#type 1 cng cylinder

Explore tagged Tumblr posts

Text

CNG Tank Manufacturer

ISO11439 Type 1 CNG Tank

DSW industry is a leading CNG tank manufacturer used for flow forming, automotive and heatincand water industries with valves, nozzles, brackets, and more.

Type 1 CNG tanks are constructed of solid steel for durability. Perfect for installation beneathvehicles and at a highly reasonable cost.Compressed natural gas is a fuel with a high level of safety due to its physical properties, whichmeet strict quality standards.

Our compressed natural gas tanks are DOT and NGV-compliant and tested to the higheststandards, guaranteeing your safety with every use.

0 notes

Text

A820606020004 Combined seal pad for SANY machinery

A820606020004 Combined seal pad SANY spare parts Mail:[email protected] 9190313000010 Photoelectric Switch 918070100070 准达扭矩扳手头S50-760 67336039420 Retainer Ring GB894.1 10 ´ï¿ËÐâ´¦Àí 21011636 Sequence Valve 918071800039 141m尼龙输送带NN200-1000-5(4.5+1.5 ) 10238906 右后边梁SFY758.6.1.1.1.9 61025094 Air Compressor 10667497 Protective Cover 532187 CONTROL STAND ASSY W/O FS 180301000009 涡流环220436(260A) (B&BARTONI) 10505248 SANY PARTS 10691856 Rear Exhaust Pipe 1 22057383 Assembly Set SPPFK080-A12 10202451 SANY PARTS 10182221 SANY PARTS 160102180003B111 Timing Case 160101060001A067 Turbine Rear Retaining Ring 10587323 SANY PARTS 522895 MOTOR, HYDRAULIC * 10505947 SANY PARTS 10233375 Screw 10039469 Thrust seat 160104000586A Temperature Sensor 160801010407A001 Water Radiator 10698028 立筋(一)Z13.7-8 21015457 Moveable Sliding Wheel Assemblage 10483310 操作台左下梁HY1.2.1.1-12 160102070071A071 Cylinder Head System [email protected] 59003420 火警标识(2)-逃生通道-左/W250×H320mm/3M 67341650474 Locating sleeve SPYS-1374 DWTZJ-DCV100/3 921030200033A Wear-Resistance Steel Plate 918070400012 CO2 180103030452A Turnable Bits 921090800012A Thermostat 10020169 中间管料坯RSC45(B).1.2.2-1L 10221547 Steel plate 10043376 角钢料坯(HZS120G.20.1.3-3) 532561 PLANET CARRIER ASSY 920070700014A 减速机总成MTDF57-4.39-M4-φ35 24918381 SANY PARTS 180604000239A Filter 10492809 SANY PARTS 10600080 SANY PARTS 10076367 Running balance valve 180108990022A skiving cutter 10027822L Spacer Sleeve 10243662 SANY PARTS 10058314 SANY PARTS 921040100002A 油缸300×65 10050370B SANY PARTS 10659992 SANY PARTS 22040465 SPK32080 body assembly SP404J70KA.ASM 10449057 ZT26 Package for fastening parts 160603020087B Element, Fuel Water Separator 61015591 Rolling Bearing 921072700020A Switch 18878004 Steel bolt 10048705B 活塞工艺半成品ZXQY52.14B-1(B)- 10470472 joint SQ170.6.2-4 10045687 BF1 Package for sealing parts 22055959 Stablizer SPPST001-A20 180999000260A Silicone Seals 22028473 Over loading pocter SP404OP03A 10273426 SANY PARTS 10639548 耳板Z10.6.9-1 10679509 Front Spindle LH 10263390 SANY PARTS 61005348 Board 160101110014B017 Fan Assembly 10680899 筋板Z11.11-03 10256260 弯板Z7.5-22 61025360 Bolt, 3/8-16 x 2 3/4 inch 920090600031A bump 10015941 Limit block 160102040014B246 Quick Coupler Fitting 54000076 V4028维达蓝色经典180克卫卷 10650798 铰链座B229900006246-2 10272094 Bent cross rod 10443983 Flat plate A 10657527 SANY PARTS 10173496 SANY PARTS 10271107 Board 528098 O-RING 258 V 75 10240131 Side Beam Ⅱ 527773 TIE PLATE 10492849 SANY PARTS 10130896 Support 180101051073A Turning Insert 10201416WD Right Rear Outrigger Oil Cylinder 10483951 Steel Pipe Assy. 10413062 SANY PARTS 24914365 Connector seat 10644763 框 架LY1.12.1 21025634 Drum, luffing, jib 921031000042A Large spiral gear 10261248 SANY PARTS 10133541 Bracket 160499000160A CNG Cylinder Assembly Skin 61026382 Washer, Plain 562144 COVER CPL. F.PLUNGER CYLINDER 10031899 Cover Plate 10420436B SANY PARTS 10015185 steel plate 10116078 Engine cover assem. 160102070083A079 Ordinary Hose Coupling 21010135 Ignition lock accessories 61024131 仪表线束H42Z2-40401 康明斯B3.3 181500000191A SDCY450K4C2 type marking 22064287 Cutting plate SP408G0105_6_HG785 Defaul 21031295 Cornicle 160508030022A Gasket For Inlet Of Catalytic Silencer 21016108 Pulley 180103021460AR Solid Carbid Bits 10017650 "角板SYM5421J.22.2-3,图纸物料作废" 21039411 Bent plate 10126025 Welding auxiliary steel reinforcement JH 10405475 SANY PARTS 168813000053A Transfer valve 10055546 Base Plate 61005213 Plumbing,Eng Cnt Module 22040205 Truck mounted crane zc00211 22027362 Reinforced plate2 SPTM-0062 180110070216A Extension Rod 10450388 活塞杆ZXQAY220.2.12-5 10448735 轴(9)BCW46D.1-15 168899002625A Element, Breather 21007943 Seesaw switch JK931-808 core insert 22010930 Reinforced plate 7 SP409H0107 160102130019A211 Bearing Cover 9181015000124 气动加注机MO-75-O 10060244 SANY PARTS 10187134 Off-chain device frame 180101030029A Thread Turning Tools 10054245 SANY PARTS 921080400065A Cab Assembly 10685394 SANY PARTS 10188921 右上封板组件BCW43.2.4.6 22012944 Supporting bent plate 3 SPM401-SH002-3-5 10505914 SANY PARTS 22033093 Tube JC10EP1W-34 92000002 SANY PARTS 10252838 Steel Pipe 21 10095338 Piping diagram RC1.7.3 921021700017A Anemometer 10488521 Flange 10635334 SANY PARTS 22022734 Tube SP190G0110 /PMGG000206 59009483 SANY PARTS 24917528 SANY PARTS [email protected] 160102170004A051 EVB Bracket Assembly Read the full article

0 notes

Text

Can Gruner’s plants integrate with existing CNG infrastructure and be used for vehicle fueling or pipeline injection?

The rise of clean energy solutions in India has shifted the focus toward sustainable and economical alternatives to conventional fossil fuels. Among these, bio cng gas plant systems have gained significant momentum, especially for their ability to serve dual purposes — generating renewable gas and seamlessly integrating with existing fuel distribution networks. This article explores whether Gruner Renewable’s plants can be connected to current CNG infrastructure for vehicle fueling and pipeline injection — and the answer is a resounding yes.

Understanding Gruner Renewable’s Bio CNG Technology

Gruner Renewable specializes in advanced bio cng gas plant systems that convert agricultural waste, cattle dung, and organic matter into high-purity biomethane. This biogas is purified to match the quality of conventional CNG, making it usable for the same end-use applications, such as powering CNG vehicles or injecting into natural gas pipelines.

Each plant is equipped with:

● Pre-treatment systems for efficient biomass handling

● Advanced digesters for optimized biogas production

● Gas upgradation units to purify biogas into bio-CNG

● Compression and bottling systems for storage and distribution

Seamless Integration with Existing CNG Infrastructure

One of the biggest advantages of Gruner’s bio cng gas plant setup is its plug-and-play capability with existing infrastructure. Here’s how:

1. Vehicle Fueling Stations

Gruner’s bio-CNG can be directly compressed and stored in high-pressure cylinders, just like conventional CNG. These cylinders can be:

● Supplied to retail fueling stations

● Used to set up standalone bio-CNG stations

● Deployed in decentralized vehicle fleets (buses, autos, delivery vans)

This makes it easy for local fuel distributors or fleet operators to integrate Gruner’s gas into their existing vehicle fueling operations without needing significant changes to infrastructure.

