#Ceramic thick film circuit

Text

Forming Processes for Ceramic Substrates

Ceramic substrates are generally ultra-thin sheets below 1mm or even around 0.3mm. Forming and sintering are both key difficulties in preparation. The flatness, surface roughness, and dimensional stability of ceramic substrates are key factors that affect the subsequent preparation of copper cladding and circuit etching of the substrate. This places high demands on the forming process of ceramic substrates. At the same time, mass production also requires the forming method to have high production efficiency and low cost.

1. Tape casting process

Tape casting is currently the most important method for forming thin films or sheets.

The basic process of ceramic substrate tape casting is preparing tape casting slurry, vacuum degassing, tape casting, sintering, etc. Tape casting has the dual advantages of high production efficiency and ultra-thinness, but due to the low density of the green body, it is easy to deform when preparing large-sized substrates. The powder forming process combining tape casting and isostatic pressing is used to increase the density of the ceramic substrate tape casting green body, further, reduce the shrinkage of the green body during sintering, and help obtain large-sized high thermal conductivity ceramic substrates.

2. Dry pressing

Dry pressing is to put powder into a mold and apply pressure through a press to press the powder into a green body of a certain shape. The dry pressing process is simple, suitable for mass production, and has a short cycle. The green body has high density, relatively precise size, small firing shrinkage, high mechanical strength of the ceramic parts, and good electrical properties. Dry pressing is suitable for pressing round and thin sheet products. The product has high density and the flatness of the substrate is easy to ensure, but it is difficult to prepare ultra-thin substrates.

3. Gel injection molding

Gel injection molding is to disperse ceramic powder in an aqueous solution or non-aqueous solution containing organic monomers and cross-linking agents to prepare a concentrated suspension with low viscosity and high solid volume fraction (>50vol%), then add initiators and catalysts, inject the suspension into the mold, and initiate the polymerization of organic monomers under certain temperature conditions, resulting in in-situ solidification molding. After low-temperature drying, a green body with high strength and machinability is obtained. Gel injection molding is suitable for the molding of ceramic substrates with a thickness of 0.6 to 10 mm, but the degree of automation and molding efficiency is relatively low. In mass production, the slurry's gravity is generally used as a power source to inject into the mold. The process has high requirements on slurry fluidity, flow mode of injection into the mold, gel time control, green body drying uniformity, etc., and quantitative control is difficult. There are currently few examples of mass production of gel injection molding for substrate molding.

4. Additive Manufacturing 3D Printing

3D printing gets rid of the limitations of molds on traditional molding. In today's increasingly competitive market, 3D printing can achieve frequent product trials and modifications, which has incomparable advantages over conventional processing methods.

0 notes

Text

CAPILLARY FILMS Solvent resistant diazo sensitised water Transferred

➡️ http://ow.ly/Cq5j308M483 ⬅️❤️

☎️01942888747 #Screenprinting #CDs #Screenprint #Screenprints

Depending on the thickness selected, it is suited to such printing applications as: electronics, circuit traces, membrane switches, halftones, CDs and DVDs, ceramic decals, posters and containers and bottles.

For detailed technical information and material safety data. Please contact us on 01942 888747

Supplied on a roll, but also available in cut to size sheets for CD & Electronic industry.

Prices on request

Ideal for all types of #Frames #Mesh #Silkscreen #Textiles #Tshirts #Illustration #Posters #Merchandise #Merch #BandMerch #Apparel #FineArt #Printmaking #Signs #HandPulled #TShirtPrinting Screen Print Industry #ScreenprintingUK #PrintLife #Ink

#screenprinting#silkscreen#screenprintinguk#screenprint#merch#merchandise#apparel#tshirts#tshirtprinting#bandmerch

0 notes

Text

The Versatility and Applications of Alumina Ceramic Substrates

The Versatility and Applications of Alumina Ceramic Substrates

Alumina ceramic substrates, composed primarily of aluminum oxide (Al2O3), are a high-performance material known for their exceptional electrical, thermal, and mechanical properties. These substrates are widely used in various industries, including electronics, automotive, and aerospace, due to their unique combination of properties that make them suitable for demanding applications.Get more news about Alumina Ceramic Substrate,you can vist our website!

Properties of Alumina Ceramic Substrates

One of the defining characteristics of alumina ceramic substrates is their high dielectric strength, which allows them to withstand high voltages without electrical breakdown. This property makes them ideal for use in electronic components where insulation and reliability are critical. Additionally, alumina substrates exhibit excellent thermal conductivity, which helps in efficient heat dissipation, a crucial factor in high-power electronic devices.

The mechanical strength of alumina ceramic substrates is another notable feature. They possess high flexural strength and fracture toughness, making them resistant to mechanical stress and deformation. This durability ensures that the substrates can maintain their structural integrity even under harsh conditions.

