Video

youtube

FreeCAD Sketching Tutorial 02 | FreeCAD Tutorial | Mechnexus

1 note

·

View note

Text

Best Practices for Prototyping in Mechanical Engineering

Prototyping is a crucial stage in the development of any mechanical engineering project. It allows engineers to test and validate their designs before moving into full-scale production. By following best practices for prototyping in mechanical engineering, professionals can ensure the efficiency, accuracy, and success of their projects. One key aspect of prototyping is the selection of materials. Engineers must carefully choose materials that closely resemble those intended for the final product. This ensures that the prototype's performance and characteristics accurately reflect the end product. Additionally, considering factors such as strength, durability, and cost during material selection is essential to create a prototype that is both functional and cost-effective. Another important best practice is to involve stakeholders early in the prototyping process. By engaging with clients, end-users, and other relevant parties from the beginning, engineers can gather valuable feedback and insights that can shape the prototype's design and functionality. This collaborative approach not only enhances the quality of the prototype but also increases stakeholder buy-in and satisfaction. Also Read-: Bearings in Medical Devices: Applications in Surgical Equipment and Diagnostic Tools Environmental Considerations in Bearing Design: Corrosion Resistance and Sealing Solutions Future Trends in Bearing Technology: Miniaturization, Smart Bearings, and IoT Integration Furthermore, utilizing advanced prototyping techniques can significantly improve the efficiency and accuracy of the prototyping process. Technologies such as 3D printing, CNC machining, and rapid prototyping allow engineers to quickly create physical prototypes with high precision and detail. These techniques enable rapid iteration and refinement of designs, leading to faster development cycles and better final products. In addition to selecting the right materials and involving stakeholders, thorough testing and evaluation are essential best practices in mechanical engineering prototyping. Engineers should conduct comprehensive testing to assess the prototype's performance, functionality, and durability under various conditions. This iterative testing process helps identify potential issues early on and allows for necessary adjustments to be made before moving to production. Collaboration and communication are also key best practices for successful prototyping in mechanical engineering. Effective communication among team members, stakeholders, and suppliers ensures that everyone is aligned on project goals, timelines, and requirements. Regular updates, feedback sessions, and progress reports help maintain transparency and accountability throughout the prototyping process. Also Read-: Materials Engineering: Advancements and Breakthroughs Human Factors in Mechanical Design: Ergonomics and User Experience The Challenges of Working in Extreme Environments as a Mechanical Engineer Moreover, documenting the prototyping process is crucial for future reference and improvement. Engineers should keep detailed records of design iterations, test results, feedback received, and decisions made during the prototyping phase. This documentation not only serves as a valuable reference for future projects but also facilitates continuous learning and process optimization within the engineering team. By following these best practices for prototyping in mechanical engineering, professionals can streamline the development process, minimize risks, and deliver high-quality products that meet or exceed client expectations. Prototyping is not just a step in the engineering process but a strategic tool for innovation and success in the field of mechanical engineering. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

The Role of Mechanical Engineers in the Medical Device Industry

Mechanical engineers play a crucial role in the development and innovation of medical devices. Their expertise in designing, testing, and manufacturing mechanical systems is essential for ensuring the safety, reliability, and effectiveness of medical devices used in healthcare settings. In this section, we will explore the specific contributions of mechanical engineers in the medical device industry and how their skills are instrumental in advancing healthcare technology. Designing medical devices requires a deep understanding of both engineering principles and medical requirements. Mechanical engineers are responsible for translating the needs of healthcare professionals and patients into functional and user-friendly devices. They work closely with healthcare providers, researchers, and other engineers to design products that meet the highest standards of quality and performance. By incorporating principles of biomechanics, materials science, and fluid dynamics, mechanical engineers can create innovative solutions that address complex medical challenges. Also Read-: Exploring Different Specializations in Mechanical Engineering Bearing Failure Modes and Analysis: Common Causes and Preventive Measures How Mechanical Engineers Contribute to Renewable Energy One key aspect of the role of mechanical engineers in the medical device industry is ensuring compliance with regulatory standards and industry guidelines. Medical devices must meet stringent regulatory requirements to ensure their safety and efficacy. Mechanical engineers are involved in every stage of the product development process, from concept design to final manufacturing, to ensure that devices meet regulatory standards such as ISO 13485 and FDA regulations. Their attention to detail and commitment to quality control are essential for obtaining regulatory approval and bringing new medical devices to market. In addition to design and regulatory compliance, mechanical engineers also play a critical role in testing and validation processes for medical devices. They are responsible for conducting rigorous testing procedures to evaluate the performance, durability, and safety of devices under various conditions. By using advanced simulation tools, prototyping techniques, and testing protocols, mechanical engineers can identify potential design flaws, optimize device performance, and ensure that products meet the needs of healthcare providers and patients. Moreover, mechanical engineers contribute to the manufacturing and production of medical devices by developing efficient production processes and quality control systems. They collaborate with manufacturing teams to optimize production workflows, select appropriate materials, and implement quality assurance measures to ensure consistency and reliability in device manufacturing. By leveraging their expertise in mechanical design and manufacturing technologies, mechanical engineers can streamline production processes, reduce costs, and enhance the scalability of medical device manufacturing operations. Also Read-: Bearing Selection Criteria: Factors to Consider in Choosing the Right Bearing Innovations in HVAC Systems: Advancements and Efficiency Bearings in Robotics and Automation: Enabling Precision and Smooth Motion Furthermore, mechanical engineers are at the forefront of innovation in the medical device industry, driving advancements in areas such as robotics, artificial intelligence, and wearable technologies. Their interdisciplinary approach to problem-solving and their ability to integrate cutting-edge technologies into medical device design are key drivers of innovation in healthcare. By pushing the boundaries of traditional engineering practices and embracing emerging technologies, mechanical engineers are shaping the future of medical devices and revolutionizing patient care. In conclusion, the role of mechanical engineers in the medical device industry is multifaceted and essential for the development of safe, effective, and innovative medical technologies. Their expertise in design, testing, regulatory compliance, manufacturing, and innovation is instrumental in advancing healthcare technology and improving patient outcomes. As the demand for sophisticated medical devices continues to grow, the contributions of mechanical engineers will be pivotal in shaping the future of healthcare and driving progress in the medical device industry. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Exploring the Ethics of Mechanical Engineering

