#Butterfly valve Manufacturers in USA

Text

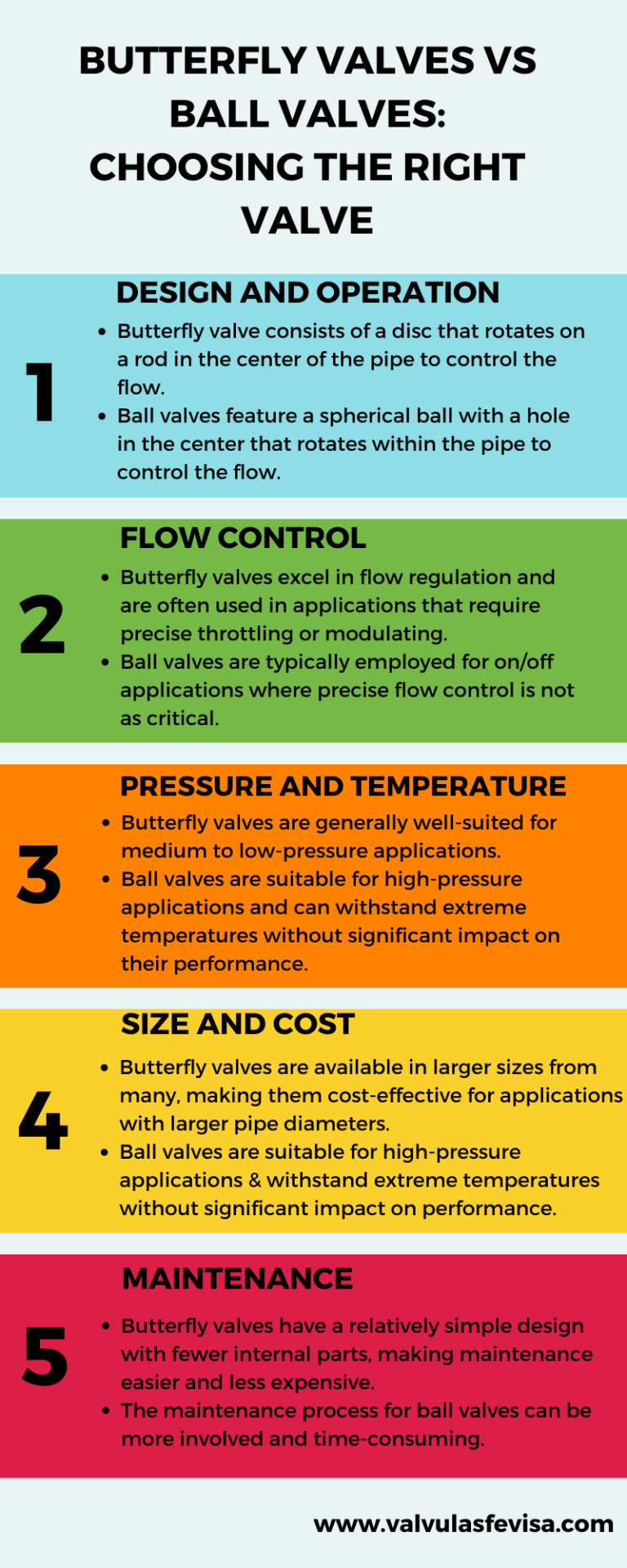

Both butterfly valves and ball valves are commonly considered. Each type has its own advantages and considerations, it is important to know several factors to determine the most suitable option for your specific needs. Consulting with valve specialists or an experienced Valve Stockist can provide valuable insights and guidance in choosing the most suitable valve for your application. We fevisa is the leading Valve Manufacturers and Valve Stockist in USA, you can contact us anytime we are always available to provide assistance.

#valve suppliers#valve manufacturers#butterflyvalves vs ballvalves#valve stockist in USA#Ball valves supplier#Butterfly valve supplier

0 notes

Text

Global Top 15 Companies Accounted for 34% of total Butterfly Valves market (QYResearch, 2021)

A thermoplastic is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Thermoplastic Butterfly Valves are made from plastic such as PVC, PP, etc.

