#selected area electron diffraction pattern

Explore tagged Tumblr posts

Text

#transmission electron microscopy#selected area electron diffraction pattern#HRTEM#Fourier transform

2 notes

·

View notes

Text

VK Global Digital's new Faridabad plant

In 2018, the leading Faridabad-based textbook publisher, VK Global Publications, got into printing and carton production by acquiring an existing plant in Manesar that had gone into NCLAT insolvency proceedings. The plant, which has extensive book and packaging printing, binding, and converting equipment, along with luxury hard box-making capacity, was renamed VK Global Digital.

The publishing group has taken about five years to learn the commercial print and carton packaging business. The carton and luxury box-making businesses were stabilized and rationalized by producing premium cartons using VK Global’s proprietary metallic hologram and Fresnel lens effects for brand protection and security.

A new Bobst diecutter and a new Bobst folder-gluer were added to the Manesar plant. However, to expand the plant with new printing, postpress, and converting equipment, it was decided to build a purpose-built factory with space for future expansion in Faridabad. Not far from the headquarters building of the publishing house, the elegant purpose-built factory, along with several additional investments in equipment, is humming.

Ambitious from the blueprint stage, the modern work and production spaces are within the elegant 250,000-square-foot load-bearing factory building. On most of the two acres alongside the building is a hydroponic greenhouse where the first horticultural crop of lettuce and kale was just maturing in mid-January.

Apart from the double-height 100,000-square-foot production space and meeting rooms on the ground floor, the 50,000-square-foot mezzanine contains prepress and open-plan management spaces. Another 100,000-square-foot load-bearing floor is not yet populated.

On one side of the ground floor are the sheetfed multicolor presses for printing cartons. Before the plant was complete, a new Heidelberg 6-color plus coater UV press was installed in February-March 2024. The 6-color coater UV press from Manesar was moved subsequently so that no customer deliveries were disrupted.

In the converting section, alongside the multiple die-cutters and folder-gluers, a new Masterwork autoplaten foil stamping machine critical for incorporating the metallic brand security features was installed. The Mecchi equipment for producing two-piece luxury boxes for electronic, personal care, and confectionery products was brought from the Manesar plant and installed in a dedicated area.

By August 2024, all the equipment from Manesar was moved, installed, and recommissioned. Although not without challenges, the entire closely managed process meant the transition to full production was practically seamless – with few or no hitches in the timely shipment of cartons.

In the double-height pressroom, there are 10 Heidelberg presses, including two 6-color coater UV presses for cartons and two 8-color perfectors for commercial and book printing. Apart from improvement in workflow and material movement in the continuous single–level space, the new converting equipment has smoothened and increased production.

Premium visual effects and brand authentication and protection

All the products produced by VK Global – books, monocartons, or luxury boxes tend – to be in the premium category for its select customers. The quality and consistency of design, paper and printing, embellishment, and brand security stand out. The company’s rich experience in security and embellishment using its holographic technology and expertise is formidable. The company uses its own manufactured transfer films to transfer a combination of metallics with holographic diffraction and optically active surface patterns and Fresnel lens effects for application on paper, PET, and BOPP.

The metallic effects are transferred onto paperboard and carton substrates from recyclable films that the company produces for in-house use and also exports. After use, the brand-secure cartons can be pulped along with other paperboard cartons.

Hence, the company is a global pioneer and exporter in creating completely recyclable book covers, cartons, or blister packs integrated with Fresnel lenses and other holography patterns. VK Global’s transfer films have been validated under EU EN 13430 certification, which classifies the products as bio-degradable. In the case of monocartons and other packaging materials such as blister packs, these effects can authenticate consumer products – easily differentiating them from counterfeit packaging and products.

Technology absorption, process, OEE, and human resource optimization

Educated in computer science, Jain, apart from his exploration of the production processes, is one of the few young printers or print businessmen who have taken an interest in the digitally enabled concepts necessary to drive efficiency in printing and packaging businesses today. For instance, he has understood many of the Heidelberg Prinect prepress, workflow, and production monitoring features that are talked about but rarely implemented. This is usually because of the large gap between the educated management and inadequately skilled personnel on the shop floor.

He sees the benefits of investing in an expert printer from Heidelberg to train his team in a sustained three-week program. “This may sound expensive, but it’s trivial compared to the cost of the presses and their complexity. To achieve efficiencies that are closer to the capacity of the individual presses and the entire workflow will require continuous training and skilling,” he says. Moreover, he suggests there are several challenges in the hypercompetitive carton business, and while efficiencies and quality need to improve, so must profitability to sustain the viability of continuous investments in human resources.

Jain has implemented the processes and calculations of overall equipment effectiveness (OEE) using the Heidelberg Prinect spectrum of digital tools. He uses the Prinect imaging engine in prepress, its scheduling features for production, and its ability to produce pallet tags for production tracking and operational material movement.

The entire project of VK Global Digital reflects a perspective of individuals actively finding out, understanding, and implementing what is already well-established and available in the technology that has been paid for. The attitude of breaking down the business challenges and the production processes is the most exciting thing about the new plant and the persistence of the next-generation management. It is heartening to witness a young technocrat aligning technology, production processes, and human resources with his aspiration to excellence without compromise.

0 notes

Text

Gold in limbo between solid and melted states

https://sciencespies.com/physics/gold-in-limbo-between-solid-and-melted-states/

Gold in limbo between solid and melted states

A schematic of the experimental setup for the time-resolved X-ray diffraction studies on the polycrystalline gold thin films. The sample is mounted perpendicular to the XFEL beam. A laser “pump” excites the sample, and then an X-ray pulse “probe” monitors the laser-induced changes at different time delays. The inset shows the X-ray diffraction patterns generated for the 300-nanometer film 50 picoseconds before and 100, 220, and 390 picoseconds after laser excitation. Credit: Brookhaven National Laboratory

If you heat a solid material enough, the thermal energy (latent heat) causes the material’s molecules begin to break apart, forming a liquid. One of the most familiar examples of this phase transition from a well-ordered solid to less-ordered liquid state is ice turning into water.

