#touchscreen hmi

Explore tagged Tumblr posts

Text

Omron Touch Screen HMI NS5-SQ10-V2 bd

Hi friends, I am here. Available: HMI, PLC, inverter, and display/monitor sales and services. For any queries, contact: 01978444849

Thank you.

0 notes

Text

#humanmachineinterface#hmi#automation#industrialautomation#hmitouchscreen#hmitouchpanel#plc#iot#engineering#scada#touchscreen#inverter#siemens#visionsensor#areasensor#doorsensor#manufacturing#towerlight#mechanicalelectrical#abb#pressuresensor#allenbradley#iiot#ipc#autonics#porsche#photoelectricsensor#rotaryencoder#proximity#proximitysensor

0 notes

Text

Revolutionizing Wire Harness Production with Automated Crimping Technology

The modern manufacturing landscape increasingly hinges on automation to boost both efficiency and accuracy. A standout innovation driving this transformation is the advent of automatic wire cutting and crimping machines. These sophisticated systems offer a host of compelling advantages, fundamentally reshaping the way wire harnesses are produced.

At the core of these machines' appeal is their ability to combine blazing-fast operation with a remarkably streamlined wire changeover process. Unlike older, more labor-intensive methods, these automated solutions harness cutting-edge Computer Numerical Control (CNC) technology. This allows for precise, computer-managed adjustments to both the leading and trailing wire ends, eliminating the need for tedious manual tweaks to cutting and stripping lengths. What's more, the integration of electrically controlled blades drastically simplifies the engineering challenges typically associated with adapting to different wire specifications. This built-in flexibility enables swift transitions between various wire types and dimensions, a critical factor in maximizing production agility and minimizing costly downtime.

Precision and Efficiency Through Digital Control

The operational backbone of automatic wire cutting and crimping machines lies in a fully digital and mathematically driven control system. Every crucial parameter—from cutting and stripping lengths to blade values, semi-stripping settings, and terminal crimping specifications—can be precisely configured via an intuitive interface. This comprehensive digital mastery, particularly the electrically adjustable blades, not only supercharges production efficiency but also positions these machines at the forefront of automation compared to other models. For instance, single-head automatic wire crimping machines are adept at handling multiple tasks: wire cutting, single-end stripping, double-end stripping, and single-end crimping, all executed with remarkable speed, stability, and intelligence. Their touchscreen interface further refines the setup experience, making all adjustments fully digitized and straightforward.

Workforce Optimization and Cost Savings

The advanced automation inherent in these machines empowers manufacturers to optimize their workforce deployment. By taking over repetitive and intricate tasks, these systems free up human capital, allowing employees to focus on more strategic, value-added activities. This shift often translates into significant reductions in overall operational costs. Another key benefit is the modular design of these machines. Their reliance on standardized components not only simplifies initial setup but also dramatically cuts down on ongoing maintenance expenses, thanks to readily available and easily replaceable parts. Equipped with cutting-edge electrical controls and proprietary software, these machines boast a highly user-friendly Human-Machine Interface (HMI). This accessibility means that even operators with minimal specialized training can efficiently manage complex wire processing, including wire and terminal changes, effectively "democratizing" the operation of such sophisticated equipment.

Conclusion

In essence, automatic wire cutting and crimping machines represent a monumental leap forward in manufacturing technology. Their synergy of high-speed performance, CNC-driven precision, electrically controlled blades, and intuitive digital interfaces offers compelling advantages over traditional approaches. These machines stand out across various categories of terminal equipment and have secured widespread adoption in today's market, garnering widespread acclaim from users for their innovative design and robust performance.

For in-depth technical resources on automatic terminal crimping machines, explore our specialized page.

2 notes

·

View notes

Text

A Practical Guide to Customizing TFT LCD Displays for Embedded Projects

When designing an embedded system, picking the right display module is more than a technical choice — it directly shapes how users interact with your product.

From medical devices and HMIs to industrial controllers and smart panels, standard TFT LCD modules may not always be enough. That’s where custom displays come in — offering flexibility in electrical interface, mechanical layout, and visual performance.

This guide covers the five key areas you should consider when customizing a TFT LCD for your embedded project.

1. FPC Layout and Pin Mapping

The Flexible Printed Circuit (FPC) connects your LCD module to the mainboard, and in custom designs, this interface is often the first thing to change.

Ask yourself:

Do you need a uniquely shaped or angled FPC to fit inside your housing?

Are there ICs, resistors, or other components on the backlight or CTP that require mechanical clearance?

Is your SBC’s connector pinout compatible with the LCD’s FPC layout?

A mismatch here can lead to signal errors, mechanical stress, or even damage to components.

2. Backlight Brightness and Color Temperature

Not all embedded devices live under the same lighting.

If your product is used outdoors or in industrial lighting, consider high-brightness backlights (≥800 nits). For environments where aesthetics and color warmth matter (like smart mirrors or indoor kiosks), choose the right LED color temperature:

3000K (Warm White): Soft, suitable for medical or ambient lighting

5000K (Neutral White): Balanced tone, accurate colors

6500K+ (Cool White): Sharper, more industrial feel

A poorly lit display can make a great device feel underwhelming.

3. Touch Panel Shape and Bonding Options

If your display includes a touch interface, customizing the Capacitive Touch Panel (CTP) is critical.

Typical customizations include:

Round corners, logo cutouts, button holes

Bonding methods:

Optical bonding: Improves visibility, reduces reflections, stronger seal

Air bonding: More affordable and easier to assemble

The bonding method directly impacts touch accuracy, display clarity, and long-term reliability.

4. Surface Treatments: AG, AR, and AF

For devices exposed to bright light or frequent finger contact, display surface treatments make a noticeable difference.

AG (Anti-Glare): Scatters reflected light, improving readability

AR (Anti-Reflection): Enhances contrast in sunlight or strong lighting

AF (Anti-Fingerprint): Reduces smudges, improves touch feel

Combining AG+AF is a common choice for public-facing touchscreen displays.

