#softwalls

Explore tagged Tumblr posts

Text

Create a serene and cozy atmosphere in your child's nursery with white wallpaper. This clean and versatile design is perfect for adding a soft and calming touch to any kids' bedroom. Easy to apply and remove, it’s an ideal choice for a peaceful and stylish nursery decor.

#NurseryDecor#WhiteWallpaper#KidsBedroom#NurseryDesign#PeelAndStick#RemovableWallpaper#ChildrensRoom#CalmingDecor#HomeDecor#InteriorDesign#AccentWall#CreativeSpaces#SoftWalls#EasyInstallation#RenterFriendly#PlayroomDecor#KidsRoomIdeas#ElegantInteriors#StylishKidsRoom#RoomMakeover#HighQualityWallpaper#CharmingDecor#ArtisticWalls#DIYDecor#PeacefulAtmosphere#KidsWallArt#ModernKidsRoom#SimpleDecor#CleanDesign#ClassicWallpaper

0 notes

Text

Music

How Bob Dylan Viciously Cut His Competition Down to Size

THINK TWICE

In this excerpt from “Talkin’ Greenwich Village,” veteran journalist David Browne revealed how Dylan could make his fellow folk singers shrink with a “withering gaze.”

David Browne

Published Sep. 16, 2024 5:00AM EDT

Michael Ochs Archives/Getty

The below has been excerpted from Talkin' Greenwich Village: The Heady Rise and Slow Fall of America's Bohemian Music Capital ©2024 David Browne and reprinted by permission from Grand Central Publishing/ Hachette Books /Hachette Book Group.

As the scene was growing more amped up, in every way, its unofficial clubhouse remained the Kettle of Fish. But with Bob Dylan’s success and the pressure and attention that came with it, the dynamics at those gatherings began to shift. In 1964 Robert Shelton of the Times watched—with a sense of wonderment rare for such a fixture on the scene—as Dylan entered the Kettle one night with the Supremes and members of the British band the Animals, whose sulking, electrified makeover of “The House of the Rising Sun” had given the ballad an audience far beyond the coffeehouse crowd. Those pop stars were a departure from the small, insular posse Dylan generally preferred, one that protected him and, many thought, egged him on as he dissected the peers and strivers at the Kettle on any given night. For extra privacy, Guido Giampieri would close and lock the front door at a late hour.

Dylan’s gang was usually led by Bob Neuwirth, his road manager, side-kick, and would- be bodyguard. An artist by trade and education, the Ohio- born Neuwirth had attended art school in Boston, where he learned to play guitar and banjo and eventually made his way into the Village; Dylan would recall first seeing him in the audience at the Gaslight. Neuwirth’s barbed-wire gibes and hipster persona were also of a piece with Dylan’s. As a source told Rolling Stone a few years later, regarding Neuwirth’s arrival in New York in 1964, “Dylan started to change at that time. Part of it was Neuwirth; he was a real strong influence on Dylan. Neuwirth [was] stressing pride and ego, sort of saying, ‘Hold your head high, man, don’t take shit, just take over the scene.’ He was the kind of cat who could influence others, work on their egos and support those egos.” Neuwirth’s striped pants would soon be seen behind Dylan on the cover of Highway 61 Revisited, the album that announced, as much as any, that the folk revival had passed its expiration date.

Thanks to his work with Dylan on records and on stage, including playing with him at the chaotic Newport Folk Festival, Kooper was often at Dylan’s table and saw how perilous it could be for anyone in the vicinity. “If Dylan focused on you, you were in trouble,” he said. “He could out- think anybody.” David Blue was a recurring member of the posse, although, as Ramblin’ Jack Elliott would recall, he was rarely if ever the brunt of Dylan’s withering gaze or comments. “Blue had a certain kind of stature,” said Elliott. “He was a large guy, way bigger than Bob, and he had a certain composed personality.”

Talkin' Greenwich Village: The Heady Rise and Slow Fall of America's Bohemian Music Capital

Hachette Books

To Dylan biographer Anthony Scaduto, Van Ronk theorized that Dylan zeroed in on particular targets for a reason: in Van Ronk’s mind, they all wanted to “get rich,” too. Whatever the motivation, the atmosphere could be fraught. “The level of ‘rapping,’ as we called it, was tough,” said Arthur Gorson, the manager who sometimes found himself amid the Kettle gang. “People fell by the wayside. They would talk about songs and someone would say, ‘Hey, man, you can’t use that word—I used that word.’ Eric Andersen was slightly damaged by Neuwirth’s taunts.” Andersen would later pen “The Hustler” about Neuwirth and those times in that bar. In the fall of 1965, Dylan him-self would unveil “Positively 4th Street,” a stern single that sliced and diced someone—or some group—who hadn’t supported him. He never specified who, but some in the Kettle posse wondered if it were one of them.

One especially tense evening, Andersen witnessed Dylan lacing into Phil Ochs. As Dylan drifted from topical writing, Ochs fully embraced it—and was being lauded for it within their world. Reviewing Ochs’s performance at Newport in 1964, Shelton opined that he was “rivaling Bob Dylan as a pro-test spokesman.” Broadside also weighed in, commenting, “Ochs is much more deeply committed to the broadside tradition.” With one album under his belt and a second, I Ain’t Marching Anymore, due in the early months of 1965, Ochs was primed to be an even more socially conscious voice of his generation than Dylan was, and the two men had a “love- hate thing,” as Paxton put it.

At the Kettle one evening, Dylan and Ochs got into a verbal match that ended with Dylan dismissing Ochs as merely a singing journalist (which, in Dylan’s defense, wasn’t too far from the truth at that point in Ochs’s career). Andersen, who had grown close to Ochs (he had encouraged Andersen to add more verses to “Violets of Dawn”) and would often crash at the apartment where Ochs lived with his wife, Alice, was suitably offended. As Andersen observed (and Scaduto also reported), Dylan turned on Ochs another night as well: “You oughta find a new line of work, Ochs. You’re not doin’ very much in this one.” As an appalled Andersen recalled, “He said it right to Phil’s face and really insulted him, and I said, ‘Stop picking on him. Cut it out.’” Dylan, said Andersen, retorted, “Look, I’m buying all the wine here. I can say whatever I want to say. What do you want me to talk about, the sunset over the Hudson and the deep blue sea?”

