#Aircraft Brake Discs Market

Text

Nami Klima Max Electric Scooter: A Comprehensive Review of Performance and Features

The Nami Klima Max is a game-changer in the electric scooter market, offering a perfect blend of power, comfort, and customization. With dual 1000W brushless hub motors, this scooter delivers impressive torque for quick acceleration, while maintaining a top speed of 42 mph.

One of the Klima Max's standout features is its smooth riding experience. The combination of dual adjustable suspension, wide 10-inch tubeless tires, and a low center of gravity ensures stability both on-road and off-road. The 30Ah LG battery provides an impressive range of up to 60 miles, making it suitable for long commutes or extended joy rides.

Safety isn't overlooked, with Logan hydraulic disc brakes offering superior stopping power. The scooter also boasts full lighting, including a 2000-lumen headlight and LED turn signals, enhancing visibility and safety during night rides.

What sets the Klima Max apart is its attention to detail. The aircraft-grade aluminum frame, waterproof design (IP55 rated), and thoughtful engineering touches like easily accessible controllers demonstrate the quality of this scooter.

For riders seeking a high-performance electric scooter with excellent build quality and customizable features, the Nami Klima Max is a compelling choice that delivers on multiple fronts.

0 notes

Text

Gluten Free Food Market 2024: Emerging Trends, Major Driving Factors, Business Growth Opportunities

Gluten Free Food Market provides in-depth analysis of the market state of Gluten Free Food manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Gluten Free Food in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Gluten Free Food Market Report:

The report offers a comprehensive and broad perspective on the global Gluten Free Food Market.

The market statistics represented in different Gluten Free Food segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Gluten Free Food are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Gluten Free Food.

Major stakeholders, key companies Gluten Free Food, investment feasibility and new market entrants study is offered.

Development scope of Gluten Free Food in each market segment is covered in this report. The macro and micro-economic factors affecting the Gluten Free Food Market

Advancement is elaborated in this report. The upstream and downstream components of Gluten Free Food and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/gluten-free-food-market-100550

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Waste to Energy (WTE) MarketMarket

Recruitment MarketMarket Share

Marketing Automation Software MarketMarket Growth Rate

Devops Tool MarketMarket Forecast

Global 3PL MarketMarket Size

X-Ray Security Screening Systems MarketMarket Growth

Aircraft and Aerospace Aluminum Casting Components MarketMarket Analysis

Web to Print Software MarketMarket Size

Global Identity Management Solutions MarketMarket Share

Global Biometric-as-a-Service MarketMarket Growth

Collision Avoidance Sensors MarketMarket

Network Copyright MarketMarket Share

IoT Fleet Management MarketMarket Growth Rate

Social Media Analytics MarketMarket Forecast

Global Infant Incubator MarketMarket Size

Bone Conduction Headphones MarketMarket Growth

Wood Based Panel MarketMarket Analysis

Cloud Content Delivery Network (CDN) MarketMarket Size

Global Prostate Cancer Nuclear Medicine Diagnostics MarketMarket Share

Global Air Disc Brakes (ADB) MarketMarket Growth

Automated Optical Inspection Systems MarketMarket

Memristors MarketMarket Share

Virtualized Radio Access Network (vRAN) MarketMarket Growth Rate

Cryogen Free Dilution Refrigerators MarketMarket Forecast

Global Chafing Fuel MarketMarket Size

Cotton Picker MarketMarket Growth

Returnable Transport Packaging (RTP) MarketMarket Analysis

Shower Cap MarketMarket Size

Global Dimethyl Carbonate (DMC) MarketMarket Share

Global Aqua Feed MarketMarket Growth

Barcode Verifiers MarketMarket

Mask Blank MarketMarket Share

Cheese Powder MarketMarket Growth Rate

Three Dimensional Fabric MarketMarket Forecast

Global PFAS Remediation Services MarketMarket Size

Channel Gate Market Market Growth

Global Mycelium Leather MarketMarket Analysis

Plethysmometer MarketMarket Size

Global Conductive Die Attach Film MarketMarket Share

0 notes

Text

Aluminum Matrix Composites, Global Top 13 Players, Market Share and Ranking (2023)

Aluminum Matrix Composites Market Summary

Aluminum Matrix Composites is a heterogeneous mixture of aluminum metal and alloys as the matrix and metal or non-metal particles/fibers as the reinforcement phase. It is widely used in automotive parts (such as engines, brake discs, gearboxes, etc.), aerospace fields (such as helicopter landing gear, aircraft support frames, etc.), and military/defense (such as heat sinks, heat sinks and substrates, etc.).

