#rivet and burr

Explore tagged Tumblr posts

Text

#etsy#shopsmall#etsyshop#etsyseller#etsyfinds#crossbodybag#fannypack#travelbag#chestbag#beltbag#etsyaccessories#leathershop#leatheraccessories#thisjustin#newarrivals#rivet and burr

0 notes

Photo

(通过 7 Essential Facts About Metal, Plastic, and Aluminum Rivets – A Precision Guide for Engineers-YI XIN Precision Metal & Plastic Ltd_Metal_Plastic)

#Metal rivets#plastic rivets#aluminum rivets#stainless steel rivets#copper rivets#rivets and burrs#rivet drill size#cnc machining#cnc machining parts#Yixin precison

0 notes

Note

What are your opinions on Hamilton and Jeffersons rivalry Mr Burr? Do you get annoyed by it? ORR do you not care at all?

Addressed to Anonymous

I find it to be well and good live entertainment! More riveting than most plays I have attended, and admission is far lest costly (ᵔ́∀ᵔ̀)

- A. Burr 🗳️

15 notes

·

View notes

Text

Articulated fingers means anchoring the first and last finger plates, with the remaining "floating", only being attached to the thin piece of leather that connects them all.

Each finger plate gets 1 rivet, except the one at the bottom, which gets two.

To save time and money, I am using rapid rivets for the inner plates, and rivets w/burrs for whenever I need to attach plates to the gloves. These nicer rivets lay flat against my skin and have the lowest risk of popping off.

I plan to use veg tan leather for the rest of the finger strips -- I realized too late that chrome tan, as seen here, will probably stretch too much over time. 😅

58 notes

·

View notes

Text

An unnecessarily long ramble about Shirase's role in Storm Bringer - Part 1

Storm Bringer's Themes and Shirase

At it's core, Storm Bringer is about the many ways someone can be dehumanized and also the many ways a person can exhibit humanity without necessarily being 'human'. Nearly every major character within this book showcases these themes from Chuuya to Adam, to Verlaine, to Dazai.

And yes, even Shirase, however I think the way these themes affect Shirase's character is overlooked a bit, because compared to everyone else, he's ordinary and often times being annoying. The dehumanization he experiences isn't some Big Bad, but that doesn't mean it's not there. The way he regains his humanity is with an internal struggle. It's not as exciting as everything else, so it's no wonder it doesn't get talked about as much.

However, I'm obsessed with it, so I'm going to talk about.

The Dehumanization of Shirase

'The young man would then rivet, wipe, and remove its burrs. Then another part would come his way. Rivet, wipe, file. Rivet, wipe, file. Rivet, wipe, file. Rivet, wipe, file. He would do that as many times as it took until he eventually thought, I've had enough of this. After finishing the next metal part, he was going to quit and go home. He had that same thought every single time he worked until the bell eventually rang, letting all the workers know that their shift was going to end in five minutes. Only during those five minutes did the young man feel some what human.'

This is how we are introduced to Shirase and for me it's one of the grimmest passages in the book. There are certainly events that are more horrifying, but this is grim in such a mundane way, and its because this is how a lot of people spend their lives. This is the type of dehumanization real people can easily relate to.

Working day after day, hour after hour as a cog in a machine, loosing everything you are to your job that you hate until the end of the day where you can regain your sense of self.

Asagiri will often not use a character's name at the start of chapter to create some mystery as to who they are, specifically he does this a lot for Dazai. However it's still interesting me that in this whole passage, it's not until the last paragraph that Shirase is named. By Chuuya. Until then, he's nobody, just a faceless worker, only becoming a person once he's relevant to the plot.

In this passage it's also noted that some of the other workers try to invite Shirase to eat together, but Shirase declines. They are all older than him, it doesn't mention any names and there's no indication that Shirase considers them his friends. Why would he? This is a place were he doesn't even feel like himself, how could he possibly form friendships?

The most interesting way, to me, that Shirase is dehumanized throughout Storm Bringer is the way several characters treat Shirase as insignificant or as someone to be used/disposed of, despite those characters being ones who we root for.

The Port Mafia treats him as a hostage, all his friends had been shipped away to different parts of Japan. He has no support network anymore, he's alone. He lives with the knowledge at any moment the Port Mafia could decide to kill him.

Murase, despite caring for Chuuya and 'wanting to show him the light' does not extend that same kindness to Shirase. He uses Shirase as a means to get Chuuya to come to the police station. Murase even bullies Shirase whilst arresting him.

'Nobody cares about small fries like you, so you've got nothing to worry about.'

It's an off-handed comment and probably to be funny and out of the context of the dehumanization theme it is. But everyone in this story is telling Shirase the exact same thing. He's worthless. Shirase isn't worth Murase's time, he isn't worth saving. Whilst Murase talks to Chuuya about living in the light, he has Shirase locked away in a dark cell left to rot. Because Shirase isn't important.

