#Automotive oil level sensors

Text

Mechanics Uncovered: A Practical Guide to Understanding Machines

In a world that increasingly relies on technology, understanding the basics of mechanics is essential, whether you're a car enthusiast, a DIY homeowner, or just looking to enhance your problem-solving skills. General mechanical knowledge encompasses a range of principles and practices that can empower you in various situations. This article will explore key aspects of mechanical knowledge, from the fundamentals of machines to practical applications in daily life.

The Basics of Mechanical Principles

At the heart of mechanical knowledge lies an understanding of how machines work. Mechanics is the branch of physics that deals with the behavior of physical bodies when subjected to forces or displacements. The key concepts include:

Force and Motion: Understanding Newton's laws of motion is crucial. The first law states that an object at rest stays at rest, and an object in motion stays in motion unless acted upon by an external force. The second law quantifies this with the formula F=maF = maF=ma (force equals mass times acceleration). The third law emphasizes that for every action, there is an equal and opposite reaction.

Energy Transfer: Energy exists in various forms—kinetic, potential, thermal, etc. Mechanical systems often convert energy from one form to another. For instance, an engine converts chemical energy from fuel into mechanical energy to move a vehicle.

Work and Power: Work is defined as the process of energy transfer that occurs when an object is moved over a distance by an external force. Power, on the other hand, measures how quickly work is done and is calculated as P=WtP = \frac{W}{t}P=tW, where PPP is power, WWW is work, and ttt is time.

Types of Mechanical Systems

Mechanical systems can be categorized into two main types: simple machines and complex machines.

Simple Machines

Simple machines are basic mechanical devices that change the direction or magnitude of a force. The six classical types are:

Lever: A rigid bar that pivots around a fulcrum to lift or move loads.

Pulley: A wheel on an axle designed to support movement and change the direction of force.

Inclined Plane: A flat surface tilted at an angle to help lift heavy objects.

Wedge: A device that tapers to a thin edge to separate materials.

Screw: An inclined plane wrapped around a shaft to convert rotational motion into linear motion.

Wheel and Axle: A circular object that rotates on a rod, allowing for easier movement of loads.

Understanding these simple machines is fundamental as they are the building blocks for more complex systems.

Complex Machines

Complex machines are combinations of simple machines working together. Examples include:

Automobiles: They integrate numerous systems, including the engine, transmission, braking, and electrical systems.

Robots: Utilizing a range of simple machines, sensors, and programming to perform tasks autonomously.

Household Appliances: Items like washing machines and microwaves use multiple mechanical principles to perform their functions efficiently.

Practical Applications of Mechanical Knowledge

Having a grasp of mechanical knowledge can be beneficial in various real-world scenarios:

DIY Projects

Understanding basic mechanics can save time and money, from assembling furniture to fixing appliances. For instance, knowing how to use levers can help you lift heavy items with ease, while an understanding of gears can assist in making effective adjustments in devices like bicycles.

Automotive Maintenance

For car owners, knowing how basic automotive systems work can prevent costly repairs. Understanding the role of the battery, alternator, and starter can help you troubleshoot issues. Regular maintenance, such as changing oil and checking fluid levels, can extend the life of your vehicle.

Problem Solving

Mechanical knowledge fosters critical thinking. When faced with a mechanical issue, such as a squeaky door or a malfunctioning tool, understanding the underlying mechanics allows you to diagnose and resolve problems more efficiently.

The Importance of Safety

While exploring mechanical systems, safety should always be a priority. Here are some key safety tips:

Wear Appropriate Gear: Safety glasses, gloves, and sturdy footwear can protect you from potential injuries.

Understand Your Tools: Familiarize yourself with how to use various tools properly to avoid accidents.

Follow Instructions: Whether working on a DIY project or performing automotive repairs, always follow the manufacturer’s instructions and guidelines.

Continuous Learning

Mechanical knowledge is not static; it evolves as technology advances. Continuous learning through workshops, online courses, or hands-on experience can enhance your mechanical skills. Consider joining local clubs or online forums where enthusiasts share tips, experiences, and knowledge.

General mechanical knowledge is a valuable asset that can enhance various aspects of life. Whether you’re tackling a DIY project, maintaining your vehicle, or simply looking to understand the machines around you, a foundational grasp of mechanical principles equips you to face challenges confidently. As you explore this field, remember that safety, continuous learning, and practical applications are key to making the most of your mechanical knowledge. Embrace the journey under the hood, and discover the empowering world of mechanics!

0 notes

Text

SmartGen | ACC5100 Controller Rolled Out

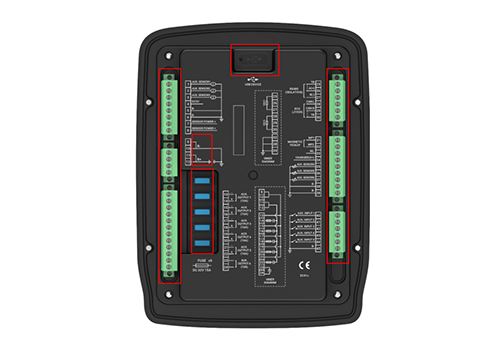

ACC5100 Diesel Air Compressor Controller is used for air compressor with diesel-driven engine to realize start/stop, data measurement, maintenance, alarm protection and “Three Remotes” functions. It can automatically adjust speed based on the discharge pressure of air compressor, and control various ECU or non-ECU diesel air compressors.

Functional Features

• Five active relay outputs connect with the positive and negative directly, no need to extend external relays with 15A capacity

Five digital inputs can be configured as active under high level or low level, which is highly flexible

Six analog sensor inputs, three of them can be configured as general resistance/current/voltage type sensor inputs

Manual DPF regeneration function supports non-road Stage IV engines

Control functions of heater, cooler, fuel pump and screw oil cooler

Real time clock, Event log (200), Maintenance (10) and ECU information display

With CANBUS port, it can collect the data, protect and control the ECU engines

With RS485 communication port, it can realize “Three Remotes” function

Advantage I: Colorful large screen, HD display

3.5-inch color LCD display, 320x240 pixel resolution, with adjustable backlight brightness

Smart LCD heating system allows it to work normally under low temperature of -40°C

Optional languages of Chinese, English and Russian, which supports custom languages

The description bar in the controller main screen can be configured, which contains ten letters/digits, or five Chinese characters

The analog parameter display area in the controller main screen can be configured, which can display different analog parameters

Advantage II: Highly integrated, installation design without fixed on cabinet

· Front panel integrates power on/off switch knob, high/low pressure switch knob, and emergency stop button to save the customer’s cost

· The connection wires between ports and components are reduced to be installed flexibly, which improves space efficiency and overall appearance

· Equipped with waterproof and dustproof screws installation

· With cover for the emergency stop button, it can avoid the touch by mistake

Advantage III: Reliable design for using safely

· It adopts 15A plug-in automotive blade fuses for easy maintenance

· Plastic sealing gasket is designed for back enclosure, which has great dustproof performance and allows it to work in extreme environment

· General Type-C port with dust cover ensures high IP level

· Connection terminals with flange structure makes the harnesses be fixed tightly

· Dual wires of B+ and B- meet the requirement of power input

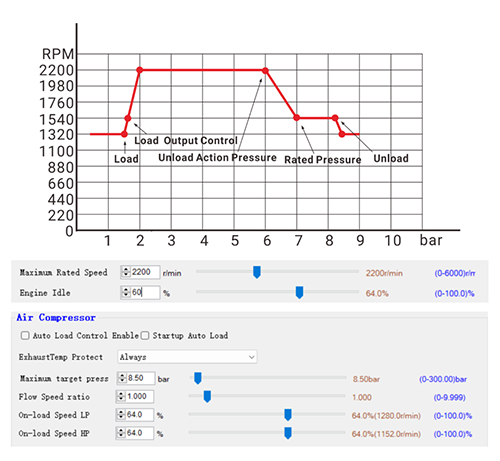

Advantage IV: Smart control of engine speed for variable need

Engine speed can be automatically adjusted based on the discharge pressure of air compressor