For a brief period, Ochs and Dylan were both managed by Albert Grossman until Ochs felt he wasn’t receiving the attention he deserved, and late in 1965 he asked Gorson to take over. (In a poke at the name of Grossman’s company, ABG, Ochs asked Gorson to use his initials for his own management firm, which became AHG.) But Ochs had an emerging star power of his own: cov-ering his January 1966 debut at Carnegie Hall for the Times, Shelton felt that Ochs still needed some seasoning and admonished his melodies and guitar playing but noted that the audience was “predominantly teenaged.”

Later that year, in preparation for recording Pleasures of the Harbor—a lavishly produced record intended to be his moment of arrival as a full- on record-ing artist���Ochs introduced songs like “Outside of a Small Circle of Friends” and “Flower Lady” at Carnegie Hall. The latter—seemingly about a mysterious middle- aged woman who would walk into Folk City and sell bouquets of flow-ers, supposedly purloined from cemeteries—was set to one of his most sumptu-ous melodies. He and Dylan weren’t far apart in some ways: they’d both grown up with rock and roll and eventually turned to acoustic music. With Kooper adding one of his recognizable keyboard parts, Ochs even recorded a plugged-in remake of his antiwar rouser “I Ain’t Marching Anymore.” But he and Dylan remained mirror images of the Village, the acoustic and the electric, the old world and the new world, circling each other and staring each other down.

David Browne is a senior writer at Rolling Stone--and author of eight books, including ‘Talkin' Greenwich Village: The Heady Rise and Slow Fall of America's Bohemian Music Capital,’ who moved to New York to attend NYU and never left. He started covering the city's music scene long ago for the New York Daily News.

David Browne

4 notes

·

View notes

Text

Revolutionize Cleanroom Technology with Softwall Cleanrooms by Ezad Cleanroom

In the ever-evolving landscape of scientific and industrial advancements, the demand for cleanroom technology is more critical than ever. Cleanrooms are specialized environments designed to maintain a controlled level of contamination, making them indispensable in a wide range of industries, including pharmaceuticals, biotechnology, electronics, and aerospace. Ezad Cleanroom offers a breakthrough solution that has been making waves in the cleanroom industry - Softwall Cleanrooms. In this comprehensive guide, we'll explore the innovative features, benefits, and applications of Softwall Cleanrooms, highlighting how they can revolutionize your cleanroom requirements.

Understanding Softwall Cleanrooms

Softwall Cleanrooms are a cutting-edge cleanroom solution designed to provide a controlled environment for sensitive processes and research. Unlike traditional hardwall cleanrooms, they feature flexible, soft-sided walls made of durable materials such as PVC or vinyl. These soft walls are supported by a sturdy frame, which can be assembled to fit the required size and configuration of the cleanroom. The flexibility of Softwall Cleanrooms is a game-changer for businesses and industries seeking a cost-effective and adaptable solution for maintaining critical cleanliness standards.

Advantages of Softwall Cleanrooms

Cost-Efficiency: One of the most prominent advantages of Softwall Cleanrooms is their cost-efficiency. Traditional hardwall cleanrooms can be expensive to construct and maintain due to their rigid structures. Softwall Cleanrooms, on the other hand, offer a more budget-friendly alternative without compromising on cleanliness standards.

Flexibility and Customization: Softwall Cleanrooms can be tailored to fit your specific needs. The soft walls can be easily adjusted or reconfigured, making it possible to modify the cleanroom layout as your requirements change. This adaptability is ideal for businesses dealing with evolving processes and research.

Quick Installation: The installation of Softwall Cleanrooms is significantly faster compared to hardwall cleanrooms. This saves valuable time and minimizes disruptions to your operations.

Mobility: If your business requires cleanroom facilities in multiple locations or if you need to relocate your cleanroom, Softwall Cleanrooms are easily disassembled and reassembled, providing a high level of mobility.

Energy Efficiency: Softwall Cleanrooms are designed to maintain optimal environmental conditions while minimizing energy consumption. This not only reduces operational costs but also supports sustainable practices.

Cleanliness Standards: Softwall Cleanrooms are engineered to meet stringent cleanliness standards. They can effectively control particle contamination and offer ISO class options to suit various applications.

Applications of Softwall Cleanrooms

The versatility of Softwall Cleanrooms makes them suitable for a wide range of applications. Some common industries and uses include:

Pharmaceuticals: Softwall Cleanrooms are essential in pharmaceutical manufacturing to maintain sterility and prevent contamination during drug production, packaging, and research.

Biotechnology: Research and development in biotechnology require controlled environments to ensure the integrity of experiments and production processes.

Electronics: The electronics industry relies on cleanroom technology to safeguard sensitive components and ensure the quality of microelectronics manufacturing.

Aerospace: In aerospace, Softwall Cleanrooms are used for the assembly and maintenance of aerospace equipment, where precision and cleanliness are paramount.

Food and Beverage: The food and beverage industry benefits from Softwall Cleanrooms for aseptic processing, packaging, and quality control.

Medical Devices: Manufacturers of medical devices use cleanrooms to create sterile and safe products for healthcare applications.

Research and Development: Softwall Cleanrooms are essential for research facilities working on cutting-edge projects, where maintaining a controlled environment is critical.

Key Considerations for Choosing Softwall Cleanrooms

When considering the adoption of Softwall Cleanrooms, there are several crucial factors to take into account:

Cleanliness Requirements: Determine the level of cleanliness needed for your operations. Softwall Cleanrooms are available in various ISO class options, allowing you to select the one that aligns with your specific standards.

Space and Layout: Assess the available space and how you plan to configure your cleanroom. The flexibility of Softwall Cleanrooms makes them adaptable to different layouts.

Environmental Control: Consider the temperature, humidity, and other environmental factors that need to be controlled within the cleanroom. Softwall Cleanrooms can be equipped with HVAC systems to meet these requirements.

Compliance and Regulations: Ensure that your Softwall Cleanroom complies with industry-specific regulations and standards. Ezad Cleanroom can assist in designing and constructing cleanrooms that meet these requirements.

Future Expansion: Plan for future expansion or reconfiguration. Softwall Cleanrooms can be easily expanded or modified to accommodate changes in your operations.

Why Choose Ezad Cleanroom for Softwall Cleanrooms

Ezad Cleanroom has established itself as a trusted provider of cleanroom solutions, including Softwall Cleanrooms. Here's why you should choose Ezad Cleanroom:

Expertise: With years of experience in the cleanroom industry, Ezad Cleanroom has a team of experts who understand the unique requirements of different industries.

Customization: Ezad Cleanroom works closely with clients to design and build Softwall Cleanrooms that align with their specific needs and cleanliness standards.

Quality Materials: We use top-quality materials for our Softwall Cleanrooms, ensuring durability and longevity.