Though melting is a fundamental process of matter, scientists have not been fully able to understand how it works at a microscopic level, owing to the lack of research capabilities with sufficient time resolution. However, the advent of X-ray free-electron lasers (XFELs) in the past decade is making the study of the mechanism of melting, as well as other ultrafast atomic-scale dynamics, possible. These instruments use free (unbound) electrons to generate femtosecond (one-quadrillionth of a second) pulses of light in the X-ray energy region. Compared with X-ray synchrotrons, XFELs have X-ray pulses of a much shorter duration and higher intensity.

Now, a team of international scientists has used one of these instruments—the Pohang Accelerator Laboratory XFEL (PAL-XFEL) in South Korea—to monitor the melting of nanometer-thick gold films made up of lots of very tiny crystals oriented in various directions. They used an ultrashort X-ray pulse (“probe”) to monitor the structural changes following the excitation of these polycrystalline gold thin films by a femtosecond laser (“pump”), which induces melting. When the X-ray pulse strikes the gold, the X-ray beam gets diffracted in a pattern that is characteristic of the material’s crystal structure. By collecting X-ray diffraction images at different pump-probe time delays on picosecond (one-trillionth of a second) scales, they were able to take “snapshots” as melting began and progressed in the gold thin films. Changes in the diffraction patterns over time revealed the dynamics of crystal disordering. The scientists selected gold for this study because it diffracts x-rays very strongly and has a well-defined solid-to-liquid transition.

The X-ray diffraction patterns revealed that melting is inhomogeneous (nonuniform). In a paper published online in the Jan. 17 issue of Science Advances, scientists proposed that this melting likely originates at the interfaces where crystals of different orientations meet (imperfections called grain boundaries) and then propagates into the small crystalline regions (grains). In other words, the grain boundaries start melting before the rest of the crystal.

“Scientists believed that melting in polycrystalline materials occurs preferentially at surfaces and interfaces, but before XFEL the progression of melting as a function of time was unknown,” said co-corresponding author Ian Robinson, leader of the X-ray Scattering Group in the Condensed Matter Physics and Materials Science (CMPMS) Division at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory. “It was known that the laser generates “hot” (energetic) electrons, which cause melting when they transfer their energy to the crystal. The idea that this energy transfer process happens preferentially at grain boundaries and thus is not uniform has never been proposed until now.”

Brookhaven Lab physicists (from left to right) Ian Robinson, Tadesse Assefa, Ming Lu, Emil Bozin, and Simon Billinge at the Center for Functional Nanomaterials cleanroom, where they fabricated polycrystalline gold films of 50-, 100-, and 300-nanometer thickness. The team used time-resolved x-ray diffraction to understand the mechanism of melting in films excited by a laser that emits optical pulses with an extremely short duration. Their analysis of the X-ray diffraction images revealed that melting (induced by the laser) starts in one place and then moves into another location. Credit: Brookhaven National Laboratory

“The mechanism of laser-induced melting is important to consider for micromachining of precision parts used in aerospace, automotive, and other industries,” added first author Tadesse Assefa, a postdoc in Robinson’s group. “The way the laser couples to the material is different depending on the pulse duration of the laser. For example, the ultrashort pulses of femtosecond lasers seem to be better than the longer pulses of nanosecond lasers for making clean cuts such as drilling holes.”

For their experiment, the scientists first fabricated thin films of varying thickness (50, 100, and 300 nanometers) at the Center for Functional Nanomaterials (CFN)—a DOE Office of Science User Facility at Brookhaven. Here, in the CFN Nanofabrication Facility, they performed electron-beam evaporation, a deposition technique that uses electrons to condense the desired material onto a substrate. The ultraclean environment of this facility enabled them to create gold films of uniform thickness over a large sample area.

At PAL-XFEL, they conducted time-resolved X-ray diffraction on these films over a range of laser power levels. Software developed by staff in Brookhaven Lab’s Computational Science Initiative handled the high-throughput analysis of the terabytes of data generated as a detector collected the diffraction pattern images. The team then used software developed by scientists at Columbia Engineering to convert these images into linear graphs.

The plots revealed a double peak corresponding to a “hot” region undergoing melting (intermediate peak) and a relatively “cold” region (the rest of the crystal) which has yet to receive the latent heat of melting. Through electron coupling, heat goes to the grain boundaries and then conducts into the grains. This uptake of latent heat results in a band of melting material sandwiched between two moving melt fronts. Over time, this band becomes larger.

An illustration of grain boundary locations (points where lines intersect) in a polycrystalline gold thin film. The zoomed-in view shows how a melt front created at these boundaries propagates into the grains after the film is excited with an optical laser. Credit: Brookhaven National Laboratory

“One melt front is between a solid and melting region, and the other between a melting and liquid region,” explained Robinson.

Next, the team plans to confirm their two-front model by reducing the size of the grains (thereby increasing the number of grain boundaries) so they can reach the end of the melting process. Because melting occurs as a wave traversing the crystal grains at a relatively slow speed (30 meters per second), it takes longer than the timing range of the instrument (500 picoseconds) to cross big grains.

They would also like to look at other metals, alloys (mixtures of several metals or a metal combined with other elements), and catalytically relevant materials, in which grain boundaries are involved in chemical reactions.

“This study represents the very beginning of how we build an understanding of the mechanism of melting,” said Assefa. “By performing these experiments using different materials, we will be able to determine if our model is generalizable.”

Explore further

Atomic movie of melting gold could help design materials for future fusion reactors

More information: Tadesse A. Assefa et al, Ultrafast x-ray diffraction study of melt-front dynamics in polycrystalline thin films, Science Advances (2020). DOI: 10.1126/sciadv.aax2445

Provided by Brookhaven National Laboratory

Citation: Gold in limbo between solid and melted states (2020, March 2) retrieved 2 March 2020 from https://phys.org/news/2020-03-gold-limbo-solid-states.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.

