#Aluminium Alloy Wheel Market

Text

Aluminium alloy wheel Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Aluminium alloy wheel Market and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Aluminium alloy wheel Market scenario, and feasibility study are the important aspects analyzed in this report.

The Aluminium alloy wheel Market is experiencing robust growth driven by the expanding globally. The Aluminium alloy wheel Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Aluminium alloy wheel Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. The global Aluminum Alloy Wheels Market size was USD 14.23 billion in 2020. The market is projected to grow from USD 16.43 billion in 2021 to USD 30.98 billion in 2028 at a CAGR of 9.5% during the 2021-2028 period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/105603

Key Strategies

Key strategies in the Aluminium alloy wheel Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Aluminium alloy wheel Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Aluminium alloy wheel Market.

Major Aluminium alloy wheel Market Manufacturers covered in the market report include:

LIST OF KEY COMPANIES PROFILED:

Status Wheels Inc. (Florida, U.S.)

Wheel Pros LLC. (Colorado, U.S.)

Fuel Off-Road Wheels (California, U.S.)

Citic Dicastal Co Ltd. (Hebei, China)

Enkei Wheels India Ltd (Pune, India)

Ronal AG (Härkingen, Switzerland)

BBS Kraftfahrzeugtechnik AG (Schiltach, Germany)

Alcoa wheels (Pennsylvania, U.S.)

MHT Luxury Wheels (California, U.S.)

Superior Industries (Minnesota, U.S.)

Alloy wheels have a widespread application due to their high resilience and lightweight. Furthermore, aluminum alloy wheels amplify the aesthetic appearance of the vehicle. Automakers are being forced to manufacture lighter, environment-friendly, and safer cars as the amount of carbon dioxide emitted is proportional to the amount of fuel consumption and the size of the vehicle; hence, reducing weight becomes a critical necessity.

Trends Analysis

The Aluminium alloy wheel Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Aluminium alloy wheel Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Aluminium alloy wheel Market Solutions.

Regions Included in this Aluminium alloy wheel Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Aluminium alloy wheel Market.

- Changing the Aluminium alloy wheel Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Aluminium alloy wheel Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Aluminium alloy wheel Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2024 to 2030?

► What are the key market dynamics influencing growth in the Global Aluminium alloy wheel Market?

► Who are the prominent players in the Global Aluminium alloy wheel Market?

► What is the consumer perspective in the Global Aluminium alloy wheel Market?

► What are the key demand-side and supply-side trends in the Global Aluminium alloy wheel Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Aluminium alloy wheel Market?

Table Of Contents:

1 Market Overview

1.1 Aluminium alloy wheel Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

308, Supreme Headquarters,

Survey No. 36, Baner,

Pune-Bangalore Highway,

Pune - 411045, Maharashtra, India.

Phone:

US:+1 424 253 0390

UK: +44 2071 939123

APAC: +91 744 740 1245

#Aluminium alloy wheel Market#Aluminium alloy wheel Market Share#Aluminium alloy wheel Market Size#Aluminium alloy wheel Market trends#Aluminium alloy wheel Market Growth#Aluminium alloy wheel Market Outlook

0 notes

Link

1 note

·

View note

Photo

Porsche “Berlin-Rome” Type 64 (1 of 2).

During 1938, Ferdinand Porsche and Major Adolf Hühnlein met, and the subject of establishing an endurance motor sport event was discussed. Hühnlein was inspired, and he set in motion a plan to organise a race from Berlin to Rome, a 1500km event that would take place in September 1939. No doubt Hühnlein’s motivation to his superiors included promoting Germany’s excellent system of Autobahns which this race would utilise, and the event would also tie in conveniently with the start of production of the KdF-Wagen.

In preparation for the race, it was decided to build three special long-distance race cars, and to Ferdinand Porsche’s delight, these were ordered and paid for by Volkswagen. For political reasons the cars were called KdF-Wagen and so in Volkswagen circles the car was known as the Type 60K10, although the Porsche engineers referred to it as the Type 64.

The 64 was to have an aluminium body, and the wheels were fully covered with removable alloy panels. Due to the event being a long-distance road race, Karl Fröhlich designed the car to carry two spare wheels in its nose, a move which meant the standard fuel tank would have to be relocated further back on the passenger side.

The engine used in the Type 64/60K10 was the standard 985cc unit as used in the KdF-Wagen, by increasing the compression ratio, power output was raised to 32 bhp at 3500 rpm.

With the race date set for September 1939, production of the three cars, Sports Car 1, 2 and 3, commenced in the summer of that year. The three chassis numbers allocated to the race cars, also referred to as the KdF-Rekordwagen, was 38/41, 38/42 and 38/43.

Karosseriewerk Reutter were given the task of making the bodies for the three cars from 0.5mm alloy sheets, but it wasn’t until 19 August 1939 that the first body was completed, a fortnight before the official start date of the Second World War. The second car was only completed on 20 December that year in a dark colour, while the third car, finished in the same silver colour as the first car, was only completed on 15 June 1940.

The plans for Porsche’s own sports car were already on the drawing board in 1947 and the first of the new 356 models was officially registered in June 1948. Just as the Type 64 had looked so ultra-modern when compared to contemporary sports machinery of the day, so too did the Porsche 356 immediately date other sports cars of the period. It was at this time that, with the war now over and plans to develop the 356 into a really competitive sports car in the market, that the old Type 64 became redundant to Porsche. Fortunately, the Swiss racing driver Otto Mathé had shown an interest in acquiring the Type 64, otherwise this crucially important piece of Porsche history may well have gone the way of its two siblings, and been scrapped.

“Otto Mathé, was one of the first, if not the very first driver, to use Porsche products for racing,” said Oliver Schmidt of the Prototyp Museum in Hamburg. Today there are two Type 64s in existence, the first being the 38/41 car Mathé bought from Porsche in 1949. The second car has been built up from the spares that Mathé bought from Porsche.

145 notes

·

View notes

Text

Royal Enfield Meteor 350 Gets Aurora Colour Variant At Rs 2.20 Lakh

Royal Enfield has widened the Meteor 350 range by launching the new Aurora variant of the cruiser.

It gets a couple of changes over other variants of the bike and comes with a price tag of Rs. 2,19,900 (ex-showroom, Chennai) which places it between the Stellar and Supernova trims of the Meteor 350.

RE Meteor 350 Thoroughly Overhauled

The new Aurora variant of the Meteor 350 comes equipped with spoke wheels and tube tyres, unlike other versions which get alloy wheels and tubeless rubbers.

Moreover, the engine case, exhaust system, and a few other components have been bestowed with chrome finishing. All of this is done to enhance the retro appeal of the bike.

You may like it : Best Bikes in India 2023

Royal Enfield Meteor 350 Aurora continues to receive the same J-series underpinnings, the 349 cc air-cooled, long-stroke engine, with 20.2 bhp and 2.75 kgm of torque, mated to a five-speed transmission.

What’s new with Aurora trim?

The trim introduces three new colourways and also debuts LED headlights to the range. Royal Enfield might make the latter feature standard with this range in the future.

You may like it : Royal Enfield Himalayan 452 Production Starts

As opposed to black treatment on all other trims, Aurora trim stands out in its classic appeal. RE is also giving Aurora LED headlights, a deluxe touring seat, aluminium switch cubes, a Tripper display for navigation and more.