Compliance and Certifications: Our cleanrooms are designed to meet industry regulations and certifications, providing peace of mind for our clients.

Support and Maintenance: Ezad Cleanroom offers ongoing support and maintenance services to ensure the long-term performance of your Softwall Cleanroom.

Conclusion

In a rapidly advancing world, maintaining stringent cleanliness standards is essential for various industries. Softwall Cleanrooms by Ezad Cleanroom provide an innovative and cost-effective solution that can adapt to the changing needs of your business while upholding the highest standards of cleanliness. Whether you're in pharmaceuticals, biotechnology, electronics, aerospace, or any other industry that requires a controlled environment, Softwall Cleanrooms are the future of cleanroom technology.

Ready to Upgrade Your Cleanroom? Contact Ezad Cleanroom Today!

Don't miss out on the benefits of Softwall Cleanrooms. Contact US Ezad Cleanroom today to discuss your specific cleanroom requirements, and let us help you revolutionize your cleanroom technology. Our team of experts is ready to provide you with a customized solution that meets your unique needs and exceeds your cleanliness standards. Upgrade your cleanroom with Softwall Cleanrooms by Ezad Cleanroom and experience the difference. Contact us now for a consultation and quote!

Original Sources: https://ezadcleanrooms.blogspot.com/2023/10/revolutionize-cleanroom-technology-with.html

0 notes

Text

Discover the Cutting-Edge Advantages of Cleatech's Softwall Cleanrooms

In the realm of modern scientific and industrial advancements, precision and cleanliness are paramount. Contaminants, even those invisible to the naked eye, can spell disaster for sensitive operations, whether in electronics manufacturing, pharmaceuticals, or research laboratories. It's in this context that Cleatech, LLC, introduces its innovative Softwall Cleanrooms – a state-of-the-art solution that offers a controlled environment where cleanliness, precision, and adaptability converge.

Understanding Softwall Cleanrooms

Cleanrooms are specialized spaces designed to control and maintain low levels of airborne particles, such as dust, microbes, and aerosol particles. These controlled environments are critical in industries where even the smallest particle can disrupt processes, compromise product quality, or jeopardize research results.

Cleatech's Softwall Cleanrooms are a testament to the company's commitment to providing high-quality, flexible, and cost-effective cleanroom solutions. These modular cleanrooms are characterized by their structure, which consists of lightweight, flexible curtains or softwalls, making them an excellent choice for various industries. Let's explore the unique advantages of Cleatech's Softwall Cleanrooms.

Enhanced Contaminant Control

The primary function of a cleanroom is to control contaminants, and Cleatech's Softwall Cleanrooms excel in this regard. The softwalls are made from durable, antistatic, and non-outgassing vinyl material that effectively isolates the cleanroom environment from the surrounding space. This isolation ensures that particles, microbes, and other contaminants are kept at bay, providing the ideal environment for sensitive processes.

Modularity and Customizability

One of the standout features of Cleatech's Softwall Cleanrooms is their modular and customizable design. They can be easily installed, modified, or expanded to meet the specific requirements of a wide range of industries. Whether you need a small cleanroom for a laboratory or a larger setup for a manufacturing facility, Cleatech's Softwall Cleanrooms can be tailored to your needs.

Energy Efficiency

In addition to their adaptable design, these cleanrooms are energy-efficient. Cleatech has incorporated energy-saving features into the Softwall Cleanrooms, such as LED lighting and low-noise, high-efficiency fans. This not only reduces operational costs but also minimizes the impact on the environment.

Compliance with Industry Standards

Cleatech's Softwall Cleanrooms are designed and manufactured to meet and exceed industry standards for cleanliness and safety. They comply with ISO 14644-1 standards for air cleanliness, ensuring that your cleanroom will maintain the necessary air quality for your specific application.

Positive Pressure and Airflow Control

Maintaining the right pressure within a cleanroom is crucial for preventing contaminants from entering. Cleatech's Softwall Cleanrooms offer positive pressure environments that help keep particles out, safeguarding sensitive processes.

Airflow control is another essential factor, ensuring that contaminants are swiftly removed from the environment. Cleatech's cleanrooms are equipped with efficient HEPA or ULPA filtration systems that guarantee optimal airflow and particle removal.

Versatile Applications

Cleatech's Softwall Cleanrooms find applications in a diverse array of industries, including:

Electronics Manufacturing: For microelectronics and semiconductor manufacturing, where even a speck of dust can lead to defects.

Pharmaceutical and Biotechnology: Ideal for research, production, and packaging processes in the pharmaceutical and biotechnology sectors.

Aerospace: In the aerospace industry, cleanrooms are vital for ensuring the reliability of sensitive equipment and instruments.

Food and Beverage: Maintaining cleanliness in food processing and packaging to ensure product safety.

Research Laboratories: For scientific experiments and research that require a controlled environment.

Cost-Effective Solutions

Cleatech's Softwall Cleanrooms offer an economical solution for those seeking cleanroom environments without the high costs typically associated with traditional hard-wall cleanrooms. Their modular design, energy efficiency, and easy maintenance contribute to long-term cost savings.

Compliance with Safety Regulations

Safety is non-negotiable in cleanroom environments. Cleatech's Softwall Cleanrooms adhere to strict safety standards to protect personnel and ensure safe working conditions.

Quick Installation and Minimal Downtime

Time is often a critical factor in setting up a cleanroom. Cleatech's Softwall Cleanrooms can be installed relatively quickly, minimizing downtime for your operations. This is particularly important for industries where time-sensitive processes are involved.

Maintenance and Support

Cleatech doesn't just provide state-of-the-art Softwall Cleanrooms; they also offer comprehensive maintenance and support services. This includes regular inspections, maintenance, and any necessary repairs, ensuring that your cleanroom continues to perform at its best.

Take the Next Step Toward Precision and Cleanliness

Cleatech's Softwall Cleanrooms offer a dynamic solution for various industries that require controlled environments. Whether you're involved in electronics manufacturing, pharmaceuticals, or research, the advantages are clear: enhanced contaminant control, modularity, energy efficiency, compliance with industry standards, positive pressure, versatile applications, cost-effectiveness, safety compliance, quick installation, and dependable maintenance support.

It's time to take the next step toward precision, cleanliness, and quality in your operations. Cleatech's Softwall Cleanrooms are the answer you've been looking for. To learn more about how Cleatech can tailor a Softwall Cleanroom to your specific needs, or to request a quote, get in touch with our team of experts today.