5. Want to Learn More?

If you’re building with platforms like RK3566, PX30, or Allwinner boards and need a reliable display solution — including driver compatibility and electrical tuning — check out our full technical article:

👉 Read the Full Custom TFT LCD Guide

You can also browse driver/device tree examples on GitHub:

📂 rocktech-tft-display-configs

2 notes

·

View notes

Text

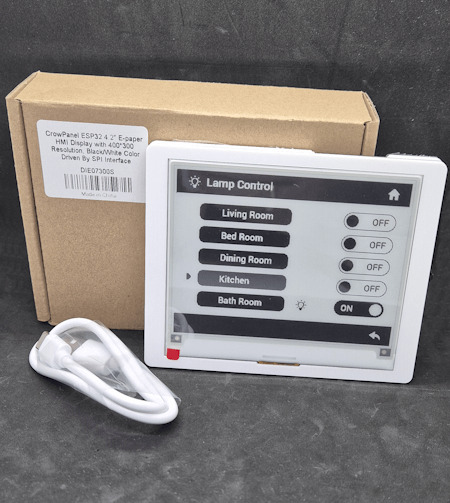

Elecrow CrowPanels vorgestellt: OLED, E-Paper und HMI-Display im Überblick

Elecrow setzt seine Innovationsreihe im Bereich Displays fort und überrascht erneut mit spannenden neuen Geräten (genannt CrowPanels). Nachdem ich bereits ein HMI-Display der Marke unter Review: Elecrow CrowPanel – Das perfekte Display für ESP32-Projekte? auf diesem Blog vorgestellt habe, freue ich mich, nun drei weitere spannende Produkte testen und meinem Publikum präsentieren zu dürfen. Die neuen Geräte – ein rundes OLED-Display, ein energiesparendes E-Paper-Display und ein vielseitiges 5-Zoll-Touch-Display mit HMI-Funktionen – bieten interessante Möglichkeiten für Maker, IoT-Enthusiasten und alle, die innovative Projekte realisieren möchten. https://youtu.be/Eb9wuOQyaVY In diesem Beitrag gebe ich euch einen Überblick über die drei neuen CrowPanels von Elecrow, ihre wichtigsten Eigenschaften und potenziellen Einsatzbereiche. In zukünftigen Beiträgen werde ich die Geräte einzeln genauer unter die Lupe nehmen und euch alle Details zu Performance, Funktionen und Praxiseinsatz liefern.

Disclaimer: Die in diesem Beitrag vorgestellten Geräte wurden mir von der Firma Elecrow kostenfrei für ein Review zur Verfügung gestellt. Dies hat jedoch keinen Einfluss auf meine Meinung oder die Bewertung der Produkte. Alle Tests und Einschätzungen basieren auf meinen eigenen Erfahrungen und sind objektiv.

Wer ist Elecrow? Ein kurzer Überblick über das Unternehmen

Elecrow ist ein Unternehmen, das sich auf die Entwicklung, das Design (einschließlich Prototyping) und die Fertigung von Elektronik spezialisiert hat. Seit der Gründung im Jahr 2014 hat sich die Firma als Anbieter von Open-Source-Hardware und elektronischen Komponenten etabliert und bedient Kunden weltweit. Mit einem Schwerpunkt auf Innovation, Qualität und erschwinglichen Lösungen unterstützt Elecrow sowohl Maker und Technikbegeisterte als auch professionelle Anwender bei der Umsetzung ihrer Projekte.

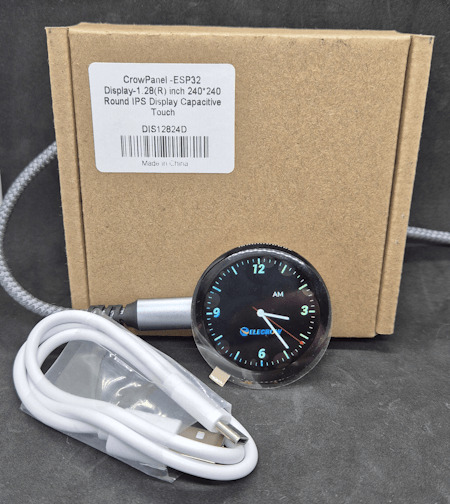

CrowPanel-ESP32 1.28" Round Display – Kompaktes Runddisplay für vielseitige Projekte

Das CrowPanel-ESP32 1.28" Round Display ist ein kompaktes und leistungsstarkes Displaymodul, das mit einem hochintegrierten ESP32-C3-Chip ausgestattet ist. Durch die Kombination eines runden 1,28-Zoll-IPS-Touchscreens mit vielseitigen Sensoren, Tasten und Schnittstellen eignet sich das Modul ideal für IoT-Projekte, Wearables oder interaktive Anwendungen. Es bietet Unterstützung für zahlreiche Entwicklungsumgebungen wie Arduino IDE, MicroPython oder PlatformIO und ermöglicht dank LVGL-Bibliothek die einfache Erstellung grafischer Benutzeroberflächen. Read the full article

3 notes

·

View notes

Text

What is the maintenance process for an automatic paper bag machine?

Investing in an automatic paper bag machine is a smart move for businesses looking to scale their packaging operations and deliver eco-friendly solutions. However, like any high-performance industrial equipment, it’s essential to maintain the machine properly to ensure consistent output, reduce downtime, and maximize its operational lifespan.

At Prakash Machineries Pvt Ltd, we not only manufacture high-quality automatic paper bag machines but also guide our clients on the best practices for maintaining them. In this article, we’ll walk you through the maintenance process—from daily upkeep to long-term care—so your machine stays efficient and productive for years to come.

Why Maintenance Matters

Regular maintenance isn’t just about avoiding breakdowns—it’s about:

Extending the life of your machine

Reducing unexpected production halts

Maintaining bag quality and consistency

Minimizing repair costs

Ensuring safety for your operators

A well-maintained machine operates smoothly, uses less energy, and supports faster return on investment.

Daily Maintenance Checklist

The foundation of a good maintenance routine starts with daily attention. These are simple yet effective steps your operator should follow every day:

✅ 1. Clean the Machine Surfaces

Wipe down the external surfaces to remove dust, paper scraps, and glue residue.

Make sure the rollers and cutters are clean to avoid smudges or improper cuts.

✅ 2. Inspect Glue Nozzles and Tanks

Check if glue tanks are full.

Clean any dried glue from nozzles to prevent clogging and uneven application.

✅ 3. Check Paper Roll Alignment

Ensure the paper is feeding smoothly without shifting or wrinkling.

Misalignment can affect bag folding, printing, and sealing.

✅ 4. Observe for Unusual Noises or Vibrations

Any unfamiliar sound might indicate a loose component or potential fault. Report and log such issues.