Advantage V: Smart control for high automation level

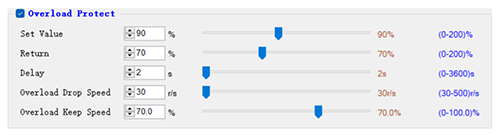

Speed down control when overloaded:

①When the load rate is too high, the speed will be automatically reduced to the stable speed

②When the load rate gets normal, the speed will return to the rated speed

③The speed down rate and delay value can be adjusted

Auto standby control:

①It can realize automatic control of standby and shutdown based on the discharge pressure

②It can be correlated with discharge pressure sensor and other auxiliary sensors

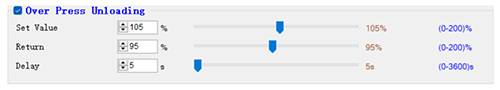

Auto unload control when overpressure:

It can realize automatic control of unloading based on the discharge pressure

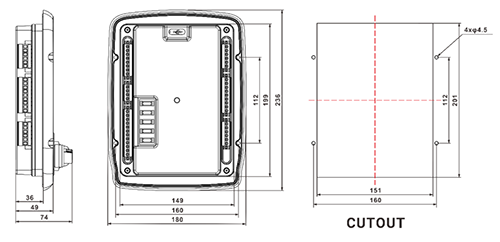

Overall Dimensions

For more product details, please contact SmartGen business personnel in your region. Welcome your order!

SmartGen, Making Control Smarter!

www.smartgen.cn

0 notes

Text

Understanding Vibration Meters: Essential Tools for Precision Monitoring

Vibration meters are invaluable instruments used across a variety of industries to measure and monitor mechanical vibrations. Whether you're working in manufacturing, engineering, or even the automotive industry, understanding how to effectively use vibration meters can make a significant difference in equipment maintenance and overall operational efficiency. In this blog, we’ll delve into what vibration meters are, their importance, and how they function to optimize machinery health and performance.

What is a Vibration Meter?

A vibration meter is a device that measures the oscillation or vibration of a machine or structure. Vibrations are common in any mechanical system, whether caused by moving parts, external forces, or imbalances. While a certain level of vibration is normal, excessive vibrations can signal potential issues, such as wear, misalignment, or mechanical failure.

By capturing data such as displacement, velocity, and acceleration, vibration meters help engineers and technicians assess the condition of rotating or reciprocating equipment. This allows for predictive maintenance, enabling operators to address issues before they lead to costly repairs or shutdowns.

How Do Vibration Meters Work?

Vibration meters work by detecting and quantifying the vibration of machinery components. Most vibration meters are equipped with an accelerometer sensor that converts mechanical movement into electrical signals. These signals are then analyzed to provide measurements that help assess the health of the equipment.

Vibration meters typically measure the following parameters:

Displacement: Measures the distance a point on the vibrating object moves from its rest position. This parameter is commonly used for low-frequency vibrations and helps in detecting misalignment or bent shafts.

Velocity: Indicates how fast the object is moving as it vibrates, providing a clearer picture of the severity of vibration, particularly in medium-frequency ranges. It’s helpful in identifying wear and tear in rotating equipment.

Acceleration: Measures the rate of change in velocity over time and is often used for high-frequency vibrations, offering insights into early signs of bearing failures or structural issues.

Why Are Vibration Meters Important?

Vibration meters are crucial for several reasons:

1. Predictive Maintenance

One of the main advantages of using a vibration meter is its ability to predict equipment failures. By regularly monitoring vibration levels, technicians can detect early signs of wear or imbalance, allowing for repairs before a critical breakdown occurs. This proactive approach saves time, reduces downtime, and minimizes costly repairs.

2. Improved Safety

Excessive vibrations can cause machines to become unstable or even dangerous. A vibration meter ensures that equipment runs smoothly, reducing the likelihood of unexpected accidents. For industries that operate heavy machinery or high-speed equipment, this safety benefit is critical.

3. Extended Equipment Lifespan

By catching potential issues early on, vibration meters help extend the lifespan of machinery. Preventive maintenance and timely repairs keep machines running efficiently for longer periods, maximizing your return on investment.

4. Energy Efficiency

Vibrating machinery tends to work harder than necessary, consuming more energy and leading to higher operational costs. Monitoring vibrations with a vibration meter can help optimize the performance of equipment, improving energy efficiency and reducing overall expenses.

5. Compliance with Industry Standards

In industries such as manufacturing, mining, and oil and gas, adhering to stringent industry regulations and safety standards is essential. Vibration meters ensure that machinery operates within safe and acceptable vibration levels, helping businesses maintain compliance with legal and regulatory requirements.

Applications of Vibration Meters

Vibration meters have a wide range of applications across industries. Some of the most common uses include:

1. Rotating Machinery

Industries that rely on rotating machinery—such as pumps, motors, fans, and compressors—benefit greatly from vibration monitoring. Excessive vibration in these machines can indicate imbalances, bearing issues, or misalignment, which can be costly if not addressed.

2. Automotive Industry

In the automotive sector, vibration meters are used to assess the condition of engines, transmissions, and other mechanical systems. Monitoring vibrations can prevent breakdowns and improve vehicle performance.

3. Aerospace

In aerospace, vibration meters are used to ensure the structural integrity of aircraft components. Even minor vibrations in an airplane's structure or engines can lead to safety concerns, making vibration monitoring critical in this high-stakes industry.

4. Building and Structural Health Monitoring

Civil engineers use vibration meters to monitor the structural health of buildings, bridges, and other infrastructure. Detecting unusual vibrations in structures can prevent disasters such as collapses or structural failures.

How to Choose the Right Vibration Meter

When selecting a vibration meter, it’s essential to consider the specific needs of your application. Here are a few factors to keep in mind:

Range of Measurement: Depending on the frequency and amplitude of the vibrations you're monitoring, choose a vibration meter that can measure the necessary parameters accurately.

Portability: If you need to monitor multiple machines across different locations, a portable vibration meter is a convenient option.

Data Logging Capability: Many modern vibration meters offer the ability to log data for long-term analysis. This is especially useful for identifying trends and making informed maintenance decisions.

Conclusion

Vibration meters play a vital role in maintaining the health and efficiency of machinery across various industries. By enabling predictive maintenance, improving safety, and reducing operational costs, these devices are essential tools for any operation that relies on mechanical systems. Understanding how to use a vibration meter effectively can save you time and money, while ensuring that your equipment operates smoothly and safely.

As technology advances, vibration meters continue to become more sophisticated, offering greater precision and ease of use. Whether you’re monitoring heavy machinery or maintaining structural integrity, investing in a reliable vibration meter is a smart choice for long-term success.

0 notes

Text

Electronic Pressure Sensors: Precision & Performance by Indication Instruments

In the fast-moving world of today’s industry, most processes are required to be maintained and controlled by pressure. The electronics of these sensors have become an important element in safety, accuracy, and reliability in many applications-from automotive to healthcare. For your smooth operation, Indication Instruments provides you with industry-standard electronic pressure sensors, precision designed.

Plot №19, Sector 6, Faridabad-121006 (INDIA)

Contact No: +91 129 4195300

Whatsapp

91 8810607901

What are Electronic Pressure Sensors?

Electronic pressure sensors are instruments that measure the force fluids or gases exert in a system. They translate a physical force of pressure into an electrical signal that can be traced and interpreted with a control system. Such sensors are particularly very important for keeping pressure levels within safe and optimal ranges in industrial machinery, automotive systems, medical devices, and many others.

Electronic Pressure Sensors of Indication Instruments’

Key Features High Accuracy: It is the high accuracy readings such that even very minute changes in pressure are detected and reported. Also, it becomes pretty much relevant for applications where industry, for instance, automotive or aerospace, demands high precision control or monitoring.

