite large and very solid, it’s impact would easily scatter him to the furthest corners of the city. Fortunately, it ricocheted over the handrail and zipped out of sight. Far off into the factory.

Plenty more where that came from.

Mono grabbed the support bar at the bend of the walkway, striving not to lose speed as he whipped around onto the new path. He leapt a sequence of steps and roughly hit the bottom rung, but with a little grumble recovered and stole back his pace.

Steam gushed and the machinery squealed, heaving pistons thrummed around him; it was hard to breath with how thick the air was. He wasn’t used to being so heated through, and the sauna seeped into his lungs, choking out his ragged breaths.

Nonetheless, his pace never faltered. Not even when a fuse clattered against the floor, too near and much too loud. The crash splint his hearing, and suddenly the rumbling groan of the factory became distant. The vibrations through the platform rattled up his thin legs, threatening to splinter his bones right inside his body. If… he had bones, like Her, that is. That was still a mystery....

The Mechanic is catching up. It’s catching up, it’s pace quickened as it closed on its quarry. A bellowing cough tore through the space between them, the force of it blunted by Mono’s impaired hearing. But he can feel it; the rocketing footfalls thrashing his swift but shorter strides. The creature has something in its clutch, he’s certain. He can’t see, won’t look – Flee! It’s right on top of him, but hasn’t decided if it should kill outright or maim him beyond recovery.

Off the side from the platform, a section of moving parts of the machine lumber methodically through their mindless operation. Mono doesn’t second guess the leap and dives off the side, aimed for one of the gears a little below. As he falls and his coat swooped around him, the dilemma of his timing surged through his mind.

Was too soon? Too late? Low. But is far!

Nonetheless, he braced his body for the impact trusting he had momentum. He dropped short, his fingertips barely catching grip of the eroded tooth of a gear. It swings upward in its clockwise motion, carrying its feathery cargo. Mono heaved up, trying to fit himself into the dip before the other tooth of the reversed gear can clench—

The tool swatted against the gear, an inch beneath Mono’s toes. His fingers popped loose, and he fell, first smacking his shoulder against a bolt in the center of the gear, then spiraling three or five full turns in his terrible descent. Somewhere in the vortex of his plunge he smashed into a corroded slate, with wires strapped across the length. In a panic he grappled for a hold, but the steam and grease wouldn’t permit anchorage. He skid backwards reaching still, and suddenly nothings beneath him….

Falling!

He crashed to the floor at last, landing somewhere beneath a canopy of winding pipes. Without allowing a brief to recover, no he shoved himself upright and scrambled for better protection among the sprawling networks. In some patches the pipes have a base extended to the cement, massive bolts skewer a plate in place. These clusters Mono shuffled around or beneath when he could, some expelled waves of heat. Other pipe bundles have a lattice frame built around them, while others have caved over time. Patches of light from the factory ceiling gleamed down, he can see enough to get around without several concussions.

Little by little, his hearing began recovering from the calamity it endured. The wheezing of machine guts and rattle of something within the pipes, pilfered through his muddled senses. It wasn’t totally restored, everything was more off and he couldn’t recall how booming the place was before the short reprieve.

His musing is abruptly shattered when a ragged gloved-hand stuffed down into a space of the pipes, not far from where he was hunched low. For a moment he stalled and held his breath, holding perfectly still. Through the clog of machinery, he couldn’t figure where the Mechanic was now. The thick, cracked fingers clawed at the gravely floor, stretching and poking to their extent. Blindly.

If move, see? Did see but didn’t grab? Miss?

Mono wasn’t sure, but if he stayed put for much longer, an eye might peer into the opening. The blackened fingers still grappled at the vacant space, sensitive to movement, maybe even smell?

Right when the hand began shuffling away, he made his move. Easing in closer to the pattern pressed into the dirty floor where the hand had clawed… he zipped by and kept going! Faster and picking up as much speed as he could, while in his half-blind-folded stance. Above somewhere a breathy snort carried over the racket of hissing pumps, the hammering boots trailed his swift trajectory somewhere to the side. The pockets of scarce radiance flickered against the swift dash of the Mechanic, bearing down on the knotted canopy but barred from an opening.

Mono didn’t chance a glance, all his focus maxed in diving in among the pipelines and anchors punched into the cement. He dropped and skid on his knees, upon reaching a barricade loaded with debris. He scrambled over himself, backtracking a few feet and took an opening in the mesh of a grate. The hole wasn’t large enough for him to push through, he barreled into the rusted metal and kept going when it vaporized with minimal resistance.

A screech shot forth overhead, too close! The pipes arched above him caged him from the Mechanic and a clear reach – maybe-MAYBE it could squeeze its hand into a gap – but not quick enough to grab for the flighty Mono. He barely glimpsed up, only to check once where he was headed in relation to his cover.

It was a little too late for him to register that the next opening he squeeze through led onto the open floor. Not even a pathway, but a break between one collision of mechanical limbs chugging away, and another Tetris of gears and hydraulics hammering away. All at once he was free of the overbearing heat, the steam evaporated and the confining embrace of the pipes shrugged away from his coat.