Feature additions

Apart from adding Aurora trim, Royal Enfield has fettled with Meteor 350’s trim-wise features list too. Top-spec Supernova trim now gets LED headlights and aluminium switchgear, taking it a notch higher than before. Astral trim now gets Royal Enfield’s Tripper screen for navigation as standard fitment.

You may like it : RE Himalayan 452 Easily Clocks Over 140 km/h – VIDEO

With base Fireball trim, Royal Enfield has added a new Black stock colour which is both elegant and standard. Powering RE Meteor 350 is a 349cc J-series single-cylinder, air-cooled motor that kicks out 20.2 bhp at 6100rpm and a peak torque of 27 Nm at 4000rpm.

This unit is paired with a 5-speed gearbox. The same powertrain is found on newly launched Bullet 350 too.

Meteor 350 is underpinned by a dual-cradle J-series chassis which is suspended on 41mm RSU telescopic suspension at the front and twin shocks at the rear. Anchorage duties are handled by a 300mm front disc and a 270mm rear disc which are aided by a dual-channel ABS as standard.

In terms of features, it comes with a semi-digital instrument console, a USB charger, circular LED DRL and a side-stand engine inhibitor, among many.

You may like it : Best Electric Bikes in India

Words from the manufacturer

Speaking about the new range and enhancements on the Meteor 350, B Govindarajan, CEO – Royal Enfield said, “As we reflect on the remarkable success of the Meteor 350 in India and international markets it is evident that the Meteor has struck a chord with many long distance riders and motorcycling enthusiasts. Its dynamic cruising ability and dependable performance have resonated deeply with our riders.

The Aurora range is a result of our constant interactions with our community of riders, where we witnessed a strong inclination towards retro-inspired cruisers. The new colourways and features are sure to elevate the pleasure of pure retro-cruising among our customers.”

#Meteor #Overhauled

2 notes

·

View notes

Text

Sky Scrap Metal: Your Go-To for Scrap Metal Solutions

Welcome to the Sky Scrap Metal blog! Whether you're a car enthusiast looking to recycle those old aluminium MAG wheels, a business owner managing scrap metal, or just curious about scrap metal prices, we’ve got you covered. At Sky Scrap Metal, we’re dedicated to offering the best solutions and information on scrap metal purchasing. Let’s dive into some key aspects of our services and what you need to know about the scrap metal market.

Aluminium MAG Wheel Scrap: What You Need to Know

Aluminium MAG wheels are not just stylish additions to your vehicle but also valuable commodities in the scrap metal market. These wheels, made from high-grade aluminium alloys, are prized for their lightweight and durability. When you're ready to part ways with your old MAG wheels, Sky Scrap Metal offers competitive prices and convenient services to help you get the best value for your scrap.

Why Recycle Aluminium MAG Wheels?

Environmental Benefits: Recycling aluminium conserves natural resources and reduces energy consumption. The process of recycling aluminium uses up to 95% less energy compared to producing new aluminium from ore.

Economic Value: Aluminium MAG wheels scrap are worth more than many other types of scrap metal due to the quality of the material. By recycling them, you can earn a decent amount while contributing to a greener planet.

At Sky Scrap Metal, we ensure a seamless process from collection to payment. Our team evaluates the condition and weight of your MAG wheels to offer a fair market price.

Car Batteries Scrap Price: Maximizing Your Returns

Car batteries are another significant category of scrap metal that we handle at Sky Scrap Metal. The scrap price for car batteries varies depending on several factors, including the type of battery and the current market conditions.

Factors Influencing Car Battery Scrap Prices

Lead Content: Most car batteries contain lead, a valuable metal in the recycling market. The more lead a battery contains, the higher its scrap value.

Battery Type: Different types of car batteries (e.g., lead-acid, AGM) have different recycling values. Lead-acid batteries, which are common, typically fetch a higher price due to the large amounts of lead they contain.

Market Trends: Scrap metal prices fluctuate based on market demand and supply. Staying updated with market trends can help you sell your scrap batteries at the optimal time.

Sky Scrap Metal offers competitive prices for car battery scrap and ensures that all batteries are disposed of responsibly, in line with environmental regulations. We provide hassle-free collection and immediate payment, making the process convenient for you.

Why Choose Sky Scrap Metal?

Competitive Pricing: We constantly monitor market trends to offer you the best prices for your scrap metal.

Eco-Friendly Practices: We adhere to strict environmental standards, ensuring that all scrap metal is recycled properly and responsibly.

Professional Service: Our team is dedicated to providing top-notch customer service, from quick responses to prompt payments.

How to Get Started with Sky Scrap Metal

Ready to recycle your scrap metal? Contact us at Sky Scrap Metal today for a quote or to schedule a pickup. Whether you have aluminium MAG wheels, car batteries, or other scrap metal, we make the process easy and profitable.

Thank you for visiting our blog! Stay tuned for more updates, tips, and news from the world of scrap metal recycling. At Sky Scrap Metal, we’re here to help you turn your scrap into cash while making a positive impact on the environment.

0 notes

Text

Applications of Aluminum Bronze Round Bar in Various Industries

Rajkrupa Metal Industries is one of the Premium Quality Aluminium Bronze Round Bar Manufacturer In India. We are now the industry leader in Aluminium Bronze Round Bar. We have consciously positioned itself as a top-tier manufacturer and retailer in the worldwide Aluminium Bronze Round Bar market due to its excellent corporate and technical people skills.

Our company, which manufactures with ISO 9001:2015 certification. We are one of the top Aluminium Bronze Round Bar Manufacturer who complies with the International Quality Standard (IQS).

Marine Industry

The marine industry is one of the primary sectors where aluminium bronze round bars are extensively used. Their excellent resistance to seawater corrosion and biofouling makes them ideal for components that are exposed to harsh marine environments. Common applications include:

Propellers and Shafts: Aluminium bronze is used for manufacturing propellers and shafts due to its high strength and resistance to corrosion, cavitation, and wear.

Valve Components: The alloy's resistance to corrosion and its ability to withstand high pressures make it suitable for valves and other fittings in marine applications.

Pumps and Bearings: Bearings and pump components made from aluminium bronze ensure long service life and reliable performance in marine conditions.

Aerospace Industry

In the aerospace industry, materials must meet stringent requirements for strength, durability, and resistance to extreme conditions. Aluminium bronze round bars fulfil these criteria, making them suitable for various aerospace applications, such as:

Landing Gear Bushings: The high strength and fatigue resistance of aluminium bronze make it ideal for landing gear bushings, which must endure significant stress and impact.

Fasteners and Connectors: These components require materials that can maintain their integrity under high loads and temperatures. Aluminium bronze provides the necessary reliability.

Engine Components: Certain engine parts benefit from the wear resistance and thermal stability of aluminium bronze, ensuring optimal performance and longevity.

Oil and Gas Industry

The oil and gas industry demands materials that can withstand corrosive environments and high pressures. Aluminium bronze round bars are well-suited for such applications, including:

Valve Seats and Stems: The excellent corrosion resistance of aluminium bronze ensures the longevity and reliability of valve components used in oil and gas extraction and processing.

Pump Components: Pumps in the oil and gas sector handle abrasive and corrosive fluids, requiring materials like aluminium bronze that can endure these harsh conditions.

Heat Exchanger Tubes: Aluminium bronze's resistance to corrosion and biofouling makes it a good choice for heat exchanger tubes, ensuring efficient and long-lasting performance.

