#static mixer working principle

Explore tagged Tumblr posts

Text

We are one of the leading manufacturers of Cork tape roll all across India at reasonable rates Tape Cork, also called anti-skid, is a wide silvery adhesive intended to seal joints in sheet metal ductwork.

Standard size: 1.6mmx50mmx100m.

One side is made of Adhesive Sticker, and the other is a cork mixture. Extremely strong, high friction coefficient, oil-resistant wax, ageing resistance. can be used as a guide roller for a cutting machine: anti-skid and wire drawing.

We offer fine quality Cork Rubber Tape to our most reliable customers, these tapes are made by using very high-grade raw material which ensures high durability. These tapes are widely available at market-leading as well as at competitive prices.

#pvc nozzle#pvc nozzle for grouting#PVC static mixer nozzle#PVC static mixing nozzle#static mix nozzle#static mixer nozzle#static mixer nozzles#static mixer working principle#why does stabilizer makes noise#without noise mixer grinder

0 notes

Text

Description: PVC high-speed Mixer designed to generate heat due to friction. The high-speed Mixers are used to mix granules with pigment paste or pigment powder or different colored granules for uniform blending. The high-speed mixer achieves heat while working is important to blend the pigment paste and polymer powder uniformly. PVC High-Speed Mixer: 1.A complete range of fully automatic high-speed mixer unit for the production of both rigid and plasticized PVC dry blends. 2. The compact unit is monoblock construction. 3. A unique mixing impeller using aerodynamic principles gives a rigid mixing action and fast frictional heating. 4.Inner stainless steel and conduction oil jacket to attain equilibrium temperature. 5. The impeller is made of stainless steel and passed the strictly Static and dynamic balance experiments. 6. The discharging mode adopts temperature-automatic control and manual control. 7.The technique of two layers of sealing a adopted in its pot cover. It has self-friction heating and electric heating modes.

0 notes

Text

Inline Static Mixer Bliss Flow Systems

Inline static mixers are an essential component in various industrial processes where consistent and efficient mixing of fluids is required. Whether it’s in the chemical, pharmaceutical, food and beverage, or water treatment industries, static mixers play a pivotal role in ensuring that substances are thoroughly blended without the need for moving parts. In this blog, we will explore what an inline static mixer is, how it works, its benefits, and why Bliss Flow Systems is your go-to supplier for high-quality static mixers.

What is an Inline Static Mixer? An inline static mixer is a device that is installed directly into a pipeline to blend two or more fluids together. Unlike dynamic mixers, static mixers do not have any moving parts. Instead, they use a series of internal elements, designed in specific geometric patterns, to create turbulence and mixing action as fluids pass through the mixer. This unique design allows for efficient mixing with minimal pressure drop and energy consumption.

How Does an Inline Static Mixer Work? Inline static mixers work based on the principles of fluid dynamics. As fluids enter the mixer, they pass through a series of strategically arranged mixing elements. These elements are typically made of stainless steel or other corrosion-resistant materials and are designed to generate flow division, radial mixing, and flow reversal. The result is a homogenous mixture of fluids by the time they exit the mixer.

The mixing process can be broken down into three main stages: Flow Division: The incoming fluid is split into multiple streams as it passes through the first set of mixing elements.

Radial Mixing: The split streams are then pushed towards the pipe walls and back to the center, ensuring radial mixing and homogenization.

Flow Reversal: Finally, the streams are reversed in direction several times, further ensuring thorough mixing of all fluid components.

Benefits of Using Inline Static Mixers Inline static mixers offer several advantages over traditional dynamic mixers:

Energy Efficiency: Static mixers do not require any external power source, making them highly energy-efficient.

Low Maintenance: With no moving parts, inline static mixers have minimal wear and tear, reducing maintenance costs and downtime.

Space-Saving Design: Their compact design allows for easy installation in existing pipelines without the need for additional space.

Versatility: Inline static mixers can handle a wide range of fluid viscosities and flow rates, making them suitable for various applications.

Consistent Mixing Quality: They provide uniform mixing results, which is crucial for quality control in sensitive processes such as pharmaceutical manufacturing or food processing.

Applications of Inline Static Mixers Inline static mixers are used in a wide range of applications, including:

Chemical Processing: For mixing chemicals and additives, controlling reaction rates, and achieving uniform product quality.

Water and Wastewater Treatment: For blending chemicals, such as coagulants and disinfectants, ensuring thorough treatment of water and wastewater.

Food and Beverage Industry: For mixing ingredients, flavorings, and additives to ensure consistent taste and quality.

Pharmaceutical Manufacturing: For homogenizing liquids and solutions to meet stringent regulatory standards.

Why Choose Bliss Flow Systems for Your Inline Static Mixer Needs? Bliss Flow Systems is a leading supplier of high-quality inline static mixers in India. Our mixers are designed to meet the rigorous demands of various industrial processes, ensuring reliable performance and durability. We offer a range of sizes and configurations to suit different applications, along with custom design options to meet specific customer requirements.

At Bliss Flow Systems, we pride ourselves on delivering top-notch products backed by exceptional customer service. Our team of experts is always ready to assist you in selecting the right static mixer for your needs and provide ongoing support throughout the product lifecycle.

Conclusion Inline static mixers are a reliable and cost-effective solution for achieving consistent fluid mixing in various industries. With their energy-efficient design, low maintenance requirements, and versatility, they are an ideal choice for any application where thorough mixing is required. At Bliss Flow Systems, we are committed to providing high-quality static mixers that meet the unique needs of our customers. Contact us today to learn more about our products and how we can help you achieve optimal mixing results.