#Physics

1 note

·

View note

Text

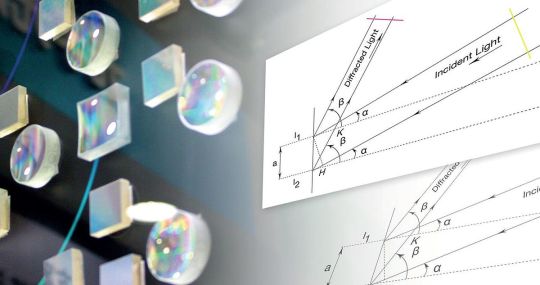

Plane Diffraction Grating

Videos For Plane Diffraction Grating

Diffraction Grating Explanation With Theory

Grating Element Of Plane Diffraction Grating

Diffraction Gratings - University Of Virginia

Plane Diffraction Grating Theory

Diffraction Grating

Diffraction Grating History Create parallel groves which enforce a phase lag with each adjacent reflection. Grooves can be transparent/opaque rulings on a transmissive material, formed by opaque lines on a mirror, or consist of tilted facets. Phase lags with integral multiples of a given wavelength interfere constructively. A diffraction grating is a periodically structure of subsequent most evenly spaced grating lines. Those grooves or opaque lines diffract the incident light depending on its periocity and microstructure. Plane ruled diffraction gratings are blazed for maximum efficiency in the first order Littrow configuration at specific wavelengths. Ruled reflection gratings are especially well suited for spectroscopic systems requiring high resolution. High efficiency at design wavelength and blaze angle.

Hitachi Diffraction Gratings Analyze a Variety of Radiations Ranging from X-rays to Infrared.

Learn2Trade is a UK-based platform specializing in educational content on trading. MYC Forex & Commodities Signals (@MYC Signals) When it comes to producing forex signals, MYC. Download Signal for Android, iOS, Linux, macOS, and Windows. Signal telegram. Telegram Forex Signals Trading is your home of profitable success rate Telegram forex signals, our members have consistently enjoyed our daily Telegram forex signals. As a way to give an opportunity for non-subscribers to benefit from our signals, we have a free Telegram Forex Signals Channel.

Hitachi diffraction gratings are adopted in a wide range of scientific and industrial fields, e.g. large spectrograph for photobiological research and Spectrophotometers for extreme ultraviolet explorer.

Videos For Plane Diffraction Grating

*

These gratings are available in North America and Europe.

Features

The diffraction gratings capable of analyzing a variety of radiations ranging from soft X-rays to far infrared are now expanding their application areas as optical elements indispensable for spectroscopy. The diffraction gratings developed by Hitachi have been used in various application areas, and are now highly evaluated as the world's foremost optical elements. For example, a total of 36 diffraction gratings having a size of 15 × 15 cm and arranged in a mosaic pattern, are adopted in the large spectrograph used in the Okazaki National Research Institutes, National Institute for Basic Biology. The spectrograph has successfully realized the world's largest artificial rainbow whose intensity is 20 times the sunlight energy right above the equator. Furthermore, the Hitachi plane diffraction gratings consisting of varied space grooves have also been adopted in the Spectrophotometers of the extreme ultraviolet explorer scheduled to be launched by NASA of the U.S.A. Hitachi has developed the reflection plane gratings and concave gratings to meet such most-advanced technological fields as exemplified above. These gratings are available in a wide variety of models to meet your diversified needs.

Large spectrograph at the Institute for Basic Biology

Diffraction Grating Explanation With Theory

Control computer

Power supply room

Condensing mirror

30 kW xenon lamp

Deflection mirror

Optical fiber room

Operation room

Illumination room

Diffraction grating

“Flying into the Rainbow' by Naoya Sakagami (In the arrival lobby of New Haneda Airport)

A tool to customize your desktop goose. Contribute to lim10dev/desktop-goose-customizer development by creating an account on GitHub. Desktop goose free. A modding launcher for the Desktop Goose by the ResourceHub project desktop-goose resourcehub resourcelauncher resourcehub-launcher desktop-goose-modding C# GPL-3.0 9.

Grating Element Of Plane Diffraction Grating

An art object representing a rainbow under the dome, which was created using the Hitachi diffraction grating parts.

*

These gratings are available in North America and Europe.

Plane Diffraction Gratings

A wide variety of high performance, mechanically-ruled diffraction gratings.

The ruling engine equipped with a highly sensitive laser interferometer is able to rule grating grooves with ultrahigh accuracy, and realizes high resolution spectroscopic instruments.

Burnishing process, by using a diamond tool, serves to form triangularly shaped echelette grooves whose surfaces are extremely smooth yielding minimum stray light.

The grooves, having an exact blaze angle, can be formed by selecting an appropriate diamond tool and measuring the groove profiles with a scanning electron microscope. These processes allow the grating to provide a highly efficient diffraction efficiency in the designed wavelength region.

Grating grooves having 2 or more different blaze anoles can be combined on a single diffraction grating. This structure allows for broader wavelength coverage.

A variety of diffraction gratings with variable spaced grooves and shapes are manufactured.

Concave Diffraction Grating

From X-rays to Infrared! Gratings can now be designed to meet specific requirements.

Coma-type aberration-corrected concave grating for high resolution Seya-amioka monochromator: This grating eliminates the coma-type aberration of the Seya-Namioka monochromator, which has been most widely used in monochromators with concave gratings that provide high resolution. Hitachi is manufacturing a wide variety of aberration-corrected gratings for Seya-Namioka monochromator which cover a wavelength range from the vacuum ultra-violet to the near infrared region.

Diffraction gratings for compact, high efficiency monochromator: These gratings are designed for normal incidence mounting. They reduce aberrations and at the same time increase the efficiency of light intensity. A as a result, a high quality of image focusing of the concave grating is available.

Diffraction gratings for flat field spectrograph: Variable space grooves enable flat-field image focusing of concave grating spectrograph. The spectrograph permits simultaneous measurement of multi-wavelength spectra when combined with a linear array detector. Gratings are designed optimally for the grazing-incidence optical system (for soft X-ray) and the normal incidence optical system (for VIS-UV ray), respectively.

Diffraction gratings for multi wavelength optical communication: A compact and efficient aberration corrected concave grating is manufactured for transmitting multiple wavelength light beams through an optical fiber and acts to separate the beams at the receiving terminal.