Mono spun around, his dry coattail swept across his knees. Go! GoGoGo!

He darted to the other side of the metal amalgamate, charging at an open portion beyond a narrow trench. A gasp of steam chuffed a meter or more off, but what caught his attention was the heap of melted skin and chains creeping through. When Mono locked view with it, the Mechanic dove toward him.

With every ounce of his dash power, Mono peeled towards what he hoped was a narrow opening beneath the grate. He stuffed his shoulders through the fence by the path and tumbled, barely making it back to his feet as he galloped awkwardly toward the crevice. The fence slowed the Mechanic but a moment, he simply hopped it and was once more clomping towards his target, gasping on the acrid fumes.

The opening was narrow and too small for the Mechanic to reach within. However, it was also very not long. It was a trap he would be cornered within, and Mono didn’t even hesitate to take in what was beyond the little tiny haven before he was hurtling out once more.

For a second, the Mechanic was stumped. It grumbled to itself, voice becoming distant and distorted by the howling conveyor belt shrieking nearby. Mono was still in the open, but he had the chance to take in the area. Get out of sight for a wink. Enough to lose the grotesque focus of the creature.

Thick cables rose high in his path, the eventual end fading from view high above. He stuffed himself between the narrow space, nearly swimming as he heaved through among available spaces. The narrow passage at least too miniscule for the Mechanics reach, quite possibly, beyond its vision. From elsewhere, a gruff bark announced its agitation. That still sounded too close.

The floor gave out suddenly, and Mono lost his grip. He toppled down a steep incline into a lower basin beneath the chugging machinery. With haste he rolled over into a crouch and gave the area a sweep with his eyes, searching for movement through the veil of fumes and ripples of heat. The edge of his hat was saturated with sweat and his scalp drenched, be blinked at the salty sting in his eyes while he struggled to peer through the blur. He thought the Mechanic was nearby again, but it hadn’t made a sound yet. It could be prowling….

Or could be sneaking up behind him!

Nothing was near which should warrant any panic. Mono kept skimming his gaze around the thick pillars, swinging machinery, all-in-all, whatever was moving. Before rising to move, he pulled back his coat from his leg and checked his knee.

A red blotch stained the pants. It didn’t hurt, or he couldn’t feel it. The cut might’ve reopened, but he did fall pretty hard. For now, he left it alone and made note on it. Worse would happen if he didn’t keep his wits, got distracted with pointless distractions.

He weaved through a pillar thicket, following beside the steep slope he skid down. At times he climbed over a broken gear or other castoff equipment, such as pipes or a random tool – usually rusted and coated in thick grease that had a foul odor. Even the twisted body of a Viewer found its way down here, but likely toppled in from the ceiling. By now, the factory was so thick with fog he couldn’t see hardly anything beyond the spires of cranking metal limbs.

Movement to the left, behind a stairway and a mesh of fortified scaffolding, spooked Mono into diving low. Even if he’s too far away and likely obscured by steam, he takes no chances and tracked the malicious shadowy patterns drifting beyond the barrier. He’s certain it is the Mechanic by instinct (and how his luck has been today), and abruptly began sifting among the pipes and dips in the floor. He detached from following the side of the slope and opted to cut directly through the corroded jungle, to the best of his ability. Down here there lay no landmarks, everything was the repeated meshing of mechanical portions gushing steam, twittering, or bellowing heat.

It takes a while of his dodging and cautious navigation – every time a pipe hissed he tucked down and hid, even if he knew it wasn’t the Mechanic - but finally, he reached the other side of the dip and another ramp. With no indication of the Mechanic, and going a while without catching that horrible thunder of boots, he’s feeling much safer. Make no mistake, Mono knows he will never be safe – him or the Thin Man – with the creature sneaking around. It lost his trail, but that wouldn’t last.

He had a hard time trying to scale up the slope, to the regular floor. It’s not that steep, but the surface has a fine swill of grease and dirt, and his feet are sort of wet too. The drama is actually tiring him out, and he relented for a while to pick his way further along and find a space that wasn’t so icky.

The floor proves to be as much of a hinderance as the Mechanic. He probably doesn’t skid around on the flat surface, on account of the layer of dirt. He can’t climb up the slant by conventional means, but it’s okay. He climbed the side of a section of scaffolding near the slope, and from there gained enough height to leap off and nearly reach the edge. When he hit the peak of the incline, he flailed his arms but managed to flop forward. With a tremendous heave, he vaulted over the slant and stands on flat ground. At last!

Where is he? This place is different, but it’s all the same factory. Vibrating wheels, tugging long conveyor belts above the floor – sometimes higher. Pipes with the little round things sprouting like weeds. He hiked along, crossing through an open path and went to the fence on the other side. So far no sign of the Mechanic; that is not good. He’s happy to not do the flee, but now where is it? Somewhere, watching?

Mono turned his gaze up, and spun around as he moved among long metal vents stretched across the floor. One of the elevated pipes forced him to crouch down very low, the surface and air about it heated, and broiled his skin through his ever faithful coat. He couldn’t recall the last time he’d been this dry, he felt like a crispy leaf discarded from a tree.

