#spc software

Explore tagged Tumblr posts

Text

What is an APQP Checklist?

An Advanced Product Quality Planning (APQP) checklist is a vital tool used in various industries to ensure the systematic development of products and processes. It serves as a comprehensive guide to managing quality throughout the product lifecycle, from initial design to production and beyond.

Importance of APQP in Quality Management

APQP plays a crucial role in maintaining product quality and customer satisfaction. By following a structured approach outlined in the checklist, organizations can:

Ensure Product Quality: APQP helps in identifying potential risks and quality issues early in the product development stage, allowing for timely mitigation measures.

Reduce Defects and Rework: Through thorough planning and risk assessment, APQP aims to minimize defects and rework, thereby reducing overall production costs.

Understanding the APQP Checklist

An APQP checklist is a document that outlines the necessary steps and requirements for implementing APQP processes effectively. It typically includes:

Definition: A clear definition of APQP and its objectives.

Components of the Checklist: Sections covering various aspects such as planning, design, process validation, and production.

Benefits of Using an APQP Checklist

The utilization of an APQP checklist offers several benefits, including:

Streamlining Processes: By following a structured approach, organizations can streamline their product development and manufacturing processes.

Enhancing Communication: The checklist facilitates effective communication among cross-functional teams, ensuring everyone is aligned with project requirements.

Facilitating Risk Management: APQP checklist helps in identifying and mitigating risks early in the product lifecycle, reducing the likelihood of costly failures.

How to Develop an Effective APQP Checklist

Developing an effective APQP checklist involves several key steps:

Gathering Relevant Information: Collecting necessary data and information related to product requirements, customer expectations, and regulatory standards.

Involving Cross-Functional Teams: Engaging representatives from various departments to ensure comprehensive input and buy-in.

Establishing Clear Criteria and Metrics: Defining specific criteria and metrics for evaluating product quality and process performance.

Implementing the APQP Checklist in Different Industries

APQP principles can be applied across various industries, including:

Automotive Sector: APQP is widely used in the automotive industry to ensure the quality and safety of vehicles.

Aerospace Industry: Aerospace companies utilize APQP to meet stringent regulatory requirements and ensure the reliability of aircraft components.

Healthcare Sector: In healthcare, APQP helps in developing safe and effective medical devices and pharmaceutical products.

Common Mistakes to Avoid When Using APQP Checklist

While APQP checklist offers numerous benefits, organizations must avoid common pitfalls such as:

Lack of Stakeholder Involvement: Failure to involve key stakeholders from different departments can lead to oversight and suboptimal outcomes.

Failure to Update the Checklist Regularly: An outdated checklist may not reflect current industry standards or regulatory requirements, compromising its effectiveness.

Ignoring Feedback and Improvement Opportunities: Organizations should actively seek feedback from users and stakeholders to identify areas for improvement and refinement.

Examples of APQP Checklist Templates

There are various APQP checklist templates available, ranging from basic to advanced, tailored to specific industry requirements.

Basic Checklist Template: Includes essential steps and requirements for implementing APQP processes.

Advanced Checklist Template: Incorporates additional features such as risk assessment matrices and validation protocols.

Tips for Maximizing the Effectiveness of APQP Checklist

To derive maximum benefit from APQP checklist, organizations should:

Provide Adequate Training: Ensure that employees are trained in APQP principles and understand how to use the checklist effectively.

Regular Audits and Reviews: Conduct periodic audits and reviews to assess compliance with APQP processes and identify areas for improvement.

Continuous Improvement Initiatives: Encourage a culture of continuous improvement, where feedback is solicited, and lessons learned are applied to enhance processes.

Case Studies: Successful Implementation of APQP Checklist

Several organizations have successfully implemented APQP checklist, resulting in improved product quality and customer satisfaction.

Future Trends in APQP Checklist Development

As technology advances and industry requirements evolve, APQP checklist development is expected to incorporate:

Integration with Digital Tools: Increasing integration with digital tools and software platforms to streamline APQP processes and enhance collaboration.

Emphasis on Sustainability: Incorporating sustainability criteria and metrics into APQP checklist to address growing environmental concerns.

Conclusion

In conclusion, an APQP checklist is a valuable tool for organizations seeking to ensure product quality, minimize risks, and enhance customer satisfaction. By following a structured approach outlined in the checklist, businesses can streamline their product development processes and stay competitive in today's dynamic market.

FAQs

What is the role of APQP in quality management?

APQP plays a crucial role in maintaining product quality by identifying potential risks and quality issues early in the product development stage.

How can organizations develop an effective APQP checklist?

Developing an effective APQP checklist involves steps such as gathering relevant information, involving cross-functional teams, and establishing clear criteria and metrics.

In which industries is APQP commonly used?

APQP principles can be applied across various industries, including automotive, aerospace, and healthcare sectors.

What are some common mistakes to avoid when using an APQP checklist?

Common mistakes include lack of stakeholder involvement, failure to update the checklist regularly, and ignoring feedback and improvement opportunities.

How can organizations maximize the effectiveness of APQP checklist?

Organizations can maximize effectiveness by providing adequate training, conducting regular audits and reviews, and fostering a culture of continuous improvement.

#Software Development India#Software Company Chennai#Best Software Product Companies in Chennai#Software Service Providers in Chennai#software companies in Anna Nagar Chennai#APQP Software#ppap software#dms software#best document manager software#internal audit software#coq software#spc software#msa software#fmea software#ccm software#gcs software#vqms software#sqms software.

0 notes

Text

BREW on a Java Sprint phone?

Did you know...

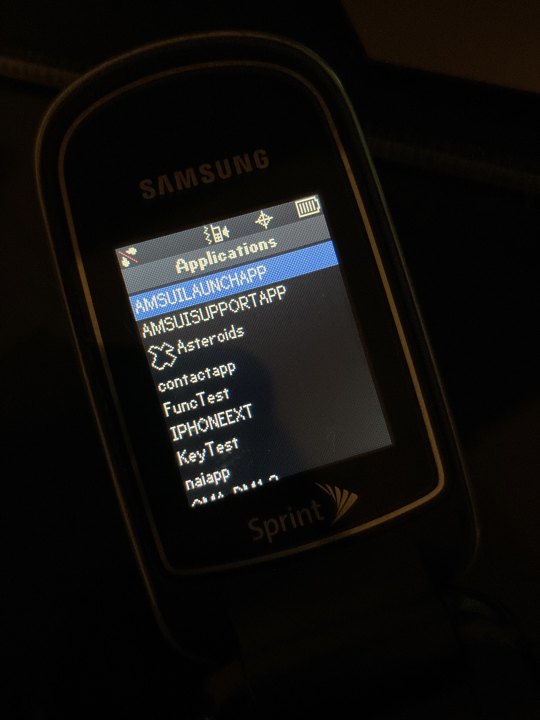

despite using Java ME for app distribution, Sprint-branded (and by extension Sprint MVNO) Samsung phones still contain traces of Qualcomm's proprietary BREW platform!

The BREW AppManager can be accessed on supported phones by dialing ##2739# and the 6-digit SPC, which can be found using an assortment of software.