Diffraction gratings for soft X-rays: Highly dispersive concave gratings for grazing-incidence mounting are available especially used for synchrotron radiation and extreme ultra-violet applications. These gratings are very effective for the application of soft x-rays whose reflectance is extremely low on a metal surface.

UV-Vis/NIR Basic Course

The basics of spectrophotometer, from 'What can an ultraviolet and visible spectrophotometer Do?' to 'Structure of a spectrophotometer.'

Science & Medical Systems

Diffraction Gratings - University Of Virginia

Analytical Systems

Spectrophotometers (UV-Vis/NIR, FL)

Related Links

© Hitachi High-Tech Corporation. 2001, 2021. All rights reserved.

Plane Diffraction Grating Theory

0 notes

Text

Investigation of Temperature Effects on Microstructure of Pure Titanium - Juniper Publishers

Abstract

In this study, pure titanium powders were sintered by sealing in quartz tubes vacuumed from oxygen for 4 hours at 3 different temperatures by using powder metallurgy method. Temperature values selected for sintering of samples are 900oC, 1000oC and 1150oC respectively. SEM, EDX, XRD tests were performed for microstructure analysis of samples produced by powder metallurgy, and finally, the effects of sintering temperature on the microstructure of pure titanium were determined by measuring the Vickers hardness values of the samples. According to the results obtained, the sintering temperature has great effects on the microstructure of pure titanium. In addition, the Vickers value measured for 900 0C as 263 kgf/mm2, for 1000oC as 382 kgf/mm2 and finally 528 kgf/m m2 for 1150oC temperature sintering.

Keywords:Pure-Ti; Sintering Temperatures; Microstructure; Powder Metallurgy

Go to

Introduction

Titanium is the most widely used implant of recent years, because of its protective effect on between bond and tissue during implantation, also triggering the formation of calcium ions around it and accelerating bone formation [1]. Titanium also experiences an allotropic α-phase to β-phase transformation at a temperature of 882oC, which causes the most important mechanical properties of the metal to be changed, particularly the flexibility. There is no guarantee that the metal undergoing allotropic transformation will remain in a continuous β-phase structure [2]. When the metal descends to room temperature, all of the weak β-phase structures can be transformed into α-phase structures. This critical transformation can be vital for these metals used in human tissues and organs [3]. Also, the microstructure of titanium implants is known to have important effects on the most important parameters of the implant, such as corrosion. Even though titanium allotropic conversion begins at 882oC, a stable microstructure at this temperature may not be possible. Therefore, it is very important to discover a temperature and homogeneous microstructure in titanium metal and a temperature value in which the elevated B phase region coexists. In this case, it has been found suitable for the same metal types to increase the small sintering temperature by starting the experiment at the temperature value where allotropic conversion starts. Therefore, in this study, starting from the allotropic transformation temperature value, three pure titanium were produced at 900oC, 1000oC and 1150oC temperatures respectively. Analyses of the samples were compared by XRD, SEM, Micro Hardness measurements. In order to produce pure titanium metals, powder metallurgy has been the chosen method for the production, considering its success in producing metals with high melting temperatures.

Go to

Experimental Methods

The powders of the metals used in this study were obtained from the Nanography company. Characteristic properties of these powders are Titanium (Ti) Purity: 99.9%, Size: 100 mesh, density 4,507 g/cm3. The metal powders pressed in an 11mm diameter pellet die for 30 minutes at 20Mpa pressure. The pressed sample sintered in oxygen vacuumed environment. The sintering process was carried out at 900oC, 1000oC and 1150oC for 4 hours respectively. sintered sample is given in Figure 1.

X-ray diffraction analysis (XRD) was performed for phase analysis of Pure Titanium and Cobalt alloys produced by powder metallurgy. Measurements were made using XRD-6100 Shimadzu, XRD scanning Range (100-900), Cu X-ray tube target, voltage = 40.0 (kV) and current = 30.0 (mA) measurement details used. Scanning electron microscopy (SEM) was used to compare the sample (P/M) particle size, pore diameters, and oxide content. The surface morphology of the samples was observed using an area emission scanning electron microscope (FEI XL30 Sirion). Hardness measurements, (Micro Hardness Tester FM-310e) was used to obtain the hardness values of the surface of the samples. Hardness values were taken under 100g load for 10 sec. Hardness values were taken from 5 different points on the surface of the sample. The average of 5 Vickers values was accepted as the final hardness value.

Go to

Results and Discussion

SEM And EDX Analysis

Figure 2 shows XRD pattern of pure titanium diffractometers sintered at 900°C, 1000°C, 1150°C respectively. Accordingly, targeted Titanium diffractometers were achieved at all 3 temperatures. The XRD cards of the titanium structures obtained were found to be 00,044,1294> Ti for all 3 samples. It is seen that α-Ti (hcp) structures are transformed to β-Ti (bcc) structures with increasing sintering temperature. Finally, the final β-Ti phases are formed at 1150°C.

Figure 3 (f) An example is provided for EDX analysis of samples. As can be seen in the picture, there is a dominant Titanium peak, and there is no oxidation in samples. SEM images of pure titanium metals produced at three different temperature values (900°C, 1000°C and 1150°C) have a more stable surface morphology. Furthermore, the pore structures seen in this sample appear to be more uniform and closer to spherical geometry. It is seen that pore diameters and grain size values decrease as sintering temperature increases.

Micro Hardness Tester

The Vickers hardness tester is the test engine that least damages the sample among the material tests. Similar properties have been reported between the Vickers hardness and mechanical properties of a material. Hardness measurements, Vickers hardness Notch machine (Micro Hardness Tester FM-310e) was used to obtain the hardness values of the surface of the samples. The hardness values were taken under a load of 100g for a 10-sec holding time. Hardness values were taken from 5 different points on the surface of the sample. The average of 5 Vickers values was accepted as the final hardness value. The average hardness values were given at Table 1.

Go to

Conclusion

Pure titanium powders are produced by powder metallurgy at different temperatures. As the sintering temperature increased, the β-phase region increased in the samples, particle sizes and pore diameters decreased and finally micro hardness values increased. Homogeneous microstructure was obtained in all three samples.