The boundary of the drumming machinery ebbed little by little, and he reached another fence. Nothing on the other side appeared out of place, aside from it looking much more open than a pathway. First confirming no movement among the fringe of heated vapor, he squeezed through the bars and examined the floor. A path was still open, but it was much wider and littered with ruble; from the ceiling, he thought. Through the haze above, something hovered, like a walkway, but higher. He followed a clear path towards a sequence of steps, which rose to a platform upon a cement block.

From this new vantage point, he gave the portions of the surrounding factory a hurried scan. With his scout satisfied, he checked on the tall stand fitted to the platform. It was almost too high to reach, if not for the chair anchored beside it. He hoisted himself onto the ratty seat and from there leapt to the slanted surface.

The corroded panel carried colored buttons, like a television remote. But many-many more. He accidentally knelt on one, and a rackety clunk rebounded from the fog above.

Mono nearly jumped out of his skin when a chain thudded to the cement floor, generating a head-splintering crack, as well as forming a shallow crater in the path he had been on.

LOUD!

He fumbled on the controls, something he hit or knocked made the chain recoil by an inch or more off the floor. Not so loud, but still! Flee!

Carefully he let himself down from the stand and took off, sliding beneath the rail and dropped to the gritty floor. He made it to the nearest fence and zipped through the bars, exactly when a racket of boots bombarded the scene. A little more cautious and not as panicked, Mono maneuvered low among the pipes and coils of wiring stretched beneath a layer of rotten, black texture.

Out there and above, the boots descended into view from a ladder he previously overlooked. It was directly behind the podium he was clambering all over!

In the dark he crouched, watching as the Mechanic plopped heavily to the floor and orbited the platform. Snuffling, grumbling to itself. It rubbed at the knob of its head beneath the cap. He hoped this time he didn’t drop anything, but he didn’t linger around to find out. He crammed himself between a narrow space among the wiring and kept going. Ever and always mindful when large pipes broiled, or a random space gushed a thin thread of steam.

For a very long while, Mono lost track of the Mechanic. A feat which never ceased to make him nervous, but he kept silent and more astute of whatever he was handling, if he had to leap onto something else. It was mostly navigate the floor beneath the machine, and one other time he climbed a chain to reach the height of the catwalk which stretched above the factories convoluted shape. Somehow in all this exploration, he didn’t hear or see trace of the creature.

He did find a doorway! More like a large bay entrance, it is something he recognized from a book. A supply entrance, for stuff to make goop! Or to send colorful boxes away. Whatever it opened up for, it was a way out to somewhere else. He found it by following a big path, which was a kind of a small road. But not like the chewed up roads that lay among the cities crumbling buildings.

A lever to the side wall should open it, he thinks. The stretched cords go to the doors at the top. Unfortunately, when he dangled from the lever, nothing happened. It drooped under his weight, but… it needed a fuse.

He let go and inspected the current fuse in the slot. It had nothing in it, he could tell by just the feel of it. Mono had hoped he was wrong, but no. Another fuse had to be around, a good one. Maybe he could take the one that awoke the factory.

But how far away was that? And dragging it, among the ruble and collapse? With the Mechanic lurking? That would be hard, if not disastrous. He’d keep the option open and try to find his way back, but the course encircling the factory was not without hazards. The whereabouts of this door remained a mystery, but if he followed the wall as closely as he could, he might manage to make it back to the other fuse.

In places, a portion of the wall caved in. Didn’t collapse entirely, but it was a wall within a wall, and not a way out. Some paths lay bloated with ruble, or parts from the machines interwoven pieces. With all the swirling fumes, he couldn’t see far, and didn’t know exactly… where he was, at any time. It was impossible to maintain a sense of direction, but a strong unknown power might be at work.

When he emerged from a division among the pipes and twisting vents, he found an area of the wall intact. Which left his route open for exploration. What caught his interest immediately was an open door and what looked like a window, but the glass was dark. And there was no rain of boards on it. Some sort of clothing or uniforms, like what the Mechanic wore, lay draped on the floor and across a bench by the wall. Belts too, with a few tools. The Mechanic did have a fuse at one point, maybe he’d find one here!

However, approaching the open doorway did spook him a bit. It reminded him… of the Hospital, for some reason. Maybe being alone, and it was dark inside. Did the lights not work? The fuse woke up the factory, but didn’t make the bay door work. The office light came on, because of the Thin Man.

Mono blinked at the ceiling. Slowly he raised his hand toward one of the lamps dangling by a cord and tried to focus, on ‘asking’ the light to come on. Asking may not be right. The Thin Man didn’t do anything, he just stood there. How did—

The first two bulbs burst in a firework of sparks, and Mono catapulted backwards. He scooted back on his butt scrambling to get up, but a sound – a not too scary noise – ensnared his attention. Poised by the bench, he looked around. It was very faint, beneath the howl of the gnashing and hiss of the factory itself. Sounded like metal-on-metal clink. He looked up.