2. Pipeline Injection

Gruner’s plants produce biomethane with methane purity exceeding 95%, matching Indian pipeline standards. Once purified and odorized, this renewable gas can be injected into existing natural gas grids.

Benefits of pipeline injection include:

● Reduced transportation costs

● Stable supply for domestic and industrial users

● Contribution to decarbonizing the overall gas mix

Gruner ensures that every bio cng gas plant is equipped with metering, odorization, and pressure regulation units to meet the safety and compliance requirements for grid injection.

Why This Integration Matters for India

India’s dependence on imported fuels and the urgent need to reduce carbon emissions create a unique opportunity for bio-CNG to shine. Here’s why integrating bio-CNG with current infrastructure is a strategic move:

a. Energy Independence

Producing clean fuel from local biomass helps reduce reliance on imported LNG and diesel. With bio-CNG compatible with the CNG vehicle ecosystem already in place, India can transition to cleaner fuels faster.

b. Minimal Disruption

Using the same nozzles, pumps, and storage for bio-CNG as fossil-based CNG ensures that fuel station owners and transport operators don’t need costly upgrades.

c. Fast Rollout Potential

Since the supporting infrastructure already exists across many urban and semi-urban locations, bio-CNG can scale faster than new fuel types requiring fresh infrastructure development.

Gruner’s Track Record and Support Systems

Gruner Renewable has successfully commissioned and partnered on projects across India. Their turnkey approach ensures:

● Site assessment and feasibility studies

● Design, fabrication, and installation

● Post-installation support and monitoring

● Integration with local CNG stations or gas grid

Moreover, Gruner offers support in getting regulatory approvals and collaborating with local gas utilities for pipeline tie-ins.

Compliance and Safety

All Gruner plants follow the Petroleum and Explosives Safety Organisation (PESO) guidelines and meet the Ministry of New and Renewable Energy (MNRE) benchmarks. For pipeline injection, the biomethane is odorized, pressurized, and monitored via SCADA systems to ensure grid safety.

For vehicle fueling, all compression and storage tanks are tested under standard Indian pressure and temperature conditions, ensuring maximum safety.

Opportunities for Dealers, Farmers, and Entrepreneurs

Gruner’s decentralized bio cng gas plant models offer income opportunities for:

● Farmers and Gaushalas: Turn agricultural or animal waste into a valuable commodity

● Fuel station owners: Add a green fuel lane with minimal modification

● Entrepreneurs: Set up and operate private vehicle fueling points in rural or industrial belts

Future-Ready: Gruner’s Innovation Edge

Gruner is already testing advanced solutions such as:

● Smart metering for pay-as-you-go bio-CNG usage

● Mobile fueling units (MFUs) to serve remote fleet operations

● AI-driven plant automation for 24x7 monitoring and fault detection

With India targeting a circular economy and net-zero emissions, Gruner’s integration-ready plants are positioned as the bridge between legacy systems and a sustainable future.

Conclusion: A Clean Fit for the Present and Future

Gruner Renewable’s bio-CNG solutions are not just future-ready — they’re ready today. Whether you’re a CNG fuel station operator, a city gas distribution company, or a clean-energy-focused entrepreneur, integrating Gruner’s plant output with your existing systems is technically feasible and financially sound.

As demand for clean fuel grows, and policies favor greener alternatives, Gruner stands out as a reliable partner offering a seamless transition from traditional to renewable energy — without the hassle of major infrastructure overhauls.

0 notes

Text

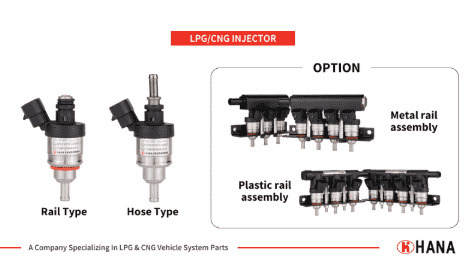

Advanced High-Performance Gas Injectors for LPG/CNG | HANA EMS

HANA EMS is a global leader in LPG and CNG vehicle system components, known for its expertise in gas injection system and a range of gas automotive components. Recognized for its deep technological know-how, accumulated experience, and proprietary knowledge, HANA EMS designs and manufactures all products in-house, leveraging its deep experience and proprietary knowledge. Their solutions are applied to vehicles worldwide, making them a trusted name in the clean energy automotive sector. HANA EMS is a global company focused on customer satisfaction, innovation, and sustainability, offering high-quality products at competitive prices, collaborating with global LPG and CNG system manufacturers, and exporting advanced components.

HANA H2001 LPG/CNG Injector:

The HANA H2001 is a high-performance top-feed gas injector rail designed for use with LPG, CNG, and LNG systems in passenger vehicles. It offers durability, low noise, and excellent heat resistance, ensuring reliable, long-term performance.

The H2001 is a compact, stainless-steel injector with a 2-way connector, available in single or rail types for 2, 3, or 4-cylinder configurations, making it easy to integrate into existing fuel systems.

Available models and connector types include H2000 (KET MG640543-5), H2001 (AMP 282104-1), and H2003 (Sumitomo 6189-0553)

The Key Features of the HANA H2001 LPG/CNG injector are as follows:

The HANA H2001 utilizes a top feed fuel injection system for efficient fuel delivery, ensuring optimal air-fuel mixture, enhanced combustion efficiency, and reduced emissions for OEM and retrofit projects.

The H2001 engine boasts exceptional quiet operation due to its refined internal construction and superior material selection, enhancing driving comfort and user satisfaction, particularly in city driving and idle conditions.

The product boasts excellent heat resistance and can operate reliably from -40°C to 120°C, thanks to its durable components designed for harsh engine conditions.

Stable fuel flow ensures smooth engine performance and reduces maintenance by delivering consistent flow rates over time.

Gold-type injectors offer customizable fuel delivery across various engines through B, C, and D nozzle options.

The product offers versatile mounting options, compatible with 2-, 3-, or 4-cylinder rail setups, and can be mounted using metal or plastic rails for seamless integration.

The product is made of high-quality stainless steel and durable polymers, providing superior wear and corrosion resistance.

The product is certified to be fully compliant with ECE and ISO standards for global safety and quality assurance.

If you are looking for a gas injector rail you can find them at HANA EMS.

Click here if you are interested in HANA EMS Products.

View more: Advanced High-Performance Gas Injectors for LPG/CNG.

HANA EMS Catalog / Instagram

0 notes

Text

CNG Tanks Cylinders Market Demand, Growth and Competitive Analysis

CNG Tanks Cylinders Market, By Material Type (Type I (Metal), Type II (Metal Liner with Hoop-Wrapped Composite), Type III (Metal Liner with Fully Wrapped Composite), Type IV (Full Composite)), Vehicle Type (Light-Duty Vehicles, Medium-Duty Vehicles, Heavy-Duty Vehicles), Application (On-board CNG Tanks, Stationary CNG Tanks), End-Use (Transportation, Industrial), Composite Type (Carbon Fiber Reinforced Composite, Glass Fiber Reinforced Composite), Distribution Channel (OEM, Aftermarket) - Industry Trends and Forecast to 2031.

Data Bridge Market Research analyzes that the global CNG tanks cylinders market which was USD 19,024.4 million in 2023, would rocket up to USD 25,889.6 million by 2031, and is expected to undergo a CAGR of 3.9% during the forecast period of 2024 to 2031. “Type I (Metal)” dominates the material type segment of the CNG tank cylinders market due to its robust and durability nature and is commonly used in various applications, especially in heavy-duty vehicles and industrial settings.

For drawing up sustainable, money-making, and profitable business strategies, CNG Tanks Cylinders Market report acts as a valuable and actionable resource which provides best market insights that are significant for all time. This report serves the clients to tackle every strategic aspect including product development, product specification, exploring niche growth opportunities, application modelling, and new geographical markets. Insights about granular analysis of the market share, segmentation, revenue forecasts and geographic regions of the market are also given in the report which supports business growth. The CNG Tanks Cylinders Market report lends a hand to businesses so that they are able to make informed, strategic and therefore successful decisions for themselves.

