#subgrade stability

Explore tagged Tumblr posts

Text

Why Construction Rings Matter Even in Pavement Engineering

Dowel bars in rigid pavement function as important load transfer devices that distribute weight across concrete slabs, stopping differential agreement and extending pavement lifespans. These essential additives require the right spacing and alignment, which is where construction rings emerge as valuable. Super Rings and similar construction rings provide the necessary support framework to maintain dowel bar positioning during concrete pouring, ensuring structural integrity throughout the pavement's service life.

The Critical Role in Infrastructure Longevity

The placement of dowel bars in inflexible pavement requires precision that cannot be performed through guide methods alone. When improperly hooked up, these bars fail to transfer loads efficiently, leading to untimely pavement deterioration and costly repairs. Construction rings manufactured to strict tolerances help maintain exact positioning during the critical concrete pouring phase. The correlation between properly installed dowel bars in rigid pavement and extended service life makes these seemingly small components remarkably significant.

Quality Super Rings feature corrosion-resistant materials that resist harsh conditions both during production and throughout the pavement's lifetime. This durability ensures that the dowel bars in inflexible pavement hold their positioning and functionality many years after installation, maintaining the structural integrity that highway departments and transportation authorities demand.

Engineering Benefits Beyond Basic Support

Construction rings contribute to pavement performance through multiple engineering mechanisms. Beyond simply holding dowel bars in rigid pavement, they provide proper alignment that ensures smooth load transfer across joints. This alignment minimizes the development of step faults between adjacent concrete slabs, maintaining ride quality and reducing vehicle damage.

Professional contractors recognize that Super Rings offer superior dimensional stability compared to generic alternatives. This stability translates into consistent dowel bar positioning, which proves crucial when temperature fluctuations cause concrete expansion and contraction. The predictable behavior of properly installed dowel bars in rigid pavement depends significantly on the quality of construction rings used during installation.

Economic Impact on Project Lifecycle

Initial material costs often drive purchasing decisions, but experienced engineers understand that construction rings represent a minimal percentage of total project expenses while significantly impacting long-term performance. The difference between premium Super Rings and substandard alternatives might be negligible in upfront costs but substantial in lifecycle value.

Highway departments increasingly specify performance requirements for dowel bars in rigid pavement that can only be achieved with precision-engineered construction rings. These specifications recognize that proper load transfer across joints reduces maintenance frequency and extends rehabilitation intervals, generating substantial taxpayer savings over decades of service.

Installation Considerations and Best Practices

Construction rings must be selected based on assignment-specific requirements including concrete thickness, predicted traffic loads, and environmental conditions. Heavy-duty Super Rings offer the stability needed for highways experiencing significant truck traffic, while standard construction rings might suffice for lighter applications. This selection process requires understanding how dowel bars in rigid pavement perform under varying load scenarios.

Temperature considerations during installation affect concrete behavior, making adjustable construction rings particularly valuable in extreme climates. The thermal expansion properties of concrete create forces that can displace dowel bars in rigid pavement unless properly secured with high-quality construction rings designed to resist these pressures.

Advancements in Materials and Design

Modern Super Rings incorporate innovative materials that resist construction-related impacts and vibration while maintaining dimensional stability. These advancements address historical challenges with dowel bar movement during concrete placement and vibration, enhancing the performance reliability of dowel bars in rigid pavement.

Forward-thinking pavement engineers continuously evaluate how construction rings interact with new concrete formulations and pouring techniques. This evolving relationship between materials and methodology drives incremental improvements in how construction rings support and position dowel bars in rigid pavement, resulting in more durable infrastructure with reduced maintenance requirements.

The seemingly small decision about which construction rings to specify can significantly impact pavement durability.

#construction rings#pavement design#load distribution#road durability#structural support#pavement layers#ring reinforcement#road engineering#subgrade stability#pavement strength#construction joints#road base design#pavement integrity#load-bearing rings#asphalt reinforcement#concrete pavement#road construction#pavement structure#engineering rings#pavement components

0 notes

Text

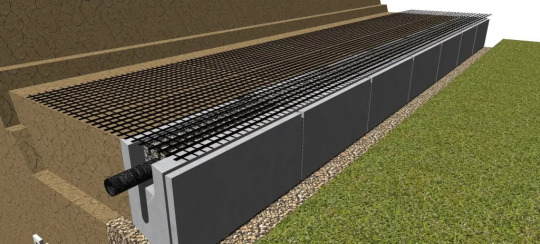

Trusted GEO Grid Manufacturer & Supplier Across India – Durable & Reliable

In the rapidly evolving construction and infrastructure sectors, the demand for innovative and sustainable materials has never been higher. One such revolutionary product gaining immense popularity is the GEO Grid a geosynthetic material used to reinforce soils and improve the structural integrity of roads, embankments, retaining walls, and more. Across India, trusted GEO Grid manufacturers and suppliers play a crucial role in delivering durable and reliable solutions tailored to diverse engineering needs.

This comprehensive blog explores the significance of GEO grids in modern construction, the qualities that define a trusted manufacturer and supplier in India, the technology behind GEO grids, their applications, and how they contribute to sustainable infrastructure development.

What is a GEO Grid?

A GEO Grid is a high-strength geosynthetic product made from polymer materials like polypropylene (PP) or high-density polyethylene (HDPE). It consists of a network of interconnected ribs that form a grid-like pattern. These grids reinforce soils and other granular materials, providing tensile strength and distributing loads more evenly.

By reinforcing the soil, GEO grids prevent soil displacement, improve load-bearing capacity, and reduce the risk of structural failures in various civil engineering applications.

Why Are GEO Grids Important in Infrastructure?

India’s infrastructure development has been growing at an unprecedented rate. From highway expansions to urban rail networks, and from embankment reinforcements to retaining structures, GEO grids have become an essential material. Here's why:

1. Enhanced Soil Stability

Soils naturally lack tensile strength, which is vital for holding structures together. GEO grids compensate for this by reinforcing weak soils, making them capable of bearing higher loads without excessive settlement or deformation.

2. Cost-Effective Solutions

Using GEO grids can significantly reduce construction costs by minimizing the need for extensive earthworks, imported aggregates, or expensive retaining walls. This leads to faster project completion and lower maintenance expenses.

3. Environmental Sustainability

GEO grids promote the use of locally available soils and materials, reducing the carbon footprint associated with transporting heavy aggregates. They also help in controlling soil erosion, preserving natural landscapes.

Key Applications of GEO Grids in India

The versatility of GEO grids makes them indispensable across multiple civil engineering projects:

Road Construction: GEO grids reinforce subgrades and base layers, improving load distribution and preventing rutting and cracking.

Railway Embankments: They stabilize the track bed, ensuring smoother and safer train operations.

Retaining Walls: GEO grids reinforce soil behind retaining walls, allowing for steeper and more stable slopes.

Slope Stabilization: They prevent landslides and soil erosion on embankments and natural slopes.

Landfills: GEO grids reinforce the layers in landfill sites, supporting heavy loads and preventing soil displacement.

Ports and Coastal Projects: Their corrosion resistance makes them ideal for reinforcing soils in marine environments.

Characteristics of a Trusted GEO Grid Manufacturer and Supplier in India

Choosing the right GEO grid manufacturer and supplier is crucial for project success. Here are the qualities to look for:

1. Quality and Compliance

Top manufacturers adhere to national and international standards (like ASTM, ISO) to ensure products meet stringent quality requirements. Durable, UV-stabilized polymers and rigorous testing protocols are essential.

2. Advanced Manufacturing Technology

Modern extrusion and weaving technologies ensure uniformity, strength, and precision in GEO grids. Manufacturers investing in research and development produce innovative products tailored to various soil and climatic conditions.

3. Comprehensive Product Range

A reliable manufacturer offers a wide range of GEO grids varying in tensile strength, aperture size, and polymer composition to meet diverse project demands.

Manufacturing Process of GEO Grids

Understanding how GEO Grid Manufacturer in Gujarat are made highlights why manufacturing quality matters:

Raw Material Selection

Manufacturers use high-quality polymers such as HDPE or PP, chosen for strength, durability, and chemical resistance.