Ethics play a crucial role in the field of mechanical engineering, guiding professionals in making decisions that impact society, the environment, and future generations. As technology advances and the world becomes more interconnected, the ethical considerations within mechanical engineering become increasingly complex and significant. Let's delve deeper into some key aspects of ethics in mechanical engineering. One fundamental ethical consideration in mechanical engineering is the responsibility to prioritize safety in design and implementation. Engineers must ensure that the products they create are safe for consumers, workers, and the general public. This involves conducting thorough risk assessments, adhering to industry standards and regulations, and continuously evaluating and improving safety measures throughout the product lifecycle. By prioritizing safety, mechanical engineers uphold their ethical duty to protect human life and well-being. Also Read-: Top Mechanical Engineering Universities Around the World Art of Design Optimization in Mechanical Engineering Influence of Mechanical Engineering in Sports Technology Another critical ethical consideration is the impact of mechanical engineering projects on the environment. Sustainability has become a central focus in the field, with engineers striving to minimize the environmental footprint of their designs and processes. This involves incorporating eco-friendly materials, optimizing energy efficiency, and reducing waste and emissions. By integrating sustainable practices into their work, mechanical engineers contribute to a healthier planet and demonstrate their commitment to ethical environmental stewardship. Integrity and honesty are core ethical values that mechanical engineers must uphold in their professional conduct. This includes being transparent about potential risks and limitations of their designs, accurately representing data and findings, and avoiding conflicts of interest. By maintaining integrity, mechanical engineers build trust with clients, colleagues, and the public, fostering a culture of accountability and ethical behavior within the industry. Also Read-: Key Skills Every Mechanical Engineer Should Possess Introduction to Bearings: Types, Functions, and Applications Role of Mechanical Engineers in the Defense Industry Ethical considerations also extend to the social impact of mechanical engineering projects. Engineers must consider the broader implications of their work on society, including issues of equity, accessibility, and social justice. This involves engaging with diverse stakeholders, listening to community feedback, and designing solutions that address the needs of all individuals, regardless of background or socioeconomic status. By prioritizing social responsibility, mechanical engineers can create more inclusive and equitable outcomes that benefit society as a whole. In addition to ethical considerations in design and implementation, mechanical engineers must also navigate ethical dilemmas that may arise in their professional relationships and interactions. This includes issues such as intellectual property rights, confidentiality, and professional integrity. Engineers must uphold ethical standards in their collaborations with colleagues, clients, and other stakeholders, ensuring that they respect the rights and interests of all parties involved. Overall, exploring the ethics of mechanical engineering is essential for guiding professionals in making ethical decisions, upholding integrity, and promoting the well-being of society and the environment. By prioritizing safety, sustainability, integrity, social responsibility, and ethical conduct in their work, mechanical engineers can contribute to a more ethical and sustainable future for all. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Influence of Lean Manufacturing Principles on Mechanical Design

Lean manufacturing principles have significantly impacted the field of mechanical design, revolutionizing the way products are developed and manufactured. By focusing on efficiency, waste reduction, and continuous improvement, lean principles have reshaped the traditional approach to mechanical design processes. One key aspect of lean manufacturing principles that has influenced mechanical design is the emphasis on minimizing waste. In the context of mechanical design, waste can manifest in various forms, such as overproduction, excess inventory, unnecessary motion, defects, and waiting time. By identifying and eliminating these sources of waste, designers can streamline the product development process, reduce costs, and improve overall efficiency. Also Read-: Best 2D CAD Drafting software of 2024 FreeCAD Integration with KiCAD Benefits of Python Programming for Mechanical Engineers Another important aspect of lean manufacturing principles is the concept of value stream mapping. This technique involves analyzing the entire product development process to identify areas of inefficiency and waste. By mapping out the value stream, designers can visualize the flow of materials, information, and resources, pinpoint bottlenecks, and implement improvements to optimize the design process. Furthermore, lean manufacturing principles advocate for the implementation of pull-based systems rather than push-based systems. In the context of mechanical design, this means designing products based on actual customer demand rather than speculative forecasts. By aligning production with customer needs, designers can reduce lead times, minimize inventory levels, and enhance overall responsiveness to market fluctuations. Also Read-: Creo+ Powerful CAD in The Cloud Understanding Pipe Schedule: A Crucial Aspect in Piping Systems Basic Guide to Nominal Pipe Size (NPS) in Piping Systems Moreover, the concept of continuous improvement, or Kaizen, is a fundamental principle of lean manufacturing that has had a profound impact on mechanical design. By fostering a culture of continuous learning, experimentation, and innovation, designers can constantly refine and enhance their design processes, leading to higher quality products, increased efficiency, and greater customer satisfaction. Additionally, lean manufacturing principles emphasize the importance of cross-functional collaboration and teamwork. In the context of mechanical design, this means breaking down silos between different departments and fostering communication and collaboration among designers, engineers, manufacturers, and other stakeholders. By promoting a collaborative environment, designers can leverage diverse perspectives, expertise, and insights to develop more innovative and optimized designs. Furthermore, the concept of standardized work, another key principle of lean manufacturing, has implications for mechanical design processes. By establishing standardized processes, procedures, and best practices, designers can ensure consistency, quality, and efficiency in their design activities. Standardized work also facilitates training, knowledge sharing, and continuous improvement efforts within design teams. In conclusion, the influence of lean manufacturing principles on mechanical design is profound and far-reaching. By embracing concepts such as waste reduction, value stream mapping, pull-based systems, continuous improvement, cross-functional collaboration, and standardized work, designers can enhance the efficiency, quality, and effectiveness of their design processes, ultimately leading to the development of superior products that meet customer needs and expectations. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Impact of Globalization on Mechanical Engineering

Globalization has significantly influenced the field of mechanical engineering, shaping practices and processes in various ways. One of the key impacts of globalization on mechanical engineering practices is the increased collaboration and exchange of ideas among professionals from different parts of the world. This has led to a more diverse and innovative approach to problem-solving within the field. Furthermore, globalization has facilitated the transfer of technology and knowledge across borders, allowing mechanical engineers to access the latest advancements and best practices from around the globe. This exchange of information has accelerated the pace of innovation in the field, leading to the development of more efficient and sustainable engineering solutions. Also Read-: Key Skills Every Mechanical Engineer Should Possess An Introduction to Bearings: Types, Functions, and Applications Role of Mechanical Engineers in the Defense Industry