Murase sets it up so Shirase's freedom is dependant on Chuuya's choice. If Chuuya agrees to be an informant, Shirase will be let go. He doesn't give Shirase the chance to fight for his own freedom because he has nothing Murase wants.

It might be annoying the amount of times Shirase claims he's 'the king' but when everyone else treats him like nothing, it's not surprising to me that he's so desperate to be recognized.

Adam, is perhaps the worst offender of this. He does not like Shirase and whilst I'm not saying he has to, he is also our main narrator through out the book. He interacts with Shirase the most. He also thinks Shirase lacks intelligence and is an annoyance. Despite being programmed to save humans, he treats protecting Shirase as a chore, even though, Shirase is the exact type of person he was meant to protect. An ordinary one.

When Verlaine attacks Shirase in the cells, Adam gives up and accepts Shirase's fate despite saying several times how terrified he is.

'Shirase's voice trembled with fear.' 'Shirase's voice quavered like never before. It took everything he had to simply stand on his own two feet.' 'He was too astonished and afraid to even to even yell out.' 'The worst thing that could happen right now would be losing Master Chuuya or me and being unable to follow with our plan to ambush Verlaine. He had two more targets remaining. There was still hope.'

He's as good as sentencing Shirase to death here because his life isn't as important as Chuuya's or his own. Shirase is disposable. Adam says as much when trying to convince Shirase to come with them. It's made all the more heartbreaking when Shirase is looking to Adam for help but Adam has ready decided he can't do anything.

He says that there was no chance of success at saving Shirase but as soon as Chuuya is in danger, Adam is able to break free from the wall he's trapped in. The possible outcomes don't matter anymore, Chuuya is in danger and he has to try and save him. Something he wasn't willing to do for Shirase.

After Shirase falls unconscious from being poisoned Adam leaves him locked in a storeroom and says he should be safe there. Despite the alarm system broadcasting that everything within the building is going to burned and everyone needs to evacuate. Implying anyone left behind will also burn. When Shirase wakes up alone, thinking he's been abandoned, he easily gets out of the storeroom, meaning anyone could have just as easily got in and killed him.

'The poison was probably meant for Master Chuuya while Shirase was merely collateral damage.'

This what Adam says about Shirase being poisoned and I can't tell if it's supposed to Adam saying how the military sees Shirase or how Adam feels about him. Because it's exactly how he treats him.

The dehumanizing way Adam treats Shirase affects how the reader views him too. Readers are already inclined to dislike Shirase after the events in Fifteen, now in Storm Bringer we spend most of our time with a narrator that also doesn't like Shirase. So when Adam exhibits a lack of care towards Shirase, calls him dumb, annoying and dismisses him, the reader is easily led into doing the same.

And it's sad because Shirase is genuinely scared and struggling throughout the story. But we almost only ever see this during the few parts that are narrated from Shirase's perspective.

Which I will talk more about in Part 2 when I discuss Shirase's overall arc and the ways in which he regains his 'humanity'.

If you read all of this, then thank you :D I hope you enjoyed

Disclaimer: This is not hate on Adam's character, I love him, however this post is about Shirase not him.

33 notes

·

View notes

Text

"HOW ONE PAIR OF RRL DENIM JEANS MAKES IT FROM A COTTON FIELD TO YOUR CLOSET" - by Ikhtier Rustamov

When Ralph Lauren founded Double RL in 1993, he was inspired by the heritage of the American West and the train-hopping, steer-wrangling, gold-panning men who helped to settle it. “It’s not fashion, it’s real stuff,” Ralph has been known to say about the line in the years since. Nothing better embodies that uniquely American quality than a pair of blue jeans (made in the first place for the hard-wearing needs of miners and cowboys). American made jeans have always been a staple in the Double RL wardrobe, but the jeans made with the “East-West” denim, which crosses the globe in pursuit of perfection, just may be the gold standard. Here’s how a single pair comes together.

All denim is made from cotton, but not all cotton is created equal: the material can vary vastly in quality depending on where it’s sourced. RRL’s East-West denim is fabricated using premium grade cotton harvested in the state of Tennessee. The crop that grows there is renowned for its extra long, uneven fibers. When eventually spun and woven, that will translate into denim that’s supremely resilient, with a unique texture that sets it apart from the pack.