Extrusion and Stretching

Polymer pellets are melted and extruded into sheets or ribs. These ribs are stretched (oriented) to enhance tensile strength, a critical feature for load bearing.

Welding and Weaving

The ribs are joined at intersections by welding or weaving to form a rigid grid. Precise control during this step ensures uniform grid geometry.

UV Stabilization

Additives are incorporated to protect the grid from UV degradation, ensuring longevity under sunlight exposure.

Advantages of Using GEO Grids in Indian Projects

Soil Reinforcement and Load Distribution

GEO grids distribute loads over a larger area, reducing stress on weak soils. This prevents differential settlement and prolongs pavement life.

Reduction in Construction Materials

The use of GEO Grid Manufacturer in Vadodara reduces the thickness of aggregate layers required, saving natural resources and reducing transport costs.

Environmentally Friendly

By stabilizing soils in situ, GEO grids minimize excavation and land disturbance, aligning with sustainable construction practices.

Flexibility and Adaptability

GEO grids conform to ground irregularities and accommodate soil movements, maintaining structural integrity in dynamic environments.

How to Choose the Right GEO Grid Supplier in India?

When selecting a GEO grid supplier, consider the following:

Product Quality: Verify certifications and test reports.

Experience: Look for suppliers with a proven track record in similar projects.

Technical Support: Ensure access to expert advice and on-site assistance.

Customer Reviews: Seek feedback from previous clients.

After-Sales Service: Confirm warranty terms and maintenance support.

As India continues its journey towards modern, resilient, and sustainable infrastructure, GEO grids have emerged as a cornerstone technology for soil reinforcement and erosion control. Trusted GEO grid manufacturers and suppliers across India provide durable, reliable, and innovative products backed by quality assurance and technical expertise.

Selecting the right partner ensures projects benefit from cost-effective solutions, enhanced structural stability, and environmental responsibility. Whether building highways, railways, retaining walls, or slope protections, GEO grids represent a smart investment for the future of Indian infrastructure.

#GEO Grid Manufacturer in Vadodara#GEO Grid Manufacturer in Gujarat#GEO Grid Manufacturer in India#GEO Grid Supplier in India

0 notes

Text

Ground Improvement Techniques for Coastal and Reclaimed Land Projects

Coastal and reclaimed lands are increasingly becoming valuable zones for urban development, ports, industrial hubs, and infrastructure expansion. However, these areas are typically composed of weak, compressible, and often waterlogged soils, which pose significant challenges to construction. To ensure safety, stability, and longevity of structures built on such land, specialized ground improvement techniques are essential.

In this article, we explore why ground improvement is crucial in coastal and reclaimed areas and the most effective techniques used to transform weak soils into stable foundations.

Why Ground Improvement Is Needed in Coastal and Reclaimed Lands

Reclaimed land is often made by depositing fill material over soft marine clay, silt, or loose sand. These soils generally have:

Low bearing capacity

High compressibility

Poor drainage

Risk of liquefaction (especially during earthquakes)

Without ground improvement, buildings constructed on these soils can experience differential settlement, foundation failure, and long-term instability. Ground treatment not only ensures structural safety but also shortens construction timelines by accelerating consolidation.

Effective Ground Improvement Techniques for Coastal and Reclaimed Sites

Several ground improvement methods are tailored to handle the unique challenges posed by coastal and reclaimed soils. The choice of technique depends on soil conditions, project size, load requirements, and environmental factors.

1. Prefabricated Vertical Drains (PVD) with Preloading

This is one of the most widely used techniques for soft clay improvement in reclaimed land projects. PVDs are synthetic drainage strips inserted vertically into the soil to reduce the drainage path. Preloading, through temporary surcharge, accelerates soil consolidation by expelling pore water faster.

Ideal for: Large-scale reclamation projects like ports, airports, and industrial zones.

2. Vibro Compaction and Vibro Replacement

Vibro Compaction uses a vibrating probe to densify loose granular soils like sand, improving bearing capacity and reducing settlement.

Vibro Replacement (also known as stone columns) is used in soft cohesive soils where granular columns are formed to reinforce the soil.

Ideal for: Coastal zones with loose to medium sand layers and underlying soft soils.

3. Dynamic Compaction

This technique involves dropping heavy weights from significant heights onto the ground surface to densify loose granular soils. It’s fast, cost-effective, and suitable for large areas.

Ideal for: Compaction of reclaimed land before road and embankment construction.

4. Deep Soil Mixing

In deep soil mixing, a binder (usually cement or lime) is mixed with in-situ soil using rotating blades. This enhances strength, reduces permeability, and improves stability.

Ideal for: Coastal areas with soft clay or silty soils and projects requiring high load-bearing capacity.

5. Jet Grouting

Jet grouting involves injecting high-pressure cement slurry into the soil to form soilcrete columns. It’s precise and can be used to control groundwater or form cut-off walls.

Ideal for: Confined urban coastal developments or under existing structures.

6. Geosynthetics and Reinforced Earth

Geotextiles, geogrids, and geocells are used to reinforce weak subgrades and improve load distribution. These are often combined with other ground improvement techniques.

Ideal for: Road embankments, sea walls, and rail lines on coastal terrain.

Considerations for Coastal and Reclaimed Projects

When planning ground improvement in coastal or reclaimed land, engineers must evaluate:

Soil investigation reports

Groundwater levels

Settlement tolerance of structures

Environmental impact

Construction timeline and budget

An integrated geotechnical design approach ensures that the right technique—or combination of techniques—is chosen for optimal results.

Conclusion

As urbanization and climate challenges push development toward coastal and reclaimed zones, ground improvement becomes not just a technical requirement but a foundational necessity. By stabilizing weak soils, enhancing bearing capacity, and reducing long-term settlement risks, ground treatment ensures that infrastructure in these sensitive areas is built on solid ground. For successful outcomes, early planning, expert consultation, and site-specific analysis are key. With the right ground improvement techniques, even the most challenging coastal soils can be transformed into reliable platforms for modern development.

0 notes

Text

Plate Load Test - Falcon Industrial Testing Laboratory

In the construction industry, ensuring the stability and load-bearing capacity of the soil is crucial before any structure is built. At FITPL, we provide accurate Plate Load Testing in Chennai, along with a wide range of geotechnical, construction materials, and environmental testing services.

This blog will cover:

What is a Plate Load Test?

Importance of Plate Load Testing in Construction

Plate Load Test Procedure

Applications of Plate Load Testing

Why Pick FITPL for Chennai Plate Load Testing?

Other Testing Services We Offer

What is a Plate Load Test?

A field test called a Plate Load Test (PLT) is carried out to ascertain the soil's bearing capacity and settling properties under a certain load. A steel plate is placed on the ground, and when weights are added incrementally, the accompanying settlement is measured. The results help engineers design foundations that can safely support structures without excessive settlement.

This test is essential for:

Shallow foundation design

Pavement construction

Assessing subgrade strength for roads and runways

Verifying soil improvement techniques

Importance of Plate Load Testing in Construction

Before constructing any building, bridge, or road, engineers must ensure the soil can withstand the expected loads. Here’s why Plate Load Testing is critical:

1. Determines Safe Bearing Capacity (SBC)

The test provides the maximum load the soil can support without excessive settlement, helping engineers design appropriate foundations.

2. Predicts Settlement Behavior

By analyzing how much the soil compresses under load, engineers can estimate long-term settlement and prevent structural damage.

3. Validates Soil Improvement Techniques

If the soil is weak, techniques like compaction, grouting, or soil replacement are used. PLT verifies if these methods have improved soil strength.

4. Ensures Compliance with Standards

By following ASTM D1194 and IS 1888:1982 (Indian Standard), plate load testing guarantees reliable and consistent results.

Plate Load Test Procedure

The Plate Load Test involves the following steps:

1. Site Preparation

Level the ground where the plate will be placed.

2. Plate Placement

The prepared surface is covered with a steel plate that is either square or circular and typically has a diameter of 30 or 45 cm.