Another important aspect of the impact of globalization on mechanical engineering practices is the expansion of markets and opportunities for professionals in the field. As companies operate on a global scale, mechanical engineers have the chance to work on projects that span across continents, gaining valuable experience and exposure to different working environments. Moreover, globalization has also influenced the supply chain and manufacturing processes in mechanical engineering. With the ability to source materials and components from various countries, engineers have more flexibility in designing and producing products. This has led to increased efficiency and cost-effectiveness in the manufacturing process. Also Read-: Deep Dive into Rolling Element Bearings: Ball, Roller, and Needle Bearings Innovations in Fluid Dynamics: Applications and Impacts Exploring the World of Smart Materials in Mechanical Design

In addition, the cultural exchange brought about by globalization has enriched the field of mechanical engineering by promoting diversity and inclusivity. Engineers now have the opportunity to work with colleagues from different cultural backgrounds, bringing unique perspectives and approaches to problem-solving. Overall, the impact of globalization on mechanical engineering practices has been profound, leading to increased collaboration, knowledge sharing, market opportunities, efficiency in manufacturing, and cultural diversity within the field. As the world continues to become more interconnected, mechanical engineers must adapt to these changes and embrace the opportunities that globalization brings to the profession. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Best Practices for Designing for Manufacturability

Designing for Manufacturability is one of the most important factor in designing a machine or mechanical system. in simple term it is process of optimization of machine part, product to reduce its manufacturing cost. A part designed with this approach must be easily manufactured at lower cost so a mechanical design engineer must take this factor in consideration while designing a mechanical part. with the help of DFM engineers and designers can streamline the production process, reduce costs, and improve the quality of the final product. One key aspect of designing for manufacturability is to consider the capabilities and limitations of the manufacturing process. Understanding how the PCB will be fabricated and assembled can help designers make informed decisions about the layout, component placement, and routing of the board. By working closely with manufacturers and considering their input early in the design process, designers can avoid potential issues that may arise during production. Also Read-: Deep Dive into Rolling Element Bearings: Ball, Roller, and Needle Bearings Innovations in Fluid Dynamics: Applications and Impacts Exploring the World of Smart Materials in Mechanical Design Another important best practice is to design for ease of assembly. This involves optimizing the layout of components on the PCB to minimize the complexity of the assembly process. By grouping related components together and following industry-standard assembly guidelines, designers can ensure that the PCB can be assembled efficiently and with minimal risk of errors. In addition to considering manufacturability during the design phase, it is also important to think about the long-term implications of design decisions. Designing for reliability involves selecting high-quality components, implementing robust testing procedures, and considering factors such as thermal management and signal integrity. By prioritizing reliability in the design process, engineers can create PCBs that are less prone to failure and have a longer lifespan. Furthermore, designing for manufacturability also involves optimizing the design for cost-effectiveness. This includes minimizing the number of unique components, reducing the complexity of the layout, and considering alternative manufacturing methods that may lower production costs. By balancing performance requirements with cost considerations, designers can create PCBs that meet the necessary specifications without exceeding the budget. Also Read-: Understanding Pipe Schedule: A Crucial Aspect in Piping Systems Basic Guide to Nominal Pipe Size (NPS) in Piping Systems The Role of Mechanical Engineers in Space Exploration Another important aspect of designing for manufacturability is to ensure compliance with industry standards and regulations. Adhering to standards such as IPC-A-600 for PCB manufacturing and IPC-A-610 for PCB assembly can help ensure that the final product meets quality and reliability requirements. By staying up to date with industry best practices and regulations, designers can avoid costly rework and delays in production. Overall, incorporating best practices for designing for manufacturability into the PCB design process can lead to more efficient production, higher-quality products, and reduced time to market. By considering manufacturability from the initial stages of design, engineers can optimize the design for ease of assembly, reliability, cost-effectiveness, and compliance with industry standards. This proactive approach can ultimately result in a smoother production process and a successful end product that meets both technical and business requirements. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Application of Virtual Reality in Mechanical Engineering

Virtual reality (VR) technology has revolutionized various industries, including mechanical engineering. Virtual prototyping is very cost effective with the help of Virtual reality technology a mechanical design engineer create and simulate product performance under various test condition with the help of VR technology. In the realm of mechanical engineering, the application of virtual reality has opened up new possibilities and enhanced the design and development processes with the help of VR tools and software, engineers can visualize, simulate, and analyze complex systems in a virtual environment, leading to improved efficiency, cost-effectiveness, and innovation in mechanical engineering projects. One of the key areas where virtual reality is making a significant impact in mechanical engineering is in the design phase. Engineers can create detailed 3D models of mechanical components and systems using VR software, allowing them to explore different design options, test functionalities, and identify potential issues before moving to the physical prototyping stage. This virtual prototyping not only accelerates the design process but also reduces the need for costly physical prototypes, saving both time and resources. Also Read-: Key Skills Every Mechanical Engineer Should Possess An Introduction to Bearings: Types, Functions, and Applications The Role of Mechanical Engineers in the Defense Industry Moreover, virtual reality enables engineers to conduct immersive simulations of mechanical systems, such as machinery, vehicles, or industrial equipment. By interacting with these virtual models in a realistic environment, engineers can evaluate performance, conduct stress tests, and optimize designs for efficiency and safety. This level of simulation accuracy and interactivity helps in refining designs and ensuring that mechanical systems meet the desired specifications and standards. Another significant application of virtual reality in mechanical engineering is in training and education. VR technology allows engineers to engage in hands-on training sessions and simulations without the need for physical equipment or machinery. This immersive learning experience helps in enhancing skills, improving problem-solving abilities, and preparing engineers for real-world challenges in a safe and controlled virtual environment. Additionally, VR-based training programs can be customized to specific mechanical engineering tasks, providing a tailored learning experience for professionals in the field. Also Read-: Emerging Trends in Mechanical Engineering Lessons Learned from Famous Mechanical Engineering Failures Utilizing FreeCAD for Rapid Prototyping Furthermore, virtual reality plays a crucial role in collaborative design and communication among mechanical engineering teams. With VR tools, engineers from different locations can work together in a shared virtual space, enabling real-time collaboration on design projects, brainstorming sessions, and problem-solving activities. This virtual collaboration fosters creativity, enhances communication, and streamlines decision-making processes, leading to more efficient and effective teamwork in mechanical engineering projects. In addition to design, simulation, training, and collaboration, virtual reality is also being utilized in the maintenance and repair of mechanical systems. Engineers can use VR technology to visualize and troubleshoot complex machinery, identify faulty components, and plan maintenance procedures in a virtual environment. This proactive approach to maintenance helps in minimizing downtime, reducing operational costs, and ensuring the optimal performance of mechanical systems over their lifecycle. Overall, the application of virtual reality in mechanical engineering is transforming the way engineers design, analyze, and optimize mechanical systems. By harnessing the power of VR technology, mechanical engineers can enhance creativity, improve efficiency, and drive innovation in their projects. As virtual reality continues to evolve and become more accessible, its integration into mechanical engineering processes will undoubtedly lead to further advancements and breakthroughs in the field. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