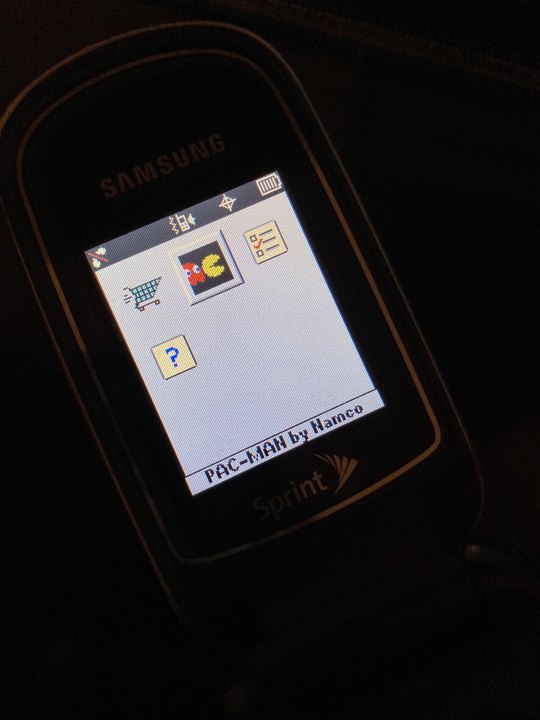

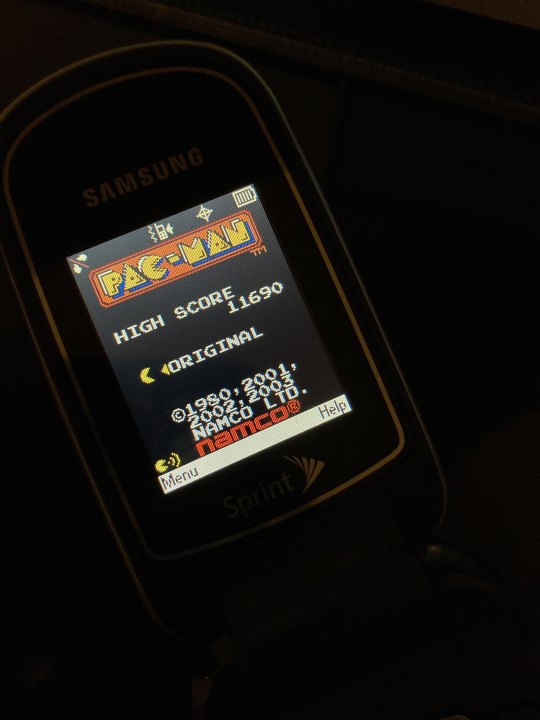

Shown above is an SPH-M240 on the stock AppManager, the modern replacement (AppUI), and a BREW 2.0 version of Pac-Man:

26 notes

·

View notes

Text

What are the main challenge does Steel industry is facing now? What are the top five key challenges and potential solutions in Steel industry?

The Tool and Die Steel industry faces several common issues that can impact productivity, quality, and overall efficiency. The top five key challenges and potential solutions:

Tool Wear and Failure: 😒Tools and Dies can experience wear and failure over time, affecting the quality of the produced parts. 👉Solution: Implement a regular maintenance schedule to inspect and replace worn-out parts. Use high-quality tool steels and coatings to enhance durability.

Material Selection: 😒 Choosing the right tool and die materials for specific applications can be challenging. 👉Solution: Conduct thorough material analysis and consider factors like hardness, toughness, and wear resistance. Collaborate with material experts to make informed decisions.

Heat Treatment Issues: 😒Inconsistent heat treatment can lead to variations in hardness and other material properties. 👉 Solution: Develop and adhere to precise heat treatment processes. Monitor and control temperature, quenching, and tempering to ensure consistent results.

Precision and Tolerance Challenges: 😒Achieving tight tolerances and precision in manufacturing can be difficult. 👉Solution: Invest in high-precision machining equipment and regularly calibrate machines. Implement quality control measures such as statistical process control (SPC) to monitor and improve tolerances.

Tool Design Complexity: 😒Complex tool and die designs can lead to increased production time and costs. 👉Solution: Utilize computer-aided design (CAD) software to streamline the design process. Optimize designs for manufacturability to reduce complexity and improve efficiency.

Addressing these common issues requires a holistic approach that combines technological innovation, skilled workforce development, and robust quality control measures.

Virat Special Steels can assess the quality, mechanical properties, structural integrity, and dimensional accuracy of their die blocks. This helps them deliver reliable and high-quality products to their customers, meeting their expectations and ensuring successful forming processes.

Contact Us Today: Ready to elevate your projects with top-quality die steel? Contact VIRAT SPECIAL STEELS PVT. LIMITED , INDIA today!

Learn More: https://www.viratsteels.com/

Any further queries feel free to contact us : Email: [email protected] or Call: +91 98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#HotWorkSteel#ToolSteel#db6steel#SteelAlloys#IndustrialMaterials#ManufacturingExcellence#MachiningSteel#SteelSupplier#H13ToolSteel

2 notes

·

View notes

Text

SPC Free Zone Company Setup: Your Complete Business Establishment Guide

Establishing your business in SPC Free Zone offers entrepreneurs a strategic gateway to the UAE market with streamlined processes and exceptional benefits.

Why Choose SPC Free Zone for Your Business?

SPC Free Zone (Sharjah Publishing City Free Zone) has evolved into a premier business destination offering competitive advantages for companies across various industries. Located strategically between Sharjah and Dubai, this free zone provides:

100% foreign ownership with no local sponsor requirements

Tax exemptions on corporate and personal income

Full profit repatriation without restrictions

Flexible office solutions from virtual to physical spaces

Efficient licensing processes with quick turnaround times

These benefits make SPC Free Zone an attractive choice for startups and established businesses looking to expand their regional presence.

Business Activities Supported

SPC Free Zone accommodates a diverse range of commercial activities, including but not limited to:

General trading and specialized commodity trading

Professional services (consulting, marketing, business services)

IT and technology solutions (software development, digital services)

Educational and training services

Creative industries (design, content production)

The free zone continues to expand its permitted activities list, making it increasingly versatile for different business models.

Step-by-Step Company Setup Process

1. Determine Your Business Activity

Verify that your intended business activity is permitted within SPC Free Zone. The administration provides clear guidelines on approved activities.

2. Select Your Company Structure

Choose between:

Free Zone Establishment (FZE): Single shareholder structure

Free Zone Company (FZCO): Multiple shareholder setup

Branch Office: For existing companies expanding to the UAE

3. Submit License Application

Prepare and submit your application with required documents:

Passport copies of shareholders

Business plan summary

Completed application forms

4. Arrange Office Space

Select from flexible options:

Virtual offices for cost-effective solutions

Flexi-desks for occasional workspace needs

Private offices for established operations

5. Complete Visa Processing

Apply for necessary visas:

Investor visas for business owners

Employee visas for staff

Dependent visas for family members

The entire setup process typically completes within 2-4 weeks, depending on document readiness and application complexity.

Required Documentation

Ensure you have these essential documents prepared:

Clear passport copies of all shareholders

Proof of address for all applicants

Business plan outlining your operations

Relevant professional qualifications (for certain activities)

Any additional documents specific to your business activity

Why SPC Free Zone Stands Out

Compared to other UAE free zones, SPC Free Zone offers distinct advantages:

Streamlined Processes: Efficient licensing and visa procedures reduce setup time

Strategic Location: Easy access to both Sharjah and Dubai markets

Growing Community: Expanding business ecosystem with networking potential

Flexible Options: Adaptable solutions for businesses of all sizes

Continuous Development: Regular addition of new permitted activities

Getting Started

With its business-friendly environment and growing infrastructure, SPC Free Zone presents an excellent opportunity for companies seeking UAE establishment. The combination of full ownership rights, tax benefits, and efficient processes makes it particularly appealing for international entrepreneurs.

Begin your SPC Free Zone company setup by consulting with business setup experts or contacting the free zone directly for the most current requirements and procedures.