Manufacturing and Customization

Alumina ceramic substrates are manufactured using various techniques, including tape casting and mold pressing. These methods allow for the production of substrates with uniform thickness and high density. The substrates can be customized into different shapes and sizes to meet specific application requirements. Laser cutting and surface metallization are common processes used to achieve the desired dimensions and surface properties.

The substrates are available in different purity levels, typically ranging from 96% to 99.6% alumina content. Higher purity levels generally result in better performance characteristics, such as increased thermal conductivity and mechanical strength. The choice of purity level depends on the specific application and performance requirements.

Applications in Electronics

In the electronics industry, alumina ceramic substrates are widely used in printed circuit boards (PCBs), power devices, and sensors. Their high thermal conductivity and electrical insulation properties make them ideal for use in high-power electronic components, where efficient heat dissipation and reliable insulation are essential. The substrates’ ability to withstand high voltages without electrical breakdown ensures the safety and reliability of electronic devices.

Alumina ceramic substrates are also used in LED packages, where their high reflectivity and thermal conductivity contribute to improved light output and thermal management. The substrates’ excellent adhesion with thin and thick film metallization allows for the integration of various electronic components, enhancing the overall performance of LED devices.

Applications in Automotive and Aerospace

In the automotive industry, alumina ceramic substrates are used in power modules and sensors. Their high thermal conductivity and mechanical strength make them suitable for use in high-temperature environments, such as engine control units and power electronics. The substrates’ resistance to thermal shock ensures their reliability and longevity in demanding automotive applications.

In the aerospace industry, alumina ceramic substrates are used in various electronic components and sensors. Their ability to withstand extreme temperatures and mechanical stress makes them ideal for use in aerospace applications, where reliability and performance are critical. The substrates’ high dielectric strength and thermal conductivity contribute to the efficient operation of electronic systems in aircraft and spacecraft.

Future Prospects

The demand for alumina ceramic substrates is expected to grow in the coming years, driven by advancements in electronics, automotive, and aerospace technologies. The development of new manufacturing techniques and the increasing focus on high-performance materials will further enhance the properties and applications of alumina ceramic substrates.

In conclusion, alumina ceramic substrates are a versatile and high-performance material with a wide range of applications in various industries. Their unique combination of electrical, thermal, and mechanical properties makes them suitable for demanding applications where reliability and performance are essential. As technology continues to advance, the role of alumina ceramic substrates in enabling innovative solutions will only become more significant.

0 notes

Text

Best Capacitors manufacturer in India

Electronic component:

An electronic component is any basic discrete electronic device or physical entity part of an electronic system used to affect electrons or their associated fields. Electronic components are mostly industrial products, available in a singular form and are not to be confused with electrical elements, which are conceptual abstractions representing idealized electronic components and elements. A datasheet for an electronic component is a technical document that provides detailed information about the component’s specifications, characteristics, and performance.

Advantages of Electronic components:

These leads connect to other electrical components, often over wire, to create an electronic circuit with a particular function (for example an amplifier, radio receiver, or oscillator). Basic electronic components may be packaged discretely, as arrays or networks of like components, or integrated inside of packages such as semiconductor integrated circuits, hybrid integrated circuits, or thick film devices. The following list of electronic components focuses on the discrete version of these components, treating such packages as components in their own right.

Classification Electronic components:

Active components rely on a source of energy (usually from the DC circuit, which we have chosen to ignore) and usually can inject power into a circuit, though this is not part of the definition.[1] Active components include amplifying components such as transistors, triode vacuum tubes (valves), and tunnel diodes.

Passive components cannot introduce net energy into the circuit. They also cannot rely on a source of power, except for what is available from the (AC) circuit they are connected to. As a consequence, they cannot amplify (increase the power of a signal), although they may increase a voltage or current (such as is done by a transformer or resonant circuit). Passive components include two-terminal components such as resistors, capacitors, inductors, and transformers.

Electromechanical components can carry out electrical operations by using moving parts or by using electrical connections.

Most passive components with more than two terminals can be described in terms of two-port parameters that satisfy the principle of reciprocity — though there are rare exceptions.[2] In contrast, active components (with more than two terminals) generally lack that property.

Explore our wide range of resistor options designed to meet your electronic component needs. Discover SMD resistors and DIP resistors, available in various power ratings and resistance values, providing versatile solutions for circuit designs.

Additionally, we offer Ceramic Varactors for applications requiring variable capacitance. For higher power applications, our Wire Wound Resistors provide excellent performance and durability. Looking for light-dependent resistors (LDRs) We have those too!

For bulk production, we offer SMD resistor reels, providing convenience and efficiency in large-scale manufacturing. Browse our selection and find the perfect resistors for your electronic projects.