This CNG Tanks Cylinders Market report comprehensively analyzes the potential of the market in the present and the future prospects from a variety of corners. Besides, it presents the company profile, product specifications, production value, contact information of manufacturer and market shares for company. This market report performs comprehensive study about industry and tells about the market status in the forecast period. It is a professional and in-depth analysis on the current state of the market. The CNG Tanks Cylinders Market report is a comprehensive analysis on the study of industry that gives number of market insights.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive CNG Tanks Cylinders Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-cng-tanks-cylinders-market

CNG Tanks Cylinders Market Overview

**Segments**

- By Type: Type 1, Type 2, Type 3, Type 4 - By Material: Metal, Glass Fiber, Carbon Fiber - By Application: Light-Duty Vehicles, Medium-Duty Vehicles, Heavy-Duty Vehicles

The global CNG tanks cylinders market is segmented based on type, material, and application. In terms of type, the market is categorized into Type 1, Type 2, Type 3, and Type 4 cylinders. Type 1 cylinders are made up of steel while Type 2 cylinders consist of a combination of steel and aluminum. Type 3 cylinders are composed of a resin-impregnated fiber-wrapped structure, and Type 4 cylinders are made with a plastic inner liner wrapped with carbon fiber. The choice of cylinder type is influenced by factors such as durability, weight, and cost.

Furthermore, the market is segmented by material into metal, glass fiber, and carbon fiber cylinders. Metal cylinders are typically made of steel and are known for their strength and durability. Glass fiber cylinders are lighter in weight compared to metal cylinders, providing advantages in terms of fuel efficiency. Carbon fiber cylinders are the most advanced type, offering high strength-to-weight ratio and corrosion resistance.

When it comes to application, the market is segmented into light-duty vehicles, medium-duty vehicles, and heavy-duty vehicles. Light-duty vehicles include passenger cars and small commercial vehicles, where CNG cylinders are used for cleaner and more economical fuel storage. Medium-duty vehicles, such as vans and buses, also employ CNG cylinders for improved efficiency. Heavy-duty vehicles like trucks and trailers utilize CNG cylinders for long-haul transportation with reduced environmental impact.

**Market Players**

- Luxfer Group - Quantum Fuel Systems LLC - Hexagon Composites ASA - Worthington Industries - Everest Kanto Cylinder Ltd - Faber Industrie SpA

Several key players operate in the global CNG tanks cylinders market, contributing to its growth and innovation. Luxfer Group is a prominent manufacturer of high-performance gas cylinders, including CNG cylinders for various applications. Quantum Fuel Systems LLC specializes in advanced fuel storage systems, offering lightweight and durable CNG tanks for automotive and transportation industries. Hexagon Composites ASA is a leading provider of composite pressure cylinders, catering to the growing demand for sustainable energy solutions. Worthington Industries is a diversified industrial company that manufactures steel CNG cylinders for storage and transportation of compressed natural gas. Everest Kanto Cylinder Ltd and Faber Industrie SpA are also notable players in the market, known for their expertise in designing and producing CNG cylinders for different sectors.

The global CNG tanks cylinders market is experiencing significant growth driven by various factors such as increasing environmental concerns, stringent emission regulations, and the growing adoption of alternative fuel vehicles. One key trend that is shaping the market landscape is the focus on lightweight and high-strength materials for CNG cylinder construction. Manufacturers are increasingly exploring advanced materials such as carbon fiber and glass fiber composites to develop cylinders that offer a balance between weight reduction, durability, and efficiency. This trend is fueled by the need for fuel-efficient vehicles that have reduced impact on the environment while maintaining high safety standards.

Moreover, the market is witnessing a shift towards the development of customized CNG cylinder solutions to cater to specific vehicle types and applications. With the rising demand for CNG cylinders across light-duty, medium-duty, and heavy-duty vehicles, manufacturers are focusing on offering tailored products that meet the unique requirements of each vehicle segment. This approach enables them to address the diverse needs of customers in terms of storage capacity, weight, and performance, thereby driving market growth and penetration.

Another key aspect influencing the global CNG tanks cylinders market is the increasing investment in research and development activities to enhance cylinder design, manufacturing processes, and safety features. Market players are investing in innovative technologies such as lightweight composite materials, advanced liner technologies, and improved valve systems to optimize the performance of CNG cylinders. These advancements not only improve the overall efficiency and reliability of CNG storage systems but also contribute to reducing operational costs and extending the service life of cylinders.

Furthermore, the market is witnessing a growing demand for CNG cylinders in emerging economies, where governments are promoting the adoption of natural gas as a cleaner and more affordable alternative to conventional fuels. The favorable regulatory environment, coupled with incentives and subsidies for CNG vehicle owners, is driving the uptake of CNG cylinders in countries with high pollution levels and a strong focus on sustainable transportation solutions. This trend presents lucrative opportunities for market players to expand their presence in new geographies and collaborate with local partners to capitalize on the growing demand for CNG tanks cylinders.

In conclusion, the global CNG tanks cylinders market is poised for significant growth, driven by technological advancements, increasing demand for lightweight and durable cylinders, and the expanding adoption of natural gas as a clean fuel source. Market players are focusing on innovation, customization, and geographic expansion to capitalize on the evolving market dynamics and cater to the diverse needs of customers across different vehicle segments and regions. With sustainability and efficiency being key priorities for the automotive industry, the demand for high-quality CNG cylinders is expected to continue rising, offering ample growth opportunities for manufacturers and suppliers in the coming years.The global CNG tanks cylinders market is witnessing a significant uptrend driven by several key factors that are reshaping the industry landscape. One notable trend is the increasing emphasis on sustainability and stringent emission regulations, leading to a higher demand for cleaner fuel storage solutions such as CNG cylinders. As governments worldwide push for greener transportation options to combat environmental issues, the adoption of CNG tanks is expected to surge, especially in emerging markets where pollution levels are notably high. This shift towards natural gas as an alternative fuel source is propelling market players to innovate and develop advanced cylinder technologies that offer both performance and environmental benefits.

Moreover, the market is experiencing a notable pivot towards lightweight and high-strength materials for CNG cylinder construction. Manufacturers are investing in research and development activities to explore carbon fiber and glass fiber composites as alternatives to traditional metal cylinders. These advanced materials not only offer significant weight reduction benefits but also enhance durability and efficiency, aligning with the industry's focus on fuel economy and reducing vehicle emissions. The adoption of lightweight materials in CNG tanks is crucial for improving vehicle performance and range while maintaining high safety standards, catering to the evolving needs of consumers and regulatory requirements.

Additionally, the customization of CNG cylinder solutions to suit different vehicle types and applications is becoming a prevalent trend in the market. With a growing demand across light-duty, medium-duty, and heavy-duty vehicles, manufacturers are tailoring their products to meet specific requirements in terms of storage capacity, weight, and performance. This approach enables market players to address the unique needs of diverse customer segments effectively, driving market penetration and growth. By offering specialized CNG cylinder solutions, manufacturers can cater to the varied demands of the automotive industry while ensuring optimal performance and safety across different vehicle categories.

Furthermore, the market is witnessing a surge in research and development investments aimed at enhancing cylinder design, manufacturing processes, and safety features. Manufacturers are leveraging innovative technologies to optimize the performance of CNG storage systems, improve efficiency, and reduce operational costs. Advanced liner technologies, lightweight composite materials, and enhanced valve systems are being integrated into CNG cylinders to enhance durability, reliability, and safety. These technological advancements not only boost the overall quality of CNG tanks but also contribute to increasing their service life and operational efficiency, positioning market players for sustained growth and competitiveness in the evolving automotive landscape.

Overall, the global CNG tanks cylinders market is on a trajectory of expansion driven by evolving consumer preferences, regulatory mandates, and technological advancements. With a focus on sustainability, lightweight materials, customization, and innovation, market players are well-positioned to capitalize on the growing demand for clean fuel storage solutions. As the automotive industry continues to prioritize efficiency and environmental responsibility, the market for CNG cylinders is set to witness sustained growth, offering opportunities for manufacturers to innovate, collaborate, and expand their presence in a dynamic and competitive market environment.

The CNG Tanks Cylinders Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-cng-tanks-cylinders-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

What insights readers can gather from the CNG Tanks Cylinders Market report?

Learn the behavior pattern of every CNG Tanks Cylinders Market-product launches, expansions, collaborations and acquisitions in the market currently.