0 notes

Text

Sevenlines-Fiber optic cabling companies in Dubai

Comprehensive Technology Solutions from Sevenlines: Enhancing Connectivity and Security in Dubai

At Sevenlines, we understand the importance of reliable technology infrastructure in today's fast-paced business environment. That's why we offer a range of comprehensive technology solutions, including structured cabling services, network cabling services, WiFi solutions, fiber optic cabling, and more. As a leading provider of technology solutions in Dubai, we have a proven track record of delivering high-quality services that meet the specific needs of our clients.

Structured Cabling Services in Dubai

Our structured cabling services in Dubai provide a reliable and efficient way to manage your network infrastructure. We design and install structured cabling systems that support your business operations and ensure maximum uptime. Our team of experts uses high-quality materials and equipment to ensure that our cabling systems are durable and scalable.

Network Cabling Services in Dubai

Our network cabling services in Dubai provide a secure and efficient way to connect your devices and systems. We offer a range of network cabling solutions, including design,installation, and maintenance. Our team of experts is experienced in providing network cabling services that meet the specific needs of our clients.

WiFi Solutions in Dubai

Our WiFi solutions in Dubai provide a reliable and secure way to connect your devices to the internet. We design and install WiFi systems that support your business operations and ensure maximum uptime. Our team of experts uses high-quality equipment and technology to ensure that our WiFi systems are fast and reliable.

Fiber Optic Cabling Companies in Dubai

As one of the leading fiber optic cabling companies in Dubai, we provide high-speed and reliable fiber optic cabling solutions. Our team of experts is experienced in designing and installing fiber optic cabling systems that support your business operations and ensure maximum uptime.

SIRA Approved CCTV Companies in Dubai

Sevenlines is one of the SIRA-approved CCTV companies in Dubai, providing high-quality CCTV solutions that meet the regulatory requirements of the Dubai government. Our team of experts is experienced in designing and installing CCTV systems that provide maximum security and surveillance.

Intercom System in Dubai

Our intercom systems in Dubai provide a secure and efficient way to manage access to your property. We design and install intercom systems that support your business operations and ensure maximum security. Our team of experts uses high-quality equipment and technology to ensure that our intercom systems are reliable and durable.

SPC and SVG Drawing in Dubai

Our team of experts provides SPC and SVG drawing services in Dubai, creating detailed and accurate drawings for your technology infrastructure. We use high-quality software and equipment to ensure that our drawings are precise and reliable.

PA and AV Solutions Dubai

Our PA and AV solutions in Dubai provide a reliable and efficient way to manage your public address and audio-visual systems. We design and install PA and AV systems that support your business operations and ensure maximum uptime. Our team of experts uses high-quality equipment and technology to ensure that our PA and AV systems are fast and reliable.

Best CCTV Installation Company in Dubai

Sevenlines is one of the best CCTV installation companies in Dubai, providing high-quality CCTV solutions that meet the specific needs of our clients. Our team of experts is experienced in designing and installing CCTV systems that provide maximum security and surveillance. We use high-quality equipment and technology to ensure that our CCTV systems are efficient and effective.

Get in Touch with Us If you're looking for comprehensive technology solutions in Dubai, look no further than Sevenlines.Contact us today to learn more about our services and how we can help enhance your technology infrastructure. Our team of experts is dedicated to providing high-quality services that meet the specific needs of our clients.

#structured cabling services in dubai#network cabling services in dubai#WiFi solutions in Dubai#Fiber optic cabling companies in Dubai#Sira approved cctv companies in dubai#intercom system in dubai#spc and svg drawing in dubai#pa and av solutions dubai#best cctv installation company in dubai

0 notes

Text

Key Capabilities to Look for in a High-Level Assembly (HLA) Manufacturing Partner

Introduction

Choosing the right High-Level Assembly (HLA) manufacturing partner is a vital move that could define the future success of your success of your product development, time to market, and customer satisfaction. Whether you're building complex medical devices, aerospace systems, or industrial automation units, your partner must have the technical expertise and infrastructure to deliver fully integrated, tested, and reliable assemblies.

This article outlines the key capabilities to evaluate when selecting an HLA partner, including mechanical, electrical, and software integration, quality certifications, and robust testing protocols.

1️⃣ Proven Expertise in Mechanical, Electrical, and Software Integration

A capable HLA partner should offer multi-disciplinary integration services, seamlessly combining hardware and software into a fully functional product.

🔧 Mechanical Integration

Experience with enclosures, housings, and thermal management

Precision in component alignment and structural assembly

Capability to handle miniature, complex, or heavy-duty mechanical parts

⚡ Electrical Integration

Assembly of wire harnesses, PCBs, and custom cable systems

Safe routing, insulation, and grounding of components

Knowledge of EMI/EMC management in high-speed electronics

💻 Software & Firmware Integration

Embedded software flashing and functional setup

Compatibility testing across hardware and software systems

Support for device communication protocols (e.g., USB, CAN, Wi-Fi, Bluetooth)

✅ Why it matters: Seamless integration ensures fewer failures, better performance, and faster product validation.

2️⃣ Industry-Specific Knowledge and Standards Compliance

Your HLA partner should understand the regulatory landscape and product requirements specific to your industry.

Examples of Industry Standards:

Medical Devices: ISO 13485, FDA 21 CFR Part 820

Aerospace & Defense: AS9100, MIL-SPEC, ITAR compliance

Industrial & Automation: UL certification, RoHS, CE

Electronics & Telecom: IPC/WHMA-A-620, ISO 9001

✅ Why it matters: Compliance with certifications ensures product safety, smooth global market entry, and regulatory peace of mind.

3️⃣ In-House Testing & Quality Assurance Protocols

A reliable HLA provider should offer comprehensive testing services to verify each unit before shipment.

Types of Testing to Look For:

Functional Testing (FCT): Verifies real-world functionality

In-circuit testing (ICT): Validates electronic performance and integrity

Burn-In Testing: Simulates prolonged use to detect failures

Environmental Stress Screening: Confirms performance under temperature, vibration, or humidity stress

Additional Quality Measures:

Root cause failure analysis

Documentation and traceability systems

Statistical Process Control (SPC)

✅ Why it matters: Thorough testing ensures long-term reliability and reduces the risk of costly field failures or recalls.

4️⃣ Scalable Production Capabilities

Whether you need a small pilot run or high-volume production, your partner should be able to scale operations efficiently.

Look for:

Flexible production lines for low- to high-mix assemblies

Automation capabilities for faster throughput

Supply chain management and component sourcing expertise

Inventory and warehousing support

✅ Why it matters: Scalability supports fast market entry and seamless ramp-up during product launches or demand spikes.

5️⃣ Engineering & Design for Manufacturability (DFM) Support

Top-tier HLA manufacturers offer engineering collaboration during product development.

Key Services:

Design for Manufacturability (DFM) reviews

Design for Testability (DFT) insights

Cost optimization recommendations

Rapid prototyping and iterative feedback

✅ Why it matters: Early engineering support reduces errors, shortens development cycles, and improves product performance and cost efficiency.

6️⃣ Transparent Communication and Project Management

Effective collaboration requires a partner who values clear communication and accountability.

Must-Have Traits:

Dedicated project managers

Regular status updates and milestone tracking

Open communication channels with engineering and QA teams

Responsiveness to design revisions or urgent issues

✅ Why it matters: A responsive partner ensures your project stays on track, financially controlled, and aligned with goals.

Conclusion

Selecting a high-quality, High-Level Assembly manufacturing partner is more than outsourcing—it's forming a strategic relationship. The right partner brings together engineering expertise, regulatory compliance, testing rigor, and scalability, empowering you to build complex products faster, more reliably, and more cost-effectively.