3. Loading Arrangement

A hydraulic jack applies gradual load to the plate.

The load is transferred through a reaction system (either dead weights or kentledge).

4. Settlement Measurement

Dial gauges measure settlement under each load increment.

Readings are taken until the settlement stabilizes.

5. Load-Settlement Curve

A graph is plotted between load vs. settlement.

The ultimate bearing capacity is determined from the curve.

6. Interpretation of Results

The Safe Bearing Capacity (SBC) is calculated by applying a safety factor (usually 2 or 3).

Applications of Plate Load Testing

Plate Load Testing is widely used in:

1. Building Foundations

guarantees that the soil can sustain commercial, industrial, and residential buildings.

2. Road and Pavement Construction

Evaluates subgrade strength for highways, airports, and parking lots.

3. Bridge Foundations

Checks the stability of soil before constructing bridge piers and abutments.

4. Retaining Walls and Embankments

Assesses soil strength to prevent slope failures.

5. Industrial Flooring

Ensures the ground can handle heavy machinery and storage loads.

Why Pick FITPL for Chennai Plate Load Testing?

At FITPL, we are a leading provider of geotechnical and construction material testing services in Chennai. Here’s why clients trust us:

✅ Experienced Engineers & Advanced Equipment – Our team uses high-precision instruments for accurate results.

✅ IS & ASTM Compliant Testing – We follow Indian and international standards.

✅ Quick and Reliable Reports – Detailed test results with professional recommendations.

✅ Comprehensive Testing Solutions – From soil testing to NDT, we cover all construction testing needs.

Other Testing Services We Offer in Chennai

Besides Plate Load Testing, FITPL provides a wide range of testing services:

1. Soil Testing Chennai

Standard Penetration Test (SPT) Chennai

Earth Resistivity Test Chennai

Triaxial Shear Test

California Bearing Ratio (CBR) Test

2. Construction Materials Testing Chennai

Concrete Testing (Compressive Strength, Slump Test)

Steel Testing Chennai (Tensile Strength, Rebound Hammer Test)

Brick & Block Testing

3. Geotechnical Investigation Chennai

Borehole Drilling & Soil Profiling

Groundwater Level Assessment

4. Environmental Testing Chennai

Water Testing Chennai (Drinking, Groundwater, Wastewater)

Air Testing Chennai (Indoor & Outdoor Air Quality)

Pollution Testing Chennai (Noise, Dust, Emissions)

5. Non-Destructive Testing (NDT) Chennai

Ultrasonic Testing (UT)

Rebound Hammer Test

Pile Integrity Testing

6. Specialized Testing

Food Quality Testing Chennai

Wastewater Testing Chennai

One essential geotechnical test to guarantee the stability and security of building projects is the Plate Load Test. At FITPL, we provide accurate and reliable Plate Load Testing in Chennai, along with a full range of soil, construction material, and environmental testing services.

Contact us

Phone Number : +91 8056159517

Website: https://fitpl.in/load-test-pile-integrity-testing-in-chennai.php

0 notes

Text

How Material Testing Labs in Abu Dhabi Contribute to Road Construction Safety? | +971 554747210

As Abu Dhabi continues to invest in world-class infrastructure, the safety and longevity of its road networks have become a top priority. With large-scale urban development, high-speed highways, and increasing traffic volumes, ensuring the structural integrity of roads is essential. This is where the role of a Material Testing Lab in Abu Dhabi becomes indispensable. These specialized labs test and validate the materials used in road construction to guarantee compliance with safety, performance, and durability standards.

Road construction is a complex process involving multiple materials such as asphalt, concrete, aggregates, soil, and bitumen. Any compromise in the quality of these materials can lead to severe consequences, including premature road failure, accidents, and costly repairs. Material testing labs serve as a critical checkpoint in the quality assurance chain, protecting public infrastructure and ensuring safe transportation networks across the emirate.

The Importance of Material Testing in Road Construction

Roads in Abu Dhabi are exposed to extreme environmental and operational stresses—blistering heat, sandstorms, heavy vehicles, and moisture infiltration. To withstand these challenges, every layer of a roadway, from the subgrade to the surface, must be constructed using high-quality materials that meet rigorous specifications.

A certified Material Testing Lab in Abu Dhabi ensures that materials:

Meet local and international standards (e.g., AASHTO, ASTM, BS, EN)

Perform reliably under climatic and mechanical stress

Minimize risks of deformation, cracking, and erosion

Support long-term performance and reduce maintenance costs

Key Materials Tested by Road Construction Labs

Material testing labs evaluate several critical components that directly affect road safety and performance:

1. Soil Testing

The stability of any road begins with the soil it is built upon. Geotechnical testing determines:

Bearing capacity

Moisture content

Soil classification (clay, silt, sand)

Compaction characteristics

Poor soil conditions can lead to subsidence, rutting, or failure of the road foundation. Testing helps engineers design appropriate ground improvement techniques and select suitable fill materials.

2. Aggregate Testing

Crushed stone, gravel, and sand are foundational to road bases and asphalt mixes. Tests include:

Gradation analysis

Los Angeles abrasion test (durability)

Aggregate crushing value (strength)

Water absorption and specific gravity

Using tested and approved aggregates ensures skid resistance, load distribution, and structural strength.

3. Asphalt Testing

Asphalt is the primary surfacing material in Abu Dhabi. Labs test for:

Bitumen content

Marshall stability and flow

Asphalt penetration and softening point

Viscosity and ductility

These tests ensure the mix is suitable for high-temperature conditions and heavy loads, reducing the risk of rutting and surface deformation.

4. Concrete Testing

Used in curbs, drainage channels, and sometimes rigid pavements, concrete must meet compressive strength and durability requirements. Tests include:

Slump test (workability)

Compressive strength test

Setting time

Air content and water-cement ratio

Concrete testing helps prevent premature cracking and structural failures in rigid road components.

Compliance with Abu Dhabi and International Standards

Material Testing Labs in Abu Dhabi operate under stringent quality control systems and follow guidelines established by:

Department of Municipalities and Transport (DMT)

Abu Dhabi Quality and Conformity Council (ADQCC)

International standards such as ASTM, AASHTO, and ISO

Testing is not just a recommendation—it is often a regulatory requirement. For government or mega-infrastructure projects, contractors must submit certified test reports to prove compliance before receiving project approvals or payments.

Role in Quality Control and Safety Assurance

Material testing labs act as an independent verification tool for road authorities, consultants, and contractors. Their data-driven insights enable:

- Design Validation

Engineers can use test results to adjust pavement design based on actual material performance, reducing the likelihood of design failure in the field.

- On-Site Quality Assurance

Labs often collect field samples of materials delivered to construction sites to ensure they match approved specifications and haven’t degraded during transport or storage.

- Construction Monitoring

Real-time testing during road construction—such as field density tests and core sampling—ensures that compaction, layer thickness, and other parameters are within limits.

- Failure Investigation

If premature road damage occurs, forensic testing helps identify root causes, such as substandard asphalt, inadequate compaction, or poor drainage design.

Contribution to Cost Efficiency and Long-Term Durability

Testing might seem like an added expense, but in reality, it saves millions in the long run. Roads that are built with tested and verified materials:

Last longer with fewer repairs

Offer better ride quality and user safety

Require less maintenance and operational downtime

Reduce liability risks for construction firms and authorities

Accreditation and Trust

Choosing an accredited Material Testing Lab in Abu Dhabi ensures that results are reliable, consistent, and legally defensible. Look for labs with:

ISO/IEC 17025 accreditation

Certification from ADQCC

Modern, calibrated equipment and qualified technicians

Proven experience in road construction projects

Case Study: Abu Dhabi Road Project Success Through Testing

In a recent road expansion project near the Al Ain region, initial test results showed that the local soil had high clay content, which could lead to water retention and instability. The material testing lab recommended the use of geo-textiles and granular sub-base to improve drainage and support. The result? A stable foundation, extended road life, and a reduced risk of surface deformation—demonstrating the real-world value of proactive material testing.