Take the leap to cleaner, more precise processes. Contact Cleatech LLC, and experience the difference of Softwall Cleanrooms. Your success begins with our expertise.

Original Sources: https://laboratoryquipment.blogspot.com/2023/10/discover-cutting-edge-advantages-of.html

0 notes

Text

0 notes

Text

North America Cleanroom Technology Market Industry Development Challenges, Opportunities, Entry Strategies, Key Manufacturers Analysis (2021-2028)

The North America cleanroom technology market is expected to reach US$ 3,024.39 million by 2028 from US$ 1,867.88 million in 2021; it is estimated to grow at a CAGR of 7.1% during 2021–2028.

North America Cleanroom Technology Market Introduction

In essence, cleanroom technology provides a controlled atmosphere with minimized levels of contaminants, including airborne microbes and particles, dust, and aerosols, which could otherwise negatively impact operational workflows. Cleanroom Technology is a fundamental asset for industries seeking to mitigate the adverse effects of airborne pollutants and fine particles during their product manufacturing processes.

The growing application of this technology in the biopharmaceutical sector, along with continuous advancements in cleanroom technologies, is a significant factor in market growth. However, the considerable financial commitment involved in establishing and maintaining cleanroom facilities presents a limitation on the widespread adoption of cleanroom technology across North America.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/TIPRE00027213

North America Cleanroom Technology Strategic Insights

Strategic insights into the North America Cleanroom Technology market offer data-centric assessments of the industry's environment, including current trends, key market players, and specific regional characteristics. These insights provide practical guidance, enabling readers to gain a competitive advantage by identifying unserved market niches or creating differentiated value propositions. By utilizing the power of data analytics, these insights assist industry participants—whether investors, manufacturers, or other stakeholders—in anticipating market changes.

Adopting a future-oriented approach is paramount, allowing stakeholders to foresee market shifts and strategically position themselves for long-term success within this evolving region. Ultimately, impactful strategic insights empower readers to make informed decisions that enhance profitability and facilitate the achievement of their business objectives within the market.

North America Cleanroom Technology Regional Insights

The geographical scope of the North America Cleanroom Technology market defines the particular regions where a business operates and competes. A comprehensive understanding of local variations, such as differing consumer preferences (for instance, demand for specific power connectors or battery longevity), changing economic conditions, and varied regulatory frameworks, is crucial for customizing strategies to suit particular markets. Businesses can expand their market presence by identifying unserved areas or adapting their product offerings to meet local demands. A well-defined market focus enables more efficient resource allocation, targeted marketing efforts, and improved positioning relative to local competitors, ultimately driving growth within those specific target regions.

NORTH AMERICA CLEANROOM TECHNOLOGY MARKET SEGMENTATION

North America Cleanroom Technology Market: By Type

Equipment

Consumable

North America Cleanroom Technology Market: By Construction Type

Standard Cleanrooms

Hardwall Cleanrooms

Softwall Cleanrooms

Pass-through Cabinets

North America Cleanroom Technology Market: By End User

Pharmaceutical Industry

Biotechnology Industry

Medical Device Manufacturers

Hospitals

Others

North America Cleanroom Technology Market: By Country

US

Canada

Mexico

North America Cleanroom Technology Market: Company Profiles

Taikisha Ltd

Kimberly-Clark Corporation

E. I. DU PONT DE NEMOURS AND COMPANY

Labconco Corporation

Azbil Corporation

Illinois Tool Works Inc.

Alpiq Holding AG

Clean Air Products

M+W Group

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

#North America Cleanroom Technology Market#North America Cleanroom Technology Market Development#North America Cleanroom Technology Market Challenges

0 notes

Text

Controlled Environments, The Impact of Japan Cleanroom Technology

0 notes

Text

Our company, Ziebaq, designs and builds various clean rooms for businesses in multiple fields, including hardwall, softwall, modular, and more. We also offer expert Cleanroom panel repair services as part of our full range of Cleanroom services.Get more information please read this blog:

0 notes

Text

0 notes

Text

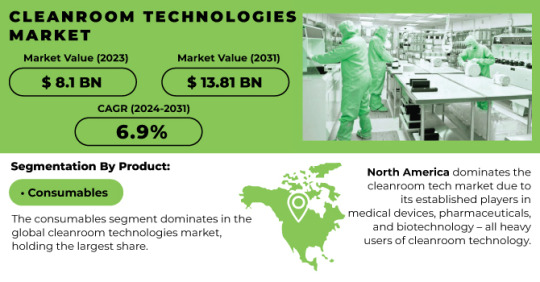

Cleanroom Technologies Market Size Forecast to Expand in 2024

The Cleanroom Technologies Market Size was valued at USD 8.1 billion in 2023 and is expected to reach USD 13.81 billion by 2031 and grow at a CAGR of 6.9% over the forecast period 2024-2031.Exploring the growth trajectory of the cleanroom technologies market reveals a dynamic landscape shaped by evolving standards and technological advancements. This niche sector, crucial across industries like pharmaceuticals, biotechnology, and electronics, is witnessing robust expansion driven by stringent regulatory requirements and the escalating demand for contamination-free environments. As companies vie to maintain impeccable manufacturing standards and ensure product integrity, innovations in cleanroom design, HVAC systems, and monitoring technologies are pivotal. The market's upward trajectory is further propelled by increasing investments in healthcare infrastructure globally, underscoring its pivotal role in safeguarding critical processes and fostering reliable production outcomes. Amidst these trends, market players are navigating towards sustainable practices and flexible solutions, underscoring a pivotal shift towards efficiency and adaptability in cleanroom operations.

Get Sample of This Report @ https://www.snsinsider.com/sample-request/2245

Market Scope & Overview

The worldwide Cleanroom Technologies Market research report includes an in-depth analysis of key market trends, company profiles, important product specifications, sales statistics, and contact information. Customers can get quantitative industry expertise by examining the most recent market data. The market research report delves deeply into the most important market trends.

During Cleanroom Technologies Market research, the impact of significant market variables such as motivators, restraints, opportunities, and threats on the industry is investigated. The underlying drivers and constraints influence global market opportunities and issues. Strategic collaborations, new product releases, initiatives, key market rivals, development factors, restrictions, and opportunities are all covered in market research.