According to the new market research report “Global Butterfly Valves Market Report 2023-2029”, published by QYResearch, the global Butterfly Valves market size is projected to reach USD 0.28 billion by 2029, at a CAGR of 4.1% during the forecast period.

Figure. Global Butterfly Valves Market Size (US$ Million), 2018-2029

Figure. Global Butterfly Valves Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Butterfly Valves include Cepex (Fluidra), Asahi Yukizai, Nibco, Sekisui, Hayward Flow Control, SAFI, Vinidex (Aliaxis), Dwyer Instruments, Hershey Valve, Galassi & Ortolani, etc. In 2021, the global top five players had a share approximately 34.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Wafer Butterfly Valve Manufacturer in USA

ValvesOnly takes pride in being a leading Wafer Butterfly Valve Manufacturer in USA, supplying high-quality valves to regions including Detriot, Texas and California. The wafer butterfly valve, with its compact and wafer-like design, is strategically positioned between flanges in a pipeline, offering a space-efficient solution for fluid control. Distinguished by the absence of extended lugs or flanges, these valves ensure a simpler and cost-effective installation process.

What is a Wafer Butterfly Valve?

A Wafer Butterfly Valve is a type of flow control device used to regulate or isolate the flow of a fluid within a system. Its unique design resembles a thin slice or “wafer.” When the valve is closed, the disc is turned to block the flow of fluid. These valves are commonly used in various industrial applications due to their compact design and ease of installation.

How does it work ?

A wafer butterfly valve operates by using a disc mounted on a central shaft to control the flow of fluid within a pipeline. The disc is typically installed between two flanges, hence the name "wafer," and is designed to rotate within the valve body. When the valve is open, the disc aligns parallel to the direction of flow, allowing fluid to pass through the pipeline with minimal obstruction. Conversely, when the valve is closed, the disc rotates perpendicular to the flow, effectively blocking the passage of fluid.

The rotation of the disc is controlled by a handle or actuator connected to the valve shaft. By turning the handle or activating the actuator, the disc can be precisely positioned to regulate the flow of fluid. This design provides quick and efficient flow control, making wafer butterfly valves suitable for a wide range of applications across various industries.

As wafer butterfly valve manufacturer in USA, our valves have various industrial applications:

1. Water and Wastewater Treatment: Ensuring efficient fluid control for water and wastewater treatment processes.

2. Chemical Processing: Crucial role in regulating fluid flow within pipelines for various chemical processing applications.

3. Petrochemical and Oil Refineries: Streamlined fluid management in demanding petrochemical and oil refinery environments.

4. Power Generation: Integral to precise flow control within fluid systems in power generation facilities.

5. Mining and Minerals: Reliable fluid control solutions enhancing operational efficiency in mining and minerals.

6. Water Distribution: Essential components in water distribution systems, facilitating optimal fluid flow.

7. Chemical Distribution: Contribution to the controlled distribution of chemicals, ensuring safety and efficiency.

8. Pulp and Paper: Valuable assets in fluid control processes within pulp and paper manufacturing.

9. Textile Manufacturing: Contributing to fluid management, these valves are vital in textile manufacturing.

10. Marine and Offshore: Designed to meet challenges of fluid control in marine and offshore applications.

Advantages:

1. Compact Design

2. Bi-Directional Flow

3. Quick Operation

4. Simple and Reliable Construction

5. Cost-Effective

6. Wide Range of Sizes

7. High Flow Capacity

8. Versatility

9. Bubble-Tight Shut-off

10. Low Maintenance

Description:

Material: Cast Carbon steel (WCC, WCB, WC6), Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F31L, F91], Duplex Steel, and Super Duplex Steel (F51, F53, F55), Cast iron, Ductile Iron.

Ends: Wafer

Pressure: PN6- PN25

Size: 2’’ to 72’’

Operation: lever operated, Gear Operated, electric actuated, pneumatic actuated.