Examine and study the progress outlook of the global CNG Tanks Cylinders Marketlandscape, which includes, revenue, production & consumption and historical & forecast.

Understand important drivers, restraints, opportunities and trends (DROT Analysis).

Important trends, such as carbon footprint, R&D developments, prototype technologies, and globalization.

Browse More Reports:

Global Food Safety Testing Market Global Extruders Market Europe 3D Machine Vision Market Global Wearable Tracking Devices Market Asia-Pacific Telehealth Market Global Foldable Display Market Europe Whole Exome Sequencing Market Global Variable Rate Technology (VRT) Market Europe Tomato Pastes and Purees Market Middle East and Africa Food Allergens and Intolerance Testing Market Global Gardening Equipment Market Global Bone Spur Market Global Coffee and Tea Processing Equipment Market Global Hypereosinophilic Syndrome Market Global Prader-Willi Syndrome Drug Market Global Bromine Market Global Medical Device Connectivity Market Global Personal Care Packaging Market Global Energy Drinks Market North America Stroke Market Global Ultra Thin Glass Market Global Chipboard Packaging Market North America Leak Detection Market Global Agoraphobia Treatment Market U.S. Database Automation Market Spain Hadoop Big Data Analytics Market Global Electronic Safety System Market Middle East and Africa Insoluble Sulfur Market for Automotive Sector – Industry Trends and Forecast to 2030 Global Storyboarding Software Market Global Mobile Number Portability Market Global Biofuel Enzyme Market Global Field Effect Transistor Market North America Audio Critical Communication Market Global Liquid Synthetic Rubber Market North America Vanilla (B2B) Market Global Employment Screening Services Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]"

0 notes

Text

STORAGE OF RENEWABLE ENERGY [CNG] AT HIGH PRESSURES

In 2022, India became the fourth largest country in the world by valuation of the automotive industry. With this massive influx of automobiles, India is leaning towards Compressed Natural Gas (CNG) as a significant renewable energy variant. CNG as a fuel helps curtail emissions from traditional fuels such as diesel and petrol. India’s projected sales of CNG vehicles will increase from 863.22 thousand units in 2021 to 1,463.46 thousand units by 2029.

Government Initiatives to Promote CNG Vehicles:

Individual states are investing heavily to build a CNG infrastructure.

Keeping the price of CNG lower than traditional fuels prompt customers to see it as a cost-saving option.

SATAT Scheme for producing automobile-grade CNG from biogas generated from waste.

The segment was dominated by passenger vehicles; sales of CNG accounted for 12.1 percent of sales at 177,410 units as against 120,070 units in 2021; carmakers are betting on CNG in a big way as it gives owners a more affordable driving option. The top CNG car manufacturers are Maruti Suzuki, Tata Motors, Hyundai, Bajaj & Mahindra.

Infrastructure:

One of the critical elements to support this boost in sales will be technology in the form of safer storage for this flammable gas at higher pressures. CNG is stored at 250 barg pressures in the cascades at filling stations and transferred into smaller cylinders, cars, buses, etc.

CNG Cylinder Types and Manufacturers:

CNG tanks can be categorized into Type 1, Type 2, Type 3, and Type 4. The type is determined primarily based on design, production method, and liner material. Generally, in India, Type 1 Cylinder comprises all steel, which is relatively economical and heavier. The varying capacity of 30 L, 60 L, and 90 L cylinders are used in 3-wheelers, cars, trucks, and buses.

Use of Compressor:

A high-pressure compressor is used in a very critical stage of the manufacturing process. The air leakage test is one of the final, conclusive tests wherein the cylinder's integrity is checked before it is given a clean chit for dispatch. Compressed air at 400 barg pressures and 200 m3/hr flows are generally required for the process.

COMPRESSORS SOLUTIONS FROM ELGI SAUER RANGE FOR CNG CYLINDER TESTING APPLICATION:

Suction pressure: max. 16 bar g Final pressure: max. 500 bar g Volume Flow Rate: max. 500 m3/ h Rated Power: max. 75 kW for Air

ORKAN series compressors are based on a flexible modular system and cover a wide output range.

High-pressure air compressors up to 500 barg

Real gas boosters with inlet pressures of up to 16 barg

Hermetically gas-tight designs with magnetic coupling

Standard products for air, nitrogen , helium , CNG , and hydrogen .

Ex-proof versions acc. to ISO 80079-34:2018 and the European ATEX directive 2014 / 34 / EU

Magnetic coupling drives for Gas Boosters.

Orkan gas boosters feature Sauer's first magnetic coupling drive for hermetically gas-tight compressors. It guarantees absolute gas tightness, is extremely low maintenance, and operates with maximum reliability.

CubeCooler

The new CubeCooler enables re-cooling temperatures more than 30% lower than conventional cooler configurations. Coolers have been arranged radially around the combined fan and flywheel for a high cooling capacity like this

#starting air compressor#high pressure air compressor#water cooled compressor#high pressure booster compressor#marine compressor#breathing air compressor#compressed natural gas compressor

0 notes

Text

PESO Certification Consultant: Your Compliance Partner for Hazardous Materials Safety in India

In India, dealing with hazardous materials, such as petroleum, compressed gases, or explosives, must encompass safety standards espoused by the government. PESO certification is of paramount significance in this case. If you are concerned with the manufacture, importation, or sale of any such material or equipment, you are obliged to comply with the Petroleum and Explosives Safety Organization (PESO) standards. A professional PESO Certification Consultant would assist you in streamlining the complex regulatory maze.

The article discusses the relevance of PESO certification, the role of the consultants and then answers a frequently asked question: "How can I get PESO certification?"

What is PESO Certification?

PESO (earlier known as Department of Explosives) under the Ministry of Commerce and Industry, Government of India, has been involved in framing the safety regulations and overseeing the manufacturing, storage, transportation, and usage of hazardous materials. This includes:

Petroleum products

Compressed gases (LPG, CNG, etc.)

Pressure vessels

Explosives and fireworks

Gas cylinders and valves

Any PESO certification becomes obligatory if you wish to enter legally into the operations of these sectors. It certifies that your product or facility is safe and complies with the specifications/quality as per Indian standards.

Why Consult a PESO Certification Consultant?

The road map through the PESO regulation and documentations becomes more of a challenge for foreign manufacturers or first-time applicants. A PESO Certification Consultant would come in handy at just such times.

Expert Guidance

A PESO consultant knows the technical and legal requirements of the various product categories. He helps you understand guidelines, interpret applicable codes, and steer clear of common compliance pitfalls.

Documentation Support

The consultant essentially assists by putting together and reviewing all necessary documentation, including drawings, test reports, certificates of conformity, etc., making sure nothing is missing or in violation of the requirements.

Coordination with Authorities

The consultant serves as a link between your company and the PESO office. They keep following up, answer the authorities' queries, and help speed up the process of approval.

Lower Risk of Rejection

When a professional consultant takes care of your submission, it minimizes the chances of errors, delay, and rejection.

Compliance Strategy Tailored to Your Needs

A PESO Certification Consultant will devise a strategy that is customized to your specific product and field, aiming to achieve certification as quickly as possible and with the fewest problems entering the market.

How Can I Get PESO Certification?

A common question that arises among manufacturers and importers is: "How can I get PESO certification?" The order of events will vary according to the category of the product, but here is a basic overview:

Step 1: Product Classification

Identify the type of product or equipment that will require PESO approval, whether it be classified as a pressure vessel, gas cylinder, valve, or storage tank.

Step 2: Selection of Testing Lab (If Applicable)

According to applicable categories, a product may need to be tested at a BIS-recognized or PESO-approved laboratory. Test reports certifying that the product meets Indian safety standards are necessary.

Step 3: Preparation of Technical Documents

Essential technical documents include:

Product drawings

Quality assurance documents

Type test reports

Material test certificates

Manufacturing licenses

ISO certifications (if available)

Step 4: Application Submission

The application is submitted to PESO online or through designated offices depending on the type of your product.

Step 5: Scrutiny and Site Inspection

PESO authorities scrutinize the application. In some cases, they may even visit the manufacturing unit or warehouse.

Step 6: Grant of Approval

After successful scrutiny of documents and completion of inspection, the PESO certificate will be issued. The certification may be time/or batch-bound depending on validity, requiring you to renew accordingly.

PESO certification agencies or professional PESO Certification Consultant services may be consulted to simplify any of the above steps.

