#2xz Series

Text

SOUZ Vacuum Pump 2X Two-stage Oil Lubricated Rotary Vane vacuum pumps

2X Belt Drive Rotary Vane Pump is almost identical to a Direct Drive Rotary Vane Pump from SOUZ VACUUM. The only difference between the two is that the belt drive Rotary Vane Vacuum Pump is driven by a belt. There are several advantages why a belt drive vacuum pump would be preferable. One of these reasons is that the belt drive Rotary Vane Vacuum Pump runs at a slower RPM therefore the temperature created is lower, the wear and tear is less, and the overall lifetime of the pump is longer.

Belt drive vacuum pump 2X series are equipped with highly durable vacuum pump assembled for pumping air from sealed vessels. It provides ultimate vacuum pressure of ≤ 1Pa.The robust design and high end vacuum makes this belt driven vacuum pump powerful system. It can be used as a stand-alone machine or as a fore-pump, process pump or titanium pump of booster pump, oil diffusion pump and molecular pump.

A choice of versions provides the right variant for every application.

Single stage oil flooded rotary vane vacuum pump : SV008-SV630

Two stage oil lubricated rotary vane vacuum pump : 2XZ-2C~2XZ-25C. T8~T60 ; 2X-4A-2X-100A

Contact us , [email protected]

Find us , www.souzvac.com

0 notes

Text

Vacuum Pumps Types

If a container is placed in natural environment, if the gas pressure inside the container is not changed, the gas pressure inside and outside the container reaches equilibrium state, which is equal to atmospheric pressure numerically. In order to achieve a vacuum inside the container, the gas inside the container must be discharged, so that the pressure of the gas inside the container is less than the pressure of the external atmosphere. Using mechanical, physical, chemical or physical chemical methods, the equipment that obtains the vacuum from the gas discharged from the container is called the vacuum pump. Vacuum pumps can be classified into compression type (varistor type) and adsorption type according to their working principles. The working principle of the compressed vacuum pump is to compress the gas at the inlet end of the pump to the outlet end and discharge it out of the pump.

Common compression vacuum pumps are: rotating mechanical pumps using expansion-compression-discharge process, turbomolecular pumps using turbine blades to remove the body, etc. The working principle of the adsorption vacuum pump is to adsorb the gas in the pump body, which has achieved the goal of reducing the gas pressure. Common adsorptive vacuum pumps are: ion pumps using ionization suction, adsorption pumps using physical or chemical adsorption, suction pumps and cryogenic condensation pumps. The biggest difference between the adsorption vacuum pump and the compression vacuum pump is that the adsorption vacuum pump does not discharge the gas out of the pump, but stores it in the pump. The vacuum degree of the former is higher than that of the latter, but the pumping speed is smaller and the suitable container is smaller. Vacuum resistance furnace uses compressed vacuum pumps, such as mechanical pumps, Roots vacuum pumps and diffusion pumps.

Various types of vacuum pumps have their own working scope. Some pumps can work directly from the atmospheric state, such as mechanical pumps and adsorption pumps. Some pumps can not work directly from the atmospheric state, such as diffusion vacuum pumps, molecular pumps, ion pumps and so on. Only when the inlet vacuum reaches a certain value can they start to work.

oil-rotary/WX-series-oil-free-rotary-vane-vacuum-pump

2XZ-Series-Two-stage-High-Speed-Rotary-Vacuum-Pump

X-Series-Single-Stage-Rotary-Vacuum-Pump

0 notes

Text

Why does the vacuum of water ring vacuum pump decrease in summer

Water ring vacuum pump is a new generation product developed by our company. It has the characteristics of strong corrosion resistance, high limit vacuum degree and large exhaust capacity. So why does the vacuum drop in summer when the water ring vacuum pump is used?

1. Under working conditions in summer, water ring vacuum pump adopts circulating water to cool working water. High temperature of circulating water will lead to the decrease of suction capacity and efficiency of water ring vacuum pump. Through analysis, the working water of the water ring vacuum pump is cooled by the refrigerated water of the central air conditioner of the power plant

2. Other conditions being unchanged, the lower the working water temperature, the smaller the influence on the vacuum of the water ring vacuum pump, while the higher the working water temperature, the greater the influence on the vacuum

3. For the double back-pressure condenser, due to the low pressure of the condenser corresponding to the low-pressure condenser, it is easy to find that the limit suction pressure of the water ring vacuum pump is higher than the value of the condenser pressure, so special attention should be paid to the influence of the rising water temperature of the water ring vacuum pump on the low-pressure condenser

4. Under low load condition, lowering the working water temperature can improve the vacuum effect of condenser of water ring vacuum pump

New large capacity turbomolecular vacuum pump

New chemical dry pump

Air-cooled dry composite screw vacuum pump

2XZ series bipolar rotary vane pump

0 notes

Photo

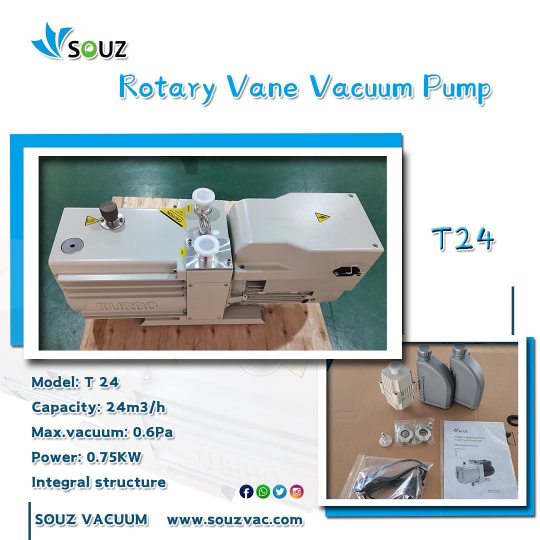

T series are named two stage oil sealed rotary vane vacuum pump that updated model on the 2XZ. Aviation aluminum material is much more environmentally. Simple structure. Convenient operation. #solarindustry #vacuumsystem #degassing #vacuumcoating https://www.instagram.com/p/Ce3GiWzJThX/?igshid=NGJjMDIxMWI=

0 notes

Photo

T model is an updated 2 stage rotary vane vacuum pump on the basic of 2XZ series. The main difference is that T model 's structure is intergral type that makes convenient maintenance. #vacuumpump #pump #vacuumservice #souzvacuumpump #freezedry #pumpservice #vacuumoven #rotaryvanepumps #industrialvacuum #pumpe #bombadevacio #pompeavide https://www.instagram.com/p/Cdpvy3aJ2Vq/?igshid=NGJjMDIxMWI=

#vacuumpump#pump#vacuumservice#souzvacuumpump#freezedry#pumpservice#vacuumoven#rotaryvanepumps#industrialvacuum#pumpe#bombadevacio#pompeavide

0 notes

Photo

Two-stage Oil-sealed Rotary vane #vacuumpump 2XZ series deliver excellent ultimate vacuum and low noise. ✌️Freeze #drying ✌️Vacuum #metallurgy processes ✌️Vacuum drying and #distillation #souzvacuumpump #bombs #vacio https://www.instagram.com/p/CbezUipLheJ/?utm_medium=tumblr

0 notes

Text

Rotary vane vacuum pump of Laboratory

Rotary vane vacuum pump is based on the original 2XZ series, which is adapted from foreign advanced technology and experience. When the inlet pressure is less than 1.33*1000Pa, the rotary vane vacuum pump can still operate continuously. It is used to extract the gas from the sealed container and make the container vacuum. It can also be used as the front pump of various high vacuum and ultra-high vacuum equipment.

Rotary vane vacuum pump is widely used in laboratories and laboratories of vacuum metallurgy, vacuum coating, solar polycrystalline silicon, monocrystalline silicon, distillation, food packaging, aviation science and technology, semiconductor, electronics, refrigeration, medical, chemical and other industries, colleges and institutes.

Rotary vane vacuum pump advantages:

1. Small size, light weight and low noise.

2. An air ballast valve is provided to remove a small amount of water vapor.

3. High vacuum limit.

4. Built-in forced oil pump, full lubrication, reliable performance.

5. It is equipped with automatic anti-return oil check valve and double safety device, which makes it easy to start.

6. When the intake pressure is less than 1.33*1000Pa, it can still operate continuously.

7. No oil leakage, no oil distribution, no pollution to the working environment.

8. It can be equipped with small caliber conversion interface and KF interface.

What-is-vacuum-heat-treatment-process

Bakeable-All-Metal-Valve-Angle-Valve

manual-ultra-high-vacuum-gate-valve

CC-series-ultra-high-vacuum-flapper-valve

0 notes

Text

Water ring vacuum pumps are sometimes used in coal industry

With the increasing emphasis on coal mine safety, higher requirements and standards will be put forward for water ring vacuum pumps used in coal mines. Efficient, fast and thorough is the main development direction of mine water ring vacuum pump. Next, we will learn about the application of water ring vacuum pump in coal industry, hoping to help you.

1. Coal refining

In the process of vacuum filtration of refined coal, it is generally required to withstand the impact of air flow and water. A water ring vacuum pump with a pre-separator is required to separate liquid under a steady pressure.

