Baoji Yumingda Metal Materials Co., Ltd. is a manufacturer of titanium and titanium alloy materials. Fully committed to supplying titanium and titanium alloy materials for partners with high quality and competitive price . The company has a complete titanium and titanium alloy material production system.

Don't wanna be here? Send us removal request.

Text

Medical titanium bar Gr5eli φ20*3050mm finished product 1500kg

Standard: ASTM F136, ASTM F67

Process: Three times titanium ingot (VAR) - Non-destructive testing 1 (ingot testing) - Sawing - Forging once - Grinding once - Forging twice - Grinding twice - Sawing - Rolling φ60 rolling mill bar - Peeling - Non-destructive testing 2 (rolling mill bar testing) - Sawing and cutting - Rolling - Rough turning - Secondary annealing - Rough grinding processing - Stress relief straightening - Fine grinding - Non-destructive testing 3 (finished product testing) - Finished product sawing - Flat head chamfering - Rough polishing - Fine polishing - Finished product inspection

Whatsapp + 86 183 9274 3987

0 notes

Text

Medical titanium bar Gr5eli φ20*3050mm finished product 1500kg

Standard: ASTM F136, ASTM F67

Process: Three times titanium ingot (VAR) - Non-destructive testing 1 (ingot testing) - Sawing - Forging once - Grinding once - Forging twice - Grinding twice - Sawing - Rolling φ60 rolling mill bar - Peeling - Non-destructive testing 2 (rolling mill bar testing) - Sawing and cutting - Rolling - Rough turning - Secondary annealing - Rough grinding processing - Stress relief straightening - Fine grinding - Non-destructive testing 3 (finished product testing) - Finished product sawing - Flat head chamfering - Rough polishing - Fine polishing - Finished product inspection

Whatsapp + 86 183 9274 3987

0 notes

Text

Titanium target GR2 φ98*40mm 600 pieces. Total 720kg

Product application: Titanium target material is a kind of target material made of titanium element, which is often used in thin film deposition technology, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD). Purity is one of the main performance indicators of target materials because the purity of target materials has a great influence on the performance of thin films. However, in practical applications, the purity requirements for target materials are not the same.

Production process: Sponge titanium selection - three times vacuum arc remelting (VAR) - forging - rolling - rough turning - fine turning - laser marking - vacuum packaging.

Surface requirements: Turning and polishing, chamfering, clean and smooth surface, no peeling, pores, cracks and other defects.

Product features:

High density: The density of the target material has been increased to 95-99% through technical transformation of the melting equipment.

High precision: Precision CNC machining center, tolerance ±0.1mm, surface roughness 3.2Ra.

Whatsapp + 86 183 9274 3987

0 notes

Text

Titanium target GR2 φ98 *40mm 300pcs. A total of 360kg

Product Application: Titanium target is a type of target made from the element titanium, commonly used in thin film deposition techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD). Purity is one of the main performance indicators of the target, because the purity of the target has a great influence on the performance of the film. However, in practical applications, the purity requirements for the target are not the same.

Production process: Titanium sponge selection - three times melting (VAR)- forging - rolling - rough turning - fine turning - laser marking - vacuum packaging.

Surface requirements: light, chamfer, clean and smooth surface, no peeling, porosity, cracks and other defects.

Product features:

High density: the density of the target material is increased to 95-99% by technical modification of the smelting equipment.

High density: the density of the target material is increased to 95-99% by technical modification of the smelting equipment

High precision: precision CNC machine with center tolerance of 0.1mm surface roughness of 3.2Ra

Whatsapp + 86 183 9274 3987

0 notes

Text

Product name: Titanium target

Product Application: Titanium target is a type of target made from the element titanium, commonly used in thin film deposition techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD). Purity is one of the main performance indicators of the target, because the purity of the target has a great influence on the performance of the film. However, in practical applications, the purity requirements for the target are not the same.

Processing technology:

Titanium sponge selection - tertiary melting (VAR)- forging - rolling - rough turning - fine turning - laser marking - vacuum packaging.

Surface requirements:

Car light, chamfer. The surface is clean and smooth, without peeling, porosity, cracks and other defects.

Product material:

Gr2 Gr5 Select the material type according to different uses.