Who Requires PESO Certification?

Manufacturers of gas cylinders, pressure vessels, and valves

Importers of foreign equipment related to petroleum and gases

Companies involved in the storage or distribution of petroleum or explosive substances

Manufacturers of LPG/CNG kits and fittings

Contractors and equipment suppliers in the oil and gas sector

If your business operates in any of the aforementioned segments, PESO compliance is far from optional; it is a prerequisite under Indian law.

Choosing the Right PESO Certification Agency or Consultant

The PESO certification agency or consultant being proposed must have:

Deep insight into PESO regulations

Experience with various product categories

Valid connection and rapport within PESO structure

Successful certification history

Clear pricing and transparent methodology

Fusion Compliance Services provides professional consultancy and end-to-end service on PESO certification. From documentation and test coordination to liaisons with regulatory authorities, we ensure that the approval process is smooth and timely.

Benefits of PESO Certification

Regulatory Compliance: Ensure legal status in India without risk of penalties.

Safety Assurance: Show commitment to product safety.

Market Access: Certifies supply to oil companies, public sector units, and large industries.

Trust and Credibility: Brings buyer confidence and builds brand goodwill.

Customs Clearance: Enables easier import/export of certified equipment.

Why Should an Indian PESO Certification Consultant Be Chosen?

The regulatory environment in India for hazardous substances and such implementations is strict. Any violation could lead to rejection of consignments, fines, or even safety incidents. Being in foreign territory for an applicant, the appointment of the PESO Certification Consultant well-versed with stipulated local rules and having direct access to concerned authorities becomes an intelligent business decision.

They help keep track of the latest changes in regulations, timely renewals, and even assist in developing new product lines or venturing into other areas. Whether you are an Indian manufacturer or a global business, a local expert will enhance your compliance success.

Fusion Compliance Services

Address: S1 520, Cloud 9, Vaishali Sector 1, Near Mahagun Metro Mall, Ghaziabad, Uttar Pradesh-201012 Phone: +91-9696966665 Email: [email protected] Website: https://fusioncomplianceservices.com

Let us help you achieve the most efficient and reliable PESO compliance.

#PESOCertification#PESOCertificationConsultant#PESOCertificationAgency#HowToGetPESOCertification#HazardousMaterialCompliance#PESOIndia#SafetyComplianceIndia#GasCylinderApproval#PressureVesselCertification#FusionComplianceServices

0 notes

Text

CNG, RNG, and Hydrogen Tanks Market Analysis: Key Players and Competitive Landscape

Growing Adoption of Clean Energy and Alternative Fuels Drives Expansion in the CNG, RNG, and Hydrogen Tanks Market.

The CNG, RNG, and Hydrogen Tanks Market Size was valued at USD 2.6 billion in 2023 & is expected to reach USD 6.6 billion by 2032 & grow at a CAGR of 10.6% by 2024-2032.

The CNG (Compressed Natural Gas), RNG (Renewable Natural Gas), and Hydrogen Tanks Market is driven by the global push toward clean energy solutions and alternative fuels. With increasing adoption in automotive, transportation, and industrial sectors, the demand for lightweight, high-strength storage solutions is surging. Advancements in composite tank technologies and government incentives for low-emission vehicles are further propelling market growth.

Key Players

Worthington Industries, Inc.

Faber Industrie SpA

Luxfer Group

Hexagon Composites ASA

Everest Kanto Cylinders Ltd.

Quantum Fuel Systems LLC.

Praxair Technologies Inc.

Avanco Group

Xinyi Beijing Tianhai Industry Co. Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co. Ltd.

Future Scope

The future of the CNG, RNG, and Hydrogen Tanks Market looks promising, with increasing investments in green energy and sustainable fuel storage solutions. The automotive industry, particularly in the commercial vehicle and public transportation sectors, is adopting CNG and hydrogen-powered vehicles to meet stringent emission regulations. Additionally, hydrogen fuel cell technology is gaining momentum, boosting the need for high-pressure storage tanks. The aviation and marine industries are also exploring alternative fuel storage options, creating new growth avenues. With continued R&D in composite tank materials, such as carbon fiber-reinforced composites, the industry is moving toward lighter, safer, and more efficient fuel storage systems.

Emerging Trends

The market is evolving with advancements in Type IV composite tanks, which offer higher durability, lower weight, and improved storage efficiency. Government policies and incentives promoting clean energy adoption are accelerating the transition toward hydrogen and RNG-based fuel systems. The rise of hydrogen refueling infrastructure and increasing investments in renewable energy projects are further strengthening market demand. Additionally, innovations in cryogenic and high-pressure storage technologies are enabling safer and more efficient energy transportation.

Key Points

Growing adoption of alternative fuel vehicles (CNG, RNG, hydrogen) to reduce carbon emissions.

Increasing demand for lightweight, high-pressure storage solutions in transportation and industrial applications.

Advancements in composite tank technologies, particularly Type IV carbon fiber tanks.

Government incentives and policies driving the adoption of clean energy fuel systems.

Expanding hydrogen refueling infrastructure and renewable gas projects worldwide.

Conclusion

The CNG, RNG, and Hydrogen Tanks Market is set for strong growth, fueled by the global shift toward sustainable energy solutions and advancements in fuel storage technology. With increasing government support, technological innovation, and rising adoption of clean energy vehicles, the market will continue to expand, shaping the future of low-carbon transportation and industrial fuel storage.

Read Full Report: https://www.snsinsider.com/reports/cng-rng-and-hydrogen-tanks-market-2191

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#CNG#RNG#and Hydrogen Tanks Market#and Hydrogen Tanks Market Size#and Hydrogen Tanks Market Share#and Hydrogen Tanks Market Report#and Hydrogen Tanks Market Forecast

0 notes

Text

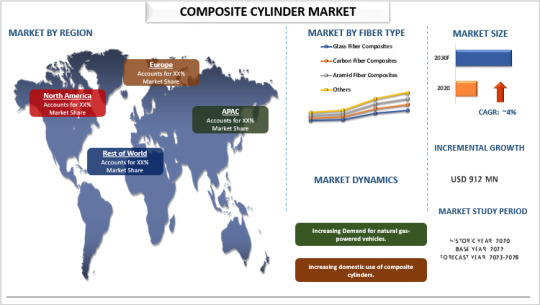

The Growth and Dynamics of the Composite Cylinder Market

The composite cylinder market has witnessed significant growth in recent years, driven by advancements in materials technology, increasing safety regulations, and a growing demand for lightweight, durable, and efficient gas storage solutions. Composite cylinders, made from high-strength fibers such as glass, aramid, or carbon embedded in a matrix of polymer resin, are becoming the preferred choice across various industries due to their superior properties compared to traditional metal cylinders.

Market Drivers

1. Technological Advancements: The development of advanced composite materials has been a key driver for the composite cylinder market. These materials offer high strength-to-weight ratios, corrosion resistance, and improved safety features. The integration of nanotechnology and improved manufacturing processes has further enhanced the performance and reliability of composite cylinders.

2. Regulatory Compliance and Safety: Stringent safety regulations and standards imposed by governments and international bodies have fueled the adoption of composite cylinders. These cylinders are designed to withstand high pressures and harsh environments, reducing the risk of leaks and explosions. Compliance with standards such as ISO 11119 and DOT specifications ensures their acceptance in various regions and applications.

3. Environmental Concerns: The growing emphasis on reducing carbon footprints and promoting sustainability has led to increased demand for eco-friendly solutions. Composite cylinders are lightweight, which reduces transportation fuel consumption and greenhouse gas emissions. Additionally, their longer lifespan compared to metal cylinders means fewer replacements and less environmental waste.

4. Rising Demand in Various Applications: Composite cylinders are used in a wide range of applications, including industrial gases, medical oxygen, automotive, aerospace, and recreational activities. The automotive industry, in particular, is witnessing a surge in demand for composite cylinders due to the increasing adoption of alternative fuel vehicles such as hydrogen and compressed natural gas (CNG) vehicles.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/composite-cylinder-market/

Market Segmentation

The composite cylinder market can be segmented based on material type, end-user, and region.

1. Material Type:

- Glass Fiber Composites: These cylinders are economical and offer moderate performance, making them suitable for applications with lower pressure requirements.