2. Dust removal

Coal mine dust is the main source of surface pollution due to its large amount and complex composition. With large water ring vacuum pump as the main pump, equipped with separation, dust removal, protection and other devices to achieve the recovery and utilization of dust in mining areas, also plays a role in purifying air.

3. Production of Antistatic Equipment

In the process of producing anti-static and flame-retardant conveyor belts and underground clothing, vacuum slurry immersion process is adopted to make anti-static and flame-retardant enter the conveyor belt, replacing the original spraying process, which is more safe and reliable.

4. Vacuum Pump Drying Cable

The insulation performance of mine cables can be easily reduced in damp mines for a long time. Using water ring vacuum pump as pumping equipment, the cables are heated by low voltage and high current, which can effectively prevent oxidation and prolong the aging process of cables under the condition of low oxygen concentration.

China-2X-Series-Rotary-Vacuum-Pump

2XZ-Series-Two-stage-Rotary-Vacuum-Pump

XD-series-single-stage-rotary-vane-vacuum-pump

0 notes

Text

Double stage rotary vane vacuum pump

rotary vane vacuum pump description

2XZ series rotary vane vacuum pump is one of the basic equipment in addition to pumping gas, can be used alone, also can be used with a booster pump, diffusion pump, molecular pump and other ultra-high vacuum pump connected together as a backing pump, widely used in electronic devices manufacturing, vacuum drying oven, filtration, impregnation, coating, welding, smelting and laboratory equipment. roots-vacuum-pump-manufacturing

Double stage rotary vane vacuum pump application:

1:Car industry

2:Food industry

3:Furnaces and plants

4:Laser technology

5:Medicinal technolog

6:Metallurgy

7:Power engineering, long-distance energy

8:Space simulation

9:Vacuum coating

Vacuum packaging, drying, distillation, concentration, loading and unloading, and attract, vacuum forming, etc. vacuum-pump-in-cvd-process

0 notes

Text

Classification of mechanical pumps commonly used in laboratory

The commonly used mechanical pump in laboratory is rotary vane vacuum pump, also known as rotary vane pump. It is composed of a stator and an eccentric rotor, mainly composed of stator, vane and rotor.

The rotor is eccentrically installed in the stator cylinder, and two blades are tightly embedded in the rotor slot. Under the spring force, it is close to the stator cylinder wall, and the air inlet and exhaust port on the stator are separated into two parts. When the rotor rotates, the space of the air inlet will be gradually expanded to absorb gas, while the space of the exhaust part will be gradually reduced, and the inhaled gas will be compressed and discharged from the exhaust port, so as to achieve the purpose of vacuumizing. The vacuum pump oil is used as sealing fluid and lubricant in the vacuum pump oil with very small saturated vapor pressure.

2xz-2 rotary vane vacuum pump is commonly used in laboratory, "2XZ" refers to double-stage direct coupled pump, "X" refers to rotary vane vacuum pump, and data after "2XZ" represents pumping rate (L / s). The two-stage pump is composed of two chambers in series. Obviously, the limit vacuum of the two-stage direct coupled pump is better than that of the single-stage pump, which can reach a vacuum degree of about 10-1pa.

Water Ring Vacuum Pump In Pulp And Paper Making Vacuum System

Roots Blower Working Process

How To Choose SSR Air Blowers

0 notes

Text

Classification of common mechanical pumps in laboratory

The commonly used mechanical pump in the laboratory is the rotary vane vacuum pump, also known as the rotary vane pump. It is composed of a stator and an eccentric rotor, mainly composed of stator, rotary vane and rotor.

The rotor is installed eccentrically in the rotor slot of the stator cylinder, which is tightly embedded with two pieces of rotary blades. Under the spring force, it is close to the cylinder wall of the stator, separating the air inlet and the air outlet of the stator into two parts. When the rotor rotates, the space of the air inlet is gradually expanded and the gas is inhaled, and the air space of the exhaust port is gradually reduced at the same time. The inhaled gas is compressed and discharged from the exhaust port, so as to achieve the purpose of vacuumizing. Vacuum pump oil is used as sealing fluid and lubricant for the whole machine and the vacuum pump oil which is not saturated with small vapor pressure.

2xz-2 rotary vane vacuum pump is commonly used in the laboratory, "2XZ" refers to two-stage direct coupled pump, "X" refers to rotary vane vacuum pump, "data behind 2XZ" refers to pumping rate (L / s). The two-stage pump is composed of two working rooms in series. Obviously, the limit vacuum of the two-stage direct coupled pump is better than that of the single-stage pump, which can reach a vacuum degree of about 10-1pa.

Rotary Vane Vacuum Pump In Oil And Gas Recovery System

What Vacuum Pump Is Used In Fertilizer Industry

Vacuum Pump Improves Coating Quality

0 notes