When evaluating HLA partners, prioritize those with proven cross-functional capabilities, strong quality certifications, and a collaborative approach. This will ensure that your innovations make it to market with precision, performance, and confidence.

0 notes

Text

ERP for Manufacturing: Reducing Waste, Boosting Output

The manufacturing industry is at a crossroads. Global competition, rising costs, and customer demands for faster, higher-quality production are pushing companies to evolve. The question is no longer whether manufacturers should adopt technology — but how to do it smartly.

That’s where ERP for manufacturing steps in.

Enterprise Resource Planning (ERP) systems have become the backbone of modern manufacturing, helping businesses eliminate inefficiencies, minimize waste, and maximize productivity. In this comprehensive guide, we explore how the right ERP system can reduce operational waste and boost production output, turning traditional factories into agile, data-driven powerhouses.

What Is ERP in Manufacturing?

An ERP system in manufacturing is a centralized software platform that integrates key business functions — inventory management, production planning, procurement, finance, quality control, HR, and more into a single, unified system.

Core Modules of a Manufacturing ERP:

Production Planning & Scheduling

Inventory & Warehouse Management

Supply Chain Management (SCM)

Quality Management

Bill of Materials (BOM)

Shop Floor Control

Maintenance Management

Financials & Accounting

1. Waste in Manufacturing: The Hidden Profit Killer

In lean manufacturing, “waste” refers to any activity that does not add value to the customer. This includes excess inventory, downtime, overproduction, waiting time, unnecessary motion, and defects.

Common Types of Waste ERP Can Address:

Inventory Waste: Overstocking or underutilized raw materials

Production Downtime: Machine idleness or labour delays

Defects & Rework: Quality control issues leading to scrap

Process Inefficiency: Redundant tasks and manual errors

Underutilized Assets: Poor resource planning or scheduling

2. Real-Time Visibility Across the Production Line

ERP systems offer real-time tracking and analytics that enable manufacturers to monitor every aspect of the production process.

Benefits of Real-Time ERP Data:

Immediate alerts on inventory depletion

Production line performance metrics

Machine downtime tracking

Live quality control feedback

Predictive maintenance notifications

This real-time insight empowers proactive decision-making, preventing waste before it happens.

3. Inventory Optimization: The Just-in-Time Advantage

ERP software helps manufacturers implement Just-in-Time (JIT) strategies by ensuring raw materials and components are ordered and delivered only when needed.

Key Features for Inventory Control:

Auto-replenishment rules

Supplier performance tracking

ABC inventory classification

Integrated demand forecasting

This leads to fewer carrying costs, less expired or damaged stock, and leaner operations.

4. Enhanced Production Scheduling and Planning

Effective production planning is the key to higher throughput with minimal disruption. ERP platforms provide advanced scheduling tools that align resources, labor, and equipment with production targets.

Tools That Improve Output:

Gantt chart-based production planners

Finite and infinite scheduling options

Material requirement planning (MRP)

Capacity planning and load balancing

The result? Fewer delays, optimized machine usage, and on-time delivery.

5. Quality Control and Defect Reduction

An ERP with built-in Quality Management Systems (QMS) ensures rigorous quality checks at every stage of production, reducing defects and waste.

Features Include:

Statistical Process Control (SPC)

Non-conformance tracking

Automated QA triggers

Root cause analysis

This not only reduces rework but strengthens customer satisfaction and brand reputation.

6. Cost Control Through Automation and Integration

Manual processes lead to data silos, human error, and duplicated efforts. ERP automates routine workflows, reduces paperwork, and syncs every department on a single platform.

ERP Automation Examples:

Auto-generated purchase orders

Barcode-based inventory scanning

IoT integration for equipment status

Auto-scheduling of preventive maintenance

This translates to lower operating costs and increased throughput.

7. Data-Driven Decision Making

A modern ERP offers robust analytics and dashboards to support strategic decisions.

Analytics That Matter:

OEE (Overall Equipment Effectiveness)

Cost-per-unit analysis

Waste-to-output ratio

Supplier reliability index

Downtime cause reports

Data-backed decisions improve resource utilization, supply chain resilience, and overall profitability.

8. Regulatory Compliance and Traceability

Manufacturers in sectors like pharma, food, and aerospace must maintain stringent compliance. ERP ensures audit readiness with built-in traceability and documentation.

Key Capabilities:

Batch and lot tracking

Audit trails

Document control

Regulatory reporting (FDA, ISO, etc.)

Avoid fines, recalls, and brand damage through automated compliance.

9. Scalability and Global Operations

ERP systems help manufacturers scale operations, whether expanding to new markets, adding product lines, or increasing output.

ERP Supports:

Multi-site operations

Multi-currency and multi-language features

Global supply chain orchestration

Role-based access control

This makes ERP a powerful ally for growth-focused manufacturing businesses.

10. Cloud-Based ERP: The Future of Manufacturing

Cloud ERP solutions are revolutionizing how manufacturers operate. With anytime-anywhere access, lower upfront costs, and seamless updates, cloud ERP is ideal for modern factories.

Key Advantages:

Faster implementation

Remote workforce enablement

Scalable infrastructure

Built-in cybersecurity and backups

It’s the foundation for Industry 4.0, smart factories, and IoT integration.

How to Choose the Right ERP for Your Manufacturing Business

Choosing an ERP system isn’t just about features — it’s about finding the right fit for your business model.

Key Considerations:

Industry-specific functionality

Scalability and modularity

User-friendliness and training support

Vendor reputation and support

Integration capabilities (IoT, MES, CRM, PLM)

Conclusion: ERP Is the Engine of Lean, Profitable Manufacturing

In today’s competitive environment, manufacturers can’t afford inefficiencies. An ERP system is no longer a luxury — it’s a necessity.

By streamlining operations, reducing waste, and boosting productivity, ERP software enables manufacturing companies to stay agile, profitable, and prepared for the future.

0 notes

Text

Business Operating Systems Software

Omnex Systems offers comprehensive Business Operating Systems (BOS) software designed to streamline and optimize enterprise operations. The BOS platform integrates quality, environmental, and operational management systems into a unified digital environment, enabling businesses to align strategy with execution across all levels. At the core of Omnex’s BOS software is a commitment to process efficiency and compliance with global standards such as ISO 9001, IATF 16949, ISO 14001, and ISO 45001. The software facilitates risk management, document control, audit management, and continual improvement using a centralized, cloud-based infrastructure. By digitizing traditional processes, Omnex helps organizations reduce manual effort, enhance visibility, and make data-driven decisions. What sets Omnex apart is its modular, scalable architecture, allowing businesses to tailor solutions to specific needs while maintaining alignment with corporate goals. Integration with tools like APQP/PPAP, FMEA, MSA, and SPC ensures seamless quality and supply chain management, making it ideal for industries like automotive, aerospace, and manufacturing. Omnex’s BOS software not only supports operational excellence but also fosters a culture of accountability and performance improvement. With real-time dashboards and analytics, organizations gain critical insights that drive efficiency, customer satisfaction, and long-term success. It is a strategic tool for companies committed to continuous improvement and global competitiveness. For more info visit us https://www.omnexsystems.com/products/boss-continual-improvement-software

0 notes

Text

Advance Innovation Group – Your Trusted Partner for Six Sigma Black Belt Certification

In today's data-driven, quality-focused corporate environment, the ability to improve processes, reduce variation, and drive measurable results is a highly valued skill. One of the most prestigious qualifications for professionals seeking leadership roles in quality and process improvement is the Six Sigma Black Belt Certification. If you’re looking to stand out and make a real impact in your organization, Advance Innovation Group (AIG) is the perfect place to begin your journey.