- Carbon Fiber Composites: Known for their high strength and lightweight properties, carbon fiber composite cylinders are ideal for high-pressure applications and are extensively used in aerospace and automotive industries.

- Aramid Fiber Composites: These provide a balance between performance and cost, offering good resistance to impacts and chemicals, thus finding use in various industrial applications.

2. End-User:

- Industrial: The industrial sector uses composite cylinders for storing and transporting gases such as oxygen, nitrogen, and argon.

- Healthcare: In the healthcare sector, composite cylinders are crucial for medical oxygen delivery systems due to their lightweight and portable nature.

- Automotive: The rise of hydrogen fuel cell vehicles and CNG vehicles has boosted the demand for composite cylinders in the automotive industry.

- Aerospace and Defense: Composite cylinders are used in aircraft for oxygen supply and in defense applications for breathing apparatuses and other critical systems.

3. Region:

- North America: The region has a well-established market for composite cylinders, driven by the presence of major manufacturers and stringent safety regulations.

- Europe: Europe is witnessing growth in the composite cylinder market due to increased adoption of alternative fuel vehicles and a strong focus on sustainability.

- Asia-Pacific: Rapid industrialization, urbanization, and the push for cleaner energy solutions are driving the market in the Asia-Pacific region.

- Rest of the World: Other regions are also contributing to market growth, particularly in niche applications and emerging markets.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=46359

Challenges and Future Outlook

Despite the positive growth trajectory, the composite cylinder market faces challenges such as high initial costs, complex manufacturing processes, and the need for specialized equipment and handling. However, ongoing research and development activities aimed at reducing costs and improving manufacturing efficiency are expected to mitigate these challenges over time.

The future of the composite cylinder market looks promising, with increasing investments in hydrogen infrastructure, advancements in material science, and expanding applications across various industries. As the world continues to transition towards cleaner energy solutions and sustainable practices, the demand for composite cylinders is set to rise, making them a vital component in the global push for a greener and safer future.

In conclusion, the composite cylinder market is poised for significant growth, driven by technological advancements, regulatory support, environmental concerns, and expanding applications. As industries continue to seek efficient and sustainable solutions, composite cylinders will play a crucial role in meeting these demands, ensuring safety, reliability, and performance in a wide range of applications.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

#Composite Cylinder Market#Composite Cylinder Market Growth#Composite Cylinder Market Share#Composite Cylinder Market Trends

0 notes

Text

Global Composite Cylinders Market - Analysis and Forecast (2020-2025)

The world market size for Composite Cylinders will hit USD 940 million by 2025, from USD 690 million by 2020 and 6.4% by CAGR between 2020 and 2025.

Thanks to their unique properties such as lightweight and not corrosive, composite cylinders are used more and more in developed and developing countries. Furthermore, they can be used as an alternative to steel cylinders. This reduces the cost of production and increases the company's sales growth. As a result, many producer investments in the composite cylinder industry have been gradually growing. Furthermore, the composite polymers are UV safe, non-corrosive, and explosion-proof. Due to this, the demand for gas and oil products is rising, these stain proof and translucent properties help measure or suggest gas in the cylinder. Furthermore, these cylinders can be transported easily because they are lightweight. This aspect also contributes to reducing transport costs.

For Free Sample Report- https://www.vynzresearch.com/energy-power/composite-cylinders-market/request-sample

Market Segmentation of Global Composite Cylinder

By Outer Casing Material

Glass Fibers

Carbon Fibers

High-Density Polyethylene

Other (medical, aerospace, marine, and defense)

The high-density polyethylene group was one of the most important outdoor casing materials and is projected in the coming years to remain the largest category. The rise in the category of high-density polyethylene is primarily based on its lightweight features and higher performance benefits.

By Tank Type

Type I

Type II

Type III

Type IV

Based on type III and type IV cylinders, the global LPG composite market is segmented. Type IV is the most common type of cylinder on the LPG composite market. During the forecast era, the cylinder type is expected to be greater and faster to develop. All the main composite manufacturers of LPG cylinders are only present in type IV tanks. The cylinders Type IV provides the highest weight reduction and increased explosive pressure in contrast to the cylinders Type I and Type III.

By End-Use Industry

Household Purpose

Hotels and Restaurants

Industrial Fuel

Industrial Process

Automotive

The global composite cylinder market will be powered by an expansion in the household segment. The composite cylinder is commonly used in homes and hotels for cooking purposes. They are commonly used in hospitals, naval, chemical, and spacecraft as oxygen cylinders. Oxygen, nitrogen, and hydrogen cylinders are also used in the chemical industry in reactions of chemical processing. CNG cylinders are widely used as fuel for automobiles in the automotive industry. Composite cylinders are commonly used for scuba diving because they are lighter in weight.

By Region

North America

Europe

Asia-Pacific

Rest of the World

Regional research in North America, Europe, Asia Pacific and Rest of the World of the worldwide composite cylinder industry is split. Asia Pacific is one of Composite Cylinder's fastest-growing markets by area. An increasing chemical and packaging industry in different developing and developed countries is likely to boost demand for composite cylinders. Other driving forces in the Asia Pacific world of composite cylinders include a greater understanding of composite cylinders and a rapid industrialization in developing economies. Moreover, North America is estimated to have a significant share of the world market for composite cylinders because of its high per-capita consumption of goods.

Competitive Landscape and Key players of Global Composite Cylinder Market

Luxfer Gas Cylinders

AMS Composite Cylinders

Hexagon Composites ASA

FABER INDUSTRIES S.P.A

Dragerwerk

Worthington Cylinders

Sinoma

Quantum Technologies

Aburi Composites

HITACHI

KOMATSU

Vektra Engineering Pvt. Ltd.

Dragerwerk AG and Co. KGaA.

There is a very large concentration in the global composite cylinder industry. Luxfer Gas Cylinder, Hexagon Composites, Aburi Composites, Faber Industry, and Worthington Cylinders are all leading producers in North America and Europe.

For Customization Request - https://www.vynzresearch.com/energy-power/composite-cylinders-market/customize-report

VynZ Research

Call: +91-996-028-8381

Toll Free (U.S. and Canada): +1-888-253-3960

Email: [email protected]

Web: https://www.vynzresearch.com

Connect with Us: LinkedIn | Facebook | Twitter

VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. We have a recognized trajectory record and our research database is used by many renowned companies and institutions in the world to strategize and revolutionize business opportunities. The company focuses on providing valuable insights on various technology verticals such as Chemicals, Automotive, Transportation, Energy, Consumer Durables, Healthcare, ICT, and other emerging technologies. READ MORE

1 note

·

View note

Text

CNG cylinder

Established in 2004, DSW has become a leading supplier of industrial and CNG cylinder, boasting over 3 million high-pressure gas cylinders and 2 million CNG steel cylinders currently in service.

The CNG-1 type cylinder is constructed entirely of steel, offering proven reliability and cost-effectiveness. However, it is also the heaviest option available, with a single tank easily weighing 350 lbs or more. This weight can reduce vehicle mileage and place additional strain on the suspension.

On the other hand, the CNG-2 type cylinder is specifically designed to store and transport compressed natural gas for various applications, including use in vehicles. These cylinders are typically constructed using high-strength materials such as steel or composite materials, and are engineered to meet stringent safety and performance standards.

DSW's CNG-1 Steel Cylinder for Vehicle (ISO11439) is produced in accordance with ISO11439 standards, making it suitable for widespread use in cars, trucks, and buses. Its characteristics of cleanliness and energy efficiency make it a compelling choice for vehicle applications.

1 note

·

View note

Text

India Construction Equipment Market Insight, Outlook, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the India construction equipment market size at USD 7.18 billion in 2022. During the forecast period between 2023 and 2029, the India construction equipment market size is projected to grow at a CAGR of 8.67% reaching a value of USD 12.78 billion by 2029. Rapid urbanization and increased public and private investments in infrastructure development projects are two key driving factors for the India construction equipment market. The Indian government’s focus on developing smart cities and expanding manufacturing sector is also expected to drive the growth of the India construction equipment market over the forecast period.

India Construction Equipment Market – Overview

Construction equipment is heavy-duty machinery and equipment designed specifically for doing construction tasks, most frequently groundwork operations. In addition to maintaining a close check on the applied quality standards, it optimizes the use of resources, such as materials, labor, finances, and the limited supply of a qualified and efficient workforce. The various types of construction equipment include those used for hoisting, excavation, hauling, grading, paving, drilling, and pile driving. Excavators, sometimes known as "diggers," are the most popular type of construction machinery because of their adaptability. On a building site, they predominate together with mining, landscaping, demolition, and other activities.