Market Segmentation Analysis

By Product

Equipment

Fan filter

HVAC

Vacuum System

Consumables

Safety

Disinfectants

By Type

Standard Modular

Hardwall

Softwall

Mobile

By End User

Pharma

Biotech

Medtech

Hospitals

COVID-19 Impact Analysis

Participants in the market will benefit from this section of the research's representation of the market environment as a result of the COVID-19 epidemic now and in the future. The research investigates the impact of COVID-19 on global and national Cleanroom Technologies Market. The COVID-19 impact analysis will aid market participants in developing pandemic mitigation policies. This study considers the demand and supply side effects of the target market. This study relied on primary and secondary research, as well as private databases and a paid data source.

Regional Outlook

The performance of various regional markets in Asia Pacific, North America, Latin America, Europe, and the Middle East and Africa was examined in the Cleanroom Technologies Market research report. Data was gathered through focus groups, questionnaires, interviews, national and geographic research, and an all-dimensional review.

Competitive Analysis

The study investigates a wide range of critical aspects influencing firm stakeholders such as suppliers, end users, dealers, and others in order to assist them in planning investments and pursuing various Cleanroom Technologies Market growth prospects. Market, prices, positioning, primary rivals, and a comprehensive data collection plan must all be consistent. The market report also includes a wide range of future market estimates based on historical data.

Key Reasons to Purchase Cleanroom Technologies Market Report

Extensive market research that considers downstream production, upstream raw materials, and current growth expectations.

Provide a basic overview of the present state of the target industry, including applications and advancements.

Conclusion

Emerging market global business research is available, including competitive landscape studies and development trends. This market research report is an excellent resource for market participants seeking to propel their businesses to success.

About Us

SNS Insider is a market research and insights firm that has won several awards and earned a solid reputation for service and strategy. We are a strategic partner who can assist you in reframing issues and generating answers to the trickiest business difficulties. For greater consumer insight and client experiences, we leverage the power of experience and people.

When you employ our services, you will collaborate with qualified and experienced staff. We believe it is crucial to collaborate with our clients to ensure that each project is customized to meet their demands. Nobody knows your customers or community better than you do. Therefore, our team needs to ask the correct questions that appeal to your audience in order to collect the best information.

Related Reports

Angioplasty Balloon Market Analysis

Animal Genetic Market Analysis

Animal Model Market Analysis

Antibody Production Market Analysis

Anti coagulation Market Analysis

0 notes

Text

Softwall Cleanroom Solutions by Modular Cleanroom India

In today's fast-paced technological landscape, maintaining a controlled environment is crucial for various industries, including pharmaceuticals, biotechnology, electronics, and healthcare. One of the most effective solutions for creating and maintaining such environments is the use of softwall cleanrooms. Modular Cleanroom India, a leading provider in this domain, offers state-of-the-art softwall cleanroom solutions designed to meet the rigorous demands of these industries.

What is a Softwall Cleanroom?

A softwall cleanroom is a type of cleanroom characterized by flexible, soft walls made from clear vinyl or other transparent materials. These walls are typically suspended from a ceiling structure, allowing for easy installation and reconfiguration. The primary purpose of a softwall cleanroom is to provide a controlled environment with a specific level of air cleanliness, defined by the concentration of airborne particles.

Key Features of Softwall Cleanrooms

Modularity: Softwall cleanrooms are highly modular, allowing for easy expansion or reconfiguration as operational needs change. This flexibility makes them an ideal choice for dynamic industries that require frequent updates to their cleanroom environments.

Cost-Effective: Compared to traditional hardwall cleanrooms, softwall cleanrooms are more affordable, making them accessible to a broader range of businesses. The cost savings come from both the materials used and the simplified installation process.

Quick Installation: The installation of softwall cleanrooms is faster and less disruptive than that of traditional cleanrooms. This ensures minimal downtime and allows businesses to maintain productivity.

Ease of Maintenance: The materials used in softwall cleanrooms are easy to clean and maintain, ensuring that the environment remains compliant with industry standards.

Versatility: Softwall cleanrooms can be used in a variety of applications, from sensitive manufacturing processes to medical laboratories and research facilities. Their adaptability makes them suitable for different cleanroom classifications, from ISO Class 9 to ISO Class 5.

Why Choose Modular Cleanroom India?

Modular Cleanroom India (modularcleanroomindia.com) stands out as a premier provider of softwall cleanroom solutions. Here’s why:

Expertise and Experience: With years of experience in the cleanroom industry, Modular Cleanroom India has the expertise to design and deliver cleanroom solutions that meet the highest standards of performance and reliability.

Custom Solutions: Recognizing that each client's needs are unique, Modular Cleanroom India offers customized softwall cleanroom solutions tailored to specific requirements. From design to installation, the company ensures that every detail aligns with the client's operational needs.

Quality Materials: Only the highest quality materials are used in the construction of Modular Cleanroom India's softwall cleanrooms. This ensures durability, longevity, and compliance with stringent industry standards.

Comprehensive Support: Modular Cleanroom India provides end-to-end support, from initial consultation and design to installation and ongoing maintenance. Their dedicated team is committed to ensuring customer satisfaction at every stage of the process.

Innovative Solutions: Staying ahead of industry trends, Modular Cleanroom India continually innovates to provide cutting-edge cleanroom solutions. This commitment to innovation ensures that their clients benefit from the latest advancements in cleanroom technology.

Applications of Softwall Cleanrooms

Softwall cleanrooms by Modular Cleanroom India are ideal for a wide range of applications, including:

Pharmaceutical Manufacturing: Ensuring a contaminant-free environment for the production of drugs and medical devices.

Biotechnology: Providing a controlled atmosphere for sensitive biological research and production.

Electronics: Protecting electronic components from particulate contamination during manufacturing.

Healthcare: Creating sterile environments for medical procedures and research.

Conclusion

For industries that require a controlled, clean environment, softwall cleanrooms are an excellent solution. Modular Cleanroom India, with its expertise, high-quality materials, and customer-centric approach, offers some of the best softwall cleanroom solutions available. To learn more about their offerings and to explore how they can help meet your cleanroom needs, visit their website at modularcleanroomindia.com.

Invest in a softwall cleanroom from Modular Cleanroom India and ensure the highest standards of cleanliness and control in your operations.

1 note

·

View note

Text

Politics

SCOTUS Chief Justice Sidelined Alito Days After Flag Scandal

FLAGPOLE POSITION

In an unusual change to SCOTUS protocols, Roberts opted to tackle a Jan.6-related case himself.

Corbin Bolies

Media Reporter

Updated Sep. 15, 2024 1:58PM EDT Published Sep. 15, 2024 1:57PM EDT

Jabin Botsford/The Washington Post via Getty

Supreme Court Chief Justice John Roberts sidelined one of the most conservative members of the high court on a pending case just days after his wife seemingly shared support for the “Stop the Steal” movement, according to a new report.