To Know More About Trends in Technical and ScientificResearch Please click on: https://juniperpublishers.com/ttsr/index.php

To Know More About Open Access Journals Please click on: https://juniperpublishers.com/index.php

0 notes

Text

Preparation and Photocatalytic Activity of Co: La: Tio2 Nanocomposites for the Degradation of Methyl Blue in Visible Light Material Science-Juniper Publishers Abstract In this study, prepared the nano composites of Co: La:Tio2 by the wet chemical method. Synthesized Tio2 and Co:La:Tio2 were characterized by X-Ray Diffractometer, SEM,TEM, UV-vis, FT-IR, Band gap energy and BET. The Tio2 and Co:La:Tio2 were used as photocatalyst for the degradation of Methyl Blue. The XRD pattern confirmed the presence of anatase and rutile phase in the catalyst. The particle size was estimated by the Scherrer’s and found 68 and 32nm for Tio2 and Co: La: Tio2 respectively. The particle morphology of the photocatalysts was found in nanodiamension. The surface area of the photocatalysts were found 37.52 and 106.68m2/g for Tio2 and Co: La.Tio2 respectively. The band gap energy of Tio2 and Co: La.Tio2 were 3.2 and 3.0eV. The photo degradation of Methyl Blue has been found maximum at 5pH, 25ppm concentration of dye, 800mg/L amount of photo catalyst and 180min illumination of visible light. The photo degradation was following the first order kinetics. Keywords: Photodegradation; Photocatalyst; Photocatalysis; Methyl blue; Nanocomposite Go to Introduction Dyes are the most resistant compounds that are found in industrial waste water causing adverse environmental problems. Most of the dyes used in the pigmentation of textiles, leather, paper, ceramics, and food-processing are derived from azo dyes. Dyes are lost with waste water during synthesis and processing [1-5]. This represents a great hazard to human and environmental health due to the toxicity of azo dyes [6]. The treatment of such pollutants can be achieved by heterogeneous photo catalysis due to its efficiency and low cost as well as to the fact that it allows complete degradation of pollutants to carbon dioxide and inorganic acids [7-9]. Titanium dioxide Tio2 is a most important nanomaterial which has attracted a great attention due to its unique properties. Titanium dioxide Tio2 have excellent merits in solar energy transferring and photocatalysis of poison compounds in environment. The chemical inertness and the non-toxicity of Tio2 have also made it a superior photocatalyst [10-13]. Titania has a large band gap (3.20ev for anatase Tio2) and therefore, only a small fraction of solar light can be absorbed [14]. Many attempts have been made to sensitize titanium dioxide to the whole visible region, such as doping with transition metals [15-16], transition metal ions [17], non-metal atoms [18] and organic materials [19]. Introduction of dopant allows Titania to absorb in the visible region but this does not necessarily mean that the doped catalyst has a better photocatalytic activity (Figure 1). Click here to view Large Figure 1 In photocatalysis, light is absorbed by an adsorbed substrate. Today, semiconductors are usually selected as photocatalysts, because semiconductors have a narrow gap between the valence and conduction bands. In order for photocatalysis to proceed, the semiconductors need to absorbed energy equal to or more than its energy gap. When Tio2 is irradiated by UV light (400nm or less), electron is excited to generate electron (e_) hole (h+) pairs.This movement of electrons forms e-/h+ or negatively charged electron/positively charged whole pairs. The hole can oxidize donor molecules. In photo generated catalysis the Photocatalytic Activity (PCA) depends on the ability of the catalyst to create electron-hole pairs, which generate free radicals able to undergo secondary reactions [20-24]. Go to Methodology Synthesis of titania by wet chemical method Click here to view Large Equation 1 Synthesis of Co:La:Tio2 nanocomposite In this method, 10ml of TiCl4 solution (1000mg/l), 2ml of 0.1M Cobalt acetate, 1ml of 0.1M Lanthanum nitrate and NaOH solution (64.5g/l) was added drop wise to water with stirring. After the resulting solution reaches pH to 7, the slurry was filtered, and the filter cake of Tio2 was washed and redispersed in water to prepare 1M of Tio2 slurry. Resulting Tio2 slurry and an aqueous solution of HNO3 were refluxed at 95 °C for 2h, cooled to room temperature and neutralized with 28% of aqueous ammonia. Then, it was filtered, washed and calcined at 400 °C [25,26]. In this study, Co:La:Tio2 nanocomposites was prepared by solution impregnation method. In this method suitable quantity of prepared Tio2 (2g) was dispersed in alcoholic cobalt acetate 10% (w/v) and lanthanum nitrate 5% (w/v). The dispersion is agitated continuously for 4 hour at 80 °C temperature. After the treatment the residue was removed through filtration and was sintered for 4hour in presence of air at 600 °C by kipping it in a silica crucible inside the muffle furnace. After sintering and slow anilling to room temperature, content was taken out from furnace and was stored in air tight bottles and was used as photocatalyst [27]. Click here to view Large Equation 2 Characterization The physical properties of metal oxide semiconductor nanocomposites that may influence significantly their use as photocatalyst are dependent on nature of crystalline phase present. Thus, phase analysis is an important parameter for this study and the prepared samples were subjected to x-ray diffraction analysis on Powder X-Ray Diffractometer. The observed X-Ray diffractogram of samples were analyzed further to estimate average grain size in the sample by Scherrer’s calculation. Since the absorption of light by photocatalyst is the most crucial step in any photocatalysed reaction, and is decided primarily by the band gap energy of material. The morphology and size of the Titania particles were analyzed by Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM). Photo-degradation of dyes In this study by the photo-catalytic degradation of Methyl Blue was investigated. A solution of dye in water: alcohol (10:1V/V) was prepared and in this solution a suitable quantity of photocatalyst (100 to 800mg/L) was dispersed. The dispersion was subjected to Visible light irradiation for varying duration and after desired irradiation the residual concentration of dye in the solution was determine spectrophotometrically by taken out suitable aliquot of dispersion and removal of photocatalyst by centrifugation. For quantitative estimation of dye concentration, initially calibration curve was obtained and it was utilized to measure the concentration in different sample aliquot obtained at different time. A quantitative estimation of dye concentration spectrometric observation when recorded only at the experimental determines λ max value which is 670nm [28-30]. Go to Results Phase identification by X-ray diffraction analysis The obtained X-Ray diffraction patterns of Titania and Co:La:Tio2 are shown in Figures 2a & 2b. The observed pattern of peaks, when compared with the standard JCPDS database, suggested that, in prepared Tio2 sample, major peaks at 2θ=25.5° 37.2, 48.3, and 54.4, which can be indexed to the (101), (004), (200), and (211) crystal facets of anatase Tio2 (JCPDS File number: 21-1272). Whereas major peaks at 2θ=26.9° and 28.2° indicate the presence of rutile phase which can indexed to the (110), (121), respectively. In case of Co:La:Tio2 sample, the observed XRD pattern indicates not only a change in the peak intensity, compared to Tio2, but even the absence of some originally observed Tio2 peaks [31]. This is, probably, due to the change in the crystallinity and grain fragmentation, when the samples were wet impregnated by cobalt and Lanthanum. Click here to view Large Figure 2 Determination of crystalline size of samples The Scherrer’s calculations were attempted to know the average size of particles/grains in the samples [32]. Although, Scherrer’s calculations are only approximate in nature, but definitely provide a first-hand idea of the Crystalline size of samples, which may be quite accurate, provided the size of crystal is below 100nm. The results of Scherrer’s calculations are presented in Table 1. The results suggest Crystal size in the samples lying in nm range. Click here to view Large Table 1 Scanning electron microscopy (SEM) The morphology of the samples was investigated by scanning electron microscopy and it resumes the most interesting outcomes. 