Future Outlook: Material Testing and Smart Roads

As Abu Dhabi moves toward smart mobility and autonomous vehicles, the demand for smoother, more durable, and precisely constructed roads will only increase. Material testing labs will play a critical role in ensuring that new-age materials such as recycled asphalt, polymer-modified binders, and nanotechnology-based additives meet performance expectations.

Conclusion

The safety and efficiency of Abu Dhabi’s road infrastructure are deeply linked to the quality of materials used during construction. A Material Testing Lab in Abu Dhabi provides the essential testing and analysis that engineers and project managers rely on to build safer, stronger roads.

From soil compaction to asphalt durability and concrete strength, these labs ensure every component meets rigorous standards, helping reduce risks, extend infrastructure lifespan, and optimize public investments.

#material testing lab in abu dhabi#material testing lab#material testing#testing lab near me#testing lab uae

0 notes

Text

Top Crushed Caliche Midland Projects Rely On | Crush Material

Top Crushed Caliche Midland – Reliable Base Material for Every Project

If you’re in Midland, TX, and searching for the best crushed caliche available, you’re in the right place. At Crush Material, we specialize in delivering high-quality caliche for construction, ranch roads, oilfield pads, and more. Our products are trusted by contractors and developers across West Texas for their strength and affordability.

What Is Caliche Used For in Midland Construction?

Caliche is a natural sedimentary rock primarily made of calcium carbonate. Known for its durability, compaction strength, and cost-effectiveness, it’s one of the most popular materials used in West Texas construction due to its abundance and reliability under extreme weather.

Top Applications of Crushed Caliche in Midland

Driveways and Road Bases Our material is widely used to create solid, dust-resistant driveways and access roads. It compacts tightly and provides a stable base layer—perfect for rural and residential applications.

Foundation Subgrades Before pouring concrete or asphalt, contractors use our spec base to reduce shifting and enhance structural stability.

Oilfield & Commercial Pads In West Texas, caliche is the go-to choice for oilfield and commercial pad sites. Its excellent load-bearing capacity makes it ideal for heavy equipment and high-traffic zones.

Parking Lots and Storage Yards Many contractors prefer caliche solutions to cover wide, flat areas. It forms a clean, low-maintenance surface resistant to weathering and wear.

Landscaping and Erosion Control From walking paths to edging and decorative coverage, it blends naturally into the local environment while acting as an erosion barrier.

Our Product Lineup in Midland

We supply high-quality crushed caliche and aggregate materials with fast delivery across Midland and surrounding areas. Pricing per ton:

Non-spec Caliche Base – $9

Spec Caliche Base – $10

57 Rock – $20

Chat (Fines) – $6

For bulk rates and delivery quotes, call us at +1 (806) 241-7274.

Why Choose Crush Material in Midland?

Learn More About Caliche in Midland

Texas DOT Guidelines – Base and Subgrade Materials

ASTM Standards – Construction Aggregate Classifications

Order Premium Caliche in Midland Today

0 notes

Text

How to Handle Basement and Concrete Floor Cracking the Right Way

When a cracked basement floor appears, it’s easy to dismiss it as a harmless flaw. But even hairline fractures can signal deeper structural issues or moisture infiltration risks. Ignoring these signs can result in progressive slab separation, mold growth, and ultimately damage that compromises the stability of the basement or the rooms above it.

The Connection Between Floors and Walls

It’s common to see floor and wall cracks appear together, especially in basements where shifting foundations or hydrostatic pressure create stress points. When both surfaces start to split, it typically indicates movement in the structure or excessive pressure caused by poor drainage around the home. Professional evaluation is necessary to determine whether these are shrinkage cracks or signs of foundation settling.

The Impact of Concrete Damage in Subgrade Areas

Hydrostatic pressure and expansive soils are two of the leading causes of cracks in concrete basement floor surfaces. These openings provide an entry point for moisture, which can degrade interior finishes and introduce musty odors or allergens. Left untreated, the problem can evolve into pooling water, floor heaving, or structural erosion. Prompt attention prevents these secondary effects from developing.

How to Properly Repair Structural Slab Cracking

When faced with separation or breaks in concrete, it’s not enough to apply a surface patch. To repair concrete cracks effectively, contractors assess the type of crack, its location, and whether movement is active. Solutions may include epoxy injections, polyurethane foam sealing, or carbon fiber stitching, depending on the damage profile. Each method is designed to restore both appearance and integrity.

Choosing the Right Crack Repair Technique

There’s no one-size-fits-all method when it comes to concrete crack repair. Active cracks, which widen or shift over time, require flexible sealing compounds that can accommodate movement. Static cracks may be permanently sealed with epoxy for long-term durability. In cases of repeated cracking, the underlying cause—such as water intrusion or foundation movement—must be resolved to prevent recurrence.

Finding a Reliable Repair Team

Not all contractors specialize in structural and subgrade surfaces. When reviewing concrete repair companies, it’s important to choose one with experience in interior slab repair, basement environments, and foundation diagnostics. Reputable providers offer moisture testing, structural analysis, and targeted treatment plans tailored to each type of crack and floor condition.

Restoring Floors Without Full Replacement

Not every issue requires ripping out and pouring new concrete. In most cases, concrete floor repair can be done with minimal disruption using modern techniques that blend strength and flexibility. These include slab jacking, sealant application, joint stabilization, and surface refinishing. The goal is to make the floor structurally sound, moisture-resistant, and level, all without the cost of full replacement.

0 notes

Text

Geomembrane Sheet: An In-Depth Guide to Contemporary Waterproof Solutions

Within the fields of civil engineering, environmental conservation, and building, fluid migration must be controlled. Ldpe film price in Delhi Geomembrane sheets fill this need. These artificial liners are employed globally for containment procedures like landfills, mining, water reservoirs, and agriculture. Geomembrane sheets have transformed liquid barrier management, supplanting older materials such as clay with more effective, strong, and economical solutions.

This article delves into all there is to know about geomembrane sheets—everything from their applications and types to their installation and benefits—culminating in an in-depth FAQ section to cover the inevitable questions.

What is a Geomembrane Sheet?

A geomembrane sheet is a low-permeability man-made synthetic membrane structure or liner employed with any geotechnical engineering product to manage fluid migration in a structure, system, or human-made project. Usually constructed from polymers such as HDPE, LLDPE, PVC, or EPDM, geomembranes are specially recognized for their superior impermeability and chemical resistance.

Types of Geomembrane Sheets

There are different types of geomembrane sheets, each being specifically designed for particular applications. The most widely used types are:

High-Density Polyethylene (HDPE) The most commonly used geomembranes are HDPE due to their high resistance to chemicals, durability, and UV stability. Ldpe plastic film Exporter in Ahmedabad They are suitable for extreme environmental conditions.

Applications: Landfill liners Wastewater treatment plants Mining tailings

Linear Low-Density Polyethylene (LLDPE) LLDPE is more adaptable and has superior subgrade form similarity compared to HDPE. It is commonly used where settlement or movement is anticipated.

Applications: Decorative pond Floating covers Canal liners

Polyvinyl Chloride (PVC) PVC geomembranes are straightforward to present and versatile but require chemical resistance and UV steadinessy. They are usually employed in projects with a low predicted life.

Uses: Tunnel liners Temporary containment Water storage

Ethylene Propylene Diene Monomer (EPDM) EPDM may be a manufactured elastic that's profoundly adaptable and weather-resistant and is broadly connected in arranging and material.

Uses: Garden ponds Roofing membranes Irrigation reservoirs

Properties of Geomembrane Sheets

Knowledge of post-manufacture properties of geomembrane sheets is important to select an appropriate product for the application. post-manufacture properties are:

Permeability Geomembranes are almost impermeable with extremely low fluid transmission rates, and post-manufacture properties are often used in containment systems.

Chemical Resistance General geomembranes are chemically resistant to many chemicals such as acids, bases, and solvents.

UV Resistance UV resistance is important for geomembranes that are exposed to sunlight. post-manufacture properties of HDPE are highly UV-stable.

Tensile Strength and Elongation High tensile strength provides the membrane with the capability to resist stress, and elongation provides it with the ability to stretch without fracturing.

