#use of geotextile

Explore tagged Tumblr posts

Text

Different Ways to Use Geotextile Fabrics

Shankar Techx is a leading geotextile fabrics manufacturer in India that also provides woven Geotextile materials for diverse requirements. These Geotextiles made of non-woven materials are used primarily for drainage, filtration and separation. The Woven geotextiles, on the other hand, are ideal for stabilization or reinforcement. For more information, contact Shankar Techx or request a quote.

#geotextile fabrics#geotextile material use#Geotextile uses#non woven Geotextile uses#use of geotextile#woven Geotextile

0 notes

Text

[later] I don't get why our pizza slices have such terrible reviews; the geotextile-infused sauce gives the toppings incredible slope stability!

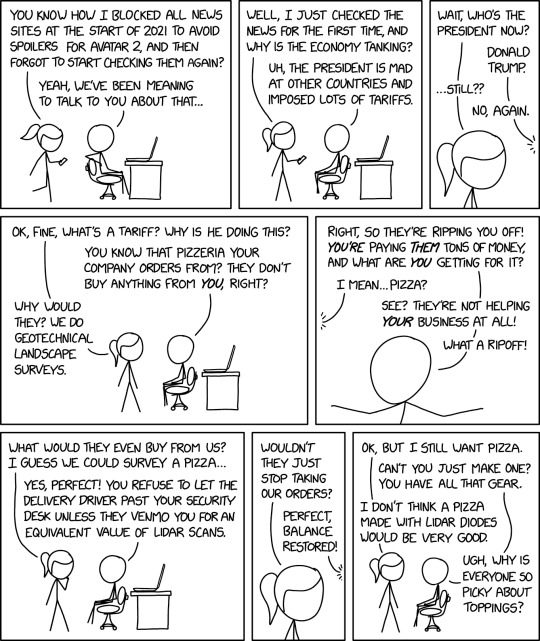

Tariffs [Explained]

Transcript Under the Cut

[Ponytail walks over to Cueball with a phone in her hand. Cueball turns away from his desk to look at her.] Ponytail: You know how I blocked all news sites at the start of 2021 to avoid spoilers for Avatar 2, and then forgot to start checking them again? Cueball: Yeah, we've been meaning to talk to you about that...

[Ponytail stops in front of Cueball.] Ponytail: Well, I just checked the news for the first time, and why is the economy tanking? Cueball: Uh, the president is mad at other countried and imposed a lot of tariffs.

[Closeup on Ponytail's head.] Ponytail: Wait, who's the president now? Cueball: Donald Trump. Ponytal: ...Still?? Cueball: No, again.

[Pan out.] Ponytail: OK, fine, what's a tariff? Why is he doing this? Cueball: You know that pizzeria your comapny orders from? They don't buy anything from you, right?

[Closeup on Cueball, arms spread.] Cueball: Right, so they're ripping you off! You're paying them tons of money, and what are you getting for it? Ponytail: I mean... pizza? Cueball: See? They're not helping your business at all! Cueball: What a ripoff!

[Pan out. Ponytail has her hand under her chin.] Ponytail: What would they even buy from us? I guess we could survey a pizza... Cueball: Yes, perfect! You refuse to let the delivery driver past your security desk unless they venmo you for an equivalent value of LIDAR scans.

[Closeup on Ponytail's head.] Ponytail: Wouldn't they just stop taking our orders? Cueball: Perfect, balance restored!

[Pan out.] Ponytail: OK, but I still want pizza. Cueball: Can you just make one? You have all that gear. Ponytail: I don't think pizza made with lidar diodes would be very good. Cueball: Ugh, why is everyone so picky about toppings?

2K notes

·

View notes

Text

Does a Patio Need a Foundation? What You Should Know Before You Build

So, you’re thinking about adding a patio. Maybe you want a cozy spot for morning coffee, a space for weekend BBQs, or just a solid upgrade to your backyard. But before you break ground, there’s one big question—does a patio need a foundation?

The short answer? It depends. Some patios can sit right on the ground, while others need a solid foundation to keep them from shifting, cracking, or sinking over time. Let’s break it down so you can figure out what works best for your home in South Bend.

Patio vs. Deck—Is There a Difference?

Before we jump into foundations, let’s clear up a common mix-up: patios vs. decks.

Patios sit directly on the ground. They’re made of materials like concrete, pavers, brick, or stone.

Decks are elevated structures, usually built with wood or composite boards, supported by posts and footings.

Decks always need a foundation, but patios? Not necessarily. The deciding factors include climate, material, and ground conditions.

When a Patio Needs a Foundation

While patios don’t need the deep foundations decks require, some situations do call for a stable base:

1. You’re Using Heavy Materials

If you’re going for a concrete slab patio or large stone pavers, you’ll need a compacted base underneath. Otherwise, over time, the weight can cause shifting or cracking.

2. You’re Dealing with Soft or Shifting Soil

South Bend’s climate can be unpredictable, with rain, snow, and freeze-thaw cycles affecting the ground. If your soil is clay-heavy or prone to erosion, a foundation helps prevent sinking and uneven settling.

3. You Want a Long-Lasting Patio

Technically, you can lay pavers right on the ground, but without a base, they’ll shift, sink, and grow weeds in between. A compacted gravel and sand base keeps everything stable.

4. You’re Building on a Slope

Got a slightly sloped yard? A foundation (or retaining wall) helps level out the area before installing your patio. Otherwise, you might end up with a lopsided setup.

When a Patio Can Skip the Foundation

There are some cases where a full foundation isn’t necessary:

If you’re using gravel or mulch for a casual, relaxed patio space.

If you’re installing interlocking pavers and using a flexible, well-compacted base.