Visit us: https://valvesonly.com/product-category/wafer-butterfly-valve

1 note

·

View note

Text

Top-Notch Butterfly Valve Gearbox Manufacturer & Supplier in the USA

Viral Industries is a well-known butterfly valve gearbox manufacturer and supplier in the USA, Europe & Canada. We offer gearboxes designed with butterfly valves, which control the flow of liquids or gases through a pipe or valve. Contact us today for the best quality butterfly valve gearboxes at the most reasonable prices.

0 notes

Text

Concentric Butterfly Valve Manufacturer

SVR Global is the top Concentric butterfly valve manufacturer in USA In New Mexico, North Carolina, and New Jersey, we are the leading provider of valves to the water and wastewater, marine, and chemical sectors. Industries frequently employ concentric butterfly valves to control the flow of liquids, gases, or slurries. Because the disc's centerline and the valve body's centerline are in line, it is known as a "concentric" valve. This kind of valve is frequently utilized in situations where tight shutdown and low-pressure drop are necessary.

A form of shut-off valve with a small and straightforward design is the concentrated butterfly valve. It is a widely used butterfly valve configuration. These valves have elastomer body lines built into them, allowing for tight, secure sealing as well as assurance that the body material won't react with the media, preventing corrosion from the impact of the fluid. They are quite simple to install, whether you need to mount them vertically or horizontally.

Industries:

Chemical Industry

Oil & Gas Industry

Petrochemical Industry

Energy Industry

LNG & LPG Industry

Marine Industry

Mining industry

Textile industry

Applications:

• Water treatment: Concentric butterfly valves are used in water treatment facilities to regulate the water flow through pipelines, tanks, and reservoirs.

• Chemical processing: Concentric butterfly valves are employed in the chemical industry to control the flow of corrosive, abrasive, or viscous fluids.

• Oil and gas: In the oil and gas sector, concentric butterfly valves are used to control the flow of fluids in pipelines, refineries, and offshore platforms, including oil, gas, and other substances.

• Power generation: Concentric butterfly valves are used in power production plants to control the flow of steam or water in turbines, boilers, and heat exchangers.

Advantages:

• Low pressure drop: Concentric butterfly valves feature streamlined disc designs that minimise pressure drop across the valve, reducing energy use and enhancing system effectiveness.

• Tight shutdown: Concentric butterfly valves offer a tight shutoff when fully closed, assisting in the prevention of leaks and ensuring the safety of the process.

• Simple design makes it simple to maintain and repair concentrative butterfly valves, minimising downtime and maintenance expenses.

SVR Global, the Concentric butterfly valve manufacturer in USA provides valves with the following specifications:

Description:

Body Material: cast carbon steel (WCC, WCB, WC6), stainless steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F31L, F91], duplex steel and super duplex steel (F51, F53, F55), cast iron, ductile Iron.

Size: 2” – 48”

Class: 150 to 300; PN 6 – PN 25

Ends: wafer, flanged, lug

Operations: lever operated, gear operated, pneumatic actuated and electric actuated.

Visit our website for more information- https://svrglobal.net/products/concentric-butterfly-valve/

0 notes

Text

Top Manufacturers of Instrumentation Valves in Usa | ArcellorControls

At ArcellorControls, we offer a wide variety of instrumentation valves, including ball valves, butterfly valves, check valves, gate valves, globe valves, needle valves, and more. We understand that different applications require different types of valves, which is why we offer a range of materials, sizes, and end connections to suit your specific needs.

0 notes

Text

Alloy 20 Valve Manufacturer in USA

Valvesonly is a leading Alloy 20 Valve Manufacturer in USA. Alloy 20 valves are industrial components constructed from Alloy 20, a highly corrosion-resistant material composed of nickel, chromium, and molybdenum.