🎯 What is Six Sigma Black Belt Certification?

The Six Sigma Black Belt Certification is a globally recognized credential that equips professionals with the tools and techniques needed to lead complex improvement projects. Black Belts are experts in the DMAIC (Define, Measure, Analyze, Improve, Control) methodology and are responsible for mentoring Green Belts, analyzing data, and solving organizational problems using statistical tools.

Unlike Green Belts who typically support project work, Black Belts are leaders—managing full-scale Six Sigma projects and driving strategic improvements.

🏆 Why Choose Advance Innovation Group?

Advance Innovation Group (AIG) has established itself as a pioneer in Six Sigma and quality management training in India. With thousands of professionals trained and a stellar track record of placements and results, AIG delivers a career-transforming experience with practical, real-world training.

Here’s why professionals across industries choose AIG for their Six Sigma journey:

✅ Expert-Led Training

Our trainers are industry-certified Master Black Belts with years of hands-on project experience. They bring the perfect mix of technical knowledge and business insight to the classroom.

✅ Practical, Hands-On Learning

At AIG, you’ll work on live projects, real case studies, and apply tools like Minitab and SPC in real-time. This ensures you’re job-ready from day one.

✅ Globally Recognized Certification

AIG’s Six Sigma Black Belt Certification is acknowledged by top employers across sectors including IT, manufacturing, healthcare, logistics, and finance.

✅ Flexible Learning Modes

Whether you’re a working professional or a full-time student, AIG offers online, weekend, and in-classroom training to suit your schedule.

✅ Lifetime Support

Once you're part of the AIG community, you benefit from ongoing project support, resume assistance, mock interviews, and access to webinars and refresher sessions—absolutely free.

📘 What You Will Learn

The Six Sigma Black Belt course at AIG covers:

DMAIC methodology in-depth

Root cause analysis & problem-solving frameworks

Advanced statistical tools using software like Minitab

Hypothesis testing, ANOVA, Regression, and Control Charts

Project selection, scoping, and ROI evaluation

Lean concepts for waste elimination

Leadership, change management & stakeholder communication

This combination of technical mastery and leadership training prepares you to become a strategic asset to any organization.

👨💼 Who Should Enroll?

This course is ideal for:

Quality Managers

Business Analysts

Engineers and Project Managers

Consultants

Professionals aiming to switch to operations or strategy roles

Green Belts ready to upgrade to the next level

If you’re serious about making data-driven decisions and leading cross-functional teams, this certification is your gateway.

💼 Career Impact of Black Belt Certification

Professionals with Six Sigma Black Belt credentials often see:

Salary hikes and promotions

Greater leadership responsibilities

Job opportunities across industries

Enhanced credibility as a process improvement expert

Whether you're looking to climb the corporate ladder or transition into a consulting role, this certification sets you apart.

📞 Contact Advance Innovation Group

Ready to elevate your career?

📱 Call: +91 78386 56001 🌐 Website: www.advanceinnovationgroup.com 📍 Locations: Available Pan-India & Online

Join the ranks of top professionals who have trusted AIG for their career growth and become a Certified Six Sigma Black Belt.

🏁 Conclusion

The Six Sigma Black Belt Certification is more than a course—it’s a career catalyst. With Advance Innovation Group, you get more than just certification—you get guidance, mentorship, and a lifelong community committed to your success.

Advance Innovation Group – Building Leaders in Quality and Business Excellence.

0 notes

Text

Video Measuring System Market Drivers: Growth in Automotive Industry Boosts Need for Dimensional Accuracy

The video measuring system market is experiencing robust growth, driven by the rising demand for dimensional accuracy and non-contact measurement solutions across multiple industries. One of the most influential forces accelerating this trend is the rapid evolution of the automotive industry. As global automakers continue to push the boundaries of performance, safety, and efficiency, precise measurement technologies such as video measuring systems have become essential tools for achieving tighter manufacturing tolerances, improving product quality, and ensuring compliance with international standards.

The Role of Dimensional Accuracy in Automotive Manufacturing

In the automotive sector, dimensional accuracy plays a critical role throughout the production lifecycle—from prototyping and assembly to final inspection. Every component, whether it's an engine block, gear assembly, or a tiny electronic part, must adhere to strict dimensional specifications to ensure performance and interoperability with other parts. Any deviation can lead to functional issues, safety risks, or costly rework.

This heightened focus on precision has increased reliance on video measuring systems, which offer non-contact, high-resolution measurement capabilities. These systems use optical sensors and advanced software to capture, analyze, and compare dimensions with micrometer-level accuracy. Unlike traditional tactile measurement methods, video-based systems can measure complex geometries without damaging or altering the part, making them ideal for delicate automotive components.

Surge in Automotive Innovations and Complex Component Designs

The modern automotive landscape is undergoing a seismic shift, with the rise of electric vehicles (EVs), autonomous driving, and lightweight material technologies. These innovations demand a new level of precision in manufacturing processes. Electric powertrains, battery enclosures, sensors, and control units must all meet rigorous quality standards, which are only achievable through high-precision metrology systems like video measuring solutions.

Additionally, the use of advanced materials such as carbon fiber composites, aluminum alloys, and high-strength plastics requires different measurement approaches than those used with conventional materials. Video measuring systems enable manufacturers to adapt quickly to these materials by offering versatile, multi-sensor inspection capabilities that accommodate varying surface types and part geometries.

Meeting Regulatory and Safety Standards

As safety becomes a top priority, global regulatory bodies have introduced stringent quality control measures that demand consistent dimensional conformity across all automotive components. From crash safety regulations to fuel economy standards, adherence to these norms relies heavily on accurate dimensional measurement.

Video measuring systems are pivotal in meeting these requirements, offering robust solutions for first-article inspections, statistical process control (SPC), and continuous production monitoring. The ability to generate detailed inspection reports and traceable measurement records helps manufacturers demonstrate compliance with ISO, ASTM, and other automotive quality standards.

Automation and Smart Manufacturing Integration

The global push toward Industry 4.0 and smart manufacturing has further accelerated the adoption of automated video measuring systems in the automotive sector. These systems can be seamlessly integrated into robotic production lines, enabling real-time inspection and feedback during the manufacturing process.

With the integration of artificial intelligence (AI), machine learning algorithms, and data analytics, modern video measuring systems offer predictive insights and process optimization capabilities. This reduces downtime, minimizes human error, and improves overall productivity—all of which are essential for automotive manufacturers operating in a highly competitive global environment.

Cost Efficiency and ROI in Automotive Operations

Despite the initial investment, video measuring systems offer considerable long-term cost savings. By catching defects early in the production process, manufacturers can avoid expensive recalls, warranty claims, and customer dissatisfaction. Moreover, the speed and efficiency of video-based inspection reduce cycle times and allow for higher throughput, ultimately improving the return on investment (ROI).

In high-volume automotive manufacturing, even a small improvement in accuracy or inspection speed can translate into substantial cost reductions. The ability to inspect hundreds of parts per shift with minimal operator intervention makes these systems indispensable on the factory floor.

Global Market Trends and Regional Demand

The global video measuring system market is expected to grow steadily, fueled in part by the expansion of the automotive industry in emerging economies such as China, India, Brazil, and Southeast Asia. These regions are witnessing increased automotive production due to rising consumer demand, favorable government policies, and growing investments from international manufacturers.

North America and Europe continue to lead in technological innovation and adoption, with major automakers investing heavily in digital manufacturing technologies. Meanwhile, Asia-Pacific is quickly catching up, with a surge in demand for compact, high-speed, and AI-integrated video measuring systems.