More Info : https://blissflowsystems.com/ Contact us : +91 9500953600

0 notes

Text

Concrete Batching Plant in Guyana

Gajjar Equipments Private Limited Offers a Concrete Batching Plant in Guyana. We are manufacturer, supplier, and exporter of Asphalt Mixing Plants, Concrete Batching Plants, Wet Mix Macadam Plants, Bitumen Pressure Distributors, Bitumen Decanters, Road Sweeping Equipment, Material Handling Conveyors, Feeding Systems, Storage Systems, Pavement Mixing Plants. Gajjar Equipments Private Limited's manufacturing unit is located in Ahmedabad, Gujarat, India. We offer Concrete Batching Plant like stationary concrete batching plant, compact concrete batching plant, precast concrete plant, concrete mixer, pan mixer, twin shaft mixer, and planetary mixer. Available Models of Concrete Batching Plant like GECS-60, GECS-75, GECS-90, GECS-120, GECS-160, GECS-200, and GECS-240. Components of a static concrete batching plant include aggregate bins, conveyor belts, a mixing unit, a control panel, cement silos, and water and additive tanks. Our Concrete Batching Mix Plant Capacity range is 60 M3 ΤΟ 240 M3 GAJJAR's GEC-S stationary concrete batch mix plants are engineered for robust storage, uniform mixing, and high production demands. Setting the industry standard for reliability and longevity, our stationary batch plants deliver consistent performance over time. They cater to both large and small projects, offering a comprehensive solution for concrete production. Capable of handling substantial production volumes, these plants are ideal for various construction needs. The stationary batch mix plants guarantee a uniform concrete mix, ensuring consistent quality with every batch. Working Principles: Aggregate Feeding Mixing Process Cement and Water Addition Discharge and Transport Gajjar Equipments Private Limited Offers a Concrete Batching Plant in Guyana including locations like Georgetown, Anna Regina, Bartica, Corriverton, Lethem, Linden, Mabaruma, Mahdia and New Amsterdam, Mahaica, Rose Hall, Parika, Triumph, and Uitvlugt. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Learning How to Add Sound and Getting Started with working in Unlit/Low-Poly Style

Most of my last week has been spent three things:

1. Actually thinking through how the game is going to work and how the story will support it

2. Building some initial assets in Blender and getting the beginnings of a stage set up in Unreal to test my understanding of working in this style. Want to make sure I'm not committing myself to something too painstaking before I start building out the map.

3. Learning how to add sound.

Game Story & Mechanics

Initially I was envisioning a more narrative game, but I want the end result to use as much of the mechanics we've learned in class as I can, so after giving it more thought and being more realistic about what I can do in the time we have, I'm making it more of a collecting game. My inspiration for this game is a mountainside Antique Mall in my home town in Vermont that also has a small Llama stable/petting zoo next to it. I really want to do a whole game set at this Antique Mall, but for now I'm re-envisioning it as a dedicated Llama petting zoo that's simply reminiscent of it.

The player is going to discover that one of the Llamas can talk, and is very good at giving advice. The player has a problem they could use some help with but the Llama doesn't consult for free...you have to pay them in feed. The feed dispenser only takes quarters, though, and you have no cash. So you have to go around collecting errant pennies and exchanging them for quarters with several locals in the area. A few will only agree to the exchange if you can fetch things for them. It'll basically be three stages of collecting things, each time allowing you to continue your conversation with the llama.

Game Assets

The assets I managed to build successfully were the penny, a llama and the feed vending machine. The llama is just a first attempt....I don't necessarily want to go for a completely blocky low/poly effect, but I need to take another pass at one to try out some other ideas. If I don't toy around with shape, then I at least want to explore hand drawn/illustrated material textures to make the visuals a little more interesting and not so typical of the aesthetic.

I actually wanted to try importing a small animation with the llama (a simple chewing animation to go with a grazing sound effect I wanted to use), but though I was successful building the animation in Blender, I couldn't manage to successfully import it into Unreal. Had to give up on it for now and just go with the static versions. There are definitely small animations and motions I want to include in the game (like with the feed vending machine) so I hope the learning curve isn't too steep for figuring out how to do it.

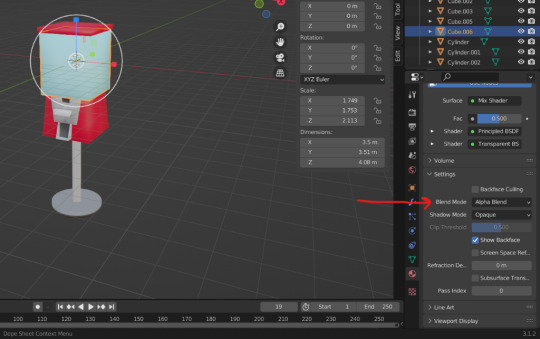

The vending machine I'm especially pleased with. Took some time to figure out how to get the glass container to be transparent, but it was immensely satisfying when I did. Turns out there's a dedicated Shader Node for transparency: Transparent BSDF. You simply use a Mixer Shader to pipe an alpha-controlled version of your color in along with your primary one. The you just use the Alpha slider in your Principled BSDF node to adjust the amount of transparency.

You also have to change the Blend Mode in the Material Properties Settings to one of the Alpha options.

Color selection and management ends up being the heavy lift when working without lighting. You have to make every material emissive and you have to be clever about varying colors on objects that overlap, otherwise you'll lose all sense of shape, depth and distinction.

Sound Design

In my first attempts at incorporating sounds, I wanted to add a suitable effect to the coin collection, and I wanted to try out having several layers of sound to place you in a wooded setting with a pack of llamas.

The coin effect was simple enough, messing around with ChipTone, but I decided also to add in a small jangling coins sound effect that I coded to execute right after the first one. Wanted to make it sound like you were adding to a stash of coins, and I think it works.

For the llamas I wanted the sound of generic woodland atmosphere, but then the sounds of the llamas just going about, so either light stomping, or huffing or something to that effect. I found a generic sound effect of horses grazing in a stable that came pretty close to exactly what I wanted. Since some of my llamas are actually eating grass off the ground, I added in another sound of more audible chomping of grass, pulling the attenuation in close so that you only hear it when you're up close to them in particular.

I put the coins around a body of water, so for kicks I added some splashing sounds that execute if you wander over it. I didn't actually tie it to the navigation event triggers, but I'm interested in figuring out how to do that.

Also spent some time this weekend just playing around with the sound machine apps, which I was having a blast with and getting way more into than I was thinking I would, so I went ahead and just created my own music for this initial sound test. I think I'll actually keep pecking away at it and make it one of the custom elements of my game.

This is the program I ended up using for the music I eventually included and a video on how to use it:

BeepBox -- Brutally Easy Music Software (Free & Open Source Too!) - YouTube

The challenge I envision for sound is working out the sound effect for the vending machine. That's a little more specific and I didn't find anything that would work online, so I think I'll have to go gonzo with that one and make a trip over to the Central Park Zoo to make my own recording. Luckily the weather has gotten warm just in time!

0 notes

Text

Key Features of Static Mixing Nozzles

Some applications require two-component structural glue for better performance and results. It’s more reliable than conventional glue, but it needs special tools, such as static mixing nozzles, to manufacture. When used with static mixing tubes, the nozzles simplify the creation of two-component structural glue in a particular ratio to make the adhesive ideal for sticking large load-bearing materials.