Weekly Maintenance Tasks

Once a week, your machine operators or technical team should perform a more detailed inspection:

🛠️ 1. Lubricate Moving Parts

Apply grease or oil to the bearings, gearboxes, and other moving components as per manufacturer recommendations.

Use high-quality lubricants to avoid buildup or corrosion.

🛠️ 2. Inspect Belts and Chains

Check for signs of wear or tension issues.

Replace any frayed belts or loose chains promptly.

🛠️ 3. Clean Sensors and Electrical Panels

Debris and dust near sensors can cause automation issues.

Use dry air to clean the control panel and PLC components safely.

🛠️ 4. Check Cutters and Blades

Inspect the sharpness and alignment of rotary or flat cutters.

Dull blades should be replaced or sharpened to ensure clean, accurate cuts.

Monthly Maintenance and Calibration

Once a month, it’s good practice to schedule deeper preventive checks:

🔧 1. Check Motor and Drive Units

Examine the servo motors, drive belts, and coupling systems.

Look for overheating signs, oil leaks, or abnormal wear.

🔧 2. Calibrate Sensors and PLC Systems

Recalibrate bag length sensors, glue sensors, and print registration systems.

Ensure your touchscreen panel (HMI) settings match production specifications.

🔧 3. Examine the Handle Unit and Printing Section (if equipped)

Inspect the handle-pasting mechanism for adhesive buildup or wear.

If using inline printing, clean the anilox rollers, plates, and ink tanks.

Spare Parts and Inventory Management

To minimize downtime, always keep critical spare parts in stock, such as

Cutting blades

Glue nozzles

Sensors

Belts

Bearings

Control relays

At Prakash Machineries Pvt. Ltd., we offer full support with spare part kits and supply you with a recommended inventory list during machine installation.

Operator Training and Documentation

A well-trained operator is your first line of defense against machine issues. Ensure your team:

Understands the machine’s interface and alert systems

Follows safety protocols during cleaning or part replacements

Keeps a maintenance logbook for tracking issues and routine service

We provide comprehensive training sessions during installation and offer ongoing support to help your operators become proficient in both operation and maintenance.

When to Call for Professional Service

While most maintenance tasks can be handled in-house, you should schedule a professional service visit in the following cases:

Sudden drop in production speed

Irregular bag sizes or gluing errors

Motor or PLC malfunctions

Electrical safety alerts

After 6–12 months of continuous use for full inspection

Our team at Prakash Machineries Pvt. Ltd. offers annual maintenance contracts (AMCs), remote troubleshooting, and on-site technician visits across India for complete peace of mind.

Conclusion: Maintenance = Maximum Uptime

An automatic paper bag machine is a powerful asset for any packaging business—but like any industrial machine, it performs best when well cared for. A simple, consistent maintenance routine can dramatically improve your machine’s efficiency, reduce breakdowns, and extend its lifespan.

At Prakash Machineries Pvt Ltd, we believe in building machines that last—and supporting them with expert guidance, spare parts, and proactive service.

Need help setting up a maintenance plan for your paper bag machine? Get in touch with Prakash Machineries Pvt Ltd today for personalized service support, spare part kits, and AMC options tailored to your machine and production goals.

#paper bag manufacturer#manufacturer#machines#paper bag#bags#v bottom#square bottom#flexo#breakfast#delicious#chocolate#cake#critical role#chris sturniolo#baking#alien stage#cooking#dan and phil

1 note

·

View note

Text

Revolutionizing Cleanroom Operations: The Power of Brinda Pharma's Mobile Laminar Air Flow (MLAF) System

In today's highly regulated and sensitive industries like pharmaceuticals, biotechnology, and micro-electronics, maintaining an immaculate cleanroom environment is not just a best practice—it's a critical necessity. Brinda Pharma Technologies understands this imperative, and that's why we're proud to offer our state-of-the-art Mobile Laminar Air Flow (MLAF) system, also known as the Mobile HEPA Trolley. This innovative solution is designed to bring unparalleled flexibility and contamination control directly to your critical processes.

What is the MLAF/Mobile HEPA Trolley?

The MLAF system is a portable, versatile, and highly effective air filtration unit engineered to provide a continuous supply of clean, HEPA-filtered air precisely where and when you need it. Unlike fixed laminar flow systems, our mobile trolley ensures that your product integrity and quality are protected even during material movement and transfer within your cleanroom or controlled environment.

Key Features and Unmatched Benefits:

Exceptional Mobility: Easily move the unit to different workstations, transfer points, or areas requiring temporary ultra-clean conditions, optimizing your workflow and facility utilization.

Guaranteed Contamination Control: Our advanced filtration technology captures an astonishing 99.999% of airborne particles down to 0.3 microns, creating a protective barrier against contaminants and safeguarding your sensitive materials.

Continuous Clean Air Supply: Equipped with an inbuilt battery, UPS (Uninterrupted Power Supply), and inverter, the MLAF system ensures uninterrupted operation for a minimum of one hour after a full charge, eliminating concerns about power fluctuations.

Versatile Design: Adaptable to various cleanroom types and sizes, the MLAF system seamlessly integrates into your existing infrastructure.

User-Friendly Operation: With intuitive controls, adjustable settings, and comprehensive operation and maintenance manuals, the system is designed for ease of use by your personnel.

Enhanced Safety: Integrated monitoring systems and built-in alarms provide an extra layer of safety and operational assurance.

GMP and Regulatory Compliance: The Brinda Pharma MLAF system meets, and often exceeds, stringent industry standards for air quality control, with full documentation provided to ensure your compliance needs are met.

How It Works:

The MLAF system operates by drawing in ambient air, which then passes through a multi-stage filtration process. Primary and secondary filters efficiently remove larger contaminants, followed by the high-efficiency HEPA filter. The purified air is then discharged in a unidirectional, laminar flow pattern, establishing a sterile zone that actively protects against airborne particulate ingress.

Customization and Support:

To further enhance functionality, our MLAF systems can be equipped with a range of accessories, including:

Pressure gauge for airflow monitoring

Clean down timer for automated cleaning protocols

Pilot light for clear operational status

Buzzer for safety alerts

UV light for enhanced sterilization

HMI+PLC Based Control System for intuitive touchscreen monitoring and parameter adjustments.