Industrial Machinery

In various industrial machinery applications, aluminium bronze round bars are used for their mechanical properties and durability. Some common uses include:

Gear and Worm Wheels: The high strength and wear resistance of aluminium bronze make it suitable for gears and worm wheels in heavy machinery.

Bushings and Bearings: Aluminium bronze bushings and bearings provide excellent performance under high loads and rotational speeds, reducing maintenance and downtime.

Wear Plates: These components benefit from the alloy's ability to withstand abrasion and impact, extending the life of machinery and equipment.

Electrical Industry

Aluminium bronze round bars also find applications in the electrical industry due to their good electrical conductivity and resistance to sparking. Examples include:

Electrical Connectors: The combination of electrical conductivity and mechanical strength makes aluminium bronze ideal for connectors and terminals.

Switchgear Components: In switchgear, the alloy's durability and resistance to corrosion ensure reliable operation and safety.

Conductive Bushings: Used in various electrical applications, aluminium bronze bushings provide a balance of conductivity and mechanical integrity.

Aluminium Bronze Round Bar Suppliers are well-known for their excellent strength, corrosion resistance, thermal and electrical conductivity, and other properties. We are also the leading Round bars manufacturer in India.

#AluminiumBronzeRoundBar#AluminiumBronzeRoundBarManufacturer#AluminiumBronzeRoundBarManufacturerinIndia#AluminiumBronzeRoundBarSuppliers#RoundbarsmanufacturerinIndia

0 notes

Text

Anatomy of a Great Electric Cycle

As the world shifts towards sustainable development and embraces more fuel-efficient technology, electric cycles are gaining traction for all the right reasons. Serving as a simple solution to the commuting challenges faced by major cities worldwide, electric cycles have witnessed a surge in popularity. While the concept of electric cycles dates back to the 18th century, it is only recently that we are witnessing their resurgence in the market.

Despite sharing many similarities with traditional bicycles in terms of their anatomy, electric cycles possess a few distinctive components that set them apart. Curious about what makes an electric cycle truly exceptional? Let's delve into the key elements that define its anatomy and ensure its enduring appeal.

What are the aspects that make an e-cycle great?

Let’s find out key aspects that make an e-cycle great:

Frame

Undoubtedly, the frame is the backbone of any cycle, including electric cycles, providing the necessary strength to withstand various terrains. The choice of material and frame geometry significantly influences the riding experience. Materials such as aluminium and carbon fibre are favoured for their lightweight yet durable properties. Additionally, the frame's geometry determines the rider's posture and stability, making it crucial in selecting the right electric cycle. A well-designed frame not only ensures stability but also adds a touch of style to your ride. Depending on your needs and preferences, e-cycles also come with aluminium alloy and High Tensile Steel frames, both with different set of usage. Like EMX+ and T-Rex Air by EMotorad, both have different frames but it all boils down to what you want.

Motor

Responsible for converting electrical energy into mechanical power, the motor propels the rider forward when accelerating. Commonly, electric cycles feature motors placed on either the front or rear hub to directly power the wheel, or on the frame to power the chain. The motor's power output is a critical factor, determining the electric cycle's ability to meet the rider's specific needs. Higher wattage motors provide longer range and easier uphill rides or commutes to your favourite distant restaurant. Motor wattage typically ranges from 250 watts to 750 watts, with speeds varying between 25 km/h to 45 km/h, adhering to local laws and regulations. In India, the standard is 250W motors because of the speed limitation set by the laws, this allows you to get an e-cycle without applying for a licence making it accessible to all. You can check out EMotorad e-cycles. The motors used are high-performance and are among the finest in the market today.

Battery

A powerful motor requires an equally robust power source, which is where the battery comes into play. The battery's capacity determines the electric cycle's range, making it a crucial component for long commutes. Lithium-ion batteries are preferred for their balance between energy density and weight. Additionally, the battery's placement contributes to weight distribution, ensuring stability and comfort throughout the ride. EMotorad electric cycles provide batteries with high capacity, this helps you stay on the road for long periods without compromising on anything.

Control System

An efficient power management system is essential to regulate the flow of electricity from the battery to the motor, ensuring smooth acceleration and optimal performance. The control system's user interface allows riders to control power levels and monitor vital information, enhancing the overall riding experience and providing riders with complete control over their electric cycles.

Brakes

Brakes are a crucial safety feature, whether for an electric bicycle or a car. Disc brakes have become the standard, offering reliable stopping power even in wet conditions. This not only enhances braking efficiency but also contributes to the overall energy efficiency of the electric cycle, ensuring a safe and enjoyable ride. All EMotorad e-cycles come with dual mechanical disc brakes which keeps you not just ahead but also safe at every turn. For more information, checkout their website.

Suspension

The type of suspension system varies depending on the intended use of the electric cycle. For riders venturing beyond smooth city roads, a reliable suspension system becomes indispensable. E-cycles, like traditional bicycles, come equipped with front and rear shock absorbers for better comfort. The type of suspension chosen depends on the intended use, whether for leisurely rides on paved paths or off-road adventures that demand robust shock absorption. EMotorad e-cycles come with standard front suspension, but the EMX+ also comes with dual suspension, making it India’s first dual suspension e-cycle. To get more information on the same, you can check it out here.

Terrain

The type of terrain plays a significant role in choosing the right electric cycle. Each cycle is designed differently, with varying anatomy to handle different terrains. It's essential to choose an electric cycle that suits your needs, ensuring a comfortable and enjoyable riding experience. All the EMotorad e-cycles are built for all terrains, whether you want something to commute or off-roading, EMotorad e-cycles are perfect for every type of rider.

Lights

Proper lighting is essential for night rides, ensuring visibility and safety. An electric cycle should be equipped with a reliable headlight and taillight to illuminate the path ahead and ensure you're visible to other road users.

Conclusion

Understanding the key components that define an electric cycle's anatomy is essential before making a purchase. Taking a test ride and identifying your needs and preferences will help you choose the perfect electric cycle for your lifestyle. EMotorad is the leading brand in the market today, and for all the good reasons. If you are in the hunt for something that has a long range and doesn’t compromise on style, you are in luck. Check out their website for more information here. Go ahead, explore your options, and embark on your electric cycling journey with confidence and excitement!

0 notes

Text

Balancing Act: Tips for Selecting the Right Wheels & Tyres Combo, Unveiling the Best Wheels & Tyres Packages in Blacktown

Embarking on the journey of upgrading your vehicle's wheels and Tyres is more than just a mere aesthetic enhancement; it's a delicate balancing act between style, performance, and functionality. The right wheels and Tyres combo can elevate your driving experience, but navigating through the plethora of options can be overwhelming. Fear not, as we unveil the secrets to mastering this balancing act and discover the best wheels and Tyre packages in Blacktown.

Understanding the Basics: Wheels & Tyres 101

Before delving into the world of wheels and Tyre packages, it's essential to grasp the fundamentals. Wheels and Tyres contribute significantly to your vehicle's performance, safety, and appearance. Wheels come in various materials such as alloy, steel, and forged aluminium, each offering distinct benefits. Tyres, on the other hand, vary in size, tread pattern, and type, catering to different driving conditions.