Roberts had initially asked Justice Samuel Alito to write the majority opinion in Fischer v. United States, a case that alleged the government went too far when it charged Jan. 6 rioters with obstruction of a federal proceeding, according to The New York Times.

Then came the Times’ May 16 report on his wife Martha-Ann Alito’s aggrieved decision to fly an upside-down U.S. flag—an emblem of the “Stop the Steal” movement, and propagated by some Jan. 6 rioters—outside their home in Virginia back in 2021, less than two weeks after the Capitol attack.

Four days later, on May 20, Roberts informed the court that he would write the majority opinion after all, according to the Times.

To switch authors on an opinion without a shift in the decision was unusual, experts told the newspaper. So was Roberts’ decision to take on yet another case for himself; he had written seven cases during the court’s most recent term, five of them among its most consequential rulings.

That 6-3 majority, split mostly along ideological lines, ruled the government must prove a defendant impaired specific elements of an official proceeding and it cannot apply the statute so broadly.

It is unclear if the episodes were linked, and the justices did not respond to the Times’ questions.

Alito remained on the case and was part of that majority, even as the Times uncovered that an “Appeal to Heaven” flag (symbolism also co-opted by Jan. 6 rioters) had also been on display at the Alitos beach home in Long Beach Island, New Jersey.

Alito told the Times that the upside-down flag was raised as part of a neighborly dispute between his wife and a neighbor over the latter’s anti-Trump sign.

In response to congressional leaders calling for his recusal in late May, Alito said he asked his wife to take the flag down but “for several days, she refused,” and he claimed he was unaware of its significance.

“The two incidents you cite do not meet the conditions for recusal,” he told Democratic Sens. Dick Durbin and Sheldon Whitehouse. “As I have stated publicly, I had nothing whatsoever to do with the flying of that flag. I was not even aware of the upside-down flag until it was called to my attention.”

5 notes

·

View notes

Text

Exploring the Different Applications of Softwall Modular Cleanrooms in Various Industries

Cleanrooms play a pivotal role in ensuring controlled environments for a wide range of industries, where precision, hygiene, and contamination control are of utmost importance. In recent years, softwall modular cleanrooms have emerged as a versatile solution, offering flexibility, cost-effectiveness, and adaptability to meet the specific needs of various industries. In this blog post, we will delve into the different applications of softwall modular cleanrooms across industries, highlighting their significance in maintaining the highest standards of cleanliness and efficiency.

What are Softwall Modular Cleanrooms?

Softwall modular cleanrooms are enclosed spaces equipped with flexible, transparent vinyl curtains that serve as barriers to control the flow of air and maintain cleanliness. Unlike traditional hardwall cleanrooms, softwall cleanrooms offer greater versatility, easy installation, and the ability to expand or reconfigure the cleanroom space as needed.

Pharmaceutical and Biotechnology Industries

The pharmaceutical and biotechnology industries are among the primary users of softwall modular cleanrooms. These controlled environments are crucial for the production of medications, vaccines, and biopharmaceuticals. Softwall cleanrooms provide an aseptic space to prevent contamination and ensure the purity of products, complying with stringent regulatory requirements. Additionally, these cleanrooms are utilized in research and development, quality control, and testing processes to maintain the integrity of sensitive materials.

Microelectronics and Semiconductor Manufacturing

In the microelectronics and semiconductor industries, even the tiniest particle can compromise the performance of delicate electronic components. Softwall modular cleanrooms offer a controlled environment for wafer fabrication, assembly, and packaging processes. They maintain Class 100 to Class 1000 levels of cleanliness, reducing defects and enhancing the overall yield of semiconductor products.

Aerospace and Defense

The aerospace and defense sectors often deal with highly sensitive and complex components that require a contaminant-free environment. Softwall modular cleanrooms ensure precision in assembly, testing, and integration of aerospace equipment. They prevent dust, moisture, and other contaminants from affecting critical systems, thus enhancing the reliability and safety of aerospace technologies.

Medical Device Manufacturing

Medical device manufacturers must adhere to strict quality standards to ensure the safety and efficacy of their products. Softwall cleanrooms facilitate the production of medical devices, ensuring they are free from contaminants and sterilized to the required levels. Cleanroom environments are crucial for the assembly of devices like implants, surgical instruments, and diagnostic equipment.

Research and Laboratories

Softwall modular cleanrooms find applications in various research and laboratory settings. They create controlled environments for conducting experiments, particularly in fields like nanotechnology, life sciences, and material research. The flexibility of softwall cleanrooms allows researchers to adapt the space for different experiments and projects, optimizing resource utilization.

Optics and Photonics

In the optics and photonics industries, precise alignment and calibration are essential for producing high-quality optical components and devices. Softwall modular cleanrooms provide the necessary conditions to prevent dust particles, ensuring optical elements maintain their performance and accuracy.

Food and Beverage Processing

In food and beverage processing, maintaining a clean and hygienic environment is critical to prevent contamination and ensure product quality. Softwall modular cleanrooms are used for food preparation, packaging, and handling, safeguarding against foreign particles and microbial contaminants.

Conclusion

Softwall modular cleanrooms have revolutionized contamination control and clean environment requirements in various industries. Their adaptability, cost-effectiveness, and compliance with industry regulations make them an attractive option for diverse applications. Whether in pharmaceuticals, microelectronics, aerospace, or any other sector that demands strict cleanliness standards, softwall modular cleanrooms offer the perfect solution for creating controlled environments that safeguard both products and processes. EZAD Cleanrooms As industries continue to evolve, the role of softwall modular cleanrooms in providing optimal cleanliness and efficiency is set to become even more significant in shaping the future of manufacturing and research.

Original Sources: https://ezadcleanrooms.blogspot.com/2023/07/exploring-different-applications-of.html

0 notes

Text

Comparing the Long-Term Cost-Effectiveness of Portable Cleanrooms and Permanent Cleanroom Installations

Cleanrooms are critical environments in various industries, including pharmaceuticals, electronics, aerospace, and biotechnology. They provide a controlled atmosphere where the level of pollutants, such as dust, microbes, and chemical vapors, is minimized to ensure product quality, process efficiency, and employee safety. When it comes to setting up cleanrooms, businesses often face a pivotal decision: should they invest in permanent cleanroom installations or opt for portable cleanrooms? In this comprehensive guide provided by Cleatech LLC, we will explore the factors that influence the cost-effectiveness of both options over the long term. By the end, you'll have a clearer understanding of which cleanroom solution suits your specific needs and budget.