Their significance in making better adhesives

Single- and two-component glue products typically come with different systems when the glue is involved. The latter consists of components A and B. Before use, they must be mixed to a specific ratio using a static mixing nozzle. External forces don’t affect the static mixing tube as only the fluid is used through the mixer for continuous cutting and reunification until the components result in a uniform mixture.

Automatic coating equipment typically requires round mixing tubes, and manual gluing may consider round or square tubes. The choice ultimately depends on the unique requirements for making the adhesive and its purpose.

Features to consider

Static mixing nozzles, are classified according to their form. Here’s an overview of each:

Bell mouth: This mixing nozzle suits 200ml and 400ml AB glue guns. It can also function with a two-component liquid mixing machine.

Bayonet: Most static mixing nozzles are spiral or bayonet-type. The working principle is after the glue comes out from rubber hose A and rubber hose B flows through the tube. It can be cut, remixed, rotated, and sheared by a spiral blade several times before it’s divided into several small parts. A spiral blade makes the glue flow rotate to the left or right to change the direction of the flow. This way, the central fluid goes to the periphery, and the surrounding fluid can move to the center for an adequate liquid mixing effect.

Twist Lock-type: These static mixing nozzles are for new 50ml glue guns. They come in different types to suit specific glue mixing ratios, such as 10:1 and 1:1. They can replace mixing tips like DP100, 3819, 08115, 08193, and 08194.

Get the right nozzles.

Static mixing nozzles must be based on standard usage specifications. These are consumables, so they require regular replacement. A handheld branch adhesive can be mixed automatically in every component’s correct volume ratio. In general, a uniform color distribution determines a homogeneous mix. The adhesive should cure quickly after mixing.

0 notes

Text

Design, Working And Advantages Of A Double Cone Blender

In the production of products for the healthcare, food, chemical, cosmetics, detergents, fertilizers, and plastics industries, mixing is a typical manufacturing step. The double cone blender is used to create a homogenous solid-solid mixture that is uniform inconsistency.

The Double Cone Blender's Working Principle

In the dry blending of free solids, double cone blenders are the most commonly utilized type of mixer. They are capable of blending a wide range of solids with varying bulk densities and percentages of the overall mixture. With each rotation of the double cone, the stuff being blended is constantly intermixed. It is common for the cycle time to be 10 minutes, although it might be longer or shorter depending on how complicated the item being mixed is.

The Design and Construction of a Double Cone Blender

Its primary body is composed of two cone-shaped parts that are welded together at their bases to form a cylindrical section in the center of the machine. During rotation, the axis of rotation is perpendicular to the axis of the cone and passes through its cylindrical part. The drive motor is housed within one of the two lateral supports that hold the blender body in place on the table. Stainless steel is used in the construction of the double cone blender. This is completely mirror polished on both the inner and outside surfaces. Ball bearings are used to support the unit, which is mounted on mild steel or stainless steel stand. The conical shape at both ends allows for homogeneous mixing and discharge while still being lightweight. The cone is statically balanced, which saves the gearbox and motor from being subjected to an excessive amount of pressure.

There is a butterfly valve of the proper diameter at one end of the cone to allow for material discharge, while openings with removable covers are provided at the other ends of the cone for material insertion and cleaning. Inside the blender, there are stainless steel baffles that serve as the driving arrangement, which is powered by a motor through a reduction gearbox. It has the capability of operating at a variable speed. For larger models, optional features such as a safety barrier, a limit switch, and a platform are available. Associated provisions include the ability to include a liquid spray system into the process in order to introduce liquids in spray form throughout the process.

A vacuum device with self-cleaning hoses can be used to introduce powders and granules into the blender body, automating the loading process. In addition to a product receiving hopper with an automated self-cleaning filter, the device is outfitted with a control panel. A retractable hermetic bellows system that is pneumatically operated can be used to load and discharge the container.

The Operation of a Double Cone Blender

Intake systems for powdery or granular materials are used to feed materials into the double cone containers, while hand-feeding is also used. The material moves in a complicated and vigorous manner due to the constant rotation of the containers, resulting in a homogeneous mixing. The conical shape at both ends aids in consistent mixing as well as a simple release of the product. Depending on the material's characteristics, paddle-type baffles can be installed on the shaft to improve mixing, consistent blending, and de-agglomeration while the material is being processed. A dust-free bin charging method ensures that only the bare minimum of material is handled. The solids are loaded into the blender through the loading hole on the side of the machine. The mixing occurs axially as a result of the movement of the powder bed across the various parts. The mixing is comprehensive, but the speed at which it occurs is dependent on the rotational speed. When the mixture is discharged, it is done so through a hermetically shutting butterfly valve that can be handled manually or by computer.

Advantages

1. With its closed container, the cone blender provides good product rolling and cross mixing.

2. The conical shape at both ends and ‘Slant' design allows for homogeneous mixing and easy discharge.

3. It mixes, blends uniformly, and de-agglomerates.

4. The cone is statically balanced, which protects the gearbox and motor from being subjected to an excessive amount of stress.

5. There are two different openings for feeding and discharging powder.

6. If necessary, paddle-type baffles can be installed on the shaft to improve mixing performance depending on the product's characteristics.

7. Contact parts are made of stainless steel, which helps to avoid corrosion and product contamination. In order to ensure minimal material handling, it features a dust-free bin charging mechanism in place.

8. Additional elements such as a spray system, a loading system, a receiving hopper, and flame-proof electrical connectors can be added.

The Double Cone Blender has a variety of uses.

1. When it comes to tablet and capsule formulations, dry powder and granules are quite useful, and the cone blender is one of the most versatile tools available.

2. In the bulk lubrication stage of tablet granule production, it is utilized for dry granule sublot mixing to enhance batch size.

3. It has the potential to be used for the dry powder to wet mixing applications as well.

4. It can be utilized in a variety of industries including medicinal, food, chemical, and cosmetic industries.

5. High mixing quality is achieved by using this device for mixing highly flowable powdered and granular materials with exceptional mixing quality.

6. It can be used for material mixing in the food, essence, dye, chemical, plastic, and rubber industries, among other things.