The Style Quotient: Finding Your Aesthetic Appeal

Your vehicle is an extension of your personality, and the right wheels can speak volumes. Consider the design, finish, and size of the wheels to complement your vehicle's overall aesthetic. Whether you lean towards sleek modern designs, classic elegance, or rugged off-road vibes, Blacktown offers a wide range of styles to cater to every taste.

Performance Matters: Striking the Perfect Balance

While style is crucial, don't compromise on performance. The right wheels and Tyre combo can enhance your vehicle's handling, acceleration, and braking. Pay attention to factors like load capacity, speed rating, and tread pattern. Blacktown's diverse driving conditions demand a balance between performance and aesthetics, and the right combo can transform your ride into a true performer on the road.

Sizing it Right: The Art of Proportions

One of the common pitfalls in selecting wheels and Tyres is choosing the wrong size. Proper sizing ensures optimal performance and prevents issues like rubbing or speedometer inaccuracies. Blacktown roads present a variety of challenges, so consult with experts to find the ideal size that aligns with both style and functionality.

Tyre Types for Every Terrain: Conquering Blacktown's Diverse Roads

Blacktown's roads are diverse, ranging from urban streets to rural terrains. Consider the Tyre type that best suits your driving needs. Whether it's all-season, summer, or winter Tires, selecting the right set ensures a smooth and safe driving experience regardless of the weather or road conditions.

Package Deals in Blacktown: Convenience and Value

Navigating the world of wheels and Tires can be simplified with package deals. Many providers in Blacktown offer comprehensive packages that include both wheels and Tyres, providing convenience and often cost savings. Look for deals that align with your preferences and budget, making the entire process a seamless experience.

Seeking Professional Advice: Blacktown's Wheel and Tyre Experts

When in doubt, consult with the experts. Blacktown boasts a community of wheel and Tyre specialists with extensive knowledge and experience. Seek their guidance to ensure you make an informed decision tailored to your specific needs.

Budget-Friendly Options: Maximizing Value for Money

While the allure of high-end, premium wheels and Tyre packages in Blacktown is undeniable, it's crucial to set a realistic budget. Fortunately, Blacktown's automotive market provides a spectrum of options to suit various budgets. Explore the diverse range of wheels and Tyres that offer a perfect balance between quality and affordability. Remember, the best choice is not always the most expensive one; it's about finding the right combination that maximizes value for your money.

Customization for Personalization: Tailoring Your Ride

Blacktown's wheel and Tyre providers often offer customization options, allowing you to tailor your wheels and Tyres to meet your specific preferences. Whether it's unique finishes, custom colours, or personalized details, adding a touch of individuality to your vehicle enhances the overall ownership experience. Embrace the opportunity to create a ride that stands out on the streets of Blacktown and reflects your distinctive style.

Maintenance Considerations: Prolonging the Lifespan of Your Investment

The journey doesn't end once you've selected the perfect wheels and Tyres combo. Regular maintenance is crucial to ensure their longevity and optimal performance. Familiarize yourself with proper cleaning techniques, Tyre rotations, and inflation levels. Blacktown's weather conditions may vary, so adapting your maintenance routine accordingly will protect your investment and keep your ride in top-notch condition.

Environmental Impact: Choosing Sustainable Options

In an era where environmental consciousness is on the rise, consider the ecological impact of your wheel and Tyre choices. Opting for eco-friendly materials, such as low rolling resistance Tyres, can contribute to fuel efficiency and reduced carbon emissions. Blacktown, like many other communities, values sustainability, and selecting environmentally friendly options aligns with the city's commitment to a greener future.

Conclusion

In conclusion, the process of choosing the right wheels and Tyre combo extends beyond mere aesthetics and performance. It involves a holistic approach that encompasses budget considerations, personalization, maintenance, and a commitment to environmental sustainability. Blacktown's automotive scene caters to all these facets, providing you with the tools and options to make a well-informed decision that enhances not only your vehicle but also your driving experience and the community at large.

For a seamless experience in selecting the perfect wheels and Tyres packages in Blacktown, look no further than B Town Wheels and Tyres. Their expertise, diverse range of packages, and commitment to customer satisfaction make them the go-to choice for transforming your ride with style and performance.

Disclaimer: This is generic Information & post; content about the services can be changed from time to time as per your requirements and contract. To get the latest and updated information, contact us today or visit our website.

0 notes

Text

Can An Alloy Wheel Be Diamond Cut?

Diamond cutting is a process used to enhance the aesthetics of alloy wheels. It involves cutting and removing a thin layer from the wheel’s surface to reveal the natural shine of the aluminum. Diamond cut alloy wheels offer improved performance and increased resale value. However, they also require higher maintenance and have limited repair options. Proper cleaning, protection from corrosion, and avoiding damage are essential for maintaining the appearance and durability of diamond cut alloy wheels.

Key Takeaways

Diamond cutting is a process that involves cutting and removing a thin layer from the surface of alloy wheels to reveal the natural shine of the aluminum.

Diamond cut alloy wheels offer enhanced aesthetics, improved performance, and increased resale value.

Maintaining diamond cut alloy wheels requires regular cleaning and polishing, protection from corrosion, and avoiding damage.

Diamond cut alloy wheels have higher maintenance requirements and limited repair options compared to other types of wheels.

Proper care and maintenance are essential for preserving the appearance and durability of diamond cut alloy wheels.

What is Diamond Cutting?

The Process of Diamond Cutting

Our state-of-the-art CNC machine designed specifically to achieve the most uncompromising finish and quality standards for diamond cut wheels. We developed proprietary steps that include the use of mills with high rigidity to reduce the cycle time and produce smoother diamond cut finish to give your wheels a unique look. DIAMOND CUT WHEEL REFINISHING It’s time to make your car’s wheels really stand out! Is your face machined wheels have gutter rash damage, or you simply want to change the look of your rims from one-tone to two-tone wheels? At an affordable price, you can have beautiful lines and shine on the standard of work for which CNC is renowned. In fact, the finish is usually markedly superior to traditional methods, when modern CNC systems are employed by our highly-trained engineers. WHAT IS A DIAMOND CUT ALLOY WHEEL? Diamond cut wheels are becoming more common on today’s makes and models, as they are available in various styles and sizes. It’s relatively easy to spot if you have diamond cut alloy wheels. The surface looks very shiny like raw alloy with very fine lines under the lacquer, and often have a different colour on the insides spokes. During the refinishing process, a think layer is cut and removed from the alloy wheel’s surface to reveal the natural aluminium shine. Then, a lacquer coat layer is applied to protect the wheel and ensure long-lasting results. Whether you drive a BMW or Mercedes, if your wheels are diamond cut, then there is only one way to properly refinish this type of alloy wheels. Our state-of-the-art CNC machine designed specifically to achieve the most uncompromising finish and quality standards for diamond cut wheels.

Benefits of Diamond Cutting

Diamond cutting offers several benefits for alloy wheels. First, it enhances the aesthetics of the wheels, giving them a unique and eye-catching look. The diamond cut finish creates beautiful lines and shine that can make your car’s wheels stand out. Second, diamond cutting can improve the performance of the wheels. The precise cutting process reduces weight and improves balance, resulting in better handling and a smoother ride. Finally, diamond cut alloy wheels have increased resale value. The high-quality finish and unique appearance make them highly desirable in the used car market.