Product Specifications:

Φ100*40, Φ98*40, Φ95*45, Φ90*40, Φ85*35, Φ65*40 are more common.

Product features:

High density: the density of the target material is increased to 95-99% by technical modification of the smelting equipment.

High density: the density of the target material is increased to 95-99% by technical modification of the smelting equipment

High precision: precision CNC machine with center tolerance of 0.1mm surface roughness of 3.2Ra

enforce standards

National standard: GB/T 16598, GB/T2965.

Us standard: ASTM B381,ASTM F67,ASTMF136, ASTM B348.

Whatsapp + 86 183 9274 3987

0 notes

Text

GR2 large-sized titanium tube fittings and titanium flanges

Customized production, specifically for the chemical industry. https://www.ymdtitanium.com

Whatsapp + 86 183 9274 3987

0 notes

Text

Fourteen titanium flanges have been inspected and are awaiting packaging for shipment.

What is this product called in your country? Is it appropriate for us to call it "flange"?

It is custom-made for the customer. The customer calls it "flange". https://www.ymdtitanium.com

Whatsapp + 86 183 9274 3987

0 notes

Text

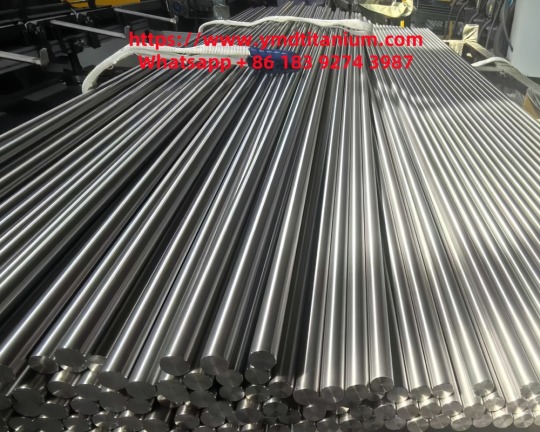

150 pieces of Gr5 titanium rods with a diameter of 20mm and a length of 1200mm, weighing a total of 255kg, are packed in one box.

22 pieces of Gr5 titanium rods with a diameter of 60mm and a length ranging from 1000 to 1200mm, weighing a total of 340kg, are packed in one box.

Whatsapp + 86 183 9274 3987

0 notes

Text

Medical titanium bar Gr5eli φ26*3050mm finished product 400kg

Standard: ASTM F136, ASTM F67

Process: Three times titanium ingot (VAR) - titanium ingot flaw detection - sawing - forging once - grinding once - forging twice - grinding twice - sawing - rolling φ60 rolling mill bar - peeling - rolling mill bar flaw detection - sawing and cutting - rolling - rough turning - secondary annealing - rough grinding processing - stress relief straightening - fine grinding - finished product flaw detection - finished product sawing - flat head chamfering - rough polishing - fine polishing - finished product inspection

Whatsapp + 86 183 9274 3987

0 notes

Text

Flat titanium flanges, raised face titanium flanges

Grades: GR1, GR2, GR5, GR7, GR9, GR12, TA1, TA2, etc.

Standards: HG/T20592-20626, GB/T9112-9113.4, SH3406, JB/T74-86.2, ANSI B16.5, ANSI B16.47, DIN, JIS, ISO, etc.

Nominal pressure: PN0.6, PN1.0, PN1.6, PN2.5, PN4.0, PN6.3, PN10.0, PN16.0, PN2.0, PN5.0, PN11.0, PN15.0 (Mpa), etc.

Whatsapp + 86 183 9274 3987

0 notes

Text

Does anyone know about this kind of titanium waste material?

Probably many people don't know about it.

Let me tell you...

This is the waste material left over from both sides of the billet after the hot rolling process of the titanium plate.