7. It can be used for medical intermediates, flavoring, graphite, coffee powder, and iron powder, among other things.

0 notes

Text

PTFE pipe introduction

The forming process of the PTFE pipe has a pressing method, an extrusion method, a hydraulic method, a welding method, a winding method, and the like, and the pressing method is mainly used. Generally, a dispersed PTFE resin having a particle diameter of 500 μm and an apparent density of 0.45 g/ml to 0.55 g/ml is used. The small diameter tube is made of a resin with a relatively large compression, and the large and medium diameter tube is made of a resin with a relatively small compression. The propellant is usually selected from solvent oils No. 200 and No. 260. The PTFE pipe is subjected to secondary processing to obtain a PTFE heat shrinkable pipe, a PTFE spiral pipe, a PTFE steel wire reinforced hydraulic pipe, and the like.

1.1, Teflon ordinary tube

The Teflon common tube is made by pressing a polytetrafluoroethylene dispersion resin at a normal temperature with an organic solvent as a squeezing agent, and then drying and sintering. According to the size of the pipe diameter, it can be divided into two types: ordinary pipe and micro pipe. Ordinary tube inner diameter > 4mm, micro tube inner diameter ≤ 4mm.

Typical formulations for the production of PTFE tubes:

Dispersed PTFE resin: 100 parts by weight

Squeezing agent: 18~24

Production process:

PTFE, squeezing agent → mixing → pressing → drying → sintering → cooling → product.

Production process parameters:

Mixing: Temperature ≤19 °C, time 10min~20min, mixing at 25 °C ~ 30 °C for more than 24h.

Billet: The compression rate is about 50mm/min and the pressure is 0~3MPa.

Pushing: the temperature of the cavity is 30 °C ~ 50 °C, the die temperature is 50 °C ~ 60 °C, the pushing rate becomes smaller with the increase of the pipe diameter, and accelerates as the wall thickness becomes smaller.

Drying: below 210 °C, 2h~3h

Sintering: batch sintering, heating rate 60 °C / h, 375 °C ± 5 °C for 4h.

Continuous sintering, drying zone 100 °C ~ 250 °C, preheating zone 250 °C ~ 330 °C, sintering zone 380 °C ~ 420 °C, cooling zone less than 300 °C.

Main equipment: mixer, pre-former, vertical pusher, drying and sintering furnace.

Uses: as insulation and conveying fluid conduits.

1.2, Teflon heat shrinkable tube

The PTFE heat shrinkable tube has the property of being heat-shrinked, so it can be tightly coated on the surface of other workpieces, making the workpiece corrosion-resistant, electrically insulating and anti-adhesive. Widely used in electrical, chemical, mechanical, printing and other industries. The maximum shrinkage of PTFE heat shrink tubing is reported to be greater than 75%.

Made of dispersed PTFE resin, the principle is that PTFE is subjected to stress during processing to produce forced high elastic deformation. This deformation is reversible, and the low temperature makes it freeze. If reheated and frozen, the forced high elastic deformation will gradually disappear and Revert to the original state.

Typical formulations for the production of PTFE heat shrink tubing:

Dispersed PTFE resin 100 (parts by weight)

Squeezing agent 20~22

Production process:

PTFE resin, extrusion aid → mixing → storage → preforming → pressing → drying → sintering → cooling → heat treatment → inflation → cooling → product.

Production process parameters:

The front part is the same as a normal PTFE tube.

Heat treatment: The process of quenching the dried and sintered pipe again after further sintering at a high temperature again, the temperature is 390 °C ± 2 °C, and the coolant is - 5 °C.

Inflation: At about 310 °C, it is filled with a compressed gas of 0198 MPa or less, and the inflation rate is 200% to 400%.

Main equipment: Inflator, the other is the same as ordinary PTFE tube.

1.3, PTFE steel wire reinforced hydraulic pipe

The ordinary PTFE tube will be ruptured under the pressure of about 40kg/cm2. When it is combined with the steel wire, the pressure resistance is greatly improved, and the maximum working pressure in foreign countries reaches 700kg/cm2. Studies have shown that the compressive strength and pulse strength of the hose are not only related to the strength of the steel wire, but also to the size of the braiding angle. When the weaving angle of the single layer weaving is 54° 44′′, the steel wire does not elongate under the internal pressure, and the length and diameter of the hose do not change, and the pressure resistance is the best.

When used as a hose for aerospace industrial hydraulic systems, in order to prevent static breakdown of the inner tube due to the flow of hydraulic oil, a small amount of conductive carbon black must be added during the manufacture of the PTFE inner tube. However, studies have found that the addition of carbon black does not completely prevent static electricity from discharging through the tube wall and increases voids.

In the 1960s, Attas manufactured a composite tube, in which the inner layer of the tube was a uniform mixture of conductive carbon black and PTFE, and the outer layer of the tube was pure PTFE. This form of inner tube layer has axial electrical conductivity, so it can remove static electricity and prevent seepage.

Its process:

Inner layer resin (including conductive carbon black), outer layer resin → compact → push → dry → cooling → inspection → weaving → fitting → inspection.

PTFE steel wire composite hoses are mainly used in hydraulic systems, air-conditioning systems, fuel systems, and oil systems on aircraft. In the civil industry, it is suitable for rubber, plastic, pharmaceutical, clothing, shipbuilding, automotive, machine tools, motors, diesel, paper and other industries for hydraulic, steam pressure, steam delivery and other soft connectors.

1.4, PTFE spiral tube

PTFE spiral tube, also known as PTFE flexible hose, has flexible properties in addition to all the excellent properties of PTFE. At present, there are two types of pure PTFE spiral tubes and chemical fibers, stainless steel wires and plastic coated glass fibers.

It is made by PTFE whole secondary processing, which is made by continuously rotating the PTFE thin-walled tube continuously through a combined mold with a temperature of 270 °C ~ 280 °C at a certain speed.

It is mainly used for the connection of the flexible connection of the corrosion-resistant and high-temperature resistant equipment, the misalignment connection, the serpentine pipeline, the pump engine and other shocking components. Shielded cables and protective cable bushings for aircraft engines.

#Teflon ordinary tube#Teflon heat shrinkable tube#PTFE steel wire reinforced hydraulic pipe#PTFE spiral tube

0 notes

Video

youtube

Perfectly Coconut Squeezed By Press Filter

Applications:

Coconut Squeeze Dewatering Equipment, Belt Press (Press Filter)Dehydrator Is Widely Used For The Dehydration Of Various Plant Wastes ,Slag Materials And Industrial Sludge, Including Brewer Slag, Beer Residue, Coco Peat, Palm Oil Residue, Ceramic Clay, Clay, Fire Clay, Coal Slime, Shrimp Shells, Food Waste, Chicken Manure, Beet Slag,Cassava Residue, Sweet Potato Residue, Corn Residue, Bagasse, Pomace, Tea Residue, Soybean Residue, Household Waste, Coffee Grounds, Sludge And Other Materials.