Conclusion

The intersection of automotive innovation and dimensional accuracy requirements is one of the primary drivers of the video measuring system market. As the industry moves toward more complex designs, higher production volumes, and tighter quality controls, the need for reliable, fast, and non-contact measurement solutions becomes indispensable.

Video measuring systems are not just a support tool but a strategic investment for automotive manufacturers aiming to stay competitive, ensure safety, and meet evolving customer expectations. With continued advancements in optics, software, and automation, the market is poised for sustained growth, fueled by the relentless pursuit of precision and efficiency in automotive engineering.

0 notes

Text

What is a Quality Engineer? Roles, Responsibilities, and Skills

Introduction

Quality is at the heart of any successful product or process—and the person responsible for ensuring this quality is often a Quality Engineer. Whether it’s in manufacturing, software development, or service delivery, Quality Engineers play a vital role in making sure everything meets high standards.

What is a Quality Engineer?

A Quality Engineer (QE) is a professional focused on maintaining and improving the quality of products, services, and processes. They are responsible for identifying issues, implementing solutions, and ensuring that both production and final outcomes align with company and customer expectations. In essence, they bridge the gap between production and perfection.

Key Responsibilities of a Quality Engineer

Quality Engineers wear many hats, and their responsibilities can vary depending on the industry. Common tasks include:

Designing and implementing quality assurance protocols

Monitoring production lines or development workflows

Investigating product failures and recommending improvements

Conducting audits and inspections

Collaborating with cross-functional teams to optimize processes

They aim to reduce errors, save costs, and maintain a consistent level of excellence across the board.

Types of Quality Engineers

Depending on the industry and role, QEs can specialize in different areas:

Manufacturing Quality Engineers – Focus on assembly lines, physical products, and factory processes

Software Quality Engineers – Test applications, automate test cases, and ensure digital systems are bug-free

Mechanical or Industrial QEs – Concentrate on machinery performance and process optimization

Process Quality Engineers – Monitor and improve internal workflows and standard operating procedures

Each specialization requires domain-specific knowledge, but all share a common goal: continuous quality improvement.

Skills Required to Become a Quality Engineer

Being a successful QE requires a blend of technical and soft skills:

Analytical thinking – For troubleshooting defects and root cause analysis

Attention to detail – Small mistakes can lead to big consequences

Knowledge of QA tools and methodologies – From Six Sigma to Agile QA practices

Communication and teamwork – Collaboration is key when resolving issues across departments

Understanding of standards and compliance – Including ISO 9001, FDA regulations, or industry-specific certifications

Quality Engineers must also be comfortable working with data, identifying trends, and proposing data-driven improvements.

Tools and Technologies Used by Quality Engineers

Depending on the environment, QEs rely on various tools to streamline their tasks. These might include:

Software Testing Tools – Selenium, JUnit, Postman, or Keploy (for AI-powered API test automation)

Data Analysis Tools – Excel, Minitab, or statistical process control (SPC) software

Issue Tracking Systems – JIRA, Bugzilla, or Trello

Automation and CI/CD Tools – Jenkins, GitLab CI, or CircleCI

These tools help improve testing efficiency, automate quality checks, and monitor performance metrics in real time.

Quality Engineer vs. Quality Assurance Engineer

Although often used interchangeably, there is a subtle distinction:

A Quality Engineer is process-focused, aiming to build quality into every step of the workflow

A Quality Assurance Engineer often focuses on testing the final output, particularly in software, to ensure it meets functional and user expectations

Both roles are essential, but Quality Engineers tend to have a broader, systems-oriented perspective.

The Role of a Quality Engineer in Agile and DevOps

In Agile and DevOps environments, QEs must adapt to rapid iteration and continuous delivery. They contribute by:

Embedding quality checks within CI/CD pipelines

Creating automated tests for real-time feedback

Collaborating with developers during sprint planning

Ensuring test coverage throughout the development lifecycle

The goal is to “shift left” and catch issues early—before they become costly problems.

Certifications and Career Path

To advance in the field, professionals often pursue certifications such as:

CQE (Certified Quality Engineer) – Offered by ASQ (American Society for Quality)

ISTQB (International Software Testing Qualifications Board) – For software testing professionals

Lean Six Sigma Green/Black Belt – For process improvement and statistical control

As for career growth, QEs can move into roles such as Quality Managers, Compliance Officers, or even CTOs in tech-driven organizations.

Why Companies Need Quality Engineers

The value of a Quality Engineer extends beyond just finding bugs or defects. Companies rely on them to:

Ensure regulatory compliance

Improve product reliability

Enhance customer satisfaction

Reduce rework and waste

Drive innovation in quality processes

In industries like healthcare, finance, and manufacturing, the role is critical to brand reputation and operational excellence.

Conclusion A Quality Engineer isn’t just a tester—they’re a proactive, strategic contributor who ensures that quality is embedded into every part of a product or process. From reducing production defects to automating software testing, QEs help teams deliver excellence consistently. As industries continue to evolve, the need for talented Quality Engineers will only grow stronger.

0 notes

Text

#Software Development India#Software Company Chennai#Best Software Product Companies in Chennai#Software Service Providers in Chennai#software companies in Anna Nagar Chennai.#APQP Software#ppap software#dms software#best document manager software#internal audit software#coq software#spc software#msa software#fmea software#ccm software#gcs software#vqms software#sqms software.

0 notes

Text

Jasa Setting HT Program Chanel Toko BSD Tangerang Tlp/Wa 0813-1729-4744

Kami menerima Setting Handy Talkie seperti : WLN, BAOFENG,MOTOROLA, SPC, SCOM COMTECK dan Masih Banyak Lainnya Biaya Setting HT : 25.000/Biji

Secara garis besarnya, cara setting HT WLN KD C1 nantinya dilakukan menggunakan sebuah aplikasi atau software pemrograman dari laptop maupun komputer (PC). Melalui aplikasi tersebut, nantinya seseorang bisa melakukan beragam pengaturan seperti menambah frekuensi dan lain sebagainya.

Maka dari itu, apabila di antara kalian ingin mensetting HT WLN KD C1, ada baiknya cari tahu terlebih dahulu bagaimana tata cara melakukannya. Nah, pada kesempatan kali ini kami akan menjelaskan mengenai cara setting HT WLN KD C1 lewat laptop atau komputer disertai tahapan persiapannya.

0 notes

Text

What Industries Benefit Most from Implementing SAFe SPC Training Professionals?

Introduction :-

In an era of rapid technological advancements and shifting market demands, organizations across industries are turning to Agile methodologies to enhance efficiency, adaptability, and value delivery. The SAFe Program Consultant (SPC) certification equips professionals with the skills to lead Agile transformations, train teams, and implement the Scaled Agile Framework (SAFe) effectively. While SAFe is applicable across various sectors, certain industries benefit significantly from employing SPC-trained professionals due to their complexity, scale, and need for continuous improvement. This blog explores the industries that gain the most from implementing SAFe SPC training professionals.

Why SAFe SPC Certification Matters

The SAFe SPC certification prepares professionals to guide organizations through large-scale Agile transformations by leveraging Lean-Agile principles. SPCs act as change agents who train teams, launch Agile Release Trains (ARTs), and align organizational goals with customer needs. Their expertise is critical in industries where streamlined processes, collaboration, and adaptability are essential for success.