The Future of Transportation: Mechanical Engineering Innovations

The future of transportation is being shaped by groundbreaking mechanical engineering innovations that are revolutionizing the way we move from one place to another. These advancements are not only enhancing the efficiency and sustainability of transportation systems but also improving the overall experience for passengers and drivers alike. One of the key areas where mechanical engineering innovations are making a significant impact is in the development of electric vehicles (EVs). The shift towards electric propulsion is driven by the need to reduce greenhouse gas emissions and combat climate change. Electric vehicles are powered by high-capacity batteries and electric motors, offering a cleaner and more sustainable alternative to traditional internal combustion engine vehicles. The integration of advanced materials, lightweight designs, and aerodynamic features in EVs is optimizing their performance and range, making them a viable option for the future of transportation. Also Read-: The Influence of Artificial Intelligence on Mechanical Engineering The Impact of Mechanical Engineering on Everyday Life Plain Bearings vs. Rolling Element Bearings: Pros and Cons Another exciting development in the realm of transportation is the emergence of autonomous vehicles. These self-driving cars are equipped with sophisticated sensors, cameras, and artificial intelligence algorithms that enable them to navigate roads, interpret traffic signals, and make real-time decisions without human intervention. Autonomous vehicles have the potential to enhance road safety, reduce traffic congestion, and provide greater mobility options for individuals with disabilities or limited access to transportation. The integration of mechanical engineering principles in the design and development of autonomous vehicles is crucial to ensuring their reliability, efficiency, and safety on the road. In addition to electric and autonomous vehicles, the future of transportation is also being shaped by advancements in high-speed rail systems. High-speed trains are designed to travel at significantly faster speeds than traditional rail systems, offering a rapid and efficient mode of transportation for long-distance travel. The integration of innovative propulsion systems, aerodynamic designs, and advanced materials in high-speed trains is enhancing their performance, comfort, and energy efficiency. These mechanical engineering innovations are transforming the way people commute between cities and regions, providing a sustainable and environmentally friendly alternative to air travel. Also Read-: The Significance of Failure Analysis in Mechanical Engineering Bearing Maintenance: Tips for Prolonging Bearing Life and Performance Career Paths for Mechanical Engineers: Beyond Traditional Roles Furthermore, the development of hyperloop technology represents a cutting-edge innovation in transportation engineering. Hyperloop systems consist of sealed tubes through which pods can travel at high speeds using magnetic levitation and low-pressure environments. This revolutionary mode of transportation has the potential to significantly reduce travel times between major cities, offering a fast, energy-efficient, and cost-effective alternative to traditional modes of transportation. The integration of mechanical engineering principles in the design and construction of hyperloop systems is essential to ensuring their safety, reliability, and performance. Overall, the future of transportation is being shaped by a diverse range of mechanical engineering innovations that are driving progress towards more sustainable, efficient, and accessible transportation systems. From electric vehicles and autonomous cars to high-speed trains and hyperloop technology, these advancements are revolutionizing the way we travel and commute in the modern world. By integrating cutting-edge technologies, materials, and design principles, mechanical engineers are playing a crucial role in shaping the future of transportation and creating a more connected and sustainable world for generations to come. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

The Role of Failure Analysis in Improving Product Reliability

Failure analysis for mechanical engineering involves the systematic investigation of failures in mechanical systems, components, or structures to determine the root cause and prevent future occurrences. This process is crucial in ensuring the reliability, safety, and efficiency of mechanical systems, especially in the context of disaster response and recovery. One key aspect of failure analysis is identifying the specific factors that led to the failure of a mechanical system. This may involve examining design flaws, material defects, manufacturing errors, improper maintenance, or external factors such as extreme weather conditions or overloading. By understanding the underlying causes of failure, mechanical engineers can implement corrective measures to enhance the resilience of systems in the face of disasters. Also Read-: Innovations in Fluid Dynamics: Applications and Impacts Exploring the World of Smart Materials in Mechanical Design The Influence of Artificial Intelligence on Mechanical Engineering Moreover, failure analysis aids in understanding the environmental and operational conditions that lead to failures. Whether it's excessive heat, moisture, mechanical stress, or electrical overloads, analyzing failures provides valuable data on how products behave under different circumstances. This knowledge is instrumental in refining designs to withstand harsh conditions and ensure optimal performance throughout the product's lifecycle. Another significant aspect of failure analysis is its role in continuous improvement. By systematically analyzing failures and implementing corrective measures, companies can iterate on their designs and manufacturing processes to enhance product reliability. This iterative approach fosters a culture of learning and innovation, driving the development of more robust and dependable products in the long run. Furthermore, failure analysis is instrumental in meeting regulatory requirements and industry standards. In sectors like electronics and PCB design, adherence to stringent regulations is paramount to ensure product safety and reliability. Failure analysis helps in identifying non-compliance issues early on, allowing companies to rectify them and maintain compliance with relevant standards. Also Read-: Deep Dive into Rolling Element Bearings: Ball, Roller, and Needle Bearings Innovations in Fluid Dynamics: Applications and Impacts Exploring the World of Smart Materials in Mechanical Design In addition to improving product reliability, failure analysis also has cost-saving implications. By addressing failure issues proactively, companies can reduce warranty claims, recalls, and customer complaints, which can be costly both in terms of finances and reputation. Investing in failure analysis upfront can lead to significant cost savings down the line by preventing expensive product failures and associated liabilities. Overall, the role of failure analysis in improving product reliability cannot be overstated. It serves as a cornerstone for quality assurance, risk mitigation, and continuous improvement in product development processes. By leveraging the insights gained from failure analysis, companies can enhance the performance, durability, and overall reliability of their products, ultimately driving customer satisfaction and loyalty. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Building a Career in Academia as a Mechanical Engineer