4 Major Advantages Of Coconut Squeeze Dewatering Equipment:

1, The Equipment Is Fully Automatic Operation For 24 Hours 2, The Processing Of Large Amount Of Material, Low Power Consumption 3, Easy To Operate, Easy To Maintain. 4. Low Moisture Content Of Slag Cake, Effectively Saving Drying Cost

Working Principle Of Coconut Squeeze Dewatering Equipment

Coconut Squeeze Dewatering Equipment,After A Certain Concentration Of Flocculant Sludge Concentrated In The Static, Dynamic Mixer Aftermixing The Sludge Tiny Solid Particles Cemented Together Floc Larger Clumps, While Separating Out Free Water, After Flocculation The Sludge Is Fed To The Filtrate Concentrated Gravitational Dewatering Belt, The Free Water Is Separated Under The Action Of Gravity, The Flow State Is Not Formed In The Sludge, And Then Sandwiched Between Two Upper And Lower Belt, After The Pre-Nip Wedge, Low Ascending Area And Pressing Force Of The High Pressure Zone, Shear Force, Gradually Squeeze The Sludge In Order To Achieve The Greatest Degree Of Mud, Water Separation, And Finally Form A Filter Cake Discharge.

As The Leader Of Coconut Squeeze Dewatering Equipment Manufacturer In China, We Are Always Right Here To Supply Best Service:

www.slagdewatering.com [email protected] Mr.Jacky Lan +86 14748325676

0 notes

Text

Complete Information about Industrial Mixers and Agitators

Mixers are used to mix, blend, or agitate two or more or substances together. They are used in the cosmetic, food, pharmaceutical, and chemical industries for mixing applications that promote chemical reactions or reactivity, especially homogenous liquid bulk during storage, and to increase heat transfer by the use of coolants.

Depending on the application, the agitation and mixing of liquid are done by one of the many agitation impellers. The main function of the impeller is to produce different types of motion so as to give different types of agitation functions.

How an Industrial Mixer and Agitator works

The main principle behind the process is the movement and the contact between the bulk heterogeneous mass and the impeller. The impeller can either serve the function to rigorously mix the bulk so as to blend it more efficiently and increase chemical reactivity, or to increase heat transfer amongst materials so as to maintain particles in suspension.

Different types of Industrial Mixers and Agitators

Depending upon the need, there are many different types of agitators and mixers available. Basically, they are anchor, propellers, turbine and gas induction. Some of them are mechanical agitators, rotating tank agitators, agitators working with pump blasting liquid, static agitators, etc. The industrial mixers and blenders may be chosen depending on the bulk that needs to be mixed, whether it is liquid and liquid, liquid and solid, gas or liquid or solid and gas. If it is liquid, it can be placed at the top, sideways or less commonly at the bottom.

Depending on the phase of the bulk, the mixer can also be termed as the kneader, dough mixer, radial flow impellers, convective blender etc. amongst others. A.T.E. Group entered the industrial machinery production a decade ago, and now it is one of the leading brands in manufacturing mixers, kneaders, and agitators for industrial purposes.

Some Industrial Agitators and their Uses

Sulzer abs RW is a submersible mixer which is ideal for municipality plants and industry, suitable agitating, mixing and blending suspension of solids. It provides high standard and efficient multiple and gear driven mixers.

Sulzer abs flow booster XSB 900 is also designed as a compact, water pressure tight unit having propellers, which help to give high thrust and hence high flow in the axial direction. The three axial propellers are equipped in a way which gives good self-cleaning effect and vibration free performance. Both the equipment is tested and have a lifetime of 100,000 hours.

0 notes

Photo

GRAIN DRIERS www.tecodryer.com

Working Principle

Fan aspirates air into combustion room through shutters and forms a controlled mixture with the gas coming from installation.

This mixture is burned by the burner. The heat formed advances along combusTİon room with the help of burner fan and upper aspirating fan and passes through transiTİon channel and is transmitted to air channels of product chamber.

Thereby heat is transferred to product and some of heated air is extracted in a controlled manner and remaining heated air enters the system again and is mixed with the atmosphere air received from cooling shutters.

Air is irculated along the system in order to reduce its humidity (saturation). Humidity of the product within this loop is reduced to desired humidity ratio and then product asses from unloading mechanism to hopper and exits the system.

Grain which is equal to the amount of product leaving the system is added to system with the help of sensors. It is prevented that heat goes toflow pipe through transition connection by means of this adding process.

General Specifacition

1.) It has galvanized and thoroughly fixed strong base structure.

2.) It allow to work easily under different products and product conditions thanks to grain intake system.

3.) Interior roof and supports ensure that humidifiedgrain passes through chamber as granulated.

4.) Turbulent air circulation is avoided thanks to low static pressure and homogenous heat dissipation.

5.) In emergency situations, machine's burning system is closed thanks to heat sensors.

6.) Temperature values is increased to maximum value from nominal by means of air mixer.

7.) Burners keep temperatures needed fixed continuously.

8.) Burner system consists of Elster Krom Schröder or Dungs brand high-safe devices.

9.) Burner system is worked by using fuels like LPG, LNG (in gas phase) and NG

10.) Grain within chambers is kept under control with emergency unloading covers.

11.) Grain storing chamber is automatic controlled and it controls feeder elevator and provides electric saving.

12.) It keeps the product within chamber without loss thanks to unloading which is made invariable by pneumatic system and desired unloading time is adjusted by means of timing mechanism.

13.) It is ensured that fans are protected from external conditions with the fan shutters fixed by

pneumatic system.

14.) High capacity fans are covered by metal sheets, black sheets and coated with static paint and burners are covered with stainless and galvanized metal sheets. Doors and covers opened into these

sections allow easy intervention.

15.) Heat loss is reduced to minimum thanks to external heat-insulation.

16.) Whole heat flow, air flow and temperature values within the system are reached and adjusted

with the Siemens control panels (PLC).