If your soil is naturally firm and doesn’t shift much with seasonal changes.

Even in these cases, you’ll still want some level of prep work—like clearing out grass and compacting the ground—to avoid future headaches.

What Type of Foundation is Best for a Patio?

Okay, let’s say you do need a foundation. What kind should you go with? Here’s a quick rundown:

1. Gravel and Sand Base (Best for Pavers and Brick)

Ideal for DIY patios

Provides drainage and prevents shifting

Requires compacting with a tamper or plate compactor

2. Concrete Slab (Best for Permanent Patios)

Durable and long-lasting

Works well in South Bend’s freeze-thaw cycles

More expensive but low maintenance

3. Crushed Stone with Geotextile Fabric (Best for Preventing Weeds and Erosion)

Great for areas with soft soil

Helps prevent weeds from growing between pavers

Adds stability while allowing drainage

4. Pier Footings (For Raised or Covered Patios)

Needed if your patio will support a structure (like a pergola or sunroom)

Ensures stability and prevents sinking

Common Patio Foundation Mistakes to Avoid

Even if you’re hiring a contractor, it’s good to know what not to do. Some of the biggest mistakes include:

Skipping the base entirely. (Sure, it saves time—until your patio starts sinking.)

Not compacting the base properly. Loose soil leads to shifting over time.

Ignoring drainage. Without proper grading, water can pool and damage your patio.

Using the wrong materials for your soil type. South Bend’s clay-heavy soil? You’ll need extra drainage layers.

Do You Need a Permit for a Patio in South Bend?

In many cases, no. Most simple patios—like pavers or a concrete slab under 30 inches high—don’t require a permit in South Bend. However, if you’re:

Adding a roof, walls, or a pergola

Digging deep footings

Building near property lines

…it’s best to check with South Bend’s building department to avoid any surprises.

Final Thoughts

If you’re investing in a patio, taking the time to prep the ground is absolutely worth it. Even a basic gravel base can prevent long-term headaches like sinking, cracking, and uneven surfaces.

Want a hassle-free way to upgrade your patio? Screenmobile South Bend specializes in outdoor solutions, from screened-in patios to retractable enclosures—giving you a beautiful, bug-free space to enjoy year-round.

Thinking about a patio upgrade? Reach out today and let’s bring your vision to life.

7 notes

·

View notes

Text

Erosion Control and Auckland Council's Approach to Erosion and Sediment Management

Erosion control is a critical component of sustainable land management, particularly in urban areas like Auckland, where development can significantly impact the environment. The Auckland Council has recognized the importance of effective erosion and sediment control measures to protect waterways, preserve natural landscapes, and ensure the health of local ecosystems.

Understanding Erosion and Its Impact

Erosion is a natural process where soil and rock are worn away by wind, water, or ice. However, human activities, such as construction, land clearing, and deforestation, can exacerbate this process, leading to increased sediment runoff. Sediment can clog waterways, reduce water quality, and harm aquatic habitats. Moreover, erosion can compromise the structural integrity of buildings and infrastructure, resulting in costly repairs and environmental degradation.

Auckland Council's Erosion and Sediment Control Guidelines

The Auckland Council has established comprehensive guidelines to address erosion and sediment control in the region. These guidelines aim to mitigate the impacts of erosion, protect water quality, and promote responsible land use. Here are some key elements of Auckland Council's approach:

1. Erosion and Sediment Control Plans (ESCPs)

For any construction or land disturbance project, an Erosion and Sediment Control Plan (ESCP) is required. This plan outlines the measures that will be implemented to minimize erosion and sediment runoff. It must be tailored to the specific site conditions and activities, ensuring that appropriate control measures are in place before any work begins.

2. Best Management Practices (BMPs)

The Auckland Council promotes a range of best management practices (BMPs) for effective erosion and sediment control. These include:

Silt Fences: Temporary barriers made of geotextile fabric, installed to intercept sediment-laden runoff and prevent it from leaving the site.

Sediment Basins: These are designed to capture sediment from stormwater runoff, allowing it to settle before the water is released into nearby waterways.

Mulching and Hydro Mulching: Applying mulch or using hydroseeding techniques to stabilize soil and promote vegetation growth, which helps bind the soil and reduce erosion.

Vegetative Buffer Strips: Establishing buffer zones of vegetation around waterways to filter sediment and absorb runoff before it reaches sensitive areas.

3. Regular Monitoring and Maintenance

To ensure the effectiveness of erosion and sediment control measures, the Auckland Council emphasizes the need for regular monitoring and maintenance. This includes inspecting control measures during and after rain events, repairing any damaged infrastructure, and ensuring that vegetation is thriving.

4. Public Education and Engagement

The Auckland Council recognizes that community involvement is vital for successful erosion control. They provide educational resources and workshops to inform landowners, developers, and contractors about the importance of erosion and sediment control and how to implement effective practices on their properties.

Conclusion

Erosion control is essential for protecting Auckland's natural resources and ensuring the sustainability of its urban environment. By adhering to the Auckland Council's guidelines for erosion and sediment management, developers and landowners can contribute to preserving the region's waterways, reducing environmental impact, and promoting responsible land use practices. With the right measures in place, we can safeguard Auckland's landscapes for future generations while fostering a healthier ecosystem.