Puncture Resistance Puncture resistance guards against installation and usage damage, particularly in adverse terrain.

Production of Geomembrane Sheets

Geomembranes are produced by a number of processes, the most prevalent being:

Blown Film Extrusion: Produces uniform thickness HDPE and LLDPE membranes.

Calendering: Principally utilized for PVC membranes.

Cover: Joins a number of layers to supply extra quality and wanted properties.

Every process influences the texture, strength, and flexibility of the final product.

Geomembrane Sheet Installation

Installation is essential for performance. Here is a step-by-step description:

Site Preparation Clear and smooth the subgrade surface. Remove sharp debris and objects to avoid punctures.

Panel Layout Geomembrane sheets are delivered in rolls and are rolled onto the site. Overlaps are designed considering wind direction and slopes.

Seaming Sheets are connected with thermal fusion welding (hot wedge or extrusion welding) to form watertight joints.

Testing Joints are tested with vacuum testing, air pressure testing, or spark testing to meet integrity.

Anchoring Edges are anchored in trenches or by mechanical fasteners to keep them from moving caused by environmental forces.

Applications of Geomembrane Sheets

Geomembrane sheets have wide applications in various industries

Waste Management Utilized in landfill caps and base liners to keep leachate from penetrating the soil and groundwater.

Mining Utilized in heap leach pads, tailing ponds, and process solution containment systems.

Water Containment Suitable for reservoirs, canals, and pond liners because they are impermeable.

Agriculture Utilized in water system lakes, water gathering, and excrement tidal ponds.

Energy Utilized in power plants for ash containment areas and cooling ponds.

Environmental Protection Prevent contamination in hazardous material containment and biogas digesters.

Benefits of Using Geomembrane Sheets

Geomembranes provide many benefits

Superior impermeability stops fluid migration.

Resistance to chemicals allows use in hazardous conditions.

Longevity and durability, commonly lasting more than 20 years with proper installation.

Cost-effective compared to conventional clay liners.

Versatility, with different materials being applicable for different purposes.

Environmentally friendly, lowering the risk of contamination.

Limitations and Considerations

Although very effective, geomembranes do have limitations:

Easily punctured during installation if not handled with care.

Needs skilled labor to be properly installed and seamed.

May degrade due to UV exposure if left exposed for long periods without covering.

High upfront expense, though with long-term payback.

Maintenance and Inspection

Regular inspections guarantee the structural integrity of the geomembrane system:

Visual inspections for breaches, punctures, or seam opening.

Leak detection systems such as geoelectric surveys can detect subsurface leaks.

Preventive actions, like covering exposed surfaces with soil or geotextiles, can prolong lifespan.

Sustainability and Environmental Impact

Geomembrane sheets are vital to environmental protection.

They ensure that groundwater and soil are not contaminated, promote sustainable waste management, and facilitate water conservation in dry areas.

Most of them are also recyclable and can be reused in some applications, which is in line with green engineering procedures.

Conclusion

Geomembrane sheets have become indispensable in various industries due to their superior containment, durability, and environmental safety. Whether you’re working on a landfill, agricultural reservoir, or mining project, Ldpe shrink film manufacturers in Gujarat choosing the right geomembrane and ensuring its proper installation is critical for long-term success. As technology advances, these synthetic liners will continue to evolve, offering even greater performance and sustainability in modern engineering.

If you’re planning a project that involves fluid containment or environmental protection, consider geomembrane sheets not as an option but as a necessity. Their unmatched versatility, strength, and cost-effectiveness make them the cornerstone of modern containment systems.

Frequently Asked Questions (FAQ) Q1: How long do geomembrane sheets last? A: Lifespan is material- and exposure-dependent. HDPE geomembranes can be more than 30 years in optimal conditions, while PVC can be 10–15 years outdoors.

Q2: Can geomembranes be repaired when damaged? A: Yes, minor tears or punctures can be repaired by heat welding patches or adhesive patches, depending on the material type.

Q3: Are geomembranes eco-friendly? A: Yes, they help protect the environment by preventing contamination. Some types are also recyclable.

0 notes

Text

Geocell for Road Construction in Dubai

Building Sustainable Roads in the Desert: The Power of Geocell for Road Construction in Dubai

The rapid growth of Dubai’s urbanization and its infrastructural expansion is renowned around the world. As Dubai continues to rise up from the sands of the desert the roads and highways have to withstand extreme conditions of weather, a heavy flow of traffic, and constant construction activity. With the harsh desert environment posing numerous challenges — such as poor soil stability, frequent sand movement, and extreme temperatures — traditional road-building methods often fall short in durability and cost-effectiveness.

To meet these issues, Geocell for Road Construction in Dubai is emerging as a novel solution. It is designed to strengthen weak soils and stop erosion Geocells are changing how roads get constructed within the UAE. The team at Modern Seal Group, we believe in providing modern infrastructure solutions that can last for a long time. Geocell technology is in the forefront of this advancement.

Geocell for Road Construction in Dubai — The Future of Sustainable Infrastructure (Call to Action: Choose Modern Seal Group Today)

Geocell used for Road Construction in Dubai is rapidly becoming the most popular option for engineers, contractors and developers who want long-term road durability within one of the most challenging environments. The three-dimensional honeycomb structures are constructed from high-density polyethylene (HDPE) that are specifically designed to contain and hold in place the granular material. When filled with soil, sand and gravel, these geocells are able to distribute the load more uniformly, decreasing stress on the soil beneath it and preventing collapse or deformation.

Modern Seal Group utilizes geocells for construction of roads throughout Dubai to construct roads that’s not just efficient in cost but also highly durable. One of the most significant benefits of geocells is the ability to offer solid ground reinforcement, even in subgrades that are sandy or soft which are prevalent across areas like the Gulf region. This results in less material requirements in addition to a reduction in excavation costs and a shorter time to construct, ultimately making it easier to save time and money.

Alongside structural strength, geocell for road construction in Dubai is also a contributor to sustainable development of the environment. In reducing the use of non-renewable aggregates and decreasing erosion of soil geocells play an important part in green construction methods. This is in line with Dubai’s plan to become a global leading city in green infrastructure and sustainable development.

Modern Seal Group has completed several projects utilizing geocells to construct roads in Dubai showing their unparalleled reliability in commercial, industrial and residential development. If it’s access roads within construction zones, highways for public use or private driveways our solutions will last for years and low maintenance.

Additionally, the intense temperatures of the UAE is often a reason for asphalt roads to break and become deteriorated. Geocell technology can reduce the risk by enhancing the load-bearing capacity and providing more thermal resistance. This is what makes geocells for roads construction Dubai not just an excellent choice for technical reasons, but also an excellent decision to invest in infrastructure that will last for a long time.

As a reputable provider within this region Modern Seal Group delivers turnkey geocell solutions from design and supply through installing and maintaining. Our experts make sure that the project meets international standards and is able to adapt to the terrain and climate of the region.

If you’re planning an entirely new road or looking to upgrade the existing one it is now the perfect time to look into geocells to build roads within Dubai. Allow Modern Seal Group guide you towards safer, more durable and more sustainable roads which can handle today’s demands and the demands of tomorrow.

Frequently Asked Questions (FAQs)

Q1: What exactly is geocells and how does it function for road building? A geocell is a cellular confinement device composed of HDPE created to stabilize soil. When employed in road building, geocells can be expanded in situ and filled with material such as gravel or soil. This results in a stronger base that distributes loads evenly and prevents erosion, particularly in Dubai’s sandy terrain.

Q2 What makes geocell the best choice to construct roads for road construction in Dubai? The desert in Dubai poses difficulties like soft subgrades and shifting sands. Geocell systems are extremely effective in stabilizing these terrains which ensures durability and efficiency. They are also able to perform well under extreme temperatures, and help reduce use, which makes them ideal suitable for use in UAE.

Q3 Are geocell roads more cost-effective than conventional roads? Yes. Geocell technology cuts down on the need to dig and filling materials that are expensive and reduces transportation costs and speeds up construction time. This can result in substantial savings when compared to traditional road construction methods.