Sample Request @ https://www.blueweaveconsulting.com/report/india-construction-equipment-market/report-sample

India Construction Equipment Market – By Propulsion Type

Based on propulsion type, the India construction equipment market is segmented into ICE, electric, and CNG/LNG. The ICE, or internal combustion engine, accounts for the largest market share. Compared to external combustion engines, internal combustion engines have a number of benefits. The internal combustion engine's direct fuel-to-cylinder combustion results in lesser heat loss, improved thermal efficiency, and less fuel consumption. However, the electric propulsion type is projected to register the highest CAGR during the forecast period owing to its lower emissions.

Impact of COVID-19 on the India Construction Equipment Market

The COVID-19 pandemic impeded the expansion of the India construction equipment market. Construction and infrastructure, manufacturing, mining, and other significant end-user industries of the construction equipment market were all directly affected by the lockdown that the Indian government imposed to stop the virus's spread. The supply chain disruptions and temporary shutdown of construction equipment production both had a detrimental impact on market expansion. However, the market is projected to gain its pace back over the post-COVID-19 period following the lockdown upliftment.

Competitive Landscape

Major players operating in the India construction equipment market include Caterpillar, CNH Industrial America LLC, Deere & Company, Doosan Corporation, Escorts Limited, Hitachi Construction Machinery Co., Ltd, Hyundai Construction Equipment Co., Ltd, J C Bamford Excavators Ltd, Komatsu Ltd, and Kubota Corporation.

To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

13328236 G0 Pin Shaft for SANY machinery

13328236 G0 Pin Shaft SANY spare parts Mail:[email protected] 10186086 Printed circuit Board 61018580 水分离器MS6-LWS-1/2-U-V-WB 180101020105A Inner Round Turning Tools 10239354 The key SRMG4530.2.1-5 24004034 Locking Device 160101100079A080 PUMP HYDRAULIC 52001858 SANY PARTS 22051140 Extension rope 5 SP463C1701 922041100004A Welding CNC System 10640068 SANY PARTS 160102200002A169 Oil Return Hose 21051092 Rubber Hose 180105010259A Tap 10259983 Tube 10143510 Pulley Shaft Assembly 59007089 SANY PARTS 10019432 角钢料坯SYM5421J.22-1(L) 22059209 Reinforcing plate SP513G0102 /S509G0103 502238 Gen 6 DEF Tank DR507H-00F7T66B 10194714 4# Out Rigger oil cylinder 22026651 Cover plate AWPSPHA-1041 160801880023A Miniature Pressure Cap 22019953 Pin SP510A5010 /4600-22009 10696688 SANY PARTS 22020773 Axe SPHIG-0547 24004748 Oil Seal 22032249 Middle frame basis SPFM203_0031_L1390 61030468 # 10242598L SANY PARTS 61001260 Spacer 10517090 SANY PARTS 22018962 Pipes–Control SP107HC03A 918080700017 温度表M27X2-L250-TA2-H60 10197957L 右角钢料坯SYM5550J.3.3.15.1-3(L) 21019360 Main chord pipe 181500000004 Console Brand 10495737 Hydraulic Device Of Transfer Loader 22032636 Base Assembly SP305GG04A 920011900022A O ring 10224104L 加强板料坯SYM5600J.3.1.2-67(L) 919062800027A U-shaped pin 59002929 SANY PARTS 10133624 bending board JH13.2.7-1 10046732 Plate(II)QY26A-R-036.1.1-2 24916814 Guide sleeve 22007553 Steel tube SP400GH0112 22030076 Pipe SPHLR-00920001 21018316 Pipe [email protected] 10268618 Limit block 22005815 Cushion block SPFXE-0008 21011353 Alternator 10442871 Protective cover cushion block 180103030378A Turnable Bits 61016884 丝杆440203026 10279295 SANY PARTS 21027428 Electromagnetic valve seat 22068691 SANY PARTS 10192181 桶身拼焊SJ500A.11.14.1 22013966 Cylinder mouting plate 1 SP104T0102 /S1 10138027 Plate 160101070011B069 Mounting, Fuel Filter 160102230002A059 Pin Dowel 21000255 Plate 10183268 Head backup plate B 10256433 SANY PARTS 61004119 Rotary Joint 10132068 SANY PARTS 10638381 SANY PARTS 10002545L 斜底板料坯QY17A.5.1-30(L) 10213747 螺塞座ZB1.3.1-22 61009340 2017013项目凝水罐V1116 180605000187A High-voltage contact screw 22055037 Plate SPKMG00656A01 10016336 side horizontal connecting plate 10437413 SANY PARTS 10214023 CushionQY100.2.6A.5.1-1 10602820L 插销料坯QY50C.1B.8-2(L) 10122841MP 行星轮ⅠJ10.1.2-13(粗加工件) 22036670 guide sleeve SPHK-0047 /HK-724 160102040013A099 Spacer Sleeve 10676493 Check Curtain 61019028 减压阀Y41W-16P DN80 22022203 SPS35000Bs-M Crane SPS35000BS-M 10100241L SANY PARTS 22069207 SANY PARTS 501418 SY235 SOM 160102310004A084 Compression Spring 10226047B SANY PARTS 10292032 SANY PARTS 10071608L SANY PARTS 10245923 SANY PARTS 24903895 Valve Block 22055384 Drawer SPPCH159-A10 59005196 Iron bars 160808010001A CNG Gassholder Assembly 10114428 SANY PARTS 10074489 Reinforced plate 160102130003A020 Trapezoidal Barrel Ring 10255799 CZ0 List for attached spare parts 10110437 Component of rear upper inner plate 1RC1 10253357 Top support 921122200016A O-RING 10008461 Suspension arm bracket 61012817 Huangshi digit control punch lower die 920111200002A Wiring Harness 61027823 Accelerant 181604000204A protective mat of tooling of leaf opex 10452441 threaded tube 160102310003B440 Tension Wheel Assembly 160102040014B203 Fastenings 21084604 SANY PARTS 10203467 SANY PARTS 10448537L SANY PARTS 10287962 Base Plate 10225333 rear cover plate 21032054 Middle plate 18335000 远程控制器L=2800-E(AMS) 10192965 定位块JT-001-6 181399000546A Sandpaper 59005422 SANY PARTS 10423870 Angle steel 181604000593B Shot-blasting Shield 10470402 Floor 181500000258A SRSC4540GC type marking 22017025 Front outrigger SP310A01-A 22063863 Cutting plate SP402F0205_6_HG70 Default 10137357 Steel Sheet 502302 BOLT-ON RUBBER PAD (EACH OF 82 - SY95) 10208076 Reinforced bar 160102020024A059 Flywheel Comp 920010800014A 二效升膜蒸发器490㎡ 10179736 Right longitudinal beam Read the full article

0 notes

Text

Compressed Natural Gas (CNG) Tank Market: Latest Trends and Business Opportunities from 2023 to 2035

Compressed Natural Gas (CNG) Tank Market Size, Share, Growth, Trends, Analysis Report 2035

Research Nester published a report titled “Compressed Natural Gas (CNG) Tank Market: Global Demand Analysis & Opportunity Outlook 2035” which delivers detailed overview of the global compressed natural gas (CNG) tank market in terms of market segmentation by material type, vehicle, tank type, and by region.

Further, for the in-depth analysis, the report encompasses the industry growth indicators, restraints, supply and demand risk, along with detailed discussion on current and future market trends that are associated with the growth of the market.

The global compressed natural gas (CNG) tank market is expected to garner a large revenue by growing at a remarkable CAGR throughout the forecast period, i.e., 2023 – 2035, owing to the rising prices of gasoline and diesel fuels, high usage of CNG globally, and low cost of natural gas. Furthermore, stringent government regulations for adoption of clean fuels are also estimated to fuel the expansion of market in the coming years.

The market is segmented by material type, vehicle and tank type. On the basis of tank type, the type 1 segment is anticipated to grab the largest share during the forecast period accounting to the cost effectiveness and rising demand for type 1 tanks from India, China, Iran and Brazil. Additionally, the metal section in the material type segment is also expected to occupy a notable market share in the near future on the back of high durability, stiffness and fatigue resistance of metals.