3(a) and 3(b) clearly show that both the prepared samples are obtained in nanometric dimension. The doping of cobalt and lanthanum is indicating that the particle size reduce due the penetration of cobalt and lanthanum in the lattice of titanium dioxide [33] (Figure 3). Click here to view Large Figure 3 Transmission electron microscope (TEM) TEM images were clearly displayed the morphology and particle size of neat Tio2 and Cobalt and lanthanum doped Tio2. From the Figure 4 we find that Cobalt and lanthanum doped modified Tio2 change the size of neat Tio2 significantly, as shown in Figure 4(a) & (b). The sizes of both modified and neat Tio2 are mono disperse about 100-200nm. Moreover, the crystal lattice line can be clearly found in the TEM images. The aggregations of both kinds of particles are caused by high surface energy; however, the agglomeration of the modified one is alleviated obviously compared with that of the neat [34]. Click here to view Large Figure 4 Surface Area Analysis (BET) Figure 5 shown the BET and adsorption and desorption plot for the Tio2 and Co:La:Tio2. With the help of Figure 6 we can determine the specific surface area, pore volume and average pore size of the Tio2 and Co:La:Tio2 photocatalyst. Table 2 shown the physical properties of Tio2 and Co:La:Tio2. The Tio2 modified by Cobalt and Lanthanum are fragmentation to some extent during thermal treatment, leading to a marked increase of the BET surface areas and the average pore radius size and decreasing of the pore volume [35,36]. Click here to view Large Figure 5 Click here to view Large Figure 6 Click here to view Large Table 2 UV-Vis spectra Aqueous suspensions solution of the photocatalysts was used for the UV absorption studies. The absorption spectrum of Tio2 consists of a single broad intense absorption at 384nm due to the charge-transfer from the valence band to the conduction band [37]. The undoped Tio2 showed absorbance in the shorter wavelength region while Co:La:Tio2 result showed a broad peak at 425nm in the higher wavelength (Figure 7). The impregnation of Co and La ions into Tio2 could shift optical absorption edge from UV to visible range, but prominent change in Tio2 band gap was observed [38]. Click here to view Large Figure 7 Band gap energy determination The band gap of samples was calculated by extrapolation of the (αhv)2 versus hv plots, where α is the absorption coefficient and hv is the photon energy, hv=(1239/λ) eV. The value of hv extrapolated to α = 0 gives an absorption energy, which corresponds to a band gap (Eg). Figure 8 yields an Eg value of 3.2eV for Tio2 and 3.0 for Co:La:Tio2 [39]. The slight decrease in band gap energy in case of Co:La:Tio2, is due to formation of subband level between valence band and conduction band caused impregnation of Co+2 and La+3 in Tio2 host. Click here to view Large Figure 8 Photo-degradation of Dyes The photo-catalytic degradation of Methyl Blue in the presence of Tio2 and Co:La:Tio2 has been studied. The solution of dye was prepared in 10:1 (V/V) ratio of water and alcohol. The known amount of photocatalyst 800mg/L was dispersed in the dye solution. The reaction mixture was illuminated under visible light, while kept continuously under agitation, for the different time intervals and different temperature. The residual concentration of dye in the reaction mixture was measured spectrophotometrically. The results obtained for the degradation of Methyl Blue is shown in Figure 9-11. Click here to view Large Figure 9 Click here to view Large Figure 10 Click here to view Large Figure 11 Effect of temperature: The effect of system temperature on photocatalysis has not attracted enough attention. But In present research, it is found that the temperature has a great effect on the photodegradation of Methyl Blue. The photocatalytic efficiency can be increased about 2-3 times if the temperature increased from 30 °C to 40 °C Because the solar energy include UV light, which can be used to activate the photocatalytic course, which is increase the temperature of photocatalytic system. The experiments showed that Methyl Blue were photodegraded in presence of photocatalyst and Visible light. The Methyl Blue was efficiently degraded shown in Figure 9. The obvious decrease of concentration of dye shows that the Tio2 and Co:La:Tio2 can serve as an effective photocatalyst [40]. Effect of concentration of dye: Effect of dye concentration Keeping the catalyst loading concentration constant at 800g/ liter of the dye solution, the effect of varying concentration of the dye was studied on its rate of degradation (from 25ppm to 100ppm) as given in Figure 10. With increasing concentration of Methyl Blue the rate of degradation was found to decrease. This is because as the number of dye molecules increase, the amount of light (quantum of photons) penetrating the dye solution to reach the catalyst surface is reduced owing to the hindrance in the path of light. Thereby the formation of the reactive hydroxyl and superoxide radicals is also simultaneously reduced. Thus there should be an optimum value maintained for the catalyst and the dye concentration, wherein maximum efficiency of degradation can be achieved [41]. Effect of irradiation time on photodegradation: The effect of irradiation time on the photodegradation of methyl blue has been studied in presence of Tio2 and Co:La:Tio2. The photodegradation of methyl blue was increased with increase irradiation time. The photodegradation was found maximum in case of Co:La:Tio2 for 180min irradiation of visible light. Fig.11 shows the effect of irradiation time on photocatalytic degradation of methyl blue. This is due to the interaction of dye molecule with the surface of photocatalyst as well as the time of irradiation increase the interaction increased. Therefore the photodegradation efficiency of photocatalyst was increased. Effect of pH of solution: The photodegradation reaction was also carried out under varying ph conditions from (2 to 9), by adjusting with H2 SO4 and NaOH, with Tio2 kept at constant amounts of 800mg/ L of dye solutions (Figure 12). The reaction was found to have low rates at acidic ranges of pH. While at pH 5 photodegradation was found maximum. This implies that less acidic conditions are favourable towards the formation of the reactive intermediates that is hydroxyl radicals is significantly enhanced, which further help in enhancing the reaction rate. On the other hand in highly acidic medium conditions for the formation of reactive intermediates is relatively less favorable and hence less spontaneous [42]. Click here to view Large Figure 12 Effect of photocatalyst amount: The effect of photocatalyst amount has been studied by applying the different amount (100ppm to 800ppm) of the photocatalyst. The photodegradation rate was found to increase by increasing the amount of photocatalyst. It is clear from the results shown in Fig.13, the photodegradation increased rapidly with increase of amount of Co:La:Tio2. This is due to the fact that introduction of Co2+ and La+3 the band gap energy decreased up to 3.0eV which enhance the photocatalytic activity [43]. Effect of photocatalyst: It is clear from the results shown in Figure 9-12 that both Tio2 and Co:La:Tio2 are effective photocatalyst for the degradation of Methyl Blue (MB) dye. However Co:La:Tio2 seems to be more effective as photo-catalyst for the degradation of Methyl Blue (MB). The prominent degradation of Methyl Blue was found in 3 hour study in the presence of Co:La:iO2 in comparison to the prepared Tio2 [44] (Figure 13). Click here to view Large Figure 13 Recyclability of photocatalyst The photocatalyst and Methyl Blue mixture was agitated, illuminated with visible light and after desired time, the mixture was centrifuge to remove the photocatalyst. The obtained photocatalyst was washed three times with distilled water