I. Understanding Portable Cleanrooms

Portable cleanrooms are self-contained, modular units that can be easily relocated and reconfigured as needed. These cleanrooms are constructed using prefabricated components and are designed to meet specific cleanliness levels, typically defined by ISO classes. Let's delve into the advantages and disadvantages of portable cleanrooms to understand their long-term cost-effectiveness better.

Advantages of Portable Cleanrooms:

Flexibility: Portable cleanrooms are highly adaptable. They can be resized, reconfigured, or moved to different locations within your facility or even to a new facility altogether. This adaptability ensures that your cleanroom can evolve with your changing production needs without the need for a significant reinvestment.

Rapid Deployment: One of the most significant advantages of portable cleanrooms is their quick setup time. Traditional cleanroom installations can take months to complete, while portable cleanrooms can be operational within weeks or even days. This rapid deployment can translate into faster returns on investment.

Cost Savings: Portable cleanrooms generally have a lower initial cost compared to permanent installations. This cost advantage can be especially appealing for businesses with budget constraints or those looking to allocate resources to other critical areas of their operations.

Tax Benefits: In some regions, portable cleanrooms may qualify for tax incentives or deductions as they are considered movable assets. This can further reduce the overall cost of ownership over the long term.

Disadvantages of Portable Cleanrooms:

Limited Customization: Portable cleanrooms may have limitations in terms of customization compared to permanent installations. Achieving highly specialized configurations or meeting unique requirements may be more challenging with portable units.

Limited Lifespan: While portable cleanrooms are designed for durability, they may not have the same lifespan as permanent cleanrooms, which are constructed with more robust materials. Over time, you may need to replace or refurbish portable units, incurring additional costs.

Maintenance Costs: Portable cleanrooms may require more frequent maintenance due to their modular nature. Regular inspections, repairs, and component replacements can add to the long-term cost.

II. Permanent Cleanroom Installations

Permanent cleanrooms are precisely designed and constructed facilities integrated directly into a building. They are built to withstand the test of time and are tailored to meet the most stringent cleanliness and environmental control requirements. Let's examine the advantages and disadvantages of permanent cleanroom installations in terms of long-term cost-effectiveness.

Advantages of Permanent Cleanrooms:

Longevity: Permanent cleanroom installations are built with durable materials and are expected to last for decades. This longevity can result in lower replacement and refurbishment costs over the long term.

Customization: Permanent cleanrooms offer virtually limitless customization options. They can be designed to precisely match your process requirements, ensuring optimal performance and compliance with industry standards.

High Cleanliness Levels: Permanent cleanrooms can achieve the highest cleanliness levels, making them suitable for industries with stringent contamination control needs, such as microelectronics and pharmaceuticals.

Operational Efficiency: Since permanent cleanrooms are purpose-built, they often require fewer ongoing modifications and adjustments. This can lead to lower maintenance costs and reduced downtime.

Disadvantages of Permanent Cleanrooms:

High Initial Costs: The upfront cost of designing and constructing a permanent cleanroom can be substantially higher than that of portable units. This can be a barrier for businesses with limited capital resources.

Inflexibility: Permanent cleanrooms are not easily reconfigurable or relocatable. If your production needs change or if you need to move your facility, the investment in a permanent cleanroom may become less cost-effective.

Extended Lead Times: Building a permanent cleanroom is a time-consuming process, which can delay the start of your operations and the realization of ROI.

III. Factors Influencing Long-Term Cost-Effectiveness

To determine which cleanroom solution is more cost-effective over the long term, you must consider several key factors that directly impact your budget and operational efficiency. Here's a closer look at these factors:

Initial Investment: The initial cost of setting up a cleanroom, including construction, equipment, and installation, is a crucial consideration. Portable cleanrooms generally have a lower upfront cost, making them more accessible to businesses with budget constraints.

Operating Costs: Evaluate the ongoing expenses associated with each type of cleanroom. This includes energy consumption, HVAC system maintenance, air filtration, and cleanroom gowning costs. Portable cleanrooms may have lower operating costs due to their smaller size and efficient HVAC systems.

Flexibility Requirements: Consider your need for flexibility and scalability. If your production processes frequently change or you plan to relocate in the future, portable cleanrooms offer a significant advantage. Permanent installations, on the other hand, are better suited for stable, long-term operations.

Cleanliness Levels: Assess the required cleanliness levels for your application. Permanent cleanrooms can achieve the highest ISO classes and are ideal for industries with stringent contamination control needs. However, if your requirements are less demanding, a portable cleanroom may suffice.

Tax and Regulatory Considerations: Investigate whether your region offers tax incentives or deductions for cleanroom investments. Additionally, ensure compliance with industry regulations, as failure to meet standards can result in costly fines and delays.

Maintenance and Repairs: Calculate the anticipated maintenance and repair costs for both portable and permanent cleanrooms. Portable cleanrooms may require more frequent upkeep due to their modular nature, potentially impacting long-term cost-effectiveness.

Life Cycle Analysis: Conduct a life cycle cost analysis to compare the total cost of ownership over the expected lifespan of your cleanroom. This analysis should include initial costs, operating costs, maintenance, and potential replacement or refurbishment expenses.

Business Growth and Market Trends: Consider your business's growth prospects and industry trends. If you anticipate significant growth or foresee evolving industry standards, a more flexible solution like portable cleanrooms might align better with your long-term strategy.

IV. Case Studies: Portable vs. Permanent Cleanrooms

To illustrate the cost-effectiveness of portable and permanent cleanrooms in real-world scenarios, let's explore two case studies from different industries.

Case Study 1: Pharmaceutical Manufacturing

Scenario: A pharmaceutical company needs a cleanroom for the production of sterile injectable drugs. They anticipate consistent production volumes for the next 15 years.

Comparison:

Portable Cleanroom: The company opts for a portable cleanroom, which requires a lower initial investment and allows for rapid deployment. Over the 15-year period, they spend less on construction, but maintenance costs are slightly higher due to the modular nature of the cleanroom.

Permanent Cleanroom: Building a permanent cleanroom involves a higher upfront cost and longer lead time. However, the cleanroom's durability and lower maintenance costs result in cost savings over the 15-year span.

Conclusion: In this scenario, the pharmaceutical company's stable production volume and long-term commitment make a permanent cleanroom more cost-effective in the long run, despite the higher initial investment.

Case Study 2: Semiconductor Manufacturing

Scenario: A semiconductor manufacturer expects rapid growth in production and technology advancements, necessitating frequent cleanroom reconfigurations.