From Tennessee, the cotton is flown across the ocean to Japan. To Okayama, specifically, a city that is to denim what Memphis is to the blues. Today, some of the world’s best American denim is made in Japan, where a centuries-old tradition for indigo-dying and fabric weaving is combined with a dedication to maintaining and using vintage narrow shuttle looms which were largely dispensed with half a century ago. In the 1900s, all denim was made on these narrow shuttle looms: slow, noisy, and costly to maintain these looms created a narrow fabric with low-tension, resulting in strong and dynamic denim, rich in texture and finished on either end with a closed selvedge edge. By the 1950s, the fabric had grown so popular that most factories switched to more efficient air-jet looms, creating more product, faster, cheaper and at a lower quality.

To create our East-West denim, we partnered with a small Okayama denim mill that is a standard-bearer in a nearly lost art. The long-staple cotton is deftly ring-spun into a soft, lofty yarn, and rope dyed a red-blue shade of indigo inspired by jeans from the 1930s. Spun and dyed, the yarn is finally woven into bolts of fabric on wooden hanger-style shuttle looms, finished with an iconic red-line of yarn through the selvedge fabric edges. Off the loom, the fabric is then Sanforized, to reduce shrinkage, and finished with a proprietary process that retains the natural “loomstate” characteristics of the denim, creating a true “hand of quality”.

From one denim mecca to the next, the finished bolts are shipped over to California — the state where jeans got their start. Here the product really takes shape: the denim is cut and sewn into finished jeans manually using methods that were common from the 1940s-1960s, but have become rare today: chain-stitching, washer burrs, hidden rivets, and handset pockets and waistbands.

American-made thread and rivets hold it all together, while an open “busted” outseam on the outside of each pant leg leaves the selvedge edge visible as a hallmark of quality. For a finishing touch, the signature RRL leather patch is applied by hand.

Once assembled, the jeans are given a final once-over for detailing and distressing. A team of artisans in Los Angeles fits each individual pair onto a special form and rough them up just a bit. Hand-sanding is one of the best ways to give a patina of age, but that’s just one piece of the tool-kit: a finished pair of pants can undergo up to 50 steps before they head out the door, and that’s without even considering the variety of vintage-inspired washes that change with every season.

With this last step, East-West Denim goes from uniform fabric to a wear-ready pair of RRL jeans.

From field to factory to weekly rotation, East-West Denim comes to life when the jeans take on the life of the wearer, weathered by the elements and the inevitable abrasions that come from daily use. Eventually, whiskers above the legs and “honeycombs” behind the knees appear. The tell-tale “track” on the outer inseam manifests. A phantom outline appears on the pocket where you always put your wallet. And then they’re not just “real stuff.” They’re really yours.

23 notes

·

View notes

Note

zote the mighty, knight of great renown,

have you been to the colosseum of fools? i’d think the combat would appeal to you, but the title, ah.. not so much, i would imagine.

i haven’t been down there, but i have been to kingdom’s edge, and, well… its not exactly a pleasant experience getting a corpse almost dropped on top of you, to be honest!

i’d rather not go there again anyway. too much… white powder. i’ve heard it’s ash from the moulting of the pale king’s old body, which.. i don’t think i like the sound of being covered in a decaying corpse.

-lifeblood anon

[ooc: HI YOUR LIFEBLOOD ANON DOODLE WAS SO <3333 CANT BELIEVE THE ZOTE HIMSELF LIKES ME,,,,,,, very glad you like lifeblood anon’s design!!!!!]

Ah, yes, I have been to the Colosseum! I fought in a spectacular battle there, downing hundreds of opponents and fulfilling a promise of glory to myself!

The combat did indeed appeal to me, what with every foe never holding back their full might! It was a riveting, but more importantly, refreshing experience, battling against experienced nail users as opposed to feral beasts!

Though, much to my disappointment, the "Fools" seemed on the path towards the latter. The lot of them were Infected, and it seemed common practice to incite infection in any creature that wasn't already, as a means of strengthening them.

I could have done without that, I will say! Luckily, I would never succumb to such a thing, as using anything other than my own will and power to enhance my abilities would be unscrupulous!

And... "ash from the moulting of the Pale King's old body"?! Is that what that horrid substance was? It positively covered that place, stuck to my cloak like burrs! I paid it little mind -- and it was flakes of molt?

...Hmph. Well, yes, I similarly find disgust in wandering through decaying flecks of a corpse.

#[[ooc: HEHE YIPPIE!!! YEA Zot is not very used to being respected so like. he appreciates it LMAO#and lifeblood means everything to me I could pick them up and squish them (affectionate)]]#prattling on

7 notes

·

View notes

Text

KARKAT TEXT ADVENTURE: BEGIN

Welcome to Karkat Text Adventure, a project by @reallygrossstuff! Below this disclaimer is the first part of the adventure itself, but before that, a few notes on what to expect from this interactive story.

This story can, potentially, contain any kink that I am willing to write, in any combination. This first page has no fetish; on some paths, there may be multiple pages with no fetish material. When that material is present, I will place bold warnings at the top of the prompt, indicating which fetishes are present. I will also tag those fetishes, so consider blacklisting ones you don't want to see here.