According to the new market research report "Global Aluminum Matrix Composites Market Report 2024-2030", published by QYResearch, the global Aluminum Matrix Composites market size is projected to reach USD 2059 million by 2030, at a CAGR of 5.4% during the forecast period.

Figure. Global Aluminum Matrix Composites Market Size (US$ Million), 2019-2030

Figure. Global Aluminum Matrix Composites Top 13 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of @Aluminum Matrix Composites include DWA Aluminium Composites, Alvant, Triton Systems, Materion, CPS Technologies, Denka, Japan Fine Ceramics, 3M, Coherent, Grinm Metal, etc. In 2023, the global top five players had a share approximately 70.0% in terms of revenue.

Figure. Aluminum Matrix Composites, Global Market Size, Split by Product Segment

In terms of product type, currently Particle Reinforced is the largest segment, hold a share of 67.1%.

Figure. Aluminum Matrix Composites, Global Market Size, Split by Application Segment

In terms of product application, currently Aerospace is the largest segment, hold a share of 40.2%.

Figure. Aluminum Matrix Composites, Global Market Size, Split by Region

Market Drivers:

1. Downstream demand growth drives the development of the composite materials industry: Aluminum-based composite materials have the advantages of light weight, high specific strength, high specific modulus and good wear resistance. They overcome the shortcomings of a single material and give full play to the advantages of the matrix material and the reinforcing material. As the production process of aluminum-based composite materials is gradually improved and the cost is controlled, the industry is expected to show a booming trend and gradually expand in the application fields of new energy vehicles, aerospace, national defense, nuclear industry and electronics.

2. Technological upgrading will accelerate the development of the aluminum-based composite materials industry: Aluminum-based composite materials are gradually maturing in manufacturing equipment and production technology/processes, which will greatly improve the production and preparation process of aluminum-based composite materials.

3. Technological progress: With the continuous improvement of the manufacturing and processing technology of aluminum-based composite materials, its performance has been improved and the scope of application has been expanded.

4. Expansion of emerging application fields: In emerging fields such as 3D printing, electronics, optics, construction and shipbuilding, there is great potential, which will help the growth of the market size.

Trend:

1. Aluminum-based nanocomposites: By introducing nanoparticles into the metal body, the thermal stability and other properties of the material can be improved. At the same time, the nanocomposites also have excellent properties such as electrical conductivity and thermal conductivity.

2. Lightweight and high strength: Aluminum-based composites are widely used in the fields of automobiles, aerospace, etc. By using lightweight composite materials, the weight of the material structure can be reduced and fuel efficiency can be improved. At the same time, reasonable design of the manufacturing process will be able to achieve the requirements of high strength and high stiffness.

3. Multifunctional aluminum-based composites: In addition to the existing high strength, high modulus and other functions, by adding functional additives such as conductive materials and flame retardants, the thermal conductivity, flame retardancy, biocompatibility and flame retardancy of the composite materials can be achieved.

About The Authors

Jiashi Dong

Lead Author

Email: [email protected]

QYResearch Nanning Branch Analyst, as a member of the QYResearch Semiconductor Equipment and Materials Department, his main research areas include automotive electronics, semiconductor equipment, materials and thermally conductive powders. Some subdivided research topics include automotive diodes, automotive inductors, automotive lidar, radio frequency power supplies, plastic sealing machines, high-purity non-ferrous metals, battery materials, precursors, electroplating equipment, thermal conductive ball aluminum, semiconductor chemical plating solutions, semiconductor coating devices, etc. At the same time, he is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Friction Products Market Exploring Key Factors Influencing Growth and Competitive Landscape By 2024-2030 | GQ Research

The Friction Products market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Friction Products market showcased a significant presence, boasting a valuation of USD 58 Million. This underscores the substantial demand for Friction Products technology and its widespread adoption across various industries.

Get Sample of this Report at https://gqresearch.com/request-sample/global-friction-products-market/

Projected Growth: Projections suggest that the Friction Products market will continue its upward trajectory, with a projected value of USD 86.4 Million by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 5.20 %, reflecting a steady and robust growth rate for the Friction Products market over the coming years.

Technology Adoption:

In the Friction Products market, technology adoption is pivotal for enhancing performance, durability, and safety across various applications. Manufacturers continually invest in advanced friction materials, bonding techniques, and manufacturing processes to meet the diverse requirements of industries such as automotive, aerospace, construction, and industrial machinery. Adoption of innovations such as ceramic composites, carbon-carbon materials, and friction modifiers enables the development of friction products with superior wear resistance, thermal stability, and frictional characteristics, addressing the evolving needs of end-users for reliable and high-performance friction solutions.