Whatsapp + 86 183 9274 3987

0 notes

Text

Finished medical titanium bar Gr5 φ20*3050mm, 1000kg, finished product flaw detection

Standard: ASTM F136, ASTM F67

Process: Three times titanium ingot (VAR) - Non-destructive testing 1 (titanium ingot flaw detection) - Sawing - Forging 1 time - Grinding 1 time - Forging 2 times - Grinding 2 times - Sawing - Rolling φ60 rolling mill bar - Peeling - Non-destructive testing 2 (rolling mill bar flaw detection) - Sawing and cutting - Rolling - Rough turning - Secondary annealing - Rough grinding processing - Stress relief straightening - Fine grinding - Non-destructive testing 3 (finished product flaw detection) - Finished product sawing - Flat head chamfering - Rough polishing - Fine polishing - Finished product inspection https://www.ymdtitanium.com

Whatsapp + 86 183 9274 3987

0 notes

Text

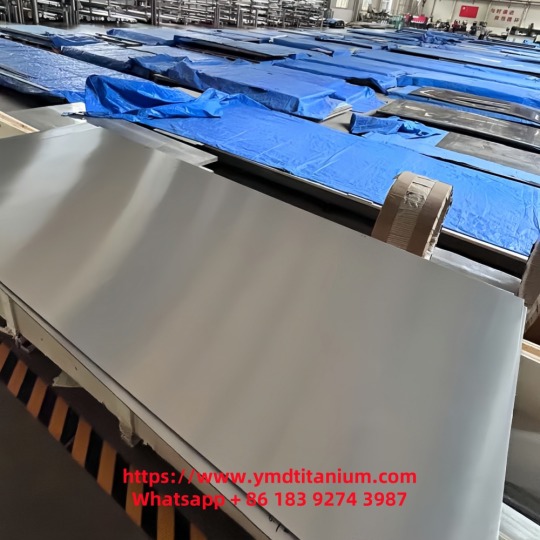

1 ton of GR2 pure titanium plate4*1000*2000mm is ready for hoisting and packaging is in progress.

Execution standards: GB/T3621-2010, ASTM B265, ASTM F67, ASTM F136, AMS4911, ASTM B381, etc.

Process: Sponge titanium - smelting - heating - forging - slab - grinding - hot rolling - annealing - grinding - cold rolling - annealing - pickling - leveling - shearing - packaging

Status: Annealed state

Whatsapp + 86 183 9274 3987

0 notes

Text

Gr2 pure titanium plate 8*1020*6000mm, 220kg/1pc packaging, loading completed

Water cutting + sanding (both sides)

Standards: GB/T3621-2010, ASTM B265, ASTM F67, ASTM F136, AMS4911, ASTM B381, etc.

Process: Sponge titanium - melting - heating - forging - billet - grinding - hot rolling - annealing - grinding - hot rolling - annealing - pickling - leveling - shearing - packaging

Status: Annealed state

Whatsapp + 86 183 9274 3987

0 notes

Text

Pure titanium thick-walled tube (Gr2)

Pure titanium thick-walled tubes, also known as thick-walled titanium tubes, refer to titanium tubes where the ratio of the outer diameter to the wall thickness is less than 20. They are mainly used as oil and gas geological drilling tubes, cracking tubes for petrochemicals, boiler tubes, etc.

Surface finish: Bright surface

Process: Tube billet → Heating → Piercing → Three-roll cross-rolling, continuous rolling or extrusion → De-tubing → sizing (or reducing) → Cooling → Straightening → Hydrostatic testing (or flaw detection) → Marking → Storage https://www.ymdtitanium.com

Whatsapp + 86 183 9274 3987

0 notes

Text

Name: Titanium Welded Tube, Titanium Alloy Welded Tube, Titanium Welded Pipe

Grade: GR5, GR2

Specification: Outer diameter of titanium tube (45.0 - 600mm), Wall thickness (0.1 - 5.0mm), Length (1000 - 8000mm)

Condition: Annealed (M)

Packaging: Customized according to customer needs or (woven bags; wooden crates; plastic film)

Inspection: X-ray radiographic inspection, hydraulic pressure test, flaring test, flattening test, etc.

Standard: ASTM B337-1995 ASTM B-338; ASTM B861-2002; ASTM B862-2002;

Whatsapp + 86 183 9274 3987

0 notes

Text

GR2 titanium sink 650*450*250mm and GR2 titanium shelf.

Who knows what the GR2 titanium sink is used for? It looks like a tool for holding mortar when laying bricks.

Whatsapp + 86 183 9274 3987

0 notes