The directions Karkat goes in this story are entirely up to you! If you want to see him do something, send in a request for him to do it, and feel free to specify things that he does or encounters along the way (though I may not include these if they don't fit the pacing or tone of that section).

This project will likely take some time. I have a tentative goal of averaging 1-2 requests per day, and no plans for when a route ends other than "when it would be satisfying to end it". Feel free to take a break from reading and come back to see what's new at a later date.

Some parts of the text will be in ALL CAPS. These are author suggestions for which directions it might make the most sense for Karkat to go. If you want him to do something else, though, please request that! As there will be many pages, please specify which page your addition is for, preferably using the title each page will be given. For example, this page is KARKAT TEXT ADVENTURE: BEGIN.

Sorry for the wall of text, but I think that's everything now! Enjoy Karkat Text Adventure and don't be shy!

---

Karkat hates the bunker before the hatch has even finished closing above him.

Earth C isn't meant to have any Skaianet bunkers - it doesn't have frog temples or meteor strikes or anything else from a pre-Game world - and yet the proof is right in front of his eyes. As the hatch seals shut and the lights come on above him, he's reminded immediately of the lab on the meteor; brushed metal walls, visible riveting, and absolutely no sensible labels on anything.

Wait, no. What's that?

Right in front of the access ladder, beside the elevator shaft and before the hallway starts corkscrewing down to his right, there's a map. A side-on view of the bunker takes up one side of the display, with each level labelled in both Alternian and English with its function. On the other side, each level gets its own diagram, showing part of the circling access hall as well as the six protruding rooms accessible from that section of hallway.

Karkat's hackles raise just looking at it. It reminds him of nothing less than a burr, the long tube boring into the earth before the 'spikes' of each room jut outwards and lock the whole structure into place.

Like a burr, the bunker needs to be removed. But also like a burr, that might not be safe - like the meteor, many of these rooms are labelled as various laboratory spaces, and there's no telling how anything in there will react to anyone's attempts to simply shrink, destroy or rewind the structure. Having drawn the short straw, it's somehow ended up Karkat's responsibility to go down, investigate the structure, decide whether it's safe to remove and how, and report back on what he finds.

Just great.

Scowling at his own poor luck, Karkat examines the map more closely. There are dozens of floors sectioned off for various purposes, everything from DORM ROOMS and CAFETERIAS to ALCHEMY LABS and ECTOBIOLOGY TUBES, as well as plenty of rooms with names that mean nothing to him in either language.

Where is he meant to start?

DORM ROOMS | CAFETERIA | ALCHEMY | ECTOBIOLOGY | OTHER

3 notes

·

View notes

Text

How to Use Brass and Copper Sheets in Industrial Projects

In the world of industrial manufacturing and construction, material selection plays a critical role in determining performance and longevity. Two of the most trusted and frequently used materials are the brass sheet and the copper sheet. These metal sheets offer durability, functionality, and flexibility, making them ideal for a wide range of industrial applications.

This blog explores how to use brass and copper sheets effectively, where they are most beneficial, and what factors you should consider before using them.

What Makes Brass and Copper Sheets Industrial Favorites?

Both brass and copper are non-ferrous metals with superior corrosion resistance and conductivity. While brass is an alloy of copper and zinc, copper is a pure element. Their chemical makeup offers different yet complementary benefits depending on the project type.

Key Reasons:

Strength and Malleability: Perfect for shaping without cracking.

High Resistance to Corrosion: Long-term durability in harsh environments.

Conductivity: Especially important in electrical and heat transfer tasks.

Compatibility with Other Materials: Can be used with steel, plastic, and wood.

Common Industrial Applications of Brass Sheet

A brass sheet is used in multiple industrial applications due to its strength and visual appeal. Some of the most common include:

1. Marine Equipment

Brass is often used in boat fittings, propellers, and engine components because of its excellent corrosion resistance in saltwater.

2. Mechanical Components

Bushings, gears, and bearings benefit from brass’s low friction and wear resistance.

3. Architectural Detailing

Used for wall panels, signage, and trim work in both interior and exterior design for its golden color and shine.

4. Electronics

It’s used for terminals, switch components, and sockets due to moderate electrical conductivity.

5. Industrial Fasteners

Brass makes high-performance screws, rivets, and nuts with anti-corrosive features.

How to Work with Brass Sheet in Industrial Settings

When working with brass sheets, here are some tips:

Use Carbide Tools: Brass is soft but can be gummy; sharp tools reduce burrs.

Annealing May Be Required: To restore softness after heavy forming.

Finishing Choices: Polished, brushed, or lacquered finishes depend on exposure and appearance needs.