It was easy climbing up onto the bench, and there he found a box. A shut up box with two clasps on one side, and hinges, with a little strap atop. He leaned against the side and tapped.

Nothing. Hmm. He shuffled and scooted the box, trying to get an easy reach at the clasps.

Something inside moved! He heard it!

Mono bounced back and crouched at the bench edge, glaring at the box. Something was inside that. Something alive. Maybe an animal. He kind of knew it wasn’t any sort of animal. But… it could be just an animal. It could.

Inching over to the box once more, he shifted it around until he could view one of the clasps. Whatever was inside thumped around, the random settling of weight there or here made it difficult to really move the clunky thing. At last, he could fix a firm grip on one clasp and tugged it. This or that way, the thing was latched hard. Like glued to the container.

With a sigh he stood back, and gave his area a good search over. He needed to stay focused, getting caught wouldn’t help anyone. He could always come back. If he got the— no, that was a dumb idea. Even without the Mechanic getting up to no good, it wouldn’t work. The worst could happen, and he didn’t want to think about that danger.

Electing no grace, Mono just rammed his shoulder to the container and let it plunge to the floor. It wasn’t a far fall, but unexpected it would be. The clasps still faced him, and now faced skyward. He plopped down onto the front and pried at the sturdy latches. With every ounce of his mightiness, he braced his feet and knee to the surface and heaved! Shoved!

Clack!

One undone. He paused to catch himself and rally up for round two! Good thing he ate before leaving. With a firm struggle, grinding his teeth, nearly losing his grip twice, the second clasp sprang free. He toppled over the lock, a little winded and sore, but completely fine. He just needed to gather his wits.

The lid was open, but he didn’t hear anything inside. He shuffled over to the opening and pried at the now visible crease, forcing it wider by a foot.

“Hey,” he whispered. Maybe it was just an animal. Whatever, he wasn’t about to climb down in there. “Psst?” he hissed. “Hai?”

At last, the whites of something eyes peered back up at him. Mono gazed in, and the contents of the box glared back. He shifted on the top of the box, forcing the lip up a bit more. The face was dirty and cheeks gaunt, he couldn’t make out the clothing. Rags, it seemed. The eyes felt so barren and accusatory, as if he invaded. Was it just the one kid?

Must’ve been, because they shot out through the side of the container, away from Mono, and hit the floor running. As he recoiled backwards, he watched them veer off to the fence and the machinery beyond, until the figure faded in the choking haze.

That wasn’t weird or anything, he reflected. Briefly, he checked around and within the container – only a peek – in case there were other kids. That… he wasn’t sure if he should be relieved or not. He settled on not thinking about it.

At least he didn’t have the awkward dealing with a kid that wanted to pack. Not that he didn’t want to pack, it was confusing right now. It would’ve been nice to have someone to help, and keep an eye out. For a little while, at least. Until they didn’t want too anymore, or something like that. He would understand this time. Sure.

Mono slipped off the container and ventured in the direction the other kid went. They likely found the space he came out of, but he needed to find another passage through the machinery. He would try and reach the office, and check if he missed any fuses.

First however, he slipped between thick cement pillars and scooted into a substantially cluttered space, overburdened with pipes and thick vents. Sleep was impossible with the sweltering fumes and the churning machinery, but he needed to stop moving for a bit. Curl up by a pipe and rest his eyes, but no sleep. Not even half sleep.

The kid bailing didn’t bother him. He understood. Getting locked up like that. Caught. Doomed. Kids helping other kids out of traps and cages wasn’t a thing. Risky business, and why bother? The kid got trapped, they were pretty bad at the one rule. Caught, you’re as good as dead. Some didn’t get as far as caged.

He shuddered.

All in the past. Focus here and now. He can’t let his guard down. He nestled down in his coat and pried one eye open, again searching the fog swirling among the cables. Clear. No movement. Alone. No one to watch. No second set of ears. No one to catch him if he fell. Just him.

Mono.

Next

#little nightmares#mono#the thin man#thin dad#little nightmares fanfic#little nightmares fanfiction#fanfic#fanfiction#i did like building the factory environment#its kind of Maw reminiscent

3 notes

·

View notes

Text

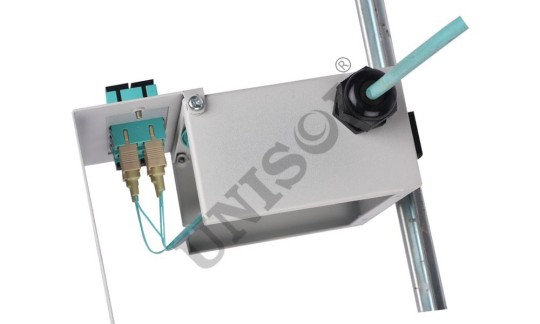

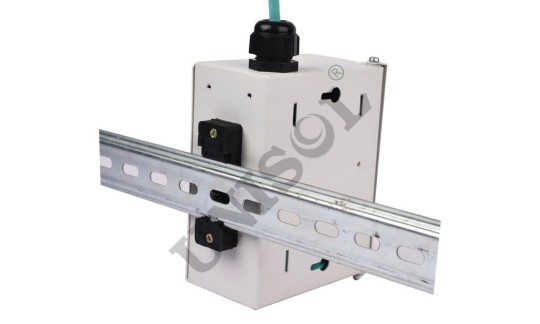

Industrial Grade Nano Din Rail Patch Panel

Industrial Grade Nano Din Rail Patch Panel

UNISOL Din Rail mount fiber optic patch panel is designed to support fusion splicing or direct termination of the fibers. Because of its compact and ruggedly designed case, it is suitable for industrial applications. The device includes a splice tray for fusion splicing. It is suitable for mounting in Din Rail mount enclosures where there are space constraints inside PLC’s and also suitable for…