Comparison:

Portable Cleanroom: The manufacturer chooses portable cleanrooms to accommodate rapid changes in production requirements. Although initial costs are lower, they incur higher relocation and maintenance expenses as they frequently reconfigure their cleanrooms over the years.

Permanent Cleanroom: While the initial investment in a permanent cleanroom is higher, the manufacturer benefits from greater operational stability, lower maintenance costs, and fewer disruptions. As they grow, the permanent cleanroom proves to be more cost-effective.

Conclusion: In this dynamic industry, the ability to adapt quickly and efficiently to changing requirements makes portable cleanrooms initially attractive. However, over time, the constant reconfiguration and maintenance costs outweigh the advantages, making permanent cleanrooms more cost-effective.

V. Tips for Making an Informed Decision

Now that you have a comprehensive understanding of the factors influencing the cost-effectiveness of portable and permanent cleanrooms, here are some tips to help you make an informed decision:

Assess Your Specific Needs: Begin by thoroughly evaluating your production requirements, cleanliness standards, and long-term growth projections. This will guide you in selecting the cleanroom type that aligns best with your objectives.

Consider ROI Timelines: Determine your expected return on investment timelines. If you need to recoup your investment quickly, portable cleanrooms may be a better choice due to their rapid deployment capabilities.

Consult with Experts: Engage with cleanroom design and construction experts who can provide valuable insights into your unique requirements and help you make an informed decision.

Perform Cost-Benefit Analysis: Conduct a detailed cost-benefit analysis that includes initial costs, operating costs, maintenance expenses, and potential future modifications or relocations.

Stay Informed About Industry Trends: Keep an eye on industry trends and regulations that may impact your cleanroom requirements. Ensure that your chosen cleanroom solution remains compliant and adaptable to future changes.

Plan for Contingencies: If you opt for a portable cleanroom, plan for contingencies such as relocation costs and potential downtime during reconfigurations. Include these factors in your cost analysis.

Explore Financing Options: Investigate financing options and incentives available in your region to make the investment more financially viable.

Prioritize Quality and Compliance: Regardless of your choice, prioritize quality and compliance with industry standards to avoid costly fines and setbacks.

Conclusion:

The decision between portable and permanent cleanrooms is a significant one with long-term implications for your business. Each option has its advantages and disadvantages, and the choice ultimately depends on your specific needs, budget, and growth projections.

Portable cleanrooms offer flexibility and rapid deployment, making them attractive for businesses with changing production requirements or limited budgets. On the other hand, permanent cleanroom installations provide durability, customization, and long-term stability, making them suitable for industries with stringent contamination control needs and stable production volumes.

By carefully evaluating your requirements, conducting a thorough cost analysis, and considering the factors discussed in this guide, you can make an informed decision that ensures the long-term cost-effectiveness of your cleanroom investment. Whether you choose portability or permanence, Cleatech LLC is here to assist you in designing and implementing the cleanroom solution that best aligns with your objectives and industry standards.

Original Sources: https://fundaily.org/2023/09/13/comparing-the-long-term-cost-effectiveness-of-portable-cleanrooms-and-permanent-cleanroom-installations/

0 notes

Text

0 notes

Text

North America Cleanroom Technology Market Size, Share, Industry Key Features, Growth Drivers (2021-2028)

The North America cleanroom technology market is expected to reach US$ 3,024.39 million by 2028 from US$ 1,867.88 million in 2021; it is estimated to grow at a CAGR of 7.1% during 2021–2028.

North America Cleanroom Technology Market Introduction

Cleanrooms are precisely controlled environments designed to minimize the presence of pollutants, including airborne microbes, particles, dust, and aerosols that can contaminate the surrounding workspace. Cleanroom Technology is fundamentally utilized across a spectrum of industries to prevent the negative impacts of airborne contaminants and microscopic particles during the production of goods.

The North American market for cleanroom technology has exhibited significant advancement, driven by the increasing adoption of cleanroom environments within manufacturing operations. Innovations in this technology, spanning high-efficiency particulate absorption (HEPA) systems, unidirectional airflow designs, and modular cleanroom solutions, are significant factors propelling market growth. A notable development in September 2019 involved a collaboration between G-CON Manufacturing and L7 Informatics, a provider of software for automation in the life sciences, to develop a fully integrated cleanroom and manufacturing software solution. This partnership involved the integration of L7's Enterprise Science Platform (ESP) into G-CON's proprietary POD cleanroom technology by the two US-based entities.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/TIPRE00027213

North America Cleanroom Technology Strategic Insights

Strategic insights into the North America Cleanroom Technology market offer a data-driven analysis of the industry landscape, encompassing current trends, key players, and regional specificities. These insights provide actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped market segments or formulating unique value propositions. By utilizing data analytics, these insights assist industry participants, including investors, manufacturers, and other stakeholders, in anticipating market shifts. A forward-looking perspective is essential, helping stakeholders in predicting market changes and positioning themselves for long-term success within this evolving region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

North America Cleanroom Technology Regional Insights

The geographic scope of the North America Cleanroom Technology market defines the specific territories in which businesses operate and compete. A comprehensive understanding of local variations, such as differing consumer preferences (e.g., demand for specific plug types or battery backup durations), diverse economic landscapes, and regulatory frameworks, is crucial for tailoring strategies to specific markets. Businesses can expand their market presence by identifying underserved areas or adapting their offerings to meet local needs. A focused market strategy allows for more efficient resource allocation, targeted marketing initiatives, and enhanced competitive positioning against local players, ultimately fostering growth within those specific regions.

NORTH AMERICA CLEANROOM TECHNOLOGY MARKET SEGMENTATION

North America Cleanroom Technology Market: By Type

Equipment

Consumable

North America Cleanroom Technology Market: By Construction Type

Standard Cleanrooms

Hardwall Cleanrooms

Softwall Cleanrooms

Pass-through Cabinets

North America Cleanroom Technology Market: By End User

Pharmaceutical Industry

Biotechnology Industry

Medical Device Manufacturers

Hospitals

Others

North America Cleanroom Technology Market: By Country

US

Canada

Mexico

North America Cleanroom Technology Market: Company Profiles

Taikisha Ltd

Kimberly-Clark Corporation

E. I. DU PONT DE NEMOURS AND COMPANY

Labconco Corporation

Azbil Corporation

Illinois Tool Works Inc.

Alpiq Holding AG

Clean Air Products

M+W Group

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

#North America Cleanroom Technology Market#North America Cleanroom Technology Market Size#North America Cleanroom Technology Market Share

0 notes