and kept in oven for 24h at 60 °C and reused for the degradation of Methyl Blue. The photodegradation of Methyl Blue by the recyclized Photocatalyst are showing in Figure 14. The result shows that the recyclized photocatalyst efficiency is slightly decreased probably due to the loss of some active sites and decrease of collection efficiency of photon [45]. Click here to view Large Figure 14 Stability of composite photocatalyst: Some kinds of experiments were carried out to confirm the photostability of polyaniline modified Tio2 photocatalysts. The FT-IR spectra of PANI-modified Tio2 particles before and after reaction were recorded as shown in Figure 9. It is found that the shape of composite IR spectrum after photocatalytic experiment is similar to that of particles before experiment. It indicates that the structure of PANI-modified Tio2 does not change during the photo catalytic process. The PANI is very stable and is not chemically transformed to other organic compounds. It has been confirmed that the PANI-modified Tio2 shows good stability under irradiation conditions and they continue to maintain perfect photocatalytic activity also after several cycles (Figure 10). A slight decrease of photoactivity after each cycle is due to slight aggregation of nanoparticles during the catalytic process. Lowering of electron-hole recombination Photoluminescence spectra have been used to examine the mobility of the charge carriers to the surface as well as the recombination process involved by the electron-hole pairs in semiconductor particles. PL emission results from the radiative recombination of excited electrons and holes. In other words, it is a critical necessity of a good photocatalyst to have minimum electron-hole recombination. To study the recombination of charge carriers, PL studies of synthesized materials have been undertaken. PL emission intensity is directly related to recombination of excited electrons and holes. Figure 15 shows the photoluminescence spectra of synthesized photocatalysts. In the PL spectra the intensity of Tio2 is higher than Co:La:Tio2 indicating rate of recombination of e-- h+ is higher in Tio2 than that of Co:La:Tio2.The weak PL intensity of Co:La:Tio2 may arise due to the impregnation of Ni in Titania lattice, which for sub band level in band gap region of Tio2. This delays the electronsholes recombination process and hence utilized in the redox, reaction leading to improved photocatalytic activity [46]. Click here to view Large Figure 15 Hydroxyl radical formation As hydroxyl radical performs the key role for the decomposition of the organic pollutants, it is necessary to investigate the amount of hydroxyl radicals produced by each photocatalyst. In this study Terephthalic Acid (TA) has been used as a probe reagent to evaluate •OH radical present in the photoreaction pathway. Figure 16 shows the PL spectra of Tio2and Co:La:Tio2 recorded Methyl Blue solution in presence of 10- 3M Terephthalic solution. OH radical attack Terephthalic, forming 2-hydroxyl Terephthalic Acid (TAOH) which gives a fluorescence signal at 426nm. The fluorescent intensity is linearly related to the number of hydroxyl radicals formed by the photocatalysts. Higher the generation of hydroxyl radical, more will be yield of TAOH and hence more intense will be the fluorescence peak. The spectra show that the intensity of peak indicating in presence of Co:La:Tio2 higher generation of more number of hydroxyl radicals compared to Tio2 [47]. Click here to view Large Figure 16 Mechanism of photooxidation process The photocatalytic mechanism is initiated by the absorption of the photon hv with energy equal to or greater than the band gap of Tio2 (3.3eV for the anatase phase) producing an electron hole pair on the surface of Tio2 nanoparticles. An electron is promoted to the Conduction Band (CB) while a positive hole is formed in the Valence Band (VB). Excited state electrons and holes can recombine and dissipate the input energy as heat, get trapped in meta stable surface states, or react with electron donors and electron acceptors adsorbed on the semiconductor surface or within the surrounding electrical double layer of the charged particles. After the reaction with water, these holes can produce hydroxyl radicals with high redox oxidizing potential [48-50]. Depending upon the exact conditions, the holes, OH radicals, O2, H2O2 and O2 itself, When the semiconductor is illuminated with light (hυ) of greater energy than that of the band gap, an electron is promoted from the VB to the CB leaving a positive hole (h+) in the valence band and an electron (e-) in the conduction band as illustrated in Figure 17. Click here to view Large Figure 17 If charge separation is maintained, the electron and hole may migrate to the catalyst surface where they participate in redox reactions with sorbed species. Specialy, h+vb may react with surface-bound H2O or OH- to produce the hydroxyl radical and ecb- is picked up by oxygen to generate superoxide radical anion (O2-), as indicated in the following equations 6-8; Absorption of efficient photons by titania (hυ ≥ Ebg = 3.2ev) Tio2+ hυ → ecb + h+vb (6) Formation of superoxide radical anion O2 + ecb → O2- (7) Neutralization of OH- group into OH by the hole (H2O ⇔ H+ + OH-)ads + h+vb → •OH + H+ (8) It has been suggested that the hydroxyl radical (•OH) and superoxide radical anions (O2 - ) are the primary oxidizing species in the photocatalytic oxidation processes. These oxidative reactions would results in the degradation of the pollutants as shown in the following equations 9-10; Oxidation of the organic pollutants via successive attack by OH radicals R + •OH → R. + H2O (9) or by direct reaction with holes R + h+ → R+ → degradation products (10) Kinetic study The pseudo-first-order rate constant (k, min-1) for the photodegradation reaction of Methyl Blue was determined through the following relation where, k can be calculated from the plot of ln (Co/Ct) against time (t), Co and Ct denote the initial concentration and reaction concentration, respectively. ln Co/Ct =k1 t……………………………………..……………1 In addition, the linear feature of plots of ln(Co/Ct) versus time (Figure 18) indicates that this photocatalytic degradation reactions follow the pseudo-first-order rate law [51-54]. The rate constant of the photocatalysis at 30 °C is 0.04260 to 0.0234min- 1. The effect of temperature and concentration are showing in Table 3. Click here to view Large Figure 18 Click here to view Large Table 3 Thermodynamic parameter study In this section an attempt has been made to calculate different activation parameters. For this the reaction has been studied at two different temperatures and with the help of observed rate / rate constant, the energy of activation (DE*), specific rate constant (kr), entropy of activation (DS*), enthalpy of activation (DH*), free energy of activation (DG*) and Arrhenius frequency factor (A) have been computed for different reactions (Table 4) [55]. The activation parameters have been calculated with the help of following equations. Click here to view Large Table 4 DE* = value of slope x 2.303R log A = Log kr (at 35 °C ) + Ea /2.303RT ΔS* = 2.303 R(log A-13) ΔG* = Ea - TΔS* ΔH*=ΔG* + TΔS* The calculated values of various activation parameters for different redox systems are as follows: Go to Conclusion Prepared nanocomposites of Co:La:Tio2 were characterized by X-Ray Diffractometer, SEM,TEM, UV- Vis, FT-IR, Band gap energy and BET. The Tio2 and Co:La:Tio2 were used as photocatalyst for the degradation of Methyl Blue. The particle size was estimated by the Scherrer’s and found 68 and 32nm for Tio2 and Co:La:Tio2 respectively. The surface area of the photocatalysts were found 37.52 and 106.68m2/g for Tio2 and Co:La.Tio2 respectively . The band gap energy of Tio2 and Co:La. Tio2 were 3.2 and 3.0eV. The photodegradation of Methyl Blue has been found maximum at 5pH, 25ppm concentration of dye, 800mg/L amount of photocatalyst and 180min illumination of visible light. The photodegradation was following the first order kinetics. For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com/ for more details click on the juniper publishers material science