Q4: How long will the road that is reinforced with geocells endure? When properly maintained and designed geocell roads are able to last for many years. They are resistant to common types of wear and tear such as cracking, rutting and erosion, even when surrounded by heavy traffic and severe weather conditions.

Q5 Could geocell be used to create temporarily-used road? Absolutely. Geocell systems are incredibly versatile and can be utilized for temporary and permanent roads. Their modular design permits fast installation and quick removal, which makes them suitable for construction access roads and infrastructure for events.

Get in touch with Modern Seal Group today to find out the ways geocells to construct roads in Dubai will elevate your next infrastructure project to unparalleled durability and sustainable.

#Geocell for Road Construction in Dubai#Geocell for Road Construction#Geocell for Road Construction in UAE

0 notes

Text

Geogrid Retaining Wall Saudi Arabia: Building Resilient Infrastructure with Shivoham Fabtech Pvt Ltd

In the challenging terrains and rapidly expanding infrastructure landscape of Saudi Arabia, traditional retaining wall solutions often fall short. Enter the modern solution: geogrid retaining wall Saudi Arabia systems. With enhanced stability, cost-effectiveness, and flexibility, geogrid walls have emerged as the preferred choice for civil engineers, developers, and government agencies.

At Shivoham Fabtech Pvt Ltd, we provide cutting-edge geosynthetic solutions tailored to Saudi Arabia’s harsh climatic and geotechnical conditions. This blog explores the benefits, applications, and science behind geogrid retaining walls—and why they're shaping the future of infrastructure in the region.

What is a Geogrid Retaining Wall?

A geogrid retaining wall is a soil-reinforced wall system that uses geogrids—synthetic polymer grids—embedded within layers of compacted fill. These grids interlock with the soil, increasing its load-bearing capacity and enabling the construction of steep slopes or vertical walls.

Unlike concrete or masonry walls that rely solely on mass or anchoring, geogrid retaining wall Saudi Arabia systems distribute pressure horizontally, improving wall stability even in areas prone to soil erosion, high heat, and seismic activity.

Why Choose Geogrid Retaining Wall in Saudi Arabia?

The Kingdom of Saudi Arabia is undergoing massive transformations in infrastructure—from NEOM City and The Line to expressways, oil and gas hubs, and desert urbanization. The unique desert environment poses challenges such as:

Unstable sandy soils

Intense temperature fluctuations

Limited water drainage

Rapid urban development timelines

Here’s why geogrid retaining wall Saudi Arabia solutions are the ideal response:

✅ Enhanced soil stability and strength

✅ Lower construction costs

✅ Faster and safer installation

✅ Excellent performance in high temperatures

✅ Durability in saline and arid conditions

Major Applications of Geogrid Retaining Walls in Saudi Arabia

1. Transportation Infrastructure

Geogrid for road construction in Saudi Arabia has become essential, especially for elevated roadways and embankments in areas like Riyadh, Jeddah, and Dammam. These geogrid systems stabilize the subgrade and help retain soil during road expansion or highway flyover projects.

Geogrid retaining walls also reduce the likelihood of settlement and cracks, making roads safer and more durable in the long term.

2. Urban Development and Real Estate

With new residential, commercial, and mixed-use zones being developed across the Kingdom, geogrid retaining wall Saudi Arabia solutions allow developers to create elevated plots and terraced landscapes. The geogrid system blends strength with aesthetic options such as modular blocks or green facings.

3. Industrial and Oil Sector Foundations

Saudi Arabia’s oil and gas installations are often located in remote and unstable terrains. The use of soil reinforcement geogrid in Saudi Arabia ensures reliable foundations for refineries, pipelines, and storage yards. The flexibility and load resistance of geogrids make them ideal for such high-load applications.

4. Slope Stabilization in Mountainous Regions

Areas like Asir and Al-Baha feature steep topography that requires reinforcement. Geogrid slope stabilization in Saudi Arabia ensures that these slopes remain intact during rainy seasons, reducing the risk of landslides or erosion.

Components and Design of a Geogrid Retaining Wall

Designing a geogrid retaining wall Saudi Arabia system requires a clear understanding of soil mechanics, geosynthetic properties, and load dynamics. Here’s what typically goes into one:

1. Facing Units

These can be concrete blocks, precast panels, or natural stone facings—offering both function and form.

2. Geogrid Reinforcement Layers

The geogrid layers are placed between compacted fill at specific intervals and extend into the retained soil to provide strength.

3. Backfill Soil

Well-compacted granular or engineered fill is used to build up the wall’s interior structure.

4. Drainage Systems

Perforated pipes, gravel layers, or geotextiles ensure proper water flow, essential for desert areas that may experience flash floods.

Why Polyester Biaxial Geogrid in Saudi Arabia Is a Preferred Choice

Polyester biaxial geogrid in Saudi Arabia has emerged as one of the top solutions for its two-directional strength and high resistance to UV radiation and chemical corrosion.

Key Advantages:

High tensile strength in both longitudinal and transverse directions

Excellent dimensional stability

Resistance to high temperatures and harsh chemicals

Lightweight and easy to transport

Long service life under desert conditions

At Shivoham Fabtech Pvt Ltd, our polyester biaxial geogrids are designed specifically for Saudi Arabia’s challenging environments, ensuring high performance and reliability.

Soil Reinforcement Geogrid in Saudi Arabia: Enhancing Weak Substrates

Much of Saudi Arabia’s terrain consists of loose, sandy, or silty soils, which are inherently weak. Soil reinforcement geogrid in Saudi Arabia is used to strengthen these substrates for applications like:

Parking lots and container yards

Airport runway expansion

Foundations for prefab structures

These geogrids confine the soil, distribute the load, and prevent deformation under stress—delivering superior performance compared to unreinforced bases.

Geogrid Slope Stabilization in Saudi Arabia: Safe Slopes, Secure Communities

In addition to retaining walls, geogrids play a vital role in slope reinforcement. Whether it’s road cuts, embankments, or natural slopes, geogrid slope stabilization in Saudi Arabia offers:

Erosion control

Support for vegetation

Stability during seismic events

Long-term durability against wind and rainfall

By installing geogrids in the form of stepped or wrapped slopes, engineers can create safe slopes that blend naturally into the landscape.

Use of Geogrids in Saudi Arabia: A Market on the Rise

The adoption of geogrids in Saudi Arabia is witnessing significant growth, thanks to the country’s massive investment in civil infrastructure, logistics, and tourism projects. From Red Sea resorts to futuristic smart cities, geogrid applications are being used for:

Retaining walls in urban areas

Load-bearing platforms in industrial zones

Reinforced soil structures near coastal and desert terrains

The construction industry is increasingly shifting from traditional methods to modern, sustainable, and efficient systems like geogrid walls.

Why Partner with Shivoham Fabtech Pvt Ltd?

At Shivoham Fabtech Pvt Ltd, we are committed to providing state-of-the-art geosynthetic solutions tailored for the Saudi market. Our experience in supplying high-performance geogrid retaining wall Saudi Arabia systems has made us a preferred partner for engineers, architects, and contractors across the Middle East.

Why Choose Us:

🏗 Technical Expertise: Custom-engineered designs for specific soil and load conditions.

🧪 Tested Quality: All products are manufactured and tested according to international standards.

⏱ Timely Delivery: We understand the value of deadlines in large-scale projects.

📞 After-Sales Support: From design consultation to on-site training and supervision.

Case Study: Highway Retaining Wall in Eastern Province

Project Scope: Construction of a 10-meter high geogrid retaining wall for a highway expansion project in Dammam.

Challenges:

Loose sandy soil

Proximity to seawater (risk of corrosion)

High summer temperatures

Solution by Shivoham Fabtech Pvt Ltd: We supplied a customized polyester biaxial geogrid in Saudi Arabia designed to withstand saline conditions and high tensile loads. The geogrid layers were installed with granular backfill and modular block facing. The result: a durable, aesthetic, and maintenance-free wall that has stood the test of time.