DÜZ TABANLI SİLOLAR

KONİK TABANLI SİLOLAR

HAVALANDIRMA SİSTEMLERİ

ELEVATÖR

ZİNCİRLİ KONVEYÖR

DAĞITICI

HELEZON

METAL KONSTRÜKSİYON

KONTROL SİSTEMLERİ

TAHIL KURUTMA MAKİNESİ

TAHIL TEMİZLEME MAKİNESİ

AKSESUARLAR TEKNİK BİLGİLER

FLAT BOTTOM SILOS CONICAL-BOTTOM SILOS VENTILATION SYSTEMS ELEVATORS CHAIN CONVEYORS DISTRIBUTORS HELEZON STEEL SAFETY CONSTRUCTION TECHNICAL SPECIFICATIONS COMMAND SYSTEMS GRAIN DRIERS GRAIN CLEANERS

СИЛОС С ПЛОСКИМ ОСНОВАНИЕМ СИЛОС С КОНУСНЫМ ОСНОВАНИЕМ СИСТЕМА ВЕНТИЛЯЦИИ НОРИЯ ЦЕПНОЙ ТРАНСПОРТЕР ДИСТРИБЬЮТОР ВИНТОВОЙ ШНЕК МЕТАЛЛОКОНСТРУКЦИИ ТЕХНИЕ ХАРАКТЕРИСТИКИ СИСТЕМА УПРАВЛЕНИЯ АКСЕССУАРЫ ЗЕРНОСУШИЛЬНОЕ ОБОРУДОВАНИЕ ЗЕРНООЧИСТИТЕЛЬНОЕ ОБОРУДОВАНИЕ

سطحة القاع صوامع المخروط المستندة إلى صومعة أنظمة التهوية مصعد

ناقل سلسلة موزع حلزوني معدن البناء المواصفات التقنية نظم الرقابة

الحبوب مجفف الحبوب آلة التنظيف

یلوی کف تخت سیلوی کف مخروطی سیستم تهویه آسانسور زنجیره نقاله

توزیع کننده مارپیچ ساختارهای ایمنی فولادی مشخصات فنی سیستم های کنترل و اتوماسیون دستگاه خشک کن غلات دستگاه تمیزکن غلات

LE SILO À FOND PLAT LE SILO À BAS CONIQUE LE SYSTÈME DE VENTILATION L’ÉLÉVATEUR CONVOYEUR A CHAINE LE DISTRIBUTEUR LA VIS DE VIDANGE CONSTRUCTION METALLIQUE SYSTÈMES DE CONTRÔLE LA SéCHEUSE DE GRAINS LA NETTOYEUSE DE GRAINS LES ACCESSOIRES INFORMATIONS TECHNIQUES

www.tecodryer.com #Silos #Grain Storage #Grain Handling Systems #Grain Dryer Machines #Grain Cleaning Machines #Grain Silos #Grain Storage Systems #Silos Systems #Steel Silo #Silos #Grain Storage #Corn Silo #Feed Silo #Sunflower Silos #Wheat Silo #grain systems www.tecodryer.com

SILOS DE ALMACENTAMIENTO DE GRANO SISTEMAS DE MANEJO DE GRANOS MÁQUINA DE SECADO DE GRANO MÁQUINAS DE LIMPIEZA DE GRANO CONSTRUCCIÓN DE ACERO SISTEMA DE AUTOMATIZACIÓN

Transportador De CadenaCinta TransportadoraEspiral AugerElevador De CangilonesAccesorios de FlujoTransportadores de Carga de Camiones

www.tecodryer.com #Silos #GrainStorage #GrainHandlingSystems #GrainDryerMachines #GrainCleaningMachines #GrainSilos #GrainStorageSystems #SilosSystems #SteelSilo #Silos #GrainStorage #CornSilo #FeedSilo #SunflowerSilos #WheatSilo #grainsystems #mısırkurutma #tahıkurutma #tanekurutma www.tecodryer.com

grain bin

grain storage

bins grain

bin prices

small grain bin

steel grain bins

grain bin

fans grain bin

house small

grain storage

bins metal

grain bin

grain bin

parts grain bin storage grain bin manufacturers grain bin companies grain bin homes