Regionally, the compressed natural gas (CNG) tank market is segmented into five major regions including North America, Europe, Asia Pacific, Latin America and the Middle East & Africa. North America is projected to witness noteworthy market growth during the forecast period, which can be attributed to the government’s consciousness to adopt cleaner fuels in the region. Moreover, Asia Pacific is expected to occupy the largest market share on the back of increasing production and consumption of CNG in the region. Request Report Sample: @ https://www.researchnester.com/sample-request-3171 High Price of Gasoline and Diesel to Drive Market Growth

Surge in international oil rates is the key reason behind the increasing rates of diesel and petrol. In addition, several countries have extended the tax incentives on compressed natural gas vehicles and their refueling. This is estimated to generate an increased product demand in the forthcoming years, which in turn is projected to boost market growth in the future.

However, the volatility in the costs of natural gas is expected to operate as key restraint to the growth of the compressed natural gas (CNG) tank market over the forecast period.

This report also provides the existing competitive scenario of some of the key players of the global compressed natural gas (CNG) tank market which includes company profiling of Luxfer Holdings PLC, Worthington Industries, Inc., Quantum Fuel Systems LLC, Hexagon Composites ASA, Xinyi Beijing Tianhai Industry Co. Ltd., Praxair Technologies Inc., Lianyungang Zhongfu Lianzhong Composites Group Co. Ltd., Avanco Group, Everest Kanto Cylinders Ltd., Faber Industrie SpA, and others. The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments. On the whole, the report depicts detailed overview of the compressed natural gas (CNG) tank market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

About Research Nester

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel Email: [email protected] U.S. Phone: +1 646 586 9123 U.K. Phone: +44 203 608 5919

0 notes

Text

CNG, RNG, and Hydrogen Tanks Market SWOT analysis, Growth, Share, Size and Demand outlook by 2031 | Quantum Fuel Systems LLC, Everest Canto Cylinders Ltd, Praxair Technologies Inc

Global CNG, RNG, and Hydrogen Tanks Market report from Global Insight Services is the single authoritative source of intelligence on CNG, RNG, and Hydrogen Tanks Market. The report will provide you with analysis of impact of latest market disruptions such as Russia-Ukraine war and Covid-19 on the market. Report provides qualitative analysis of the market using various frameworks such as Porters’ and PESTLE analysis. Report includes in-depth segmentation and market size data by categories, product types, applications, and geographies. Report also includes comprehensive analysis of key issues, trends and drivers, restraints and challenges, competitive landscape, as well as recent events such as M&A activities in the market.

CNG, RNG, and Hydrogen Tanks are all types of fuel tanks. CNG is a compressed natural gas tank, RNG is a renewable natural gas tank, and Hydrogen Tanks are used to store hydrogen fuel. CNG and RNG tanks are used to store natural gas that can be used as a fuel, while Hydrogen Tanks are used to store hydrogen fuel that can be used in fuel cells.

Request Sample Report – https://www.globalinsightservices.com/request-sample/GIS20589/

Key Trends

There are several key trends in CNG, RNG, and Hydrogen Tanks technology.

First, the cost of CNG, RNG, and Hydrogen Tanks is declining. This is due to the increased production of natural gas, which has led to economies of scale. Second, the efficiency of CNG, RNG, and Hydrogen Tanks is improving. This is due to the development of new technologies, such as high-pressure cylinders and composite materials.

Key Drivers

The key drivers of the market for these tanks are the need for energy storage, the efficiency of the tanks, and the cost of the tanks. The need for energy storage is the primary driver of the market for CNG, RNG, and hydrogen tanks. These tanks are used to store energy so that it can be used when needed. The efficiency of the tanks is another key driver of the market. The tanks must be able to store the energy efficiently so that it can be used when needed.

Market Segments

By Gas Type

Compressed Natural Gas

Hydrogen

By Material Type

Metal

Carbon Fiber

Glass Fiber

By Application

Fuel Tank

Transportation Tank

By Region

North AmericaUS

Get A Customized Scope to Match Your Need Ask an Expert – https://www.globalinsightservices.com/request-customization/GIS20589

Key Players

Quantum Fuel Systems LLC

Everest Canto Cylinders Ltd

Praxair Technologies Inc

Avanco Group

Faber Industrie SpA

Luxfer Group

Hexagon Composites ASA

Worthington Industries Inc

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Excel data pack included with all report purchases

Robust and transparent research methodology

Ground breaking research and market player-centric solutions for the upcoming decade according to the present market scenario

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1–833–761–1700

0 notes

Text

Why you should undergo specific training certifications for handling dangerous cargo

A dangerous cargo or hazardous material or hazmat is any substance or material that is being transported which poses an unreasonable risk to health, safety, and property when it is transported for commercial purposes. According to the latest reports, Dangerous cargo has been the cause of more than twenty-five percent of shipping incidents. Governments across the globe have realized that all stakeholders need to work in synergy with each other to safeguard people, infrastructure, environment, assets, etc. from damage by hazardous chemicals and other types of dangerous cargo. It is a fact that improper identification of dangerous cargo, unstable loads, mistakes during the unpacking process, etc. has wreaked havoc on land, air, and sea. The most important requirement for reducing accidents involving dangerous cargo is proper identification, packaging, safe transportation, legitimate communication of the hazards through appropriate color-schemed labeling, etc. During land transportation, a lot of emphasis needs to be put on adequate skilling of the driver.

Which law regulates the transportation of dangerous cargo in New Zealand?

A dangerous cargo endorsement is actually a life and asset saving tool. In New Zealand, the transportation of dangerous cargo is guided by the Land Transport Rule 45001/1 Dangerous Goods 2005. Earlier, the activity of carrying dangerous cargo was guided by the Land Transport Rule: Dangerous Goods 1999 brought into effect on the 3rd of May 1999. The present rule was brought into effect on the 27th of June 2005. This act clearly states that the driver of vehicles carrying dangerous goods needs to have additional endorsements on his or her valid New Zealand driving license. The driver transporting dangerous goods also needs to go through a proper certification process to pick up the necessary skills required to transport dangerous cargo safely.

Which goods are classified as dangerous cargo?

It is also a fact that many necessary goods of regular use also pose an acute danger. The goods classified as dangerous cargo by the 2005 Act are ammunition, fireworks, oxyacetylene cylinders, aerosol canisters, welding cylinders, LPG cylinders, CNG cylinders, compressed air cylinders for scuba diving, diesel, petrol, methylated spirits, epoxy resin, etc. The list also includes a few swimming pool chemicals, dishwasher detergents, and even a few commercial and household cleaning products. Although these products may seem harmless, they have a great potential to cause accidents when transported in high volume. They have a chance of leaking, exploding, generating toxic fumes, etc. when subjected to high temperatures, continuous vibrations, static electricity, arbitrary pressure variations, etc.

What does the driver need to do?

Therefore, it is evident that the transportation of hazardous goods needs a specially trained, especially skilled driver. To drive a heavy vehicle such as a truck, a valid Truck Licence NZ is a statutory requirement. Apart from trucks, heavy vehicles such as trailers, heavy forklifts, buses, etc. can only be driven with a legitimate heavy vehicle license. The driver must have the correct license from the four classes of a license issued for driving heavy vehicles in New Zealand. Special endorsements are also required. The driver carrying dangerous cargo or hazardous goods needs to make a valid application for D, F, R, T, W DL19 endorsement. He or she also needs to present a valid New Zealand driver’s license. He or she can also present two other forms of identification and have a valid certificate to prove that he or she has passed the D endorsement course. He or she also needs to show a recent and valid eyesight certificate. After this, the applicant can apply for a D endorsement. However, it should be noted the endorsement needs to be made on his or her valid New Zealand driving license. A proper legitimate course ensures that the person is equipped with the requisite knowledge, experience, and special skills required for transporting dangerous goods in the safest manner possible. A MEWP Training NZ includes lessons on the identification of hazards and the training required for operating mobile elevated work platforms safely. MEWP courses normally include the operation of scissor lifts, self-propelled boom lifts, etc.

These courses enable a person to promote health and safety and save millions for a business by avoiding accidents.

Business Name: Roadtrain Ltd

Country: New Zealand

Address: 59B Bond Street, West Invercargill, Invercargill 9810

Email: [email protected]

Contact No: +64272232837

0 notes