#Erosion Control#Sediment Management#Auckland Council#Environmental Protection#Urban Development#Best Management Practices#Erosion and Sediment Control Plans#Silt Fences#Sediment Basins#Hydro Mulching#Community Engagement#Sustainable Land Management#Water Quality#Vegetative Buffer Strips#Stormwater Management

2 notes

·

View notes

Photo

Vertical gardening is becoming very popular with urban, sub urban and rural gardeners alike. It saves space by growing upwards which keeps plant off the ground and out of reach from a lot of insects that can harm the plants. You will need:

An electric drill with a hole cutting bit that will cut a 5 – 7cm hole

A 2 or 3mm drillbit for the watering pipe

A length of PVC downpipe 100mm or 150mm diameter. (The length will = the height of the unit)

End cap for the downpipe

A narrower diameter (15mm or thereabouts) length of downpipe for watering. Make it about 8 – 10cm longer than the downpipe. If you have a pressurised irrigation system, you can use a length of soak hose instead

A cork

A knife

Duct tape

A length of geotextile (or hessian would do) for wrapping the watering pipe

Twine for tying the fabric to the watering tube

Good fertile soil (test it if you can – strawbs prefer it slightly acidic)

1 litre or so of coarse gravel

Strawberry plants (I used a mixture of different varieties)

A few companion plants (nasturtiums or marigolds)

Large tub or box (to stand unit in whilst filling)

Fixing collar or ties

Step 1: Cutting Decide on length of unit and cut the tower tube and watering tube accordingly. Don’t forget to make the watering tube 8-10cm longer! I made mine the height of the outside staircase outside as it gets pretty good sun there and the rails give me something to secure the unit to.

Step 2: Drilling the watering tube Drill vent holes in watering tube. Only drill these in the top 2/3 of the tube as the water will run down to the bottom plants. If you put holes all the way down the upper planter won’t get quite enough water as it will all rush out the lower holes. If you think you will do a good job of capping off the base end of the tube, you can put one small hole at the bottom so it doesn’t go anaerobic in there.

Step 3: Completing the watering tube Cut the geotextile or hessian to the shape that will cover the holes in the watering pipe. You don’t want roots getting in there and clogging it up.

Step 4: Cutting the holes in the tower Cut the holes in the tower tube. Remember that one side will face the wall so only put holes on the surfaces that will get sunlight. I made 3 rows of holes and staggered them with holes about 20cm depth apart vertically. Leave the last 20cm intact with no holes. Some of this will be a reservoir of the lower level plants

Step 5: Filling Place the large container against the wall – a corner is best so the tube is less likely to fall over. Place end cap over the base of the tube. Insert watering tube then fill the bottom 10 cm with coarse gravel.

How to Build a Pipe Garden

981 notes

·

View notes

Text

Non-Woven GEO Textile Exporter

As a trusted Non-Woven GEO Textile Exporter, we deliver high-quality geosynthetic solutions engineered for durability, filtration, and soil stabilization across global markets. Manufactured using premium synthetic fibers and advanced needle-punched technology, our non-woven geotextiles offer excellent strength, permeability, and resistance to environmental stress. Ideal for road construction, drainage systems, erosion control, and infrastructure projects, our products meet international quality standards.

#Non-Woven GEO Textile in Gujarat#Non-Woven GEO Textile Exporter#Non-Woven GEO Textile Supplier in India#Non-Woven GEO Textile in Vadodara

0 notes

Text

Yuzhimu nonwoven geotextiles can also reinforce the road structure. They have a high interface friction, which helps to restrain and strengthen the aggregate layers in the road.

Contact us today: www.yuzhimu.com

#Nonwovenfabricmanufacturer

#Bicomponentspunbondnonwoven

#NonwovenFabric

#FlexibleTwoStepNonwovenFabric

0 notes

Text

🌍 GLOBAL RECONSTRUCTION: THE POLICY SHIFT HUMANITY NEEDS NOW

Across the planet—from war-ravaged cities to flood-stricken coasts—entire communities lie in ruin. As conflicts rage and climate disasters multiply, we stand at a turning point. The old ways of aid are not enough. Piecemeal projects, slow disbursements, and tariff-blocked supply chains cannot match the scale of human suffering or the urgency of the planetary emergency.

We need a global policy shift—one that treats reconstruction as an investment in planetary stability and shared prosperity. No tariffs. Best-value procurement. Local labor. Sovereign-scale solutions. Here’s what it will take to rebuild every war-torn and climate-impacted region on Earth, and what we gain in return.

🏗️ I. SCOPE OF INFRASTRUCTURE REBUILT

A. Core Sectors

• Housing – Modular homes, temporary shelters, permanent builds • Schools – K–12, vocational, tertiary institutions • Hospitals & Clinics – Emergency care, trauma centers, mobile units • Retail & Markets – Community markets, grocery stores, logistics hubs • Emergency Services – Fire stations, police posts, civil defense • Communications – Towers, satellite internet, community internet cafés • Atmospheric Scrubbing – Carbon capture units, green walls, algae farms

B. Estimated Area Needing Rebuild

• War zones (Gaza, Syria, Yemen, Sudan, Ukraine): ~150,000 sq km • Climate zones (Bangladesh, Sahel, Pakistan floods, island nations): ~250,000 sq km → Total Estimated Area: ~400,000 sq km

🧱 II. MATERIALS NEEDED PER 1 SQUARE KILOMETER

• Housing – Concrete, rebar, wood, insulation, roofing → $5 million • Schools & Clinics – Bricks, steel frame, electrical, plumbing → $2 million • Retail/Markets – Cement, prefab metal panels → $1 million • Emergency Services – High-durability materials, solar kits → $1.5 million • Communications – Fiber optics, towers, batteries, servers → $1 million • Atmosphere Scrubbing – Bioreactors, scrubbers, biochar, trees → $500,000 • Roads & Transport – Asphalt, gravel, buses, geotextiles → $4 million

→ Total Materials per km²: ~$15 million

🚛 III. LOGISTICS & TRANSPORT COSTS (PER KM²)