grain bin bar

grain bin lids

grain storage bins prices

grain bin aeration fans

cone bottom grain bins

the grain bin

small grain bin prices

overhead grain bin

wooden grain bin

grain bin ladders

grain bin roof

grain bin capacity

grain bin aeration

grain bin dealers

1 ton grain bin

grain bin moving

grain bin hoppers

grain bin door

grain bin sweep

moving grain bins

grain bin anchors

grain bin movers

large grain bins

building grain bins

grain bin measurement

grain bin shed

measuring grain bins

grain bin panels

grain bin rings

moving a grain bin

grain bin sheets

overhead grain storage bins

grain bin garage

old grain bin

grain moisture tester

grain moisture testers

grain moisture tester for sale

grain tester

portable grain moisture tester

moisture tester for grain

moisture tester grain

handheld grain moisture tester

grain tester moisture

best grain moisture tester

grain testers

dole grain moisture tester

shore grain moisture tester

mt 16 grain moisture tester

moisture meter

log moisture meter

moisture meter price

moisture meter for logs

firewood moisture meter

electronic moisture meter

moisture content meter

lumber moisture meter

corn moisture meter

seed moisture meter

pinless moisture meter

water moisture meter

paddy moisture meter

moisture meters for sale

buy moisture meter

wheat moisture meter

hardwood moisture meter

portable moisture meter

drywall moisture meter

where can i buy a moisture meter

professional moisture meter

handheld moisture meter

laser moisture meter

moisture test meter

where to buy a moisture meter

moisture meter for lumber

where to buy moisture meter

rice moisture meter

sheetrock moisture meter

cheap moisture meter

plaster moisture meter

moisture meter plaster

non destructive moisture meter

non invasive moisture meter

moisture meter logs

moisture detection meter

moisture meter woodworking

masonry moisture meter

maize moisture meter

good moisture meter

seed moisture meter prices

moisture meter for paddy

moisture meter for rice

moisture and humidity meter

moisture humidity meter

electric moisture meter

moisture meter manufacturer

electrical moisture meter

moisture meter company

agricultural moisture meters

moisture meter test

moisture level meter

moisture meter non invasive

moisture meter accuracy

moisture meter levels

moisture meter online

moisture meter scale

moisture meter suppliers

sawdust moisture meter

rice moisture meter price

moisture meter firewood

flour moisture meter

moisture meter calibration

moisture meter pinless

screed moisture meter

carbide moisture meter

tsmm1 moisture meter

motomco moisture meter

moisture meter uses

grain auger

small grain auger

grain auger parts

grain auger manufacturers

grain auger prices

electric grain auger

4 inch grain auger

auger grain

grain auger accessories

4 grain auger

hydraulic grain auger

brandt grain augers

grain transfer augers

grain auger tube

flexible grain auger

sakundiak grain augers

grain auger gearbox

grain auger motor

6 grain auger

grain king augers

6 inch grain auger

3 inch grain auger

grain auger spouts

grain silo auger

grain auger engines

grain silo

grain silo for sale

grain silo homes

silo grain

small grain silo for sale

small grain silo

grain silo house

grain silo manufacturers

metal grain silo

grain silo homes for sale

old grain silos for sale

steel grain silo

grain bin silo

large grain silo for sale

metal grain silo for sale

grain silo parts

silo for grain

grain steel silo for sale

grain silo roof for sale

grain silo homes plans

grain silo bar

grain silo transport

short grain silo

old grain silo

grain silo industry

grain silo roof

grain moisture meter

grain moisture meter price

moisture meter for grains

grain moisture meter for sale

grain moisture meter manufacturers

grain moisture

moisture meter grain

grain moisture analyzer

protimeter grain moisture meter

grain moisture meter online

grain moisture probe

grain of moisture

grain moisture meter calibration

grain auger for sale

auger for sale

used auger for sale

used grain augers for sale

corn auger for sale

small grain auger for sale

4 inch grain auger for sale

feed auger for sale

pencil auger for sale

fertilizer auger for sale

electric grain augers for sale

portable grain augers for sale

used grain augers sale

pencil augers for sale

tractor auger for sale

used hydraulic auger for sale

drill fill augers for sale

grain bin auger for sale

transfer auger for sale

used auger sale

auger tube for sale

grain auger for sale used

belt augers for sale

8 inch grain auger for sale

seed augers for sale

6 inch grain auger for sale

grain drill fill auger for sale

grain auger motors for sale

pto auger for sale

brandt auger for sale

utility auger for sale

wheatheart auger for sale

6 inch auger for sale

silos for sale

corn silo

silo homes

wheat silo

silo manufacturers

feed silo

silo

steel silo

corn silo for sale

silo bin

feed silo for sale

agricultural silos

used silos

the silo

silo building

silo restaurant

used silo for sale

minion silo

corn silo house

maize silo

building a silo

small silo

silo suppliers

metal silo

seed silo

small silo for sale

barn silo

silo corn

malt silo

a silo

steel silo for sale

silo staves

grain bins for sale

small grain bins for sale

grain storage bins for sale

grain bin fans for sale

feed bins for sale

grain bin aeration fans for sale

used grain bins for sale

metal grain bins for sale

grain bins for sale used

corn bins for sale

steel grain bins for sale

used grain storage bins for sale

seed bins for sale

corn storage bins for sale

silo grain bins for sale

grain bin rings for sale

grain bin roof for sale

large grain bins for sale

silo bins for sale

used bins for sale

grain bin floor for sale

grain bin dryers for sale used

grain bin panels for sale

1000 bushel grain bin for sale

10000 bushel grain bin for sale

5000 bushel grain bin for sale

grain bin house for sale

grain bin sheets for sale

used feed bins for sale

grain bin lids for sale

used grain bins sale

moisture tester

corn moisture tester

wood moisture tester

moisture tester for wood

seed moisture tester

firewood moisture tester

log moisture tester

forage moisture tester

portable moisture tester

steinlite moisture tester

rice moisture tester

grain storage

storage of grains

grain storage containers

storage for grain

grain storage building

grain storage tower

grain storage for sale

grain storage facility

grain storage tanks

grain storage sheds

storage grains

temporary grain storage

grain storage rings

grain storage structures

food grain storage

grain dryer

grain dryer machine

grain dryers manufacturers

grain dryer prices

small grain dryer

grain dryer manufacturers

gt grain dryers

mecmar grain dryer

mobile grain dryer

grain bin dryer

batch grain dryers

continuous grain dryer

grain bin dryers

grain dryer fan

reconditioned grain dryers

mecmar grain dryers prices

grain dryer design

grain dryers for sale

used grain dryers for sale

mobile grain dryers for sale

gt grain dryer for sale

mc grain dryers for sale

mecmar grain dryer for sale

batch dryer for sale

batch grain dryers for sale

gt 580 grain dryer for sale

used batch grain dryers for sale

used mc grain dryers for sale

digital moisture meter

digital grain moisture meter

digital moisture meter price

digital moisture meter for grains

digital soil moisture meter

digital moisture meter for maize

digital moisture meter for paddy

digital grain moisture meter price

used grain bins

used grain silos for sale

used grain dryers

used grain augers

used grain bin prices

used grain silo

used grain storage bins

used mobile grain dryers

used grain conveyors for sale

used grain handling equipment

grain storage silos

storage silo

silo storage

silo grain storage

silos for grain storage

grain storage silos for sale

silos for storage of grains

grain storage silos manufacturers

metal silos for grain storage

silo storage system

storage silos manufacturers

wheat storage silos

storage silos for sale

grain storage silos suppliers

storage of grains in silos

feed storage bins

corn bin

seed bin

corn storage bins

rice bin

chief bins

bin ring

twister bins

used feed bins

overhead feed bins

ring bin

dry bin

feed auger

brandt augers

corn auger

seed auger

used auger

agricultural auger

sakundiak auger

pencil augers

transfer auger

pencil auger price

auger equipment

wheat auger

conveyor auger

auger elevator

auger farming

auger manufacturing

corn dryer

corn dryer for sale

corn dryer machine

used corn dryers for sale

small corn dryer

grain drying systems

grain storage systems

grain dryer systems

temporary grain storage systems

grain handling systems

grain bin drying systems

grain bin systems

grain systems