Transitioning from a purely technical role in mechanical engineering to a career in academia can be a rewarding and fulfilling journey for professionals in the field. While the path may present its challenges, the opportunities for growth, knowledge sharing, and making a lasting impact on future generations of engineers are significant motivators for many individuals. Here, we explore the steps and considerations involved in building a successful career in academia as a mechanical engineer. 1. Pursuing Advanced Education: One of the fundamental requirements for establishing a career in academia is obtaining advanced education in mechanical engineering or a related field. This typically involves pursuing a master's degree or a Ph.D. to deepen your expertise in a specific area of mechanical engineering. Advanced degrees not only enhance your technical knowledge but also demonstrate your commitment to continuous learning and research, essential qualities for an academic career. Also Read-: Exploring the World of Smart Materials in Mechanical Design The Influence of Artificial Intelligence on Mechanical Engineering The Impact of Mechanical Engineering on Everyday Life 2. Research and Publications: Engaging in research activities and publishing your findings in reputable journals are essential components of an academic career. As a mechanical engineer, conducting research allows you to contribute to the advancement of the field, explore innovative solutions to complex problems, and establish yourself as an expert in a particular area of specialization. Publishing your work not only disseminates knowledge but also enhances your credibility and visibility within the academic community. 3. Teaching Experience: Developing strong teaching skills is another critical aspect of building a successful career in academia. As a mechanical engineer, you may have the opportunity to teach undergraduate or graduate courses, mentor students, and supervise research projects. Effective teaching requires the ability to communicate complex technical concepts clearly, engage students in active learning, and provide valuable guidance and feedback. Cultivating a passion for teaching and fostering a supportive learning environment are key to becoming a respected educator in academia. Also Read-: Career Paths for Mechanical Engineers: Beyond Traditional Roles Exploring Different Specializations in Mechanical Engineering How Mechanical Engineers Contribute to Renewable Energy 4. Collaborations and Networking: Building a network of professional connections within the academic and engineering communities is essential for career advancement. Collaborating with colleagues on research projects, attending conferences and workshops, and participating in professional organizations can help you stay informed about the latest developments in the field, establish collaborations, and create opportunities for research funding and career growth. Networking also allows you to exchange ideas, seek mentorship, and build relationships that can support your academic endeavors. 5. Grant Writing and Funding: Securing research funding through grants and fellowships is a crucial aspect of an academic career in mechanical engineering. Developing strong grant writing skills, identifying funding opportunities, and crafting compelling research proposals are essential for sustaining your research activities and pursuing innovative projects. Successful grant acquisition not only supports your research endeavors but also enhances your reputation as a productive and influential researcher in the academic community. 6. Professional Development and Continued Learning: Continuing education and professional development are vital for staying current with advancements in mechanical engineering and enhancing your skills as an academic professional. Engaging in workshops, seminars, and conferences, pursuing certifications, and participating in training programs can broaden your knowledge base, expand your skill set, and keep you competitive in the academic job market. Embracing lifelong learning and seeking opportunities for growth are key to building a successful and fulfilling career in academia as a mechanical engineer. In conclusion, pursuing a career in academia as a mechanical engineer offers a unique opportunity to combine your passion for engineering with a commitment to education, research, and knowledge dissemination. By pursuing advanced education, engaging in research and publications, developing teaching skills, building professional connections, securing research funding, and prioritizing professional development, you can establish yourself as a respected academic professional and make a meaningful impact on the field of mechanical engineering. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Exploring the Challenges of Renewable Energy Integration

Renewable energy integration presents a complex set of challenges that must be addressed to fully leverage the benefits of sustainable energy sources. One of the key challenges is the intermittency of renewable energy generation, which can lead to fluctuations in power supply and demand. This intermittency is particularly evident in solar and wind energy, where generation levels are dependent on weather conditions. Another significant challenge is the need for efficient energy storage solutions. While renewable energy sources are abundant, the ability to store excess energy for use during periods of low generation is crucial for ensuring a reliable power supply. Developing cost-effective and scalable energy storage technologies is essential to overcoming this challenge and maximizing the potential of renewable energy integration. Also Read-: Exploring Different Specializations in Mechanical Engineering How Mechanical Engineers Contribute to Renewable Energy Innovations in HVAC Systems: Advancements and Efficiency Grid integration is also a major hurdle in the transition to renewable energy. The existing power grid infrastructure was primarily designed to accommodate centralized fossil fuel-based power plants, making it necessary to adapt the grid to support decentralized renewable energy sources. This involves upgrading transmission and distribution systems, implementing smart grid technologies, and enhancing grid flexibility to accommodate variable renewable energy inputs. Furthermore, policy and regulatory frameworks play a critical role in facilitating renewable energy integration. Incentives, subsidies, and regulations can influence the deployment of renewable energy technologies and drive investment in clean energy infrastructure. Clear and consistent policies that support renewable energy development are essential for creating a conducive environment for sustainable energy growth. Also Read-: Human Factors in Mechanical Design: Ergonomics and User Experience The Challenges of Working in Extreme Environments as a Mechanical Engineer The Role of Failure Mode and Effects Analysis (FMEA) in Design Interconnection challenges also arise when integrating renewable energy into the grid. Coordinating the connection of multiple renewable energy sources to the grid while maintaining grid stability and reliability requires advanced grid management techniques and coordination among different stakeholders. Ensuring seamless integration of diverse renewable energy systems without compromising grid performance is a key focus area for grid operators and energy planners. Moreover, the economic viability of renewable energy projects is a significant consideration in the integration process. While the costs of renewable energy technologies have been declining, upfront investment costs and uncertainties around long-term returns can pose barriers to widespread adoption. Implementing financial mechanisms such as feed-in tariffs, power purchase agreements, and green bonds can help mitigate financial risks and attract investment in renewable energy projects. In addition to technical and economic challenges, public acceptance and awareness are crucial for successful renewable energy integration. Engaging with local communities, addressing concerns about visual impact, noise, and land use, and promoting the benefits of clean energy are essential for gaining public support and overcoming resistance to renewable energy projects. Overall, addressing the challenges of renewable energy integration requires a holistic approach that encompasses technological innovation, policy support, grid modernization, financial incentives, and stakeholder engagement. By overcoming these challenges, we can accelerate the transition to a sustainable energy future and unlock the full potential of renewable energy sources for a cleaner and greener world. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Innovative Solutions in Mechanical Engineering