Industries That Benefit Most from SAFe SPC Professionals

1. Information Technology (IT) and Software Development

The IT sector is one of the primary beneficiaries of SAFe SPC training. With complex projects involving multiple teams, tight deadlines, and frequent changes in requirements, SAFe provides a structured framework for scaling Agile practices across large enterprises. SPCs help:

Align development teams with business goals.

Facilitate faster delivery through Agile Release Trains.

Improve collaboration between technical and non-technical stakeholders.

2. Manufacturing

Manufacturing companies benefit immensely from Lean principles embedded in SAFe. SPCs play a crucial role in optimizing production workflows, reducing waste, and ensuring quality control. By implementing SAFe practices:

Organizations can streamline supply chain management.

Teams can align production schedules with customer demand.

Continuous improvement initiatives can reduce defects and enhance efficiency.

3. Healthcare

The healthcare industry faces unique challenges such as regulatory compliance, patient-centric care, and technological integration. SPCs help healthcare organizations adopt SAFe to:

Streamline processes like patient data management and treatment workflows.

Ensure compliance with industry standards while maintaining agility.

Foster collaboration between medical staff, IT teams, and administrative departments.

4. Finance and Banking

Financial institutions operate in highly regulated environments that demand precision, security, and adaptability. Implementing SAFe with the guidance of SPCs enables these organizations to:

Accelerate digital transformation initiatives.

Enhance customer experiences through faster product delivery.

Maintain compliance while innovating financial services.

5. Telecommunications

The telecom industry requires agility to manage vast networks, launch new services, and address customer demands swiftly. SPCs help telecom companies:

Coordinate cross-functional teams for seamless service delivery.

Optimize network operations using Lean principles.

Drive innovation in areas like 5G deployment and IoT integration.

6. Retail and E-Commerce

In retail and e-commerce, customer satisfaction hinges on speed and adaptability. SAFe-trained SPCs enable businesses to:

Align marketing campaigns with inventory management systems.

Improve responsiveness to market trends through Agile planning.

Deliver enhanced shopping experiences by integrating technology seamlessly.

7. Automotive

The automotive industry benefits from SAFe’s focus on Lean product development cycles. SPCs help automotive companies:

Manage complex supply chains efficiently.

Accelerate innovation in areas like electric vehicles and autonomous driving.

Ensure alignment between design teams, manufacturing units, and suppliers.

How SPC Professionals Drive Success Across Industries

1. Leadership in Agile Transformations

SPCs act as leaders who guide organizations through the complexities of scaling Agile practices across departments. Their ability to train teams and align stakeholders ensures smoother transitions during transformations.

2. Enhanced Collaboration

By implementing SAFe’s structured approach to collaboration, SPCs foster better communication between teams—reducing silos and enabling faster decision-making.

3. Continuous Improvement

SPCs embed a culture of relentless improvement within organizations by leveraging metrics like flow efficiency, throughput, and predictability.

4. Value Delivery at Scale

SPCs ensure that organizations deliver maximum value by aligning processes with customer needs while maintaining quality standards.

Conclusion

Industries such as IT, manufacturing, healthcare, finance, telecommunications, retail, and automotive stand to gain significant advantages from employing SAFe SPC professionals. These experts bring the skills needed to navigate complex transformations while driving efficiency, collaboration, and continuous improvement.

As businesses increasingly adopt Agile methodologies at scale, investing in SPC training for employees becomes a strategic move to stay competitive in today’s dynamic market landscape. Whether you’re part of a tech startup or a global enterprise, leveraging the expertise of certified SAFe Program Consultants can propel your organization toward greater agility and success!

0 notes

Text

SAFe Practice Consultant SAFe-SPC 6.0 Questions and Answers

Preparing for the SAFe Practice Consultant (SAFe-SPC) 6.0 Exam can be a challenging task, but with the right resources, you can ensure success. The latest SAFe Practice Consultant SAFe-SPC 6.0 Questions and Answers from Cert007 provide an up-to-date and comprehensive way to get well-prepared. Cert007 offers real exam-style questions and expert insights to help you pass your certification on the first attempt. Whether you are a beginner or an experienced Agile professional, these resources will significantly enhance your knowledge and confidence.

What is the SAFe Practice Consultant (SPC) Certification?

The SAFe Practice Consultant (SPC) certification is designed for Agile professionals who act as change agents in implementing SAFe (Scaled Agile Framework) in organizations. These individuals bring in-depth technical expertise and leadership skills to drive business agility, improve software delivery, and create lean-agile business processes.

SPCs come from various backgrounds, including:

Business and technology leadership

Portfolio, program, and project management

Process leads and Agile coaches

Architects and analysts

External consultants and transformation leaders

By earning this certification, you demonstrate your ability to implement SAFe at an enterprise level and lead Agile transformations effectively.

SAFe-SPC 6.0 Exam Details

Before diving into study strategies, it’s important to understand the structure of the exam. Exam Component Details Duration 120 minutes Number of Questions 60 Passing Score 80% Delivery Web-based, closed book, no outside assistance Cost First attempt included in course registration fee (if taken within 30 days) Retake Fee $250 Retake Policy - 1st Retake: Immediately after failure - 2nd Retake: After 10 days - 3rd Retake: After 30 days - Further Retakes: 30-day wait required

Since the SAFe-SPC 6.0 Exam is challenging, it’s crucial to study strategically using real exam questions like those from Cert007 to ensure success on the first attempt.

Exam Domains and Key Topics

The SAFe-SPC exam covers multiple domains that test your knowledge of SAFe principles, Agile leadership, portfolio management, and transformation strategies. Let’s explore these domains in detail:

1. Thriving in the Digital Age and Business Agility (4-6%)

Understanding how businesses must adapt in the digital era

The role of SAFe in driving business agility

Core competencies required for a successful Agile transformation

2. Becoming a Lean-Agile Leader (12-14%)

Adopting a Lean-Agile Mindset

Implementing SAFe Core Values and Principles

Creating an Agile culture through leadership

3. Establishing Team and Technical Agility (4-6%)

Building cross-functional Agile teams

Ensuring built-in quality in Agile development

Organizing Agile Release Trains (ARTs) to optimize value delivery

4. Building Solutions with Agile Product Delivery (15-17%)

Applying Customer-Centricity and Design Thinking

Prioritizing the ART Backlog

Program Increment (PI) Planning for iterative delivery

Continuous Delivery Pipeline and DevOps practices

5. Exploring Lean Portfolio Management (9-11%)

Aligning the Portfolio Strategy with Enterprise Goals

Managing Lean Budgets and Guardrails

Creating an Efficient Portfolio Flow

6. Leading the Change (4-6%)

Becoming a transformational leader

Understanding the SAFe Implementation Roadmap

7. Reaching the SAFe Tipping Point (2-4%)

Establishing a clear Vision for Change

Building a Powerful Guiding Coalition

8. Designing the Implementation (7-9%)

Identifying Value Streams and Agile Release Trains (ARTs)

Developing an effective Implementation Plan

9. Launching an Agile Release Train (4-6%)

Preparing teams for the ART launch

Training Agile teams for success

10. Coaching ART Execution (5-7%)

Providing ongoing coaching to Agile teams

Using Inspect and Adapt to drive continuous improvement

11. Enhancing the Portfolio (9-11%)

Scaling SAFe across the organization

Implementing Lean Governance and Agile Portfolio Operations

12. Accelerating to Business Agility (10-12%)

Establishing an Organizational Learning Culture

Measuring and growing Agile maturity

How to Prepare for the SAFe-SPC 6.0 Exam?

1. Study with Cert007’s Latest SAFe-SPC 6.0 Questions and Answers

Using real exam questions from Cert007 gives you an advantage by familiarizing you with exam patterns and helping you practice real-world scenarios.