portable grain dryer

portable grain auger

portable grain bins

portable grain moisture meter

small portable grain augers

portable grain dryer for sale

grain drying equipment

grain testing equipment

grain handling equipment

grain equipment

grain storage equipment

grain silo prices

silo homes prices

grain storage silo prices

metal grain silo prices

silo prices

seed dryer

maize dryer machine

maize dryer

seed dryer machine

bin dryer

continuous dryer

seed dryers

gt dryers

agricultural dryers

seed dryer manufacturers

bin dryers

mobile maize dryer

moisture machine

moisture testing machine

moisture machine price

moisture checking machine

maize drying machine

grain bin cost

grain dryer cost

cost of grain bins

grain bin house cost

cost of a grain bin

low cost grain storage structure

grain storage costs

rice dryer machine

rice dryer

rice dryer machine price

rice dryer design

rice grain dryer

grain bin auger

grain bin auger parts

grain bin unloading auger

grain bin sweep auger parts

grain bin unloading auger prices

grain bin sweep auger

grain bin unloading auger parts

auger bin

bin auger

drying grain

grain drying fans for sale

grain drying fans

grain drying machine

drying of grains

grain drying technology

grain drying bins

grain silo cost

cost of grain silo

grain silo homes cost

cost of a grain silo

grain silo house cost

crop storage

wheat storage

wheat storage containers

corn storage

storage pyramid

crop storage systems

1000 bushel grain bin

100 bushel grain bin

5000 bushel grain bin

10000 bushel grain bin

500 bushel grain bin

3000 bushel grain bin

20000 bushel grain bin

grain leg for sale

grain conveyor for sale

grain handling

grain tank

grain legs

grain conveyor

grain containers

grain probe for sale

grain tanks for sale

grain handling conveyors

grain leg

pyramids for storing grain

grain elevator manufacturer

grain aeration

0 notes

Text

A static mixer nozzle is a device used to mix two or more fluids together without the need for any moving parts. It is often used in chemical and manufacturing processes where it is important to ensure that two or more fluids are thoroughly mixed together.

The design of a static mixer nozzle typically consists of a series of stationary elements or baffles that are arranged in a specific pattern to achieve optimal mixing. As fluids flow through the nozzle, they are forced to pass through these baffles, which create turbulence and increase the contact between the fluids. This results in a more efficient mixing process and a more uniform distribution of the components in the mixture.

Static mixer nozzles can be made from a variety of materials, including metals, plastics, and ceramics, depending on the specific application and the chemical properties of the fluids being mixed.

#pvc nozzle#pvc nozzle for grouting#PVC static mixer nozzle#PVC static mixing nozzle#static mix nozzle#static mixer nozzle#static mixer nozzles#static mixer working principle#why does stabilizer makes noise#without noise mixer grinder

1 note

·

View note

Text

Inline Static Mixer Bliss Flow Systems

Inline static mixers are an essential component in various industrial processes where consistent and efficient mixing of fluids is required. Whether it’s in the chemical, pharmaceutical, food and beverage, or water treatment industries, static mixers play a pivotal role in ensuring that substances are thoroughly blended without the need for moving parts. In this blog, we will explore what an inline static mixer is, how it works, its benefits, and why Bliss Flow Systems is your go-to supplier for high-quality static mixers.

What is an Inline Static Mixer? An inline static mixer is a device that is installed directly into a pipeline to blend two or more fluids together. Unlike dynamic mixers, static mixers do not have any moving parts. Instead, they use a series of internal elements, designed in specific geometric patterns, to create turbulence and mixing action as fluids pass through the mixer. This unique design allows for efficient mixing with minimal pressure drop and energy consumption.

How Does an Inline Static Mixer Work? Inline static mixers work based on the principles of fluid dynamics. As fluids enter the mixer, they pass through a series of strategically arranged mixing elements. These elements are typically made of stainless steel or other corrosion-resistant materials and are designed to generate flow division, radial mixing, and flow reversal. The result is a homogenous mixture of fluids by the time they exit the mixer.

The mixing process can be broken down into three main stages:

Flow Division: The incoming fluid is split into multiple streams as it passes through the first set of mixing elements.

Radial Mixing: The split streams are then pushed towards the pipe walls and back to the center, ensuring radial mixing and homogenization.

Flow Reversal: Finally, the streams are reversed in direction several times, further ensuring thorough mixing of all fluid components.

Benefits of Using Inline Static Mixers Inline static mixers offer several advantages over traditional dynamic mixers:

Energy Efficiency: Static mixers do not require any external power source, making them highly energy-efficient.

Low Maintenance: With no moving parts, inline static mixers have minimal wear and tear, reducing maintenance costs and downtime.

Space-Saving Design: Their compact design allows for easy installation in existing pipelines without the need for additional space.

Versatility: Inline static mixers can handle a wide range of fluid viscosities and flow rates, making them suitable for various applications.

Consistent Mixing Quality: They provide uniform mixing results, which is crucial for quality control in sensitive processes such as pharmaceutical manufacturing or food processing.

Applications of Inline Static Mixers Inline static mixers are used in a wide range of applications, including:

Chemical Processing: For mixing chemicals and additives, controlling reaction rates, and achieving uniform product quality.

Water and Wastewater Treatment: For blending chemicals, such as coagulants and disinfectants, ensuring thorough treatment of water and wastewater.

Food and Beverage Industry: For mixing ingredients, flavorings, and additives to ensure consistent taste and quality.

Pharmaceutical Manufacturing: For homogenizing liquids and solutions to meet stringent regulatory standards.

Why Choose Bliss Flow Systems for Your Inline Static Mixer Needs? Bliss Flow Systems is a leading supplier of high-quality inline static mixers in India. Our mixers are designed to meet the rigorous demands of various industrial processes, ensuring reliable performance and durability. We offer a range of sizes and configurations to suit different applications, along with custom design options to meet specific customer requirements.

At Bliss Flow Systems, we pride ourselves on delivering top-notch products backed by exceptional customer service. Our team of experts is always ready to assist you in selecting the right static mixer for your needs and provide ongoing support throughout the product lifecycle.

Conclusion Inline static mixers are a reliable and cost-effective solution for achieving consistent fluid mixing in various industries. With their energy-efficient design, low maintenance requirements, and versatility, they are an ideal choice for any application where thorough mixing is required. At Bliss Flow Systems, we are committed to providing high-quality static mixers that meet the unique needs of our customers. Contact us today to learn more about our products and how we can help you achieve optimal mixing results.

More Info : https://blissflowsystems.com/ Contact us : +91 9500953600

0 notes

Text

A static mixer nozzle is a device used to mix two or more fluids together without the need for any moving parts. It is often used in chemical and manufacturing processes where it is important to ensure that two or more fluids are thoroughly mixed together.

The design of a static mixer nozzle typically consists of a series of stationary elements or baffles that are arranged in a specific pattern to achieve optimal mixing. As fluids flow through the nozzle, they are forced to pass through these baffles, which create turbulence and increase the contact between the fluids. This results in a more efficient mixing process and a more uniform distribution of the components in the mixture.

Static mixer nozzles can be made from a variety of materials, including metals, plastics, and ceramics, depending on the specific application and the chemical properties of the fluids being mixed

#pvc nozzle#pvc nozzle for grouting#PVC static mixer nozzle#PVC static mixing nozzle#static mix nozzle#static mixer nozzle#static mixer nozzles#static mixer working principle#why does stabilizer makes noise#without noise mixer grinder

1 note

·

View note