They are indications by indication instruments, therefore capable of perceiving a very wide range of pressure values, making them applicable in various industrial settings where pressures could either be low as in HVAC units, or highly elevated as in hydraulics.

Robustness & Reliability: Indication Instruments designs sensors with exceptional properties that enable them to be more resistant to several environmental factors, and they could, therefore, endure for long and even function uniformly with time irrespective of very high temperatures as well as aggressive environments.

Easy Installation: The Indication Instruments’ sensors are designed to fit well into several industrial systems; thus their installation is plain easy. Whether one seeks to replace old equipment or introduce new ones, Indication Instruments’ electronic pressure sensors integrate easily.

Compact Design: Our pressure sensors function so effectively yet are designed to be rather compact, thereby making them ideal for any application where space may be a significant restraint.

Applications of Electronic Pressure Sensors

Electronic pressure sensors are broadly used on a very wide basis in virtually all kinds of industries:

Automotive Industry: These sensors are positioned to measure the conditions in a car, which include the pressure of the tire, engine oil, and fuel system so that it improves performance as well as security.

HVAC Systems: Our pressure Tractor Sensors are always important in pressure control because it maintain pressure within the HVAC systems to preserve the maximum level of energy management.

Health care: Ventilators and oxygen supply systems use pressure sensors to provide a desired service to the patient and simultaneously protect the patient.

Industrial Automation: Pressure sensors would be a handy tool for the regulation of pressure in hydraulic and pneumatic systems in that safe and effective operation exists within manufacturing operations.

Why Indication Instruments?

Indication Instruments is the name we have entrusted our trust to for the last 30 years — we have faced reliable sensing solutions along with new ideas. We know how to address the point of view of the element in pressure sensing and continuously tell everyone how we remain committed to excellence in all of these areas.

Quality Assurance: Our electronic pressure sensors are tested against stringent industry standard as our objective.

Tailor-made Solutions: We give the clients tailor-made solutions to fit all that each application requires for it. This way, we attempt to have every application at its highest state for each.

Global Reach: Having a range of contented customers across the world in different industries, it is the way for us to get to the client’s needs for quality products in time each time.

Conclusion:

Pressure sensing technology requires nothing less than reliable accuracy. Indication Instruments developed some of the most advanced electronic Truck Sensors to meet every niche demand of the modern industry, from the automobile and healthcare to industrial automation. The precision and high performance define smooth and safe running operations.

Indication Instruments is investing in quality electronic pressure sensors. No matter your application, you simply can’t do any better. Call us today to learn more about our products and how we may design a package for your business.

1 note

·

View note

Text

Powering Progress with Cutting-Edge Solutions in UAE

In the modern industrial landscape, efficiency and power are critical factors that determine the success of any operation. Turbochargers have emerged as essential components in various industries, including automotive, marine, and power generation. These devices are designed to boost the performance of engines by increasing the amount of air that enters the combustion chamber, resulting in more power and efficiency. The use of turbochargers not only enhances the output of engines but also contributes to reduced fuel consumption and lower emissions, making them a vital component in today’s environmentally-conscious world.

Demand for Turbochargers in the UAE’s Industrial Sector

The UAE, with its rapidly growing industrial sector, has seen a significant increase in the demand for high-performance turbochargers. Industries such as oil and gas, shipping, and construction require engines that can deliver maximum power with optimal efficiency. The harsh operating conditions in these sectors make it essential to have reliable and durable turbochargers that can withstand extreme temperatures and pressures. As a result, there is a growing market for Solenoid Valve Supplier in UAE, offering cutting-edge solutions that meet the specific needs of various industries.

The Role of Sensors in Enhancing Industrial Automation

In addition to turbochargers, sensors have become indispensable in the realm of industrial automation. Sensors are used to monitor and control various parameters such as temperature, pressure, and flow, ensuring that industrial processes run smoothly and efficiently. The integration of sensors into industrial systems has revolutionized the way businesses operate, enabling real-time monitoring and data collection. This not only improves operational efficiency but also helps in predictive maintenance, reducing the risk of unexpected equipment failures.

Increasing Demand for Sensor Suppliers in UAE

As industries in the UAE continue to embrace automation, the demand for advanced sensors is on the rise. Solenoid Valve Supplier in UAE are at the forefront of this technological shift, providing a wide range of sensors that cater to the diverse needs of different sectors. Whether it’s for monitoring temperature in a refinery or detecting movement in a manufacturing plant, these suppliers offer solutions that enhance the safety, efficiency, and reliability of industrial operations. A Sensor supplier in the UAE ensures that companies have access to the latest sensor technologies, enabling them to optimize their processes and improve overall performance.

The Synergy Between Turbochargers and Sensors

The integration of turbochargers and sensors in industrial applications creates a powerful synergy that drives efficiency and performance. Turbochargers enhance engine power, while sensors provide the necessary data to monitor and control engine conditions. This combination allows industries to achieve higher levels of productivity and reliability, ensuring that their operations run at peak efficiency. As the industrial sector in the UAE continues to evolve, the importance of these components cannot be overstated.

The Future of Industrial Automation in the UAE

Looking ahead, the future of industrial automation in the UAE is bright, with continuous advancements in technology and an increasing focus on innovation. Companies are now seeking solutions that not only enhance efficiency but also contribute to sustainability. The development of smart sensors and energy-efficient turbochargers is paving the way for a more sustainable industrial landscape. As the UAE continues to lead in industrial innovation, the demand for high-quality turbochargers and sensors is expected to grow.

In conclusion, the UAE’s industrial sector is poised for significant growth, driven by advancements in technology and the increasing adoption of automation. The role of a reliable turbocharger supplier and sensor supplier in the UAE is crucial in supporting this growth by providing cutting-edge solutions that meet the evolving needs of industries. For more information on sourcing these essential components, visit hauberkglobal.com.

0 notes

Text

Precision in Monitoring: MeasureX Pressure Transmitters

In today’s fast-paced industrial environment, monitoring and control systems play a pivotal role in ensuring safety, efficiency, and reliability. One of the most critical devices in this ecosystem is the pressure transmitter. Whether in oil and gas, manufacturing, HVAC systems, or water treatment facilities, pressure transmitters are integral to maintaining accurate control and preventing costly failures. Among the leading names in this field is MeasureX, known for its precision-engineered sensors and measurement solutions.

What is a Pressure Transmitter?

A pressure transmitter is a device used to measure the pressure of gases, liquids, or steam. It converts the pressure it senses into an electrical signal that can be interpreted by monitoring systems, which then provide real-time feedback or control adjustments. Pressure transmitters are essential in industries where precise pressure control is vital for safety and efficiency, including chemical processing, oil extraction, food and beverage manufacturing, and HVAC systems.

The basic working principle involves a sensor that detects pressure changes and converts these changes into electrical outputs. These outputs are then sent to a control system, which uses the data to adjust or monitor the pressure levels within the system. Pressure transmitters can measure both absolute and differential pressure, depending on the application.

Key Benefits of Pressure Transmitters

1. Enhanced Safety: Industries such as oil and gas require real-time pressure monitoring to avoid dangerous overpressures, which can lead to equipment failure, environmental disasters, and even loss of life. Pressure transmitters provide continuous data, ensuring that critical pressure thresholds are never breached, thus enhancing workplace safety.

2. Improved Efficiency: By providing real-time pressure data, pressure transmitters help optimize operations. Whether controlling the flow of liquids in pipelines or ensuring the right amount of steam in a boiler, accurate pressure measurement ensures that systems run at their peak efficiency.

3. Cost Savings: Accurate pressure monitoring reduces the risk of equipment wear and tear, as well as the need for emergency repairs due to overpressure situations. This leads to lower maintenance costs and longer equipment life spans, saving companies time and money in the long run.

4. Versatility Across Industries: Pressure transmitters are incredibly versatile and can be used across a wide variety of applications. Whether it’s in clean environments like food production or harsh environments such as mining and oil rigs, they can be designed to suit different needs.

MeasureX: A Leader in Pressure Transmitters

MeasureX is a trusted name when it comes to precision measurement solutions. With a range of high-quality pressure transmitters, MeasureX caters to industries that require accurate, reliable, and robust pressure sensing solutions. Here's why MeasureX stands out:

1. High Accuracy and Precision: MeasureX’s pressure transmitters are designed to provide the highest level of accuracy, even in the most demanding applications. This level of precision ensures that systems operate smoothly and efficiently, avoiding costly errors.

2. Wide Range of Applications: From industrial automation to aerospace and automotive industries, MeasureX offers a variety of pressure transmitters to suit different environments and requirements. Whether it’s low-pressure or high-pressure applications, MeasureX has a solution.

3. Robust and Durable Design: MeasureX pressure transmitters are built to last. With rugged designs that can withstand extreme conditions, they are ideal for harsh environments where durability is paramount. Their products are resistant to temperature fluctuations, vibration, and corrosion, making them perfect for industries such as mining and oil exploration.

4. Customization Options: MeasureX understands that different industries have different requirements. That’s why they offer customizable pressure transmitters that can be tailored to specific applications. Whether you need special mounting options, different output configurations, or unique pressure ranges, MeasureX can provide solutions that meet your needs.

5. Real-Time Monitoring Capabilities: MeasureX pressure transmitters are designed to integrate seamlessly with modern control systems. Their advanced technology allows for real-time pressure monitoring and data transmission, enabling industries to respond quickly to changing conditions and maintain optimal performance.

The Importance of Choosing the Right Pressure Transmitter

Choosing the right pressure transmitter for your specific application is crucial. Here are a few factors to consider when selecting a pressure transmitter:

1. Pressure Range: Make sure the pressure transmitter you choose is capable of measuring the range of pressures you expect in your system. MeasureX offers a wide range of pressure transmitters suitable for both low-pressure and high-pressure applications.

2. Accuracy: The precision of the transmitter is critical in ensuring accurate data for control and safety systems. MeasureX pressure transmitters are known for their high accuracy, even in extreme conditions.

3. Environmental Conditions: Different industries present different environmental challenges, such as extreme temperatures, humidity, or exposure to corrosive substances. MeasureX designs transmitters that can withstand a variety of harsh conditions, ensuring long-lasting reliability.

4. Output Signal: Ensure that the pressure transmitter you choose is compatible with your control system. MeasureX pressure transmitters offer a range of output signals, making them adaptable to various monitoring setups.

The Future of Pressure Transmitters with MeasureX

As industries continue to evolve, so too will the demand for more advanced pressure transmitters. With the rise of smart factories, Internet of Things (IoT) devices, and automated systems, the need for precise, real-time pressure data will only increase. MeasureX is at the forefront of this technological shift, offering innovative solutions that integrate seamlessly with the latest monitoring and control systems.

In conclusion, pressure transmitters play a vital role in today’s industrial landscape, and MeasureX is leading the charge with its cutting-edge products. Whether you’re in manufacturing, energy, or automation, MeasureX’s pressure transmitters provide the accuracy, reliability, and durability you need to keep your operations running smoothly and safely.

Click Here For More Information : https://www.measurex.com.au/product-category/pressure-sensors/pressure-transmitters/

Contact Us For More Information

Phone Number : (0) 39558 2420

Email : [email protected]

Address : Unit 14/42 Garden Blvd, Dingley Village VIC 3172, Australia

0 notes

Text

Understanding Pressure Switches: Essential Components for Reliable System Control

Pressure switches are crucial devices used in various industries to monitor and control fluid or gas pressure within systems. These elements are essential for guaranteeing the safety, efficiency, and functionality of machinery and equipment. Whether in industrial processes, HVAC systems, or automotive applications, pressure switches offer reliable performance and prevent potential hazards by maintaining optimal pressure levels.

At its core, a pressure switch operates by activating or deactivating a circuit when a predetermined pressure level is reached. This mechanism helps regulate pressure to Avoid overpressurization scenarios that may result in equipment damage or operational failures. Pressure switches come in two primary varieties: mechanical and electronic.

Mechanical pressure switches use a diaphragm or bellows that moves in response to pressure changes. This movement actuates a set of electrical contacts, either opening or closing them based on the pressure level. These switches are robust, relatively simple, and suited for a wide range of applications. On the other hand, electronic pressure switches utilize sensors and microprocessors to monitor and control pressure. They offer higher precision and can provide more detailed feedback, such as digital readouts and programmable settings.

One of the primary benefits of using pressure switches is their ability to enhance safety. By ensuring that systems do not exceed safe pressure limits, these switches help prevent catastrophic failures and extend the lifespan of equipment. For example, in hydraulic systems, a pressure switch can shut down the pump if the pressure exceeds a set threshold, preventing potential damage to the system and reducing maintenance costs.

In HVAC systems, pressure switches are used to regulate air and refrigerant pressures, ensuring efficient operation and preventing damage to compressors. In automotive applications, these switches monitor oil and fuel pressures, contributing to the vehicle's overall reliability and performance.

Several factors must be considered when selecting a pressure switch, including the pressure range, operating environment, and compatibility with the system. Choosing the right pressure switch is crucial for achieving accurate and reliable performance.

In conclusion, pressure switches are indispensable components that play a significant role in maintaining system integrity and operational efficiency across various applications. By understanding their types, benefits, and selection criteria, industries can better harness their capabilities to ensure safety and enhance performance.

0 notes

Text

"Smart Cars Need Smart Sensors: The Evolution of Automotive Technology"

Market Overview and Report Coverage

The automotive sensor market for Original Equipment Manufacturers (OEM) is experiencing significant growth due to the increasing demand for advanced vehicle safety systems, emission controls, and enhanced driving experiences. Automotive sensors are critical components that monitor and control various aspects of a vehicle's performance, including engine functions, safety features, and environmental impact. The rise of electric vehicles (EVs), autonomous driving technologies, and stringent emission regulations are key factors driving the expansion of this market.

According to Infinium Global Research, the global automotive sensor market for OEMs is expected to witness robust growth from 2023 to 2030. The ongoing advancements in sensor technology, including miniaturization, improved accuracy, and integration with artificial intelligence, are further accelerating the adoption of automotive sensors in modern vehicles. Additionally, the increasing focus on connected cars and the integration of Internet of Things (IoT) technologies is propelling market growth.

Market Segmentation

By Type:

Pressure Sensors: These sensors are used to monitor various pressure levels in the vehicle, including tire pressure, fuel pressure, and oil pressure. The demand for pressure sensors is growing due to their critical role in ensuring vehicle safety and performance.

Temperature Sensors: Temperature sensors monitor engine temperature, exhaust gas temperature, and other critical temperatures within the vehicle. They are essential for optimizing engine performance and reducing emissions.

Position Sensors: Position sensors include throttle position sensors, camshaft position sensors, and crankshaft position sensors. These sensors provide vital data for engine control and are crucial for the smooth operation of the vehicle.

Oxygen Sensors: Oxygen sensors play a key role in controlling the air-fuel mixture in the engine, optimizing fuel efficiency, and reducing emissions. The increasing emphasis on emission control standards is driving the demand for these sensors.

Speed Sensors: Speed sensors are used to monitor the speed of the vehicle's wheels, transmission, and engine. They are critical components for anti-lock braking systems (ABS), traction control systems, and electronic stability control systems.

Other Sensors: This category includes various other sensors, such as rain sensors, light sensors, and occupancy sensors, which enhance the comfort, convenience, and safety of the vehicle.

By Application:

Powertrain: Automotive sensors in the powertrain are essential for monitoring and controlling the engine, transmission, and exhaust systems. They help improve fuel efficiency, reduce emissions, and enhance overall vehicle performance.

Safety and Security: Sensors used in safety and security applications include those for airbags, seat belts, collision detection, and lane departure warning systems. The growing emphasis on vehicle safety standards is driving the demand for these sensors.

Body Electronics: Sensors in body electronics are used for climate control, lighting, infotainment systems, and other convenience features. The increasing consumer demand for enhanced in-car experiences is boosting the adoption of these sensors.

Chassis: Sensors in the chassis are used for braking systems, suspension control, and steering systems. They play a crucial role in ensuring vehicle stability and handling, especially in advanced driver-assistance systems (ADAS).

Telematics and Infotainment: Sensors in telematics and infotainment systems enable connected car features, such as GPS navigation, vehicle tracking, and entertainment systems. The growing trend towards connected and autonomous vehicles is driving the adoption of these sensors.

Sample pages of Report: https://www.infiniumglobalresearch.com/form/1059?name=Sample

Regional Analysis:

North America: The North American market, led by the United States, is expected to maintain a strong position in the global automotive sensor market. The region’s focus on innovation, safety standards, and the development of autonomous vehicles is driving market growth.

Europe: Europe is a mature market for automotive sensors, with countries like Germany, France, and the UK leading the adoption of advanced sensor technologies. The region's stringent emission regulations and focus on automotive safety are key growth drivers.

Asia-Pacific: The Asia-Pacific region is anticipated to experience the fastest growth, driven by the rapid expansion of the automotive industry in countries like China, Japan, and India. The increasing demand for electric vehicles and the growing focus on vehicle safety are contributing to market growth.

Latin America and Middle East & Africa: These regions are also expected to witness significant growth, fueled by rising automotive production, increasing disposable incomes, and a growing focus on vehicle safety and emission standards.

Emerging Trends in the Automotive Sensor Market (OEM)

Several key trends are shaping the future of the automotive sensor market. The integration of sensors with artificial intelligence and machine learning is enabling predictive maintenance and enhancing the capabilities of advanced driver-assistance systems (ADAS). The shift towards electric and autonomous vehicles is driving the development of new sensor technologies, including LiDAR, radar, and ultrasonic sensors. Additionally, the increasing demand for connected cars is leading to the integration of IoT technologies, enabling real-time data collection and analysis for improved vehicle performance and safety.

Major Market Players

Bosch: A global leader in automotive sensor technology, Bosch offers a wide range of sensors for various applications, including powertrain, safety, and ADAS. The company’s strong focus on innovation and quality has helped it maintain a leading position in the market.

Continental AG: Continental is another key player in the automotive sensor market, known for its advanced sensor solutions for safety, powertrain, and body electronics. The company is heavily invested in developing sensors for autonomous and electric vehicles.

Denso Corporation: Denso, a leading automotive supplier, provides a variety of sensors used in powertrain, safety, and body electronics applications. The company’s commitment to developing environmentally friendly and energy-efficient technologies is driving its growth in the market.

Sensata Technologies: Sensata specializes in developing sensors for safety, powertrain, and chassis applications. The company’s focus on reliability and performance has made it a preferred choice for OEMs around the world.

Aptiv PLC: Aptiv is known for its advanced automotive sensors and systems, particularly in the areas of safety and connectivity. The company is at the forefront of developing sensor technologies for connected and autonomous vehicles.

Report Overview : https://www.infiniumglobalresearch.com/market-reports/global-automotive-sensor-market-oem

0 notes

Text

PCB cleaning chemicals

Advanced Solutions for PCB Maintenance and Assembly

In the fast-evolving world of electronics, maintaining the integrity and performance of printed circuit boards (PCBs) is crucial. PCB Cleaning Machines, PCB cleaning chemicals, Acrylic Conformal coating, PU Conformal Coating, Robotic dispensers, Robotic dispensing machines, Dispensing caps, fluid dispensing system, and Electric Screwdrivers are vital components in ensuring optimal PCB functionality and longevity. Here’s a comprehensive guide to understanding how these tools and materials contribute to PCB maintenance and assembly.

Effective PCB Cleaning Techniques with Cutting-Edge Machines and Chemicals

Keeping PCBs clean is the first step towards ensuring their reliability and performance. PCB Cleaning Machines are designed to remove contaminants, such as flux residues, dust, and oils, that can affect the functionality of the circuit board. These machines employ various methods, including ultrasonic cleaning, spray cleaning, and vapor degreasing, to achieve a thorough cleanse.

To complement these machines, PCB cleaning chemicals play a pivotal role in dissolving stubborn residues without damaging the delicate components of the PCB. These chemicals are specially formulated to work with PCB Cleaning Machines, ensuring that every nook and cranny of the board is free from contaminants. By regularly using PCB Cleaning Machines and the right PCB cleaning chemicals, manufacturers can significantly reduce the risk of failures and extend the lifespan of their products.

Protective Coatings: The Role of Acrylic and PU Conformal Coatings

Once a PCB is clean, the next critical step is to protect it from environmental factors such as moisture, dust, and chemicals. Acrylic Conformal coating is a popular choice for providing this protection due to its excellent dielectric properties and ease of application. This type of coating is ideal for general-purpose applications where the PCB needs to be shielded from humidity and contaminants. Acrylic Conformal coating not only enhances the durability of the PCB but also allows for easy rework if needed.

For more demanding environments, PU Conformal Coating offers superior protection. Polyurethane-based coatings are known for their excellent chemical resistance, making them suitable for PCBs that are exposed to harsh conditions. PU Conformal Coating is particularly beneficial in industrial and automotive applications, where PCBs are subjected to extreme temperatures and chemicals. Both Acrylic Conformal coating and PU Conformal Coating provide a reliable barrier, ensuring that the electronic components continue to function effectively, regardless of external conditions.

Precision in Assembly: The Importance of Robotic Dispensers and Fluid Dispensing Systems

As PCB designs become more complex, the need for precision in applying adhesives, sealants, and other fluids becomes paramount. Robotic dispensers are revolutionizing the assembly process by providing accurate and repeatable dispensing of materials. These machines are equipped with advanced sensors and control systems that ensure the precise application of fluids, reducing waste and improving efficiency. A Robotic dispensing machine can handle various materials, from solder paste to adhesives, ensuring that each component is secured correctly.

In conjunction with robotic dispensers, fluid dispensing systems are essential for controlling the flow of materials during the assembly process. These systems include a range of components such as pumps, valves, and Dispensing caps, all designed to ensure the consistent and controlled release of fluids. Dispensing caps are particularly important in preventing leaks and ensuring that the right amount of material is applied to each part of the PCB. By integrating Robotic dispenser and fluid dispensing systems into the production line, manufacturers can achieve higher levels of precision and consistency, leading to better product quality.

Essential Tools for Assembly: The Best Electric Screwdrivers

No assembly line is complete without reliable tools, and when it comes to securing components onto a PCB, Electric Screwdrivers are indispensable. The Best Electric Screwdrivers offer torque control, speed adjustment, and ergonomic design, making them suitable for high-volume production environments. Whether it’s for assembling consumer electronics or industrial equipment, the Best Electric Screwdriver ensures that screws are driven accurately and consistently, reducing the risk of damage to the PCB.

In today’s competitive market, investing in quality tools and equipment like PCB Cleaning Machines, Acrylic Conformal coating, PU Conformal Coating, Robotic dispensers, fluid dispensing systems, and Electric Screwdrivers is essential for any electronics manufacturer. These tools not only enhance the quality and reliability of the products but also improve efficiency, leading to cost savings and higher customer satisfaction. By understanding and utilizing these advanced solutions, manufacturers can stay ahead in the ever-evolving electronics industry. Visit here - https://mectronics.in/

0 notes

Text

The Importance of Regular Auto Repair in Philadelphia for Vehicle Longevity

Owning a vehicle in Philadelphia isn’t just about getting from point A to point B. It’s about safety, reliability, and keeping your car running smoothly for years. But how often do you think about regular maintenance and auto repairs? We get it—life moves fast in Philly, and keeping up with routine checkups on your car can fall low on the list of priorities. However, if you want to maximize the lifespan of your vehicle, regular maintenance is the key. Neglecting this could cost you more down the road, both financially and in terms of vehicle performance.

At SB Automotive, we’ve helped countless Philly drivers keep their cars in peak condition. Here’s why regular auto repair is crucial for your vehicle’s longevity and what you can do to ensure it runs smoothly for years.

Why Regular Auto Repair is Essential

When you buy a vehicle, you’re making a significant investment. And like any investment, it needs regular care to maintain its value. According to a recent survey by AAA, the average annual cost of vehicle ownership is over $9,000 when factoring in repairs, maintenance, fuel, and depreciation. The good news? Regular maintenance can drastically reduce the likelihood of costly repairs later on.

Here are just a few reasons why staying on top of auto repairs is a smart move for vehicle longevity:

Prevents Small Issues From Becoming Big Problems

Most of the time, a vehicle doesn’t just suddenly break down. There are minor warning signs—whether it’s strange noises, warning lights, or sluggish performance. When you address these issues early with regular repairs, you avoid more significant, more expensive fixes down the road. Think of it as catching a minor leak before it turns into a flooded engine.

Increases Fuel Efficiency

Regular maintenance, such as oil changes, tyre rotations, and brake checks, ensures your car operates at its best. Poorly maintained vehicles burn more fuel. According to the U.S. Department of Energy, fixing a serious maintenance problem—such as a faulty oxygen sensor—can improve fuel mileage by as much as 40%. With rising gas prices, this is more reason than ever to keep your vehicle in shape.

Boosts Safety

Safety is a top priority for any driver. Regular repairs ensure that critical components like brakes, tyres, and suspension are in optimal condition. The National Highway Traffic Safety Administration (NHTSA) estimates that 13% of all car accidents are caused by mechanical failure. Keeping up with maintenance minimizes the risk of your vehicle malfunctioning on the road, ensuring your safety and that of your passengers.

Maintains Resale Value

If you ever plan to sell or trade in your vehicle, its maintenance history will significantly affect its value. A well-maintained vehicle with regular service records is far more attractive to buyers than a car with a spotty repair history. You’ll likely get a much better price when you consistently care for your car.

What Regular Maintenance Includes

You might be wondering—what does regular auto repair entail? Here’s a checklist of the most important services you should schedule to keep your car running smoothly:

Oil Changes: Every 5,000 to 7,500 miles, depending on the type of oil used.

Tire Rotations and Alignment: Around every 6,000 miles, or as your mechanic recommends.

Brake Inspection: Ideally, brakes should be inspected every time you get an oil change.

Fluid Levels: Transmission fluid, brake fluid, and coolant should all be checked regularly.

Air Filter Replacement: Typically recommended every 15,000 to 30,000 miles.

S.B. Automotive offers comprehensive maintenance packages that cover all these essentials, so you don’t have to worry about missing a critical service.

Interesting Facts About Auto Repair and Maintenance

Did you know that neglecting your car’s oil can lead to engine failure? A study found that regular oil changes could have avoided 22% of engine repairs.

According to Kelley Blue Book, proper maintenance can increase a car’s resale value by 10% to 20%, making it a sound financial decision in the long run.

Vehicles in urban areas like Philadelphia are more prone to wear and tear due to stop-and-go traffic, road conditions, and the need for frequent braking.

How to Stay on Top of Regular Repairs

Staying on top of repairs and maintenance doesn’t have to be a hassle. At S.B. Automotive, we recommend scheduling routine services in advance to ensure your car is always in peak condition. Here are a few tips to help you stay on top of it all:

Set Reminders: Use your phone or a calendar to remind you of upcoming services. Most mechanics, including SB. Automotive, can help you schedule maintenance.

Listen to Your Car: Don’t ignore strange noises or warning lights. If your vehicle feels or sounds different, getting it checked out is always better.

Choose a Reliable Repair Shop: A trustworthy mechanic will keep you informed and prioritize what needs immediate attention. At S.B. Automotive, we provide transparent pricing and expert advice, ensuring you get the best care possible.

Conclusion

In a busy city like Philadelphia, your car is your lifeline. Regular auto repairs aren’t just about avoiding breakdowns—they’re about protecting your investment, improving your car’s performance, and ensuring your safety. By staying on top of routine maintenance and repairs, you’ll save money in the long run and enjoy a smoother, safer ride.

If you’re looking for a reliable, local auto repair shop in Philadelphia, S.B. Automotive is here to help. Our team of experienced mechanics is committed to keeping your vehicle running like new. Schedule your next service with us and keep your car on the road for years.

0 notes

Text

Load Cells Market Analysis by Current Status and Growth Opportunities, Top Key Players, And Forecast By 2030

The Insight Partners introduces its new market research as “Load Cells Market Industry Analysis| 2031”. The company specializes in syndicated market research and consultation services. Through this research company is offering both qualitative and quantitative data assisting Load Cells market investors.

Key Chapters Under This Research

Current Market Scenario and Estimates to 2031

Market Drivers, Opportunities, and Trends

Market Competition Analysis

This chapter offers insights on established and new entrant Load Cells market players. Understanding competition helps companies understand their position in the market. Through this chapter, the report offers insights on threats and opportunities ahead of Load Cells market players. Comparing pricing strategies and organic growth strategies used by key market participants provides opportunities for growth in the Load Cells market.

Report Attributes

Details

Segmental Coverage

Type

Single Point Load Cell

Compression Load Cell

Shear Beam Load Cell

S-Type Load Cell

Others

End User

Healthcare

Oil and Gas

Agriculture Equipment

Aerospace and Defense

Automotive

Consumer Electronics

Others

Geography

North America

Europe

Asia Pacific

and South and Central America

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

ABB Ltd.

OMEGA

Honeywell International Inc

Interface, Inc.

TE Connectivity

PCB Piezotronics, Inc

FUTEK Advanced Sensor Technology, Inc

Keli Sensing Technology (Ningbo) Co.,Ltd.

Measurement Specialists

Zhonghang Electrical Measuring Instrument Co., Ltd

Other key companies

Research Methodology

This Load Cells market report includes findings based on scrutiny of different factors impacting on business environment. Both primary and secondary methods of research are used to generate insights. Details on Load Cells market share, key players, micro-financial pointers, and other demographic factors.

Key market players are analyzed for their market share and overall growth in the industry. Based on forecast duration, these key market players are evaluated for their incomes. This market research brings local, regional, and national level information on the market

Go-To-Market Framework:

Development trends, competitive landscape analysis, supply-side analysis, demand-side analysis, year-on-year growth, competitive benchmarking, vendor identification, CMI quadrant, and other significant analysis, as well as development status.

Customized regional/country reports as per request and country-level analysis.

Potential & niche segments and regions exhibiting promising Load Cells market growth are covered.

Analysis of Load Cells Market Size (historical and forecast), Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM), Market Growth, Technological Trends, Market Share, Market Dynamics, Competitive Landscape, and Major Players (Innovators, Start-ups, Laggard, and Pioneer).

Key Benefits for Buyers

Strategic Insights to increase per-customer revenue and overall consumer experience.

Assistance and strategic roadmap to device marketing tactics

Details-oriented approach, authorized information, and new optimal business solutions

Preferred target demographic, regions, and market channels

Customized Insights and Consultation services.

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

Gas Sensor Market - Forecast(2024 - 2030)

Gas Sensor Market Overview

The market for Gas Sensor is forecast to reach $1.66 billion by 2030, growing at a CAGR of 8.5% from 2024 to 2030. The Gas Sensor Market is estimated to witness a sustainable growth over the forecast period majorly because Gas Sensor plays a major role in giving security, safety and various applications in Industries and other workplaces. Gas Sensor have their own respective features and provides various utilities. Gas sensors generally provide a measurement of the concentration of various gases such as CO, CO2, NOx, SO2 and Others by different sensors such as Combustible Gas Sensors, Infrared Point Sensors, Electrochemical Gas Sensors, Metal Oxide Semiconductor, Photo Ionization Detection, Paramagnetic and and Others. Gas sensors are commonly included as part of a health and safety system within the workplace, with portable instruments designed for protecting all workplaces when working in potentially hazardous areas. These vast features at various End-Use industries such as water treatment, food and beverage etc drives its market growth in global market. On the other hand, high installation and maintenance cost are the major challenges affecting its market growth. In recent years, there has been a notable trend towards integrating gas sensors with Internet of Things (IoT) platforms and smart devices. This integration allows for real-time monitoring, remote control, and data analysis of gas levels in various environments. Gas sensor manufacturers are increasingly incorporating wireless connectivity, such as Bluetooth, Wi-Fi, or LoRaWAN, into their products to enable seamless communication with smartphones, tablets, and cloud-based platforms. These smart gas sensors offer enhanced functionalities like predictive maintenance, anomaly detection, and customizable alerts, making them indispensable for industrial, environmental, and domestic applications. Moreover, the proliferation of smart homes and smart cities initiatives further drives the demand for gas sensors capable of interfacing with intelligent infrastructure for efficient resource management and enhanced safety measures. With growing concerns about air pollution and its detrimental effects on public health and the environment, there is an increasing demand for gas sensors tailored for air quality monitoring applications. Governments and regulatory bodies worldwide are implementing stringent environmental standards and regulations, mandating the continuous monitoring of pollutants such as carbon monoxide, nitrogen dioxide, sulfur dioxide, ozone, and particulate matter. This regulatory landscape drives the adoption of gas sensing technologies across industries, including automotive, industrial manufacturing, healthcare, and smart cities development. Gas sensor manufacturers are responding by developing innovative solutions with higher sensitivity, accuracy, and multi-gas detection capabilities to address the evolving requirements for environmental monitoring and compliance. Additionally, advancements in miniaturization and cost reduction techniques are making gas sensors more accessible for widespread deployment in indoor and outdoor air quality monitoring networks, fostering a sustainable approach towards mitigating air pollution and safeguarding public health.

Report Coverage

The report: “Gas Sensor Market– Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Gas Sensor Market.

By Sensor Type– Combustible Gas Sensors, Infrared Point Sensors, Ultrasonic Sensors, Electrochemical Gas Sensors, Metal-oxide-semiconductor Sensors (MOS sensors) and Others.

By Structure – Fixed and Portable Gas Sensor.

By Technology– Wire and Wireless Gas Sensor.

By End-Use Industry – Oil & Gas, Industrial, Automotive, Mining and Metal, Residential, Healthcare, Water treatment, Food & Beverages and Others.

By Geography - North America (U.S, Canada, Mexico), South America (Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC (China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa).

Request Sample

Key Takeaways

● The Gas Sensor Market is estimated to witness a sustainable growth over the forecast period majorly role in giving security, safety and various applications in Industries and other workplaces.

● Due to increasing extraction and shipping of resources in various Oil and Gas Industries, the scope of different Gas Sensors has increased rapidly which boost its market growth.

● Ongoing Industrialization and Urbanization in major economies such as USA, Canada, China, India and others, the presence of harmful gases in atmosphere and increased rapidly which uplifts the demand of Gas Sensors in global market.

● With the rise in Governmental regulations and Environmental concerns against the rising air pollution intensity with hazardous gases in atmosphere, installation of Gas Sensors in all workplaces and near hospitals and Other public places tends to drive the market growth.

Gas Sensor Market Segment Analysis - By Structure

Portable Gas Sensors has dominated the Gas Sensor Market at 70% share in 2023 as compared to the Fixed Gas Sensors. The demand for Portable Gas Sensors is growing because in various Power plant and Oil & Gas Industries, the pipelines contain many hazardous elements that can cause short and long-term health problems if workers are exposed improperly. With Portable Gas Sensors and Detectors, one can examine any leaks and presence of any hazardous gas which can affect environment and industries and can be resolved quickly. Mainly Portable Gas Sensors operate through a wireless system, which allows them to check for gases remotely providing inspection of level of gases in certain areas from a safe distance. These vast features tend to drive the market of Portable Gas Sensors in global market.

Inquiry Before Buying

Gas Sensor Market Segment Analysis - By End-Use Industry

Oil & Gas Industries hold the largest market in Gas Sensor Market at 22.4% share in 2023. The various Inspection methods which it offers to the Oil & Gas Industries as they mainly constitute in operation of many gases from extraction to production by transferring through pipelines. Thus, the requirement of Gas sensors increases rapidly. With the advancement in technologies, the adoption of Portable Gas Sensors offers wireless examination of various levels of gases operating in the system. This helps them to check for gases remotely providing inspection of various hazardous gases certain areas from a safe distance. These vast features tend to drive the market of Gas Sensors in Oil & Gas Industries.

Gas Sensor Market Segment Analysis - By Geography

North America has been accounted for being the highest market at 47% share in 2023 among all the regions by geography. The market growth in this region is predominantly rising due to fast-growing economies such as China, India, Japan and Others. Increasing rate of Urbanization and Industrialization with high population densities in these economies tends to uplift the Gas Sensor Market in these regions. Due to large number of Oil & Gas Industries, Power plants, Healthcare and high air pollution intensity in atmosphere of these regions, the installation Gas Sensors tends to boost the market growth. On the other hand, APAC is closely followed by North America due to the rapid growth of Industries and rise in Environmental concerns due to air pollution tends to uplift the market growth of Gas Sensor.

Schedule a Call

Gas Sensor Market Drivers

Rise in Industrialization and Urbanization drives market growth

Fast growing economies in Asia-Pacific and North America are contributing exponentially in Gas Sensor Market. Due to rise in Urbanization and Industrialization, the demand for Gas Sensors in various Oil & Gas industries, Healthcare, Power plants has increased rapidly. This has promoted the developments in manufacturing of Gas Sensors from fixed systems to portable systems among which the adoption of Wireless Gas Sensors has brought a major uplift in its market growth. To maintain safety and security in the workplace of these industries, the adoption of Gas Sensors has brought a major boost in the market growth.

Rise in Governmental Regulations and Environmental Concerns

With the rise in Governmental Regulations of maintaining a pollution-free city in various regions has brought a huge demand of Gas Sensors in global market. Gas sensors helps in examining the various hazardous gases in the atmosphere and provides the measurement of the concentration of various gases such as CO, CO2, NOx, SO2 and Others in major workplaces and Industries and Other public places. This tends to drive the demand of Gas Sensor Market globally. Moreover, with the rise in Environmental Concerns to reduce the emission of harmful gases especially in Industrial regions to secure nearby Ecosystem. Gas sensors are commonly installed in industrial regions as part of a health and safety system within the workplace as well nearby ecosystem are the key factors boosting the growth of the Gas Sensor Market globally.

Gas Sensor Market Challenges

High Installation and Maintenance Cost

One of the major challenges faced by Gas Sensor Market globally is the High Installation and Maintenance Cost. The advancement in technologies has brought the manufacturing of Portable Wireless Gas Sensors, which provides examining the air purity and inspecting various hazardous gases in the atmosphere as well as in Industries where workers cannot have physical access thus providing examining from a safe distance. But, these systems require high installation cost which restraints end users from purchasing these systems. Moreover, it requires high maintenance cost as the components used in manufacturing of these Gas Sensors are of specific types of unique technology. These are the major challenges which restraint the Gas Sensor Market growth globally.

Buy Now

Gas Sensor Market Landscape

Product launches, acquisitions, and R&D activities are key strategies adopted by players in the Gas Sensor Market. The Gas Sensor Market is dominated by major companies such as Dragerwerk Ag & Co.KGAA, AMETEK, Honeywell International Inc., ABB Ltd., General Electric Co., Emerson Electric Co., Figaro Engineering Inc., Ametek Inc., Siemens AG, Trolex Ltd., Enerac Inc. and California Analytical Instruments Inc.

Acquisitions/Technology Launches/Partnerships

● In June 2023, Alphasense, the UK-based manufacturer of sensors for air quality monitoring and safety gas detection, has launched a compact new sensor format for portable devices.

● In Oct 2023 Sensata Launches First A2L Leak Detection Sensor Certified for Multiple HVAC Refrigerants. The new leak detection sensors support HVAC manufacturers’ transition to refrigerants with a lower global warming impact.

#Gas Sensor Market#Gas Sensor Market size#Gas Sensor Market industry#Gas Sensor Market share#Gas Sensor Market top 10 companies#Gas Sensor Market report#Gas Sensor Market industry outlook

0 notes

Text

Industrial Wastewater Treatment Plant Market Scope & Growth Projection till 2032

Industrial Wastewater Treatment Plant Market provides in-depth analysis of the market state of Industrial Wastewater Treatment Plant manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Industrial Wastewater Treatment Plant in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Industrial Wastewater Treatment Plant Market Report:

The report offers a comprehensive and broad perspective on the global Industrial Wastewater Treatment Plant Market.

The market statistics represented in different Industrial Wastewater Treatment Plant segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Industrial Wastewater Treatment Plant are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Industrial Wastewater Treatment Plant.

Major stakeholders, key companies Industrial Wastewater Treatment Plant, investment feasibility and new market entrants study is offered.

Development scope of Industrial Wastewater Treatment Plant in each market segment is covered in this report. The macro and micro-economic factors affecting the Industrial Wastewater Treatment Plant Market

Advancement is elaborated in this report. The upstream and downstream components of Industrial Wastewater Treatment Plant and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/industrial-wastewater-treatment-plant-market-100570

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Pulse Electromagnetic Field Therapy Devices MarketMarket

Liquid Sodium Silicate MarketMarket Share

Cold Chain Monitoring MarketMarket Growth Rate

Ships Ballast Water System MarketMarket Forecast

Global Touch Screen Controllers MarketMarket Size

Shipbuilding and Offshore Rig Fabrication and Repair MarketMarket Growth

Quartz Monitor Crystals MarketMarket Analysis

Marine Fleet Management Software MarketMarket Size

Global Software Development Tools MarketMarket Share

Global Automotive Remote Diagnostics MarketMarket Growth

Industrial Ethernet Cables MarketMarket

Energy Recovery Ventilation System MarketMarket Share

Machine Control System MarketMarket Growth Rate

Supply Chain Visibility Software MarketMarket Forecast

Global Wealthtech MarketMarket Size

Energy Storage Battery For Microgrids MarketMarket Growth

Online Tutoring MarketMarket Analysis

Flat Panel Satellite Antenna MarketMarket Size

Global Office Suites MarketMarket Share

Global RV Rental MarketMarket Growth

Electric Trucks MarketMarket

Digital Commerce Platform MarketMarket Share

Uhmwpe Sheet MarketMarket Growth Rate

Low Light Level Imaging Sensors MarketMarket Forecast

Global Small and Medium Business (SMB) Software MarketMarket Size

Anticoagulant Reversal Drug MarketMarket Growth

Crude Oil Desalter and Electrostatic Dehydrator MarketMarket Analysis

Optical Transceivers MarketMarket Size

Global Machinable Ceramic MarketMarket Share

Global Spherical Silica Powder MarketMarket Growth

Private Cloud Services MarketMarket

Quartzite MarketMarket Share

Dual Brightness Enhancement Film (DBEF) MarketMarket Growth Rate

Battery Free RFID Sensor MarketMarket Forecast

Global Integrated Revenue and Customer Management (IRCM) for CSPs Software MarketMarket Size

acs-self-climbing-formwork-marketMarket Growth

Eltrombopag Olamine API MarketMarket Analysis

Mascara Cream MarketMarket Size

Global X-Ray Irradiators MarketMarket Share

Global HER2 Antibody MarketMarket Growth

0 notes

Text

Predictive Maintenance Market: Insights and Future Projections

According to a recent report by Meticulous Research®, the predictive maintenance market is on a robust growth trajectory, projected to reach $79.1 billion by 2031. This impressive growth, estimated at a compound annual growth rate (CAGR) of 30.9% from 2024 to 2031, reflects a significant shift in how industries approach asset management and maintenance.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5936n

Key Drivers of Growth

The surge in predictive maintenance adoption is largely attributed to the need for reduced maintenance costs and enhanced asset performance. As industries continue to deploy advanced predictive maintenance solutions in complex infrastructure systems, the demand for these technologies has accelerated.

Challenges and Restraints

Despite its promising outlook, the market faces challenges. Data privacy and security concerns are significant factors that could restrain growth. Additionally, the sector is grappling with a shortage of skilled professionals, which poses a challenge to widespread implementation and innovation.

Opportunities on the Horizon

The expansion of predictive maintenance into new domains, such as healthcare devices and navigation systems, presents exciting growth opportunities. These advancements are likely to drive further market expansion and attract new players.

Emerging Trends

Recent trends in the predictive maintenance market include the integration of digital twins and augmented reality (AR). These technologies are reshaping maintenance strategies, providing more accurate predictions and interactive, real-time insights.

Market Segmentation

The predictive maintenance market is diverse, encompassing various segments:

- Offering: Includes software, hardware (sensors like vibration, temperature, pressure, acoustic, ultrasonic, and more), data acquisition systems, connectivity devices, and services (professional and managed).

- Deployment Mode: Cloud-based and on-premise solutions.

- Organization Size: Large enterprises and small to medium-sized businesses.

- Technology: Features include IoT, AI and machine learning, cloud connectivity, modern databases and ERP systems, advanced analytics, and digital twins.

- Application: Covers areas such as vibration analysis, oil analysis, acoustics monitoring, motor circuit analysis, infrared thermography, and temperature monitoring.

- End-Use Industries: Spans manufacturing, energy & utilities, automotive & transportation, aerospace & defense, oil & gas, healthcare, construction & mining, IT & telecom, among others.

- Geography: Analyzed on both country and regional levels.

Industry Competitors

The report also provides a detailed analysis of industry competitors, offering insights into the competitive landscape and strategic positioning within the market.

As the predictive maintenance market evolves, keeping abreast of these trends and developments will be crucial for stakeholders aiming to leverage opportunities and navigate challenges in this dynamic field.

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

MV Auto: Premier Auto Services in Armadale

When it comes to maintaining your vehicle, finding a reliable and trustworthy auto service provider is essential. MV Auto in Armadale is your go-to destination for comprehensive auto services, ensuring your vehicle remains in optimal condition. This blog explores the top-notch services offered by MV Auto, making it the preferred choice for auto services Armadale.

Why Choose MV Auto in Armadale?

MV Auto has built a reputation for excellence, thanks to its commitment to quality service, skilled technicians, and customer-centric approach. Here are some compelling reasons to choose MV Auto for your auto service needs:

Experienced Technicians: MV Auto employs highly trained and experienced technicians who are proficient in handling a wide range of vehicle makes and models. Their expertise ensures accurate diagnostics and efficient repairs.

Comprehensive Services: From routine maintenance to complex repairs, MV Auto offers a comprehensive range of services to meet all your automotive needs. Whether it’s a simple oil change or a complete engine overhaul, they’ve got you covered.

State-of-the-Art Equipment: Utilizing the latest diagnostic tools and equipment, MV Auto ensures that your vehicle receives the best possible care. This advanced technology allows for precise troubleshooting and efficient service.

Customer Satisfaction: At MV Auto, customer satisfaction is a top priority. The friendly and professional staff go the extra mile to ensure that every customer has a positive experience. Transparent communication and fair pricing further enhance customer trust.

Services Offered by MV Auto