Common Applications of Diamond Cutting

When it comes to diamond wheel refurbishment service, we highly recommend using the services of JR Alloy Wheel Repair. Their team of experts, with over 15 years of experience combined, can perform this service in-house at the highest quality in the market. They have state-of-the-art CNC machines designed specifically to achieve the most uncompromising finish and quality standards for diamond cut wheels. With their proprietary steps and use of mills with high rigidity, they can reduce the cycle time and produce a smoother diamond cut finish, giving your wheels a unique look. Whether you have gutter rash damage or simply want to change the look of your rims, JR Alloy Wheel Repair can make your car’s wheels really stand out. Trust them to provide long-lasting results and an unmatched original look finish to your alloy wheels.

Alloy Wheels and Diamond Cutting

What are Alloy Wheels?

Alloy wheels are a popular choice for car owners due to their lightweight and stylish design. They are made from a combination of aluminum and other metals, which gives them strength and durability. Alloy Wheel Repair is an important service that car owners should consider when facing alloy wheel problems. JR Alloy Wheel Repair is a trusted provider of alloy wheel repair services, offering high-quality workmanship and exceptional results. Their team of experienced professionals can fix various issues such as scratches, dents, and curb damage. By using their services, car owners can restore the appearance and functionality of their alloy wheels, ensuring a smooth and safe driving experience.

How are Alloy Wheels Made?

Alloy wheels are made using a process called casting, where molten aluminum is poured into a mold and allowed to cool and solidify. This creates a strong and lightweight wheel that is resistant to corrosion. After the casting process, the wheels undergo various machining processes to achieve the desired design and finish. One popular method is diamond cutting, which involves using a CNC machine to remove a thin layer from the wheel’s surface, revealing the natural aluminum shine. Diamond cut alloy wheels offer enhanced aesthetics and can enhance the driving experience. If you have diamond cut alloy wheels and need them fixed, I highly recommend using the services of JR Alloy Wheel Repair. They are experts in alloy wheel repair and can ensure that your wheels are restored to their original condition.

Introduction to Diamond Cutting on Alloy Wheels

Diamond cut wheels are becoming more common on today’s makes and models, as they are available in various styles and sizes. It’s relatively easy to spot if you have diamond cut alloy wheels. The surface looks very shiny like raw alloy with very fine lines under the lacquer, and often have a different colour on the insides spokes. During the refinishing process, a thin layer is cut and removed from the alloy wheel’s surface to reveal the natural aluminium shine. Then, a lacquer coat layer is applied to protect the wheel and ensure long-lasting results. Whether you drive a BMW or Mercedes, if your wheels are diamond cut, then there is only one way to properly refinish this type of alloy wheels. Our state-of-the-art CNC machine designed specifically to achieve the most uncompromising finish and quality standards for diamond cut wheels.

Advantages of Diamond Cut Alloy Wheels

Enhanced Aesthetics

When it comes to alloy wheels, one of the key factors that can greatly enhance the overall appearance of your vehicle is the diamond cut finish. The diamond cut finish gives your wheels a unique look with beautiful lines and shine. Whether you have a sporty car or a modest daily driver, opting for diamond cut alloy wheels can instantly elevate the aesthetics of your vehicle.

By choosing diamond cut alloy wheels, you can transform the look of your rims from one-tone to two-tone wheels, adding a touch of sophistication and style. With our team of experts and state-of-the-art CNC machines, we can provide this service in-house at the highest quality in the market, ensuring an unmatched original look finish to your alloy wheels.

For those who prefer a subtle yet elegant appearance, diamond cut alloy wheels are the perfect choice. The precision and attention to detail in the diamond cutting process create a refined and polished look that complements any vehicle.

If you want to enhance the aesthetics of your vehicle and give your alloy wheels a stunning finish, we highly recommend using the services of JR Alloy Wheel Repair. With their expertise and years of experience, they can fix any alloy wheel problems and ensure your wheels look their best.

Improved Performance

For improved performance and optimal driving experience, it is highly recommended to use the services of JR Alloy Wheel Repair. With their expertise and specialized techniques, they can effectively fix any alloy wheel problems you may have. Whether it’s repairing minor damages or restoring the wheel’s original condition, JR Alloy Wheel Repair is the go-to solution. Their team of professionals is dedicated to providing top-notch service and ensuring customer satisfaction. Don’t hesitate to call us today and let JR Alloy Wheel Repair take care of your alloy wheel needs.

Increased Resale Value

When it comes to selling your vehicle, the condition of your alloy wheels can greatly impact its resale value. Alloy Wheel Repair is a crucial service that can help you maintain the appearance and functionality of your wheels, ultimately increasing the value of your car. By addressing any damages or imperfections, such as scratches or curb rash, Alloy Wheel Repair ensures that your wheels look their best and give potential buyers a positive impression. Investing in Alloy Wheel Repair is a smart choice if you want to maximize the resale value of your vehicle.

Disadvantages of Diamond Cut Alloy Wheels

Higher Maintenance Requirements

When it comes to diamond cut alloy wheels, one important aspect to consider is the higher maintenance requirements. Refurbishing service is often necessary to keep these wheels in top condition. Due to the delicate nature of the diamond cutting process, the wheels are more prone to scratches and damage. Regular cleaning and polishing are essential to maintain their shine and prevent corrosion. Additionally, it is important to protect the wheels from harsh chemicals and road debris that can cause further damage. To ensure the longevity of your diamond cut alloy wheels, it is recommended to use the services of JR Alloy Wheel Repair. Their expertise and experience in fixing alloy wheel problems make them the ideal choice for maintaining the beauty and functionality of your wheels.

Reduced Durability

Reduced durability is a significant concern when it comes to alloy wheels. The constant exposure to outdoor elements and the wear and tear from daily use can take a toll on the wheels’ structural integrity. It is essential to understand that alloy wheels are consumable products, and they will inevitably wear out and get scraped over time. While minor scrapes may not be noticeable to someone who is unaware of the damage, it is crucial to accept that low-profile wheels are prone to a few scrapes here and there. However, if you want to maintain the top-notch condition of your alloy wheels, it is advisable to seek professional repair services. JR Alloy Wheel Repair offers excellent services for fixing alloy wheel problems, ensuring that your wheels regain their original durability and appearance.

Limited Repair Options

When it comes to repairing alloy wheels with diamond-cut faces, the options are unfortunately limited. Unlike other types of alloy wheels, diamond-cut wheels can only be “fixed” a few times before the imperfections become permanent. This means that if your diamond-cut wheels sustain damage, you may have to live with the imperfections or invest in a new set of wheels. It’s important to note that the intricate machining process used to create diamond-cut wheels makes them more susceptible to damage and limits the repair options available. In such cases, it is highly recommended to seek professional assistance for wheel repair. JR Alloy Wheel Repair offers specialized services for fixing alloy wheel problems, including diamond-cut wheels. Their highly-trained technicians have the expertise and knowledge to restore your wheels back to their showroom condition. By utilizing their services, you can ensure that your alloy wheels receive the necessary care and attention they require.

Maintenance and Care for Diamond Cut Alloy Wheels

Cleaning and Polishing

For professional alloy wheel repair services, we highly recommend using the services of JR Alloy Wheel Repair. They specialize in fixing alloy wheel problems and have over 15 years of experience in the industry. With their team of experts and state-of-the-art CNC machines, they can provide high-quality repairs and refinishing for diamond cut wheels. Whether your wheels have gutter rash damage or you simply want to change the look of your rims, JR Alloy Wheel Repair can help. They offer affordable prices and ensure long-lasting results. Trust them to give your alloy wheels an unmatched original look finish.