We manufacture Alloy 20 Valve of the following types:

Alloy 20 Gate Valves

Alloy 20 Ball Valves

Alloy 20 Check Valves

Alloy 20 Globe Valves

Alloy 20 Diaphragm Valves

Alloy 20 Plug Valves

Alloy 20 Butterfly Valves

Alloy 20 Pressure Relief Valves

Alloy 20 Needle Valves

Alloy 20 Control Valves

Description:

Available material: Alloy20 (N08020)

Size: 1/2” to 12”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Ends: Socket Weld, Flanged, Wafer, Lug, Threaded, Buttweld

Operations: Lever Operated, Handwheel, Electric Actuated and Pneumatic Actuated, Gear Operated

Visit us: https://valvesonly.com/product-category/alloy-20-valves/

0 notes

Text

Butterfly Valve Manufacturer in USA

Butterfly Valve Manufacturer in USA

SVR Global is the best Butterfly valve manufacturer in USA. In a process system, a butterfly valve is utilised to control the fluid flow. It is made up of a plate or disc with a circular shape positioned on a shaft in the middle of the valve body. A handle or an actuator may spin the disc, which moves it in a plane perpendicular to the fluid's flow direction.The complete flow of fluid through the valve is permitted when the disc is spun in a direction parallel to the direction of the flow of fluid. The disc entirely stops fluid flow when it is turned perpendicular to the flow direction. The amount of fluid flow is determined by the disc's rotational speed.

SVR Global, the Butterfly valve manufacturer in USA manufacture valves that are widely used for waste water, fire protection and in gas supply industries as well.

Types of Butterfly Valves:

Wafer Butterfly Valve

Lug Butterfly Valve

Buttweld Butterfly valve

Concentric butterfly valve

AWWA Butterfly valve

Triple Offset Butterfly Valve

Double Offset Butterfly Valve

Flanged Butterfly Valve

Industries:

Chemical Industry

Oil & gas Industry

Petrochemical Industry

Technical gases

Energy industry

Textile industry

Water and wastewater industries

Description:

Body Material: Cast Carbon steel (WCC,WCB, WC6), Stainless Steel, [SS316, SS304, SS316L, SS904L, CF8, CF8M, F31L, F91], Duplex Steel and Super duplex Steel (F51,F53,F55) , Cast iron, Ductile Iron.

Size – 2” – 48”

Class: 150 to 300; PN 6 – PN 25

Ends: Wafer, flanged, lug

Operations: Lever and Gear operated, Pneumatic and Electric actuated.

Visit our website to know more: https://svrglobal.net/products/butterfly-valve/

0 notes

Text

0 notes

Text

Industrial valve Manufacturer in USA

Valvesonly is a premier Industrial Valve Manufacturer in the USA, revered for its exceptional offerings in the field of industrial valves. These indispensable devices serve the critical function of regulating the flow of liquids, gases, and slurries within various applications. Through adept manipulation, they enable the seamless control of fluid dynamics within pipelines and conduits.

Valvesonly is a premier Industrial Valve Manufacturer in the USA, renowned for offering top-tier products of the highest caliber. Our valve offerings are celebrated for their effectiveness, longevity, and cost-effectiveness. Clients frequently endorse our valves due to their peak quality and precisely tailored design.

Diverse categories of Industrial valves include:

Gate Valves: These valves are strategically placed in wider pipe sections to exert precise control over liquid flow. They exhibit versatile designs with options like rising stems or non-rising stems. Gate valves find application across industries such as textiles, power generation, refineries, petrochemical plants, and paper factories.

Ball Valves: Employing a spherical mechanism to manage and navigate fluid flow, ball valves are pivotal in controlling both flow and pressure in gas distribution systems. They also play a crucial role in reducing pressure within gas storage connections.

Butterfly Valves- Characterized by their capacity to regulate flow and provide controlled limitation, butterfly valves serve a multitude of purposes. From water supply and wastewater treatment to fire protection, gas supply, and applications in chemical and oil industries, they hold a significant presence.

Globe Valves: Sporting an S-shaped channel, globe valves excel as control valves, offering precise modulation of fluid flow. They often find use in high-point vents and low-point drains, where accuracy is paramount.