Always Use Proper Ventilation: When soldering or cutting to avoid inhaling fumes.

Copper Sheet in Industrial Applications

The copper sheet stands out for its excellent conductivity and resistance to extreme temperatures. It is heavily used in power plants, electrical panels, and manufacturing plants.

1. Electrical Power Systems

Copper sheets are the backbone of switchboards, transformers, and circuit breakers due to unmatched conductivity.

2. Heat Exchangers

High thermal conductivity makes copper perfect for cooling systems, boilers, and radiators.

3. Chemical Processing

Copper resists most acids and chemical agents, suitable for reactors and tanks.

4. Roofing and Gutters

Industrially, copper roofs are used for factories and public buildings because of weather resistance and lifespan.

5. Medical Equipment

Antibacterial properties make copper perfect for operating tables, fixtures, and hospital accessories.

Best Practices for Using Copper Sheets in Industry

Here are a few expert tips when using copper sheets:

Handle with Gloves: Prevents oxidation from skin oils.

Soldering Techniques: Use proper flux and solder for clean, strong joints.

Pre-plan Cutting Paths: To minimize material waste and ensure precision.

Protective Coating: Apply sealants if exposed to open-air environments.

Factors to Consider When Choosing Between Brass and Copper

FeatureBrass SheetCopper SheetCompositionCopper + Zinc99.9% Pure CopperConductivityMediumVery HighColorGold-LikeReddish-BrownStrengthHigher Tensile StrengthSofter, More DuctileAntimicrobialYesYesBest Use CasesFittings, Hardware, Decorative WorkElectrical, Medical, Thermal Systems

Which Sheet is Best for Your Industrial Project?

If you're working on:

Electrical applications → Choose copper sheet

Decorative or load-bearing elements → Use brass sheet

Corrosive environments → Both are suitable, but brass may perform slightly better

High-temperature zones → Copper is more thermally stable

Environmental Benefits of Brass and Copper

Both metals are 100% recyclable and can be reused without any degradation in quality. This contributes significantly to reducing industrial waste and supports sustainable manufacturing.

Additional Advantages:

Low Carbon Footprint: Recycling consumes less energy.

Economic: Scrap value remains high, reducing net material cost.

Compliance Friendly: Meets global standards for green building and LEED certifications.

Why Precision Matters in Sheet Metal Use

Precision-cut brass and copper sheets help industries achieve:

Efficient Assembly

Tighter Tolerances

Fewer Production Errors

Higher Product Life Cycle

Investing in laser-cut or CNC-machined sheets may cost more upfront but ensures long-term savings and performance.

Where to Get the Best Quality Sheets?

It is crucial to source your material from verified suppliers that offer test certificates, grade information, and finish options.

You can explore:

✅ Brass Sheet - Rajshree Metals

✅ Copper Sheet - Rajshree Metals

These sheets are manufactured as per industry standards and are available in multiple thicknesses and grades.

Conclusion

Whether you’re running an industrial workshop, designing precision components, or fabricating custom installations, brass sheets and copper sheets offer unmatched performance and reliability. They not only improve the functional output of your project but also ensure a long service life with minimal maintenance.

0 notes

Text

Interview with Jenn Bregman

The Last Hamilton

Sarah Brockman Book 1

Jenn Bregman

Crooked Lane Books

Feb 11th, 2025

The Last Hamilton by Jenn Bregman intertwines history within a mystery. The conspiratorial plot involves a secret society established by Alexander Hamilton to protect U.S. gold reserves from foreign and domestic enemies. The question throughout the story is, “Did Alexander Hamilton hide enough gold to prevent anyone from cornering the market and ruining the US?”

The characters need to answer that question to find out what happened to the last heir of Alexander Hamilton, Elizabeth Walker. The police are wondering if she jumped in front of a subway train or was pushed to her death. Her husband, Ralph, and her best friend Sarah Brockman, know that she was terrified, frantic, and manic during her last days. Sarah received a cryptic message, and Ralph recalls her running mysterious errands to search for a strange antique key including in a piano at the Hamilton Grange (the house Hamilton built in New York City). Then, Sarah receives a box of tattered documents and shows them to Ralph.

Working together to find answers to Elizabeth’s death, they are stunned to discover that Elizabeth was part of a secret society established by Hamilton himself to keep America safe. Also investigating her death is Detective Deborah Schwartz who knows Sarah and Ralph are hiding something. To make matters worse, Sarah’s co-worker Pierce Burr shares sensitive intelligence about gold reserves with his devious friend Timothy who works for the Treasury Department and is trying to thwart her efforts to find the truth. Pierce and Timothy are trying to involve foreign interference in the international gold market.

The story has a great plot, intriguing characters, and a lot of suspense. Readers will feel they are back in time during revolutionary days and then jump forward to today where the twists add to a riveting storyline.