Electronic components like Resistors, Capacitors, Inductors, semiconductor ICs, Relays form the backbone of all the technological advances today. With these, you can design any system, any model for your project.

As the saying goes “You want it, we got it” and we at robu take extra pride in providing the highest quality products to fulfill your ideas at the best price.

All products are shipped within 24 hours and delivered right to your doorstep with the minimum shipping charges.

Film resistors are essential components in electronic circuits, offering precise resistance values. Browse our comprehensive selection of film resistors, including carbon film and metal film variants, renowned for their stability and reliability. Explore various wattages, tolerances, and sizes suitable for diverse applications, from basic circuits to intricate electronic projects.

With exceptional temperature stability and low noise performance, our film resistors ensure optimal functionality in your designs. Whether you’re a hobbyist or a seasoned engineer, find the perfect film resistors to meet your requirements and elevate your projects.

Trust in our quality offerings for dependable performance and seamless integration into your circuits.

1 note

·

View note

Text

Aluminum Nitride Ceramic PCB

Aluminum Nitride (AlN) is currently the best ceramic substrate material accessible. Its properties of high thermal conductivity (170 W/mK) combined with being a strong dielectric and a low expansion rate (CTE) make it the material of choice today as a substrate or package for high-power LEDs, ICs, sensors and many other components and circuits.

Reasons why you should choose Aluminum Nitride PCB for your project

Aluminum Nitride (AlN) PCBs offers several compelling reasons, especially in applications where thermal management, high-frequency performance, and reliability are critical. Here are some key reasons to consider using AlN PCBs:

·Exceptional Thermal Conductivity: AlN ceramics have excellent thermal conductivity properties, making them highly effective at dissipating heat generated by electronic components. This property is crucial for maintaining component reliability, extending the lifespan of electronics, and preventing overheating-related failures.

·High-Frequency Performance: AlN PCBs exhibit low signal loss and minimal signal distortion, making them well-suited for high-frequency and microwave applications. They provide reliable signal transmission and are ideal for RF (Radio Frequency) circuits, microwave antennas, and advanced communication systems.

·Electrical Insulation: AlN ceramics possess excellent electrical insulation properties. They have a high dielectric strength, preventing electrical leakage and ensuring the isolation of electrical components and signals. This insulation is essential for maintaining signal integrity and preventing unintended electrical connections.

·Mechanical Strength: AlN ceramic substrates have good mechanical strength, with the ability to withstand mechanical stresses during manufacturing, assembly, and operation. This mechanical robustness contributes to the overall reliability of electronic systems.

·Compatibility with Semiconductor Devices: The thermal expansion coefficient of AlN is relatively close to that of silicon, a common material used in semiconductor devices. This compatibility allows for efficient heat transfer from semiconductor components, reducing the risk of thermal stress and enhancing their performance and longevity.

·High-Power and High-Temperature Applications: AlN PCBs are well-suited for high-power electronic components and high-temperature environments. They can efficiently dissipate heat from power amplifiers, voltage regulators, LEDs, and other heat-generating devices.

·Longevity and Reliability: The superior thermal management provided by AlN PCBs contributes to the longevity and reliability of electronic systems, reducing the risk of premature component failures due to overheating.

·Wide Range of Applications: AlN PCBs find application in various industries, including aerospace and defense, telecommunications, medical devices, automotive, and industrial electronics. They are versatile and suitable for demanding electronic applications.

·Customization: AlN PCBs can be customized to meet specific design requirements, including layer count, dimensions, and design layout, ensuring that they are tailored to the needs of the application.

·Efficient Heat Dissipation: The exceptional heat dissipation properties of AlN PCBs allow for the effective management of thermal issues without the need for additional cooling mechanisms, such as heat sinks or fans.

In conclusion, choosing Aluminum Nitride (AlN) PCBs offers lots of advantages, including superior thermal conductivity, high-frequency performance, electrical insulation, and mechanical strength. These properties make them a preferred choice in applications where traditional PCB materials may not meet the stringent requirements for thermal management and reliability. At Hitech Circuits, we supply both Aluminium Nitride PCB (AlN) processed by thick film process (Silver/silver palladium metalization) as well as Direct Plated Copper Technologies (DPC), with copper tracks and pads.

#AINPCB #ceramicpcb

0 notes

Text

SMD Thick Film Resistor, Global Market Size Forecast, Top 14 Players Rank and Market Share

SMD Thick Film Resistor Market Summary

Surface Mount Device (SMD) thick film resistors are electronic components used in circuitry to control the flow of electric current. These resistors are made using a thick film deposition process, where a resistive paste is printed onto a ceramic substrate and then baked to form the resistive element. SMD thick film resistors are designed for surface mounting onto printed circuit boards (PCBs), offering advantages like space efficiency, ease of automated assembly, and good stability under various operating conditions. They come in various sizes and power ratings, catering to different application needs. The "thick film" aspect refers to the thicker layer of resistive material compared to thin film resistors, providing different electrical and thermal properties.