Application Diversity:

Friction products find application across a wide range of industries and end-uses, including braking systems, clutch assemblies, transmission components, and industrial friction materials. From automotive brake pads and aircraft braking systems to industrial clutches and friction discs, the versatility of friction products enables their adaptation to diverse operating conditions and performance requirements. Additionally, friction materials play a critical role in specialized applications such as wind turbine brakes, elevator systems, and railroad braking systems, highlighting their significance in ensuring operational safety and efficiency across various sectors.

Consumer Preferences:

Consumer preferences in the Friction Products market are influenced by factors such as reliability, performance, cost-effectiveness, and environmental sustainability. End-users prioritize friction products that offer consistent braking performance, minimal noise and vibration, and extended service life, particularly in safety-critical applications such as automotive braking systems. Preferences also extend to environmentally friendly friction materials with reduced heavy metal content, low dust emissions, and recyclability, aligning with regulatory requirements and consumer demand for eco-friendly solutions.

Technological Advancements:

Technological advancements drive innovation in friction product materials, formulations, and manufacturing processes, leading to improvements in performance, efficiency, and sustainability. Developments in nanotechnology, surface engineering, and composite materials enable the design of friction products with enhanced tribological properties, reduced weight, and improved thermal stability. Moreover, advancements in additive manufacturing (3D printing) and precision machining techniques facilitate the production of custom-designed friction components tailored to specific application requirements, accelerating product development cycles and enabling rapid prototyping of novel friction solutions.

Market Competition:

The Friction Products market is characterized by intense competition among global and regional manufacturers vying for market share and differentiation. Established players leverage their technological expertise, R&D capabilities, and brand reputation to maintain leadership positions, while emerging entrants focus on niche markets or specialized applications to gain traction. Pricing strategies, product quality, and aftersales support are key factors influencing purchasing decisions in this competitive landscape, prompting companies to invest in innovation, strategic partnerships, and market expansion initiatives to sustain competitive advantage.

Environmental Considerations:

Environmental considerations are increasingly important in the Friction Products market, given concerns over pollution, resource depletion, and regulatory compliance. Manufacturers prioritize the development of eco-friendly friction materials with reduced environmental impact, such as asbestos-free brake pads and low-metallic friction formulations. Additionally, efforts to optimize manufacturing processes, minimize waste generation, and recycle end-of-life friction products contribute to environmental sustainability and circular economy principles. By adopting cleaner production technologies and adhering to stringent environmental regulations, industry stakeholders mitigate the environmental footprint of friction product manufacturing and usage, promoting sustainable practices throughout the value chain.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

Akebono Brake

Nisshinbo

Bosch

Continental

GMP Friction Products

Tenneco

Shandong Longji

BorgWarner

Brembo S.p.A.

Aisin Seiki Co.Ltd.

The research report provides a comprehensive analysis of the Friction Products market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-friction-products-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731 Website - https://gqresearch.com/

#FrictionProducts#AutomotiveIndustry#IndustrialMachinery#Sustainability#ElectricVehicles#MarketAnalysis

0 notes

Text

NASA Space Tech Spinoffs Benefit Earth Medicine

As NASA innovates for the benefit of all, what the agency develops for exploration has the potential to evolve into other technologies with broader use here on Earth. Many of those examples are highlighted in NASA's annual Spinoff book including dozens of NASA-enabled medical innovations, as well other advancements.

This year's publication, NASA's 2024 Spinoff, features several commercialized technologies using the agency's research and development expertise to impact everyday lives, including:

- Spherical "squishy" robots capable of dropping into dangerous situations before first responders enter

- "Digital winglets" aircraft-routing technology that's enabling increased fuel efficiency and smoother flights

- Lighter, more durable disc brake designs that produce less dust than traditional disc brakes

- Computer software to help businesses and communities cope with and recover from natural disasters like wildfires

- New 3D printing methods to additively manufacture rocket engines and other large aluminum parts

Squishy Robotics' Tensegrity Sensor Robots help first responders determine their approach to a disaster scene. Firefighters used the robots during a subway attack exercise at the 2021 Unmanned Tactical Application Conference to detect gas leaks and other hazards. Credits: FLYMOTION LLC

"As we continue to push new frontiers and do the unimaginable, NASA's scientists and engineers are constantly innovating and advancing technologies," said NASA Administrator Bill Nelson. "A critical part of our mission is to quickly get those advances into the hands of companies and entrepreneurs who can use them to grow their businesses, open new markets, boost the economy, and raise the quality of life for everyone."