#Juniper Publishers#juniper publishers group#material science#composite materials#biological materials

0 notes

Text

Wettability modification of the AISI 304 and 316 stainless steel and glass surfaces by titanium oxide and titanium nitride coating

Publication date: 1 December 2017 Source:Surface and Coatings Technology, Volume 330 Author(s): Jorge Estrada-Martínez, José Reyes-Gasga, Ramiro García-García, Nancy Vargas-Becerril, Martín Guadalupe Zapata-Torres, Nora Violeta Gallardo-Rivas, Ana María Mendoza-Martínez, Ulises Paramo-García The improvement of the conductive and inhibitory properties of the stainless-steel electrodes used in an electrochemical environment by the application of coatings is of great interest in the field of, for example, heavy crudes, among others. And titanium-based materials, such as titanium dioxide (TiO2), titanium oxide (TiOx) and titanium nitride (TiN), are good candidates as coatings because of their anti-corrosive properties. This work reports the contact angle variation of a water drop measured on the surfaces of samples of AISI 304 and 316 stainless steel and of glass when coated with TiO2, TiOx and TiN films of approximately 600nm thick. The films were produced by sputtering by varying the power and the gas flow parameters. Chemical and structural analysis by X-ray diffraction (XRD), energy division of the characteristic x-ray spectroscopy (EDS) and selected area electron diffraction (SAED) patterns in the transmission electron microscope (TEM) confirm the presence of the TiO2, TiOx and TiN phases in the films produced. On the glass surface, the contact angle ranged from 10° (hydrophilic behavior) on uncoated glass to 92° (hydrophobic behavior) on coated glass. Coating the surface of the AISI 316 and 304 stainless steel with these films also increased the contact angle up to 90°. The TiN films roughness, measured by atomic force microscopy (AFM), and average particle size, measured by scanning electron microscopy (SEM) and TEM, favored the increment of the contact angle.

Graphical abstract

Read more from Journal of Safety Research http://ift.tt/2z1NQxq

0 notes