Brinda Pharma Technologies is a trusted name in manufacturing and exporting high-quality cleanroom equipment. We offer comprehensive services, including delivery, professional installation, validation, and reliable annual maintenance contracts (AMCs) to ensure the long-term performance and efficiency of your MLAF system.

Applications Across Industries:

The versatility and effectiveness of the MLAF system make it indispensable across a wide array of industries, including:

Pharmaceutical manufacturing

Biotechnology research and production

Laboratories

Micro-electronics assembly

Aerospace

API and excipient manufacturing

Food manufacturing

Advanced indoor agriculture

Empower your operations with the superior contamination control and operational flexibility of Brinda Pharma's Mobile Laminar Air Flow (MLAF) / Mobile HEPA Trolley.

For more information and to explore how the MLAF system can benefit your specific requirements, please visit our product page: MLAF - Mobile Laminar Air Flow / Mobile HEPA Trolley.

0 notes

Text

Omron Touch Screen HMI NS5-SQ10-V2 bd

0 notes

Text

Tube Furnace Manufacturer

At furnacemanufacturer, we take pride in being a trusted and leading Tube Furnace Manufacturer, providing high-quality, precision-engineered tube furnaces designed to meet the demanding needs of laboratories, research institutions, and industrial applications. With a commitment to innovation, durability, and customer satisfaction, we deliver advanced thermal processing solutions that exceed industry standards.

What is a Tube Furnace?

A tube furnace is an essential piece of equipment used for high-temperature heat treatment applications, such as material testing, sintering, calcination, annealing, and chemical vapor deposition. These furnaces consist of a cylindrical heating chamber with a heating element and a central tube, typically made of ceramic or quartz, through which samples are heated in a controlled atmosphere.

Why Choose furnacemanufacturer as Your Tube Furnace Manufacturer?

As a reputed Tube Furnace Manufacturer, we understand the critical role that heating systems play in various sectors such as metallurgy, ceramics, semiconductors, and academic research. Here’s what sets us apart:

1. Custom-Built Designs

We design and manufacture tube furnaces in various configurations including horizontal, vertical, and split-type models to suit specific client requirements. Our furnaces are available in single-zone, multi-zone, and gradient temperature zone options to ensure optimal thermal uniformity.

2. Wide Temperature Range

Our furnaces operate efficiently across a wide temperature range, typically from 300°C to 1800°C, depending on the model and the type of heating element used (Kanthal, molybdenum disilicide, or silicon carbide). This makes them suitable for a broad spectrum of scientific and industrial heating processes.

3. Energy Efficiency & Safety

We incorporate high-quality insulation materials and precision temperature control systems to ensure maximum energy efficiency. Safety features such as over-temperature protection, door interlocks, and digital controllers come standard with every furnace.

4. Advanced Control Systems

Our tube furnaces are equipped with user-friendly digital PID temperature controllers, programmable logic controllers (PLCs), and touchscreen HMI interfaces for accurate and automated operation. Remote monitoring and data logging capabilities are also available for quality assurance and compliance.

5. Robust Construction

Each furnace is built using corrosion-resistant materials and heavy-duty frames to ensure long-term durability and stable performance even under extreme conditions.

Applications of Our Tube Furnaces

As a top Tube Furnace Manufacturer, furnacemanufacturer caters to various industries including:

Research Laboratories – for testing material properties and thermal experiments.

Semiconductor Industry – for annealing wafers, oxidation, and diffusion processes.

Metallurgy – for sintering, brazing, and other high-temperature treatments.

Chemical Processing – for pyrolysis and decomposition of chemical compounds.

Ceramics & Glass – for firing and heat treatment of specialty materials.

Our Commitment to Quality & Support

At furnacemanufacturer, every product undergoes stringent quality checks and testing to ensure compliance with ISO and CE standards. Our experienced team provides technical guidance, customization, installation assistance, and prompt after-sales service to ensure smooth and hassle-free operation for our clients.

Global Reach, Local Support

With a strong distribution network and presence across major cities and industrial hubs, we serve clients both nationally and internationally. Our commitment to timely delivery, transparent communication, and affordable pricing makes us a preferred Tube Furnace Manufacturer among clients worldwide.

Get in Touch

If you are looking for a reliable and experienced Tube Furnace Manufacturer, trust furnacemanufacturer to deliver tailored heating solutions that enhance your productivity and research capabilities. Contact us today for a free consultation, product brochure, or custom quote.

0 notes

Text

Forming the Future: Exploring Double Deck Compression Technology

In the evolving world of materials processing and component manufacturing, efficiency, precision, and space optimization are critical to staying competitive. Enter the Double Deck Compression Forming Machine—an advanced piece of industrial equipment designed to significantly boost productivity in high-volume compression molding operations. This dual-level system is revolutionizing the way manufacturers approach composite material forming by doubling throughput without doubling floor space.Get more news about double deck compression forming machine,you can vist our website!

What Is a Double Deck Compression Forming Machine?

This specialized machine features two vertically aligned forming decks within a single press framework, allowing simultaneous molding operations at two levels. It is primarily used in compression molding—an established method for shaping thermoset and thermoplastic composites—where heat and pressure are applied to form materials into predetermined shapes.

Each deck operates independently or synchronously, depending on the production requirement. The technology is widely used in the automotive, aerospace, household goods, and construction sectors, where high precision and scalability are essential.

Key Components and Operation

The machine typically includes:

Upper and Lower Press Units: Each equipped with its own mold set and hydraulic system. These units apply controlled pressure and heat to shape the material.

Heating Plates: Designed to reach and maintain specific temperatures suitable for curing composite materials.

Advanced PLC Control Systems: Programmable Logic Controllers (PLCs) allow operators to monitor and manage individual cycles for each deck in real time.

Safety and Interlock Systems: Ensure both levels function safely during concurrent operations.

Advantages of the Double Deck Configuration

The defining feature of this machine—two mold decks—translates into several strategic advantages:

Double the Output: Two molds running simultaneously mean a significant increase in production without proportional increases in labor or factory floor requirements.

Space Efficiency: Stacked operation utilizes vertical space, making it ideal for workshops or factories where horizontal expansion is limited.

Energy Optimization: Shared hydraulic and control systems lower overall energy consumption per unit produced.

Flexible Operation: The decks can run similar or different molds, allowing manufacturers to diversify production without additional equipment.