• Transport by sea: $25 per ton (bulk freight) • Overland trucking: $0.20/km per ton • Air transport (electronics & medical kits): $1.50/kg • Staging & warehousing per km²: $200,000

→ Average logistics & transport per km²: $800,000

👷 IV. LABOR DEMAND & WAGE COSTS (PER KM²)

• 200 construction laborers × $600/month → $1.2 million • 10 engineers & architects × $2,500/month → $300,000 • 50 teachers, medics, admin × $800–2,000/month → $1 million • 10 IT & telecom workers × $1,500/month → $180,000 • 20 foresters & climate workers × $500–1,000/month → $200,000

→ Total labor per km²: ~$2.88 million

💰 V. COST SUMMARY PER KM² REBUILD

• Materials: $15 million • Transport: $800,000 • Labor: $2.88 million • Admin & Overhead: $320,000

→ Total per km²: $19 million

🌍 VI. GLOBAL SCALE OF THE PROJECT

• Total area: 400,000 km² • Total cost: 400,000 km² × $19 million = $7.6 trillion USD

📈 VII. REVENUE TO NATIONAL SUPPLIERS

• If 70% of inputs are domestically sourced: → $5.3 trillion USD in revenue across participating nations

• Major beneficiary sectors: – Cement and concrete – Steel and construction components – Timber and prefab housing – Telecom and digital infrastructure – Carbon scrubber technology and bioreactor manufacturing

👩🔧 VIII. JOB CREATION ESTIMATES

• Jobs per km²: ~290 → Total jobs: 290 × 400,000 = 116 million new jobs

Sector breakdown: • Construction – 80 million • Education & Health – 20 million • Tech & Telecom – 8 million • Environmental restoration – 8 million

🔧 IX. BEST-VALUE POLICY PRINCIPLES (NO TARIFFS)

• Use modular prefabrication to reduce costs by 30–40% • Employ local labor with fair wage guarantees • Deploy open-source architectural plans to scale quickly • Apply bulk purchasing models to cut per-unit costs by 20–30% • Remove tariff barriers to speed delivery and reduce price inflation

This is not just reconstruction—it’s global recovery, job creation, and climate readiness in one unified strategy.

The cost for the rebuilding of the human condition exceeds the US national budget so sovereign wealth will be needed. This will surpass the need for budget constraints, taxes, debt, or other bureaucratic barriers to providing urgent humanitarian aid. The profit motive as you can see above has not been overlooked there is no reason not to proceed.

#PlanetaryRecovery#PostWarReconstruction#ClimateResilience#NoTariffs#PeaceEconomy#BestValueTrade#GlobalRebuild#DecolonizeAid#LocalJobsGlobalJustice

0 notes

Text

Premium rPET Black Masterbatches, Textile Grade rPET Chips & Food Grade rPET Chips

In a world steadily advancing towards sustainability, recycled PET (rPET) has become the cornerstone of eco-conscious manufacturing. Our company stands at the forefront of innovation in the recycled plastic industry by offering high-performance rPET Black Masterbatches, rPET Chips Textile Grade, and rPET Chips Food Grade solutions.

What is rPET? A Revolution in Plastic Manufacturing

rPET (Recycled Polyethylene Terephthalate) is a highly sustainable, cost-effective material made by recycling post-consumer PET bottles. It significantly reduces plastic waste and carbon footprint, making it a preferred material across industries.

rPET Black Masterbatches – Enhanced Performance for Sustainable Applications

Our rPET Black Masterbatches are specifically engineered to deliver superior color dispersion, UV resistance, and thermal stability when compounded with recycled PET resins.

Key Features of Our rPET Black Masterbatches:

High Jetness & Deep Color: Produced using premium carbon black for intense black shade and consistent dispersion.

Excellent Thermal Stability: Suitable for high-temperature processing and extrusion applications.

Eco-Friendly: Formulated with sustainability in mind, containing high percentages of recycled content.

Low VOC Emission: Complies with global environmental and health safety regulations.

Optimized for Various Applications: Textile fibers, packaging, films, containers, automotive interiors, and construction components.

Applications of rPET Black Masterbatches:

Textile Industry: Used in black dope-dyed polyester yarns, spun fibers, and nonwoven fabrics.

Packaging Sector: Ideal for manufacturing black PET bottles and containers with a glossy finish.

Automotive: Enhances aesthetic appeal and durability in interior panels and trims.

Construction: Used in geomembranes, plastic sheeting, and roofing membranes for UV stability.

rPET Chips Textile Grade – For a Greener Textile Future

Our Textile Grade rPET Chips are tailored for high-performance textile manufacturing. Derived from 100% post-consumer PET bottles, they meet stringent global textile standards and deliver unmatched consistency in fiber spinning.

Specifications of Textile Grade rPET Chips:

Intrinsic Viscosity (IV): 0.76 – 0.85 dl/g

Color (L-Value): Above 76 for optimum brightness

Moisture Content: < 50 ppm

Contamination Level: Negligible, thanks to advanced filtration systems

Heavy Metal Content: Compliant with OEKO-TEX® and REACH standards

Advantages of Textile Grade rPET Chips:

High Spinnability: Uniform IV ensures smooth fiber formation and less yarn breakage.

Cost-Effective: Reduces raw material costs while supporting sustainable manufacturing.

Dye Affinity: Excellent compatibility with various dye classes for vibrant color results.

Mechanical Properties: Maintains high tensile strength and elongation properties in fibers.

Applications in the Textile Industry:

Polyester Staple Fiber (PSF)

Filament Yarn (FDY/POY/DTY)

Nonwoven Fabrics for Medical & Hygiene

Upholstery and Home Furnishings

Industrial and Geotextiles

rPET Chips Food Grade – Safe, Sustainable, and Superior

Our Food Grade rPET Chips are manufactured through a multi-stage washing and decontamination process, ensuring they are safe for direct contact with food. These chips meet global food safety certifications, making them the preferred choice for leading packaging companies.