View On WordPress

#din rail adapter#din rail box#din rail box enclosure#din rail connectors#din rail enclosure#din rail enclosure box#din rail fiber optic patch panel#din rail fiber patch panel#din rail housing#din rail mount#din rail mount box#din rail mount enclosure#din rail mount fiber patch panel#din rail mounted connectors#din rail mounted patch panel#din rail mounting adapter#din rail outlet#din rail panel#din rail patch panel#enclosure din rail#enclosure with din rail#fiber optic patch panel din rail mounted#mini din rail#Panduit din rail patch panel#patch panel din rail#rack mount din rail#what is a din rail#what is din rail

0 notes

Text

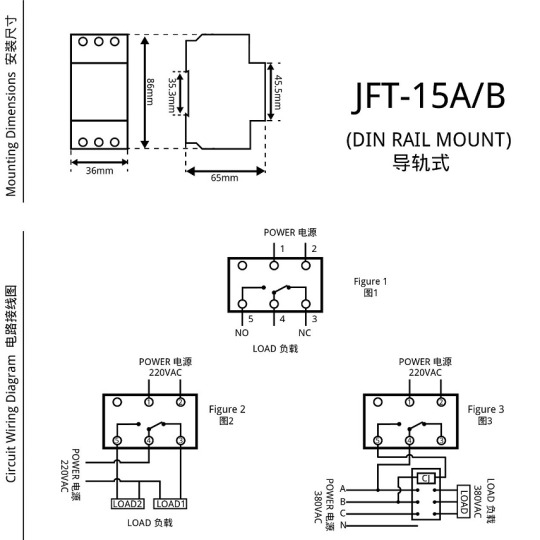

JFT-15 Series Digital Programable Time Switch (DIN Rail Mount)

Introduction

The JFT series digital programmable timer switch can automatically turn on or off the power of various electrical equipment according to the time set by the user. JFT series microcomputer time-controlled switch is composed of LCD digital display, programmable IC chip, buttons, switch components, etc. It is widely used in street lights, neon lights, advertising signs, production equipment, assembly lines, broadcasting equipment and other equipment. The JFT series time-controlled switch adopts a new patch technology, which can effectively avoid the phenomenon of false welding and missing welding, and has the characteristics of stable performance, low power consumption, and light weight. JFT-15 has a built-in rechargeable nickel hydrogen battery, which can avoid data loss due to power failure, and there is no need to worry about the inconvenience caused by the inability to replace the battery in time. JFT-15 has two output terminals: a normally open terminal (NO) and a normally closed terminal (NC). JFT-15A uses a flip-type panel protection cover, and JFT-15B uses a transparent panel protection cover. The panel protection cover can effectively prevent dust and prevent the keys from being touched by mistake.

Parameters

JFT-15A/B

Timer Range: 1min≤t≤168h (cycle work daily or weekly) Operation Voltage: AC220V/50Hz (or other customized voltage) Operation Temperature: -10℃~50℃ Operation Humidity: <95% Switching Capacity: 16A (resistive load) Number of Settings: 8 groups per day Battery: Built-in rechargeable nickel-metal hydride battery Consumption Power: ≤5W Time Error: ≤2s/day (25℃) Weight: 120g Dimensions: 86×36×65mm Mounting: Rail

Dimensions & Wiring Diagram

JFT-15A/B

Terminal introduction: PORT 1 and PORT 2 are power terminals; PORT 3 is normally closed terminal; PORT 4 is common terminal; PORT 5 is normally closed terminal Wiring diagram: If you need to control a single-phase normally closed load (LOAD1) and a single-phase normally open load (LOAD2), you can connect them as shown in Figure 2. If you need to control a three-phase load, you can connect it as shown in Figure 3.

JFT-15A/B dimensions and wiring diagram

Instructions For Use (How to set)

Please make sure that you have understood the functions of all the buttons on the panel (button area), and perform the actual operation according to the instructions.