Mechanical engineering is a field that constantly evolves, driven by the need for more efficient, sustainable, and cost-effective solutions. In today's fast-paced world, innovation is key to staying ahead of the curve and meeting the demands of modern industries. Let's explore some of the cutting-edge solutions that are shaping the future of mechanical engineering. One of the most exciting developments in mechanical engineering is the integration of artificial intelligence (AI) and machine learning algorithms into design processes. These technologies have revolutionized the way engineers approach problem-solving by enabling them to analyze vast amounts of data, identify patterns, and optimize designs in ways that were previously unimaginable. By harnessing the power of AI, engineers can create more efficient and reliable systems, leading to significant advancements in various industries. Also Read-: The Role of Failure Mode and Effects Analysis (FMEA) in Design The Influence of Environmental Regulations on Mechanical Engineering Integrating Machine Learning into Mechanical Engineering Processes Another area of innovation in mechanical engineering is the use of additive manufacturing, commonly known as 3D printing. This technology has transformed the traditional manufacturing process by allowing engineers to create complex geometries and intricate designs with unprecedented precision. Additive manufacturing not only reduces production costs but also enables rapid prototyping and customization, making it a game-changer for industries ranging from aerospace to healthcare. Furthermore, sustainability has become a central focus in modern mechanical engineering practices. Engineers are increasingly incorporating eco-friendly materials, energy-efficient systems, and renewable energy sources into their designs to minimize environmental impact. By prioritizing sustainability, mechanical engineers are not only meeting regulatory requirements but also contributing to a greener and more sustainable future for generations to come. Also Read-: Human Factors in Mechanical Design: Ergonomics and User Experience The Challenges of Working in Extreme Environments as a Mechanical Engineer The Role of Failure Mode and Effects Analysis (FMEA) in Design Innovative solutions in mechanical engineering also extend to the realm of robotics and automation. The integration of advanced robotics systems into manufacturing processes has led to increased efficiency, productivity, and safety in industrial settings. Collaborative robots, known as cobots, are designed to work alongside human operators, enhancing workflow and streamlining production processes. Automation technologies, such as robotic arms and automated guided vehicles, have revolutionized industries like automotive manufacturing, logistics, and warehousing. Moreover, the Internet of Things (IoT) has opened up new possibilities for mechanical engineers to create smart, interconnected systems that can communicate, analyze data, and make autonomous decisions. IoT-enabled devices, sensors, and actuators are being integrated into mechanical systems to enable real-time monitoring, predictive maintenance, and remote operation. This connectivity not only enhances system performance but also provides valuable insights for continuous improvement and optimization. In conclusion, innovative solutions in mechanical engineering are driving the industry forward by pushing the boundaries of what is possible. From AI-powered design processes to sustainable practices, additive manufacturing, robotics, and IoT integration, engineers are embracing cutting-edge technologies to create smarter, more efficient, and sustainable solutions for the challenges of tomorrow. By staying at the forefront of innovation, mechanical engineers are shaping a future where technology meets sustainability to create a better world for all. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

The Impact of Industry 5.0 on Mechanical Engineering

Industry 5.0 represents a significant shift in the manufacturing landscape, bringing with it a wave of technological advancements that are reshaping the way mechanical engineering operates. This new era is characterized by the integration of digital technologies, automation, and data exchange in manufacturing processes, leading to a more interconnected and efficient industry. The impact of Industry 5.0 on mechanical engineering is profound, influencing various aspects of design, production, and maintenance in the field. One key area where Industry 5.0 is making a substantial impact on mechanical engineering is in the realm of design innovation. With the advent of advanced software tools and simulation technologies, engineers now have access to powerful resources that enable them to create more complex and optimized designs. The use of computer-aided design (CAD) software, for instance, allows engineers to visualize and test their designs in a virtual environment before physical prototyping, leading to faster iteration cycles and improved product quality. This emphasis on design innovation is crucial in a competitive market where speed to market and product differentiation are key factors for success. Also Read-: Basic Guide to Autodesk Inventor and How Does It Work? Top 10 Courses to Join After Mechanical Engineering Open-Source CAD Software for Linux Operating System Moreover, Industry 5.0 is revolutionizing the production processes in mechanical engineering through the adoption of smart manufacturing technologies. The integration of Internet of Things (IoT) devices, robotics, and artificial intelligence (AI) in manufacturing facilities is enabling a higher degree of automation and efficiency. Smart factories equipped with interconnected sensors and actuators can collect real-time data on production processes, enabling predictive maintenance, reducing downtime, and optimizing resource utilization. This shift towards smart manufacturing not only enhances productivity but also improves the overall quality and consistency of manufactured products. In addition to design and production, Industry 5.0 is also transforming the way maintenance and servicing are approached in mechanical engineering. The implementation of predictive maintenance strategies, enabled by the Internet of Things and machine learning algorithms, allows engineers to anticipate equipment failures before they occur. By analyzing data from sensors embedded in machinery, maintenance schedules can be optimized, reducing unplanned downtime and extending the lifespan of critical assets. This proactive approach to maintenance not only saves costs but also enhances operational reliability and safety in industrial settings. Also Read-: Best Mechanical Design Software 2024 Best 2D CAD Drafting software of 2024 FreeCAD Integration with KiCAD Furthermore, Industry 5.0 is driving collaboration and connectivity across the mechanical engineering ecosystem. The concept of the digital twin, a virtual representation of a physical product or system, is gaining traction in the industry, enabling engineers to simulate and monitor the performance of assets in real-time. This digital twin technology facilitates cross-functional collaboration between design, production, and maintenance teams, fostering a more integrated and agile approach to engineering projects. By leveraging digital twins, engineers can streamline communication, identify potential issues early on, and make data-driven decisions throughout the product lifecycle. In conclusion, the impact of Industry 5.0 on mechanical engineering is multifaceted, encompassing design innovation, smart manufacturing, predictive maintenance, and collaborative practices. As the industry continues to embrace digital transformation, mechanical engineers are presented with new opportunities to enhance efficiency, quality, and sustainability in their work. By leveraging the latest technologies and embracing a holistic approach to engineering processes, professionals in the field can navigate the challenges and seize the benefits of Industry 5.0 to drive innovation and competitiveness in the evolving manufacturing landscape. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Role of CAD Software for Mechanical Engineering Drawing