Cost Savings: Enhanced throughput and reduced footprint ultimately lead to lower cost per part.

Application in Modern Industries

In automotive manufacturing, for example, the double deck compression forming machine is used to produce lightweight yet strong components like interior panels, battery enclosures for electric vehicles, and underbody shields—all from composite materials. The aerospace industry uses it to form parts that require both high-performance materials and repeatable manufacturing cycles. Even consumer goods industries apply this technology for molding plastic or fiber-reinforced products at scale.

Technological Trends and Innovations

Modern iterations of these machines are integrating smart manufacturing features, including:

IoT Monitoring: Real-time data collection and remote diagnostics.

Servo-Driven Hydraulics: For improved pressure control and energy efficiency.

Quick Mold Change Systems: Reducing downtime between production runs.

Human-Machine Interfaces (HMIs): Touchscreen interfaces that enhance user control and training efficiency.

Conclusion

The Double Deck Compression Forming Machine stands at the intersection of innovation and practicality. By enabling simultaneous operations in a compact footprint, it empowers manufacturers to meet increasing demand without compromising on quality or efficiency. As industries continue to seek scalable, eco-conscious production methods, this machine proves to be a versatile and future-ready asset on the modern factory floor.

0 notes

Text

Empowering Smarter Operations: The Role of HMIs & Inverters in Industry 4.0

In today’s connected manufacturing landscape, agility and user-centric control are key to staying ahead. At Dropship Automation Solutions, we specialize in equipping industries with the tools that make intelligent automation possible. In this blog, we highlight two game-changing technologies—Human-Machine Interfaces (HMIs) and Industrial Inverters—which serve as the control and power optimization centers of modern production lines.

Whether you're enhancing operator interaction or fine-tuning motor performance, HMIs and inverters offer real-time insight and precision that define the future of factory automation.

1. HMIs: Bridging Humans and Machines

What HMIs Do Human-Machine Interfaces are interactive platforms that allow operators to control, monitor, and configure machines visually. From touchscreen panels to advanced SCADA systems, HMIs streamline operations by offering real-time system data in a user-friendly format.

Common HMI Types & Industrial Use Cases

Types: Basic Text Panels, Graphic Displays, Web-Based Interfaces, SCADA Systems

Applications: Process visualization, alarm handling, production analytics, remote access

Benefits: Faster decision-making, simplified control, error reduction, centralized monitoring

Why HMIs Matter Without HMIs, navigating industrial systems would require complex, manual processes. HMIs empower workers with intuitive interfaces, real-time diagnostics, and interactive control—making operations more agile, transparent, and efficient.

2. Inverters: Optimizing Energy for Performance

What Inverters Do Inverters convert fixed-frequency electrical power into variable frequency and voltage—allowing motors to operate at optimal speeds based on load demands. They are essential for energy-efficient motor control and system adaptability.

Inverter Types & Industry Applications

Types: General-purpose inverters, vector control inverters, regenerative inverters

Applications: HVAC systems, water treatment plants, material handling, machine tools

Benefits: Energy savings, reduced power surges, extended equipment life, precise control

Why Inverters Matter Inverters not only improve energy efficiency but also add flexibility to production processes. They reduce mechanical stress, cut operational costs, and enable speed variation—essential for adapting to real-time production needs.

Unified Intelligence: The Power of HMIs + Inverters

Now imagine a fully connected workspace where:

HMIs visualize inverter performance and allow on-the-fly adjustments,

Inverters regulate motor speed based on data from the HMI,

Together, they enable energy optimization and simplified control.

This integration fosters predictive maintenance, remote configuration, and faster troubleshooting—building a smarter, leaner manufacturing system.

Conclusion: Unlock Productivity with Next-Gen Interfaces & Control

As the shift to intelligent factories accelerates, investing in responsive control and adaptive power systems becomes non-negotiable. At Dropship Automation Solutions, we provide robust HMIs and cutting-edge inverters designed for the rigors of Industry 4.0.

✅ Ready to improve operational control and energy efficiency? Let’s build your smart factory together.

📞 Contact: +1 (234) 288-1755 📧 Email: [email protected] 📍 Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

CrowPanel Advance 7“ HMI von Elecrow – großes Display, großer Funktionsumfang

Mit dem CrowPanel Advance 7“ hat Elecrow ein spannendes All-in-One-Display im Sortiment, das nicht nur durch seine Größe auffällt. Das Touch-Display bringt alles mit, was man für moderne IoT- oder UI-Projekte braucht: Ein hochauflösendes IPS-Panel, einen leistungsstarken ESP32-S3 mit KI-Funktionen und zahlreiche Schnittstellen. Ich habe mir das Panel in den letzten Tagen genauer angeschaut – hier kommt mein erster Eindruck. https://youtu.be/mYx4jaoDOHQ Hinweis: Das hier vorgestellte Produkt – das CrowPanel Advance 7“ HMI – wurde mir von Elecrow kostenfrei für ein Review zur Verfügung gestellt. Der Beitrag spiegelt ausschließlich meine persönliche Meinung wider. Es gab keinerlei Vorgaben oder Einflussnahme auf Inhalt oder Bewertung.

Technische Daten – kompakt zusammengefasst

Hier die wichtigsten Eckdaten auf einen Blick: - Displaygröße: 7 Zoll IPS, 800x480 Pixel - Touch: Kapazitiver Touchscreen - Controller: ESP32-S3, Dual-Core, 240 MHz, mit KI-Unterstützung - Speicher: 16 MB Flash + 8 MB PSRAM - Schnittstellen: USB-C, GPIOs, microSD, Audio, Kamera-Port - Betriebssysteme/Sprachen: Unterstützt Arduino, LVGL, MicroPython und Meshtastic - Stromversorgung: 5 V via USB-C Diese Kombination macht das Panel zu einer interessanten Lösung für viele Anwendungen – ob als HMI (Human Machine Interface), Info-Terminal, DIY-Steuerung oder sogar als kleines Smart-Home-Display.

Ausgepackt und begutachtet

Das Panel kam gut verpackt bei mir an. Im Lieferumfang enthalten war neben dem Display auch ein passendes USB-C-Kabel sowie eine kleine Stiftleiste für GPIO-Anschlüsse. Das Gehäuse wirkt solide, die Rückseite ist sauber verarbeitet und bietet mehrere Befestigungspunkte, z. B. für den Einbau in ein Gehäuse oder Frontpanel. Was mir besonders gefallen hat: Trotz seiner Größe ist das Gerät erstaunlich leicht und flach. Das macht es deutlich einfacher, das Panel in eigene Projekte zu integrieren – z. B. in eine Steuerbox oder ein Dashboard.