The medical innovations include the first wireless arthroscope – a small tube carrying a camera inserted into the body during surgery – to receive clearance from the U.S. Food and Drug Administration, which benefited from NASA's experience with spacesuits and satellite batteries. Technologies for diagnosing illnesses like the coronavirus, hepatitis, and cancer have also stemmed from NASA's space exploration and science endeavors. Even certain types of toothpaste originated from the agency's efforts to grow crystals for electronics.

Additional 2024 Spinoff highlights include developments under NASA's Artemis campaign, like a small, rugged video camera used to improve aircraft safety and a new method for detecting defects or damage in composite materials. Meanwhile, another spinoff story details the latest benefits of fuel cell technology created more than 50 years ago for Apollo, which is now poised to support terrestrial power grids based on renewable energy.

The book also features several technologies NASA has identified as promising future spinoffs and information on how to license agency tech. Since the 1970s, thousands of NASA technologies have found their way into many scientific and technical disciplines, impacting nearly every American industry.

"As NASA's longest continuously running program, we continue to increase the number of technologies we license year-over-year while streamlining the development path from the government to the commercial sector," said Daniel Lockney, Technology Transfer program executive at NASA Headquarters in Washington. "These commercialization success stories continually prove the benefits of transitioning agency technologies into private hands, where the real impacts are made."

Spinoffs are part of NASA's Space Technology Mission Directorate and its Technology Transfer program. Tech Transfer is charged with finding broad, innovative applications for NASA-developed technology through partnerships and licensing agreements, ensuring agency investments benefit the nation and the world.

To read the latest issue of Spinoff, visit:

https://spinoff.nasa.gov

Read the full article

0 notes

Text

Revolutionizing Precision by CNC Components Manufacturers

CNC (Computer Numerical Control) is a machining technology. Products are created by removing material from a so-called workpiece using various cutting tools. At the same time, the production process is automated by software – the tool or workpiece moves according to the code, and the machine operator performs only auxiliary operations, such as changing tools or setting the workpiece. CNC machining by CNC components manufacturers makes it possible to produce high-precision parts from a CAD (computer-aided design system) file with excellent physical and mechanical properties. Due to the high level of automation, CNC machining is competitive for single pieces & short runs, as well as for serial and mass production.

CNC manufacturing process

The CNC manufacturing process of a product can be broken down into four main steps:

1. An engineer designs a CAD model.

2. A technologist based on CAD/CAM software prepares a control program for the CNC machine.

3. The operator inserts the tool, and workpiece into the CNC machine and starts the control program.

4. The CNC machine performs all the processing operations – material removal.

CNC Machine Applications Industries

Aerospace

The aerospace industry encompasses all modes of air transport, from massive Airbus A380 aircraft that carry hundreds of passengers to spacecraft designed to fly to the International Space Station, the Moon, and even Mars. Aerospace technology is characterized by incredible precision that is difficult to achieve with conventional tools, which is why CNC machines by CNC-turned parts manufacturers were the perfect solution.

CNC in Aviation

The CNC machine plays a crucial role in the fast and accurate production of the parts that are used in the operation of every component of the aircraft. Such tools are used to create engine parts, cockpit equipment, aircraft skin, wings, and other parts.

CNC in the space industry

CNC is used at NASA, SpaceX, and Roscosmos enterprises to provide rockets with parts of any size and shape with incredibly high fitting accuracy. They produce spare parts for engines, computer equipment, parts for various systems, and spacecraft hulls.

Car

Car shop manager Rocky Helms has a lot of work to do. He oversees the workshop of the world-famous racing team Richard Childress Racing (RCR). The company's 24 employees work two shifts a day to produce the 170,000 parts needed to service the RCR.

The workshop itself occupies 7,000 square meters on a 210,000 square meter campus. Since its inception in 1969, RCR has played 17 championships and won more than 200 times in three NASCAR Major Series, including three Daytona 500 races (1998, 2007, 2018) and three Brickyard 400 races (1995, 2003, 2011).

To increase the production of cars and maintain maximum productivity in the workshop, the RCR is equipped with the latest material handling technologies, including the Roland MODELA MDX-540 benchtop mill.

According to Helms, the machine can do the work in 10 minutes that a person does in 10 hours. RCR uses Roland to mill engine and brake parts, wheel discs, and shock absorbers. The device is also used to create carbon fiber parts & to engrave identification numbers on parts.

Medical

In the space industry, it is customary to say: "There is no repair shop in space." The quality, precision, and reliability of each part must be impeccable because once it leaves the planet, it just has to work. The same applies to the medical field. If the prosthetic implant does not work properly, it affects the health and well-being of the patient. When the operation is complete, the part simply needs to function.