CAD (Computer-Aided Design) software plays a crucial role in the field of mechanical engineering, particularly in creation of Machine Model and manufacturing drawings. CAD is backbone of Machine design it helps mechanical engineers to conceptualize, create, and refine their designs, leading to more efficient and precise outcomes in form of manufacturing drawing. In this article we will learn importance of CAD software for mechanical engineering. One of the primary advantages of CAD software is its ability to streamline the design process from concept generation to manufactured part. with the help of specialized CAD tools, mechanical engineers can create detailed and intricate drawings with a high level of accuracy. These drawings serve as the blueprint for various mechanical components, systems, and structures, providing a visual representation of the engineer's ideas and concepts. CAD software allows for the creation of 2D and 3D models, enabling engineers to visualize their designs from different perspectives and make necessary adjustments before moving to the production phase. Also Read-: Lessons Learned from Famous Mechanical Engineering Failures Utilizing FreeCAD for Rapid Prototyping Exploring Geometric Dimensioning and Tolerancing (GD&T) Moreover, CAD software facilitates collaboration among engineers and other professionals involved in disaster response and recovery. Through the use of cloud-based platforms and real-time sharing features, team members can work on the same design simultaneously, regardless of their physical location. This level of collaboration enhances communication, accelerates decision-making processes, and ensures that all stakeholders are on the same page when it comes to design specifications and requirements. Another key benefit of CAD software is its ability to generate accurate and detailed documentation. Mechanical engineers can create comprehensive drawings that include precise measurements, material specifications, and assembly instructions. This documentation is essential during the manufacturing and construction phases, as it provides clear guidelines for fabricators, contractors, and technicians. In the context of disaster response and recovery, having detailed documentation is crucial for ensuring that the designed systems and structures meet safety standards and regulatory requirements. Also Read-: Basic Guide to Choosing ISO or ASME Standard for 2D Drawing Meaning of PN and DN in Valves Basic Guide to UC Bearing Number Designation CAD software also enables mechanical engineers to simulate and analyze the performance of their designs under various conditions. Through virtual testing, engineers can identify potential weaknesses, optimize performance, and ensure the reliability of their systems. This capability is particularly valuable in disaster-prone areas, where structures and systems need to withstand extreme environmental conditions and external forces. By conducting simulations and analyses using CAD software, engineers can enhance the resilience and durability of their designs, ultimately contributing to more effective disaster mitigation and response strategies. In addition to design and analysis, CAD software plays a vital role in documentation and record-keeping. Engineers can maintain a digital archive of their designs, revisions, and project history, ensuring that valuable information is preserved for future reference. This documentation is invaluable in the aftermath of a disaster, as it provides insights into the original design intent, construction details, and maintenance requirements of critical infrastructure. Having access to this information can expedite the recovery process and facilitate the rebuilding of essential systems and facilities. Overall, CAD software is an indispensable tool for mechanical engineers involved in disaster response and recovery efforts. From initial design conceptualization to final documentation, CAD software enhances the efficiency, accuracy, and collaboration capabilities of engineers, enabling them to deliver innovative and resilient solutions in the face of adversity. By leveraging the power of CAD technology, mechanical engineers can play a pivotal role in mitigating the impact of disasters, rebuilding infrastructure, and creating a safer and more sustainable future for communities worldwide. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