Display & Touch – ein echter Hingucker

Das 7-Zoll-IPS-Display überzeugt direkt beim ersten Einschalten: Die Farben sind kräftig, die Blickwinkelstabilität ist hervorragend und die Auflösung ist für diese Größe völlig ausreichend. Auch der Touchscreen reagiert präzise und flüssig – so, wie man es von einem kapazitiven Panel erwartet. Es fühlt sich an wie ein kleiner Tablet-Bildschirm, allerdings offen für deine eigenen Ideen und Projekte.

Viel Power unter der Haube: ESP32-S3

Das Herzstück des Panels ist ein ESP32-S3 – ein leistungsfähiger Mikrocontroller mit zwei Kernen, 240 MHz Taktfrequenz und integrierten Funktionen rund um künstliche Intelligenz (KI). In Kombination mit dem großzügigen Speicher (16 MB Flash, 8 MB PSRAM) eignet sich das Gerät nicht nur für einfache UI-Anwendungen, sondern auch für Projekte mit Machine Learning oder Bildverarbeitung – zum Beispiel in Verbindung mit einer angeschlossenen Kamera.

Schnittstellen & Möglichkeiten

Ein Blick auf die Anschlussmöglichkeiten zeigt: Das Panel will mehr sein als nur ein Display. Neben USB-C (für Daten und Strom) sind auch ein microSD-Karten-Slot, ein Audio-Ausgang, ein Kamera-Port und eine GPIO-Stiftleiste vorhanden. Damit lässt sich das CrowPanel leicht erweitern und in größere Projekte einbinden – sei es zur Datenspeicherung, als Audioplayer oder zur Anbindung an Sensoren und Aktoren. Read the full article

2 notes

·

View notes

Text

What is the price range of a high-speed V-bottom paper bag making machine in India?

As India steadily transitions towards eco-friendly packaging alternatives, the demand for paper bags—particularly V-bottom paper bags—has increased exponentially. Whether it's for groceries, medicine, bakery items, or garments, these lightweight, recyclable paper bags are now a staple across industries.

If you're planning to start or expand your paper bag manufacturing business, one of the first questions you’re likely to ask is:

"How much does a high-speed V-bottom paper bag making machine cost in India?"

At Prakash Machineries Pvt. Ltd, we specialize in manufacturing state-of-the-art V-bottom paper bag machines designed for Indian conditions and high-volume production. In this article, we break down the price range, the factors influencing cost, and why a machine from Prakash Machineries Pvt. Ltd offers long-term value for your investment.

🛠️ Factors That Influence the Price

Let’s explore what causes the price of a paper bag machine to vary so much:

✅ 1. Production Speed

Speed is one of the biggest cost factors. A machine that produces 600 bags per minute costs more than one that produces 150 bags per minute, but the productivity and return on investment (ROI) are significantly higher.

✅ 2. Bag Size Flexibility

Machines that allow for a wider range of bag sizes (width, length, bottom fold) often require more robust design and control systems—making them slightly more expensive.

✅ 3. Paper Compatibility

At Prakash Machineries Pvt. Ltd, our machines are designed to run on a variety of papers like Kraft, newsprint, and recycled paper. Machines that can handle higher GSMs (thicker papers) and coated papers require stronger feeding and cutting systems.

✅ 4. Printing Options

Adding a flexographic inline printing unit (1-color or 2-color) will increase the machine cost by ₹2–₹5 lakhs, but allows you to print branding directly onto the bag—saving time and money in the long run.

✅ 5. Automation and Features

Modern machines come with:

Touchscreen HMI panels

Servo motors

Automatic tension control

Error detection systems

These features add to the cost, but drastically improve productivity and reduce downtime.

✅ 6. After-Sales Service and Brand Reputation

Brands like Prakash Machineries Pvt. Ltd are known for their high-quality components, durability, and excellent after-sales support. While the upfront cost may be slightly higher than unknown brands, the reliability and longevity of the machine ensure better ROI over time.

🏭 Who Needs a High-Speed Machine?

A high-speed V-bottom paper bag machine is ideal for:

Packaging material suppliers

Food service vendors

Exporters

Paper product wholesalers

Government or FMCG contract suppliers

If you're catering to bulk orders or supplying bags across regions, a machine with 300–600 BPM speed can help you meet large demands without delays.

📈 What’s the ROI (Return on Investment)?

Let’s say you invest in a ₹15-lakh machine that produces 400 bags per minute. That’s:

24,000 bags per hour

1.92 lakh bags in 8 hours

Over 5 lakh bags per week, assuming 6 working days

Even with modest pricing of ₹0.30–₹0.60 per bag, the ROI can be achieved in just a few months.

At Prakash Machineries Pvt. Ltd, our machines are engineered for low maintenance and long-term durability, ensuring your investment keeps delivering value year after year.

🔧 Why Choose Prakash Machineries Pvt. Ltd

Here’s what sets our machines apart:

✅ High-speed output up to 600 BPM

✅ Support for multiple bag sizes

✅ Inline flex0 printing (optional)

✅ Touchscreen controls & automation

✅ Indian engineering with global quality

✅ On-site training and installation

✅ Spare parts availability & service support

We offer complete guidance—from machine selection to setup and production training—so you get the most from your investment.

Investing in a high-speed V-bottom paper bag machine is a smart move in today’s eco-conscious and regulation-driven market. While prices may vary depending on features, a quality machine from Prakash Machineries Pvt. Ltd ensures high productivity, long-term savings, and strong customer support.

Whether you're just starting or expanding, we have a model to fit your production needs and budget.

📞 Ready to get started? 🌐 Visit www.prakashoffset.com or contact our experts today to get a personalized quotation and machine demo. Let’s build your future in paper bag manufacturing—bag by bag.