1 Description of buttons and indicators

CLOCK (): Press to display your local time (it should be set by yourself: you can press and hold the "CLOCK" key to enter the "Time Adjustment Mode", and adjust the "WEEK", "HOUR", and "MINUTE" key to set the local time). PS: If no operation is performed within 30 seconds, the timer switch will automatically display the local time. TIMER(): Press to enter the "Editing Mode", and then set the time to switch the load by adjusting the "WEEK", "HOUR", and "MINUTE" key. WEEK (D+): Adjust week or day. There are various working modes, such as "Five-day Mode" (Monday to Friday), "Six-day Mode" (Monday to Saturday), "Weekend Mode" (Saturday, Sunday), "Daily Mode" (Monday to Sunday), and "Three-day Mode" (Mon-Wed-Fri; Tue-Thu-Sat; Mon-Tue-Wed; Thu-Fri-Sat). HOUR (H+): Adjust hour. MINUTE (M+): Adjust minute. AUTO/MANU (MANUAL): Switch the three switching mode of "ON", "AUTO" and "OFF". For multiple-output timer switches, the output combination can be configured through the "AUTO/MANU" key when in the "Editing Mode" RESET/RECALL (Cancel/Restore, C/R): Press to cancel or restore the timing setting. PS: For products with button lock function, press the " RESET/RECALL " key four times to lock or unlock all buttons. C: Long press the "C" key to clear all settings of the timer switch. POWER LED: When the Power LED (red) is on, it means that the timer switch has been successfully connected to the power source. WORK LED: When the Power LED (red) and the Work LED (green) are on at the same time, it means that the load is powered on.

2 Operating instructionsStep 1. Timing setting (on)

Press the " TIMER " button to enter the "Editing Mode". At this time, the "ON1" symbol will appear at the bottom left of the LCD screen (that is, the first time to turn on the load, as shown in Figure 4), and then press the "WEEK" to select Working Mode, and then press the "HOUR" and "MINUTE" keys to input the required switching on time.

Step 2. Timing setting (off)

Press the " TIMER " button again, the "1OFF" symbol will appear at the bottom left of the LCD screen (that is, the first time to turn off the load, as shown in Figure 5), and then press the "WEEK" to select Working Mode, and then press the "HOUR" and "MINUTE" keys to input the required switching off time. At this time, the first group of timing setting has been completed.

Timing Setting 1

Step 3. Timing setting (number of groups)

After completing the first group of timing setting, press the "TIMER" button again, the LCD display will show the "ON2" symbol, and you can set the second set of time setting. According to actual needs, you can repeat steps 1 and 2 to set many groups (the maximum programmable group number depends on the product's built-in chip). If you want to exit the "Editing Mode", you can press the "CLOCK" key to exit it.

Step 4. RESET/RECALL

After setting a group of time, for example, turn on the load at 18:30 every day (Figure 6), and turn off the load at 23:20 every day (Figure 7). If you want to cancel this group, you can press the "RESET/RECALL" button to delete this group of time settings. At this time, the group of time will be reset to the initial state, that is, "--: --" (Figure 4 and Figure 5). Under certain conditions (without any key operation or switching to other interfaces within 20 seconds after cancel operation), just press the "RESET/RECALL" button again to restore this group of time settings.

Step 5. AUTO/MANU

The timer switch has two switching modes: automatic and manual. In the automatic mode, the timer switch will be set according to the timing of steps 1 to 3, and the load will be automatically turned on or off at the corresponding time without human intervention. In manual mode, the load must be turned on or off by manual adjustment. The specific operations are as follows: 1) If you need to turn on the load manually, you can click the "AUTO/MANU" button to switch the "▼" symbol on the display to the "ON" position (Figure 8). At this time, the load will always be in the on state and cannot be turned off automatically. 2) If you need to turn off the load manually, you can click the "AUTO/MANU" button to switch the "▼" symbol on the display to the "OFF" position (Figure 9). At this time, the load will always be in the off state and cannot be turned on automatically. 3) If you need to switch the load automatically, you can click the "AUTO/MANU" button to switch the "▼" symbol on the display to the "AUTO" position (Figure 10). At this time, the working state of the load will be switching automatically according to the timing setting, without being interfered by humans.

Timing Setting 2

When you think there is a fault (FAQs)

Note: When the product fails, please disconnect the power first, and then check the equipment! 1 Check the week If the timer switch does not turn on or turn off the load at the set time, it may be that the "WEEK" is not adjusted correctly, please check or reset it according to the method introduced in "Timing Setting". 2 Check the time groups If the first point is confirmed to be correct, but the load still cannot be switched correctly on time, the reason will be that the extra time group has not been cancelled. Please refer to the method introduced in "Timing Setting" to delete it. PS: Only when the display shows "--: --", it means the time group is deleted successful; if it displays "00:00", it means 0 o'clock (24 o'clock), not the deleting success. 3 Check the switching mode If the above two points are confirmed to be correct, but the timer switch still does not work normally, it may be that the timer switch is working in "Manual Mode". You can first adjust the "AUTO/MANU" key to set the timer switch to the right working state of the load (ON or OFF), then switch to the "Automatic Mode". 4 Check the fuse If the above three points are correct and the timer switch still cannot work normally, please open the rear seat insurance cover (terminal cover) and check whether the fuse has been blown. If it is blown, please replace with a new 0.1A~0.3A fuse. 5 Check the power supply If the Work LED (or Output LED) is on when the timer switch is working, but the load cannot be switched normally, please check whether the voltage of the power supply is too low. If the timer switch is burned out, please check whether the power supply voltage exceeds the rated voltage of the product and whether the power cable is connected incorrectly. 6 Please replace the battery If the LCD screen does not display or the display is not clear, replace the battery with the same specification. (Only for timer switch with replaceable batteries) 7 Please contact us or local distributor If the fault cannot be eliminated by the above methods, please contact us or the distributor (dealer) in your local area.