Figure. SMD Thick Film Resistors Product Picture

Source: Secondary Sources and QYResearch, 2024

According to the new market research report “Global SMD Thick Film Resistor Market Report 2023-2030”, published by QYResearch, the global SMD Thick Film Resistor market size is projected to reach USD 2.55 billion by 2030, at a CAGR of 6.3% during the forecast period.

Figure. Global SMD Thick Film Resistor Market Size (US$ Million), 2019-2030

Above data is based on report from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

Figure. Global SMD Thick Film Resistor Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Above data is based on report from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of SMD Thick Film Resistor include Yageo, KOA, Walsin Technology, Vishay, Fenghua Advanced Technology, Ta-I Technology, Panasonic, Samsung Electro-Mechanics, Rohm, UniOhm, etc. In 2023, the global top 10 players had a share approximately 84.0% in terms of revenue.

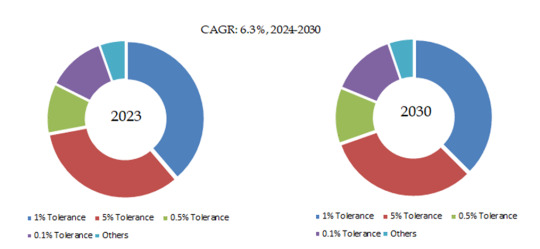

Figure. SMD Thick Film Resistor, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030.

In terms of product type, 1% Tolerance is the largest segment, hold a share of 38.7%,

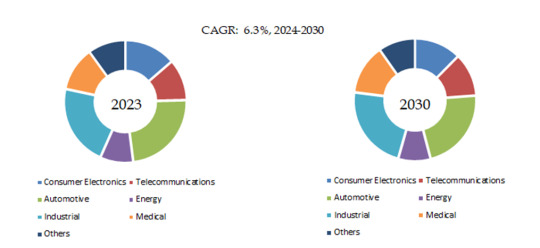

Figure. SMD Thick Film Resistor, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030.

In terms of product application, Automotive is the largest application, hold a share of 23.4%,

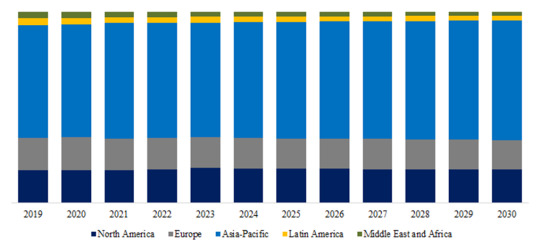

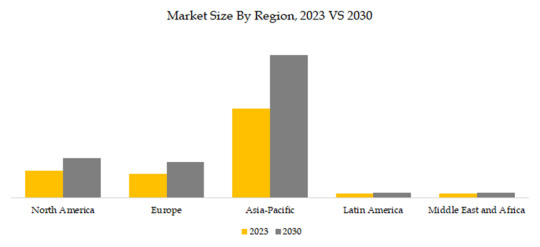

Figure. SMD Thick Film Resistor, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030.

Market Drivers:

D1: Consumer Electronics Boom: The continuous growth in consumer electronics, including smart devices, home appliances, and entertainment systems, has contributed to the demand for SMD Thick Film Resistors in various applications.

D2: There is a stable demand for SMD thick film resistors in the automotive, industrial, medical, Telecommunication, energy and other fields of various countries.

D3: Growth in Demand in Emerging Economies such as China, India, Southeast Asia, Brazil etc.

Restraint:

R1: Price Volatility: Fluctuations in raw material prices used in SMD Thick Film Resistors, can affect production costs and subsequently impact pricing strategies.

R2: The design and R&D of SMD Thick Film Resistors require high-tech talents, and enterprises are facing the risk of brain drain.

R3: Global Economic Conditions: Economic downturns or uncertain market conditions can lead to reduced consumer spending on electronic devices, impacting the demand for SMD Thick Film Resistors.

Challenges:

C1: Miniaturization Demands: As technology advances, there's a constant need for smaller and more compact electronic devices. This requires SMD Thick Film Resistors to be even smaller while maintaining or improving performance, posing a challenge in manufacturing and precision.

C2: Cost Pressure: The market often experiences price pressure due to competitive forces and cost-cutting demands from manufacturers. Balancing quality and cost-effectiveness become crucial to sustain profitability.