Check Valves: Relying on internal pressure rather than external forces, check valves facilitate the opening and closing of fluid passages. They are essential components in pumps, compressors, steam boilers, chemical plants, and power generation facilities.

Plug Valves- Known for their simplicity, ease of maintenance, and affiliation with the quarter-turn valve family, plug valves are invaluable in gas pipelines, handling slurries, and managing environments with high levels of debris.

Safety Valves: Engineered to respond to excess pressure in vessels or equipment, safety valves are instrumental in averting catastrophic failures. Their role extends to preventing further fluid release once normal conditions are reinstated.

Control Valves: These power-operated devices are instrumental in regulating or manipulating fluid flow across various mediums, including gas, oil, water, and steam.

Description-

Available materials: Ductile iron, Monel, WCB, WCC, WC6, LCB, LCC, SS304, SS316, CF8, CF8M, CF3, CF3M, Aluminum Bronze, Bronze, Brass, F55, F53, F51, Inconel, Titanium

Class: 150 to 2500

Nominal Pressure: PN6 to PN450

Size: ½” to 80”

Ends: Flanged, Wafer, Lug, Buttweld, Socket weld, Threaded

Operations: Lever operated, Gear operated, Electric actuated, Pneumatic actuated

0 notes

Text

Stainless Steel Valve Manufacturer in USA

Valvesonly is the leading Stainless steel valve manufacturer in USA. We supply high quality valves to various industries in Mexico, Brazil, Kuwait, and Algeria. Stainless steel valves are mechanical devices that control the flow of fluids or gases through pipes or tubes. They are made of stainless steel, a corrosion-resistant alloy of iron, carbon, and other metals.

The working of a stainless steel valve depends on the type of valve and its application. However, most valves work on the principle of controlling the flow of fluid or gas by opening or closing a passageway.

Valvesonly is the leading Stainless steel valve manufacturer in USA.

The following is a general overview of how a basic stainless steel valve works:

1. Flow control: The valve is installed in a pipeline or system to control the flow of fluid or gas. The valve can be designed to allow full flow, throttling flow, or complete shut-off.

2. Valve stem movement: When the actuator is energized, it moves the valve stem up or down or rotates it, depending on the type of valve. This movement opens or closes the valve disc or ball.

3. Sealing: When the valve is closed, the valve disc or ball contacts the valve seat, creating a tight seal that prevents fluid from flowing through the valve.

4. Actuator control: The actuator can be controlled manually or automatically, depending on the application. In automatic control, the actuator receives signals from a controller that senses the process conditions, such as pressure, temperature, or flow rate.

5. Maintenance: Regular maintenance of the valve is necessary to ensure its proper functioning. This includes inspecting the valve for wear and tear, replacing worn-out parts, and lubricating the moving parts.

Valvesonly is well known for Stainless steel valve manufacturer in USA and are preferred for their durability, high strength, and resistance to corrosion, high temperature, and pressure.

Type of Stainless steel valves:

• Stainless Steel Gate valve.

• Stainless Steel Ball valve.

• Stainless Steel Butterfly valve.

• Stainless Steel Globe valve.

• Stainless Steel Basket strainer.

• Stainless Steel Dual Plate Check Valve

• Stainless Steel Swing Check valve

• Stainless Steel Plug Valve

Advantages of Stainless Steel Valves:

• well-resistant to corrosion.

• It is suitable for frequent use.

• high degree of hardness, high temperature resistance, pressure resistance, extended service life, and corrosion resistance.

Industries of stainless steel valve:

• Oil and gas

• Chemical processing

• Water and wastewater treatment

• Power generation

Description:

Body material: Stainless Steel (SS316, SS304). SS904, 904L

Class: 150 to 2500, PN16 – PN 450

Size: ½” – 48”.

Ends: Socket weld, buttweld, flanged, threaded.

Operation: Gear operated, Electric Actuated and Pneumatic Actuated, Hand wheel operated.