Global trends indicate that the need for medical implants will increase, as will the competition in the market. According to Seco Tools, about five major suppliers are vying for 85 percent of the orthopedic parts market, with more than 200 companies vying for the remaining 15 percent.

The manufacturing process of orthopedic implants includes cutting, grinding, 3D printing, and other operations on CNC devices by CNC machining parts factory. The machine performs roughing, finishing, milling, T-slot machining, chamfering, and deburring. The goal is to achieve the required surface finish, reducing the need for time-consuming manual processing. Five-axis milling and grinding machines provide advantages when working with complex shapes and contours of prosthetic implants. Thanks to CNC, the production time is significantly reduced & the accuracy is increased. Modern technology is capable of processing almost any material, including titanium and ceramics.

0 notes

Link

0 notes

Text

Crafting Perfection: The Art of CNC Machine Services

Precision and efficiency are of the utmost significance in today's quick-paced manufacturing sector. To meet the ever-increasing demands of customers, companies are turning to CNC (Computer Numerical Control) machines for their job work services. One such leading player in the market is Kashdra Group, which has carved a niche for itself with its exceptional CNC Machine Job Work Services.

What is a CNC Machine?

CNC Machine refers to the process of outsourcing manufacturing tasks to CNC machines. These machines are controlled by computer programs, enabling precise and repetitive operations, resulting in high-quality end products. The services offered under CNC machine job work include milling, turning, drilling, cutting, and grinding, among others.

Advantages

Unmatched Precision and Accuracy

Outstanding precision and accuracy are hallmarks of CNC machines. The use of advanced software and computer control ensures that every product is manufactured with consistent quality, meeting tight tolerances and specifications.

Increased Productivity

With the ability to operate continuously and autonomously, CNC machines significantly enhance productivity. They can work 24/7, minimizing downtime and maximizing output, which is crucial for meeting project deadlines and handling bulk orders.

Versatility in Material Options

CNC machines can process a wide range of materials, including metals, plastics, wood, and composites. This versatility allows companies to explore various options for their products and choose the most suitable material for their specific needs.

Cost-Effectiveness

Though the initial setup cost of CNC machines may be higher, their long-term benefits outweigh the investment. Reduced labor costs, minimal material wastage, and higher production rates make CNC machines a cost-effective choice.

Flexibility and Customization

CNC machines can be easily reprogrammed to produce different products, making them highly flexible and adaptable. This feature is especially beneficial for businesses catering to diverse markets with varying demands.

Applications

Automotive Industry

The automotive industry extensively relies on CNC machines for the precise manufacturing of engine components, transmission parts, brake discs, and other vital automotive parts.

Aerospace Sector

In the aerospace sector, where precision and safety are paramount, CNC machines are utilized to fabricate intricate components for aircraft and spacecraft.

Electronics and Telecommunication

CNC machines play a vital role in the production of electronic components, such as circuit boards and connectors, ensuring that the devices function flawlessly.

Medical Devices

The medical industry benefits from CNC machines in the manufacturing of medical implants, prosthetics, and surgical instruments, where accuracy is crucial.

Furniture and Interior Design

CNC machines are also employed to create intricate and custom-designed furniture and interior décor items, giving businesses a competitive edge in the market.

Kashdra Group - Your Trusted CNC Machine Job Work Partner

Among the leading providers of CNC machines is us, we are renowned for our expertise and commitment to excellence. With state-of-the-art infrastructure and a team of skilled technicians, we deliver top-notch solutions to clients from various industries.

Why Choose Kashdra Group?

Cutting-Edge Technology

We boast a vast array of advanced CNC machines equipped with the latest technology, ensuring impeccable results.

Skilled Workforce

Our highly trained workforce is adept at handling complex projects with precision and efficiency, adhering to strict quality control measures.

Customization and Innovation

We understand the importance of customization and innovation. We work closely with clients to understand their requirements and provide tailored solutions to meet their unique needs.

Timely Delivery

Committed to meeting deadlines, we ensure that orders are completed and delivered on time, reducing any delays in the clients' production process.

Competitive Pricing

Despite offering top-notch quality, we maintain competitive pricing, making their services accessible to businesses of all sizes.

Explore Custom Solutions for Your Industry!

We understand that each industry has unique requirements. Whether you're in the automotive, aerospace, electronics, medical, or furniture sector, they have the expertise to provide tailored solutions that match your specific needs. Embrace innovation and precision by partnering with us for your CNC machine job work requirements. Contact us to learn more about our capabilities and explore the possibilities for your industry.