Protection from Corrosion

When it comes to protecting your alloy wheels from corrosion, it is important to take the necessary steps to ensure their longevity and appearance. One effective way to prevent corrosion is by using a high-quality protective coating. Belsize Park residents can rely on the services of JR Alloy Wheel Repair for expert advice and top-notch solutions. Additionally, regular cleaning and maintenance can help remove any dirt or debris that may contribute to corrosion. It is also recommended to avoid harsh chemicals or abrasive cleaners that can damage the wheel’s finish. By following these simple steps, you can keep your alloy wheels looking their best and protect them from corrosion.

Avoiding Damage

To protect your alloy wheels from damage, it is important to take certain precautions. One of the best ways to avoid damage is to be more careful while driving and parking. Avoid hitting curbs or potholes, as these can cause scratches and dents on your wheels. Additionally, consider using rim protectors or rim blades for added protection against scrapes and scratches. Another option is to switch to a set of winter tires during the colder months, as they provide more rubber and can help prevent damage. Finally, if your alloy wheels do get damaged, it is recommended to seek professional repair services. JR Alloy Wheel Repair is a trusted provider that specializes in fixing alloy wheel problems. Their expertise and experience ensure that your wheels are repaired to the highest standard, restoring their appearance and functionality.

Maintenance and care for diamond cut alloy wheels is essential to keep them looking their best and to prolong their lifespan. Regular cleaning with a non-abrasive wheel cleaner is recommended to remove dirt and brake dust. It is also important to avoid using harsh chemicals or abrasive materials that could damage the wheel’s finish. Additionally, it is recommended to apply a protective coating or sealant to the wheels to help prevent corrosion and maintain their shine. If your alloy wheels are in need of repair or refurbishment, JR Alloy Wheel Repair is here to help. As alloy wheel repair specialists servicing Wembley and the London areas, we offer free online wheel repair quotes. Contact us now to get a free quote and restore your alloy wheels to their former glory.

Conclusion

In conclusion, diamond cut alloy wheels are becoming increasingly popular due to their unique style and appearance. The use of CNC machining technology allows for precise and high-quality refinishing of these wheels, resulting in a superior finish compared to traditional methods. Whether you want to repair damaged wheels or change the look of your rims, CNC machines can achieve remarkable results. With our state-of-the-art CNC machine and experienced team, we offer the highest quality diamond cut wheel refinishing services in the market. Give your car’s wheels a standout look with our expert services.

Frequently Asked Questions

What is diamond cutting?

Diamond cutting is a process in which a thin layer is cut and removed from the surface of an alloy wheel to reveal the natural aluminum shine. It is then coated with lacquer for protection and a long-lasting finish.

What are alloy wheels?

Alloy wheels are wheels made from a combination of aluminum and other metals. They are known for their lightweight and high-performance characteristics.

How are alloy wheels made?

Alloy wheels are made through a casting or forging process. The metal is heated and poured into a mold to form the wheel shape. It is then machined and finished to achieve the desired design.

What are the advantages of diamond cut alloy wheels?

Diamond cut alloy wheels offer enhanced aesthetics, improved performance, and increased resale value. The shiny finish and unique design make them visually appealing, while the removal of material can reduce weight and improve handling. Additionally, the high-quality finish adds value to the vehicle when selling or trading it in.

What are the disadvantages of diamond cut alloy wheels?

Diamond cut alloy wheels require higher maintenance compared to other wheel finishes. The thin layer of aluminum is more susceptible to damage and corrosion. They are also less durable and may require specialized repair options.

How should diamond cut alloy wheels be maintained and cared for?

To maintain diamond cut alloy wheels, regular cleaning and polishing are necessary. It is important to protect them from corrosion by applying a protective coating. Avoiding damage, such as curb rash or impact, is also crucial to preserving their appearance and functionality.

Article Source : https://jralloywheelrepair.co.uk/can-an-alloy-wheel-be-diamond-cut/

0 notes

Text

With the industry’s ongoing demand for tyres, one such common is the Alloy Wheel. Alloy Wheel is a blend of two or more metals along with Aluminium and Nickel is what wheels are made with. In the market, there are a variety of tyres available with different functions.

Alloy wheel repairs in Manchester

#Alloy wheel repairs Manchester#Alloy wheel repairs#Alloy Wheel Welding Manchester#Alloy wheel welding#Cracked wheels Manchester

0 notes

Text

2024 Kawasaki ZX-6R Launched In India At Rs. 11.09 Lakh

2024 Kawasaki ZX-6R

Kawasaki ZX-6R launched in India boasts a higher 130 bhp peak power from its 636cc in-line 4 engine

Team Green Returns after more than three years. We are talking about the new Ninja ZX-6R in all its glory. After being showcased at the 2023 iteration of the India Bike Week, the 2024 Kawasaki ZX-6R has been launched at Rs 11.09 lakh (ex-sh). This is a recurring model for Indian market that was earlier on sale a couple of years ago.

You may like it : New RE Himalayan 452 vs KTM Adventure 390 Drag Race

2024 Kawasaki ZX-6R price & colours

At Rs 11.09 lakh, the Kawasaki ZX-6R’s closest rival in terms of price, capability and performance is the Rs 11.81 lakh Street Triple RS. In Kawasaki’s lineup, the ZX-6R is positioned in between the Z900 (Rs 9.29 lakh) and the Kawasaki Ninja 1000 SX (Rs 12.20 lakh).

Green has introduced the supersport in two colours — Metallic Graphite Grey / Metallic Diablo Black and Lime Green / Ebony, but unfortunately, not the 40th year anniversary edition.

You may like it : Best Bike in India 2024

2024 Kawasaki ZX-6R Colour

The ZX-6R now gets four riding modes – Sport, Road, Rain and Rider (customisation) – which each have a preset level of power and traction control, except the Rider mode.

Kawasaki Ninja ZX-6R specs

The liquid-cooled, 636cc, inline-four engine is now rated for a maximum of 129hp at 13,000rpm and 69Nm of torque at 11,000rpm, which is a decrease of 1hp and 1.8Nm over the BS4 bike. Weight has also gone up to 198kg, an increase of 2 kilos over its predecessor.

6-speed gearbox, slipper clutch, sealed chain, Kawasaki Traction Control (KRTC), power modes (Full/Low), Kawasaki Intelligent ABS (KIBS), and Kawasaki Quick Shifter (KQS) (upshifts only) are part of package too. There is an eco riding indicator too and the 4.3-inch TFT display offers smartphone connectivity.

You may like it : Aprilia RS 457 Accessories list Revealed

2024 Kawasaki ZX-6R -front view

Suspension setup includes 41mm Showa Big Piston (SFF-BP) USD telescopic front forks and Uni-Trak gas-charged rear mono-shock. Both suspensions get compression, rebound and preload adjustability. The 17-inch alloy wheels are wrapped with 120-70 front and 185-55 rear tyres.

Dropping anchors on this beast are dual 310mm discs at the front with radially-mounted 4-piston calipers and a single 220mm disc at the rear with a single-piston caliper. All of this is mounted on an aluminium perimeter frame with a 1,400 mm wheelbase and 129.5 mm ground clearance. Fuel tank is 17L in capacity and has a 198 kg kerb weight.

