Don't wanna be here? Send us removal request.

Text

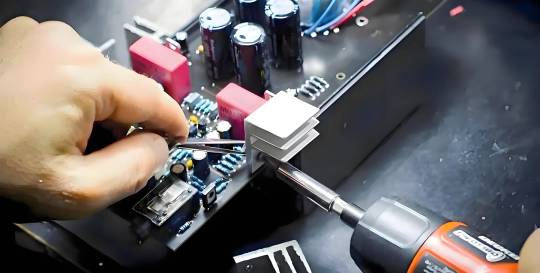

Explore the advantages of single-sided PCBs, including cost-effectiveness, simplicity, and ease of manufacturing. Learn about their production process and common applications in consumer electronics, LED lighting, and more.

0 notes

Text

Viasion Technology: Your Trusted Partner for Quality PCB Manufacturing Solutions

In today’s fast-paced tech world, electronics are everywhere—from smartphones and wearables to medical devices and industrial systems. Behind every smart gadget or complex system lies a network of well-designed printed circuit boards (PCBs) that bring it all to life. At Viasion Technology, we’re proud to be one of the most trusted names in PCB manufacturing, offering high-quality, customized PCB solutions to companies all over the world.

Whether you're a startup prototyping a new device or an established business scaling up production, Viasion is here to help you turn your ideas into reality—with precision, reliability, and cost-efficiency at the core of everything we do.

Why Choose Viasion for Your PCB Needs?

Since 2007, Viasion has been delivering exceptional PCB fabrication and assembly services from our headquarters in Shenzhen, China. With over 17 years of experience, we’ve served clients across various industries, including medical, automotive, industrial control, IoT, and consumer electronics.

Our team combines engineering expertise with state-of-the-art technology to ensure every board we produce meets the highest international standards. From prototype to production, we offer end-to-end services that help streamline your product development cycle.

Comprehensive PCB Capabilities

At Viasion, we understand that no two projects are the same. That’s why we offer a broad range of PCB types and services to meet your exact technical and budgetary requirements. Some of our core offerings include:

1. Copper PCB Board Manufacturing

Copper PCB boards are the backbone of modern electronics. They offer superior conductivity, excellent heat dissipation, and high durability—perfect for high-power applications. Whether you need single-layer, double-layer, or multi-layer copper boards, we have the expertise to deliver consistent quality.

Our copper PCBs are widely used in LED lighting, power electronics, automotive systems, and more. Plus, we offer a range of thickness options and custom finishes to suit your specific needs.

2. Flex PCB and Flex PCB Board Production

Looking for a lightweight, space-saving alternative to traditional rigid PCBs? Flex PCBs (also known as flex PCB boards) are your go-to solution. These boards can bend, twist, and fold, making them ideal for compact devices and dynamic applications.

At Viasion, we manufacture high-quality flexible boards that perform well under stress and resist vibration. Whether you need single-sided, double-sided, or multilayer flexible circuit boards, our team can guide you through the entire process—from material selection to final inspection.

3. Flexible Circuit Board Solutions

Our flexible circuit board options are engineered for durability and versatility. These boards are especially useful in wearable tech, mobile phones, and aerospace systems where space and weight are critical concerns.

We ensure that each flexible PCB goes through rigorous testing to meet the most demanding requirements. With Viasion, you can count on flexible solutions that don’t compromise on performance.

4. FR4 PCB Manufacturing

FR4 is one of the most popular materials used in PCB production due to its excellent strength-to-weight ratio and thermal resistance. Our FR4 PCB solutions are suitable for everything from simple consumer electronics to high-end industrial controls.

We offer FR4 boards in various thicknesses, copper weights, and surface finishes. Whether you’re building a prototype or scaling to mass production, we’ll make sure your FR4 PCBs are manufactured to your exact specs.

5. Metal Core PCB (MCPCB) Fabrication

If your project demands superior thermal management, our metal core PCB (MCPCB) options are the ideal choice. With aluminum or copper cores, these boards can efficiently dissipate heat, which is crucial in high-power LED and automotive applications.

At Viasion, we manufacture single-sided, double-sided, and multilayer MCPCBs that combine thermal performance with electrical reliability. Our advanced manufacturing techniques ensure minimal thermal resistance and excellent mechanical strength.

Industries We Serve

Our PCBs are found in a wide array of products across industries, including:

Automotive: Durable and heat-resistant PCBs for electric vehicles and ADAS systems.

Medical Devices: High-precision boards for diagnostic equipment and patient monitoring systems.

Industrial Control: Reliable PCBs for automation, robotics, and smart manufacturing.

Consumer Electronics: Compact and cost-effective boards for wearables, smart gadgets, and more.