Attentions

1 For those equipment (such as medical equipment and large equipment, etc.) that may cause life safety accidents or cause major harm to society due to the error of the timer switch, please do not choose this timer switch. 2 For those equipment (large heaters or cold storage, etc.) that may cause major property losses due to the error of the timer switch, ensure that there is sufficient design margin when using this timer switch, and take safeguard measures such as the double protection circuit. 3 Do not repair, disassemble or modify this timer switch by yourself. If you need to repair and check it, please be sure to entrust a dealership or other authorized unit. 4 Do not touch any terminal on the timer switch after it powered on. 5 This timer switch cannot work in humid, corrosive and high metal content gas environment. And do not let the timer switch come into contact with oil or water.

0 notes

Text

Overview of FHX Ultra HD Fiber Enclosures

Today, more and more cables are used in data centers, thus high-density cable management devices become more popular and essential than before. Taking FHD fiber enclosure as an example, a high density 1RU rack mount fiber enclosures can hold up to 4 HD fiber adapter panels (FAPs) or 4 HD MPO/MTP cassettes. And now, FS.COM has launched the new FHX series ultra HD fiber enclosures, which efficiently optimize space utilization and save more cost in rack cable management. So, let’s learn more about FHX ultra HD fiber enclosures.

Rack Mount Fiber Enclosure

Before learning about FHX ultra HD fiber enclosures, we need to know what are rack mount fiber enclosures. In fact, a range of modern rack mount enclosures conform to the DIN 41494 and IEC 291-1 international standards. They are available in various rack unit configurations, such as 1RU, 2RU, 3RU, 4RU and 6RU. And they are designed in cable patching, storage and protection for rack fiber cable management in the data center. The rack mount fiber enclosure is generally made for standard 19 inch rack mounting, which is constructed of steel material. Molded front and back doors shall be removable for cabling and connector installation. Generally, 1RU and 2RU enclosures shall provide full front and back access with a drawer that slides forward and backward. 3RU and 4RU enclosures shall feature a fixed bulkhead design.

Why Ultra HD Fiber Enclosure Is Needed?

As today’s high density data centers migrate from 10 to 40 and 100 gigabit speeds, network switching products are available with port line cards that use more than 1,000 fibers per chassis switch for 10G fiber applications. And 40/100Gb switches are projected to use more than 4,000 fibers per chassis where parallel optics is used. These high fiber count requirements demand ultra HD fiber enclosure solutions that will reduce the overall footprint and simplify cable management and connections to the electronics.

FHX 1RU Rack Mount Ultra HD Fiber Enclosure (FHX-1UFSP)

FHX-1UFSP is FS.COM’s FHX series high density 1RU rack mount fiber enclosure, which is designed for 19-inch rack-mount and available for FHX series of Cassettes or FAPs up to 144 fibers, in order to organize and protect fiber optic backbone terminations. The FHX ultra HD fiber enclosures are a comprehensive line of fiber distribution enclosures that provide a high density flexible and modular system for managing fiber terminations, connections, and patching in data center application to maximizing rack space utilization and minimizing floor space. The followings are three main features of FHX 1RU rack mount ultra HD fiber enclosure:

(1) Flexibly Design to Meet Ultra High Density and Data Rate Deployment

Up to 144 fibers capacity for LC interface within 1RU

Suitable for upgrade to 40G/100G or expand fiber infrastructure and premium construction

Improve the utilization of space to make sure air flow more smoothly in data center

(2) Innovative and Optimum Manageability with FHX Fiber Enclosure

FHX ultra high density enclosure is designed with optimum serviceability and manageability. The system enables data center technicians to quickly and safely complete MACs while simultaneously providing the scalability to increase density as business demands evolve.

Split tray and adjustable rails design make front and back cassette accessibility, eliminating circuit disruptions.

With self-developed cable manager in the bottom, providing greater management in higher density situation.

Aluminum alloy shell protect the inner fiber components and also enhance enclosure service life.

(3) Multiple Installation Combination for 144 Fibers

FHX fiber enclosures can be converted to support either 8-port or 12-port cassettes and adapters, by moving and changing the rails. This gives you the maximum freedom to deploy any network architecture, fiber infrastructure, network type, either duplex or parallel.

Tips:

Kindly notes that the above fiber enclosure is equipped with 21 pcs adjustable tray rails as default.

The above fiber enclosure is compatible with all FHX Fiber System Components, which can accept up to 18 FHX MTP-8 to LC fiber cassettes, 12 FHX MTP- 12 to LC fiber cassettes or FHX fiber adapter panels or FHX conversion cassettes.