1 note

·

View note

Text

Efficient Recycling Solutions for Light Metal Scrap

Recycling is an essential practice in today’s environmentally conscious world, and at Sky Scrap Metal, we’re committed to making it easier and more profitable for you. When it comes to light metal scrap, Aluminium MAG WHEEL scrap, and lead acid batteries scrap, our expertise ensures that you get the best value while contributing positively to the environment.

Light Metal Scrap: A Valuable Resource

Light metal scrap, often overlooked, plays a crucial role in the recycling industry. These metals, typically including aluminium, magnesium, and titanium, are highly sought after due to their lightweight properties and extensive use in various industries. At Sky Scrap Metal, we understand the significance of light metal scrap, and our efficient recycling processes help in extracting maximum value from these materials. By recycling light metal scrap, we not only conserve natural resources but also reduce the energy consumption associated with the production of new metals. This process helps in minimizing the environmental impact, making it a sustainable choice for businesses and individuals alike.

Aluminium MAG WHEEL Scrap: High-Value Recycling

Aluminium MAG WHEEL scrap is another lucrative resource in the recycling market. These wheels, commonly used in automobiles, are made from high-quality aluminium alloys that can be recycled efficiently. The recycling process for Aluminium MAG WHEEL scrap involves melting down the aluminium and refining it for reuse in various industries, including automotive and construction. At Sky Scrap Metal, we specialize in the collection and recycling of Aluminium MAG WHEEL scrap, ensuring that our clients receive competitive prices while contributing to a circular economy. Recycling aluminium not only conserves bauxite ore but also reduces greenhouse gas emissions, making it an environmentally friendly option.

Lead Acid Batteries Scrap: Safe and Profitable Disposal

Lead acid batteries are widely used in vehicles and industrial applications, but they pose significant environmental hazards if not disposed of properly. The lead and sulfuric acid components in these batteries can contaminate soil and water, leading to serious environmental issues. At Sky Scrap Metal, we prioritize the safe and responsible recycling of lead acid batteries scrap. Our state-of-the-art facilities ensure that the hazardous materials are handled with care, and the lead is extracted and refined for reuse. By recycling lead acid batteries scrap, you not only earn money but also contribute to a safer environment by preventing harmful substances from entering the ecosystem.

Why Choose Sky Scrap Metal?

Sky Scrap Metal is your trusted partner in the scrap metal recycling industry. We offer competitive prices, efficient services, and a commitment to environmental sustainability. Whether you have light metal scrap, Aluminium MAG WHEEL scrap, or lead acid batteries scrap, we provide a hassle-free experience from collection to payment. Our team of experts ensures that all materials are recycled in compliance with Australian standards, guaranteeing both safety and environmental responsibility.

By choosing Sky Scrap Metal, you’re not just earning money; you’re making a positive impact on the planet. We believe in building long-term relationships with our clients, offering personalized services tailored to meet your specific needs. With years of experience in the industry, we have the knowledge and resources to handle any volume of scrap, ensuring that you get the best value for your materials.

In conclusion, recycling scrap metal is not only a profitable endeavor but also a crucial step towards sustainability. At Sky Scrap Metal, we’re dedicated to helping you achieve both financial and environmental benefits. Contact us today to learn more about how we can assist you with your light metal scrap, Aluminium MAG WHEEL scrap, and lead acid batteries scrap recycling needs. Together, we can create a cleaner, greener future.

0 notes

Text

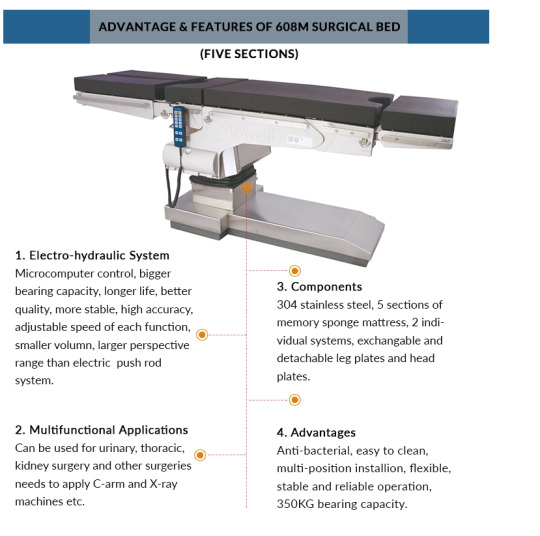

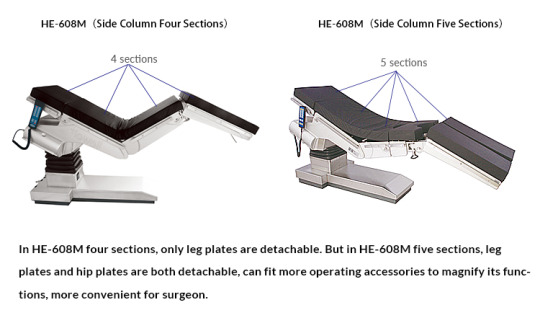

Orthopedic Operating Table Traction Frame

Orthopedic Operating Table Traction Frame

Model: Side-end column design, ideal for orthopedic surgeryCarbon fiber table plate, aluminium alloy table frame, 304 stainless steel column and base

It can be used with C arm and G arm machine

This classic table comes with advanced microcomputer control and high level electro-hydraulic system. The unique side column design of it makes the bigger space for surgery and X-ray, C or G-arm operating. It’s the best choice for urology, nephrology, thoracic surgery, and other surgeries for lower body. It’s special design and superior material makes a very elegant appearance, will certainly be a quality combine industry beauty factor for the OT.

Features

* Driven by electric hydraulic that makes lower noise, and with better stability and flexibility also longer lifetime. The main

components of electric hydraulic are from top supplier of the world. Reliable, stable, and easy to operate.

* With 7CM thick of memory foam makes the mattress comfortable and relaxing for patients. Special designed mattress cover is anti-static and very easy to clean.

* The unique T-shape base design of it leaves more space for surgeon to stand around, is also better for X-ray equipment to be moved and operated during surgery. The 4 hidden wheels below can avoid stumble risk, and with mechanical brake to guarantee better stability.

* The table frame, cover of column and base are made of fine 304 stainless steel which with mat polishing. Makes the table remain fine look and with low light reflecting which is better for surgeon and other participates in OT.

Orthopedic Operating Table Traction Frame

Whatsapp+8615146602893

email:[email protected]

Advantage: 1. The trapezoidal carbon fiber traction arm with high light transmission will not interfere with the inspection, fluoroscopy and imaging of the upper and lower, left and right, and inclined planes of the C-shaped arm during surgery. 2. The modular structure design can not install the traction arm on the healthy side, leaving enough space for the doctor to operate and the C-arm 3. The left and right movable traction arms are convenient for doctors to adjust the patient's muscle axis during surgery 4. The patented rapid traction device on the traction arm, combined with the stretch handles on both sides, can quickly and easily stretch the patient's lower limbs 5. The full retractor is made of nickel-chromium stainless alloy steel, which is strong, durable and easy to clean. 6. The tractor has a laser-engraved fine-tuning tractor ruler, which can clearly and accurately control the retraction distance of the tractor. 7.A single traction arm can be placed.