Elise Cooper: How did you get the idea for the story?

Jenn Bregman: My husband and I lived in New York for about 12 years. The city lives and breathes Revolutionary era history. I became immersed in it and have a fondness for revolutionary times. The inspiration for the story came at that point. I read the Ron Chernow book and fell in love with Alexander Hamilton. Plus, I always have been interested in legacy issues and how the past continues through generations. Then the story just grew. Most of the historical facts in this book are accurate.

EC: What about the financial aspect of the story?

JB: I went to law school at UCLA where I met my husband. Then I became a Big Law litigator who practiced in Los Angeles and New York. I worked on Wall Street for many years and in banking compliance and trading. This part of the story was my life, so I did not need to do any research.

EC: What was true?

JB: 48 Wall Street, the first bank of New York, does have a raised basement. It is possible the vaults are there. The part about Fort Knox is a basis in speculation. There has never been a full accounting of the gold depositories in the US because the government does not want it. One of the facts that is true. It took the US four years to give the German bank back their gold bars. And it is true there is no accounting. Also, the piano in the story that had a little matchbox draw underneath is still at the Hamilton Grange.

EC: What was the role of Alexander Hamilton, his daughter, Angelica, and the handkerchief?

JB: He has an active and passive role. He put in place the vision for America within a secret society. He set up a trove to set up this secret society. Angelica became mentally disabled through the grief of losing her brother. The only thing that would soothe her is to play the piano over and over. The piano that I speak about is at the Hamilton Grange. The clue was a picture of Angleica with the handkerchief and the piano.

EC: How would you describe Elizabeth?

JB: Charming, stressed, short tempered at a certain point in the story, and feels she has a legacy. She has great virtue, integrity, courage, and strength. Elizabeth always gave of her time to support the Hamilton legacy.

EC: How would you describe Sarah?

JB: Tough, fair, loyal, and courageous with a conscience. She is sometimes conflicted. She has more layers than Elizabeth.

EC: What about Ralph?

JB: Kind, gentle, resourceful, sweet, creative, trusting, and anxious during this point in the story.

EC: What about Pierce Burr?

JB: He is anti-hero, manipulative, and self-centered. He was greedy, someone who wanted to gain money and prominence. He also wanted to save his family legacy. He allowed the greed to cloud his eyes.

EC: What role did Detective Schwartz play?

JB: She is inquisitive, analytical, wise, and suspicious. She is seasoned because she knew that both Sarah and Ralph were hiding something but let it run its course.

EC: Next book?

JB: I am working on it now. Some of the characters will continue including Sarah but not Hamilton. The next book takes place shortly after this book and will be a thriller.

THANK YOU!!

0 notes

Text

Corrosion Causes and Prevention in Flue Gas Desulfurization Systems

Flue gas desulfurization refers to the process of removing sulfur oxides (SO₂ and SO₃) from flue gas or other industrial waste gases. This technology plays a crucial role in controlling environmental pollution and improving air quality. However, flue gas desulfurization systems face corrosion issues during long-term operation. Therefore, effective anti-corrosion measures are essential.

I. Overview of Construction Methods

The glass flake resin anti-corrosion material consists of dispersed glass flakes mixed with a viscous resin to form a paste-like composite. The application process resembles building plastering. Workers use trowels and scrapers to apply the material to the protected surface at the required thickness. After applying, they remove bubbles and compress the material to arrange the glass flakes in a specific direction, allowing it to cure and set. The differences in properties between resin and cement materials make the application more challenging.

II. Main Characteristics of Construction

Manual Operation: The application of glass flake resin is manual. The quality of the work largely depends on the skills and proficiency of the workers.

Surface Quality Control: The quality of the anti-corrosion layer, the arrangement of glass flakes, and the thickness depend on the worker's technical level and experience.

Sealing Requirements: The glass flake anti-corrosion layer must be completely sealed, especially at ends, joints, and corners. To prevent stress concentration and misalignment of flakes, reinforcing measures such as glass cloth should be used.

Mixing Equipment: Mixing equipment should be available during construction to minimize the formation of air bubbles.

Safety Protection: The working environment for glass flake resin is harsh and poses fire and health hazards. Therefore, safety measures are crucial.

III. Structural and Surface Requirements for the Protected Metal Shell

Strength and Rigidity: The protected metal shell must possess sufficient strength and rigidity to prevent damage to the anti-corrosion layer during transport, installation, and construction.

Construction Conditions: The structure of the metal shell must meet construction requirements and allow for manual application.

Welding Requirements: All structural components that require welding (or riveting) must be completed before construction. If welding is necessary afterward, appropriate measures must be taken. All external pipeline flanges should be open, and the equipment must pass inspection according to design specifications.