#paper bag#paper#machines#paper bag manufacturer#manufacturer#square bottom#v bottom#baking#alien stage#cake#chris sturniolo#cooking#critical role#dan and phil#breakfast#delicious#chocolate

1 note

·

View note

Text

Shape with Confidence – Advanced C Channel Roll Forming by Jugmug

In today’s age of industrial precision and structural performance, C channel profiles are more than just pieces of metal—they are the backbone of strong, dependable frameworks. At the heart of these robust profiles lies the C Post Channel Roll Forming Machine, and no one understands this better than Jugmug RollForming. With years of engineering expertise, Jugmug has become a name synonymous with precision forming, durability, and customer-focused innovation.

What Is a C Channel Roll Forming Machine?

A C Channel Roll Forming Machine, also known as a C Post Roll Former, is used to manufacture C-shaped steel sections from metal coils. These profiles are widely used in:

Construction (purlins, wall studs)

Industrial shelving

Cable tray supports

Solar panel mounting structures

Automotive and transportation frames

The forming process ensures accurate dimensions, clean edges, and consistent shapes, which are critical for structural stability and assembly efficiency.

Why Jugmug RollForming?

With a heritage of craftsmanship and a passion for innovation, Jugmug RollForming has revolutionized how industries view roll forming. Here's why Jugmug leads the pack in C Channel Roll Forming:

1. Precision Engineering

Jugmug’s machines are designed using advanced CAD/CAM systems and assembled with CNC-manufactured components. The result is ultra-precise forming even at high speeds, with tolerance control up to ±0.5mm.

2. Heavy-Duty Build Quality

Built with rugged structural frames, hardened rollers, and wear-resistant shafts, these machines are engineered for long-term, high-volume performance without breakdowns.

3. High-Speed Automation

Equipped with PLC control systems, servo motors, and hydraulic punching/cutting, Jugmug’s C Post machines reduce human error and improve productivity. The touchscreen HMI makes operation simple and intuitive.

4. Customization on Demand

Every business has unique needs. Jugmug provides tailor-made C channel forming machines, whether you require:

Variable sizes and gauges (1.2 mm to 3 mm)

Manual or fully automatic operation

In-line punching, embossing, or logo marking

Quick-change cassette design for multiple profiles

Applications of C Channel Profiles

The C profiles manufactured using Jugmug’s machines find applications in:

Construction

Used as wall studs, roof purlins, girts, and base plates due to their load-bearing capacity and resistance to warping.

Solar Panel Mounting

C channels are widely used to fabricate the structural framework for solar PV systems.

Automotive Chassis & Framework

Because of their strength-to-weight ratio, C channels are ideal for reinforcing vehicle bodies and cargo enclosures.

Racking & Storage Systems

Industrial shelving systems often rely on C profiles for their modular, load-bearing structure.

Customer Success Stories

Jugmug RollForming has delivered its C channel machines across India and globally. Many manufacturers in the solar, automotive, construction, and logistics sectors report:

30% increased output

Reduced material wastage

Quick ROI (within 12-18 months)

Minimal downtime

After-Sales Support & Training

Jugmug doesn’t stop at selling the machine—it partners with you throughout the journey. Their post-sale support includes:

Installation & operator training

Preventive maintenance plans

Spare parts availability

Remote troubleshooting support

Annual servicing packages

Their team of qualified engineers is just a call away, offering pan-India coverage and global service reach.

Green Manufacturing with Jugmug

In alignment with sustainability goals, Jugmug machines are designed to optimize energy usage and reduce raw material waste. The machines feature:

Servo-driven motors for low energy consumption

Smart sensors for real-time quality control

Eco-friendly hydraulic systems

By adopting Jugmug’s forming systems, manufacturers not only boost output but also reduce their carbon footprint.

Conclusion: Shape with Confidence

When strength, accuracy, and speed matter, Jugmug RollForming’s C Channel Roll Forming Machine delivers with unmatched precision. Whether you are scaling up production or entering new markets, Jugmug ensures your foundation is strong—both literally and technically.

Shape your future with confidence—partner with Jugmug RollForming.

#C channel roll forming machine#C post forming machine manufacturer#C profile making machine India#Jugmug RollForming machines#Structural roll forming equipment#Roll forming machine for solar structures#Best C channel machine in India

0 notes

Text

Global Resistive Industrial Touchscreen Market: Forecast to 2032

Global Resistive Industrial Touchscreen Market size was valued at US$ 1.23 billion in 2024 and is projected to reach US$ 1.78 billion by 2032, at a CAGR of 4.7% during the forecast period 2025-2032

Resistive Industrial Touchscreen Market Overview

The Resistive Industrial Touchscreen Market comprises a segment of human-machine interface (HMI) technologies used in industrial environments. These touchscreens operate based on pressure applied to the screen surface. Typically composed of two flexible layers with a gap between them, resistive touchscreens register input when the top layer is pressed down to touch the bottom layer.

Unlike capacitive screens, resistive screens do not require conductive input and can be operated with a stylus, gloved hand, or any object. This makes them especially valuable in harsh, contaminated, or sensitive environments where precision, cleanliness, and glove-use are required.

Industrial applications include factory automation, control systems, manufacturing dashboards, oil and gas equipment interfaces, chemical processing monitors, and rugged field devices. The market encompasses both hardware (touchscreen panels and displays) and software (touch interface systems and drivers).

This report provides a deep insight into the global Resistive Industrial Touchscreen Market, covering all its essential aspects. This ranges from a macro-overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Resistive Industrial Touchscreen Market. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Resistive Industrial Touchscreen Market in any manner.

Get Full Report : https://semiconductorinsight.com/report/global-resistive-industrial-touchscreen-market/

Resistive Industrial Touchscreen Key Market Trends :

Rising Demand in Harsh Industrial Environments Industries like oil & gas and mining are increasingly adopting resistive touchscreens due to their durability and ability to function in extreme conditions.

Shift Towards Rugged Touchscreen Interfaces There’s a growing preference for rugged and reliable interfaces in manufacturing and automation sectors to improve operational efficiency.

Integration of Touchscreens in Legacy Systems Companies are retrofitting resistive touchscreens into older industrial systems due to their compatibility and cost-effectiveness.

Increased Adoption in Emerging Economies Rapid industrialization in Asia-Pacific and Latin America is boosting the adoption of industrial touchscreens across multiple sectors.

Growth in Food & Beverage Automation Touchscreens are being widely used in the food industry due to their resistance to contaminants and ease of cleaning.

Resistive Industrial Touchscreen Market Regional Analysis :

North America:Strong demand driven by EVs, 5G infrastructure, and renewable energy, with the U.S. leading the market.