Orthopedic Operating Table Traction Frame

Whatsapp+8615146602893

email:[email protected]

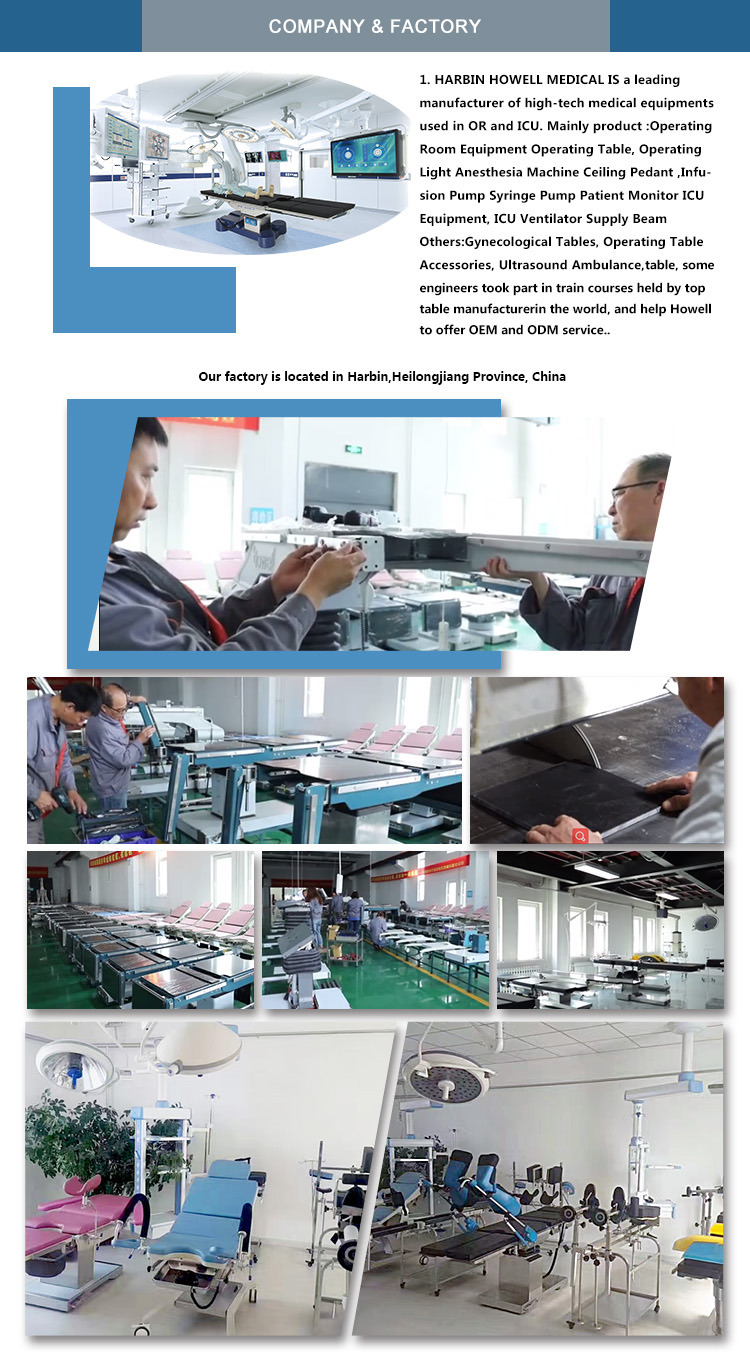

Harbin Howell Medical is a leading manufacturer of high-tech medical equipments used in OR and ICU, mainly: Operating Room Equipment: Operating Table Operating Light Anesthesia Machine Ceiling Pedant Infusion Pump Syringe Pump Patient Monitor ICU Equipment: ICU Ventilator Supply Beam Others: Gynecological Tables Ultrasound Ambulance Howell advocates resolve technical difficulties comprehensively base on excellent technical R&D; to satisfy customer requirements and demand; to create technical value through application experience; to explore the market on spirit of cooperation; to realize development sustainability of enterprise and brand adhere to wining respect from the market and customers. R&D team has more than 10 years experience in the line of operating table, some engineers took part in train courses held by top table manufacturer in the world. Every year, 10% of turnover invests in R&D department. Howell has achieved the leading position in technical level among domestic industry through continuous scientific technology innovation, moreover, the Company will continue to put more investment into R&D, aiming to exceed international standards. Leading products and perfect service has served for numerous domestic and foreign customers, helping customers to create value and social contribution through application of leading technology, in the future, Howell will continue to provide high quality products and services to partners in manufacturing, creation and conception and focus on the line of high-tech operating table, aiming to become the leading enterprise and brand in the supplier of operating table. Howell accumulated valuable experience in supplying accessories to equip with top brand tables, and there is a mold factory owned by Howell. All these advantages give us more power to supply OEM even ODM service to world partners.

0 notes

Text

0 notes

Text

Passenger car Alloy Wheels is The Newest Market Tread

Alloy wheels are manufactured by die-casting aluminium alloy into a wheel shape and then finishing it with various coatings and polishing as per the market demands.

For more information on passenger car alloy wheels visit https://www.rockman.in/

#alloy wheel#Aluminium die casting#auto parts manufacturers in india#automotive component manufacturers#two wheeler parts manufacturers in india

0 notes

Text

How do Electric Bicycles Work – Everything You Need to Know!

Across many parts of the world, bicycles are the most preferred medium for travelling short distances. And, with the innovation of electric bicycles, travelling has become more fun and thrilling. The e-bicycles have taken over the convenience of cars and have raised the economy of bicycles globally. Furthermore, many bicycles in the market are now within the common man’s budget. Depending on your need and preferable features, you can get an e-cycle according to your needs at a better price.

Advantages of an e-Bicycle

Easy Pedalling

Since e-bicycles are powered by batteries, when it comes to pedalling, a throttle is used to help you in the act of pedalling. Pushing on a pedal-assisted bicycle makes a small motor work that boosts cycling in rough terrains without trouble. In simple words, an e-bicycle makes every pedal more powerful while providing an easy cruise even when your legs do the work.

Speed

On an e-bicycle, the harder you pedal, the bigger the boost increasing your speed. An e-bike is faster than a regular bicycle, but at the same time, they are not motorcycling. You will not exceed a certain speed limit, but you will go fast enough to save time on your commute while enjoying your surroundings.

Important Parts of an Electric Bicycle

Batteries

Your smart e-cycle comes with large battery packs, generally placed between the wheels on your cycle’s frame. In an electric bicycle, batteries are the most crucial since they drive you from one place to another. Theoretically, a bicycle can work on any battery; in reality, the best kind of battery is not too heavy but also has a high amount of power.

As a result, heavy lead-acid batteries are not the best choice for an electric bicycle. But most electric bicycles today use lightweight lithium-ion batteries. These kinds of batteries are expensive, but they also perform better.

Frame

The main aspect of the frame of an electric bicycle is generally made out of a light aluminium alloy. Overall, a bicycle’s weight depends on the frame’s weight. The frame’s weight also influences the distance you travel before charging your batteries. Moreover, in an electric bicycle, there have to be strong spokes on the bicycles. It is because an electric motor with higher torque spins the cycle wheel, and the torque could buckle or bend the spokes if they are lightweight.

Read More at (Original Source): cityoftips.com

0 notes