Maintenance Conditions: Equipment that contains internal components and requires frequent maintenance must be suitable for installation and repair without damaging the lining.

Welding Structure: The metal shell should primarily use welded structures. If riveting is necessary due to special circumstances, countersunk rivets should be used.

Surface Treatment: The surfaces of the metal shell must be clean and smooth, free of weld slag and burrs. Welded areas should be flat, with protrusions not exceeding 1mm. If they exceed this height or are rough, they should be ground down with a grinder.

Sandblasting: The metal shell must undergo strict sandblasting and rust removal.

Pre-Construction Completion: All processing, welding, pressure tests, and leak tests must be completed before construction. After construction, no welding is allowed on the shell.

By following these measures, we can effectively enhance the anti-corrosion performance of flue gas desulfurization systems, extend the equipment's lifespan, and ensure the safe and stable operation of the system.

Contact Us

If you have any questions about the anti-corrosion measures for flue gas desulfurization systems or other related products, please feel free to contact us. Darko is dedicated to providing high-quality anti-corrosion solutions to help businesses achieve sustainable development.

0 notes

Text

#shopsmall#etsy#etsyseller#etsyshop#Rivet and Burr#etsy finds#etsy gifts#holiday gift shop#holiday gifts

0 notes

Text

Cold heading of screws is the process of using a mold to compress and deform the wire with external force, making the wire into the required length and extruding the nut. Cold heading is widely recognized as the most suitable additive process for producing standard fasteners such as bolts, screws, nuts, rivets, and dowels.

Because the advantages of cold heading are quite prominent. It is an advanced production process with high precision, high efficiency, high quality and low consumption, which can save raw materials, improve production efficiency, reduce costs, and is suitable for mass production. Cold heading is a screw that uses the plastic deformation of metal to transform wire into the desired shape, greatly reducing the loss of raw materials caused by cutting, improving material utilization, and reducing waste. With the cooperation of molds, cold heading can process fasteners with various complex shapes and difficult cutting processes. Moreover, molds can be reused for mass production, improving production efficiency and making them suitable for large-scale production needs.

The screws formed by cold heading have no burrs and are relatively smooth. After processing, the screws basically do not need to be cut or heat-treated.

Moreover, the hardness and strength of the screws after cold heading are higher than those of the raw materials, and they can also improve fatigue strength. For example, some fasteners that originally needed to be made of high-strength materials can be replaced with slightly lower strength materials if cold heading is used to produce fasteners that meet strength requirements, which greatly saves

0 notes

Text

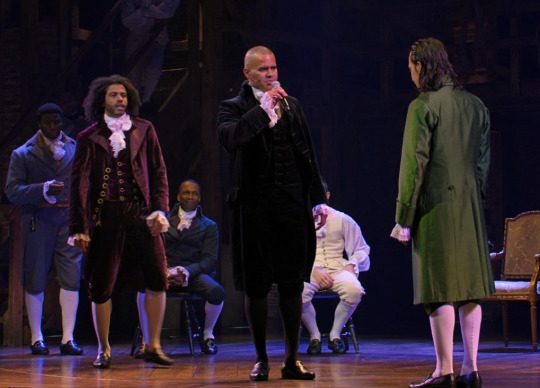

HAMILTON

Lin-Manuel Miranda’s Hamilton, adapted from the Broadway phenomenon to Disney+, is a riveting cinematic experience that captures the groundbreaking spirit of the stage production. Seamlessly blending history with modern storytelling, Hamilton is a dazzling display of creativity, emotion, and artistry.

Plot and Narrative

At its core, Hamilton is a biographical musical based on the life of Alexander Hamilton, one of America’s Founding Fathers. Adapted from Ron Chernow's biography, the film chronicles Hamilton’s journey as an immigrant who rises to political prominence, his tumultuous personal life, and his eventual tragic demise. The narrative is presented with a fresh perspective, intertwining Hamilton’s ambitious climb with America’s struggle for independence and self-definition.

What makes Hamilton unique is its approach to storytelling. The film blends historical events with contemporary themes, making a centuries-old story feel immediate and relevant. It reframes the founding of America through a modern, diverse lens, asking audiences to reexamine history in ways that resonate with today’s social and political discourse.

Performances

The performances in Hamilton are electrifying. Lin-Manuel Miranda leads the cast as the titular character, delivering a heartfelt portrayal of Hamilton’s brilliance, flaws, and relentless ambition. Leslie Odom Jr. is a standout as Aaron Burr, Hamilton’s foil and eventual rival. His nuanced performance, coupled with his powerful vocals in songs like “Wait for It” and “The Room Where It Happens,” is unforgettable.