C3: Technological Advancements: Rapid advancements in technology lead to newer materials, manufacturing processes, and innovative designs. Keeping up with these advancements requires substantial investments in research and development to stay competitive.

About the Authors

Wei Qin

Lead Author

Semiconductor and Electronics

Email: [email protected]

About QYResearch

QYResearch founded in California, USA in 2007. It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Ceramic PCB manufacturing(from Hitech Circuits Co., Limited)

Ceramic PCB have good High thermal conductivity, ceramic substrate and conductor performance, excellent chemical and thermal stability. Excellent corrosion resistance, it widely used in semiconductor,Sensor and microelectronic circuit packaging pcb, High-brightness Led chip carrier board, automotive electronics and lighting components, high-power electronic component heat dissipation materials, etc.

Why Purchase Your Ceramic PCBs from HITECH CIRCUITS?

At HITECH CIRCUITS, we are dedicated to producing and selling quality PCBs to all of our customers. With over 15 years of experience in the electronic industry we are committed to producing custom ceramic PCBs that meet up with the various electronic devices at hand.

Our professionals manufacture nothing but top-notch ceramic PCBs that are developed to tackle your demands. In addition, we assure that you will get nothing but the best and affordable prices for all the quality ceramic PCB we manufacture. Regardless of the quality of the printed circuit boards that you want, it will be gotten at a decent price.

Ceramic PCB Parameter

Ceramic PCB in high pressure, high insulation, high frequency, high temperature, and high reliable and minor volume electronic products, then Ceramic PCB will be your best choice.

Why Ceramic PCB has such excellent performance?

96% or 98% Alumina (Al2O3), Aluminum Nitride (ALN), or Beryllium Oxide (BeO)

Conductors material: For thin film technology, thick film technology, it’ll be silver palladium (AgPd), gold pllladium (AuPd); For DCB (Direct Copper Bonded) it’ll be copper only

Application temp: -55~850C

Thermal conductivity value: 16W~28W/m-K (Al2O3); 150W~240W/m-K for ALN , 220~250W/m-K for BeO;

Max compression strength: >7,000 N/cm2

Breakdown Voltage (KV/mm): 15/20/28 for 0.25mm/0.63mm/1.0mm respectively

Thermal expansion conefficient(ppm/K): 7.4 (under 50~200C)

Contact Us

You can submit a custom request and get a price quote.

[email protected], from Cynthia.

1 note

·

View note

Text

Different types of chip resistors

Here are the types of Chip resistors

Thin Film Resistors: These are made by depositing a thin resistive film on a ceramic substrate. They offer high precision and stability, suitable for precise applications.

Thick Film Resistors: Unlike thin film resistors, thick film resistors have a thicker resistive layer. They are cost-effective and widely used in general-purpose applications.

Metal Film Resistors: These resistors have a metal film deposited on a ceramic rod. They provide better stability and accuracy compared to carbon film resistors.

Carbon Film Resistors: In carbon film resistors, a thin film of carbon is deposited onto a ceramic rod. They are inexpensive and commonly used in consumer electronics.

Metal Oxide Resistors: Metal oxide resistors are made by depositing a metal oxide film on a ceramic substrate. They offer high power handling capabilities and stability at high temperatures.

Wirewound Resistors: These resistors consist of a wire wound around a ceramic or fiberglass core. They provide high precision and are suitable for high-power applications.

Network Resistors: These are combinations of multiple resistors in a single package. They offer convenience in circuit design by providing multiple resistance values in one component.

0 notes

Text

Understanding High Power Resistors: Applications, Types, and Considerations

High power resistors are indispensable components in various electronic circuits where power dissipation is a critical factor. From industrial machinery to automotive systems, these resistors find applications in diverse fields. This article aims to explore the significance of high power resistors, their types, applications, and important considerations in selection.

Understanding High Power Resistors: A resistor is a passive two-terminal electrical component that opposes the flow of electrical current. High power resistors, as the name suggests, are designed to handle significant power levels without experiencing thermal overload or degradation in performance. They are built to dissipate large amounts of power efficiently, thereby maintaining stability and reliability in electronic circuits.

Applications of High Power Resistors: High power resistors find applications across a wide range of industries and electronic systems, including:

1. Power Electronics: In power supplies, inverters, converters, and motor drives, who discovered resistor are used for current sensing, voltage division, and load balancing.

2. Industrial Machinery: In industrial automation and control systems, high power resistors are employed for braking, snubber circuits, and dynamic braking resistors in motor control applications.

3. Automotive Industry: In automotive electronics, high power resistors are utilized in ignition systems, battery management systems, and electric vehicle powertrains for functions like voltage regulation and current sensing.

4. Renewable Energy: In solar inverters, wind turbine generators, and battery energy storage systems, high power resistors play a crucial role in managing power flow, voltage stabilization, and fault protection.