IoT Applications: Custom PCB solutions optimized for wireless communication and low-power consumption.

What Sets Viasion Apart?

✅ Experienced Team – Our engineers have years of hands-on experience in PCB design, manufacturing, and testing.

✅ Advanced Facilities – Our ISO9001, ISO13485, and UL-certified factory is equipped with modern machines and inspection tools.

✅ Flexible Order Quantities – From one-off prototypes to full-scale production, we can handle orders of any size.

✅ Strict Quality Control – Every board goes through electrical testing, AOI inspection, and functional checks before shipping.

✅ Global Reach, Local Support – While we’re based in China, we serve clients worldwide, offering responsive communication and fast lead times.

Getting Started with Viasion

Starting a project with us is easy. Just send your PCB Gerber files and specifications, and we’ll get back to you with a quick quote. Need help optimizing your design for manufacturing? Our team offers DFM (Design for Manufacturability) feedback at no additional cost.

We’re more than just a manufacturer—we’re your engineering partner every step of the way.

Let’s Build Something Great Together

Whether you’re working on a next-gen wearable or an industrial control system, you need a PCB partner you can trust. At Viasion Technology, we combine technical know-how with personalized service to deliver PCBs that meet your performance and budget expectations.

From copper PCB boards and flexible circuit boards to FR4 PCBs and metal core PCBs, we’ve got you covered with comprehensive capabilities and a proven track record.

0 notes

Text

To directly analyze the Rogers 4350B, let us first discuss what we mean when citing high-performance RF/microwave laminate material. Prefabricated RF/microwave circuits work at frequencies generally in the range of MHz to GHz, when frequencies go high any little change in the dielectric properties of the substrate material causes signals to distort, get lossy, and degrade.

0 notes

Text

0 notes

Text

Choosing the Right PCB: A Guide to Modern Circuit Board Technologies

Introduction: Why PCB Type Matters

Selecting the right PCB type is crucial for ensuring the performance, reliability, and cost-effectiveness of your electronic product. From the widely-used FR4 PCB to specialized solutions like flex rigid PCB, the choices are vast. This blog breaks down the major types of PCBs including copper PCB board, flex PCB, and metal core PCB to help guide your decision.

1. Copper PCB Board: Built for Performance

The copper PCB board is renowned for its high thermal and electrical conductivity. These boards are often used in applications requiring durability and high current carrying capacity, such as industrial machinery and automotive electronics. Their robustness makes them indispensable in harsh environments.

2. Flex PCB and Flex PCB Board Technology

A flex PCB, or flex PCB board, is constructed using materials that allow the board to bend during installation or use. These are ideal in devices where space and weight savings are critical, such as smartphones, medical tools, and aerospace components.

3. Versatility of the Flexible Circuit Board

The flexible circuit board excels in dynamic applications. Unlike traditional boards, it can bend, twist, and fold to fit into limited spaces, reducing the need for complex wiring and connectors. Its adaptability is a key benefit in wearables and miniaturized electronics.

4. Why FR4 PCB is a Go-To Choice

FR4 PCBs are made from a composite material consisting of woven fiberglass and epoxy resin. They offer excellent strength-to-weight ratio, moisture resistance, and electrical insulation. Common in computers and home appliances, FR4 remains a cost-effective and reliable option.

5. Metal Core PCBs for High-Power Needs

Metal core PCBs feature a metallic base for superior heat dissipation. They're the preferred choice in LED lighting systems, motor controllers, and heavy-duty applications. The ability to withstand thermal stress sets them apart from traditional PCB types.

6. Benefits of Flex Rigid PCBs

A flex rigid PCB merges flexibility with structural integrity, allowing engineers to design circuits that need both movement and stable anchoring. This is especially useful in foldable electronics, digital cameras, and instrumentation panels where space optimization is key.

7. Rigid Flex Circuit Boards in Compact Devices

A rigid flex circuit board provides both rigid support and flexible routing in a single board. This design reduces assembly time and improves signal integrity, making it ideal for high-speed data transfer devices and embedded systems.

8. Importance of Prototype PCB Assembly in Product Development

No matter how great the design, testing is vital. Prototype PCB assembly enables quick iterations and debugging before final production. Whether you're using a flex PCB or a metal core PCB, prototyping helps validate your concept, improve efficiency, and ensure a successful product launch.

Conclusion

Choosing the right PCB—from copper PCB board to rigid flex circuit board—depends on your project’s specific needs. Understanding the unique advantages of each type allows you to make informed decisions, streamline production, and deliver better-performing electronics. With the right PCB technology and proper prototype PCB assembly, you can bring even the most ambitious electronic designs to life.