Conclusion: Stronger, Smarter Walls with Geogrid Retaining Systems

As Saudi Arabia continues to invest in futuristic infrastructure, sustainable and high-performance solutions like geogrid retaining wall Saudi Arabia systems are proving indispensable. They offer a reliable alternative to traditional retaining structures while enhancing safety, aesthetics, and cost-efficiency.

Shivoham Fabtech Pvt Ltd is proud to be at the forefront of this geosynthetic revolution—empowering civil engineers and project managers with innovative, customizable geogrid solutions designed for the desert.

Get in Touch with Shivoham Fabtech Pvt Ltd

Looking to integrate a geogrid retaining wall Saudi Arabia system into your next project?

#geogrid retaining wall Saudi Arabia#Geogrid for Road Construction in Saudi Arabia#geogrid slope stabilization in Saudi Arabia#soil reinforcement geogrid in Saudi Arabia#Polyester Biaxial Geogrid in Saudi Arabia#geogrids in Saudi Arabia

0 notes

Link

1 note

·

View note

Text

Concrete Crack Repair: Restoring Structural Integrity and Long-Term Durability

Concrete is one of the most widely used construction materials in the world. It’s strong, versatile, and long-lasting — but it’s not immune to damage. Over time, cracks can develop due to weather changes, ground movement, heavy loads, or poor installation. Left untreated, these cracks can compromise both the appearance and safety of your structure.

That’s where concrete crack repair comes in. Whether you’re dealing with hairline surface cracks or deeper structural issues, repairing damaged concrete promptly may prevent further deterioration, save on costly replacements, and maintain compliance with safety standards.

This guide explores the causes of concrete cracks, the different types of repair methods, and why choosing professionals like concrete crack repair specialists is essential for high-quality, lasting results.

Common Causes of Concrete Cracking

Before diving into repair methods, it's important to understand why cracks occur in the first place. These issues often arise due to one or a combination of the following:

Shrinkage during curing: As concrete dries and hardens, it contracts. If not properly controlled, this may lead to surface-level cracks.

Thermal expansion and contraction: Changes in temperature cause concrete to expand and contract. Over time, this can stress the material and lead to fractures.

Excessive load stress: Driveways, footpaths, and slabs bearing constant weight (like vehicles or machinery) may develop pressure cracks.

Subgrade settlement: If the soil or base beneath the concrete shifts or erodes, the unsupported slab may crack or sink.

Poor construction practices: Inadequate reinforcement, incorrect mix ratios, or lack of control joints can all contribute to premature cracking.

Understanding the root cause is crucial to selecting the most appropriate repair method — which is why property owners are encouraged to consult experts like trusted crack repair services for an accurate assessment.

Types of Concrete Cracks

Not all cracks are created equal. Some are purely cosmetic, while others indicate deeper structural concerns. Here's a breakdown:

Hairline cracks: Narrow surface cracks that typically don’t affect structural integrity but may still allow water ingress.

Settlement cracks: Often caused by shifting soil beneath a slab, leading to uneven or sunken areas.

Heaving cracks: Result from ground movement or tree roots pushing up the slab.

Structural cracks: Wider, deeper fissures that may compromise the stability of load-bearing elements.

Expansion cracks: Develop from thermal movement and often follow a straight path near joints.

Early identification helps ensure a timely repair and minimises the risk of further complications.

Popular Methods of Concrete Crack Repair

Once the type and cause of the crack are determined, professionals select from several proven repair techniques. Each method varies in complexity and suitability depending on the location and severity of the damage.

1. Epoxy Injection

Best for narrow, deep cracks in structural concrete, epoxy resins bond the surfaces and restore original strength. This method is ideal for beams, columns, and slabs where strength retention is critical.

2. Polyurethane Sealants

Flexible and water-resistant, polyurethane is used in areas prone to moisture or movement. It doesn’t restore structural capacity but helps prevent water ingress.

3. Routing and Sealing

This method involves enlarging the crack and filling it with a sealant. It’s useful for wide, non-structural cracks in pavements, driveways, or car parks.

4. Stitching

For structural repairs, metal staples or rods are inserted across the crack and anchored with epoxy. It’s a more invasive method but highly effective for major splits.

5. Slab Jacking (or Mudjacking)

Used when concrete has sunk or tilted, this process involves pumping a stabilising grout beneath the slab to lift and level it. It’s common in sidewalks and floors.

6. Overlay Systems

In cases of extensive surface cracking, applying a new concrete overlay may restore visual appearance and surface performance.

Expert concrete repair solutions evaluate the condition of the structure and recommend the most suitable technique, ensuring the repair isn’t just cosmetic but functional and durable.

When to Call in the Professionals

While minor cracks may seem like easy DIY fixes, improper repairs may lead to recurring problems or hidden damage. Consider hiring a professional if:

Cracks exceed 2mm in width or are spreading

There’s visible movement or tilting of the slab

Cracks are accompanied by water damage or mould

The damage occurs on load-bearing or vertical structures

You’re unsure of the underlying cause

Experienced teams bring diagnostic tools, safety equipment, and high-performance materials that most homeowners don’t have access to — making the repair both safer and longer-lasting.

On Tumblr's Home Repair Projects, many users have shared before-and-after photos that show the difference a proper repair makes — especially for driveways, pool surrounds, and balconies.

Concrete Repair in Residential vs. Commercial Settings

While the core techniques remain similar, the scale and objectives may differ between residential and commercial projects.

Residential Concrete Repairs:

Driveways

Garage slabs

Garden paths

Patios

Pool decks

Commercial & Industrial Concrete Repairs:

Warehouse floors

Parking structures

Commercial pavements

Loading docks

Retaining walls

Businesses especially benefit from working with concrete crack repair specialists who understand deadlines, public safety, and access logistics for larger, high-traffic areas.

Preventing Future Cracks

Once repaired, keeping concrete in good condition helps extend its life and prevents new issues. Here are a few practical tips:

Seal the surface: Use high-quality sealants to protect against moisture, stains, and chemical damage.

Ensure proper drainage: Avoid water pooling on or around concrete surfaces.

Control heavy loads: Don’t exceed weight limits for driveways or suspended slabs.

Use control joints: These guide the natural movement of concrete and help prevent uncontrolled cracking.

Schedule regular inspections: Early detection of minor faults may prevent major repairs down the line.

For more advice on concrete care and outdoor structure maintenance, check out resources on Tumblr Home Design & DIY.

Why Choose SONAA for Concrete Crack Repair?

SONAA delivers industry-leading trusted crack repair services with a team of trained technicians, engineers, and project managers. Here's what sets them apart:

Detailed diagnostics and structural assessment

Certified methods and high-quality materials

Minimal disruption to properties or businesses

Strict compliance with Australian Standards

Proven track record across residential, commercial, and strata sectors

End-to-end project management and reporting

By choosing SONAA, property owners can expect workmanship that lasts — not just a surface fix.

0 notes

Text

What is the Best Concrete Mix for Driveways?

When it comes to installing or replacing a driveway, choosing the right concrete mix is a decision that significantly affects the strength, longevity, and appearance of your surface. At BellevueNebraska, we understand that your driveway is more than just a parking spot—it's a vital part of your home’s first impression and functionality.

In this blog post, we’ll dive into the best types of concrete mixes for driveways, what to consider when choosing one, and answer some common questions about driveway concrete to help you make the best choice.

Why Choosing the Right Concrete Mix Matters

Concrete is not a one-size-fits-all solution. Different projects require different mixes depending on several factors such as load, climate, and finish. Driveways, in particular, bear the constant stress of vehicles, changing temperatures, water exposure, and freeze-thaw cycles. Choosing the wrong mix could lead to cracking, chipping, or premature wear.

Recommended Concrete Mix for Driveways

For most residential driveways, the recommended concrete mix is a high-strength mix of 4000 psi (pounds per square inch) with a water-to-cement ratio of 0.45–0.50. This type of mix balances workability, durability, and strength.

Key Elements of the Ideal Mix:

Compressive Strength: 4000 psi or higher

Aggregate Size: Typically ¾-inch for better bonding

Air Entrainment: 5–7% to protect against freeze-thaw damage

Water-to-Cement Ratio: Between 0.45 and 0.50 to reduce shrinkage and cracking

Let’s explore what each of these factors means for your driveway.