Technical Specifications of Food Grade rPET Chips:

Intrinsic Viscosity (IV): 0.80 – 0.88 dl/g

Acetaldehyde (AA) Content: < 1 ppm

L-Value: > 78, ensuring clarity and brightness

Moisture Content: < 30 ppm

Complies With: EFSA, FDA, BIS, and FSSAI regulations

Why Choose Our Food Grade rPET Chips?

Food Safety Certified: Each batch undergoes rigorous migration testing to ensure safety.

Crystal Clarity: Ideal for transparent packaging solutions with no yellowing or hazing.

Strong Barrier Properties: Excellent moisture and gas barrier properties for extended shelf life.

High Processability: Suitable for blow molding, injection molding, and thermoforming.

Applications in Food Packaging:

Mineral Water & Carbonated Beverage Bottles

Food Trays & Containers

Microwaveable PET Packaging

Caps & Closures

Our Manufacturing Excellence – Quality at Every Step

We utilize state-of-the-art decontamination and extrusion lines from globally reputed brands to ensure uniformity, consistency, and safety of all our rPET products. Our in-house lab is equipped with advanced testing instruments for:

IV Measurement

Color Spectrophotometry

AA Testing

Heavy Metal Analysis

Melt Flow Indexing

Every bag of rPET Black Masterbatch, Textile Grade Chips, and Food Grade Chips is meticulously tested to ensure it surpasses the industry's most stringent standards.

Certifications and Compliance

We understand that product quality is nothing without global compliance. That’s why all our rPET products are certified with:

Global Recycled Standard (GRS)

OEKO-TEX®

FDA / EFSA Approvals (for Food Grade)

ISO 9001:2015 and ISO 14001:2015

REACH & RoHS Compliant

Global Export Reach and Customization Options

We supply rPET Chips and Masterbatches to more than 30 countries across North America, Europe, the Middle East, and Asia-Pacific. We offer:

Custom Formulations for desired IV, color tone, and additive packages

Private Labeling

Bulk Packaging Options (Jumbo Bags, HDPE Bags, etc.)

Just-in-Time Delivery Model for clients worldwide

Conclusion – Your Trusted Partner for rPET Solutions

Choosing our rPET Black Masterbatches, rPET Chips Textile Grade, and rPET Chips Food Grade ensures you are not just investing in quality, but also contributing to a circular economy. Whether you're in packaging, textiles, or consumer goods, our solutions empower your brand to be sustainable, compliant, and innovative.

Partner with us to redefine the future of recycled plastics.

0 notes

Text

The Benefits of Using Geotextile Fabric for Waterproofing!

Shankar Techx is a leading geotextile manufacturers in India. We offer 5 Common Types of Geotextile Fabric for Waterproofing. Like; Non woven geotextile, woven geotextile, Composite geotextiles, etc. To know about Advantages of Using Geotextile Fabric for Waterproofing, visit our blog!

#geotextile manufacturers in India#Non woven geotextile#woven geotextile#geotextile fabric for waterproofing#fabric for waterproofing#benefits of using geotextile#geo fabric manufacturers#geotextile fabric#woven filter fabric manufacturer#ground cover suppliers

0 notes

Text

Fully Drawn Yarn vs Drawn Yarn: What’s the Difference and When to Use Each?

In the world of technical textiles, choosing the right yarn can make all the difference in performance, durability, and application-specific success. At Sanathan Textiles, we understand how critical it is for industries to select the right fiber input for their specialized needs. Two frequently used yarn types in this space are Fully Drawn Yarn (FDY) and Drawn Yarn (DY). Though they may sound similar, their properties and applications vary significantly.

This blog will clarify the distinctions between the two and guide you on when to use each, especially for high-performance applications in technical textiles.

What is Fully Drawn Yarn (FDY)?

Fully Drawn Yarn, or FDY, is a high-tenacity, continuous filament yarn produced through a single-step spinning and drawing process. At Sanathan Textiles, we manufacture FDY using advanced machinery that ensures uniformity, strength, and superior dimensional stability.

Key Characteristics of FDY:

High tensile strength

Excellent dimensional stability

Uniform denier and tenacity

Smooth texture and consistent dye uptake

FDY is ideal for high-speed weaving and knitting, where fabric uniformity and durability are essential. It eliminates the need for post-spinning drawing, streamlining production and ensuring better performance in the final product.

Common Applications:

Automotive seat covers

Airbags

Industrial sewing threads

Luggage fabrics

Geotextiles and protective clothing

What is Drawn Yarn (DY)?

Drawn Yarn, also known as flat yarn or simply DY, is made by drawing partially oriented yarn (POY) through rollers to align the polymer chains and improve tenacity. Unlike FDY, drawn yarn involves a separate drawing step, giving manufacturers flexibility in customizing yarn properties.

Key Characteristics of Drawn Yarn:

Good strength and durability

Slightly lower tenacity than FDY

Economical for various non-critical technical applications

Suitable for specific finish or texture requirements

At Sanathan Textiles, we engineer drawn yarns that cater to clients looking for specific mechanical properties, finish types, or process compatibility in their applications.

Common Applications:

Filtration fabrics

Tent and awning materials

Liners and interlinings

Nonwoven textiles

Packaging textiles

FDY vs Drawn Yarn: A Quick Comparison

Fully Drawn Yarn (FDY) and Drawn Yarn (DY) differ in several important ways. FDY is produced using a single-step process that combines spinning and drawing, resulting in a yarn with higher tenacity and excellent dimensional stability. It offers a smooth, uniform surface and is ideal for high-performance applications such as airbags, luggage fabrics, and protective clothing. Although it may be slightly more expensive, its durability and consistency justify the investment.

On the other hand, Drawn Yarn (DY) is produced in two steps, starting with spinning and followed by a separate drawing process. This method allows for more control over texturizing and mechanical properties, making DY a cost-effective solution for moderate to light technical textile applications like filtration fabrics, nonwoven textiles, and tent materials. While DY has slightly lower tenacity and dimensional stability than FDY, it provides flexibility and affordability for less demanding use cases.

0 notes

Text

Gravel Grids for Heavy Traffic Areas: Durable Solutions for Lasting Strength

Because of its inexpensive, natural look, and straightforward setup, gravel is a preferred option for parking lots, driveways, and access routes. Standard loose gravel, however, frequently gets moved when used in high traffic locations to cause ruts, potholes, and uneven surfaces. This can not only create drainage problems but also complicate maintenance. Engineered systems meant to keep gravel in place even under intense loads and frequent use, Gravel Grids come in then.

We'll examine what gravel grids are, why they fit well for high-traffic uses, and how they can convert unstable surfaces into solid, low-maintenance ones in this piece.

What Are Gravel Grids?

Composed of sturdy materials such HDPE (high density polyethylene) or recycled plastic, gravel grids—also known as ground reinforcement grids or gravel stabilizers—interlocking panels. To offer structural stability and stop displacement, they are positioned under or within a layer of gravel. The gravel is contained by grid cells to provide a strong, permeable surface suitable for anything from passenger cars to big agricultural equipment and heavy trucks.

Depending on the intended application, gravel grids come in several thicknesses and patterns. Industrial-grade grids with deeper cells and greater loadbearing capabilities are advised for heavy duty applications.

Why Gravel Grids Work For Heavy Traffic

1.Uperior Load-Bearing Capacity

Gravel grids distribute weight across a wider surface area, reducing pressure on the sub-base and preventing localized wear and sinking. High-quality grids can support loads of up to 250 tonnes per square meter, making them suitable for parking lots, fire lanes, RV parks, and even construction site access roads.

2. Prevents Rutting and Displacement

Without reinforcement, loose gravel is easily pushed aside by vehicle tires or foot traffic, leading to uneven surfaces. Gravel grids anchor the stones in place, drastically minimizing movement. This means no more ruts, no more muddy patches, and no need to continually top up gravel.

3. Low Maintenance And Cost-Effective

Because gravel grids reduce erosion and material displacement, they minimize ongoing maintenance needs. You’ll spend less on gravel replenishment and surface leveling over time. Additionally, installing gravel grids can often be more affordable than paving with

Ideal Uses For Gravel Grids In Heavy Traffic Areas

Versatile and suitable in many high traffic situations, gravel grids can be used:

Driving Ways: Commercial or residential driveways subjected to regular vehicle traffic.

Parking Areas: From small lots to overflow event parking, parking areas range from private to public.

Access Roads: Particularly on distant residences, business sites, or agricultural land.

Emergency Routes: Fire access roads need solid, all-weather surfaces.

Construction Yards: are where huge machinery often traverses unpaved earth.

Key Features To Look For

Think about the following qualities while selecting gravel grids for high traffic areas:

Load Rating: Make sure the grid system is rated for the kind of traffic you foresee.

UV Resistance: Extended sunlight exposure can degrade certain polymers; UV-stable materials extend the grid's life.

Cell Depth And Wall Thickness: Thicker walls and deeper cells increase load-carrying capacity and stability.

Permeability: Good Plastic Gravel Grids lets water pass through, so avoiding puddles and increasing environmental friendliness.

Interlocking Mechanism: Grids that are firmly linked create a coherent surface resistant against drifting.

Installation Tips For Maximum Performance

Prepare the Base Properly:

Long-term success depends on right base preparation involving excavation, compaction, and geotextile membrane laying.

2.Use The Right Type of Gravel:

Prefer angular gravel over rounded stones since it locks into the grid cells more thoroughly.

3.Level and Compact: After filling the grid, make sure the surface is even and well compacted for easy use.

4.Edge Restraints: Installing edge restraints helps stop grids from spreading or lifting over time.

Sustainable And Eco-Friendly Option

Gravel grids are environmentally responsible as well as strong. Many are created from reused materials; the permeable character of gravel surfaces helps lower surface runoff and encourage groundwater recharging. Unlike concrete, gravel grid systems enable a greener, cooler surface that mingles seamlessly with surroundings.

Final Thoughts

Though regular gravel surfaces suffer from heavy traffic, gravel grids provide a simple, clever answer integrating sustainability, utility, and durability. Investing in gravel grids means fewer maintenance issues and better performance over the long run whether you're repairing a commercial parking lot or improving a rural access road.

With the correct installation and good quality materials, gravel grid systems can offer decades of service even in the most difficult circumstances. It might be time to stabilize your surface from the bottom up if you are weary of shifting stones and potholes.

0 notes

Text

Advanced Technical Textiles for Aerospace Applications

The global technical textiles market is set to experience robust expansion, reaching a valuation of USD 241.5 Billion by 2035, rising from USD 230.9 Billion in 2025, and reflecting a CAGR of 6.2% between 2025 and 2035. This market is driven by growing applications across healthcare, construction, automotive, aerospace, agriculture, and military sectors.

Technical textiles are engineered fabrics designed for performance rather than aesthetics. These textiles offer high durability, superior mechanical strength, thermal resistance, and chemical stability, making them indispensable across multiple industries. Increasing investments in R&D, advancements in fiber technology, and demand for sustainable solutions are transforming the industry.

With the rising adoption of smart textiles, fire-resistant materials, antimicrobial fabrics, and biodegradable fibers, technical textiles are at the forefront of modern industrial evolution. Government initiatives, environmental regulations, and industrial advancements further fuel market growth, pushing manufacturers to innovate sustainable, high-performance materials.

Discover key market opportunities – Request your sample report now!

Market Growth Drivers

The Smart Textiles Revolution: Wearable Technology & IoT Integration

Smart textiles, embedded with sensors, conductive fibers, and IoT-driven components, are reshaping industries by offering real-time data analytics, biometric monitoring, and adaptive response functionalities. The rise of health tracking wearables, military smart uniforms, and sports performance-enhancing apparel has created a significant demand surge.

Healthcare: Textile-based biosensors for real-time patient monitoring and wound-dressing fabrics with drug-delivery capabilities.

Military & Defense: Smart textiles with thermal regulation, camouflage adaptation, and moisture resistance for enhanced battlefield efficiency.

Sports & Fitness: Compression garments integrated with heart rate sensors and muscle monitoring functionalities.

Sustainability and Circular Economy Principles

The global push toward eco-friendly and sustainable textile production is shaping market dynamics. Stringent environmental regulations are compelling manufacturers to adopt bio-based fibers, recycled materials, and biodegradable coatings.

Bio-Based Technical Textiles: Increased use of organic cotton, hemp, and algae-based fibers.

Closed-Loop Recycling: Innovative recycling technologies to reclaim fibers from industrial waste.

Low-Impact Dyeing Processes: Reduction of water and energy consumption in fabric processing.

The Growing Role of Medical Textiles

The healthcare industry’s demand for high-performance medical textiles is escalating due to rising hygiene concerns, infection control measures, and advanced wound care solutions. The expansion of biodegradable surgical textiles, drug-releasing fabrics, and antimicrobial hospital linens is a major market driver.

Wound-Healing Textiles: Smart bandages embedded with nanoparticles for infection detection and healing acceleration.

Antimicrobial Hospital Linens: Reduced pathogen transmission in medical facilities.

Biodegradable Surgical Textiles: Elimination of medical waste pollution.

Automotive Textiles: Enhancing Safety, Comfort, and Sustainability

The automotive industry is rapidly integrating technical textiles for enhanced performance, durability, and sustainability. Lightweight, heat-resistant, and durable materials are essential for electric vehicles (EVs), autonomous driving, and high-performance automobiles.

Fire-Resistant & Thermal-Insulating Fabrics: Enhanced passenger safety and vehicle endurance.

Recycled & Sustainable Interior Fabrics: Automakers are prioritizing eco-friendly materials for upholstery and soundproofing.

Smart Car Seats: Integrated sensors for automated climate control and ergonomic adjustments.

Geotextiles Driving Infrastructure & Construction Growth

The construction and civil engineering sectors rely on geotextiles for road stabilization, erosion control, and soil reinforcement. With increasing urbanization, infrastructural development, and climate change mitigation efforts, geotextiles are witnessing exponential demand.

Road Construction: Increased adoption of high-strength, UV-resistant fabrics for road durability.

Erosion Control: Water-permeable geotextiles to prevent soil degradation.

Drainage Systems: Advanced filtration textiles improving water management in urban projects.

Discover Key Market Trends – Read the Complete Report! https://www.futuremarketinsights.com/reports/technical-textiles-market

Shifts in the Technical Textiles Market (2025-2035)

Nanotechnology in Textiles: Development of self-cleaning, moisture-wicking, and odor-resistant fabrics.

Revolutionary Smart Fabrics: AI-powered textiles with adaptive temperature control and real-time health monitoring.

Circular Economy Integration: Full-scale implementation of recycled and bio-based textile solutions.

Automation in Textile Manufacturing: AI-driven production lines reducing waste and labor dependency.

"The global technical textiles market is undergoing a significant transformation, driven by advancements in material science, sustainability initiatives, and growing demand in critical sectors such as healthcare, automotive, and defense. Smart textiles and bio-based fabrics will play a crucial role in the future market landscape," says Nikhil Kaitwade, Associate Vice President at Future Market Insights (FMI).

Key Takeaways from Technical Textiles Market Study

The market is projected to reach USD 241.5 Billion by 2035.

Smart, sustainable, and medical textiles are the fastest-growing segments.

The Asia-Pacific region remains the dominant market leader.

Geotextiles and automotive textiles are expected to witness the highest adoption rates.

Government policies and sustainability regulations will shape future market expansion.

Country-Wise Analysis

United States

Leading medical textiles hub, with a focus on biodegradable surgical fabrics.

Automotive sector embracing recyclable and lightweight textile solutions.

United Kingdom

Strong emphasis on sustainable textile manufacturing.

Increased R&D funding in smart textiles and nanotechnology.

European Union

Government regulations driving eco-friendly textile innovations.

Growing aerospace textile industry for fire-resistant and lightweight fabrics.

Japan

Smart textile leadership with integration of AI-driven functionalities.

Advanced filtration textiles for high-tech industries.

India

Emerging as a global leader in technical textile production.

Government initiatives like the National Technical Textiles Mission (NTTM) promoting market expansion.

Competitive Landscape

The technical textiles market is highly competitive, with key players focusing on innovation, sustainability, and strategic collaborations to strengthen their market position. Notable companies include:

DuPont: A leader in material science, DuPont offers a range of technical textiles, including protective fabrics and medical textiles, emphasizing innovation and sustainability.

Freudenberg Group: Specializing in nonwoven fabrics, Freudenberg caters to automotive, construction, and healthcare sectors, focusing on technological advancements and global expansion.