Types of High Power Resistors: High power resistors are available in various types to suit specific application requirements. Some common types include:

1. Wirewound Resistors: Constructed by winding resistance wire onto a ceramic or fiberglass core, wirewound resistors offer high power dissipation capabilities and excellent stability over a wide temperature range.

2. Thick Film Resistors: Thick film resistors feature a resistive element printed onto a ceramic substrate, providing a compact and cost-effective solution for high power applications.

3. Metal Film Resistors: Metal film resistors utilize a thin film of metal deposited onto a ceramic substrate, offering high precision and stability for moderate to high power applications.

Considerations in Selection: When selecting ceramic resistor for a specific application, several factors must be considered:

1. Power Rating: Choose a resistor with a power rating sufficient to handle the maximum power dissipation expected in the circuit.

2. Temperature Coefficient: Consider the temperature coefficient of the resistor to ensure stable performance over the operating temperature range.

3. Resistance Tolerance: Select resistors with tight tolerance values to maintain accuracy in circuit operation.

4. Mounting Configuration: Determine the appropriate mounting configuration (surface mount, through-hole, or chassis mount) based on the mechanical constraints of the application.aluminium resistor

High power resistors are essential components in electronic systems requiring efficient power dissipation and reliable performance. By understanding the different types, applications, and considerations in selection, engineers can choose the most suitable high power resistors to meet the requirements of their designs, ensuring optimal performance and longevity.

Source Url:-https://sites.google.com/view/powerresistorcom47/home

0 notes

Text

Best Technology Co., LTD: Your Premier Ceramic PCB Supplier for Cutting-Edge Solutions

Elevate your electronic designs with Best Technology Co., LTD, a trusted Ceramic PCB supplier offering unparalleled precision and innovation. Explore our comprehensive range of ceramic circuit boards for superior performance in various industries. Your pathway to advanced technology starts here!

1 note

·

View note

Text

Tape-casting: Method for producing electronic ceramic sheets

High-performance ceramic materials have the characteristics of high strength, high hardness, wear resistance, and corrosion resistance, and are widely used in energy, information, aerospace, electronics, biology and medicine, and other fields. The ceramic molding method is an important factor in determining ceramic performance, and tape casting is currently one of the commonly used methods for producing electronic ceramic sheets.

Tape-casting

Tape casting refers to a molding method in which solvents, dispersants, binders, plasticizers, and other ingredients are added to ceramic powder to obtain a uniformly dispersed and stable slurry, and a film of the required thickness is produced on a tape casting machine.

Compared with other molding processes, tape casting has many advantages: the equipment and process are simple and can be produced continuously; single-phase or multi-phase ceramic sheet materials can be prepared; the product has small defects, uniform performance, high production efficiency, and can be operated continuously; uniform It can be produced in large and small batches and is suitable for industrial production. The biggest feature of tape casting is that it is very suitable for the preparation of large thin plate ceramic parts, which is difficult to achieve by pressing or extrusion molding processes. However, there are also some problems with tape casting. The main reason is that the binder content is high, so the shrinkage rate of the blank is large during the discharging glue process, and the thin sheets are prone to defects such as cracking, curling, and uneven thickness.

Tape-casting process

Tape casting was first used in the fields of papermaking, paint, and plastics. It is a long-standing molding technology that mainly includes processes such as slurry preparation, ball mill mixing, molding, drying, degreasing, and sintering.

Process flow chart for preparing ceramic substrates by tape casting

First, the ceramic powder and dispersant are added to the solvent (water or organic solvent), and the particles are agglomerated through ball milling or ultrasonic oscillation, and the solvent is allowed to wet the powder, and then the binder and plasticizer are added, and the particles are obtained by secondary ball milling. Stable and uniform slurry; then the slurry is formed on a casting machine to obtain a green body; then dried to evaporate the solvent, and the binder forms a network structure between the ceramic powders to obtain a green body film; and then the green body is formed The raw film is machined to obtain the specific shape required; finally, the required finished product is obtained through degreasing and sintering.

Application

Due to its simple equipment, continuous operation, high production efficiency, and uniform body performance, the tape casting method has become an important method for preparing large-area, ultra-thin ceramic substrates and is widely used in the electronics industry, energy industry, and other fields.

Also used in monolithic capacitor tiles, Al2O3 substrates for thick film and thin film circuits, piezoelectric ceramic diaphragms, structural ceramic sheets, capacitors, thermistors, ferrite and piezoelectric ceramic bodies, and hybrid integrated circuit substrates. It is also used in the field of mobile phone ceramic covers.