0 notes

Text

Valve Manufacturer in USA

SVR Global is the leading and top rated Valve Manufacturer in USA. We provide customized valves according to the needs and requirements on our customers. With the help of our team of experts we strive to provide customers satisfaction by understanding the technical needs of our clients. Our products are used in industries such as Chemical industry, Energy Industry, Automobile Industry, Mining and Oil and Gas Industry and many more.

Our product range includes:

· Gate Valve

· Globe Valve

· Ball Valve

· Plug Valve

· Check Valve

· Control Valve

· Safety Valve

· Butterfly Valve

GATE VALVE

A gate valve is operated by detaching a barrier from the fluid stream. They are quite compact and do not disturb the flow of fluid. This type of valve can be either parallel or have a shape of wedge. It provides a safe and a secure seal thus providing no leakage. Gate valves allow the fluid to flow freely without any disturbance, resulting in very less loss of pressure.

Globe Valve

A Globe valve is a type of valve that controls the flow of mediums. It has a body which is spherical in shape attached with a disc and a ring seat. It’s main function is throttling that is to regulate/control the flow. The valve’s design and structure is in such a way that allows the liquid to flow in a different direction by itself.

Ball Valve

A ball valve is a device used to control the flow which is controlled by a moveable ball situated in the middle. The flow of medium can be started or stopped by rotating the ball by roughly a quarter turn. They are durable and provide long life span and provides tight sealing even when not operated for a long time.

PLUG VALVE

The plug valve is also known as quarter turn valve. It is used when rapid and quick action is needed. This type of valve has cylindrical shaped body that rotates to control the flow of medium. It has sideways openings that allows the flow of fluid through the stopper. Its main function is to start or stop the flow.

CHECK VALVE

A Check valve is a type of a valve that allows the fluid to pass through only one way. In this type of valve there body consist of two opening passage one for medium to enter and the other for fluid to exit. They are also known as non-return valve. Its main function is to prevent backflow. As its name suggest it only works one way and doesn’t require any external control.

CONTROL VALVE

Control valve is a valve that is electrically operated to regulate and control the flow of fluid through a pipeline. It can sustain fluid flow from the smallest to the largest extent. To regulate the flow of medium it adjust the position of the disc which is controlled by an actuator. They are durable and have to the ability to operate quickly and efficiently.

SAFETY VALVE

The safety valve opens itself to optimize the excess pressure to the desired level. They are also a known as the pressure relief valve. These valves main function is to protect boilers from excess pressure and to control the pressure downstream. Safety valves are very efficient and are open quickly to avoid any damages and disasters.

BUTTERFLY VALVE

A butterfly valve is used to start, stop or control the flow of fluids. They are quarter-turn rotary valve. When the disc is rotated to the the valve opens or closes which in turns allows of quick and safe shutdown. They have a secure seal and is relatively light when compared to ball valves.

Body Material: Cast Carbon steel (WCC,WCB, WC6), Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F31L, F91], DUPLEX STEEL and Super duplex Steel (F51,F53,F55) , Cast iron, Ductile Iron.

Size: DN50 to DN1200

Class: 150 to 300; PN6 – PN25

Ends: lugged, flanged, wafer

Operations: pneumatic actuated , electric actuated, Lever operated, gear operated

SVR Global offers a wide range of products and is the premium valve manufacturer in USA

Visit our site for more information- https://svrglobal.net/

0 notes

Text

Valves' Various Types and Specifications

Industrial valves are produced by L&T Valves Limited, a business with roots, for pipingprojects.us under the Audco brand. Valve Manufacturer in USA are used in a variety of industries, including the oil & gas, petrochemical, power generation, and water treatment sectors.

Audco valves can regulate the flow of liquids, gases, and other materials through pipelines and other industrial systems. These include ball valves, gate valves, globe valves, check valves, butterfly valves and plug valves, among other variations. Valve Manufacturer in USA have the ability to function in high-temperature and high-pressure situations make these valves known.

The industrial sector respects Valve Manufacturer in USA for their highly quality and durability. Their applications span from simple on-off flow controllers to more complex systems requiring precise control and regulation.

Types of Audco Valves

There are several types of Audco valves available from Valve Manufacturer in USA, each created to satisfy the needs of diverse industrial applications. The following are some of the typical Audco valve types:

Ball valves: With the help of a rotating ball, these valves control the flow of fluids via the valve. They are commonly employed in applications that need exact control and a tight shut-off.

Gate valves: The flow of fluids through a gate valve is controlled by a gate or wedge-shaped disc. They are typically used when complete flow control and little pressure drop are required.

Globe valves: To control the flow of fluids through a globe valve, a globe-shaped disc is employed. They are frequently used in situations where a substantial pressure drop and precise flow control are required.

Check valves: To prevent liquids from flowing backward through the valve. They are typically utilised in circumstances where reversing fluid flow could damage equipment or activities.

Butterfly valves: To control the flow of fluids through a butterfly valve, a disc-shaped component is used. They are typically employed when quick on-off control and little pressure drop are required.

Plug valves: Plug valves use a cylindrical or tapered plug to control the flow of fluids through the valve. They are widely utilised in applications that require precise control and a tight shut-off.

Among the typical Audco valve variations, these are only a handful. All of the additional valve types that Audco offers have been specifically designed to meet various industrial requirements.

Audco Valves Specification

Depending on the type of valve and the particular application it is meant for, Audco Valves dealers' specifications can change. However, the following are some typical characteristics of Audco valves:

Size: Audco valves are available in a range of sizes, typically with diameters between 1/2 inch and 48 inches.

Rating for pressure: Audco valves have a wide range of pressure tolerances, with typical ratings between Class 150 and Class 2500.

Temperature range: Some Audco valves can resist extremely low temperatures of -196°C to 815°C, while others are designed to operate in a specific range of temperatures.

Material: Audco valves are available in a variety of materials to fit different industrial needs, including carbon steel, stainless steel, cast iron, bronze, and other alloys.

End connections: Among the end connections offered for Audco valves are flanged, threaded, and welded connectors.

Audco valves come in a wide range of kinds, including ball, gate, globe, check, butterfly, and plug valves, as was already mentioned.

Standards are followed in the production of Audco valves, including those set by API, ASTM, ASME, ANSI, and other organisations.

These are just a few of the common qualities that an Valve Manufacturer in USA might have. The precise requirements may vary depending on the application's specific requirements and the type of valve being utilised.

0 notes

Text

Hastelloy Valve Manufacturer in USA

Valvesonly is famous for Hastelloy Valve Manufacturer in USA. We manufacture various hastelloy valves for industries in Saudi Arabia, UAE, Israel, Jordan and Egypt. Hastelloy has a unique combination of attributes that provide them with significantly stronger corrosion resistance capabilities compared to traditional alloys. The two main Hastelloy are nickel-molybdenum (Ni-Mo) and nickel-chromium (Ni-Cr). It is used widely for highly corrosive chemical acids. The properties of Hastelloy valves are designed in ranges of valves that are having good corrosion resistance into the reducing atmosphere, and good resistance to the strong solution of oxidizing like cupric chloride and ferric.

Types of Hastelloy valves:

o Hastelloy check valves

o Hastelloy globe valves

o Hastelloy Plug valves

o Hastelloy butterfly valves

o Hastelloy ball valves

o Hastelloy gate valves

Advantages of Hastelloy valves:

· Excellent corrosion resistance

· Good machinability

· It can be cold worked

Applications of Hastelloy valves:

o Chemical Equipment

o Petrochemicals

o Gas processing

o Sea water equipment

o Power generations

Description:

Body material: Hastelloy C276, B3

Size: 1/2" to 12"

Class: 150 to 800

Nominal Pressure: PN25 to PN100

Ends: Flanged, threaded, wafer, lug, socket weld, Buttweld

Valvesonly is the best Hastelloy Valve Manufacturer in USA which provides premium quality products which comes in various materials and designs. All the products are tested according to requirements and standards of clients.

https://valvesonly.com/product-category/hastelloy-c276-b3-valves/

0 notes

Text

Butterfly Valve Gerabox Manufacturer in the USA

Viral Industries is a well-known Butterfly Valve Gearbox manufacturer in the USA. We are a renowned manufacturer, supplier, and exporter of butterfly valve gearboxes used to control the flow of liquid through a pipe or valve. For more information, contact us today.