Europe:Growth fueled by automotive electrification, renewable energy, and strong regulatory support, with Germany as a key player.

Asia-Pacific:Dominates the market due to large-scale manufacturing in China and Japan, with growing demand from EVs, 5G, and semiconductors.

South America:Emerging market, driven by renewable energy and EV adoption, with Brazil leading growth.

Middle East & Africa:Gradual growth, mainly due to investments in renewable energy and EV infrastructure, with Saudi Arabia and UAE as key contributors.

Resistive Industrial Touchscreen Market Segmentation :

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments.

Market Segmentation (by Application)

Oil & Gas

Chemical

Food & Beverages

Mining & Metal

Automotive

Others

Market Segmentation (by Type)

Hardware

Software

Key Company

Advantech

Cypress Semiconductor

Dell

B&R Industrial Automation

Elo Touch Solutions

Fujitsu

Hewlett Packard Enterprise

LG Electronics

Panasonic

Planar Systems

Kontron

Schneider Electric

Siemens

Beckhoff Automation

Captec

American Industrial Systems

Drivers

Durability and Resistance to External Factors Resistive touchscreens are ideal for industrial use due to their resistance to dust, moisture, and harsh chemicals.

Cost-Effectiveness Compared to Capacitive Screens These touchscreens are generally more affordable, making them a preferred choice for industries with budget constraints.

Growing Automation in Manufacturing The shift toward smart factories and digital interfaces is fueling the demand for robust touchscreen solutions.

Restraints

Limited Multi-Touch Functionality Unlike capacitive touchscreens, resistive variants often lack advanced features like multi-touch, limiting their use in modern applications.

Slower Response Time Resistive touchscreens may have slower reaction speeds, which can impact efficiency in high-speed industrial environments.

Competition from Capacitive and Infrared Technologies The growing adoption of alternative touchscreen technologies may hinder resistive market growth.

Opportunities

Adoption in Hazardous Work Environments There’s strong potential for resistive touchscreens in sectors that require operation with gloves or in explosive environments.

Expansion in Emerging Markets Countries like India, Vietnam, and Brazil are seeing increased adoption due to industrial expansion and digital transformation.

Technological Improvements in Resistive Touch Panels Ongoing R&D is enhancing the accuracy and responsiveness of resistive touchscreens, making them more competitive.

Challenges

Maintaining Competitive Edge Against Modern Technologies Companies need to innovate to keep resistive touchscreens relevant amid advanced alternatives.

Customization Requirements for Diverse Industries Tailoring products to specific industrial needs can be resource-intensive and complex.

Integration with Modern Control Systems Ensuring seamless compatibility with newer industrial systems remains a technical challenge.

Get A Sample Report : https://semiconductorinsight.com/download-sample-report/?product_id=96484

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Flash Memary Market

Overview of the regional outlook of the Flash Memary Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

Customization of the Report In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Related Reports :

Contact us:

0 notes

Text

Why Siemens HMI is a Game-Changer in Automation

In the present days of industrial developments, there has been an unusual demand for intelligent, reactive, and reliable interfaces. At the core of this innovation lies the Siemens HMI solution, an interface bridging the gap between human operators and complex machines. From managing a small production setup to a fully automated facility, Siemens offers HMI panels for differing operational requirements.

A real-world example of Siemens HMI in action can be seen in aviation - learn how Siemens HMI is streamlining airport baggage handling systems with precision and automation.

Why Choose Siemens HMI?

The Siemens HMI technology ensures that your machines are not simply connected, but intelligent, intuitive, and easy to control. Under the SIMATIC series, Siemens offers a range of HMI systems allowing operators to easily monitor, control, and adjust a machine's processes. Whether it's changing the temperature in a food processing unit or setting the speed of motors in a manufacturing plant — Siemens HMI gives you utmost control and real-time data access.

These HMI solutions are flexible and scalable. As your needs for production grow, your Siemens SIMATIC HMI system will be able to grow with you to support new functions, new users, and new machines.

Explore the Power of Siemens SIMATIC HMI

The Siemens SIMATIC HMI portfolio ranges from simple key panels to high-performance interface panels with multi-touch capabilities. With a fast processor, high-resolution display, and intuitive navigation controls, these panels ensure quick operation for the most demanding applications.

Besides the fast speed, Siemens HMI panels also promise a long life supported by frequent firmware updates and enhanced security features, making sure that your investment stays secure and ready for the future.

Touchscreens That Are Really Easy to Use with Siemens SIMATIC Panel Touch

The days of clunky buttons with limited interaction are over. The Siemens SIMATIC panel touch range brings the highest level of touch capability with easy navigation, gesture support, and brilliant displays. These panels are ideal for control systems that demand both time sensitivity and ease of access.

Touch panels make for great user experience, letting you make fast adjustments to the workings of machines yourself, view detailed information, and recognize faults, all at a glance. And built rugged, they work their way almost everywhere into the industries of oil & gas, pharmaceuticals, food & beverage, and logistics, to name a few.

Learn more in Siemens HMI vs. Other HMI Solutions: Why Choose Siemens?

Integration Made Easy

Seamless integration with other Siemens automation products such as PLCs and SCADA systems is one of the principal advantages of using Siemens SIMATIC HMI systems. Incidentally, this causes efficient consolidations in industrial control systems-and alongside that, lesser maintenance-related stresses and minimized error rates.

Apart from the support for communication protocol offered by Siemens HMI panels making it rather easy to interface with third-party systems should there be a need for such interaction, it is this flexibility that makes Siemens a very popular choice among system integrators and plant managers all over the world.

For deeper insights, check out Human Machine Interface Siemens: Improving Operational Productivity.

Real Results from Every Industry

The Siemens HMI systems have proved their efficacy in real-time situations ranging from factory automation and process control to building management and energy monitoring. With fast boot-up times, customizable user interfaces, and sophisticated data visualization, these panels greatly enhance operational productivity and machine availability.

Conclusion

If your plan is to improve control in industrial automation with Naksh Technology Solutions LLP or to update a rather dated set of operator interfaces, then consider picking Siemens HMI systems. The company provides a whole range of solutions, which include Siemens SIMATIC HMI and Siemens SIMATIC panel touch, so you can count on market-leading innovativeness, reliability, and performance.

Smart HMI is a big difference; Siemens means technology plus efficiency.

0 notes