0 notes

Text

Massive growth of Aircraft Wheels Market 2030 with high CAGR in Coming Years with Focusing Key players like UTC, Safran, Meggit, Honeywell, Parker Hannifin, etc

Aircraft wheels are an essential component of an aircraft’s landing gear system. They provide support and stability during landing, takeoff, and ground operations. Here are some of the key features and types of aircraft wheels:

For Download Sample Report Click Here: https://www.globmarketreports.com/request-sample/209986

Construction: Aircraft wheels are typically made of aluminum or magnesium alloy, and they are designed to be lightweight and durable. They consist of a hub, rim, and tire assembly.

Tire type: There are two main types of aircraft tire: bias-ply and radial. Bias-ply tires are made of layers of rubber and fabric, while radial tires have steel belts that run perpendicular to the tire’s circumference. Radial tires offer better performance and longer life, but they are more expensive.

Tread pattern: Aircraft tires have different tread patterns depending on the intended use. Tires used for paved runways have smooth treads, while those used for unpaved runways have deeper treads for better traction.

Size: Aircraft wheels come in different sizes depending on the size and weight of the aircraft. Larger aircraft require larger wheels to support their weight.

Brake system: Aircraft wheels are typically equipped with a brake system that helps to slow the aircraft during landing and taxiing. The brake system consists of brake discs, calipers, and hydraulic lines.

Retraction system: Many aircraft wheels are designed to retract into the aircraft’s fuselage during flight to reduce drag and improve aerodynamics. The retraction system is typically controlled hydraulically or electrically.

Aircraft wheels are subject to strict maintenance and inspection requirements to ensure their continued safe operation. This includes regular inspections for wear, damage, and corrosion, as well as lubrication and adjustment of the wheel bearings.

0 notes

Text

Aircraft Carbon Brake Disc Market Revenue, Future And Business Analysis By Forecast 2032

The global aircraft carbon brake disc market size is expected to have a positive outlook during the forecast period from 2022 to 2032. The global market is predicted to reach around US$ 1,136.23 Million in 2022 and is anticipated surge to a high of US$ 2,034.81 Million by the year 2032. The global aircraft carbon brake disc market was valued at around US$ 1,071.92 Million in 2021.

The market is expanding as a result of carbon brake discs working as a feasible substitute for steel brakes and offering significant weight reductions when compared to the latter. Additionally, carbon brake discs are known to wear consistently and function better as the temperature rises. As a result, market valuation is likewise increasing over time and is predicted to continue growing in the upcoming years.

Due to its widespread use in takeoffs, landings, manoeuvring, halting, and landing aircraft, the global market for aircraft carbon brake discs is experiencing a significant increase in sales volume. To assure the safety of the flights, high carbon brake disc rotors are quickly being found; additionally, they are consumer parts that release the brakes simultaneously. The aircraft carbon brake disc is a cutting-edge brake mechanism, according to the analysts at FMI.

It is clear that aircraft carbon brake discs are lighter and have greater heat dissipation properties when compared to reinforced carbon brake discs made of steel. Additionally, it does not alter the high-temperature energy absorption properties. Therefore, it has been predicted that an important part of the aviation sector is the directional control of an aircraft during ground operations. As a result, the market for carbon brake discs for aircraft is anticipated to increase significantly during the given period.

Key Takeaways

The aircraft carbon fiber reinforced carbon brake discs are thicker as compared to the steel rotor used in the aircraft and are remarkably light. Attributed to this feature, the widespread adoption of a carbon brake disc in the aircraft industry is witnessed over the forecast period.

The aircraft carbon brake disc is capable of withstanding temperatures more than 50% higher than steel component brakes. In addition to that, it has been revealed while analyzing that the aircraft carbon brake discs are capable of withstanding2-3 times the heat of a steel brake in non-aircraft applications.

Overall lower costs are associated with the aircraft carbon brake discs since they require minimal maintenance. The minimum operating costs are combined with brake life improvement, lower consumption of fuel, and compact aircraft feasibility is driving the market size of aircraft carbon brake discs.

The ease of retrofitting by manufacturing and engineering technologies is expected to lower the costs for specific aircraft models. Therefore, aircraft carbon brake discs are highly preferred by aircraft manufacturers.

The surge in demand for air passengers has led to a surge in the demand for aircraft, which is further anticipated to drive growth in the aircraft carbon brake disc market over the assessment period.

While analyzing the aircraft carbon brake disc market, it has been identified that the market has gained significant traction over recent years owing to the excessive utilization of these discs in aircraft. The aircraft carbon brake disc market has been gaining popularity over the forecast period, due to its rapid usage in military and commercial aircraft for gliding, taking off, and landing. This aspect is witnessed to be the key growth prospect for the industry and has resulted in a considerable upsurge of demand in the carbon brake disc forum.

For more information: https://www.futuremarketinsights.com/reports/aircraft-carbon-brake-disc-market

Competitive Landscape

The manufacturers are focusing on capitalizing on improving the functionality of aircraft carbon brake discs for better handling of the ground procedures along with catering to the rising demand for safety for the air-passengers. The prominent key players are majorly focusing on product development and are also emphasizing offering certified products through quality brake systems with technological advances in order to increase their brand value.

In addition to that, various key players in the aerospace industry are anticipated to take stringent measures in order to mitigate steep falls in their revenues and demand, thereby propelling market expansion in the upcoming years.

More Insights into the Aircraft Carbon Brake Disc Market

North American region is expected to account for the largest market share over the recent years by accounting for a CAGR of around 5.1% throughout the forecast period. This region has been experiencing rapid growth in terms of aircraft production and is likely to dominate the market share for aircraft carbon brake discs in the upcoming years.

Key Segments in the Aircraft Carbon Brake Disc Market

By Material Type:

Carbon-Carbon

Carbon-Composite

By Aircraft Type:

General Aviation

Commercial Aircraft

Narrow Body Aircraft

Wide Body Aircraft

Regional Jets

Military Aircrafts

By Fit Type:

First Fit

Retro Fit

0 notes

Text

0 notes

Text

Bendix abs power cable

In the same facility avionics and other electronic hardware was designed, manufactured, and documented in technical manuals. Starting in the 1950s or before, Bendix Pacific designed, tested, and manufactured hydraulic components and systems, primarily for the military. In the fall of 2018, TRW was assumed by ZF Ind of Germany and the Bendix brake trademark was licensed to Germany's OPTIMAL, where it resides today. (TRW had already assumed control over Lucas Girling Brake Division years earlier.) The Bendix Electronic Control Unit division was divested to Siemens-VDO a part of giant Robert Bosch GmbH and formed the foundation of the VW Digifant system and later Bosch Motronic Electronic Control Units introduced in the late 1980s. When Allied Signal took over Bendix in the 1980s, it quickly divested the brake and steering division to TRW to focus on aerospace applications and railcars.

Considered one of the best hubs on the market, at the time. followed by the Bendix "70" and Bendix "80" hub. Also, just as reliable, was the Bendix "Red Band" and "Red Band II" single speed coaster brake hub. During the 1960s, Bendix also dabbled in bicycle hardware, producing a reliable, totally self-contained, 2-speed "Kick-Back" planetary rear axle with coaster braking. In the 1960s, Bendix automotive brakes blossomed with the introduction of fixed-caliper disc brakes and the "Duo-Servo" system (which became, virtually, a de facto world standard for drum brakes). In 1956, Bendix introduced " Electrojector", a true multipoint electronic fuel injection system, which was optional on several 1958 models of automobiles built by Chrysler Corporation. In 1924 Vincent Bendix had acquired the rights to Henri Perrot's patents for Drum brake/drum and shoe design. Bendix manufactured both hydraulic brake systems and a vacuum booster TreadleVac for its production lines for decades. At first it manufactured brake systems for cars and trucks, supplying General Motors and other automobile manufacturers. Bendix was formally founded in 1924 in South Bend, Indiana, United States. By 1940 Bendix had sales running around $40 million, and in 1948 General Motors sold its interest in Bendix as it wanted to focus on its expanding automotive operations. Breech became president of Bendix, moving from General Motors Corp., and after performing brilliantly for Bendix by introducing GM management philosophies he then attracted the attention of Henry Ford II who induced him over to Ford Motor Company where he finished his career. It acquired Bragg-Kliesrath brakes in the late 1920s. Bendix in the 1920s owned and controlled many important patents for devices applicable to the auto industry, for example, brakes, carburetors, and starting drives for engines. purchased a 24% interest in Bendix in 1924, not to operate Bendix but to maintain a direct and continuing contact with developments in aviation, as the engineering techniques of the auto and aircraft were quite similar then. By using this screw with the Eclipse Machine Company, Bendix had a good foundation for his future business plans. Bendix granted permission to his invention which was described as "a New York device for the starting of explosive motors." This company made a low cost triple thread screw which could be used in the manufacture of other drive parts.

1.1.4 Avionics, military and governmentįounder and inventor Vincent Bendix initially began his corporation in a hotel room in Chicago in 1914 with an agreement with the struggling bicycle brake manufacturing firm, Eclipse Machine Company of Elmira, New York.

1.1.3 'Dashaveyor' Automated Guideway Transit.

0 notes

Text

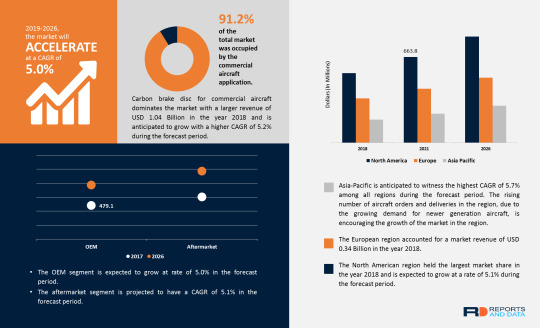

Aircraft Carbon Brake Disc Market Study, Competitive Strategies, Key Manufacturers, New Project Investment and Forecast till 2026

Aircraft Carbon Brake Disc Market Study, Competitive Strategies, Key Manufacturers, New Project Investment and Forecast till 2026

The market research report on the Global Aircraft Carbon Brake Disc Market published by Reports and Data has been formulated through a series of extensive primary and secondary research and further verified and validated by industry experts and professionals. The well formulated research report aims to provide the readers a better understanding of the industry and help them formulate strategic…

View On WordPress

#Aircraft Carbon Brake Disc Analysis#Aircraft Carbon Brake Disc Industry#Aircraft Carbon Brake Disc Market#Aircraft Carbon Brake Disc Market Forecast#Aircraft Carbon Brake Disc Market Growth#Aircraft Carbon Brake Disc Market Insight#Aircraft Carbon Brake Disc Market Research#Aircraft Carbon Brake Disc Market Share#Aircraft Carbon Brake Disc Market Trends#Aircraft Carbon Brake Disc PDF Report#Aircraft Carbon Brake Disc Research#Competitive Analysis

0 notes

Text

Aircraft Carbon Brake Disc Market 2019 – Huge Growth Opportunities and Expansion by 2025 | Research Informatic

The Aircraft Carbon Brake Disc Market research report covers a wide range of industry elements and components, as well as providing up-to-date and accurate market data. It depicts the regional growth trends as well as potential opportunities. It provides a comprehensive analysis of the market's primary segments through the use of charts and figures. The information in the report has been confirmed by a number of credible sources, including newspapers, magazines, journals, and other reliable sources. The Aircraft Carbon Brake Disc Market research report helps to achieve revenues and tremendous benefits in the future by presenting an unbiased overview of the market.

Visit: https://researchinformatic.com/reports/aircraft-carbon-brake-disc-market/77

Key Competitors

The report provides information that will help stakeholders evaluate investment suitability and market players acquire opportunities for partnerships, collaboration, and agreements.

Here is the list of some of the key players:

Safran

Meggitt

Honeywell

UTC Aerospace Systems

Xi`an Aviation Brake Technology

Chaoma Technology

Rubin Aviation Corporation JSC

Hunan Boyun New Materials

Beijing Beimo Gaoke Friction Material

Yantai Luhang Carbon Materials

SGL Group

Lantai Aviation Equipment

Mersen

Beijing Baimtec Material

Market Assessment

The Aircraft Carbon Brake Disc Market research report examines the market environment and demand from 2019 to 2026. It examines the current state of the market and its future prospects on a global and country level. The research report sheds light on various aspects of the industry by analyzing the market using value chain analysis.

Get Sample Report: https://www.researchinformatic.com/sample-request/77

Market Segmentation

The market is divided into four categories: product, type, application, and geography. Segmentation makes it easy to understand the market and acknowledge the information in the precise manner.

By Material Type (Carbon-Carbon, Carbon-Composite)

Fit Type (First Fit, Retro Fit), Aircraft Type (General Aviation, Military Aircrafts)

Sales Outlook (OEM Sales, Aftermarket)

Geographical Segmentation

The Market is segmented into South America, North America, Asia and Pacific region, Middle East and Africa, and Europe, based on regional distribution.

Enquire Now: https://www.researchinformatic.com/inquiry/77

Synopsis of the report

The report analyzes regional growth trends and future opportunities

A detailed analysis of each segment provides relevant information

The data gathered in the report is researched and verified by analysts

The report gives realistic information on supply, demand, and future projections.

Contact Us:

George Miller

1887 Whitney Mesa

Dr. Henderson, NV 89014

+1 775 237 4147

https://researchinformatic.com

#Aircraft Carbon Brake Disc Market#Aircraft Carbon Brake Disc Market Future#Aircraft Carbon Brake Disc Market Insight#Aircraft Carbon Brake Disc Market Share#Aircraft Carbon Brake Disc Market Opportunity

0 notes