0 notes

Text

Canada Hospitals and Clinics Market Pointing to Capture Largest Growth - 2030

https://theprose.com/post/714346/usa-industry-consulting-service-market-2023-latest-trending-industry-is-booming-globallyhttps://theprose.com/post/714348/europe-roads-and-highways-consulting-service-market-outlook-2023-size-players-cost-structureshttps://theprose.com/post/714351/usa-heating-coil-for-heat-treatment-market-report-pointing-to-capture-growth-2029https://theprose.com/post/714354/europe-metal-pallet-pooling-marketstatistics-industry-planning-structurehttps://theprose.com/post/714356/usa-transaction-monitoring-for-financial-services-market-2023-size-share-trends-growthhttps://theprose.com/post/714359/europe-transaction-monitoring-for-healthcare-market-future-scope-demands-2029https://theprose.com/post/714362/usa-non-woven-adhesives-for-adult-incontinence-market-to-witness-huge-growth-by-2029https://theprose.com/post/714364/usa-underground-brine-iodine-market-2029-growing-rapidly-with-latest-trendhttps://theprose.com/post/714367/europe-communication-networks-market-2023-demand-future-scopehttps://theprose.com/post/714370/usa-kiosk-printer-supplies-market-advancing-the-growth-globally-by-trendshttps://theprose.com/post/714380/europe-sliding-door-market-2023-overview-forecast-study-2029https://theprose.com/post/714375/europe-inkjet-coding-equipment-market-segmented-by-type-application-end-userhttps://theprose.com/post/714383/europe-carbon-steel-hole-saws-market-challenges-opportunities-size-sharehttps://theprose.com/post/714385/europe-hygienic-butterfly-valves-market-2023-booming-across-globe-by-segmentshttps://theprose.com/post/714386/usa-coreless-holding-furnaces-market-analysis-by-leading-manufacturers-2023-2029https://theprose.com/post/714387/europe-carbon-fiber-laminates-market-2023-2029-explained-effective-movementshttps://theprose.com/post/714390/usa-3d-printed-nanomaterials-market-hitting-new-heights-between-2023-2029https://theprose.com/post/714392/europe-dsl-tester-market-outlines-the-growth-factors-2029https://theprose.com/post/714393/usa-digital-resistivity-meters-market-2023-latest-trending-industry-is-booming-globallyhttps://theprose.com/post/714395/europe-ceramic-antennas-in-electronic-devices-market-outlook-2023-size-players-cost-structureshttps://theprose.com/post/714396/usa-automatic-liquid-filling-machines-market-report-pointing-to-capture-growth-2029https://theprose.com/post/714398/europe-fpc-antennas-marketstatistics-industry-planning-structurehttps://theprose.com/post/714400/usa-rugged-embedded-solutions-market-2023-size-share-trends-growthhttps://theprose.com/post/714402/europe-rugged-computer-systems-market-future-scope-demands-2029https://theprose.com/post/714404/usa-robotic-process-automation-in-finance-market-to-witness-huge-growth-by-2029https://theprose.com/post/714405/usa-semi-automatic-bagging-machines-market-2029-growing-rapidly-with-latest-trendhttps://theprose.com/post/714406/europe-inflatable-stand-up-paddle-board-market-2023-demand-future-scopehttps://theprose.com/post/714407/usa-electric-center-console-boats-market-advancing-the-growth-globally-by-trendshttps://theprose.com/post/714408/europe-airboats-market-2023-overview-forecast-study-2029https://theprose.com/post/714409/europe-electric-pontoon-boats-market-segmented-by-type-application-end-user

0 notes