Conclusion

Fiber enclosures can provide easy-to-manage cabling environments and strong protection for fiber optic cables. 1RU rack mount fiber enclosures are the most commonly used size in data center server racks cable management.

0 notes

Text

UNISOL Miniature Din Rail Patch Panel offers up to 24 ports for connection and is designed to be compact in order to save cabinet space. These DIN rail LIUs can be installed in substation automation networks to give as many fiber connections as possible in the smallest amount of space. The maximum number of cable entries that the fiber enclosure can support is four. They are used in the oil and gas, CCTV and surveillance, rail signalling and control, process automation and control systems, renewable energy, and power transmission industries, where they can be mounted on the backplane or side panel of a compact cabinet. Various adapters, including ST, SC, FC, and LC, can be added to this fiber patch panel.

#24 port#din rail#patch panel#cctv#unisol#unisol communication#what is din rail patch panel#what is fiber product#https://www.unisolcommunications.com/24-port-mini-din-rail-mount-liu/

0 notes

Text

UNISOL Micro Din Rail Patch Panel offers up to 12 ports for connection and is designed to be compact in order to save cabinet space. These DIN rail LIUs can be installed in substation automation networks to give as many fiber connections as possible in the smallest amount of space. The maximum number of cable entries that the fiber enclosure can support is four. They are used in the oil and gas, CCTV and surveillance, rail signalling and control, process automation and control systems, renewable energy, and power transmission industries, where they can be mounted on the backplane or side panel of a compact cabinet. Various adapters, including ST, SC, FC, and LC, can be added to this fiber patch panel.

#unisol#micro#din#rail#patch panel#12 port#micro din rail patch panel#cctvsecuritycameras#cctv#cctv camera

0 notes

Text

6 Port Nano Din rail Patch panel

UNISOL Nano Din Rail Patch Panel offers up to 6 ports for connection and is designed to be compact in order to save cabinet space. These DIN Rail LIUs can be installed in substation automation networks to give as many fiber connections as possible in the smallest amount of space. The maximum number of cable entries that the fiber enclosure can support is two. They are used in the oil and gas, CCTV and surveillance, rail signalling and control, process automation and control systems, renewable energy, and power transmission industries, where they can be mounted on the backplane or side panel of a compact cabinet. Various adapters, including ST, SC, FC, and LC, can be added to this fiber patch panel.

0 notes

Photo

Nano din rail liu | Din rail patch panel | 6 port patch panel | Unisol

We designed 6 port patch panels for industrial use with a Din rail. This Din rail patch panel is used to terminate the fiber up to six cores.

#din rail fiber patch panel#din rail patch panel#fiber optic patch panel din rail mounted#din rail enclosure#din rail fiber optic patch panel#din rail mount fiber patch panel#din rail mounted patch panel#patch panel din rail

0 notes

Photo

Micro din rail liu | Din rail patch panel | 12 port patch panel|Unisol

Unisol communications designed to provide 12 port patch panel with a din rail for industrial use. miniature din rail liu can reinforce to terminate up to 12 cores.

#din rail fiber patch panel#din rail patch panel#fiber optic patch panel din rail mounted#din rail enclosure#din rail fiber optic patch panel#din rail mount fiber patch panel#din rail mounted patch panel#patch panel din rail#in rail connectors#din rail connectors

0 notes

Photo

Nano din rail liu | Din rail patch panel | 6 port patch panel | Unisol

We designed 6 port patch panels for industrial use with a Din rail. This Din rail patch panel is used to terminate the fiber up to six cores.

FOR MORE DETAILS :

https://www.unisolcommunications.com/6-port-nano-din-rail-mount-liu.php

#din rail fiber patch panel#din rail patch panel#fiber optic patch panel din rail mounted#din rail enclosure#din rail fiber optic patch panel#din rail mount fiber patch panel#din rail mounted patch panel#patch panel din rail#din rail connectors#din rail mount

0 notes

Video

youtube

Nano din rail LIU | Micro din rail LIU | Mini din rail LIU | Unisol

We designed three kinds of Din rail liu like Nano din rail liu, Micro din rail liu & Mini din rail liu which is used to terminate 6, 12, 24 fibers respectively.

0 notes

Video

youtube

Din Rail Fiber Patch Panel | Din Rail Enclosure | Din Rail Liu | Unisol

Unisol designed Four models of Din rail patch panels such as Nano, Micro, Mini, & Medium, all of which are frequently situated next to the terminating device.

#din rail mount enclosure#din rail mounting adapter#din rail mount#din rail box#din rail adapter#din rail mount fiber patch panel#din rail mounted patch panel

0 notes

Photo

Micro din rail liu | Din rail patch panel | 12 port patch panel | Unisol

Unisol communications designed to provide 12 port patch panel with a din rail for industrial use. miniature din rail liu can reinforce to terminate up to 12 cores.

#din rail fiber patch panel#din rail patch panel#din rail connectors#din rail box#din rail mount#din rail adapter#din rail enclosure box#rack-mount din rail#din rail mount enclosure#din rail mounting adapter#Panduit din rail patch panel#din rail housing#mini din rail

0 notes