2. Understand SAFe Principles Thoroughly

Study the SAFe framework, principles, and implementation roadmap

Focus on Lean-Agile leadership and Agile Release Trains (ARTs)

3. Take Practice Tests

Use mock exams to assess your readiness

Identify weak areas and improve them before taking the real exam

4. Join SAFe Study Groups and Forums

Engage in discussions with certified SPCs

Learn from others’ experiences and exam tips

5. Attend SAFe Training and Workshops

Get hands-on experience with case studies and real-world implementations

Final Thoughts

Becoming a SAFe Practice Consultant (SPC) is a significant achievement that positions you as a key change agent in Agile transformations. To pass the SAFe-SPC 6.0 Exam, it’s essential to:

��� Use updated questions and answers from Cert007

✅ Master the SAFe framework and Agile principles

✅ Take practice tests and assess your knowledge

✅ Participate in SAFe workshops and discussions

With the right study approach and resources, you can confidently ace your certification and take your Agile career to the next level.

0 notes

Text

General Introduction of SCARA cobots Used in Quality Inspection

SCARA (Selective Compliance Assembly Robot Arm) cobots are increasingly being used in quality inspection applications due to their precision, speed, and flexibility. Here are some key applications of SCARA cobots in quality inspection: Key applications of SCARA cobots in quality inspection 1. Visual Inspection - Defect Detection: SCARA cobots equipped with high-resolution cameras and machine vision systems can inspect products for defects such as scratches, cracks, or misalignments. - Dimensional Accuracy: They can measure dimensions of parts to ensure they meet specified tolerances. 2. Surface Inspection - Texture and Finish: SCARA cobots can be used to inspect the surface texture and finish of products, ensuring they meet quality standards. - Coating Thickness: They can also measure the thickness of coatings or paints applied to surfaces. 3. Assembly Verification - Component Presence: SCARA cobots can verify the presence and correct placement of components in an assembly. - Torque and Force Measurement: They can be equipped with sensors to measure the torque and force applied during assembly, ensuring proper fastening. 4. Electrical Testing - Continuity and Resistance: SCARA cobots can perform electrical tests such as continuity and resistance checks on PCBs and other electronic components. - Functional Testing: They can also be used to perform functional tests on electronic devices to ensure they operate correctly. 5. Leak Testing - Pressure Decay: SCARA cobots can be used to perform leak tests by measuring pressure decay in sealed components. - Bubble Testing: They can also be used to detect leaks by submerging components in a liquid and looking for bubbles. 6. Laser Scanning - 3D Scanning: SCARA cobots equipped with laser scanners can create 3D models of parts and compare them to CAD models to detect deviations. - Profile Measurement: They can also measure the profile of parts to ensure they match the required specifications. 7. Sorting and Grading - Quality Grading: SCARA cobots can sort products based on quality grades determined by inspection criteria. - Defective Product Removal: They can also remove defective products from the production line. 8. Data Collection and Analysis - Real-Time Monitoring: SCARA cobots can collect inspection data in real-time and feed it into a central system for analysis. - Statistical Process Control (SPC): They can be integrated with SPC software to monitor and control the quality of the manufacturing process. Advantages of Using SCARA Cobots in Quality Inspection: - High Precision: SCARA cobots offer high repeatability and accuracy, essential for quality inspection tasks. - Speed: They can perform inspections quickly, increasing throughput. - Flexibility: SCARA cobots can be easily reprogrammed for different inspection tasks, making them versatile. - Consistency: They provide consistent inspection results, reducing human error. - Integration: SCARA cobots can be easily integrated into existing production lines and work alongside human operators. Challenges during SCARA applications: - Initial Setup: Setting up a SCARA cobot for quality inspection can require significant initial investment and expertise. - Complexity: Some inspection tasks may require advanced programming and integration with other systems. - Maintenance: Regular maintenance is required to ensure the cobot operates at peak performance. Overall, SCARA cobots are a valuable tool in quality inspection, offering a combination of precision, speed, and flexibility that can significantly enhance the quality control process in manufacturing. End-of-Arm Tooling (EOAT) is a critical component in SCARA cobot applications, especially in quality inspection tasks. The choice of EOAT depends on the specific inspection requirements, such as the type of inspection (visual, dimensional, surface, etc.), the nature of the product, and the environment. Below are some common EOAT types used in SCARA cobot quality inspection applications: 1. Vision Systems (Cameras and Sensors) - High-Resolution Cameras: Used for visual inspection tasks like defect detection, component presence verification, and dimensional measurement. - 3D Cameras: For capturing depth information and performing 3D scanning or profile measurements. - Infrared (IR) Cameras: For thermal inspections or detecting heat-related defects. - Laser Scanners: For precise 3D scanning, surface profiling, and dimensional accuracy checks. 2. Probes and Sensors - Contact Probes: Used for tactile measurements, such as checking dimensions, surface roughness, or alignment. - Force/Torque Sensors: For measuring applied force or torque during assembly verification or functional testing. - Ultrasonic Sensors: For detecting internal defects or measuring material thickness. - Laser Displacement Sensors: For non-contact measurement of distances, thicknesses, or surface profiles. 3. Grippers - Vacuum Grippers: For handling delicate or flat-surfaced objects during inspection. - Mechanical/electrical Grippers: For securely holding parts during inspection or sorting tasks. - Magnetic Grippers: For handling ferromagnetic materials. - Soft Grippers: For handling fragile or irregularly shaped objects without causing damage. 4. Specialized Inspection Tools - Leak Testers: For pressure decay or bubble testing to detect leaks in sealed components. - Electrical Test Probes: For continuity, resistance, or functional testing of electronic components. - Surface Finish Sensors: For measuring surface texture, roughness, or coating thickness. 5. Laser Systems - Laser Profilers: For creating 3D models of parts and comparing them to CAD designs. - Laser Micrometers: For high-precision dimensional measurements. - Laser Marking Systems: For marking defective parts or adding traceability information. 6. Illumination Systems - LED Lights: Integrated with cameras to provide consistent lighting for visual inspections. - Structured Light Projectors: For enhancing 3D scanning and surface inspection accuracy. 7. Custom Tooling - Multi-Function Tools: Combining multiple EOAT types (e.g., a camera, gripper, and sensor) into a single tool for complex inspection tasks. - Adaptive Tooling: Tools that can adjust their configuration based on the inspection requirements. Factors Influencing EOAT Selection: 1. Inspection Type: The nature of the inspection (visual, tactile, dimensional, etc.) determines the appropriate EOAT. 2. Product Characteristics: Size, shape, weight, and material of the product being inspected. 3. Speed and Precision: High-speed inspections may require lightweight EOAT, while high-precision tasks may need advanced sensors. 4. Environment: Considerations like cleanroom requirements, exposure to dust or moisture, and temperature conditions. 5. Integration: Compatibility with the SCARA cobot and other systems (e.g., vision systems, PLCs). Examples of EOAT in Quality Inspection Applications: - PCB Inspection: Vision systems with high-resolution cameras and electrical test probes. - Automotive Parts Inspection: Laser scanners for 3D profiling and force sensors for assembly verification. - Medical Device Inspection: Soft grippers and ultrasonic sensors for handling and internal defect detection. - Packaging Inspection: Vacuum grippers and LED-illuminated cameras for defect detection and sorting. By selecting the appropriate EOAT, SCARA cobots can perform a wide range of quality inspection tasks with high accuracy, efficiency, and repeatability. The flexibility of EOAT also allows for easy adaptation to new inspection requirements, making SCARA cobots a versatile solution in manufacturing quality control. Read the full article

0 notes