Daveed Diggs, who doubles as Marquis de Lafayette and Thomas Jefferson, brings infectious energy and wit to the screen, while Renée Elise Goldsberry (Angelica Schuyler) and Phillipa Soo (Eliza Hamilton) provide emotional depth and soaring vocals that anchor the story’s more intimate moments. Jonathan Groff’s King George III, though a smaller role, steals scenes with his hilariously pompous portrayal and catchy numbers.

Music and Choreography

The music of Hamilton is its beating heart. Miranda’s masterful blend of hip-hop, R&B, jazz, and traditional Broadway styles gives the film its unique identity. The lyrics are densely packed with wit, historical references, and emotional weight, rewarding multiple viewings. Songs like “My Shot,” “Helpless,” and “Satisfied” are not just catchy but serve to deepen character and advance the story.

The choreography, designed by Andy Blankenbuehler, is equally impressive. The ensemble cast, often in perpetual motion, enhances the narrative with dynamic and symbolic movements. The rotating stage, a feature retained from the stage production, adds an extra layer of visual interest, giving the filmed version a kinetic energy that feels cinematic.

Cinematic Adaptation

Though Hamilton is a filmed stage performance rather than a traditional film adaptation, director Thomas Kail effectively captures the theatricality of the production while making it accessible for the screen. Close-ups highlight the actors’ nuanced expressions, and clever camera angles offer perspectives not possible in a live theater setting. The film retains the intimacy and immediacy of the live experience while broadening its reach.

Themes

Hamilton explores timeless themes of legacy, ambition, love, and the complexity of the American experiment. It asks poignant questions about whose stories are told and remembered, challenging traditional historical narratives.

Final Thoughts

Hamilton is more than just a filmed musical—it’s a cultural phenomenon that redefines how history can be presented. With its stellar cast, innovative music, and bold storytelling, it’s a triumph of both theater and film. Whether you’re a history buff, a musical theater enthusiast, or a newcomer to the genre, Hamilton is a must-watch.

1 note

·

View note

Text

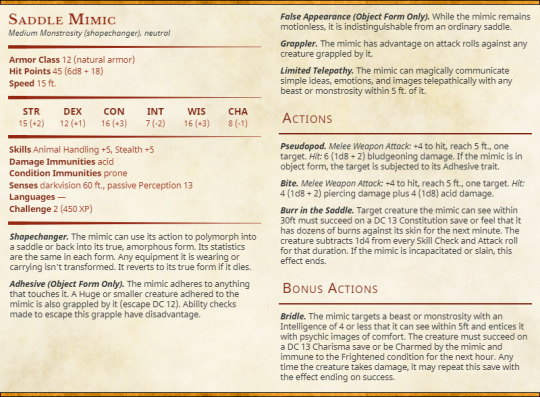

Just Another Mimic Monday

Finding a few horses with their reins loosely tied to a tree in the forest wasn't a common occurrence, but the animals weren't skittish as your party approached to investigate. Not far off there was a small campsite that had clearly been attacked by some beast but the horses were spared. Having a steed for the trip would certainly be better than walking! When it was clear that a horse was calm and comfortable in your presence,you grabbed the saddle and swung yourself up into it. Though, now your hands… your rump… your legs are stuck to the leather. Rivets slowly turn to eyes and stitching to teeth as you find yourself sitting atop a mouth! The horse trotted off without a care, hopefully your companions can catch up soon! Roll for initiative.

Developed by a horse-riding bandit gang, saddled mimics were bred to both keep their riders in the saddle and horses calm in the heat of battle. Its adhesive nature worked wonders for the first, and the monstrosities' strange nature for the second. As is often the case, however, the malleable mimics changed in ways that couldn't be predicted. They gained the ability to transfer the irritation they often felt when a burr or the like caught on them to other creatures, which proved even more useful for the bandits. What didn't prove useful was the mimics developing first empathy for horses and then a way to communicate and command them. When faced with a choice between bandits or horses for their next meal, the horses won out.

#dnd#dnd5e#dungeonsanddragons#ttrpg#horrorgames#horrorrpg#dndhomebrew#dndhomebrewmonsters#dndmonsters#justanothermimicmonday

0 notes

Text

Setting rivets. One tool sets the burr (washer) -- you can set it as tight as you'd like, or keep looser for articulation. Then you clip, and then peen the end til it's smoothly domed over.

There is another tool you can use the dome the back side (which is normally flat), if that is the side you want visible.

Rivets like this are a bear to remove if you make a mistake, but it's nice knowing they won't pop by accident. I also don't have to order different shank lengths - I just buy the longest rivets I can, and then clip them to the size I need.

Left arm done, minus straps and some misc finishing.

Working on the pauldrons. Pattern is from Prince Armory. Woodcut design from Albrecht Dürer's apocalypse series.

Need to ink and dye, burnish, then final assembly. Today was just a dry fit.

125 notes

·

View notes