Ahlstrom-Munksjö: This company provides fiber-based solutions, including filtration and medical textiles, with a strong emphasis on sustainability and product development.

Recent Developments

Sustainable Polyester Recycling: A startup, Reju, is addressing the polyester crisis by developing a chemical recycling process that recycles polyester into polyester, aiming to tackle the environmental impact of polyester production.

Reach out to Sales to Secure Your Copy of the Report Now!

Technical Textiles Market Segmentation

By Application:

Agrotech

Buildtech

Hometech

Indutech

Sportech

Packtech

Mobiltech

Meditech

Clothtech

Geotech

Protech

Oekotech

By Process:

Nonwoven

Composites

Others

By Region:

North America

Latin America

Western Europe

Eastern Europe

East Asia

South Asia Pacific

Middle East and Africa

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analystsworldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc. Christiana Corporate, 200 Continental Drive, Suite 401, Newark, Delaware - 19713, USA T: +1-347-918-3531 For Sales Enquiries: [email protected] Website: https://www.futuremarketinsights.com LinkedIn| Twitter| Blogs | YouTube

0 notes

Text

Felt fabrics have quietly shaped the world for centuries. From insulating ancient yurts in Central Asia to reinforcing modern roadways, their uses are widespread. Recently, felt has attracted attention not just on construction sites but also on couture runways. Felt was once used primarily for heavy-duty geotextile work, but now it has become a versatile and sustainable option for modern lifestyle and fashion products. This crossover from infrastructure to high fashion reveals just how adaptable felt can be.

What are felt geotextiles? Geotextile felt is a densely packed, non-woven fabric usually made from synthetic fibers such as polyester or polypropylene. Sustainable variants use natural fibers like jute and wool. Felt is used to stabilize soil, control erosion, filter drainage, and make subgrades for railways and roads. Thanks to its durability, porosity, and breathability, felt geotextiles perform well in both dry and wet environments. These qualities also make them suitable for consumer goods.

Why does felt work in fashion? In the context of fashion, felt offers a soft and yet structured texture, which is a unique quality. Designers employ such fabrics to add volume, introduce a tactile element to their collections, and create sculptural silhouettes. It also offers several other benefits in this particular context, such as sustainability, zero fraying, insulation, and durability. These benefits are even more important than aesthetics as they align with the fashion values held highly nowadays. Felt is a highly sustainable option as it can be made using biodegradable fibers and recycled materials. The material also does not fray when cut, and this is why it enables seamless and creative designs and simplifies manufacturing.

Felt is a naturally warm material, and this makes it an ideal option for outerwear.

The overlap to runways from roadways Felt is an effective material in infrastructure projects because of qualities like strength, form retention, and water resistance. These qualities also carry over rather well to fashion applications. There are several product segments where felt is gaining momentum in terms of crossover, such as outerwear, accessories and footwear, and lifestyle and home products. These days, you can see thicker wool felts in high-end coats, capes, and jackets, and they draw inspiration from industrial-grade materials. These days, brands are also using recycled felt to make sustainable shoes, hats, and bags.

Felt is also being used to make table runners, laptop sleeves, storage bins, and wall décor, as well as the material offers the perfect combination of utility and form, traits that you get in geotextile engineering as well!

Felt and circular economy — sustainable synergy These days, there is an increasing emphasis on upcycling and circular design in both the fashion and construction industries, and this has made felt the perfect candidate for cross-sector innovation. The most prominent examples in this case are closed-loop manufacturing and upcycled geotextiles. Felt left over from industrial projects can be sanitized, reused, and processed to make commercial products such as bags and mats. Some environmentally conscious brands these days are working with companies that make industrial felt to create sustainable fashion accessories. Such a symbiotic relationship promotes waste reduction while providing felt with a stylish second life as well.

Felt of the future — innovation ahead Textile innovators and materials scientists these days are exploring hybrid felts by blending synthetic and natural fibers to create enhanced water resistance, breathability, and fire retardancy. The result of all this effort has been a new generation that feels just at home at a fashion show as it does on a construction site. On top of that, laser-cutting and 3D (three-dimensional) felting technologies are also helping create zero-waste and ultra-precise design methods, which can make the material more adaptable to manufacturing processes being followed nowadays. Felt is a fabric that does not have any limits — it is equally good at adding flair to fashion and stabilizing railways as well. In fact, its journey across industries is a testament to its incredible versatility as a material. It is capable of moving between artistic expression and technical utility with equal felicity, and this opens up a hitherto unexplored world of possibilities for designers, sustainability advocates, and engineers in equal measure. Since both the infrastructure and fashion industries are facing increasing pressure to be more environmentally conscious, felt has become a material that is already ready to evolve and created to last.

0 notes

Text

Non-Woven GEO Textile in Vadodara

Discover high-quality Non-Woven GEO Textile in Vadodara, Gujarat engineered for superior strength, durability, and environmental performance. Designed for soil stabilization, drainage, and erosion control, our non-woven geotextiles are crafted using advanced needle-punch technology. Ideal for road construction, railways, landfills, and infrastructure projects, they ensure long-term reliability and cost-effectiveness.

#Non-Woven GEO Textile in Gujarat#Non-Woven GEO Textile Supplier in India#Non-Woven GEO Textile in Vadodara#Non-Woven GEO Textile Exporter

0 notes

Text

Yuzhimu nonwoven fabric is widely used in diverse industries including filtration, carpet, automotive, construction, and geotextiles due to their superior strength, uniformity, and bonding efficiency.

Contact us today: www.yuzhimu.com

#Nonwovenfabricmanufacturer

#Bicomponentspunbondnonwoven

#NonwovenFabric

#FlexibleTwoStepNonwovenFabric

0 notes