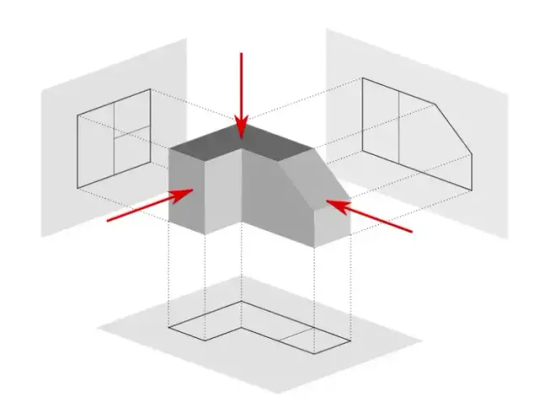

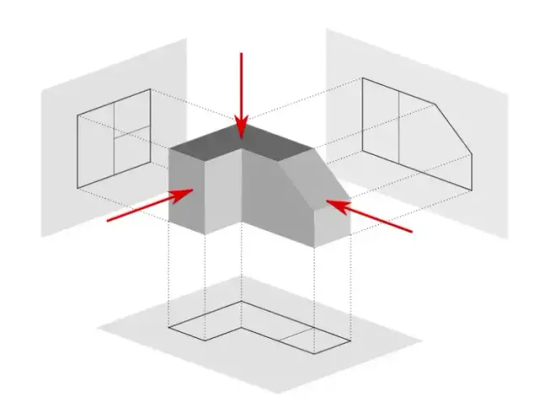

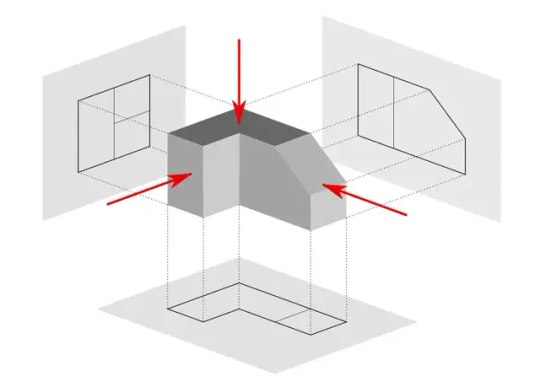

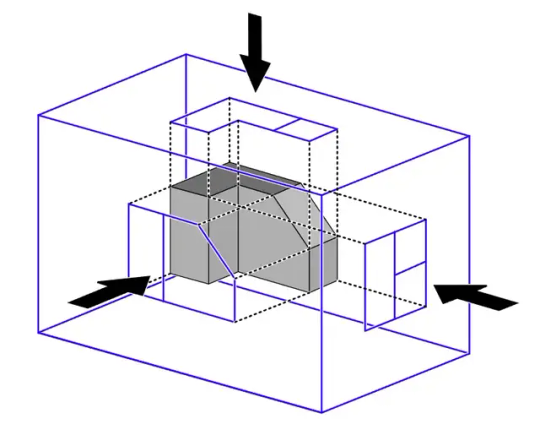

Exploring Multiview Projection in Mechanical Drawings

If you are a mechanical design engineer and had worked with many companies then you may have worked with 1st angle and 3rd angle of projection some companies use 1st and angle and some companies use 3rd angle of projection method to create 2D technical drawing. If fact all modern 3D modeling software like SolidWorks and Autodesk Inventor provide option to choose your projection method either 1st angle or 3rd angle. 2D drawings are very important to part get manufactured Although 3D CAD models are dominating the CAD design with 3D printing but 2D drawings still haven’t lost their importance. It does not matter which software you have used to modeled your part for a manufacturer and fabricator only matter is 2D drawing. In mechanical industry around the globe uses either 1st angle projection method or 3rd angle projection method. In this article we will discuss ISO or ASME Standard for 2D Drawing. Also Read-: The Influence of Artificial Intelligence on Mechanical Engineering The Impact of Mechanical Engineering on Everyday Life Career Paths for Mechanical Engineers: Beyond Traditional Roles If we look at global scenario of adoption of 1st and 3rd angle of projection European countries use ISO standards while Americans, UK, and Australians prefer the ASME standards over ISO but after all it is manufacturer choice weather they prefer 1st angle or 3rd angle of projection. Let’s understand ISO Standards: First Angle Projection Method

ISO recommends First angle projection method while detailing object with first angle of projection, it gives you a feeling that you are making your drawings in an opaque box. In first angle of projection method for drawing the projection plane lies behind the object. In this method engineer look at the object and makes him sketch its front view at the back of the object. Downside of first angle of projection is it involves heavy imagination and adjustment in drawings. Let’s understand ASME Standards: Third Angle Projection Method

As a Mechanical engineer here in India 3rd Angle project method is very popular and used by many manufacturer and fabricator because it requires less imagination as compared to first angle of projection it simple as What You See Is What You Get. In Third angle of projection plane is assumed to be transparent and in between the object and the observer, third angle of projection gives a sense of putting the object flat on the drawing sheet. In Third angle of projection as the drawings are exactly as the object appears, makes it easy to engineer to combine all the views of the object in drawing and imagine the entire object with less effort that is the beauty of third angle of projection. Also Read-: The Role of Mechanical Engineers in the Defense Industry The Impact of Industry 4.0 on Mechanical Engineering Tips for Successful Project Management in Mechanical Engineering Both the projection methods have wide acceptance around the world. If you are an engineer and working in design services, then you have to use projection method as per client location. While creating the technical drawing it is recommended that avoid hidden line as much as you can because hidden lines come uninvited interpretation, misconception and may provide misleading information. It is advised that take auxiliary view. If you are using modern CAD software, then you can set your projection method before placing your base view. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes

Text

Introduction to Geometric Dimensioning and Tolerancing (GD&T)

Geometric Dimensioning and Tolerancing (GD&T) is a fundamental aspect of mechanical engineering that plays a crucial role in ensuring the accuracy and quality of designs and manufacturing processes. GD&T not only helps mechanical engineer to achieve accuracy but also help to reduce the manufacturing cost. In simple terms GD&T is standardized system of symbols and terminology is used to define and communicate the geometric requirements of mechanical parts and assemblies. with the use of GD&T into daily practice a Mechanical design engineer can effectively convey design intent, specify allowable variations, and ultimately improve the functionality and performance of products. Top 4 Major Advantages of using Geometric Dimensioning and Tolerancing-: - Main benefit of using GD&T is it helps to save money because it allows design engineer to give suitable tolerance which helps to increase production and it also helps to optimize the cost. - GD&T process assure that all dimension and tolerance mentioned on drawing will be achieved. - GD&T standard are adopted by all digital 2D and 3D design so if you use ant CAD tool you will get GD&T symbol. - GD&T is standard language among the engineer so there is no any mistake of assumption and interpretation. One of the key benefits of GD&T is its ability to provide a clear and unambiguous way to communicate design requirements. Traditional methods of dimensioning and tolerancing often rely on basic linear measurements, which can be open to interpretation and lead to inconsistencies in manufacturing. In contrast, GD&T utilizes a set of symbols, modifiers, and rules that define the allowable variations in form, profile, orientation, and location of features within a part. GD&T standardized approach helps to eliminate confusion and ensures that all stakeholders, including designers, manufacturers, and quality control personnel, have a common understanding of the design specifications. Also Read-: Plain Bearings vs. Rolling Element Bearings: Pros and Cons Significance of Failure Analysis in Mechanical Engineering Bearing Maintenance: Tips for Prolonging Bearing Life and Performance Moreover, GD&T enables mechanical engineers to establish more precise tolerances based on the functional requirements of a part. When mechanical design engineer applies geometric controls such as flatness, parallelism, perpendicularity, and circularity, engineers can specify the allowable deviations in a way that directly relates to how the part will function within the larger assembly. This results in improved part interchangeability, reduced scrap and rework, and enhanced overall product quality. Another advantage of GD&T is its ability to promote design optimization and innovation. By accurately defining the geometric requirements of a part, engineers are encouraged to explore creative solutions that meet those requirements while minimizing material usage, weight, and cost. The use of GD&T can lead to more efficient designs, improved manufacturability, and enhanced product performance, ultimately benefiting both the manufacturer and the end-user. Also Read-: Lessons Learned from Famous Mechanical Engineering Failures Utilizing FreeCAD for Rapid Prototyping Exploring Geometric Dimensioning and Tolerancing (GD&T) In addition to its role in design and manufacturing, GD&T also plays a vital role in ensuring the safety and reliability of mechanical systems, particularly in critical applications such as aerospace, automotive, and medical devices. By specifying precise geometric tolerances, engineers can minimize the risk of functional failures, ensure proper assembly and alignment, and enhance the overall performance and longevity of the system. Overall, Geometric Dimensioning and Tolerancing (GD&T) is an essential tool for mechanical engineers involved in the design, manufacturing, and quality control of mechanical components and systems. By embracing the principles of GD&T, engineers can improve communication, enhance design accuracy, promote innovation, and ultimately deliver products that meet the highest standards of quality and performance. “Thank you for reading! If you found this article insightful and valuable, consider sharing it with your friends and followers on social media. Your share can help others discover this content too. Let’s spread knowledge together. Your support is greatly appreciated!” Read the full article

0 notes