0 notes

Text

CAPILLARY FILMS Solvent resistant diazo sensitised water Transferred @kissel.wolf

➡️ http://ow.ly/Cq5j308M483 ⬅️❤️

☎️01942888747 #Screenprinting #CDs #Screenprint #Screenprints

Depending on the thickness selected, it is suited to such printing applications as: electronics, circuit traces, membrane switches, halftones, CDs and DVDs, ceramic decals, posters and containers and bottles.

For detailed technical information and material safety data. Please contact us on 01942 888747

Supplied on a roll, but also available in cut to size sheets for CD & Electronic industry.

Prices on request

Ideal for all types of #Frames #Mesh #Silkscreen #Textiles #Tshirts #Illustration #Posters #Merchandise #Merch #BandMerch #Apparel #FineArt #Printmaking #Signs #HandPulled #TShirtPrinting Screen Print Industry #ScreenprintingUK #PrintLife #Ink

0 notes

Text

Thick film resistor

Thick film resistor includes the integration of thick film and thin film technologies to create electronic circuits and elements on a single substrate. It includes using a ceramic or a flexible substitute that acts as the foundation for mounting your passive and active electronic components.

0 notes

Text

thick film

Discover the cutting-edge capabilities of Hybrid-Tek in ceramic circuit boards, hybrid integrated circuits, and thick film technology. Visit our website to learn more about our advanced solutions.

0 notes

Text

TO-3P/220/247/254/257/258/264 Aluminum Nitride Ceramic Thermal Pads For MOSFET Transistor IGBT Transistor Heat Sink

Innovacera Ceramic Thermally Conductive Interface Pads are designed to provide a preferential heat-transfer path between heat-generating components, heat sinks, and other cooling devices. The pads are used to fill air gaps caused by imperfectly flat or smooth surfaces which should be in thermal contact. The pads are made of ceramic materials such as alumina ceramic and aluminum nitride, which help in providing enhanced thermal conductivity and excellent insulation performance. Typical applications include Power Devices, Integrated Circuit (IC) chip packaging heat conduction, MOSFET Transistor, IGBT Transistor Heat Sink, MOS Transistor, heat sink interface, LED board Thermal Interface Material (TIM), Chip ON Film (COF) heat conduction.

TO-3P-220-247-254-257-258-264 Aluminum Nitride Ceramic Thermal Pads Without Hole For MOSFET Transistor IGBT Transistor Heat Sink

A ceramic heat sink is a device that dissipates heat-dissipating electronic components in an electrical appliance.

The whole structure of the ceramic heat sink increases the heat dissipation area in contact with the air, which greatly enhances the heat dissipation effect, and the heat dissipation effect is better than that of the super copper and aluminum.

Ceramics are insulated, resistant to high temperatures, oxidation, acid and alkali, cold and thermal shock, and low coefficient of thermal expansion, ensuring stability in high and low temperatures or other harsh environments.

Ceramics can withstand high current, can be high voltage, can prevent leakage breakdown, no noise, will not generate coupling parasitic capacitance with power tubes such as MOS, and thus simplify the filtering process.

Aluminum nitride ceramic thermal insulator pads are ceramic materials with outstanding properties such as high thermal conductivity and high electrical resistance. In addition, it is featured advantages such as high hardness, corrosion resistance, low dielectric constant and dielectric loss, and low CTE. Aluminum nitride ceramics have excellent thermal conductivity (7-10 times that of alumina ceramics), as the thermal expansion coefficient of silicon is similar, as a new generation of ceramic materials, more and more people pay attention to it.

Ceramic Thermal Pads Installation Steps:

①Clean the target surface: Clean the dust or stains on the surface of the object to be installed, and then align the hole position of the ceramic insulating sheet;

②Power tube bonding: Stick the power tube on the ceramic insulating sheet;

③Fixed the insulation sheet: Use screws to fix the power tube and ceramic insulating sheet on the installation object.

Regular Size:

For Package Type: TO-3P / TO-220 / TO-247 / TO-264 / TO-3/TO-254/TO-257/TO-258, With Hole or Without Hole.

TO – 3P, 25*20*1mm (other thickness is available, too);

TO-220, 20*14*1mm (other thickness is available, too);

TO-247, 22*17*0.635mm (other thickness is available, too);

TO-264, 28*22*1mm (other thickness is available, too);

TO-3, 39.7*26.67*1mm (Rhombus shape).

TO-254, 34*24*1mm (other thickness is available, too);

TO-257, 40*28*1mm (other thickness is available, too);

TO-258, 50.8*50.8*1mm (other thickness is available, too);

Other standard sizes:

25.4*25.4mm;

114.3*114.3mm;

152*152mm;

190.5*138mm…..;

Customized sizes are available.