Strength and Durability

4000 psi concrete is a strong mix capable of handling vehicle loads without cracking. In areas with heavy use (such as RV or truck driveways), you may even consider 4500 psi or 5000 psi.

Air-Entrained Concrete

This is especially important in colder climates like Nebraska. Air entrainment introduces tiny air bubbles into the concrete, allowing it to expand and contract without cracking as temperatures fluctuate.

Water-to-Cement Ratio

This is a crucial factor in concrete performance. Too much water weakens the concrete, while too little can make it hard to work with. Keeping the ratio in the sweet spot ensures the right mix of strength and workability.

Additives and Enhancements

To make your driveway even better, certain additives can be included:

Fibers: Help control cracking

Plasticizers: Improve flow without adding more water

Sealants: Protect the surface from oil, moisture, and stains

These enhancements add durability and reduce long-term maintenance.

Tips for Pouring a Durable Driveway

Even the best concrete mix won't last long if not installed correctly. Here are a few tips we always follow at BellevueNebraska:

Use steel rebar or mesh: To add reinforcement

Proper subgrade preparation: Ensures stability and prevents sinking

Control joints: Allow for natural expansion and contraction

Curing process: Proper curing is essential for strength—use blankets or sealers to retain moisture

Maintenance Matters

Once installed, a concrete driveway should be sealed every 2–3 years to protect it from the elements. Avoid using deicing salts in the first winter, as they can damage fresh concrete. Regular cleaning and prompt oil stain removal will also extend the life of your driveway.

Frequently Asked Questions (FAQs)

1. What is the best concrete mix ratio for driveways?

For a residential driveway, a 4000 psi mix with a 0.45–0.50 water-to-cement ratio is ideal. It combines strength, durability, and workability. In colder regions, make sure the mix is air-entrained.

2. How thick should a concrete driveway be?

The standard thickness for most residential driveways is 4 inches. For driveways that support heavy vehicles, 5 to 6 inches is recommended. Thicker slabs can better resist cracking and structural stress.

3. How long should I wait before driving on new concrete?

You should wait at least 7 days before driving on a new concrete driveway. However, full strength is typically reached around 28 days, so avoid heavy vehicles until then if possible.

4. Can I use regular concrete for a driveway?

Regular concrete (like 2500–3000 psi) can be used, but it may not last as long under daily vehicle stress. For best results, opt for a higher strength like 4000 psi, especially in regions with freeze-thaw cycles or heavy use.

5. Does concrete color or finish affect durability?

The color or decorative finish does not impact the strength, but certain finishes (like broom finishes) provide better traction. Sealing decorative concrete is important to protect the surface and maintain appearance.

Final Thoughts

Your driveway is a major investment, and choosing the right concrete mix is the foundation (literally!) of a long-lasting surface. At BellevueNebraska, we specialize in crafting durable, professional-grade driveways using the best practices and mixes suited to our Nebraska climate.

Whether you're planning a new driveway or replacing an old one, our team is ready to deliver a solution that looks great and lasts for years.

Get in Touch

Have questions or need a quote for your concrete driveway in Bellevue, NE? Contact BellevueNebraska today and let us help you choose the right mix and finish for your home.

#ConcreteDriveway#DrivewayConstruction#ConcreteMixTips#BellevueNebraska#HomeImprovement#DrivewayMaintenance#ConcreteRepair#NebraskaHomes#OutdoorProjects#ResidentialConstruction

0 notes

Text

Plate Load Testing chennai - Falcon Industrial Testing Laboratory

When it comes to construction materials testing in Chennai, the plate load testing chennai is a crucial geotechnical investigation method used to determine the bearing capacity of soil. At FITPL, we provide reliable plate load testing services in Chennai to ensure the stability and safety of your construction projects.

What is a Plate Load Test?

Before building pavements, foundations, or other structures, the plate load test is a field test used to determine the soil's ability to support loads.This test helps engineers understand how much load the soil can withstand without excessive settlement.

Why is Plate Load Testing Important?

Ensures safe foundation design

Prevents uneven settlement of structures

Helps in optimizing construction costs

Complies with geotechnical investigation standards

Plate Load Test Procedure

Site Preparation – The test area is cleared and leveled.

Plate Placement – A steel plate (usually 300mm to 750mm in diameter) is placed on the ground.

Load Application – Incremental loads are applied using a hydraulic jack, and settlement is measured.

Data Recording – Load vs. settlement data is recorded until the soil reaches its failure point.

Analysis: Settlement parameters and bearing capacity are ascertained.

Applications of Plate Load Testing in Chennai

Plate load testing is widely used in:

Building construction – To assess foundation stability

Road and pavement construction – To check subgrade strength

Industrial projects – For heavy machinery foundations

Bridge construction – To ensure safe load distribution

Other Testing Services in Chennai

At FITPL, we offer a wide range of construction materials testing and geotechnical investigation services, including:

1. Soil Testing in Chennai

Standard Penetration Test (SPT) in Chennai – Measures soil density and strength

Earth Resistivity Test in Chennai – Assesses soil’s electrical resistance for earthing systems

2. Building Materials Testing in Chennai

Steel Testing in Chennai – Ensures quality and strength of reinforcement bars

Non-Destructive Testing (NDT) in Chennai – Evaluates concrete strength without damage

3. Environmental Testing in Chennai

Water Testing in Chennai – Checks purity and contamination levels

Air Testing in Chennai – Monitors indoor and outdoor air quality

Pollution Testing in Chennai – Assesses environmental impact

Wastewater Testing in Chennai – Ensures compliance with disposal standards

4. Food Quality Testing in Chennai

Ensures food safety and regulatory compliance

Why Choose FITPL for Plate Load Testing in Chennai?

Experienced geotechnical engineers

Advanced testing equipment

Accurate and reliable results

Fast turnaround time

Compliance with IS standards

The plate load test is an essential part of geotechnical investigation in Chennai, ensuring the safety and durability of construction projects. In order to satisfy industry standards, FITPL offers thorough soil, building material, and environmental testing services.

For plate load testing and other construction material testing services in Chennai, contact FITPL today!

Ensure your project’s stability with professional plate load testing in Chennai!

Contact us

Phone number : +918056159517

Website: https://fitpl.in/load-test-pile-integrity-testing-in-chennai.php

0 notes

Text

What Makes Soil Testing Labs in Abu Dhabi Essential for Infrastructure Projects? | +971 554747210

With the UAE experiencing rapid development, especially in cities like Abu Dhabi, the demand for robust infrastructure continues to grow. From towering skyscrapers and commercial hubs to smart cities and transportation networks, these ambitious projects depend heavily on reliable ground conditions. That’s where soil testing lab in Abu Dhabi become indispensable.

Soil testing isn’t just a regulatory checkbox—it’s a scientific and engineering cornerstone that ensures the safety, stability, and longevity of infrastructure projects. This blog delves into why soil testing labs are vital to Abu Dhabi's infrastructure landscape, what services they provide, and how they contribute to sustainable urban growth.

Why Is Soil Testing Crucial for Infrastructure?

Before any foundation is laid, understanding the properties of the underlying soil is a prerequisite. Every structure, whether it’s a high-rise building, bridge, or road, relies on the soil beneath it for support. Faulty or insufficient soil analysis can lead to catastrophic structural failures, legal liabilities, and costly delays.

Key reasons why soil testing is essential for infrastructure:

Ensures foundation stability

Determines load-bearing capacity

Identifies soil compaction levels

Detects groundwater levels and contamination

Supports compliance with construction regulations

Soil testing labs in Abu Dhabi play a frontline role in these evaluations, guiding engineers and developers with precise data.

Types of Infrastructure Projects That Rely on Soil Testing in Abu Dhabi

1. Residential and Commercial Construction

Whether it's a villa or a commercial complex, proper soil analysis helps determine the type of foundation required—shallow, deep, or pile-supported.

2. Highways and Roads

Soil compaction and moisture content testing are crucial in preventing road failures, potholes, and subsidence.