0 notes

Text

Viasion Technology Co., Ltd. stands out as a leading PCB manufacturer, offering a comprehensive range of services including copper, flexible, and FR4 boards. With over 40,000 square feet of manufacturing space and a workforce of approximately 1,600 professionals, Viasion is well-equipped to handle both low and medium-volume PCB fabrication and assembly. The company serves over 1,000 customers worldwide across various industries such as consumer electronics, automotive, medical devices, industrial automation, and telecommunications. Operating under ISO 9001:2015 and ISO 13485:2016 certifications, Viasion ensures that all PCBs undergo rigorous testing and inspection processes to meet international standards.

0 notes

Text

Viasion Technology Co., Ltd., established in 2007 and headquartered in Shenzhen, China, offers comprehensive PCB solutions, including copper, flexible, and FR4 boards. Their services encompass PCB fabrication, assembly, and electronic manufacturing services (EMS), catering to both small and medium-volume requirements. Viasion's commitment to quality is evident through certifications like ISO 9001:2015 and ISO 13485:2016, ensuring adherence to international standards. With a dedicated team and state-of-the-art facilities, Viasion provides efficient and cost-effective solutions, making them a reliable partner for diverse industries seeking high-quality PCB products.

0 notes

Text

Viasion Technology, a leading PCB manufacturer based in Shenzhen, offers specialized solutions including copper, flexible, and FR4 boards. Each PCB type is engineered for specific industry needs—from high-heat electronics to compact, wearable devices. With certifications like ISO 9001 and ISO 13485, Viasion emphasizes quality, innovation, and reliability across various sectors including automotive, medical, and telecom. Their scalable production facilities support both small and medium-volume demands.

0 notes

Text

Viasion Technology Co., Ltd., established in 2007 and headquartered in Shenzhen, China, offers a comprehensive range of high-performance printed circuit boards (PCBs) tailored to meet diverse application needs. Their offerings include copper PCBs for superior heat dissipation in high-power devices, flexible PCBs ideal for space-constrained applications like wearables and medical equipment, and FR4 PCBs that balance performance and cost-effectiveness. Viasion adheres to international standards, operating under ISO 9001:2015 and ISO 13485:2016 certifications, ensuring rigorous testing and inspection processes. With a workforce of approximately 1,600 professionals and multiple manufacturing facilities, Viasion is equipped to handle both low and medium-volume PCB fabrication and assembly. Their PCBs find applications across various industries, including consumer electronics, automotive, medical devices, industrial automation, and telecommunications.

0 notes

Text

Discover top-quality copper PCB boards at Viasion, a major manufacturer of advanced PCB solutions. Their offerings include flex PCBs, flex PCB boards, and flexible circuit board copper PCB boards, catering to diverse industries like automotive, medical, and consumer electronics. Viasion also specializes in FR4 PCBs, known for durability and performance. With capabilities in both prototyping and mass production, Viasion delivers high-reliability solutions tailored to your needs. Whether you're looking for rigid or flexible designs, their experienced team ensures precision and quality. Visit Viasion to explore cutting-edge copper-based PCB technology and customized circuit board solutions.

0 notes

Text

Top Teflon PCB Manufacturers for High-Frequency Applications

ViasionPCB is a trusted Teflon PCB manufacturer, specializing in high-frequency and RF applications. With advanced materials like Rogers and PTFE-based laminates, their PCBs offer low signal loss, high thermal stability, and excellent dielectric properties. Whether for telecommunications, aerospace, or radar systems, Viasion ensures precision, reliability, and compliance with industry standards.

Website URL: https://www.viasionpcb.com/teflon-pcb/ Location - USA Email at - [email protected]

0 notes

Text

Finding Quality Ceramic PCB Suppliers: What ViasionPCB Recommends

ViasionPCB collaborates with trusted ceramic PCB suppliers to ensure high-performance and reliable circuit boards for demanding applications. These suppliers provide premium materials like Alumina (Al₂O₃), Aluminum Nitride (AlN), and Beryllium Oxide (BeO), known for their excellent thermal conductivity and electrical insulation. With advanced manufacturing techniques, including laser drilling and precision metallization, they guarantee high-quality, multilayer ceramic PCBs. Suppliers also adhere to strict industry standards such as ISO 9001 and RoHS compliance, ensuring durability and reliability. Whether for LEDs, power electronics, aerospace, or medical devices, ViasionPCB's supplier network delivers cost-effective and scalable solutions for various industries.

For More Details Please Visit Our Website - https://www.viasionpcb.com/ceramic-pcb/

Email at - [email protected], [email protected]

Location - USA

0 notes

Text

High-Frequency PCBs: Key Features & Leading Manufacturers

High-frequency PCBs are essential for high-speed and RF applications, ensuring signal integrity, low loss, and minimal interference. ViasionPCB specializes in manufacturing high-performance high-frequency PCBs, designed for industries such as 5G, aerospace, automotive radar, and medical technology.

These PCBs use advanced materials like Rogers, Taconic, and PTFE substrates, which provide low dielectric loss and stable performance at high frequencies. With precision-controlled impedance, ViasionPCB ensures that high-frequency signals travel efficiently without degradation.

Manufacturing high-frequency PCBs requires advanced techniques, such as laser drilling, tight tolerance etching, and multilayer stack-up designs. ViasionPCB leverages state-of-the-art production facilities and strict quality control measures to guarantee high reliability and durability.

As a leading high-frequency PCB manufacturer, ViasionPCB provides customized solutions to meet specific client requirements, ensuring optimal electrical performance for critical applications.

For More Details Please Visit Our Website -

Loctation - USA

Email at - [email protected]

0 notes

Text

How SMT PCB Assembly Improves Efficiency and Performance?

Surface Mount Technology (SMT) PCB assembly enhances efficiency and performance by enabling compact, high-speed, and cost-effective electronics manufacturing. China PCB Assembly utilizes automated SMT processes, ensuring precise component placement and reducing errors. With high-density PCB designs, SMT allows for faster signal transmission and improved functionality. The elimination of through-hole drilling streamlines production and lowers manufacturing costs. Advanced soldering techniques, such as reflow soldering, enhance connection reliability. SMT also supports miniaturization, making it ideal for modern consumer electronics, aerospace, and medical devices. With rigorous quality control, China PCB Assembly ensures high-performance SMT solutions for all industries.

For More Details Please Visit Our Website - https://www.chinapcbassembly.com/smt-assembly/

Email at - [email protected] Call us at - 0086-755-26735910 Location - Building C, Yuyuan Industrial Park, No. 94 of Fuyuan 1st Road, Bao’an District, Shenzhen, China

0 notes

Text

Why Choose Alumina PCBs? Benefits and Applications Explained

Alumina PCBs are highly durable, thermally efficient, and ideal for high-power and high-frequency applications. They offer excellent heat dissipation, making them perfect for LED lighting, power electronics, and automotive systems. Compared to traditional PCBs, alumina ceramic provides superior mechanical strength and electrical insulation. These PCBs also resist corrosion and withstand extreme temperatures, ensuring long-term reliability. ViasionPCB Assembly specializes in high-quality alumina PCB manufacturing with precision and cost-effective solutions. Our expertise ensures top performance for industrial, medical, and aerospace applications. Choose Viasion for reliable, high-performance alumina PCB solutions tailored to your needs!

Email at - [email protected], [email protected] Call Us At - 0755 2673 5910 Skype: viasion1

0 notes

Text

How to Find Reliable Low-Cost PCB Assembly Services?

Finding a low-cost PCB assembly service without compromising quality requires careful evaluation. Look for certified manufacturers like China PCB Assembly that offer cost-effective solutions with strict quality control. Choose a provider with automated assembly processes, bulk component sourcing, and efficient production techniques to reduce costs. Ensure they provide testing services like AOI and X-ray inspection for defect-free PCBs. Compare pricing, turnaround times, and customer reviews to make an informed decision. China PCB Assembly delivers affordable, high-quality PCB assembly solutions for businesses of all sizes.

For More Details Please Visit Our Website - https://www.chinapcbassembly.com/low-cost-pcb-assembly/

Email at - [email protected] Call us at - 0086-755-26735910 Location - Building C, Yuyuan Industrial Park, No. 94 of Fuyuan 1st Road, Bao’an District, Shenzhen, China

0 notes

Text

How Quick Turn PCB Assembly Accelerates Product Development?

Quick turn PCB assembly plays a crucial role in accelerating product development by reducing lead times and enabling faster iterations. China PCB Assembly provides rapid prototyping and production, allowing engineers to test and refine designs quickly. With streamlined manufacturing processes and advanced technology, they ensure high-quality, reliable PCB assemblies in a short timeframe. This fast turnaround helps businesses meet tight deadlines, reduce costs, and speed up time-to-market. Their ISO-certified quality control guarantees precision and performance in every build. Whether for prototyping or small-batch production, their services keep your projects on track. Partner with them today to bring your ideas to reality—faster!

For More Details Please Visit Our Website -https://www.chinapcbassembly.com/quick-turn-pcb-assembly/

Email at - [email protected] Call us at - 0086-755-26735910 Location - Building C, Yuyuan Industrial Park, No. 94 of Fuyuan 1st Road, Bao’an District, Shenzhen, China

0 notes