Regular Size drawing:

TO-3P/220/247/254/257/258/264 Aluminum Nitride Ceramic Thermal Pads For MOSFET Transistor IGBT Transistor Heat Sink

Machine detail:

Technology data

Name

Technology requirement

Remark

1

Machine size

Thickness

as per drawing

2

Flatness

0.01

3

Camber

≤2‰

4

Surface roughness

Ra≤0.5

5

Appearance request

Smooth surface, no dirt, water stains, watermarks, no chip, cracks, edge breakage, scratches, and other defects

6

Clean request

After ultrasonic cleaning, clean again with alcohol, dry, and bake in time to ensure that there are no water stains and watermarks on the surface

7

Package request

After machining, products are placed in special pearl-cotton packaging boxes as required for turnover and transportation to avoid defects such as bruises and scratches.

ALN Product Package requirement:

(1) The product is cleaned according to the requirements, after completely dried, placed in the special pearl cotton packaging box,

(2) One group of 100 pieces of products is placed in the small cells in the packaging box. There are 5 cells in each packaging box, and 500 pieces can be placed in total (as shown in the picture).

(3) After each version of the packaging box is filled with products, it needs to wrap the film tightly, and attach the quantity label (Picture);

(4) Put the pearl-cotton packing box into the outer carton, and paste the specification and quantity label on the surface.

(5) Package carton size: 21*21*12cm

(6) Gross weight: 1.5kgs

TO-3P-220-247-254-257-258-264 Aluminum Nitride Ceramic Thermal Pads Without Hole For MOSFET Transistor IGBT Transistor Heat Sink Package

Read the full article

#ALNThermalPads#AluminaNitridePads#AluminaNitrideThermalPads#CeramicHeatSink#ceramicinsulatorpads#ceramicthermalinsulatorpads#CeramicThermalPads#thermalinsulatorpads

0 notes

Text

Covid-19 Impact On Lithium Ion Battery Separator Market Research Report 2022-2032

In 2032, the lithium ion battery separators market is projected to generate US$ 3,256.7 Million while growing at a CAGR of 7.2%. In 2022, the market is anticipated to be worth US$ 1,624.9 Million. Lithium ion batteries are anticipated to be used extensively throughout the transition from fuel-based to zero-emission electric cars.

Automobiles, storage technologies, and consumer electronics will all experience exponential expansion during the coming ten years. The market saw a growth rate of 5.3% between 2016 and 21.

The Lithium ion battery separator shutdowns the mechanism of the battery when abnormal heat generation occur with the battery cell. Lithium ion battery separators are also used to prevent physical contact between anode and cathode while facilitating ion transport thereby preventing short circuit and increasing reliability of the lithium ion battery.

Lithium ion battery separator are primarily manufactured from non-woven fiber, polymer films and ceramic material, where porous membrane are commonly used with these materials in manufacturing of lithium ion battery separator due its low manufacturing cost, prevent mixing of chemicals and improved mechanical properties.

Key manufacturers of the market are shifting from use of polymer separator to ceramic coated lithium coated lithium ion battery separators which improved life cycle and increase the performance of lithium ion battery.

Request Sample Copy of Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-2292

Global Lithium Ion Battery Separator Market: Key Players

The key players of lithium ion battery separator includes Asahi Kasei Group, Daramic, Entek International LLC, Targray Technology International Inc., Freudenberg & Co. KG, Mitsubishi Plastics Inc., TEIJIN Limited, Porous Power Technologies LLC, UBE Industries Ltd., W-Scope Corporation, SK Innovation Co Ltd, Celgard LLC and Sumitomo Chemical Company Limited

Research and development department of manufacturing companies are focusing on reducing the thickness of separator by using nonwoven materials and increasing thermal stability & wettability by using composite separators. Key players of the market such as Ube Industries, SK Innovation etc. are expanding their production capacities in foreign regions to strengthen their global presence.

Global Lithium Ion Battery Separator Market: Segmentation

The global lithium ion battery separator market is segmented based on material used:

Polypropylene (PP)

Polyethylene (PE)

Nylon

Others ( nanofibers and microfibers materials )

The global lithium ion battery separator market is segmented based on temperature resistance:

10 oC -25 oC

130 oC-135 oC

The global lithium ion battery separator market is segmented based on thickness:

16µm

20µm

25µm

Global Lithium Ion Battery Separator Market: Region-wise outlook

Growing demand of smart phones and tables in developing countries of Asia Pacific such as India and China. This rise in demand lead to boost the consumption of portable batteries results in the growth of lithium ion battery separator market, globally.

Japan holds the maximum share in the global lithium ion battery separator market followed by North America. Whereas significant growth lies Western Europe for coming years. In addition Middle East and Africa and Eastern Europe holds the minimum share in lithium ion battery separator market.

Browse latest Market Reports@

https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes